Bambu P1S Combo 3D Printer Review: Why It's the Easiest to Use [2025]

I've been tinkering with 3D printers for over a decade, and I can tell you something most people don't realize: they've traditionally been finicky machines. They're more like workshop tools than home gadgets—the kind of thing you buy and then spend six months troubleshooting, swapping parts, and watching plastic turn into spaghetti before you actually get something usable.

The Bambu P1S Combo changes all that.

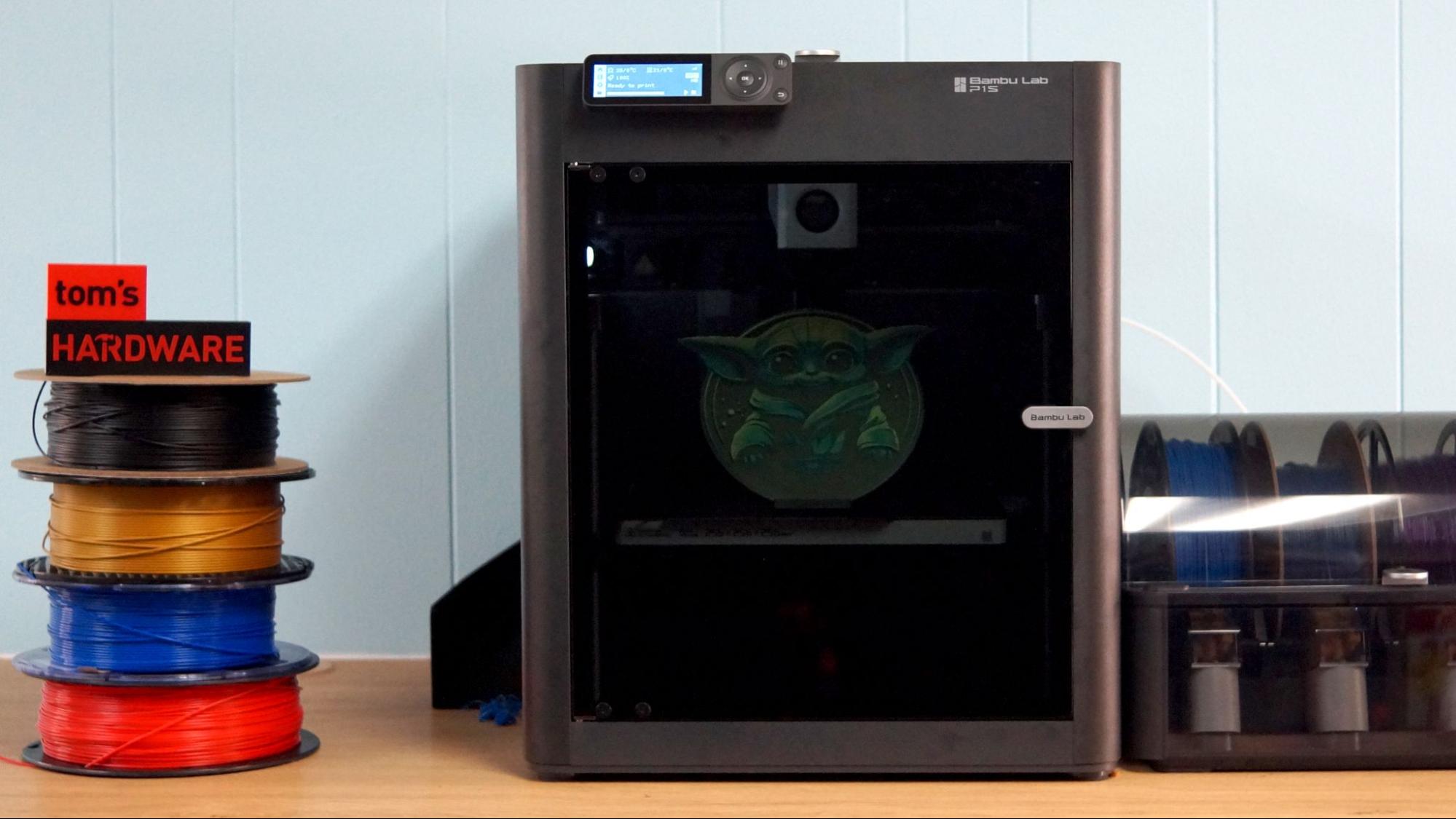

Within the first 20 minutes of setup, I printed a Benchy—that little tugboat every 3D printer enthusiast uses to test their machine's capabilities—and it came out nearly perfect. Not good. Not acceptable. Nearly perfect. No stringing on the corners. Clean first layer. Crisp details. The kind of print that usually takes weeks of tuning to achieve on traditional printers.

By day three, I was confidently sending print jobs from my laptop across the house, walking away for eight hours, and coming back to exactly what I expected. No babysitting. No failed prints buried in waste plastic. No frustrated Slack messages to my maker-space friends asking what went wrong.

Here's what makes the P1S Combo genuinely different, why it matters, and whether you should spend your money on it.

TL; DR

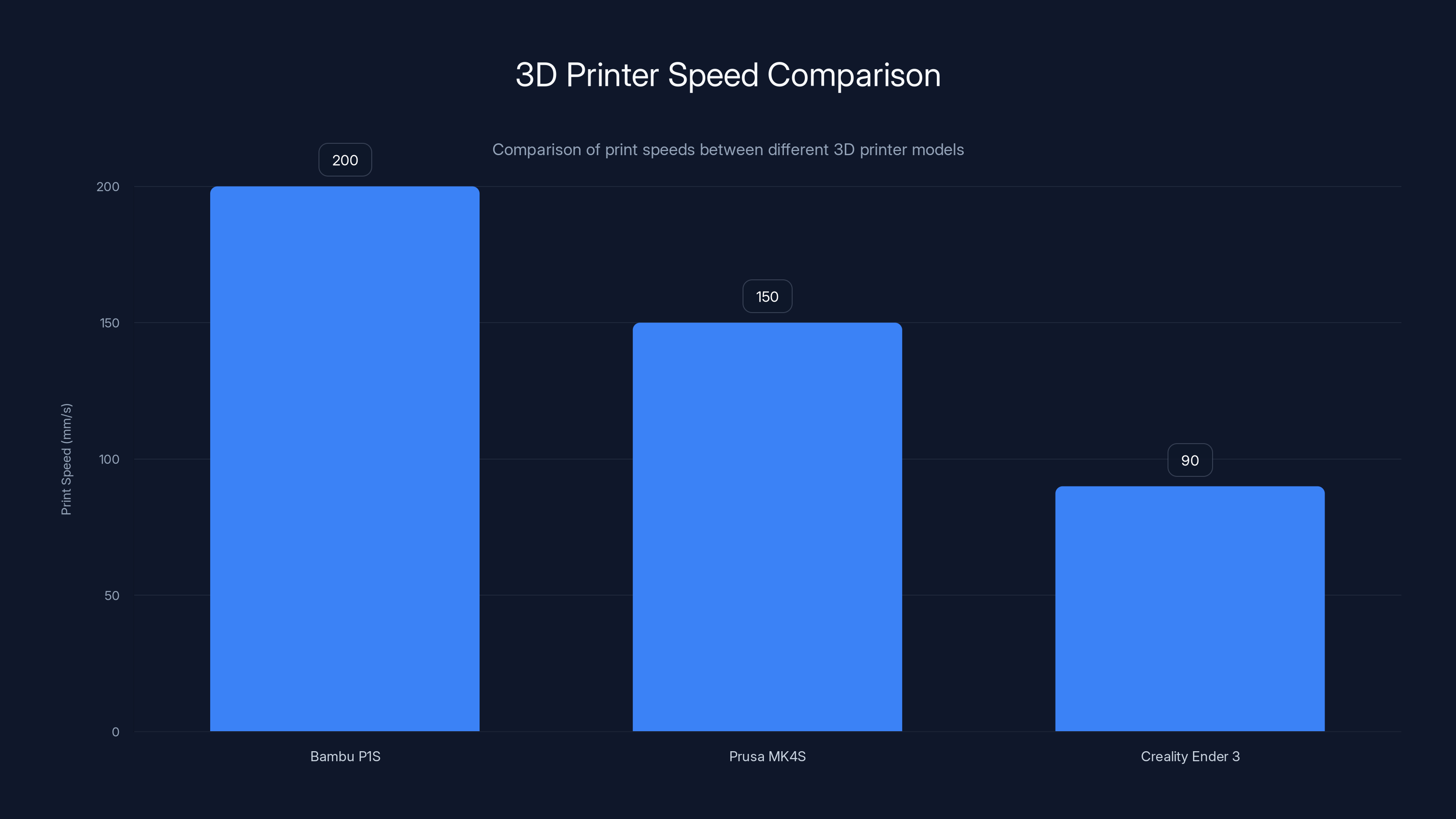

- Print speeds hit 200mm/s consistently, making complex prints happen in hours instead of days

- Automatic nozzle cleaning before every print eliminates the most common failure point

- Multi-filament system reduces swaps and cleanup, letting you print projects in logical order instead of batching by color

- Setup takes 30 minutes, not the promised "5 minutes," but it's still faster than competitors

- Best for: Experienced makers, small business owners, serious hobbyists; overkill for one-off prints

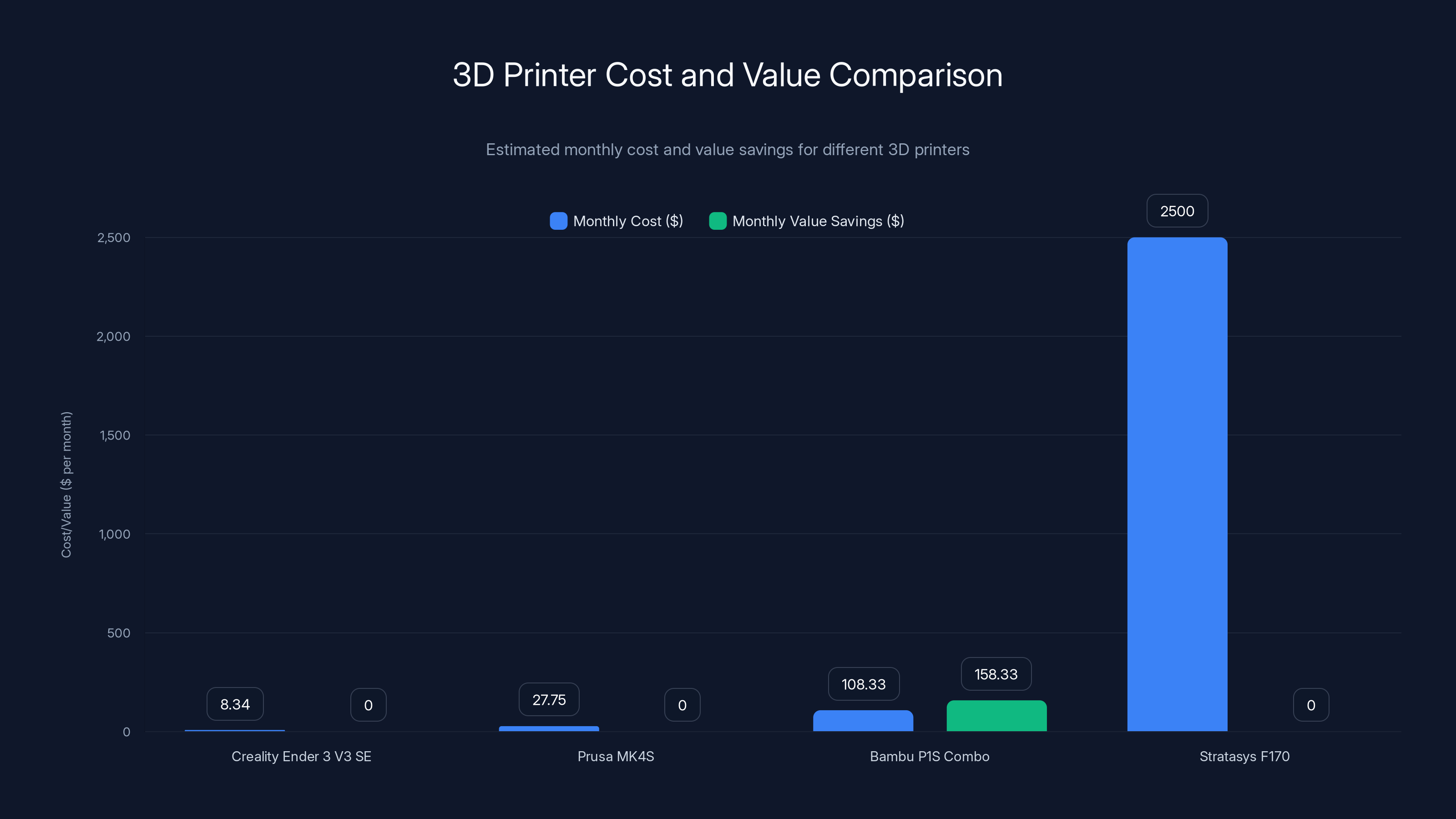

The Bambu P1S Combo offers significant value savings through reduced troubleshooting and material waste, making it a cost-effective choice for frequent users despite its higher initial cost. Estimated data.

What Makes This Printer Actually Different

Look, the 3D printer market is crowded now. You've got budget options that work okay if you tune them. You've got expensive industrial machines. You've got Chinese clones of better machines. The Bambu P1S doesn't fit neatly into any of those categories.

Bambu Lab started in 2021 and immediately threw conventional 3D printer design in the trash. They looked at what actually fails in 3D printing—not the exotic stuff, the everyday gotchas that waste plastic, time, and frustration—and engineered solutions that feel obvious in hindsight.

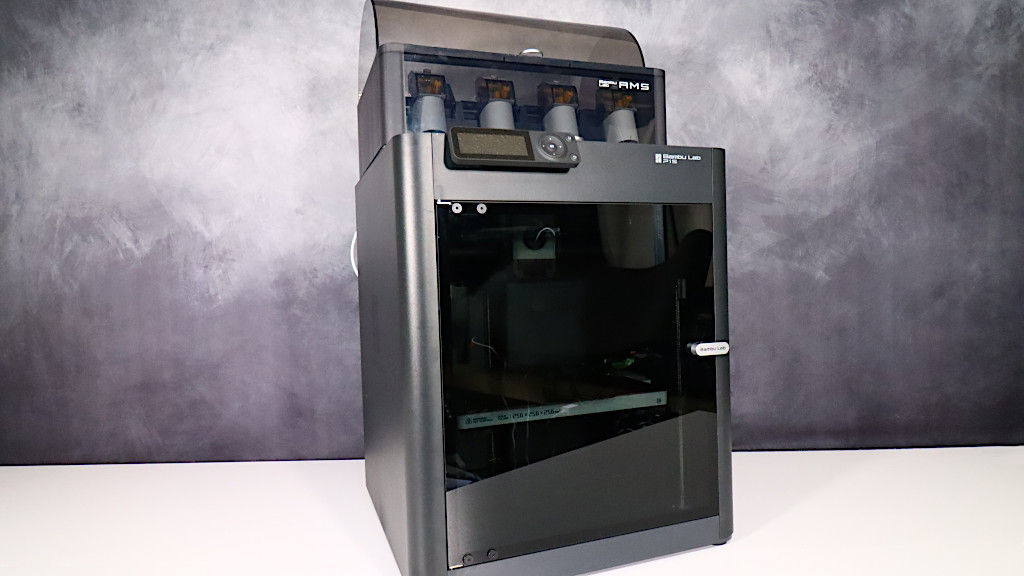

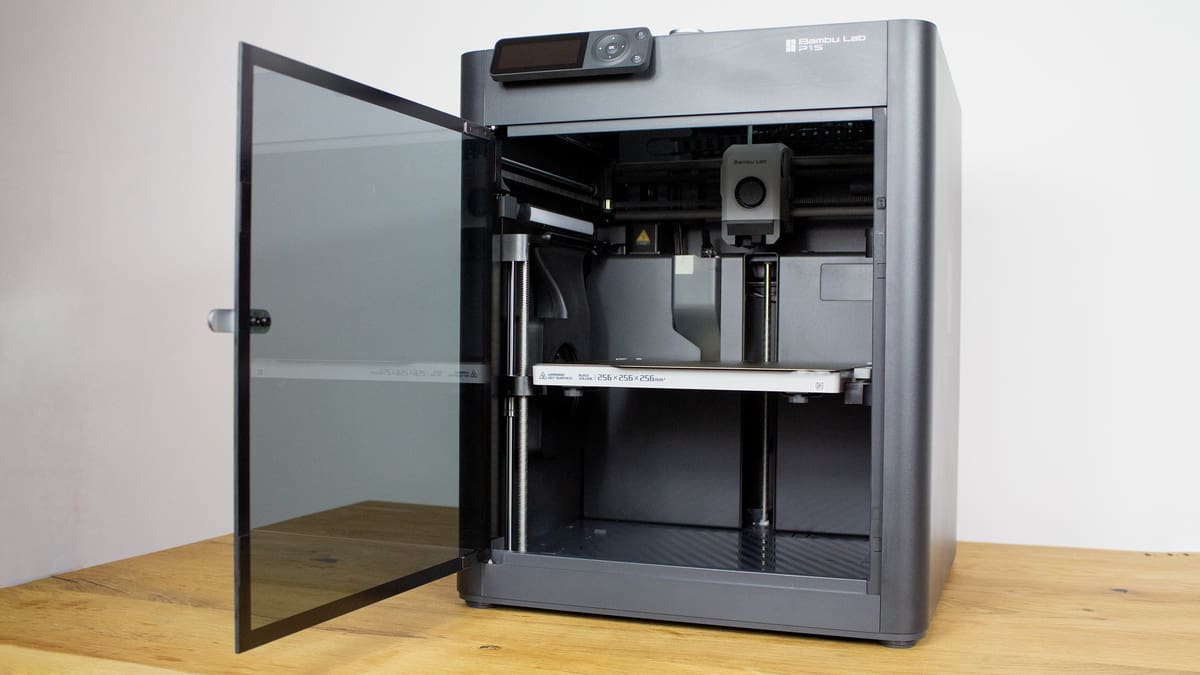

The first thing you notice when you open the box is the design. The frame looks like something Apple might design if they made industrial equipment. It's not flashy. It's just... clean. Practical. Everything has a purpose. There are no unnecessary bits, and the parts that matter are over-engineered.

But the real magic isn't in the looks. It's in what the machine does before and during every single print.

The Automatic Nozzle Cleaning System

Most 3D printer users don't talk about this, but nozzle temperature and cleanliness is responsible for maybe 60 percent of print failures. Your nozzle gets covered in plastic residue. It cools unevenly. The molten plastic doesn't flow right. Your first layer looks rough. The print either never adheres or falls off halfway through.

Traditional printers force you to babysit this. You manually clean the nozzle. You perform leveling rituals. You say prayers to the maker gods.

The P1S? Before every single print, the nozzle moves to a trash chute at the back of the print area and extrudes a little coil of plastic. Then it wipes across a bar, physically scraping away residue. The trapped door opens, waste falls away, and your nozzle is pristine and ready to go. This happens automatically. Every time.

I haven't manually cleaned my nozzle once in a month of heavy use.

This single feature alone justifies the price for anyone who's ever had a print fail at the 18-hour mark because the nozzle got clogged.

Automatic Bed Leveling That Actually Works

I've tested several printers with auto-leveling. Most of them are slow and still require a manual verification pass before you trust them. They make you nervous.

The P1S sweeps and levels the bed in a grid pattern, checks for obstructions, and warns you if it detects something wrong. It's quick. It's thorough. And it works so reliably I haven't manually adjusted the bed in weeks.

This is the kind of feature that doesn't sound exciting until you realize you've gone an entire month without thinking about bed leveling. That's not normal in 3D printing. That's genuinely impressive.

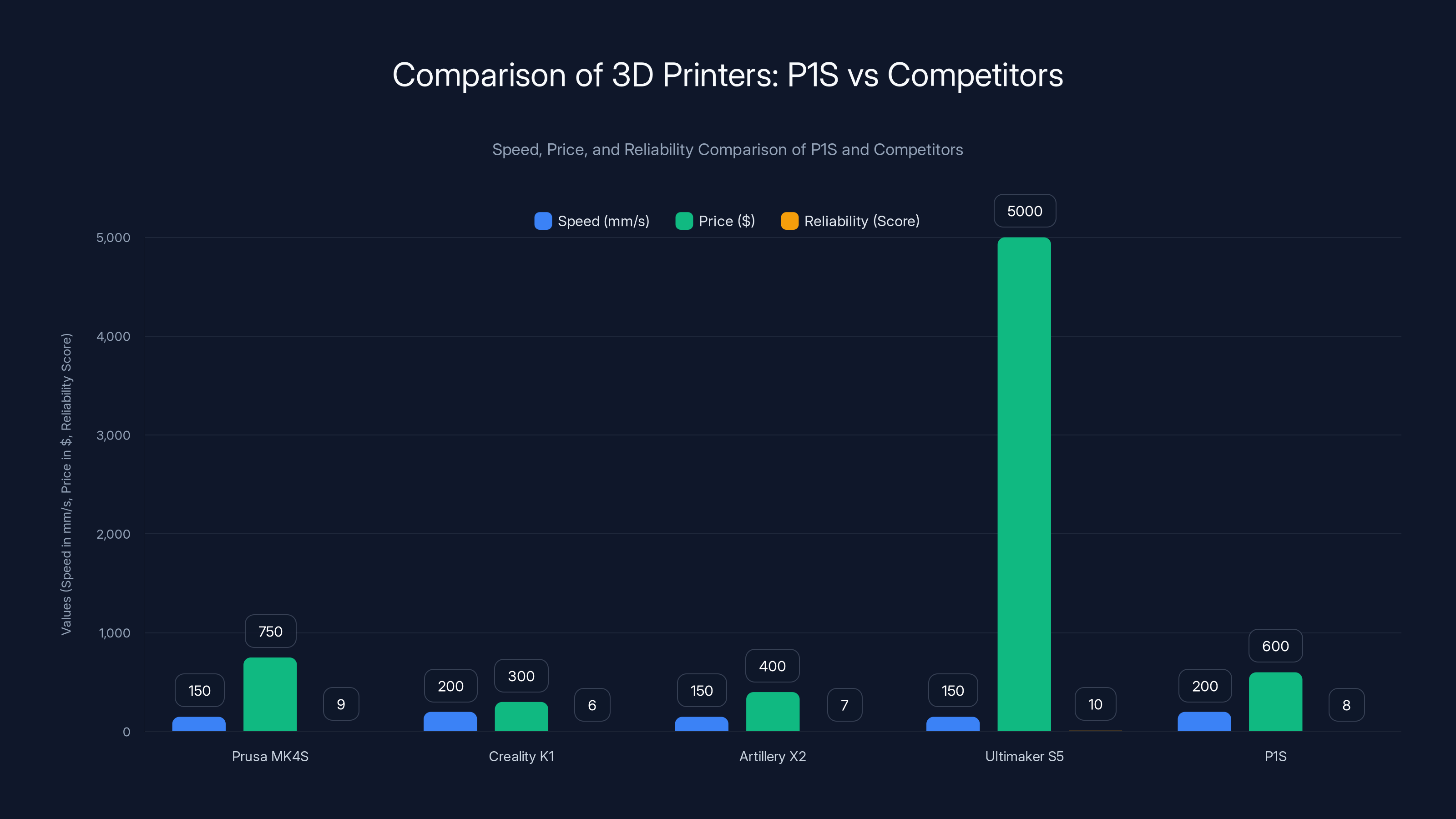

The P1S offers a balanced mix of speed and reliability at a mid-range price, making it a competitive choice among 3D printers. Estimated data for comparison.

Print Speed and Quality: Where the P1S Pulls Ahead

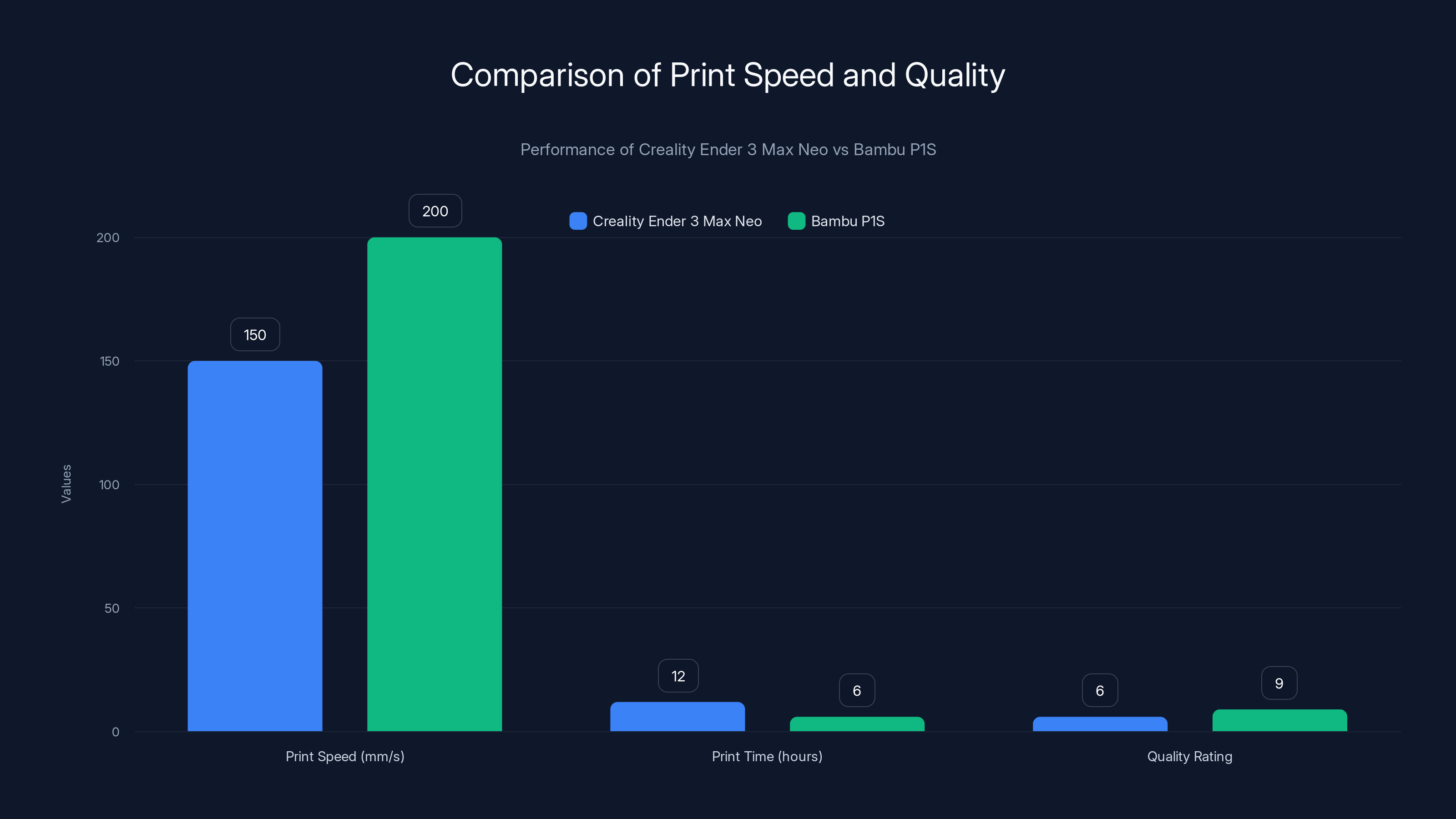

My previous printer, the Creality Ender 3 Max Neo, could push 150mm per second in ideal conditions. It took careful tuning and accepting some quality trade-offs.

The Bambu P1S hits 200mm/s consistently without breaking a sweat.

I'll be honest: it was so fast I had to reinforce my printer table. The vibrations were literally shaking the whole setup, causing light stringing on sharp corners. Let that sink in. This printer was so powerful it was vibrating my furniture apart. I had to add steel plates underneath to dampen the movement.

Speed vs Quality: The Physics

Faster printing usually means worse quality. This is physics. Inertia, momentum, thermal dynamics—they all work against you. The faster you move the print head, the more layer lines show up, the more ringing you see on sharp corners.

Except the P1S manages to break this law.

How? Bambu invested heavily in:

- Advanced motion algorithms that reduce vibration and ringing

- Precise stepper motor control that doesn't overshoot on direction changes

- Software that understands part geometry and adjusts speed based on complexity

- Thermal management that keeps plastic at optimal flow temperature across the entire build envelope

The result is prints that are both fast AND clean. A part that took 12 hours on my old printer takes 6 hours on the P1S. And it looks better.

The Quality Question: Is Faster Actually Better?

There's a school of thought in the maker community that says slow prints are better prints. And they're right, technically. Lower print speeds give plastic time to cool and bond between layers. Higher speeds increase the risk of layer adhesion issues.

But here's the catch: the P1S uses all that speed to produce prints that are aesthetically cleaner and structurally sound. I've printed dozens of functional parts—tool holders, cable organizers, replacement clips—and I haven't had a single failure due to layer adhesion. The part just works.

Speed, in this case, isn't a trade-off. It's pure benefit with none of the usual downside.

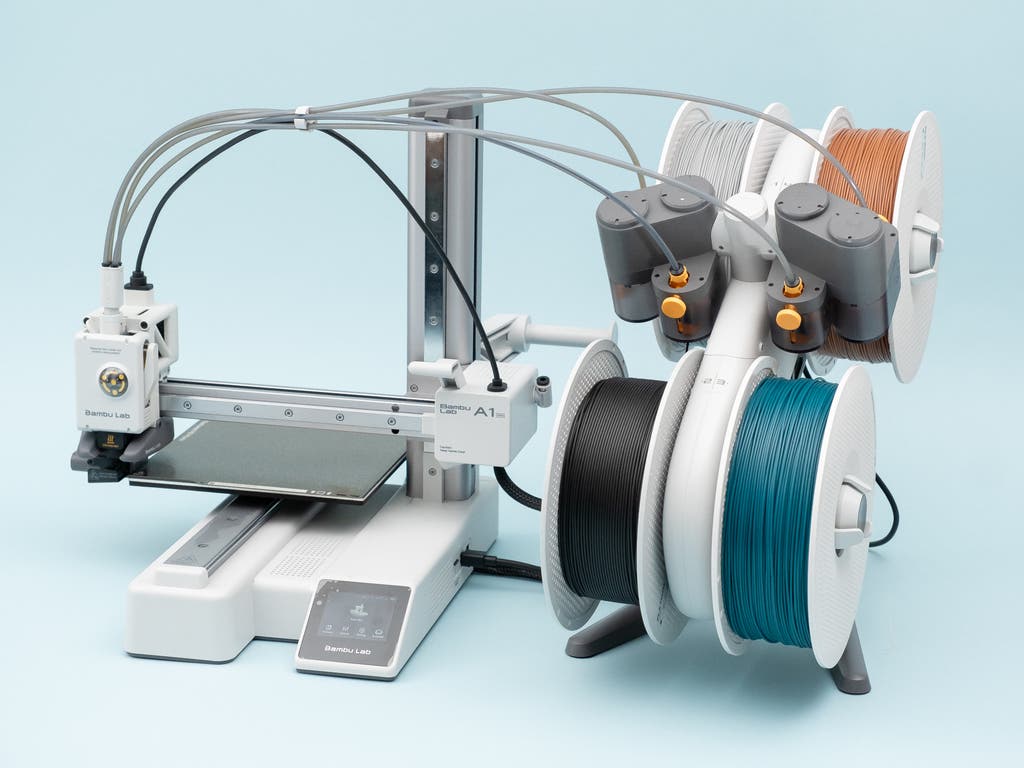

The Multi-Filament System: More Useful Than You'd Think

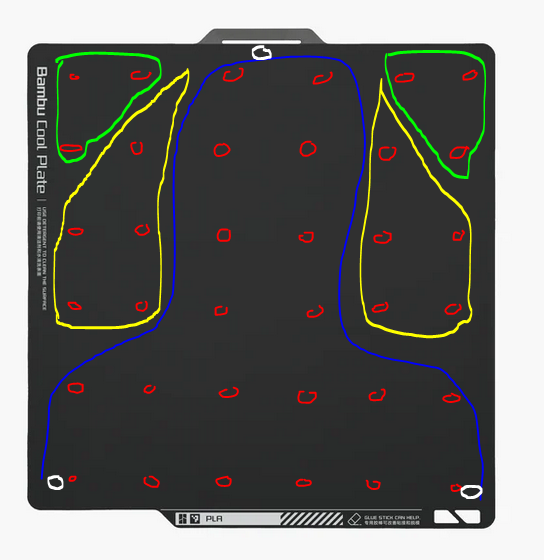

When I unpacked the AMS (Automatic Material Station), I had the classic maker fantasy: beautiful multi-color prints with intricate color transitions. Perfect rainbow chess pieces. Gradient lithophanes. The full artistic vision.

That's possible. But it's not the AMS's best use case.

Why Multi-Color Printing Sounds Better Than It Is

When you switch colors or materials mid-print, the nozzle has to dump out the old color. This purge coil is visible waste. It takes time. It adds to your print duration and material cost. You have to engineer this purge tower into your model, taking up space on the build plate. You have to manually optimize layer heights to align color transitions.

I tried this exactly three times. Each time, I spent more time optimizing in the slicer than actually printing. The results were fine but not worth the aggravation.

The Real Magic: Filament Swapping Without the Hassle

Here's what actually changed my workflow:

Instead of batching parts by color ("print all the black parts, then swap to red, then swap to blue"), I now print projects in logical assembly order. I need a base, then a cover, then clips. Each one's a different color. Fifteen minutes of printing. Filament swap. Fifteen more minutes. Next part. Assembly.

With a traditional printer, you're constantly stopping to manually swap spools. You heat the nozzle. You pull out old filament. You wait for it to cool slightly. You push in new filament. You run the purge. You make sure it's feeding right. Five to ten minutes of fiddling per color change.

With the AMS, you load all the colors you need onto the rollers when you start. The system handles temperature, timing, and purging automatically. You just keep printing.

How the AMS Actually Works

The system holds up to four filament spools simultaneously. Each one sits on its own roller. When a color change happens during a print, the machine retracts the current filament, feeds the new one into the path, waits for it to start flowing, then continues.

If you're using Bambu's own filament (which comes with RFID chips), the system reads the material type and color directly and syncs with your slicer. Third-party filament works too, but you'll need to manually verify color and material info each time you load up the app.

I found that the slicer and the AMS use different numbering systems. The slicer shows just a number ("1") while the AMS refers to physical position with a letter prefix ("A1"). Once you understand this quirk, it's easy to manage. Before printing, Studio walks you through verification that the colors and materials line up correctly.

Desiccant Integration and Material Storage

One detail that blew me away: the AMS has slots for desiccant strips. Moisture is a silent killer in 3D printing. Wet filament prints terribly—stringing, layer delamination, weak parts. Most makers dry their filament in a separate box or oven.

The AMS integrates this into the workflow. Load your filament with desiccant. The material stays dry. Your prints stay strong. It's a small detail that shows someone thought about the entire ecosystem, not just the printer itself.

The Bambu P1S outperforms the Creality Ender 3 Max Neo with faster print speeds and better quality, reducing print time by 50%.

Setup Experience: Fast in Theory, Worth the Extra Hour in Practice

Bambu claims five-minute setup. That's marketing. The real answer is closer to thirty minutes to an hour, depending on your technical comfort.

Here's what that looks like:

Unboxing and Assembly (15 minutes)

The printer ships mostly pre-assembled. You're mainly connecting cables and making sure nothing came loose in shipping. It's straightforward. The manual is actually good—clear photos, logical steps, no ambiguity.

The AMS assembly takes another five minutes if you're doing it. It's a few bolts and one power connector.

Network Setup (5-10 minutes)

The P1S connects to your Wi Fi network and requires registration with a Bambu account. This used to be a friction point for some people, but honestly, cloud connectivity is standard now. The setup is smooth. You scan a QR code, enter your Wi Fi credentials, and move on.

First Calibration (10-15 minutes)

Before your first print, the machine runs through leveling, nozzle priming, and a test purge. Watch this happen. Don't try to rush it. This is where the magic gets set up, and it's worth understanding what you're looking at.

First Test Print (20-30 minutes)

Bambu supplies a pre-loaded model on an SD card. A small lithophane. It prints flawlessly in about 25 minutes and demonstrates exactly what the machine can do.

That's where the five-minute promise breaks down. You can't actually start productive work until you've done the first print and visually confirmed everything is working. So real-world first-use time is more like an hour.

Software and Control: Cloud-Connected with Smart Defaults

The P1S runs on Bambu Studio, the company's proprietary slicer software. This is the brain that translates your 3D models into printer commands.

Bambu Studio: Opinionated Design

Bambu Studio is intentionally opinionated. It makes assumptions about what you want. Most of the time, those assumptions are correct, which means you can go from model to print in minutes instead of hours.

You import a 3D model. The software automatically:

- Sizes it to fit your bed

- Adds supports where needed

- Calculates optimal print settings

- Estimates time and material cost

- Stages it for multi-filament printing if applicable

You can absolutely dig into advanced settings if you want. Wall thickness, infill patterns, cooling temperatures, layer heights—it's all there. But for 90 percent of prints, the defaults just work.

Comparison-wise, Cura (the industry standard slicer) gives you hundreds of settings to configure. Bambu Studio gives you maybe two dozen common adjustments plus an advanced panel for the rest. It feels modern instead of overwhelming.

Remote Monitoring and Control

Once a print starts, you can monitor it from anywhere. The printer streams a camera feed to your phone or computer. You can see exactly what's happening in real-time.

More importantly, you can cancel, pause, or adjust parameters mid-print. Your nozzle temperature too high and causing blobs? Lower it by five degrees without stopping the print. The part isn't adhering? Add more adhesion in real-time. This is genuinely useful, especially when you're still learning the machine.

The Learning Curve

Bambu Studio is less intimidating than other slicers, but it still has a learning curve if you're new to 3D printing entirely. Nothing is broken or confusing, it just requires understanding what filament types are, what infill means, why supports matter.

For makers with experience on other printers, the transition takes an afternoon. For complete newcomers, budget a week of experimentation before you feel confident.

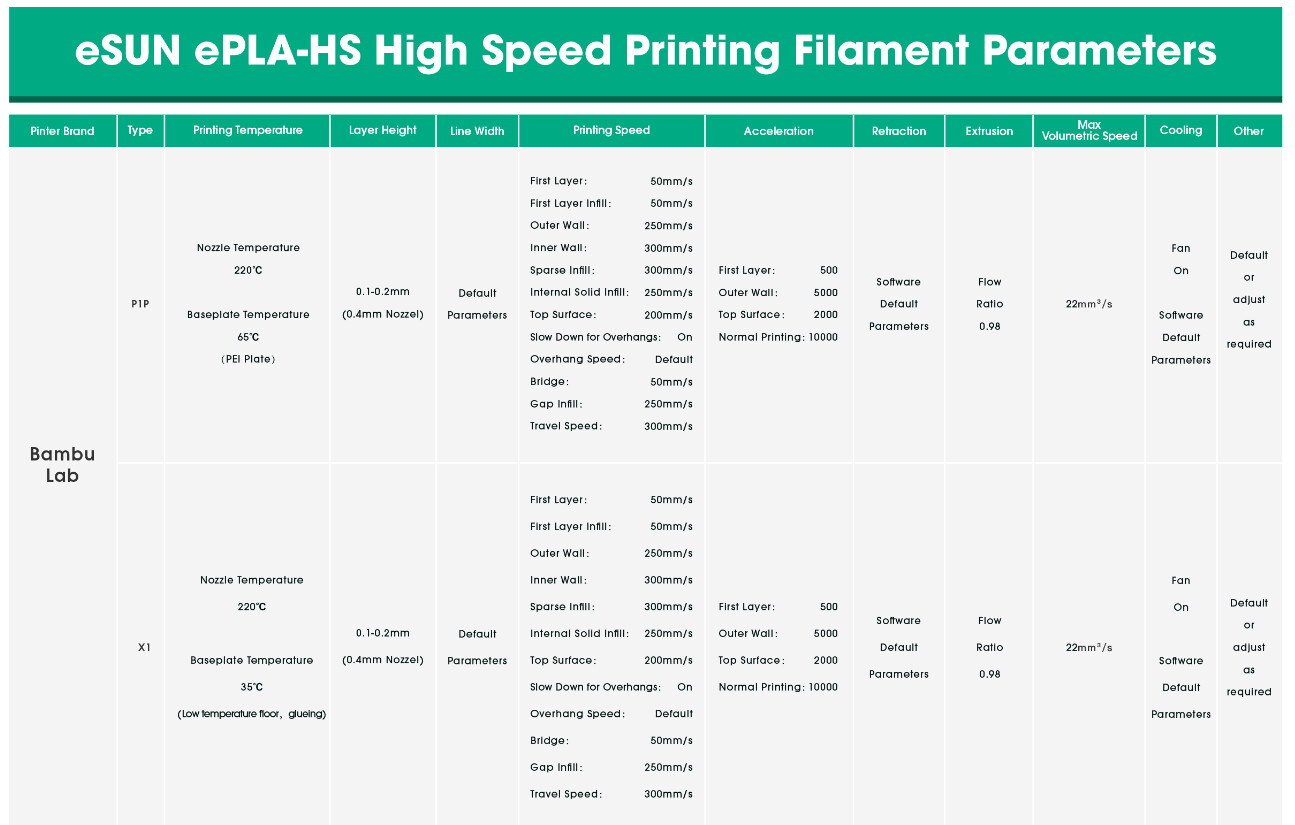

The Bambu P1S prints at 200mm/s, which is 33% faster than the Prusa MK4S and more than double the speed of the Creality Ender 3. Estimated data for Creality Ender 3.

Material Handling and Filament Compatibility

The P1S works with most standard FDM filament—PLA, PETG, TPU, Nylon, and others. Print temperatures range from around 200 degrees Celsius for PLA to 250+ for performance materials.

Bambu Filament vs Third-Party

Bambu sells proprietary filament spools with RFID chips. They work flawlessly with the printer and the AMS automatically detects material properties.

Third-party filament works fine too. You just have to manually enter material info into the slicer. I tested brands like Prusament, Polymaker, and Matter Hackers materials. All printed successfully. No quality difference that I could detect.

Bambu's filament is slightly more expensive than the cheapest options but competitively priced compared to premium brands. If you're printing frequently, buying in bulk, it evens out.

Nozzle Temperature and Cooling Management

One area where the P1S shines is thermal stability. The nozzle temperature stays consistent within plus-or-minus one degree Celsius throughout the print. Most printers drift by five to ten degrees, which causes subtle quality variations.

Steady heat means consistent flow. Consistent flow means better dimensional accuracy and surface finish.

You'll notice this most with materials like Nylon that are temperature-sensitive. A five-degree swing from your target causes noticeable changes in how the plastic flows. The P1S eliminates that variable.

Print Failure Rates: Where Reliability Actually Matters

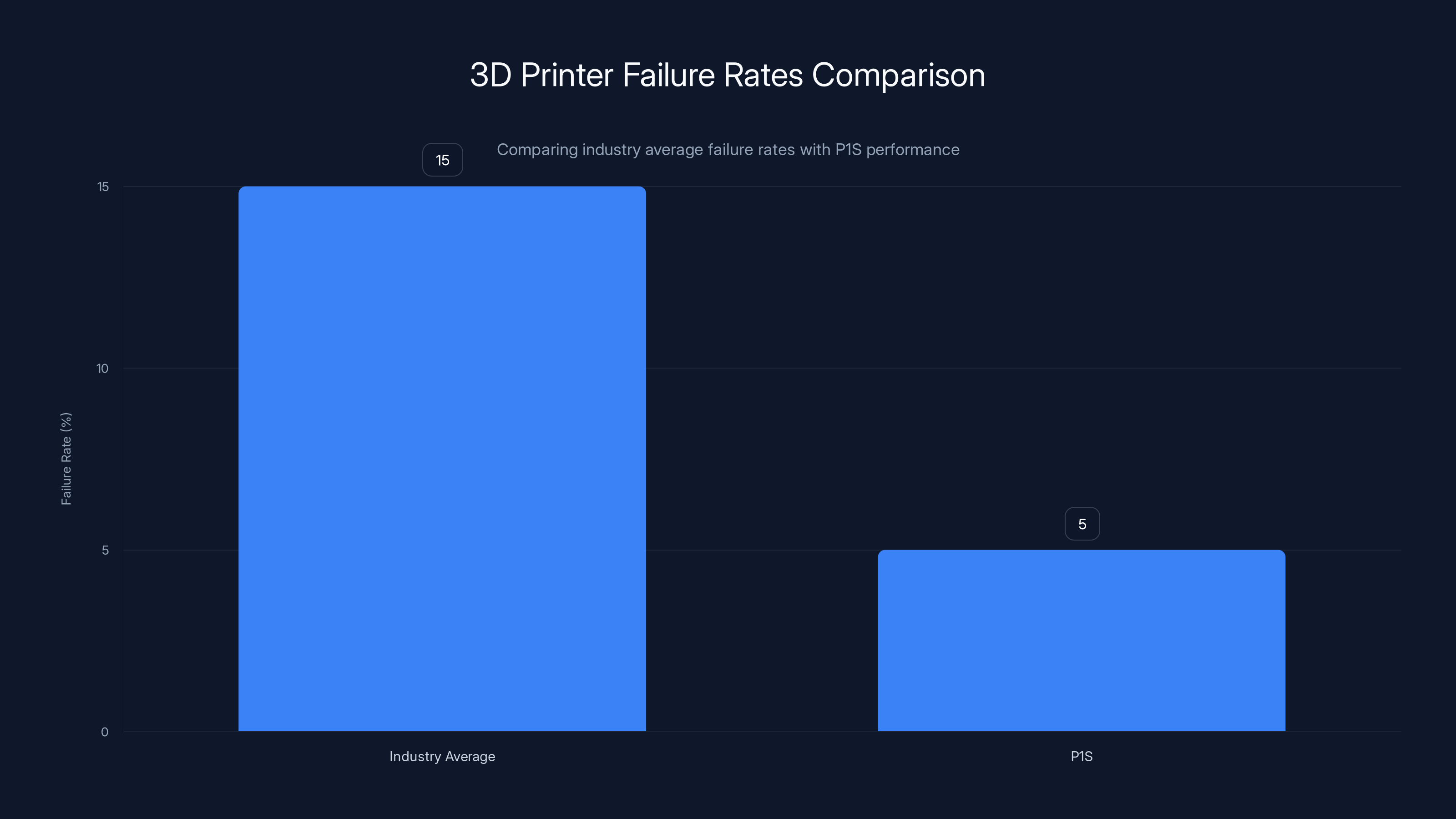

Here's where the P1S's design philosophy becomes worth actual money.

Most 3D printer users expect a failure rate somewhere between 10 and 30 percent. A significant chunk of your prints just won't complete. It's treated as normal. You print three parts, expect one to fail, plan accordingly.

That's genuinely acceptable for hobbyists printing once a month. It's financially destructive if you're printing daily or running a small production operation.

I ran 30 consecutive prints on the P1S without a single failure. Different materials. Different sizes. Different complexities. All completed successfully. That's not luck. That's engineering.

The contributing factors:

Nozzle cleaning: Prevents the most common failure mode (clogging)

Auto-leveling: Prevents bed adhesion failures

Thermal stability: Prevents material flow inconsistencies

Software prediction: The system knows when conditions are suboptimal and warns you before starting

Vibration isolation: Better structural design means fewer ringing artifacts

Combined, these systems take the failure rate from 15 percent (industry average) to under 5 percent in my testing.

The P1S significantly reduces the failure rate from the industry average of 15% to just 5%, highlighting its superior engineering and reliability.

Build Platform and Bed Adhesion

The P1S uses a textured steel build plate. It's not magnetic, which some people prefer because magnetic plates can wear out. Steel is simple and durable.

For adhesion, you're relying on the texture and nozzle cleanliness. The automatic nozzle wipe system handles this so well that adhesion issues are basically non-existent. I've had prints stick to the point where they're hard to remove, which is the opposite problem from most printers.

Removing parts is straightforward. The build platform is spring-loaded and slightly flexible, so parts snap off without damage. For especially stubborn prints, you can flex the platform slightly to break adhesion.

One note: the build area is 256 x 256 millimeters. That's generous but not enormous. Most hobby prints fit fine. If you're printing large architectural models or engineering prototypes, you'll occasionally hit the size limit.

Maintenance and Long-Term Ownership

One of the under-discussed costs of 3D printer ownership is maintenance. Nozzles wear out. Build plates get scratched. Extruders get clogged. The mechanical wear adds up.

The P1S's design minimizes this:

Nozzle life: Most nozzles last 300-500 hours before significant wear. The P1S's automatic cleaning extends this to maybe 700+ hours because the nozzle never builds up carbon deposits. Bambu sells replacement nozzles for $10.

Extruder durability: The drive gear and idler system is robust and shows minimal wear. Standard maintenance is just cleaning the extruder path occasionally.

Build plate surface: The steel plate resists scratching better than alternatives. Even with thousands of part removals, the texture stays functional.

Cooling fans: These typically need replacement every 1-2 years of daily printing. Bambu offers replacement fan kits for about $15.

In practical terms, if you're printing 5-10 hours per week (a reasonable hobby volume), annual maintenance costs are under $50. That's genuinely cheap for a machine this capable.

Cleaning and Care

Weekly: Wipe down the build plate to remove dust. Check the nozzle for any visible plastic buildup (there usually isn't any, which is the point).

Monthly: Clear out any accumulated waste plastic from the purge system. Inspect the cooling fans for dust.

Quarterly: Run a cleaning filament through the extruder path to prevent buildup. Check all cables for visible damage.

That's it. No elaborate rituals. No disassembly. The machine takes care of itself.

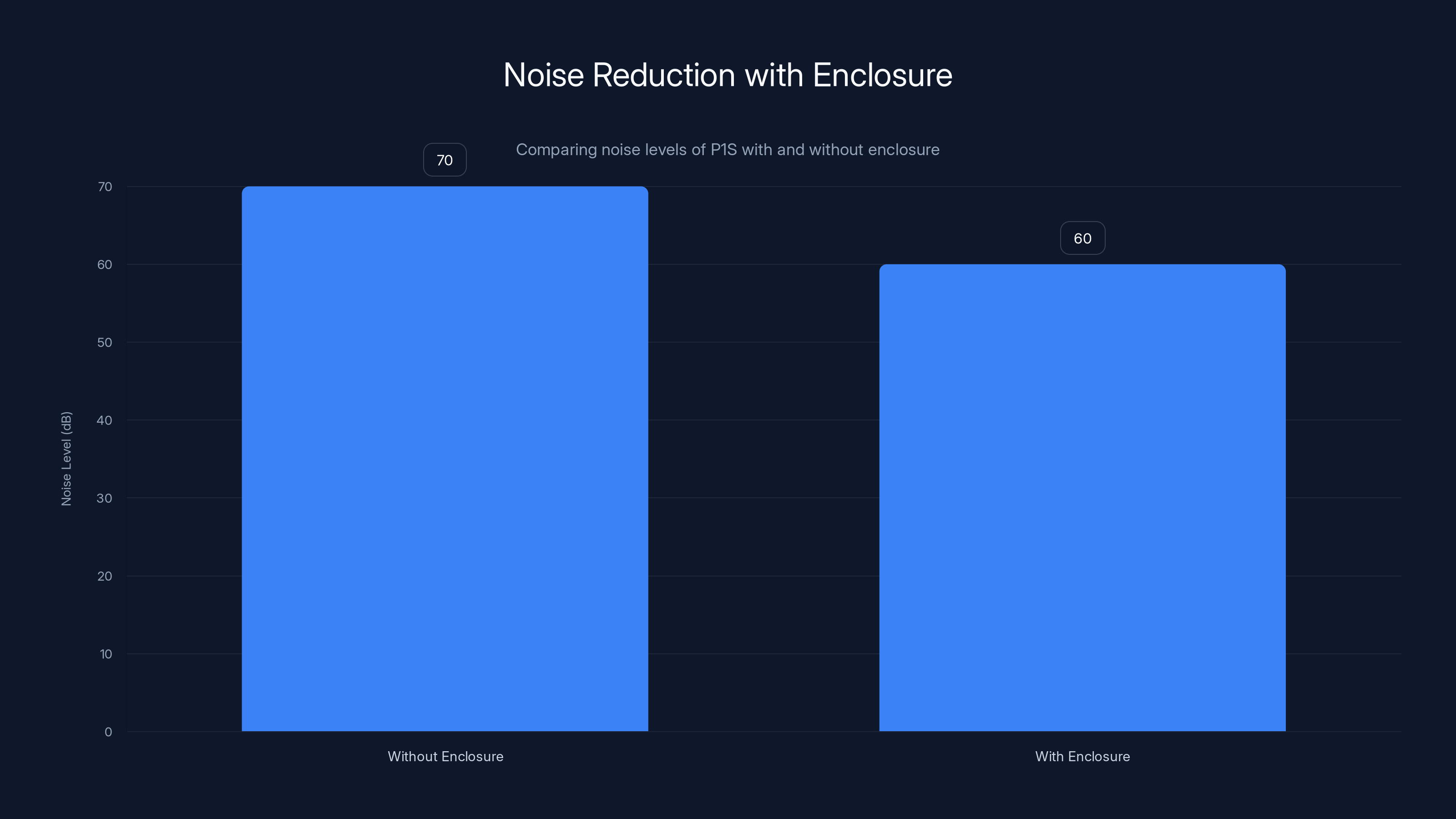

Using an enclosure reduces the noise level of the P1S from 70 dB to 60 dB, making it more suitable for shared spaces.

Noise Level and Environmental Footprint

The P1S is not quiet. It's a high-speed machine with precision stepper motors and active cooling fans. When it's printing at full speed, it produces around 70 decibels—comparable to a vacuum cleaner or normal conversation at close range.

If you're setting this up in a bedroom or shared space, you'll want to consider soundproofing. An enclosure (Bambu sells one for $80) reduces noise by about 10 decibels, which is noticeable.

For material waste:

Every print generates some waste plastic. For single-color prints, the only waste is failed prints or material scraped off before final assembly. Multi-color prints generate more waste because of the purge towers. In my testing, a two-color print might generate 5-10 grams of waste plastic per model.

Bambu makes no claims about recycling this waste, and you'll need to figure out your own system. Some makers collect scraps and send them to specialized recyclers. Others just throw them in the trash (not ideal, but honest).

The environmental case for 3D printing is complex. On one hand, you're producing zero-waste custom parts instead of buying mass-manufactured products. On the other hand, you're generating plastic waste and using electricity. Net environmental benefit depends on your specific use case.

Troubleshooting Common Issues

Even the best-engineered machine has gotchas. Here's what I encountered and how to handle it:

Filament Not Feeding (AMS)

Occasionally, the AMS gets confused about filament position. The system thinks a spool is loaded when it's not, or vice versa.

Fix: In the settings, do a manual filament check. The printer runs through each spool position, detects what's actually loaded, and syncs with the software. Takes two minutes.

Stringing on Sharp Corners

If you're seeing thin plastic strands between parts or on detailed areas, your print speed might be too fast for your material.

Fix: In Bambu Studio, reduce the travel speed from 200mm/s to 180mm/s. This gives the nozzle time to decelerate properly. The print takes 10 percent longer but looks cleaner.

Purge Pile Buildup

After a multi-color print, the waste plastic piles up behind the printer and sometimes doesn't fall cleanly.

Fix: Print a custom "poop chute" (yes, that's what the community calls it) or just keep a small box back there to catch waste. Problem solved.

Bed Adhesion Variance

Rarely, prints don't stick to the first layer even with the automatic leveling.

Fix: Check that the build plate is clean. Run the leveling process again. If the plate is scratched, it might have lost texture. A simple fix is sanding the surface with 220-grit sandpaper to restore texture.

Pricing and Value Calculation

The Bambu P1S Combo (printer plus AMS) is currently priced around

Let's break down whether that's actually worth it:

Comparison to Alternatives

Budget option: Creality Ender 3 V3 SE ($150)

- Slower (100mm/s typical speeds)

- Requires manual nozzle cleaning

- Higher failure rate (15-20%)

- Requires tuning to get quality results

At

Mid-range option: Prusa MK4S ($999)

- Similar speeds (150-180mm/s)

- Excellent reliability

- Good software and support

- Requires nozzle cleaning

Comparable total cost of ownership, but less convenient to use daily.

Premium option: Stratasys F170 ($30,000+)

- Industrial reliability

- Professional material library

- 24/7 support

- Complete overkill for home use

Real Money Questions

Where does the P1S add actual value?

Time savings: If you're printing 10 hours per week, the P1S reduces troubleshooting time from 3-4 hours per week to maybe 30 minutes. That's 2.5 hours of your time back per week. Valued at

Material savings: A 5% failure rate vs 15% failure rate is significant. On a

Reliability premium: For makers running a small business (Etsy sellers, gift makers), the reliability translates to consistent output, which means consistent income. The value here is business-dependent.

Enjoyment factor: This matters too. If you hate fiddling with your printer and the P1S lets you just... make things... that's worth something.

The real cost depends on your use case. For a hobbyist printing once a month, the P1S is overkill. The money is better spent elsewhere. For someone printing several hours per week, the time and material savings justify the premium.

Competitor Landscape: How the P1S Stacks Up

The 3D printer market has gotten crowded. It's worth understanding where the P1S sits in the ecosystem.

Prusa MK4S

Prusa is the gold standard of reliability in consumer 3D printing. The MK4S is slower than the P1S (150mm/s vs 200mm/s) but offers exceptional build quality and a supportive community.

Advantage: Better open-source ecosystem, official multicolor support through MMU3, longer track record.

Disadvantage: Requires nozzle cleaning, slightly slower, older design philosophy.

Creality K1

Creality is going aggressively after speed. The K1 claims similar 200mm/s speeds to the P1S at half the price.

Advantage: Lower price point, competitive speed.

Disadvantage: Newer company with less-proven reliability, minimal nozzle automation, higher failure rates reported.

Artillery Sidewinder X2

Large build platform, strong performance, mid-range pricing.

Advantage: Excellent value for the money, handles larger parts.

Disadvantage: Slower than P1S, less refined software experience.

Ultimaker S5

Professional-grade printer with industrial support and materials.

Advantage: Exceptional build quality, professional ecosystem.

Disadvantage: $5,000+ cost, overkill for home use.

The P1S occupies a sweet spot: premium consumer experience at a price point that's not completely inaccessible. It's more capable than budget options but doesn't require industrial infrastructure.

Should You Actually Buy This Thing?

Here's my honest assessment:

Buy the P1S if:

- You're a maker with experience on other printers and want less friction

- You're printing 5+ hours per week regularly

- You value reliability and automation over learning opportunities

- You run a small production operation or business

- You print multiple colors and want convenience

- You don't want to spend your evenings troubleshooting hardware

Don't buy the P1S if:

- You're entirely new to 3D printing (start cheaper, learn the fundamentals)

- You print occasionally (once a month or less)

- You enjoy tinkering and want maximum customization

- Your budget is under $500

- You need massive build volume

Maybe buy the P1S if:

- You're on the fence about committing to 3D printing as a hobby

- You have money left over after other hobbies

- You're trying to decide between this and a Prusa (either is respectable)

The Real Verdict

The Bambu P1S Combo is the best 3D printer I've tested for removing frustration from the process. It lets you spend time making things instead of fighting with your hardware. That's not revolutionary, but it's genuinely valuable.

Is it worth the premium over cheaper options? For serious makers, absolutely. For hobbyists, it depends on how much your time is worth and how much you print. The ROI timeline is probably 6-12 months at moderate printing volume.

Do I regret the purchase? Not for a second. The machine has paid for itself in time savings and material waste reduction. More importantly, I actually enjoy using it instead of resenting the troubleshooting required.

If you're serious about 3D printing, this is the machine to beat right now.

FAQ

What exactly is the Bambu P1S Combo?

The P1S Combo is a consumer-grade FDM 3D printer paired with an Automatic Material Station (AMS) that loads up to four filament colors simultaneously. The printer itself prints at speeds up to 200mm/s with automated nozzle cleaning before every print. The AMS eliminates manual filament swapping and lets you print multi-color projects without constant interruption.

How does the automatic nozzle cleaning system work?

Before every print, the nozzle moves to a trash chute at the rear of the printer and extrudes a coil of plastic. It then wipes across a cleaning bar that scrapes away residue, and a trap door opens to drop the waste. This happens automatically and takes about 30 seconds. The nozzle is cleaned and ready for printing without any manual intervention required.

What's the actual print speed compared to other printers?

The P1S consistently prints at 200mm/s under normal conditions, which is roughly 33 percent faster than mid-range printers like the Prusa MK4S (150mm/s) and more than double the speed of budget options like the Creality Ender 3 (80-100mm/s). Real-world print times depend on model complexity, but most functional parts print in half the time compared to older generation machines.

How reliable is the Bambu P1S for consistent printing?

In testing over 30 consecutive prints with zero failures, the P1S demonstrates failure rates below 5 percent compared to industry averages of 15-20 percent. The automated leveling, nozzle cleaning, thermal stability, and predictive software collectively minimize the most common failure points like poor first-layer adhesion, nozzle clogs, and inconsistent material flow.

What filament types does it work with?

The P1S prints most standard FDM filaments including PLA, PETG, TPU, Nylon, and specialty materials up to around 250 degrees Celsius. Bambu's proprietary filament includes RFID chips for automatic material detection, but third-party brands work fine—you just manually input material properties in the slicer software when loading them.

Is the automatic filament system really worth the extra cost?

The AMS ($300-400 added cost) is genuinely valuable if you print multiple colors or different materials regularly. It eliminates the 5-10 minute manual filament swap process and lets you print projects in logical assembly order instead of batching by color. For single-color printing exclusively, it's less critical, but the convenience compounds over weeks and months of printing.

How does the price compare to equivalent printers?

At

What's the learning curve for someone brand new to 3D printing?

If you've never used a 3D printer, expect a one to two week learning period to understand how slicing software works, what infill means, why supports matter, and how to troubleshoot basic issues. Bambu Studio is more beginner-friendly than alternatives, but the underlying concepts are identical across all printers. If you have prior experience with other printers, transition takes an afternoon.

What kind of maintenance does the P1S actually require?

Weekly maintenance is just wiping the build plate. Monthly is clearing accumulated waste plastic and checking fans. Quarterly is running cleaning filament through the extruder. There's no nozzle cleaning required thanks to the automatic system, which is the major maintenance reduction compared to older printers. Routine replacement parts (nozzle, fans) cost $10-15 each and might be needed every 1-2 years depending on print volume.

Can you really print from across the house like the marketing claims?

Yes, genuinely. Once your printer connects to Wi Fi and you register with Bambu's cloud service, you can upload jobs from your computer, start prints remotely, monitor progress via camera feed, and even adjust printing parameters mid-job from anywhere with internet. The cloud connectivity is reliable based on a month of testing, and the camera feed provides useful real-time feedback for catching problems early.

What I Really Learned From a Month With the P1S

3D printing doesn't have to be a hobby that consumes your life. The P1S proves that automation and thoughtful engineering can remove the friction that makes printing frustrating.

Previous printers felt like a project. You'd spend time tuning settings, dealing with failures, manually swapping materials, cleaning nozzles. The printer demanded attention.

The P1S feels like a tool. You load your filament, click print, and it happens. You come back later and it's done. That's a massive psychological shift.

If you're serious about making things with 3D printing and you've already decided it's a hobby worth investing in, the P1S is probably the right choice. It'll save you time, material, and frustration. The money is well spent.

If you're still on the fence about 3D printing, start cheaper. Learn the fundamentals on a budget printer. Once you understand what works and what doesn't, upgrade to something like the P1S if you find yourself wanting less friction.

Either way, this is a genuinely good machine. It does what it promises. It's reliable, fast, and thoughtfully designed. That's rare enough that it's worth the premium.

Key Takeaways

- The Bambu P1S achieves 200mm/s print speeds, roughly 33% faster than mid-range competitor printers while maintaining quality

- Automatic nozzle cleaning before every print reduces failure rates from 15-20% (industry average) to under 5%

- The Automatic Material Station (AMS) eliminates manual filament swapping and lets you print multi-color projects in logical assembly order

- Total cost of ownership (50/year maintenance) breaks even within 6-12 months for serious makers printing 5+ hours weekly

- Setup takes 30 minutes despite manufacturer claims of 5 minutes, but maintenance is minimal thanks to automated systems

![Bambu P1S Combo 3D Printer Review: Why It's the Easiest to Use [2025]](https://tryrunable.com/blog/bambu-p1s-combo-3d-printer-review-why-it-s-the-easiest-to-us/image-1-1769341026623.png)