Chinese Robot Vacuum Companies Pivoting to EVs: The Manufacturing Shift & What It Means for Global Markets

Introduction: The Unexpected Journey from Robotics to Automotive

When you think of robot vacuum companies, electric vehicles probably aren't the first thing that comes to mind. Yet at the Consumer Electronics Show in recent years, a fascinating trend has emerged that challenges conventional industry boundaries: established consumer electronics manufacturers are leveraging their core competencies to enter the automotive sector. This shift represents more than just corporate diversification—it reflects a fundamental transformation in how global manufacturing works, where supply chain expertise, engineering talent, and production capabilities transcend traditional product categories.

The story begins with companies like Dreame, a Chinese robotics and smart home leader that built its reputation on intelligent cleaning devices and connected home automation. Rather than remaining confined to the vacuum and home appliance market, Dreame made a bold strategic move by establishing two luxury electric vehicle brands: Nebula Next and Kosmera. These weren't minor side projects or experimental ventures—they were presented at one of the world's largest technology conferences as serious, fully-developed automotive brands with sleek prototypes and ambitious market positioning.

This manufacturing pivot isn't isolated. Roborock, another leading Chinese robot vacuum manufacturer, established its own electric vehicle company in 2023. Xiaomi, the sprawling Chinese consumer electronics conglomerate known for smartphones and smart home devices, launched its first production electric vehicle in 2024. Even Apple, despite eventually abandoning its decade-long automotive project, spent years exploring how its design and engineering expertise could translate into the vehicle space, as highlighted in a recent report.

For Western observers accustomed to siloed industries and specialized manufacturers, this trend may seem counterintuitive or even reckless. How can a company that excels at manufacturing small, autonomous cleaning devices suddenly develop the expertise to produce luxury electric sports cars? Shouldn't automotive companies stick to automobiles, and consumer electronics companies stay in their lane?

The answer lies in understanding the profound shifts happening in manufacturing, supply chain architecture, and the underlying technologies that power modern products. When you deconstruct an electric vehicle, you discover that many of its most critical components—battery management systems, motor controllers, sensor integration, autonomous navigation algorithms, lightweight materials processing, and AI-powered software—are the same technologies that Chinese electronics companies have been perfecting for over a decade.

This comprehensive analysis explores why this pivot makes strategic sense, how Chinese companies are executing these transitions, what advantages they possess, what risks they face, and what this means for the global automotive and electronics industries. By examining specific case studies, market data, supply chain factors, and competitive dynamics, we can understand not just why robot vacuum companies are becoming EV manufacturers, but what this transformation reveals about the future of manufacturing in the 21st century.

Part 1: Understanding the Core Strategic Logic Behind the Pivot

The Manufacturing Foundation: Why Robotics Experience Translates to Automobiles

On the surface, robot vacuum manufacturing and electric vehicle production appear to operate in completely different universes. A Roborock or Dreame robot vacuum is a relatively small, autonomous device that navigates domestic spaces using sensors, AI algorithms, and mechanical components. An electric vehicle is a large, complex machine carrying passengers at highway speeds, subject to rigorous safety standards and regulatory requirements.

Yet the core manufacturing challenges, engineering disciplines, and technological competencies overlap far more than most observers realize. Robot vacuum manufacturers have spent years perfecting several critical capabilities that directly apply to EV production:

Battery Management and Power Electronics: Modern robot vacuums rely on lithium-ion battery systems with sophisticated battery management systems (BMS) that optimize charging, discharging, temperature control, and cell balancing. These exact same technologies, scaled up significantly, form the foundation of electric vehicle propulsion systems. Companies like Dreame and Roborock have developed in-house expertise in lithium chemistry, thermal management, and electrical system design that transfers directly to automotive applications.

Motor Control and Drivetrain Systems: Autonomous vacuum cleaners require precision motor control systems that manage speed, torque, and power distribution to wheels and brushes. These brushless DC motor controllers and drive electronics represent foundational knowledge for electric vehicle motor management. The algorithmic complexity of controlling multiple motors simultaneously in a vacuum cleaner provides experience that proves valuable when managing multi-motor EV drivetrains or individual wheel motors in advanced EV architectures.

Sensor Integration and Navigation: Perhaps most significantly, robot vacuum companies have become experts at integrating diverse sensor arrays—LiDAR, cameras, ultrasonic sensors, accelerometers, and gyroscopes—into a unified navigation and mapping system. This experience with sensor fusion, real-time environmental mapping, and obstacle detection directly supports autonomous driving capabilities in vehicles. The SLAM (Simultaneous Localization and Mapping) algorithms developed for vacuum navigation provided foundational research for automotive autonomy systems.

Autonomous Navigation Algorithms: Building an algorithm that enables a vacuum to navigate a home autonomously, learn the layout, optimize cleaning patterns, and handle unexpected obstacles requires sophisticated artificial intelligence and machine learning. These algorithmic approaches scale remarkably well to vehicle navigation, path planning, and autonomous driving—albeit with significantly increased complexity for highway driving versus home navigation.

Wireless Connectivity and IoT Infrastructure: Robot vacuums operate as sophisticated IoT devices with cloud connectivity, mobile app integration, over-the-air updates, and remote monitoring capabilities. Developing robust, secure, and scalable systems for managing fleets of connected devices translates directly to the telematics, cloud services, and connected car infrastructure that modern EVs require.

When you examine the engineering talent, manufacturing processes, and technological competencies within companies like Dreame, you find teams who have spent years solving problems that seem trivial until you realize their profound complexity. How do you manufacture lightweight components with tight tolerances at scale? How do you manage supply chains for electronics components globally? How do you optimize manufacturing processes to reduce costs while maintaining quality? How do you design products that balance performance, longevity, and affordability? How do you integrate software, electronics, and mechanical systems into a unified product?

These aren't trivial challenges, and companies that have solved them at scale in the vacuum market possess enormous advantages when entering the automotive sector.

The Supply Chain Advantage: Why Chinese Electronics Companies Have Structural Advantages

Beyond the technological and engineering foundations, Chinese consumer electronics manufacturers operate within supply chain ecosystems that provide substantial structural advantages for vehicle manufacturing. This isn't merely about labor costs—a persistent but reductive explanation for Chinese manufacturing advantages. Rather, it reflects decades of investment in industrial clusters, component suppliers, materials science capabilities, and manufacturing infrastructure that have accumulated in specific regions of China, particularly the Pearl River Delta.

When a company like Dreame decides to manufacture electric vehicles, it doesn't start from scratch sourcing components globally at premium prices. Instead, it can tap into an extraordinarily dense ecosystem of component suppliers, many of which it already has relationships with from its vacuum and smart home business. The same suppliers providing lithium-ion battery cells, electric motors, power electronics components, and control systems for vacuum cleaners can scale up production for automotive applications.

This proximity and existing relationship network reduces several critical friction points in vehicle manufacturing. Supply chain negotiation times compress dramatically when you can discuss increased volume with suppliers you've worked with for years. Quality control becomes simpler when suppliers understand your engineering standards and manufacturing practices. Rapid prototyping accelerates when you can quickly obtain custom components from nearby suppliers rather than international procurement processes. Cost optimization improves when you leverage existing supply agreements and manufacturing relationships.

Chinese manufacturing clusters have also accumulated extraordinary expertise in specific subsystems that vehicles require. The Shenzhen and greater Pearl River Delta regions have developed world-leading capabilities in battery technology, consumer electronics manufacturing, precision machining, materials science, and semiconductor assembly. When a company enters vehicle manufacturing, it can tap into this accumulated expertise through partnerships, hiring, and acquisition rather than developing everything in-house.

Additionally, Chinese manufacturers have invested heavily in manufacturing automation, quality control systems, and process optimization that reduces unit costs even as complexity increases. The same precision manufacturing techniques used for smartphone components can be adapted for EV components. The same quality assurance protocols used for millions of consumer electronics can scale to automotive manufacturing.

Technological Crossovers: What Vacuums Teach Us About Vehicle Design

Beyond manufacturing foundations, robot vacuum companies have developed specific technological expertise that directly accelerates EV development. The most obvious crossover involves autonomous driving and vehicle navigation systems.

Robot vacuums represent some of the most sophisticated autonomous systems in consumer use. A modern Roborock vacuum doesn't just randomly move around a room—it creates a detailed 3D map of the environment, plans optimal cleaning routes, recognizes furniture and obstacles, adapts to different room types, and coordinates complex behaviors across multiple rooms. Developing this autonomous capability required deep expertise in computer vision, LiDAR processing, path planning algorithms, real-time processing under computational constraints, and robust sensor fusion.

These exact technological competencies form the foundation of autonomous vehicle development. The difference between a vacuum navigating a home and a car navigating highways is primarily one of scale, speed, and safety requirements—not fundamental algorithmic differences. Companies with proven autonomous navigation expertise in consumer environments have significant advantages developing autonomous driving systems for vehicles.

Robot vacuum companies have also accumulated extensive experience with machine learning systems that improve over time. A modern vacuum learns your home layout, your cleaning habits, and optimizes its behavior based on interaction patterns. This machine learning infrastructure translates directly to EV systems that adapt to driver behavior, optimize energy consumption, and improve autonomous capabilities through continuous learning.

Another significant technological crossover involves power management and efficiency optimization. Robot vacuums operate under stringent power constraints—they must provide sufficient runtime to clean an entire home on a single charge while maintaining reasonable charging times. This constraint-driven design mentality drives relentless efficiency optimization across every system. Engineers at vacuum companies have spent years squeezing additional runtime and performance from finite battery capacity through clever hardware design, algorithmic optimization, and system integration.

These efficiency-focused design practices transfer directly to EV development, where battery range represents a critical competitive metric. Companies that have optimized every milliwatt of power consumption in vacuum motors, sensors, and processors bring that same efficiency mindset to EV drivetrains, onboard electronics, and autonomous systems.

Part 2: The Dreame Story—From Cleaning Robots to Luxury EVs

Dreame's Market Position and Core Competencies

Dreame, founded in 2015, emerged as one of China's fastest-growing smart home and robotics companies. The company achieved remarkable success in the fiercely competitive robot vacuum market, eventually becoming one of the top manufacturers globally. By the mid-2020s, Dreame had established itself not just as a vacuum manufacturer but as a comprehensive smart home platform company offering robot vacuums, robotic mops, air purifiers, and connected home devices.

What distinguishes Dreame from typical consumer electronics manufacturers is the breadth and depth of its technological capabilities. The company invested heavily in artificial intelligence, computer vision, autonomous navigation systems, and cloud-based IoT infrastructure. More importantly, Dreame developed these capabilities not through acquisition but through organic research and development, building internal teams of engineers, data scientists, and roboticists.

By 2023-2024, Dreame possessed several competitive advantages that positioned it unusually well for automotive expansion. The company had achieved substantial scale in manufacturing, with production facilities optimized for precision electronics and robotics. It had established supply chain relationships with component manufacturers across China's Pearl River Delta region. It had developed significant software and AI capabilities that powered advanced autonomous features. And critically, it had access to capital and investor confidence that comes from successful scale-up in consumer electronics.

The Two-Brand Strategy: Nebula Next and Kosmera

Rather than launching a single EV brand under the Dreame name, the company created two distinct automotive brands, each with different market positioning and design philosophies. This approach offered several strategic advantages.

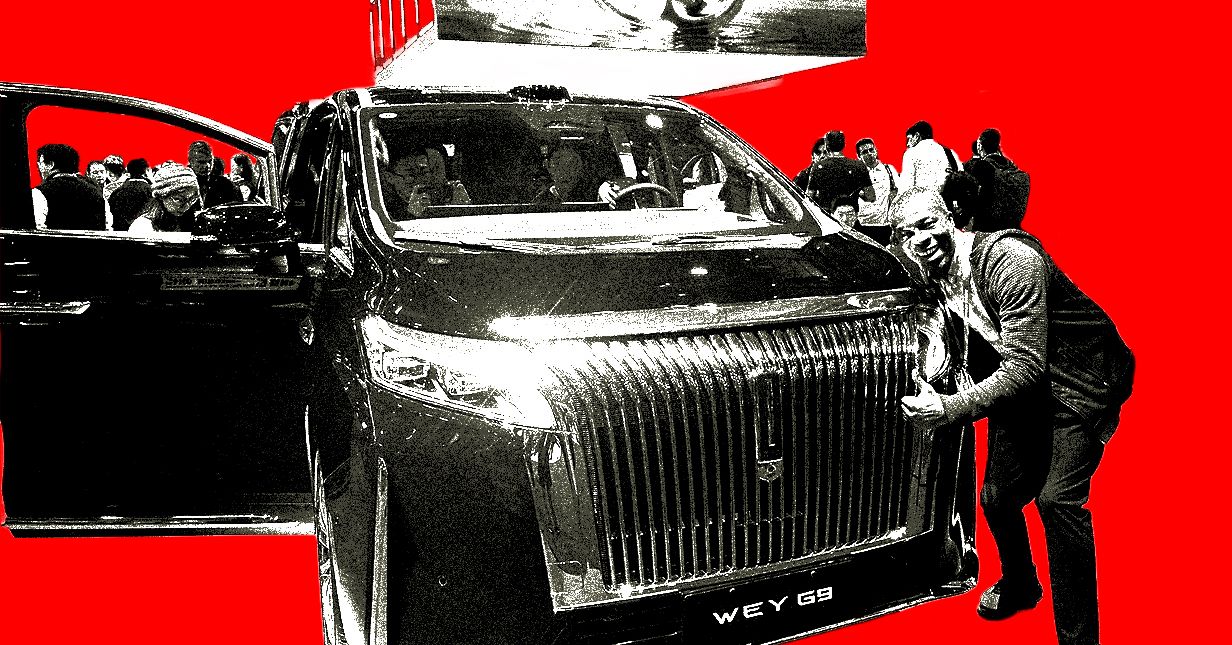

Nebula Next was positioned as a performance-oriented luxury electric vehicle brand, emphasizing sleek design, advanced technology, and premium positioning. The prototypes showcased at CES featured futuristic styling, high-tech interiors, and emphasis on autonomous and connectivity features.

Kosmera, meanwhile, was conceptualized as a luxury lifestyle EV brand, potentially targeting different market segments or international markets with distinct brand identities and positioning.

This two-brand strategy accomplished several objectives simultaneously. First, it allowed Dreame to explore multiple market segments without constraining itself to a single brand identity. Luxury EVs exist across a spectrum from performance-focused (like Tesla's high-performance variants) to lifestyle-focused (like luxury EV startups emphasizing comfort and design). By creating two brands, Dreame could potentially address multiple segments.

Second, the separate branding provided organizational and operational independence. Each brand could develop its own design language, target different customer demographics, and pursue distinct go-to-market strategies without being constrained by a shared corporate identity. This flexibility proves valuable in automotive markets where brand perception and differentiation drive purchasing decisions.

Third, the two-brand approach created perceived distance from the Dreame corporate parent, allowing these luxury automotive brands to develop independent reputations in automotive enthusiast circles. Consumers considering a luxury EV might not immediately connect it to a vacuum cleaner company, which could reduce potential brand perception issues.

The Technology Foundation: Autonomous Driving and EV Platforms

The Nebula Next and Kosmera prototypes showcased at CES revealed significant technological ambitions extending far beyond basic electric propulsion. According to reports and industry analysis, both brands were developing autonomous driving capabilities that represented some of the most advanced systems in development globally.

Dreame's robot vacuum autonomy expertise provided the foundation for these automotive autonomous systems. The company's computer vision algorithms, sensor fusion techniques, and path planning systems that enable vacuum robots to navigate homes autonomously translated remarkably well to vehicle autonomous systems. The technical challenge of autonomous navigation increases dramatically when transitioning from home environments to highways, but the fundamental algorithmic approaches show strong continuity.

Both brands were also developing full EV platforms designed for manufacturing scale. Rather than building hand-crafted prototypes, Dreame was clearly engineering production-viable vehicle architectures with modular battery systems, scalable motor platforms, and flexible interior architectures that could accommodate different vehicle sizes and configurations.

The integration of advanced connectivity features reflected Dreame's strength in IoT and cloud platforms. Both brands featured sophisticated vehicle-to-cloud communication systems, over-the-air update capabilities, and cloud-based autonomous driving features. These telematics platforms leverage Dreame's experience managing millions of connected smart home devices simultaneously.

Market Challenges and Competitive Positioning

Despite the technological foundation and strategic advantages, Dreame's automotive ventures face significant challenges that extend beyond manufacturing expertise. The Chinese EV market has become extraordinarily competitive, with established players like BYD, NIO, XPeng, and Li Auto investing billions in autonomous driving, battery technology, and vehicle platforms. International competition from Tesla, established luxury automakers, and new entrants creates additional pressure.

The transition from consumer electronics to vehicles also involves regulatory complexities that vacuum manufacturing never requires. Safety standards for vehicles exceed consumer electronics by orders of magnitude. Crash safety, emission compliance, autonomous system validation, and liability frameworks all present novel challenges requiring specialized expertise and regulatory navigation.

Brand perception represents another challenge. Consumers considering a $100,000+ luxury EV might have reservations about purchasing from a company primarily known for vacuum cleaners. While the two-brand strategy partially addresses this concern, the association remains a potential marketing headwind.

Part 3: Roborock's Automotive Venture—The Earlier Pivot

Roborock's History and Market Leadership

Roborock, founded in 2014, achieved remarkable success competing against established consumer electronics giants. The company developed technologically sophisticated robot vacuums that competed effectively globally, particularly in premium market segments. By the early 2020s, Roborock had established itself as one of the world's leading robot vacuum manufacturers alongside iRobot and Bissell.

Roborock's technology roadmap closely paralleled Dreame's, with investments in autonomous navigation, computer vision, AI-powered features, and cloud-based services. The company achieved particular recognition for its advanced mapping algorithms, multi-level home support, and integration with smart home ecosystems.

Critically, Roborock developed strong technological capabilities in several areas that would prove valuable for automotive applications. The company's R&D investments in motor control, power electronics, sensor integration, and autonomous navigation created organizational competencies extending far beyond vacuum manufacturing. Engineers at Roborock understood the challenges of building sophisticated autonomous systems operating under computational and power constraints—precisely the challenges that EV engineers face.

The Automotive Venture: Timing and Opportunity

In 2023, Roborock announced the establishment of an automotive venture focused on electric vehicle development. Rather than launching full vehicle production immediately, Roborock adopted a more measured approach, establishing the organizational infrastructure, recruiting talent, and developing initial platform concepts. This measured pace reflected lessons from the vacuum market, where sustainable competitive advantage requires deep technological development and careful market timing.

Roborock's automotive entry occurred at an optimal moment in the EV market evolution. The global EV market was transitioning from early adoption to mass market, with more consumers considering electric vehicles as mainstream transportation. Autonomous driving capabilities, once viewed as far-distant possibilities, were becoming increasingly tangible with companies like Waymo and Tesla demonstrating advanced autonomous systems. Battery technology was improving rapidly, reducing costs and increasing range, making EVs increasingly competitive with traditional vehicles.

For Roborock, this timing meant entering the EV market when technological foundations were solid enough for production vehicles while remaining early enough to establish competitive advantage before the market consolidated around a few dominant players.

Technological Leverage Points for Roborock's EV Ambitions

Roborock possessed specific technological advantages that informed its automotive strategy. The company's expertise in lightweight material handling—critical for keeping vacuum robots efficient—transferred to EV design, where reducing weight to maximize range represents a constant engineering challenge.

Roborock's software architecture for managing autonomous devices across multiple rooms, handling edge cases, and continuously improving through machine learning provided valuable experience for autonomous vehicle systems. The company's ability to optimize complex mechanical systems to work reliably in millions of homes demonstrated manufacturing maturity that translated to automotive quality requirements.

The company's supply chain relationships, developed through years of global vacuum distribution, provided networks that could expand to support automotive component sourcing. Many of the electronic component suppliers supporting robot vacuum manufacturing also supply automotive components, creating natural expansion paths.

Part 4: Xiaomi's EV Success—The Proven Model

Xiaomi's Unique Position in Chinese Tech

Xiaomi represents an even more ambitious example of this manufacturing pivot, though by many accounts, the company's automotive venture has proven more successful than Dreame's. Founded in 2010, Xiaomi grew from smartphones to become one of China's most comprehensive consumer electronics companies, encompassing not just phones but smartwatches, tablets, laptops, televisions, home automation devices, and an enormous ecosystem of connected hardware.

Xiaomi's appeal to this analysis lies in the company's proven ability to enter and succeed in adjacent markets outside its core smartphone business. The company didn't simply manufacture multiple product categories—it developed genuine technological and operational competencies in each sector, competing successfully against specialized manufacturers.

The SU7 and Xiaomi's Automotive Entry

In 2024, Xiaomi launched the SU7, a premium electric sedan that represents one of the most sophisticated vehicle launches from any electronics company. The SU7 represents far more than a vanity project or experimental venture—it embodies a serious, well-capitalized, and technologically advanced automotive platform, as noted in Electrek's coverage.

The SU7 demonstrates how Xiaomi leveraged its accumulated expertise from consumer electronics into vehicles. The vehicle features sophisticated autonomous driving capabilities, integrated cloud connectivity, over-the-air update architecture, and advanced electronics integration that reflects years of Xiaomi's consumer electronics expertise.

Xiaomi's unique advantage stemmed from its position within the broader Xiaomi ecosystem. The company had developed extensive expertise in battery technology through its extensive consumer electronics manufacturing. Its software architecture for managing large ecosystems of connected devices provided infrastructure for vehicle telematics. Its industrial design capabilities, honed through millions of smartphones and tablets, informed the SU7's aesthetic and ergonomic design.

The SU7 launched with meaningful production volumes and serious market positioning, suggesting Xiaomi had invested appropriately in manufacturing infrastructure, supply chain development, and market positioning. Early market reception proved positive, with substantial pre-orders and positive reviews from automotive analysts.

What Xiaomi's Success Reveals About Manufacturing Pivots

Xiaomi's EV venture demonstrates that manufacturing pivots from consumer electronics to vehicles can succeed when executed with sufficient capital, technological depth, and market timing. The company didn't rush vehicles to market—it invested years in platform development, supply chain establishment, and regulatory navigation.

Xiaomi's success also reflects the company's unique advantage as a comprehensive consumer electronics platform. The SU7 could integrate deeply with Xiaomi's existing ecosystem of smart home devices, wearables, and connectivity services. Consumers purchasing the SU7 could enjoy seamless integration with their Xiaomi tablets, smartwatches, and home devices. This ecosystem advantage represents something that pure automotive manufacturers struggle to replicate.

Part 5: Apple's Failed Automotive Project—Lessons in Complexity and Reality

The Ambition and Scale of Apple's Automotive Effort

Before discussing successful automotive ventures from electronics companies, it's crucial to acknowledge Apple's ultimately unsuccessful multi-billion dollar automotive project. For over a decade, beginning around 2014, Apple invested substantial resources in developing an electric vehicle, code-named "Project Titan." The project reportedly employed thousands of engineers, consumed billions of dollars, and represented one of the most ambitious private sector automotive initiatives ever undertaken.

Apple's automotive ambition reflected the company's confidence in its design capabilities, engineering excellence, and manufacturing prowess. If any consumer electronics company possessed the resources, talent, and technical depth to develop a vehicle, it seemed like Apple. The company's track record in transforming entire product categories—from smartphones to tablets to smartwatches—suggested it could apply similar innovation to automobiles.

Why Even Apple Couldn't Succeed

Yet despite all these advantages, Apple ultimately abandoned its automotive project in 2024, acknowledging that the challenges exceeded what the company was willing to undertake. This failure provides crucial lessons for understanding both the difficulties of automotive manufacturing and the limits of technology company expertise.

Automotive manufacturing involves regulatory, liability, and safety requirements that dwarf consumer electronics. A defective smartphone results in poor reviews and returns. A defective vehicle results in injuries, deaths, lawsuits, and regulatory action. The safety validation and regulatory compliance requirements for vehicles fundamentally exceed anything Apple had experienced in consumer electronics.

Vehicles also require enormous capital investments in manufacturing infrastructure, supply chain development, and dealer networks (for many markets). Apple's asset-light model in consumer electronics, relying on contract manufacturers, doesn't translate cleanly to vehicles, where numerous manufacturers require customized facilities and supply chain integration.

The lifespan and service requirements of vehicles differ fundamentally from consumer electronics. Consumers expect smartphones to function for 3-4 years. Vehicles are expected to last 10-15 years or more, requiring spare parts support, service infrastructure, and regulatory compliance over decades. Building this long-term infrastructure represents a fundamentally different commitment than consumer electronics.

What Apple's Failure Teaches About Chinese Electronics Companies

Apple's failure in automotive manufacturing raises important questions about whether the manufacturing pivots by Dreame, Roborock, and other Chinese electronics companies can ultimately succeed. If Apple—arguably the world's most capable technology company—couldn't sustain an automotive venture, what makes other electronics companies confident they can succeed?

Several factors differentiate Chinese electronics manufacturers from Apple. First, these companies are entering the Chinese EV market, which operates with different regulatory frameworks and customer expectations than the global automotive market Apple was targeting. Second, Chinese electronics companies are operating within local manufacturing ecosystems with existing supply chains, regulatory relationships, and market knowledge that Apple would have needed to develop. Third, companies like Dreame and Roborock have lower profitability requirements and longer investment timelines than Apple, enabling them to invest in automotive ventures that might not generate profits for years.

Yet Apple's cautionary example suggests that even with tremendous advantages, electronic devices companies face substantial challenges transitioning to automotive manufacturing at scale. The barriers involve far more than manufacturing expertise—they encompass regulatory navigation, liability frameworks, capital requirements, and organizational culture changes that prove surprisingly difficult.

Part 6: The Broader Trend—Multiple Electronics Companies Entering Automotive

Beyond Robot Vacuums: The Comprehensive Pivot Movement

While robot vacuum companies receive the most attention for pivoting to vehicles, a broader movement is underway among Chinese electronics manufacturers entering automotive. Companies spanning consumer electronics, consumer robotics, telecommunications equipment, and consumer appliances are simultaneously exploring automotive ventures.

This simultaneous movement suggests the pivot isn't an isolated anomaly but reflects fundamental economic and technological trends making automotive entry increasingly feasible for non-traditional manufacturers. The convergence of electric propulsion, autonomous driving, software-defined vehicles, and changing consumer expectations has lowered traditional barriers to automotive entry.

Where automobile manufacturing once required specialized expertise unique to automotive companies, the skills increasingly demanded reflect broader technology trends. Software development, artificial intelligence, battery chemistry, motor control, and user interface design represent competencies that large technology companies possess more deeply than traditional automakers.

The List of Electronics Companies Exploring Automotive

Beyond Dreame, Roborock, and Xiaomi, numerous other Chinese electronics and technology companies have announced or launched automotive initiatives. These include smartphone manufacturers, consumer appliance companies, home automation platforms, and telecommunications equipment companies. This breadth of participation suggests the automotive entry represents not isolated decisions by specific companies but a strategic reorientation across entire Chinese industrial sectors.

Leading telecommunications equipment companies, traditionally focused on networking infrastructure, have established automotive subsidiaries developing autonomous driving systems and vehicle connectivity platforms. Consumer appliance manufacturers have announced EV development programs. Smart home platform companies have explored vehicle integration strategies. This distributed participation suggests automotive manufacturing is becoming increasingly accessible to technology companies with relevant expertise.

Part 7: Manufacturing Excellence and the Supply Chain Advantage

How Chinese Supply Chains Reduce Automotive Development Risk

One persistent explanation for Chinese companies' ability to enter automotive manufacturing relates to the exceptional manufacturing infrastructure concentrated in specific Chinese regions. The Shenzhen and Pearl River Delta region represents perhaps the world's highest concentration of consumer electronics manufacturing capabilities, component suppliers, materials science expertise, and manufacturing automation.

When a Chinese electronics company decides to manufacture vehicles, it operates within an ecosystem of component suppliers, materials providers, and manufacturing services that have developed over decades specifically for consumer electronics. This ecosystem includes established relationships, quality assurance protocols, and cost optimization practices that transfer remarkably well to automotive applications.

A robot vacuum company considering EV manufacturing can leverage suppliers it already partners with for battery cells, electric motors, power electronics, and control systems. These suppliers understand the company's engineering standards, quality requirements, and production volumes. The relationships, once established, create switching costs that make expansion into automotive manufacturing less disruptive than it would be for companies building supply chains from scratch.

The Cost Advantage of Integrated Supply Chains

Chinese electronics companies also benefit from integrated supply chains where numerous suppliers operate in close geographic proximity, enabling rapid iteration, quick component modifications, and just-in-time manufacturing practices. This geographic concentration reduces supply chain complexity and enables manufacturing flexibility that geographically dispersed supply chains struggle to achieve.

When an engineer at Dreame or Roborock identifies an improved battery pack design, materials supplier, or motor configuration, they can engage with suppliers and iterate rapidly in ways that companies without proximate supply chain relationships cannot replicate. This flexibility proves invaluable during vehicle development when numerous design iterations, component variations, and optimization explorations occur.

The cost advantages extend beyond mere labor arbitrage. Chinese manufacturers have invested heavily in automation, precision manufacturing, and quality control systems that enable competitive pricing even as manufacturing moves toward higher-value products like vehicles. The same process optimization techniques used for smartphone components apply to EV components.

Part 8: Technological Competencies That Transfer

Battery Technology and Energy Management Systems

Among the most critical technologies transferring from consumer electronics to vehicles involves battery technology and energy management systems. Robot vacuum companies, smart home device manufacturers, and consumer electronics companies have invested substantially in lithium-ion battery research, battery management systems, thermal management, and energy optimization.

Modern robot vacuums utilize sophisticated battery management systems that monitor individual cells, optimize charging profiles, predict remaining runtime, and protect against dangerous conditions like overcharging or thermal runaway. These exact same capabilities, scaled for larger battery packs with higher power demands, form the foundation of EV battery systems.

Companies like Dreame have developed in-house battery chemistry expertise, working with suppliers to develop custom cell formulations optimized for their specific applications. This battery chemistry knowledge provides significant value in EV development, where battery performance, cost, and longevity represent critical competitive metrics.

Autonomous Navigation and Sensor Fusion

Perhaps the most sophisticated technology transfer involves autonomous navigation systems. Modern robot vacuums represent among the most sophisticated autonomous systems deployed at consumer scale globally. A Roborock S8 Pro Ultra combines LiDAR, cameras, ultrasonic sensors, and accelerometers into a unified mapping and navigation system that creates detailed 3D environments, plans optimal paths, and adapts to dynamic changes.

Developing this autonomous capability required decades of research into simultaneous localization and mapping (SLAM), sensor fusion algorithms, real-time obstacle detection, and path planning optimization. Companies that have solved these challenges in consumer environments have significant advantages developing autonomous vehicles, where the challenge increases in scale and complexity but remains algorithmically similar.

The difference between a vacuum autonomously navigating a home and a vehicle autonomously driving on highways primarily involves scale, speed, and safety requirements rather than fundamental algorithmic differences. Companies with proven autonomous navigation expertise can accelerate autonomous vehicle development by adapting existing algorithms to higher-speed, highway-driving contexts.

Motor Control and Power Electronics

Robot vacuum companies have developed expertise in motor control and power electronics through years of optimizing motor efficiency, implementing advanced control algorithms, and managing power distribution across multiple motors. A modern vacuum with main motor, brush motors, and water pump motors requires sophisticated control electronics coordinating these systems while managing total power consumption.

These motor control competencies transfer directly to EV powertrains, where efficiency optimization and precise motor control represent critical performance metrics. EV manufacturers must continuously optimize motor efficiency to maximize range. Robot vacuum companies have spent years solving precisely this problem within the constraint of limited battery capacity.

Software Architecture and Cloud Services

Consumer electronics companies have developed sophisticated software architectures supporting cloud services, over-the-air updates, remote monitoring, and integration with broader device ecosystems. A modern Dreame or Roborock device functions as a sophisticated IoT endpoint connected to cloud services, receiving software updates, reporting telemetry, and participating in broader smart home ecosystems.

Building robust, secure, and scalable cloud platforms capable of managing millions of connected devices simultaneously provides valuable experience for EV manufacturers, who require similar infrastructure for vehicle telematics, autonomous driving data collection, and fleet management.

Part 9: Market Dynamics and Competitive Positioning

The Evolving Chinese EV Market

The Chinese electric vehicle market has evolved dramatically over the past decade. In 2013, EVs represented less than 1% of Chinese vehicle sales. By 2023-2024, EVs exceeded 40% of new vehicle sales in major Chinese cities, with some projections suggesting EVs could represent 50%+ of the market within several years. This rapid market evolution created unprecedented opportunities for new entrants.

Unlike automotive markets in developed countries, where distribution networks, dealer relationships, and established consumer preferences create high barriers to entry, the Chinese market rewarded technological innovation and rapid iteration. Consumers willing to adopt new vehicle technologies enabled startup manufacturers and non-traditional automotive companies to achieve market share before established automakers optimized their EV offerings.

Competition From Traditional Automakers and EV Specialists

Despite the favorable market conditions, Chinese electronics companies entering automotive face intense competition from both established automakers and specialized EV manufacturers. BYD, originally a battery company that entered vehicle manufacturing, has become one of the world's largest EV manufacturers. NIO, XPeng, and Li Auto, pure-play EV companies, have achieved substantial market presence and capital valuations.

International automakers including Tesla, BMW, Volkswagen, and others have invested heavily in Chinese EV manufacturing and distribution, competing aggressively for market share. This competition continues intensifying, with numerous new entrants, established manufacturers, and technology companies all pursuing automotive opportunities.

For electronics companies like Dreame and Roborock, competing successfully requires not just technical excellence but also brand establishment, distribution networks, service infrastructure, and long-term capital commitment. Building these capabilities in parallel with vehicle development represents a profound challenge.

The Role of Autonomous Driving in Competitive Differentiation

One area where electronics companies particularly competitive advantage involves autonomous driving. The sophistication required for advanced autonomous systems—computer vision, machine learning, real-time processing, sensor integration—aligns with strengths of technology companies more than traditional automakers.

Companies like Tesla demonstrated that autonomous driving capabilities could serve as primary competitive differentiators enabling premium pricing and customer loyalty. For electronics companies entering the market, developing autonomous driving systems competitive with market leaders represents a critical path to establishing differentiation.

Xiaomi's SU7 specifically emphasized advanced autonomous driving capabilities as a key value proposition. Similarly, Dreame's Nebula Next and Kosmera brands have highlighted autonomous driving among their primary technological features. For these manufacturers, autonomous driving represents an area where their technological strengths provide competitive advantage.

Part 10: Manufacturing Challenges and Execution Risks

The Capital Requirements of Automotive Manufacturing

While electronics companies possess relevant technological capabilities, automotive manufacturing demands capital investments that even successful electronics companies find substantial. Establishing manufacturing facilities, developing supply chains, building service networks, and funding long-term R&D requires capital commitments measured in billions of dollars.

Xiaomi, with its position as one of China's most valuable technology companies and substantial cash reserves, could fund automotive ventures from cash flow. Dreame, while successful, operates at a smaller scale and may require external capital, partnerships, or strategic investors to sustain automotive development through profitability.

The capital requirements extend beyond manufacturing facilities to include autonomous driving development, safety validation testing, regulatory compliance navigation, and establishing service and warranty infrastructure. These parallel investments create substantial financial burdens that require multi-year commitments with no guarantee of profitability.

Supply Chain Complexity and Component Availability

While Chinese manufacturers benefit from integrated supply chains, automotive manufacturing introduces complexity beyond consumer electronics. Vehicles require numerous components and subsystems with specifications, quality standards, and delivery timelines that exceed consumer electronics.

Semiconductor availability represents a particular challenge. The post-COVID semiconductor shortage demonstrated how supply disruptions for specific high-value components can halt entire vehicle production lines. Electronics companies accustomed to flexibility in component sourcing face automotive suppliers with longer lead times, less flexibility, and higher minimum volumes.

Battery cell availability represents another critical constraint. As EV market growth accelerates, battery cell manufacturing capacity becomes a bottleneck limiting production expansion. Companies without direct relationships with battery manufacturers or internal battery production capacity face supply constraints that limit growth.

Manufacturing Quality and Regulatory Compliance

Automotive manufacturing quality standards and regulatory requirements exceed consumer electronics by substantial margins. Vehicles must meet rigorous safety standards, emissions regulations, and liability requirements that vary by market. Establishing manufacturing processes, quality assurance systems, and regulatory compliance infrastructure requires specialized expertise and organizational culture.

Consumer electronics companies accustomed to iterating rapidly and deploying software fixes may struggle adapting to automotive environments where design changes require costly retooling and regulatory re-certification. The transition from rapid iteration cultures to deliberate automotive development processes represents a fundamental organizational challenge.

Part 11: The Smart Glasses Parallel—Broader Technology Company Ambitions

The Rise of Chinese AR/VR Eyewear

Interestingly, the same electronics companies pivoting to automotive manufacturing are simultaneously pursuing opportunities in adjacent technology categories. At the same consumer technology conference featuring the Nebula Next and Kosmera vehicles, over three dozen Chinese companies showcased advanced augmented reality and virtual reality glasses.

Companies like Rokid, a Hangzhou-based manufacturer, are developing AR/VR glasses with sophisticated optical systems, advanced computer vision capabilities, real-time translation features, and integration with cloud services. These glasses represent sophisticated integration of semiconductor, optical, and software technologies—precisely the competencies that successful electronics companies possess.

The simultaneous pursuit of vehicles and advanced eyewear by the same companies suggests they view these categories as natural extensions of existing competencies rather than unrelated diversifications. Both require optical technologies, autonomous capabilities, sensor integration, cloud services, and consumer-facing user interfaces. Both enable delivery of AI-powered features to consumers. Both represent early-stage markets with substantial long-term potential.

Real-Time Translation as a Capability Proxy

The real-time translation feature in Rokid's glasses demonstrates the translation of underlying AI capabilities across product categories. The translation system requires speech recognition, language processing, and real-time inference—capabilities that benefit equally from experience in robotics, autonomous vehicles, and smart home systems.

A company with experience deploying AI features across millions of autonomous vacuum cleaners globally possesses deep expertise in language processing, on-device inference, cloud communication, and integrating AI features into consumer products. These same capabilities enable real-time translation in glasses, autonomous driving in vehicles, and voice control across smart home ecosystems.

This common technological substrate—artificial intelligence, autonomous systems, sensor integration, cloud services—explains why advanced technology companies can pursue opportunities across seemingly unrelated product categories. The underlying engineering challenges remain substantially similar even as product manifestations differ.

Part 12: The Role of Government Support and National Strategy

Chinese Government Policies Supporting EV Development

The ability of electronics companies to enter automotive manufacturing reflects partially from supportive government policies creating favorable conditions for EV development and new entrant vehicles. The Chinese government has consistently prioritized EV adoption through subsidies, purchase incentives, charging infrastructure investment, and preferential policies for new energy vehicles.

These policies reduce barriers for new entrants by ensuring market demand for electric vehicles while providing financial support for manufacturing infrastructure, research and development, and commercialization. Companies entering the market benefit from established charging networks, consumer subsidies, and regulatory frameworks specifically designed to encourage EV adoption.

Additionally, Chinese government policies encourage innovation in autonomous driving, battery technology, and vehicle manufacturing. Research subsidies, tax incentives, and industrial policy support development of EV-related technologies, enabling companies to invest more in R&D than would be possible in more competitive, less-subsidized markets.

Strategic National Interest in EV Leadership

China's determination to achieve leadership in automotive manufacturing, particularly electric vehicles and autonomous driving, reflects strategic national interests beyond economics. Automotive manufacturing represents a significant industrial base, employment driver, and technology leadership indicator. The central government's commitment to EV development creates favorable conditions for domestic manufacturers while potentially constraining international competitors.

For Chinese electronics companies, this strategic context means government support—through subsidies, infrastructure investment, preferential regulations, and market protection—reduces risks and improves probability of success. Operating in a government-supported market provides advantages unavailable to competitors in less-supported markets.

Part 13: International Expansion and Global Market Challenges

Differing Market Dynamics Outside China

While Chinese electronics companies can leverage their domestic competitive advantages in China's market, international expansion presents substantially greater challenges. Global automotive markets operate with different consumer preferences, regulatory frameworks, distribution networks, and competitive dynamics than the Chinese market.

In developed markets like North America and Europe, established luxury automakers, dedicated EV manufacturers, and international brands command substantial market share and consumer loyalty. New entrants—particularly those without established automotive reputations—face consumer skepticism, regulatory obstacles, and distribution challenges that domestic Chinese competitors don't encounter.

The transition from dominance in Chinese domestic markets to competitive viability in international markets represents the critical test for these automotive ventures. Companies like Xiaomi with strong international consumer electronics brands might leverage existing brand equity. But for Dreame and Roborock, primarily known as vacuum manufacturers globally, establishing automotive credibility in international markets remains an open question.

The Regulatory Landscape in Different Markets

Automotive regulations vary substantially across major markets. European Union regulations emphasize emissions standards, pedestrian safety, and data privacy. North American regulations focus on crash safety, emissions, and vehicle electronics standards. Chinese regulations accommodate Chinese manufacturers and reflect government priorities.

Navigating these different regulatory frameworks requires establishing compliance infrastructure, testing facilities, and regulatory expertise in each market. For electronics companies without automotive history, this regulatory navigation represents a significant challenge requiring years of development and substantial capital investment.

Establishing Distribution and Service Networks

Even if vehicles meet regulatory standards, international expansion requires establishing distribution networks, service infrastructure, and warranty support. These distribution and service networks cannot be rapidly deployed—they require partnerships with established dealers, investment in service facilities, and development of local expertise.

In China, where direct-to-consumer sales have become increasingly common and manufacturers control distribution, this challenge proves less significant. In international markets with established dealer networks and consumer expectations for service infrastructure, establishing competitive distribution becomes a multi-year challenge.

Part 14: The Broader Implications for Manufacturing and Industry Structure

The Blurring of Industry Boundaries

The movement of robot vacuum companies, smartphone manufacturers, and consumer electronics companies into automotive manufacturing represents a fundamental shift in how industries are structured. Traditional industry boundaries—where automotive companies manufactured vehicles, consumer electronics companies made gadgets, and telecommunications companies provided connectivity—are dissolving.

This boundary blurring reflects underlying technological convergence where different product categories increasingly share common substrates: artificial intelligence, autonomous systems, sensor integration, battery technology, and software platforms. When the underlying technologies become shared, traditional industry boundaries become less relevant to competitive positioning.

Companies with excellence in AI, autonomous systems, sensor integration, and software development can apply these competencies across product categories, from vehicles to robots to glasses to smart home devices. Industry expertise becomes less important than technological capability in underlying competencies.

Implications for Established Automakers

The entry of electronics companies into automotive manufacturing raises profound questions about traditional automakers' future competitiveness. Established automotive manufacturers excel at mechanical engineering, manufacturing efficiency, and supply chain management. But as vehicles increasingly become software-defined, autonomous, and connected, competitive advantage increasingly derives from AI, software development, and autonomous systems expertise.

Traditional automakers have responded with substantial investments in autonomous driving, software development, and EV platform development. However, many legacy automakers struggle with software development culture, organizational agility, and AI expertise compared to dedicated technology companies.

The entry of technology companies into automotive manufacturing may accelerate already-occurring consolidation in automotive manufacturing, with successful manufacturers emerging from both traditional automotive and technology sectors.

The Future of Specialized vs. Generalist Manufacturers

Another implication involves the relative competitiveness of specialized manufacturers versus diversified conglomerates. Historically, specialized manufacturers competing within single industries achieved advantages through focused expertise. Yet the movement toward software-defined products, autonomous systems, and AI-powered features creates advantages for diversified companies with broad technology expertise.

A company like Xiaomi that spans smartphones, smart home devices, consumer robotics, and now vehicles can achieve advantages through technology leverage across product categories. Roborock and Dreame, while narrower in scope than Xiaomi, still benefit from technology transfer across autonomous systems, battery management, sensor integration, and cloud services.

Traditional specialized manufacturers—whether automotive companies focused solely on vehicles or electronics companies focused solely on specific consumer categories—may face disadvantages competing against diversified technology companies leveraging technology across multiple product categories.

Part 15: The Role of Artificial Intelligence and Machine Learning

AI as a Core Competitive Differentiator

Across all these manufacturing pivots—from Dreame's vehicles to Roborock's automotive ambitions to Xiaomi's SU7—artificial intelligence and machine learning emerge as core competitive differentiators. The vehicles showcase autonomous driving capabilities, intelligent energy management, predictive maintenance, and integration with AI assistants.

Electronics companies have invested in AI competencies far longer and more intensively than traditional automakers. Companies like Dreame have deployed machine learning algorithms across millions of devices, accumulating experience in on-device inference, cloud-based AI services, and continuous model improvement through data collection.

This AI expertise provides substantial competitive advantage in developing autonomous vehicles, where machine learning systems for perception, prediction, planning, and control represent core vehicle capabilities. Traditional automakers, while investing substantially in autonomous driving, often lack the deep AI expertise developed over decades by dedicated technology companies.

Continuous Learning and Adaptation

Modern AI systems improve continuously through data collection and model retraining. Electronics companies have built organizational capabilities for managing these continuous improvement cycles across millions of devices. When a Dreame vacuum deploys a firmware update improving navigation efficiency or cleaning patterns, the company captures telemetry, retrains models, and deploys improvements.

These organizational capabilities for continuous AI model improvement, data collection, privacy-preserving analytics, and federated learning transfer directly to vehicle development. Vehicles equipped with autonomous driving require continuous improvement of perception models, prediction systems, and planning algorithms. Companies with experience managing these continuous improvement cycles across millions of consumer devices possess significant advantages.

The Data Advantage

Companies with millions of deployed autonomous devices collecting data about environments, navigation, and human behavior possess enormous data advantages for training autonomous systems. A company like Dreame or Roborock, with millions of vacuums deployed globally collecting data about home environments, floor plans, and navigation, has accumulated datasets that prove invaluable for training autonomous vehicle systems.

Data-driven advantage in AI systems often proves more important than theoretical model sophistication. Companies with access to larger, higher-quality datasets can train systems that outperform competitors using less data, regardless of theoretical model advantages. The data collected from millions of autonomous vacuums navigating real-world home environments provides training data valuable for vehicle autonomous systems navigating real-world driving environments.

Part 16: Competitive Strategy and Differentiation Approaches

Ecosystem Integration as Competitive Strategy

One strategy distinguishing electronics company entrants involves ecosystem integration. Rather than developing vehicles as standalone products, these companies integrate vehicles into broader ecosystems of connected devices and services. Xiaomi's approach involves deep integration between the SU7 and existing Xiaomi smart home devices, wearables, and services.

A Xiaomi vehicle owner can control home devices from the vehicle, receive alerts on smartwatches, and integrate vehicle data with broader smart home systems. This ecosystem integration creates value that dedicated automotive manufacturers struggle to replicate without partnerships or acquisitions.

Roborock and Dreame could pursue similar strategies, integrating vehicles with smart home platforms, autonomous cleaning devices, and connected home services. These ecosystem advantages create switching costs and enhance customer value propositions beyond standalone vehicle capabilities.

Cost Advantage as Differentiation

Chinese electronics companies also pursue differentiation through cost advantage. By leveraging integrated supply chains, manufacturing automation, and efficient component procurement, these companies can achieve cost structures enabling attractive pricing compared to international competitors.

Xiaomi's SU7 pricing significantly undercut comparable Tesla and international luxury EV pricing while offering competitive autonomous driving and feature richness. This cost advantage, enabled by efficient manufacturing and integrated supply chains, represents a substantial competitive weapon in price-sensitive markets.

For Roborock and Dreame, similar cost advantages could enable competitive positioning against more established automotive brands, particularly in price-sensitive market segments.

Brand Repositioning and Perception Management

As discussed earlier, electronics companies entering automotive must manage brand perception challenges. Consumers considering luxury vehicles may view companies primarily known for consumer electronics with skepticism. Managing this perception shift requires substantial marketing, positioning through premium features and autonomous capabilities, and time to establish automotive credibility.

Dreame and Roborock's strategy of establishing separate automotive brands partially addresses this perception challenge by creating distance from consumer electronics heritage. Xiaomi's more direct approach leverages the company's existing brand equity and premium positioning achieved through years of consumer electronics success.

Part 17: The Role of Investment and Capital Markets

Private Capital and Strategic Investment

Much of the automotive expansion by electronics companies is funded not through traditional automotive finance but through technology sector investment, venture capital, and strategic partnerships. These funding sources bring different expectations, timeframes, and performance metrics than traditional automotive financing.

Venture capital and private equity investors in technology sectors commonly accept longer paths to profitability than automotive finance would support. This enables companies to invest in long-term platform development, autonomous driving research, and market establishment without immediate profitability pressure.

Strategic investors—including other technology companies, battery manufacturers, and autonomous driving specialists—provide capital while also enabling technology partnerships, supply chain collaboration, and market access. These strategic investments serve purposes beyond simple capital provision.

Public Market Capital Raising

Some automotive ventures by electronics companies have pursued or may pursue public capital markets to fund continued expansion. Going public provides capital at scale but also brings pressure for near-term profitability and financial performance that could constrain long-term strategic investments.

The trajectory of companies like NIO and XPeng—pure-play Chinese EV manufacturers that went public—provides cautionary tales about capital market pressures. Early growth-focused investment giving way to profitability demands as public market investors grow impatient. Electronics companies entering automotive will likely face similar pressures if pursuing public capital.

Part 18: Risk Factors and Potential Failure Modes

Technology Risk and Autonomous Driving Challenges

Developing autonomous driving systems capable of matching Tesla's advanced autopilot or Waymo's autonomous vehicle systems represents an enormous technical challenge. Companies with limited autonomous vehicle development experience may underestimate the complexity of developing reliable, safe autonomous systems.

The gap between prototype autonomous systems demonstrated in controlled environments and production autonomous systems operating reliably across diverse real-world conditions proves far larger than many engineers expect. Companies entering the market may find autonomous driving development timelines extending far beyond initial projections, delaying competitive vehicle launches.

Manufacturing Scaling and Quality Issues

Successfully manufacturing millions of vehicles with consistent quality represents a profound challenge that numerous automotive startups have underestimated. Electronics companies, accustomed to manufacturing in high volumes but with products substantially smaller and simpler than vehicles, may encounter unexpected manufacturing quality challenges.

Getting manufacturing quality correct for millions of vehicles involves not just technical challenges but organizational culture transformation, supplier quality management, and complex supply chain coordination. Electronics companies accustomed to rapid iteration and software fixes cannot apply similar approaches to vehicles where manufacturing errors prove costly and dangerous.

Capital Inadequacy and Funding Challenges

Despite adequate initial capital, automotive ventures prove capital-intensive beyond many entrepreneurs' expectations. Developing multiple vehicle platforms, expanding manufacturing capacity, establishing distribution networks, and building service infrastructure requires capital sustained over many years. Companies may face capital constraints limiting expansion or requiring unfavorable fundraising.

Market Saturation and Competition Intensification

The Chinese EV market, initially characterized by favorable growth and limited competition, has become increasingly saturated as established automakers launch aggressive EV campaigns and numerous domestic startups pursue similar strategies. Market saturation threatens initial growth projections and creates challenges achieving profitability.

Companies entering with optimistic market share expectations may discover competitive intensity preventing market share achievement. Several pure-play EV manufacturers have faced profitability challenges or consolidation pressure as competition intensified.

Part 19: Long-Term Viability and Industry Consolidation Predictions

The Likely Consolidation Outcome

Historically, industry consolidation follows technology disruption. The automotive industry itself experienced dramatic consolidation in the early 20th century as numerous manufacturers consolidated into a small number of major companies. The current EV revolution will likely follow similar patterns, with numerous entrants eventually consolidating into a smaller number of viable competitors.

Despite the optimism about electronics companies successfully entering automotive, the historical pattern suggests that many—perhaps most—will eventually exit the industry, consolidate, or merge with stronger competitors. Companies lacking sufficient capital, technological depth, manufacturing excellence, or market positioning will face increasing pressure as competition intensifies and profitability demands increase.

Which Electronics Companies Likely Succeed

Among electronics companies pursuing automotive ventures, those most likely to achieve long-term viability likely include:

- Xiaomi, leveraging its broad ecosystem, established international brand, and significant capital resources

- Battery-focused manufacturers, whose core competency in battery technology provides direct competitive advantage

- Companies with strong autonomous driving capabilities, enabling differentiation beyond basic EV platforms

- Manufacturers with existing service infrastructure, enabling support for vehicles without building from scratch

- Companies pursuing strategic partnerships or joint ventures with established automakers, reducing independent capability requirements

Dreame, Roborock, and similar pure-play robotics companies, while possessing relevant technological capabilities, face greater challenges achieving viable automotive positions without strategic partnerships or significant capital influx.

The Role of Strategic Partnerships

Some electronics companies may pursue automotive viability through strategic partnerships rather than independent ventures. Joint ventures with established automakers, technology collaborations with autonomous driving specialists, or acquisition by larger automotive conglomerates could provide viable paths for smaller electronics companies.

These partnerships could enable electronics companies to apply their technological capabilities within larger organizations with established automotive expertise, manufacturing infrastructure, and market presence. The outcome would be less a victory for electronics companies entering automotive independently and more a reshaping of automotive development with technology company expertise integrated within larger corporate structures.

Part 20: Conclusion—The Future of Manufacturing and Industry Boundaries

The Larger Significance of the Manufacturing Pivot

The movement of robot vacuum companies, smartphone manufacturers, and other electronics companies into vehicle manufacturing represents far more than interesting corporate strategy or business diversification. Rather, it reflects fundamental technological and economic shifts transforming how manufacturing operates, how competitive advantage develops, and how industry boundaries are structured.

The convergence of electrification, autonomous systems, artificial intelligence, and software-defined products has lowered traditional barriers separating automotive manufacturing from consumer electronics manufacturing. Companies possessing excellence in autonomous systems, AI development, sensor integration, and software architecture can apply these competencies across product categories that historically required industry-specific expertise.

Xiaomi's successful launch of the SU7, Dreame's development of luxury EV brands, and Roborock's automotive ventures all demonstrate that electronics companies can achieve meaningful progress in automotive manufacturing. Yet Apple's abandoned automotive project demonstrates that scale, capital, and existing competencies don't guarantee success in automotive markets with unique regulatory, liability, and organizational challenges.

What This Reveals About Future Manufacturing

The manufacturing landscape of the coming decades will likely feature greater diversity of participants than historical automotive manufacturing. Rather than automotive manufacturing remaining concentrated among traditional automakers, expect a mixture of:

- Traditional automotive manufacturers optimizing their EV and autonomous driving capabilities

- Technology companies leveraging their AI, software, and autonomous system expertise in vehicle manufacturing

- Battery and component specialists whose core competencies provide unique competitive advantages

- Diversified conglomerates leveraging technology across multiple product categories

- Strategic partnerships and joint ventures combining traditional automotive expertise with technology company capabilities

The competitive winners will likely combine traditional automotive strengths (manufacturing excellence, supply chain management, regulatory expertise) with technology company strengths (AI capabilities, software development, autonomous systems, user experience design). Companies unable to integrate these diverse competencies will face increasing competitive pressure.

The Implications for Consumers

For consumers, this diversification of automotive manufacturing participants promises continued innovation in vehicle capabilities, features, and pricing. Technology company entrants will push autonomous driving capabilities, AI features, and software integration further than traditional automakers might pursue independently. Competition from non-traditional manufacturers will maintain pricing pressure, making advanced vehicle technologies accessible to broader consumer segments.

Simultaneously, consolidation and exit of unsuccessful entrants may disrupt consumer experiences as some automotive brands prove unsustainable. Consumers purchasing vehicles from unsuccessful manufacturers may face service infrastructure challenges, warranty support limitations, or even complete business failure.

The Broader Economic Transformation

Beyond automotive manufacturing, the manufacturing pivot of electronics companies reflects broader transformation in how global manufacturing operates. The concentration of technological expertise, manufacturing infrastructure, and capital in specific regions—particularly the Shenzhen and Pearl River Delta regions of China—enables previously impossible cross-industry manufacturing transitions.

Companies can leverage accumulated expertise, supply chains, and manufacturing infrastructure to enter adjacent markets far more rapidly and cost-effectively than would be possible building from scratch. This capability transforms competitive dynamics not just in automotive but across industries experiencing technology-driven transformation.

Companies that successfully build broad technological expertise across multiple product categories—artificial intelligence, autonomous systems, sensor integration, battery technology, software architecture—can apply these competencies across diverse markets. The future will likely feature greater diversification of manufacturers across industries as technological convergence enables previously impossible cross-industry expansion.

Final Perspective

The pivot of robot vacuum companies into electric vehicles isn't an anomaly or a cautionary tale—it represents an early indicator of how manufacturing, industry structure, and competitive advantage are transforming. Some electronics companies entering automotive will succeed and establish viable positions in vehicle manufacturing. Others will eventually exit, consolidate, or merge. Most will discover that automotive manufacturing proves far more challenging than their consumer electronics experience suggested.

Yet the underlying drivers—electrification, autonomous systems, software-defined products, and artificial intelligence—will continue attracting technology companies with relevant capabilities into automotive manufacturing. The automotive industry of 2035 will look substantially different from the industry of 2015, with participants from diverse backgrounds competing through different competencies than traditional automakers historically required.

For Dreame, Roborock, and other electronics companies pursuing automotive manufacturing, the outcome remains uncertain. They possess relevant technological competencies and cost advantages. Yet they face formidable challenges in capital requirements, regulatory compliance, manufacturing complexity, and brand establishment. Success isn't guaranteed, but the fundamental rationale for their attempts reflects real technological and economic shifts that will reshape manufacturing for decades to come.

When robot vacuum companies pivot to electric vehicles, they're not crazy—they're reading the technological and economic shifts correctly. Whether they execute successfully remains an open question that will be answered only through years of development, substantial capital investment, and navigating challenges more complex than any faced in consumer electronics manufacturing.