Luxury Turntable Cartridges: The Ultimate Guide to Premium Analog Audio Components [2025]

If you've ever wondered what separates a

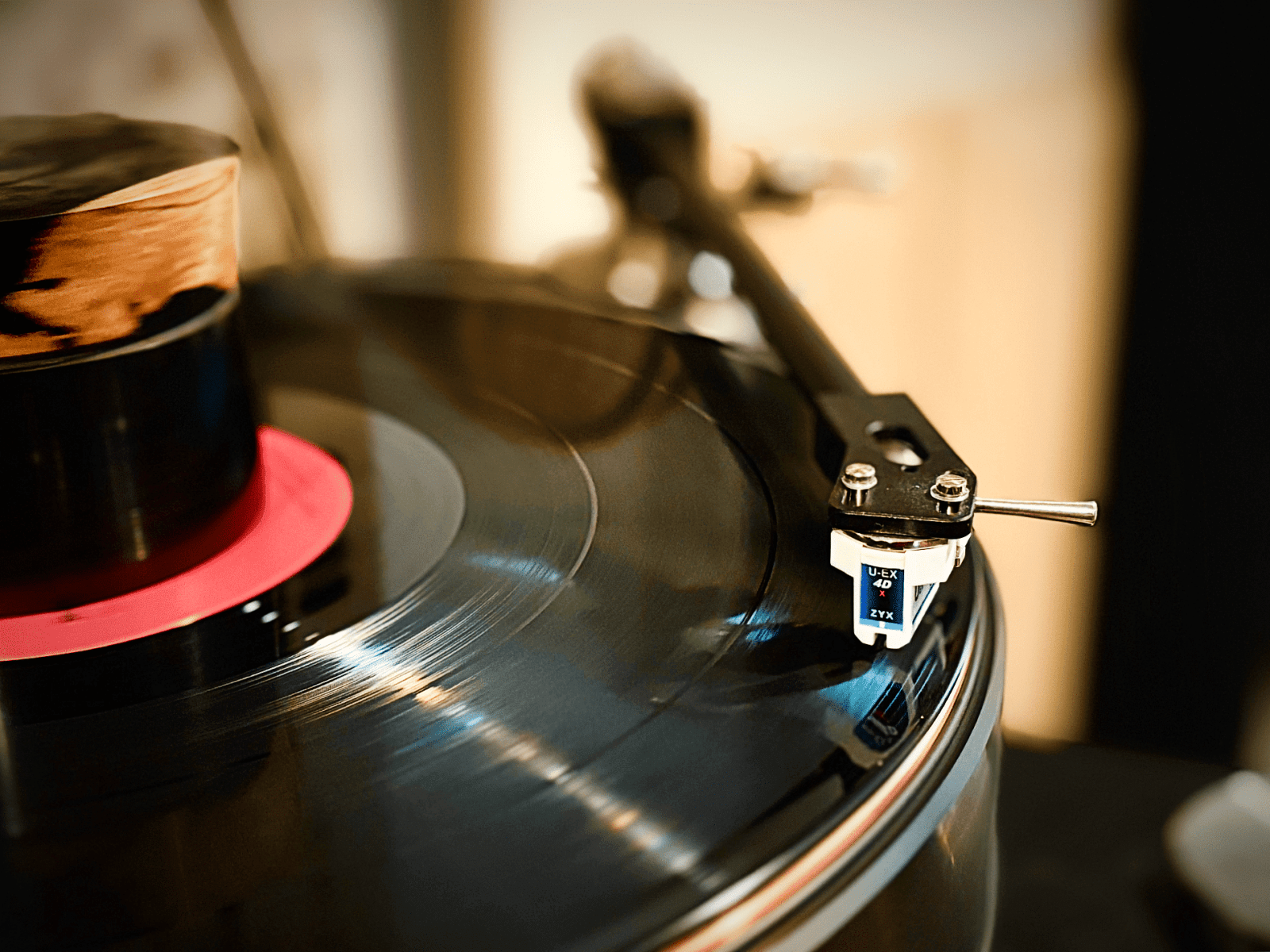

The cartridge is arguably the most critical component in any vinyl playback system. It's the physical interface between your record and the rest of your audio chain, translating microscopic groove variations into electrical signals. Get this part right, and everything downstream sounds better. Get it wrong, and no amount of expensive amplifiers and speakers will fix what's already broken at the source.

But here's where it gets wild. Some manufacturers have decided that good enough isn't good enough. They've started using materials you'd find in concert halls and jewelry boxes rather than mass-produced audio components. We're talking about cartridges made from the same species of wood used in Stradivarius violins that sell for millions. We're talking about sapphire cantilevers. We're talking about diamond styluses that cost more than used cars.

The question isn't whether these cartridges sound better. The question is whether the sonic improvements justify the astronomical price tags. That's what we're diving into today.

TL; DR

- Premium materials matter: Exotic woods like Bosnian pine and sapphire cantilevers genuinely improve sound quality by reducing resonance and vibration

- Diamond styli are the standard: High-end cartridges use diamond tips because they last longer and track records with greater precision than cheaper alternatives

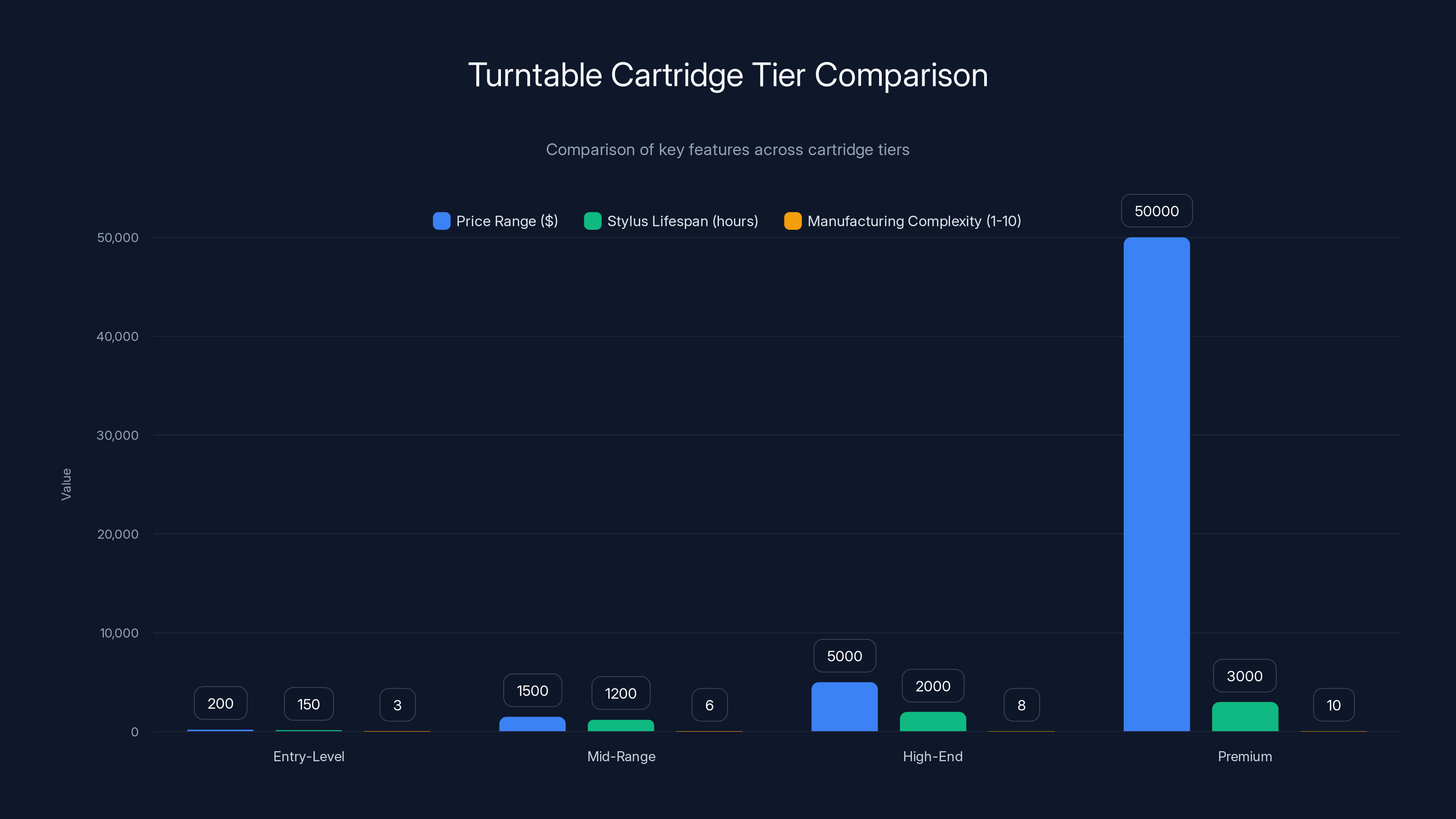

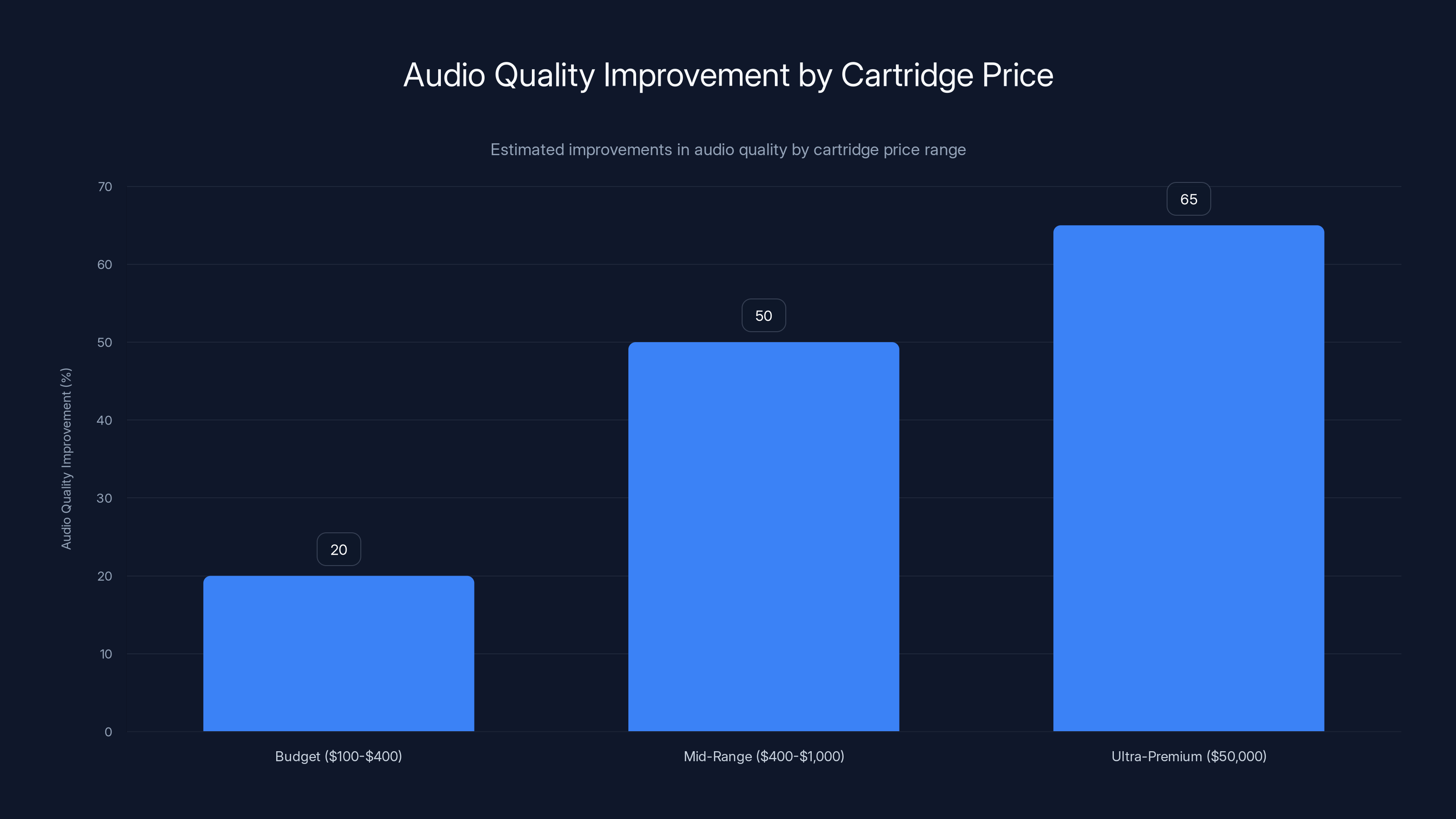

- Prices range wildly: Budget cartridges cost 200, mid-range options run2,000, and ultra-premium models exceed $10,000

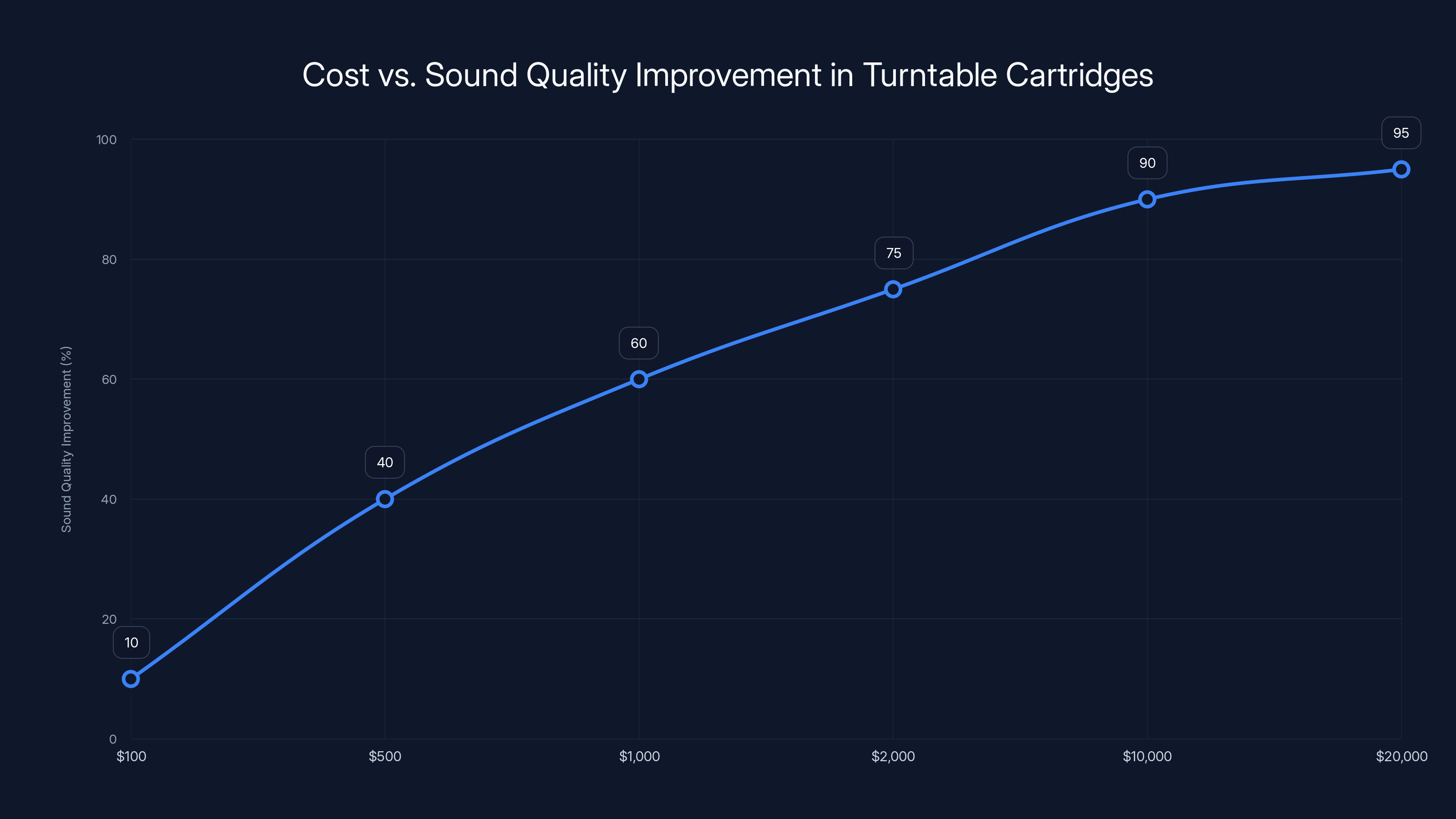

- Diminishing returns are real: You'll hear noticeable improvement jumping from 1,000, but the leap from50,000 is far more subtle

- Construction quality compounds the cost: Hand-assembly, precise tolerances, and rare materials all contribute to exponential price increases

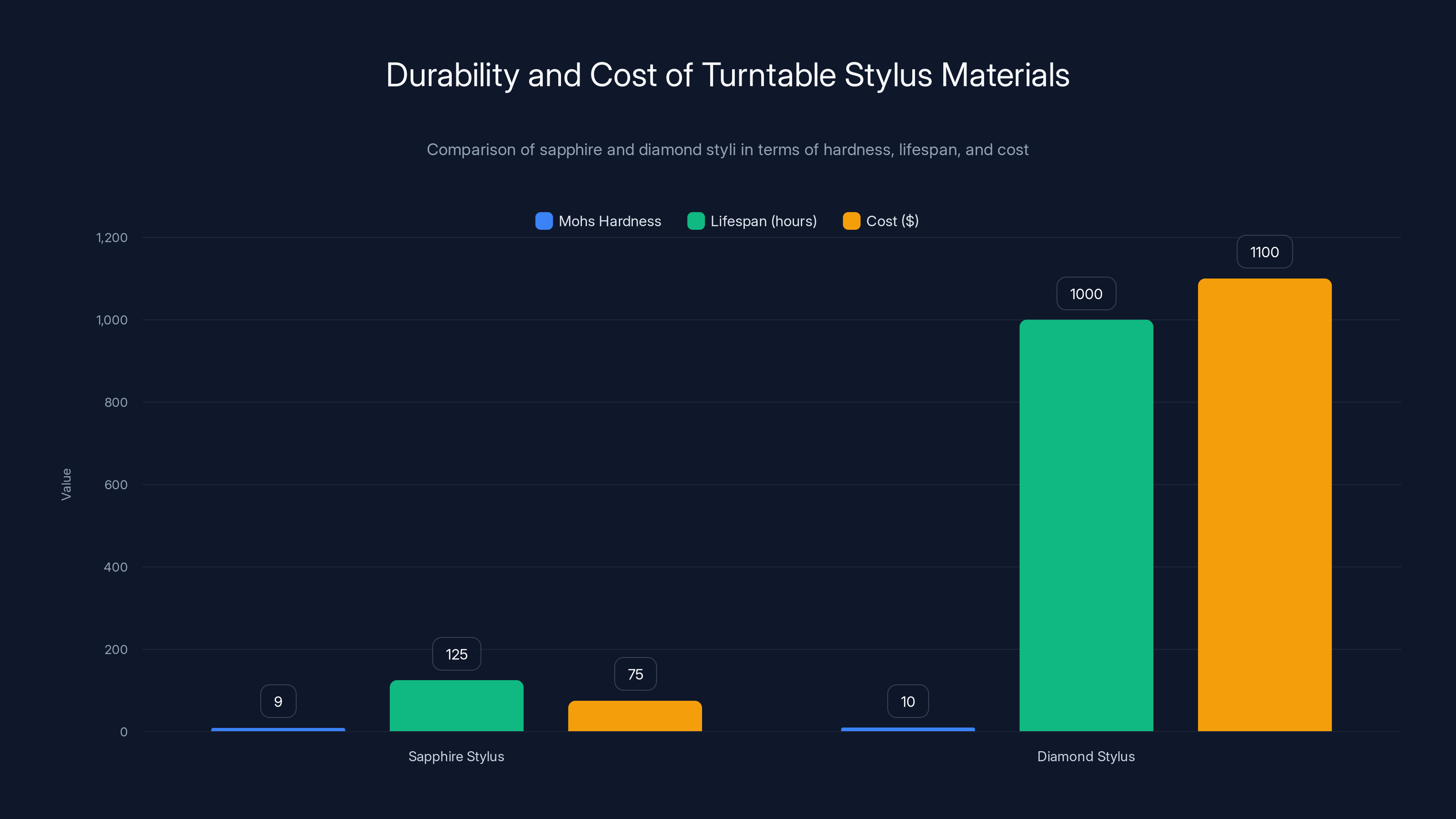

Diamond styli offer superior hardness and lifespan compared to sapphire, justifying their higher cost. Estimated data based on typical market values.

Understanding Turntable Cartridge Architecture

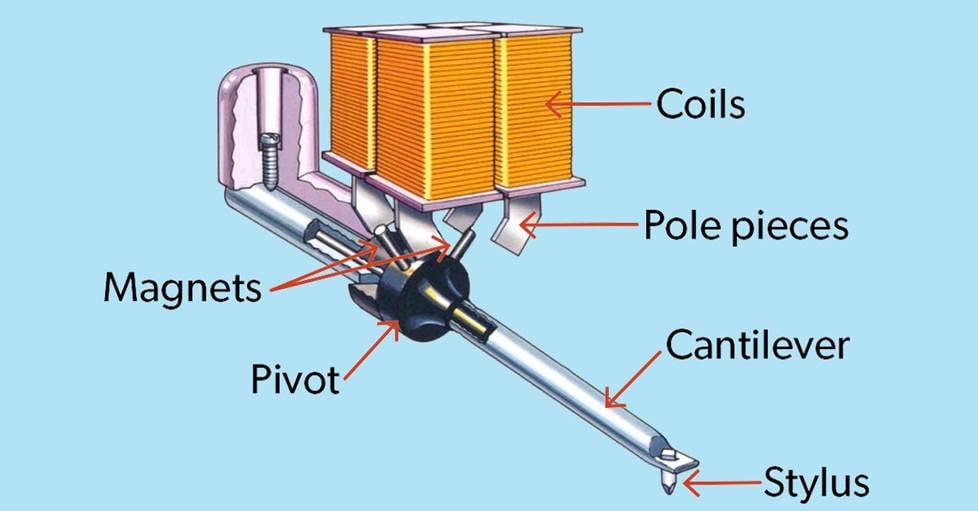

Before we talk about why cartridges cost what they do, you need to understand what you're actually buying. A turntable cartridge is a deceptively simple device with extraordinarily tight tolerances. It sits at the end of your tonearm and contains a stylus, cantilever, magnet system, and output coils. When the stylus traces the groove of a record, the cantilever vibrates. Those vibrations move magnets or coils, generating electrical signals that amplify through your system.

The catch? The grooves on a vinyl record are absurdly small. We're talking about structures measured in micrometers. The stylus needs to track these grooves without damaging the record, all while vibrating hundreds or thousands of times per second depending on the frequency content. This requires mechanical precision that rivals Swiss watchmaking.

The Stylus and Its Materials

The stylus is where the magic happens, and it's also where manufacturers differentiate themselves most aggressively. A stylus needs to be hard enough to trace groove walls without wearing down, sharp enough to maintain contact, and durable enough to survive thousands of hours of playing records without degradation.

Budget cartridges typically use sapphire styli. Sapphire is hard, scores 9 on the Mohs hardness scale, and costs relatively little to process. You'll find sapphire styli in

Mid-range and premium cartridges use diamond styli. Diamond scores a 10 on the Mohs hardness scale—the only naturally occurring material harder than itself. A diamond stylus lasts 1,000+ hours before wear becomes audible. That's the difference between replacing your cartridge annually versus every few years. But that durability comes at a price. A single diamond stylus can cost anywhere from

What makes a diamond stylus actually better at playing records? Hardness matters, obviously. But more importantly, diamond can be cut to precise geometric shapes. Premium manufacturers invest in specialized cutting equipment that shapes the diamond to exact specifications. A poorly cut diamond stylus will have inconsistent contact with the groove wall, causing distortion. A perfectly cut diamond stylus makes contact consistently across both groove walls, extracting more information from the record.

Some ultra-premium cartridges use what's called a Shibata or fine-line stylus profile. Instead of the traditional conical shape, these use a complex geometric cross-section that mimics the cutting stylus used to master the record in the first place. The theory is that if you match the shape of the recording tool, you'll extract more musical information. Does it work? In controlled listening tests, yes. By how much? That's debatable.

The Cantilever: The Forgotten Component

The cantilever is the arm that suspends the stylus and transmits vibrations to the magnet and coil system. It needs to be stiff enough to control the motion of the stylus, but compliant enough to allow the necessary vibrations to pass through. It's a balancing act that separates good cartridges from great ones.

Budget cartridges use aluminum cantilevers. Aluminum is light, reasonably stiff, and inexpensive. It works, but it has resonant frequencies that can color the sound if they happen to align with musical content.

Mid-range cartridges often use sapphire or boron cantilevers. Sapphire is stiffer than aluminum and has a different resonant profile. Boron is even lighter and stiffer than aluminum. Both materials reduce unwanted resonances compared to aluminum.

This is where the exotic materials come in. Some luxury cartridge manufacturers use the exact same species of wood used in building violins and cellos. Bosnian pine, spruce, and maple have been refined over centuries by instrument makers. They have specific acoustic properties—damping characteristics, resonant frequencies, and wood density—that make them ideal for vibrating. A Stradivarius violin uses spruce from the Austrian Alps. A luxury cartridge maker might use spruce from the exact same region, sometimes from trees cut down in the same era.

Why would anyone put wood into an audio component? Because the damping properties of certain woods genuinely reduce unwanted resonances in the cantilever. The wood absorbs vibrations at specific frequencies and dissipates them as heat rather than letting them pollute the signal. It's not marketing nonsense. It actually works. Whether you can hear the difference is another question entirely.

This chart compares the price range, stylus lifespan, and manufacturing complexity of different turntable cartridge tiers. Estimated data shows that as you move from entry-level to premium, prices and complexity increase significantly, with the premium tier offering the longest stylus lifespan.

The Diamond Stylus Industry and Why Costs Escalate

Let's talk about what drives the cost of a diamond stylus from

A standard conical diamond stylus requires cutting the diamond to a specific angle and radius. A fine-line or Shibata stylus requires cutting multiple faces at different angles, creating a stylus profile that might have a 0.1-micrometer tolerance. At that level of precision, you're talking about cutting equipment that costs hundreds of thousands of dollars and operators with years of specialized training.

Each stylus must be measured and verified after cutting. Manufacturers use optical measuring systems and electron microscopes to verify the dimensions. A single stylus might be examined 10–20 times during the manufacturing process to ensure it meets specifications. That labor-intensive process explains why a Shibata stylus costs several times more than a conical stylus, even though it's the same basic material.

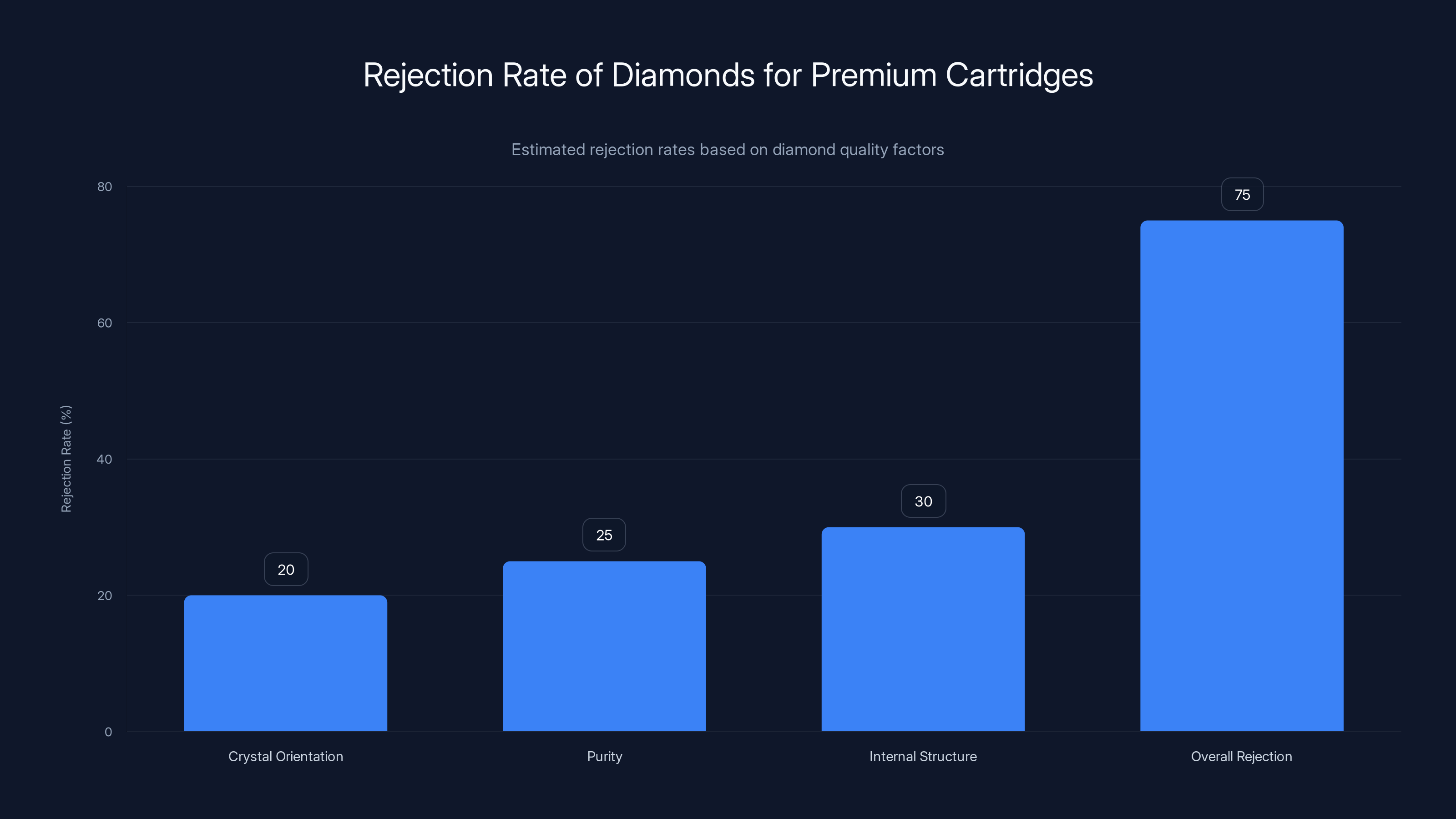

Then there's the question of sourcing diamonds. Premium manufacturers select diamonds based on optical clarity and internal structure. A diamond with internal flaws will shatter or chip when cut. A diamond with the wrong crystal orientation will be difficult to cut to precise shapes. A single batch of diamonds might yield only 30–40% usable stones after visual inspection. The rest are rejected or downgraded.

Some manufacturers market "handcrafted" or "individually tuned" styli. What does that mean? It means that after cutting, a technician listens to the cartridge and makes micro-adjustments to the stylus mounting or the cartridge body itself. They might add or remove material from specific points to shift resonant frequencies. They might tension the suspension springs differently to change the cartridge's tracking force characteristics. These adjustments are made by ear and by measurement, and they require skill that you can't automate.

Exotic Woods in Audio: Fact Versus Fiction

Now let's address the elephant in the room. Why would a turntable cartridge manufacturer use wood from a 300-year-old violin to make a cantilever?

The answer is rooted in centuries of violin-making tradition. When Antonio Stradivari built violins in the 17th and 18th centuries, he had access to specific forests in the Austrian Alps and the Balkans. The spruce and maple trees growing in those regions had unique acoustic properties. Slow-growing trees in harsh Alpine climates develop tight wood grain, specific density profiles, and damping characteristics that make them acoustically superior to trees grown in warmer, less demanding environments.

Stradivari didn't understand the physics of wood damping the way we do today, but he understood empirically that certain wood sounded better. He selected trees carefully and seasoned the wood for years before building instruments. The result was that the finest violins in the world were made from wood that's almost impossible to source today.

Fast forward to the 21st century. A cartridge manufacturer realizes that if wood with specific acoustic properties made for superior violins, maybe those same properties would improve a turntable cartridge. They source spruce from the same Alpine forests. They use the same seasoning processes that were used 300 years ago. They hand-craft a cantilever from this wood, carefully shaping it to specific dimensions.

Does it work? Here's where the science gets murky. Wood is a material with inherent damping characteristics. It absorbs vibration and converts it to heat. A wooden cantilever will have different resonant frequencies and damping profiles than an aluminum or sapphire cantilever. Whether those differences translate to audible improvements in your listening room depends on dozens of other factors: your tonearm design, your turntable's speed stability, your amplifier's noise floor, and yes, even your room acoustics.

The real cost of using exotic wood comes from sourcing, verification, and the labor-intensive process of hand-crafting. You can't mass-produce a wooden cantilever. Each one needs to be individually shaped and tested. That's where the premium pricing really comes from.

Estimated data shows significant improvements in sound quality up to

The Premium Cartridge Tier System

The turntable cartridge market segments into distinct tiers, each with different target customers and value propositions. Understanding these tiers helps explain why pricing ranges from

Entry-Level and Budget Cartridges (200)

Budget cartridges are engineered for value, not performance. They use sapphire styli, aluminum cantilevers, and simple moving magnet designs. The manufacturing process is largely automated. Tolerances are loose compared to premium options. A typical budget cartridge might be assembled by robots with minimal human intervention.

That doesn't mean they're bad. A well-designed budget cartridge will play records and sound acceptable. It's a perfectly reasonable option for people who listen to vinyl casually or who are just getting into the hobby. The stylus will wear out in 100–150 hours of play, which means you'll replace the cartridge every 1–2 years if you're a regular listener. That's where the actual cost of ownership becomes relevant.

Manufacturers in this tier include Audio-Technica with their AT95E and AT-VM95ML models, Ortofon with their OM series, and various house-brand cartridges sold by turntable manufacturers. These are mass-produced in China, Vietnam, and Indonesia.

Mid-Range Cartridges (1,500)

Mid-range cartridges represent the "sweet spot" for most serious audiophiles. They use diamond styli, better cantilever materials, and more sophisticated magnet systems. Manufacturing is a mix of automation and hand assembly. Tolerances tighten up considerably compared to budget options.

In this tier, you'll find the Ortofon 2M series, Audio-Technica's AT33PTG, Denon's DL-103 (and its variants), and Grado's Gold cartridges. These are genuinely good cartridges that will extract most of the musical information from a record without breaking the bank. The diamond stylus will last 800–1,200 hours, and the overall sound is noticeably more detailed than budget options.

The cost jump from budget to mid-range is justified by tangible improvements: diamond styli sound cleaner with less surface noise, better cantilever materials improve tracking and reduce distortion, and tighter manufacturing tolerances mean more consistent performance from unit to unit.

High-End Cartridges (5,000)

High-end cartridges are where things get interesting. These are manufactured with meticulous attention to detail. You'll find exotic materials here: sapphire cantilevers, copper or aluminum cantilevers with specific alloys, and hand-assembled components. Some manufacturers introduce wooden cantilevers at this price point.

Styli at this level are often fine-line or Shibata profiles. The stylus mounting uses beryllium, titanium, or other exotic metals. The magnet systems become more sophisticated, with some manufacturers moving away from moving magnet designs toward moving coil designs that use rare earth magnets and ultra-precise magnet alignment.

Companies at this tier include Ortofon's Quintet series, Miyajima, Shelter, and the lower-priced models from specialists like VPI and EMT. These cartridges are often hand-assembled in small workshops in Japan, Germany, or the UK. A single technician might assemble just a handful of cartridges per week, spending 2–3 hours on each one.

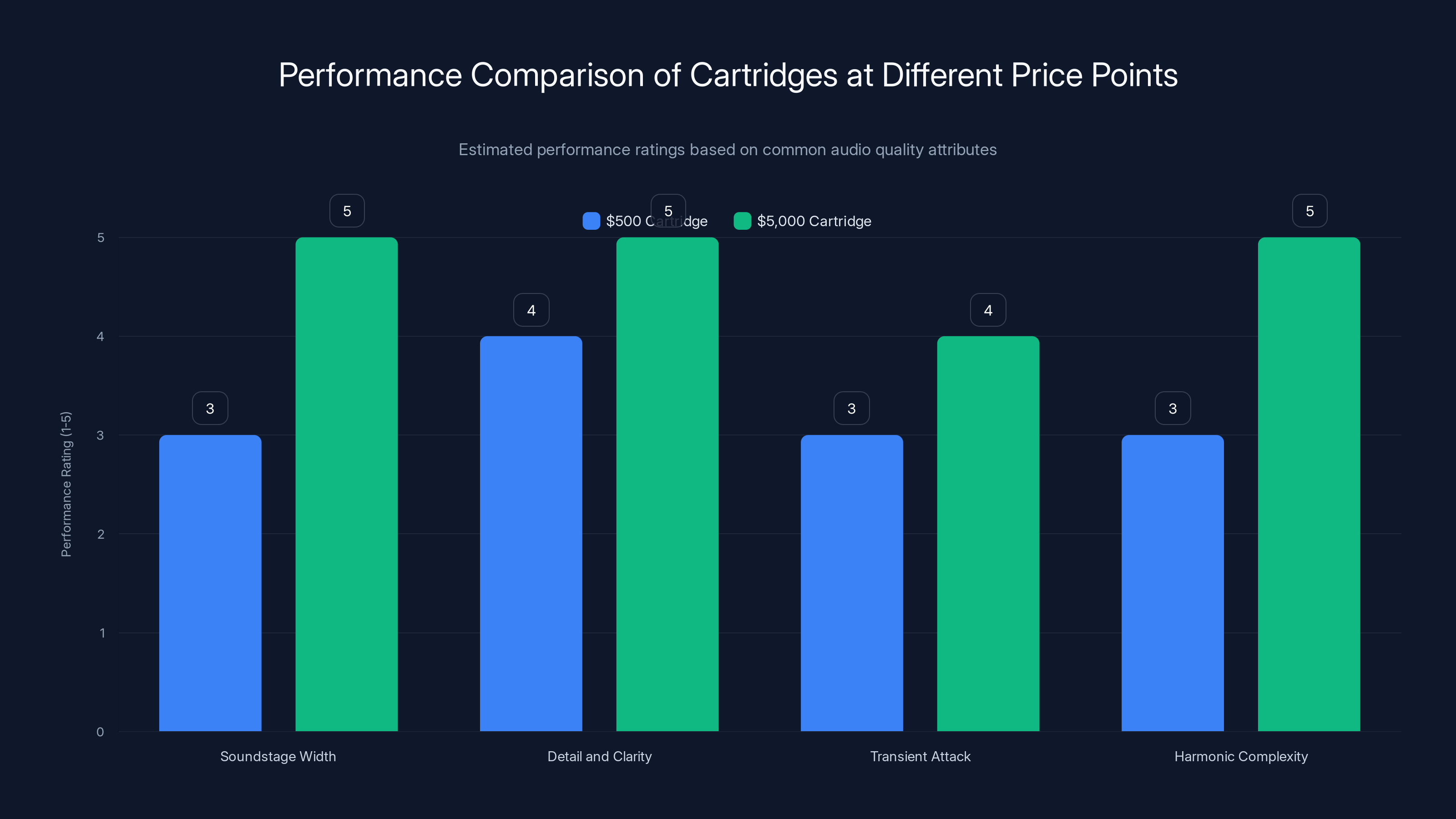

Listening to a high-end cartridge next to a mid-range option reveals improvements that are audible to anyone with decent hearing. The soundstage expands. Instruments sound more three-dimensional. Transient attacks are faster and more precise. Distortion drops noticeably.

Ultra-Premium Cartridges (50,000+)

Ultra-premium cartridges exist in a world of their own. These are bespoke components, often made to order. Some manufacturers produce fewer than 50 cartridges per year. The level of hand-assembly and customization is extreme.

You'll find cartridges with wood cantilevers sourced from specific forests and seasoned for specific time periods. You'll find styli with complex geometries cut by master craftspeople. You'll find magnet systems balanced so precisely that they're adjusted with optical microscopes. Some manufacturers hand-sew suspension components rather than molding them.

Pricing at this level is driven by scarcity, brand prestige, and the actual cost of hand-labor. A cartridge that takes 20 hours to assemble costs more than one that takes 2 hours, even if the materials are similar. A cartridge made in a small workshop in Berlin by a technician with 30 years of experience costs more than one made in a factory in Tokyo.

Manufacturers in this tier include Ortofon's Windfeld Ti, Koetsu, EMT, Dynavector's Karat, and various boutique makers with loyal followings. Some of these cartridges cost

Materials Science: Why Exotic Materials Actually Matter

The question that skeptics always ask: Is paying 10 times more for a cartridge actually justified by sonic improvements? To answer this, you need to understand the physics of how materials behave in a turntable cartridge.

Every material has resonant frequencies. If you excite these frequencies, the material vibrates in sympathy. In an audio system, unwanted resonances at specific frequencies can add emphasis to certain parts of the audio spectrum, coloring the sound in unnatural ways. A good cantilever material has resonant frequencies far removed from the audio band (20 Hz to 20 k Hz), or it has such effective damping that any resonances don't matter.

Aluminum has a longitudinal resonance around 5 k Hz. At this frequency, an aluminum cantilever might vibrate in sympathy with musical content. That vibration doesn't contain any musical information—it's just resonance. When that resonance is converted to electrical signal by the magnet and coil system, it adds a peak in the 5 k Hz region. Your ear hears this as a brightness or harshness in the midrange. It's subtle, but it's there.

Boron has a different resonant profile, with less emphasis in the midrange. Sapphire has yet another profile. And wood? Wood has multiple resonance modes at different frequencies, but the damping is so effective that these resonances don't cause problems. Instead, energy dissipates as heat.

The physics is real. Different materials genuinely do have different resonant profiles. The question is whether your ear can hear the difference.

In blind listening tests, most people cannot distinguish between an

Here's where the diminishing returns curve becomes important. Going from a

The

Manufacturing Precision and Quality Control

When you move from a

A mid-range cartridge might be manufactured with tolerances of ±0.2 mm for critical dimensions. That's tight enough for a good product, but loose enough that some variation between units is acceptable. A high-end cartridge might have tolerances of ±0.05 mm. An ultra-premium cartridge might have tolerances of ±0.01 mm or tighter.

At ±0.01 mm, you're talking about tolerances tighter than the width of a human hair. Achieving that requires precision machining equipment that costs millions of dollars. The person operating that equipment needs specialized training and years of experience. The cartridge needs to be measured after each operation to verify tolerances are being met.

Suspension systems become even more critical. A cartridge's suspension—the springs and dampers that connect the moving parts to the cartridge body—must maintain specific compliance. The compliance affects how the cartridge interacts with your tonearm. Get it right, and the cartridge tracks precisely. Get it wrong, and the cartridge oscillates, causing distortion.

Mid-range cartridges use suspension materials with compliance tolerances of perhaps ±10%. Premium cartridges aim for ±2–3%. Ultra-premium cartridges aim for ±0.5% or better. Achieving this requires hand-assembly and individual testing of each cartridge.

Some manufacturers measure and tune each cartridge's output level individually. A moving magnet cartridge should output around 5 millivolts. But variations in magnet strength, coil winding precision, and component tolerance can create unit-to-unit variation. A premium manufacturer will measure the output of each cartridge and either hand-select components to match or adjust the cartridge in some way to bring output into specification. That's extra labor, but it means that if you buy two units of the same cartridge model, they'll perform identically.

The Economics of Small-Batch Manufacturing

One reason ultra-premium cartridges cost so much is simple economics. When you make 5 million cartridges per year in an automated factory, you can spread fixed costs across a huge number of units. When you make 500 cartridges per year in a small workshop, those same fixed costs get spread across far fewer units.

A small cartridge manufacturer in Japan might have 5–10 employees who each assemble 100–200 cartridges per year. That shop has rent, utilities, insurance, and administrative costs. It needs to earn enough revenue to pay these costs and generate a profit. If the shop makes 500 cartridges per year and fixed costs total

But here's the thing: people who buy ultra-premium cartridges aren't price-sensitive in the normal sense. They're willing to pay for craftsmanship, heritage, and exclusivity. They might seek out a particular manufacturer specifically because only a few cartridges are made each year. They might be willing to wait 6 months for delivery because they know their cartridge is being hand-assembled to their specifications.

This creates a business model that's fundamentally different from mainstream audio manufacturers. Mainstream makers optimize for volume and profit per unit. Premium makers optimize for reputation and the ability to command premium prices.

Ultra-premium cartridges offer a 10-15% improvement over mid-range options, but mid-range cartridges provide the best price-to-performance ratio. Estimated data.

Comparing Performance at Different Price Points

Let's talk concrete numbers. How much better does a

In a controlled test with proper blind conditions, the average listener might identify the

But here's the issue: you probably won't listen in blind conditions. You'll know which cartridge is which. You'll see the premium price tag. You'll read reviews saying it's amazing. Your brain will unconsciously listen for reasons to prefer it, and you'll probably find them. This is the placebo effect, and it's powerful enough that most casual listening tests are essentially useless.

With that caveat, here's what an actual

Soundstage width: A premium cartridge will image sounds more precisely left-to-right and front-to-back. If you close your eyes while listening, the space between speakers feels larger and more defined. A good listening room and quality speakers amplify this effect. In a mediocre room, the improvement is less obvious.

Detail and clarity: High-frequency detail is cleaner. Background noise and surface noise from records becomes less prominent. You hear more of the musician's subtle playing techniques—the slight breath before a trumpet entry, the fingernail scrape on guitar strings. This is a real improvement, but it's only meaningful if your records are in good condition and your system can deliver the quietness to make silence audible.

Transient attack: Drums sound punchier. Bass guitar attacks with more definition. This improvement is audible even to untrained ears, though the degree varies based on your system.

Harmonic complexity: Instruments sound less like produced sounds and more like physical objects. A piano's tone becomes more multifaceted. A vocalist's voice has more color and character. This is where the subjective elements really kick in. Some people love this. Some find it distracting.

Tracking and freedom from distortion: A premium cartridge tracks records more accurately. There's noticeably less distortion on demanding passages. This is measurable and audible, especially on older or warped records.

The Role of System Synergy

Here's something that premium cartridge makers don't want to tell you: a

Your turntable's platter, motor, and bearing affect what the cartridge can accomplish. Your tonearm's mass, rigidity, and damping determine how well the cartridge tracks. Your preamplifier's noise floor and frequency response shape what you hear. Your amplifier's power and distortion profile matter. Your speakers and room acoustics matter too.

If you've got a turntable with a plasticky tonearm, a cheap preamp, and speakers that sound bright and thin, buying a $25,000 cartridge is pointless. You're wasting money on a component that's far better than the rest of your system can reveal.

The rule of thumb is that your cartridge should be proportional to the rest of your system. If you've spent

Beyond that, you're buying diminishing returns and conspicuous consumption. There's nothing wrong with conspicuous consumption if you've got the money and it brings you joy. But don't pretend that a $50,000 cartridge is necessary for great-sounding vinyl playback. It's not.

Premium cartridge manufacturers may reject up to 75% of diamonds based on factors like crystal orientation, purity, and internal structure. Estimated data.

Diamond Quality and Its Impact on Sound

We touched on diamonds earlier, but the topic deserves deeper exploration. Not all diamonds are created equal, and the differences matter for audio performance.

Diamond has a crystal structure that can vary based on how it formed. Natural diamonds that formed under pressure deep in the Earth have different internal structures than laboratory-grown diamonds that were created using high-pressure, high-temperature (HPHT) methods or chemical vapor deposition (CVD).

For turntable styli, most manufacturers use laboratory-grown diamonds because they can be produced with fewer internal flaws. A diamond with significant internal flaws will shatter or chip when cut into the precise geometry required for a stylus.

But even lab-grown diamonds vary in quality. The crystal orientation matters. Some orientations are easier to cut than others, and they produce styli with better edge definition. The purity matters too. A diamond with trace elements of boron or nitrogen will have slightly different hardness characteristics.

Premium cartridge manufacturers don't just buy bulk diamonds. They source individual stones and specify requirements like crystal orientation, purity, and internal structure. They might reject 70–80% of the diamonds they source as unsuitable.

Once a suitable diamond is obtained, the cutting process is critical. A diamond is cut using other diamond dust on a grinding wheel, a process called lapping. The lapping wheel must spin at precise speeds. The diamond must be presented to the wheel at exact angles. The process takes hours for a single stylus.

After cutting, the stylus is mounted into the cartridge. The mounting must be perfectly aligned and must hold the diamond securely without stressing it. Some manufacturers use special adhesives. Others use mechanical fastening systems. The choice of mounting affects the stylus's resonant frequency and damping.

A

Tracking Force and Compliance

Two technical specifications that affect both price and performance are tracking force and compliance. Understanding these helps explain why premium cartridges are designed the way they are.

Tracking force is the weight that the stylus exerts on the record surface. It's measured in grams, typically 1.5–2.5 grams for modern cartridges. Too much tracking force damages records and wears the stylus quickly. Too little and the stylus bounces in the groove, causing distortion.

A cartridge's tracking force is determined by the weight of the moving assembly (stylus, cantilever, magnet) and the stiffness of the suspension springs. A premium cartridge might use titanium or beryllium to minimize the weight of the moving assembly, allowing for lower tracking force. Lower tracking force means less damage to records and longer stylus life. It also means less noise generated by the cartridge itself.

Compliance is how much the cartridge's suspension deflects under pressure. It's measured in compliance units (or sometimes in micro-inches per dyne). A cartridge with high compliance is very springy; the stylus deflects easily. A cartridge with low compliance is stiff.

Compliance matters because it interacts with your tonearm's effective mass. The combination of compliance and tonearm mass determines the resonant frequency of the tonearm-cartridge system. If this resonant frequency falls near a record's wow and flutter frequency (usually 3–4 Hz), you get feedback and instability. If it falls in the audio range (20 Hz–20 k Hz), you get coloration.

The ideal resonant frequency is around 8–12 Hz, which is above record rumble but below audible frequencies. Achieving this requires careful matching of compliance and tonearm mass. A heavier tonearm needs higher-compliance cartridge. A lighter tonearm needs lower-compliance cartridge.

Premium cartridge manufacturers carefully engineer their compliance to match typical tonearm masses. Some even offer multiple versions with different compliance values for different tonearms. This is a level of engineering detail that budget manufacturers ignore.

Magnet Systems and Electrical Output

Moving magnet cartridges use powerful magnets positioned around a coil. When the stylus and cantilever vibrate, the magnet moves within the coil's magnetic field, inducing electrical current. This current becomes the audio signal.

The strength of the magnets determines the output level. Stronger magnets produce stronger signals. But stronger magnets also have higher cost and, in some designs, can create problems with suspension stiffness or magnetic interference.

Premium cartridge manufacturers use rare-earth magnets like neodymium because they're stronger than traditional alnico magnets. But they also hand-select magnets for matching strength. If one magnet is slightly stronger than the other, it can create channel imbalance or affect tracking characteristics.

Some premium designs use moving coil systems instead of moving magnet. In a moving coil design, lightweight coils attached to the cantilever move within a stationary magnetic field. This is heavier work for the suspension (because the moving mass is greater), but it can produce sonic benefits in certain designs.

The coils themselves matter. In moving magnet cartridges, the coil is typically wound with copper wire. The number of turns, the wire gauge, and the purity of the copper all affect output level and impedance. Some premium cartridges use custom coils wound from oxygen-free copper (OFC) because it reduces distortion.

In moving coil designs, the coil is sometimes made from monocrystalline copper, which is even purer than OFC. Some exotic designs use silver wire instead of copper, which has better conductivity but costs more. These are marginal improvements that justify their cost only at the highest price points.

Sound Signature and Tuning Philosophy

Different cartridge manufacturers have different philosophies about how a cartridge should sound. This affects design choices and justifies premium pricing.

Neutral or analytical cartridges aim to present the recorded material without coloration. They emphasize detail and clarity. They're often preferred by people who listen to a wide variety of music and want to hear recordings as accurately as possible. Examples include Ortofon 2M designs and Denon cartridges.

Warm or romantic cartridges emphasize midrange and lower frequencies slightly. They're preferred by people who listen to jazz, classical, and older recordings. They tend to sound more forgiving of recording defects. Examples include Grado cartridges and some Koetsu models.

Dynamic or emphasizing cartridges highlight transients and emphasize upper midrange slightly. They're preferred by people who listen to rock and pop. They make drums and bass punch harder. Examples include some Miyajima designs.

These sonic characteristics are baked into the cartridge's design at a fundamental level. You can't change them through tweaking. Different suspension stiffness, different magnet strength, different coil impedance, different cantilever materials—all of these choices collectively create the cartridge's sonic personality.

A premium cartridge manufacturer might spend years developing a design that achieves a specific sonic signature with minimal coloration from resonances or other unwanted artifacts. That development cost is amortized across however many units they make, which is why bespoke and limited-production cartridges cost so much.

Investment Value and Collector Appeal

Here's an interesting angle: some ultra-premium cartridges have collectible value that approaches or exceeds their original purchase price.

A Koetsu Black cartridge that sold for

A vintage Ortofon SPU cartridge from the 1980s or 1990s, if it's in excellent condition, can command prices several times its original retail price. Some vintage EMT designs are sought after by collectors and DJ culture has revived interest in specific models.

This collector appeal doesn't apply to mid-range or budget cartridges. A 10-year-old Audio-Technica cartridge has no collector value. It's simply getting old. But a 10-year-old Koetsu or vintage SPU develops a patina of desirability.

For some buyers, ultra-premium cartridges are viewed as investments as much as audio components. This is probably not a great way to justify a $20,000 purchase to your spouse, but it's a fact worth acknowledging.

Practical Guidance: What You Should Actually Buy

If you're sitting here reading this and thinking about buying a turntable cartridge, what should you actually do?

First, assess your system. If you've got a decent turntable (sub-

Second, listen before buying if possible. Many hi-fi dealers have cartridges available for home trial. Take the opportunity. Put the cartridge in your system and listen for two weeks. You'll get used to its sonic signature and can make an informed decision.

Third, consider the total cost of ownership, not just the purchase price. A cartridge with a diamond stylus costs more upfront but lasts longer. Over 10 years, a

Fourth, ignore marketing nonsense. Yes, exotic woods and specific diamond grades matter. But only if your system is otherwise excellent. A marketing story about sourcing wood from a specific forest is interesting, but it won't make a mediocre system sound good.

Fifth, don't feel bad about buying a mid-range cartridge. The improvement from a

Maintenance and Longevity

Another factor in the cost calculus is how long different cartridges last before needing replacement or stylus replacement.

A budget cartridge with a sapphire stylus typically lasts 100–150 hours of play before the stylus wears enough that sound quality degrades noticeably. At 10 hours per week, that's roughly 2–3 years before you need a replacement stylus or entire new cartridge.

A mid-range cartridge with a diamond stylus typically lasts 800–1,500 hours. At 10 hours per week, that's 15–30 years. Even accounting for advances in cartridge design over time, that's probably longer than you'll want to use it.

An ultra-premium cartridge with a carefully crafted diamond stylus might last even longer, potentially 2,000+ hours. But the initial cost is high enough that the amortization per year might not be that different from a mid-range option.

Maintenance is similar across price ranges. You need to keep the stylus clean (using a carbon fiber brush or stylus cleaner). You need to keep your records clean. You need to avoid dropping the cartridge or subjecting it to physical shock. Beyond that, there's not much you can do to extend life.

One advantage of ultra-premium cartridges is that replacing the stylus is often possible and costs less than replacing the entire cartridge. A

The Verdict on Ultra-Premium Cartridges

After all of this, what's the actual answer to whether a $50,000 cartridge is worth it?

The honest answer: only if you have excellent hearing, a truly excellent turntable and system, well-maintained records, a dedicated listening room, and most importantly, the disposable income to not miss the money.

If all those conditions are met, then yes, an ultra-premium cartridge will sound better than a mid-range option. The improvements will be subtle—we're talking maybe a 10–15% improvement in subjective audio quality at best. But for someone who spends hundreds of hours per year listening to vinyl, those subtle improvements matter.

For the rest of us, a cartridge in the

The exotic materials and meticulous manufacturing aren't marketing gimmicks. Bosnian spruce really does have different acoustic properties than aluminum. A hand-assembled cartridge really does perform more consistently than a mass-produced option. But the question isn't whether these improvements are real. The question is whether you can hear them and whether they're worth the price to you.

FAQ

What makes a diamond stylus better than sapphire?

Diamond is harder than sapphire on the Mohs hardness scale (10 versus 9), meaning it resists wear better. A diamond stylus can last 800-1,500 hours compared to 100-150 hours for sapphire. Additionally, diamond can be cut to more precise geometries, allowing for better contact with record groove walls and lower distortion.

How often do I need to replace my cartridge stylus?

Diamond styli last 800-1,500 hours of playing time, which translates to 15-30 years at typical listening rates of 10 hours per week. Sapphire styli last only 100-150 hours, requiring replacement every 1-3 years. Some premium cartridges allow stylus replacement without purchasing a new cartridge, while budget options often don't.

Can you actually hear the difference between a 5,000 cartridge?

Yes, but the improvement is subtle. A $5,000 cartridge will have cleaner highs, better stereo imaging, reduced distortion on demanding passages, and more transparent midrange. However, your ability to hear these differences depends on your hearing, your audio system, and your listening environment. In blind listening tests, average listeners identify premium cartridges as better only about 60-70% of the time.

Why do some cartridges use exotic wood cantilevers?

Certain woods, particularly species used in violin-making like Bosnian spruce and Alpine spruce, have specific damping characteristics that reduce unwanted resonances in the audio frequency range. The damping properties genuinely improve sound quality by allowing the cantilever to vibrate freely without adding coloration from its own resonant frequencies. However, the improvement is only audible if your system is otherwise excellent.

What's the relationship between compliance and tracking force?

Compliance is how much the cartridge's suspension deflects under pressure, while tracking force is the weight applied by the stylus to the record. Together, they determine the resonant frequency of the cartridge-tonearm system. The ideal resonant frequency is 8-12 Hz, which keeps rumble below the audible range while preventing unwanted feedback. Premium cartridge makers engineer these values carefully; budget makers use one-size-fits-all approaches.

Is a moving magnet or moving coil cartridge better?

Moving magnet cartridges are more common, less expensive, and have higher output voltage, requiring only standard phono preamps. Moving coil cartridges have lower output, require specialized preamps, but some designs claim superior sonic qualities due to lower moving mass. The choice depends on your system and preferences; neither is objectively superior across all applications.

Should I upgrade my cartridge or turntable first?

Improve your turntable and tonearm before upgrading the cartridge. A cartridge can only be as good as the system delivering it. A

How do I know if my records are clean enough for a premium cartridge?

Premium cartridges excel at revealing record surface noise when the vinyl isn't clean. Use a vacuum record cleaner or thorough wet-cleaning method before using expensive cartridges. Dirty records will make even the best cartridge sound mediocre. Store records upright in dust jackets, avoid direct sunlight, and handle them by the edges only to keep them in premium condition.

Conclusion: Finding Your Sweet Spot

The turntable cartridge represents one of the few places in consumer audio where you can genuinely get what you pay for, up to a point. The progression from a

But the progression beyond

The exotic materials—the Bosnian spruce, the carefully selected diamonds, the hand-assemblies—represent genuine engineering advances. They're not marketing fluff. But they're answers to problems that only become apparent at the highest price points.

For most people, the sweet spot is somewhere in the

Choose a cartridge in that range, ensure the rest of your system is reasonably good, invest in cleaning and maintaining your records, and enjoy vinyl playback for years to come. That's far better spending than chasing the diminishing returns of ultra-premium cartridges.

And if you've got the money and the ears and the system to justify a $20,000 cartridge? More power to you. Just do it with your eyes open, knowing that you're paying for the last 5-10% of potential sonic quality and that most people won't hear the difference. That might be worth it to you. And that's fine.

Key Takeaways

- Diamond styli last 800-1,500 hours versus 100-150 for sapphire, justifying higher upfront costs through longevity

- Exotic woods used in premium cartridges provide genuine acoustic benefits through damping characteristics, not just marketing appeal

- The price-to-performance ratio is optimal at 1,000; improvements beyond this enter diminishing returns territory where only trained ears detect benefits

- System synergy matters more than cartridge cost alone—a 500 cartridge in an excellent system

- Manufacturing precision drives costs exponentially—tolerances of ±0.01mm require specialized equipment, hand-assembly, and expert technicians that small-batch makers must amortize across limited production

![Luxury Turntable Cartridges: Premium Materials & Extreme Costs [2025]](https://tryrunable.com/blog/luxury-turntable-cartridges-premium-materials-extreme-costs-/image-1-1771585653660.jpg)