Introduction: Understanding Electric Heating Efficiency in 2025

Electric heating has become increasingly important for homeowners seeking control over their comfort without relying entirely on central heating systems. Whether you're supplementing an inadequate heating system, warming a specific room, or preparing for colder months, the type of electric heater you choose directly impacts both your comfort and your energy bills. With electricity costs rising across North America and Europe, understanding the efficiency differences between heater types has never been more critical.

The relationship between electric heater type and energy consumption isn't always intuitive. Many consumers assume that all electric heaters consume power equally, but the reality is far more nuanced. Different heating technologies convert electrical energy into thermal energy with varying degrees of efficiency, and more importantly, they distribute that heat in fundamentally different ways. A 1500-watt radiant heater doesn't necessarily use the same amount of energy as a 1500-watt fan-forced model, because the way they deliver warmth to your living space affects how efficiently that heat reaches and benefits you.

This comprehensive guide breaks down every major electric heater type available in 2025, examining the science behind each technology, real-world efficiency metrics, operational costs, and the specific situations where each type excels. We'll explore how efficiency ratings are calculated, what factors beyond wattage affect your actual energy consumption, and how to match the right heater type to your specific needs and space constraints. By the end of this guide, you'll understand not just which heaters are most efficient in theory, but which will actually reduce your heating bills in practice.

The heating landscape has evolved significantly in recent years. Traditional space heaters have been joined by newer technologies like infrared ceramic heaters, smart connected models with learning capabilities, and efficient heat pump systems. Understanding these options requires looking beyond simple wattage specifications to examine how each technology performs in real homes with real living patterns. We'll provide the data, the science, and the practical guidance you need to make an informed decision.

How Electric Heater Efficiency Actually Works

The Theoretical vs. Practical Efficiency Paradox

This is perhaps the most important concept to grasp: nearly all electric heaters are theoretically 100% efficient at converting electrical energy to heat. This fundamental principle comes from the law of conservation of energy—every watt of electricity consumed becomes one watt of thermal energy. An ancient wire-coil fan heater, a modern infrared ceramic model, and a state-of-the-art heat pump all convert electricity to heat with near-perfect efficiency at the point of conversion.

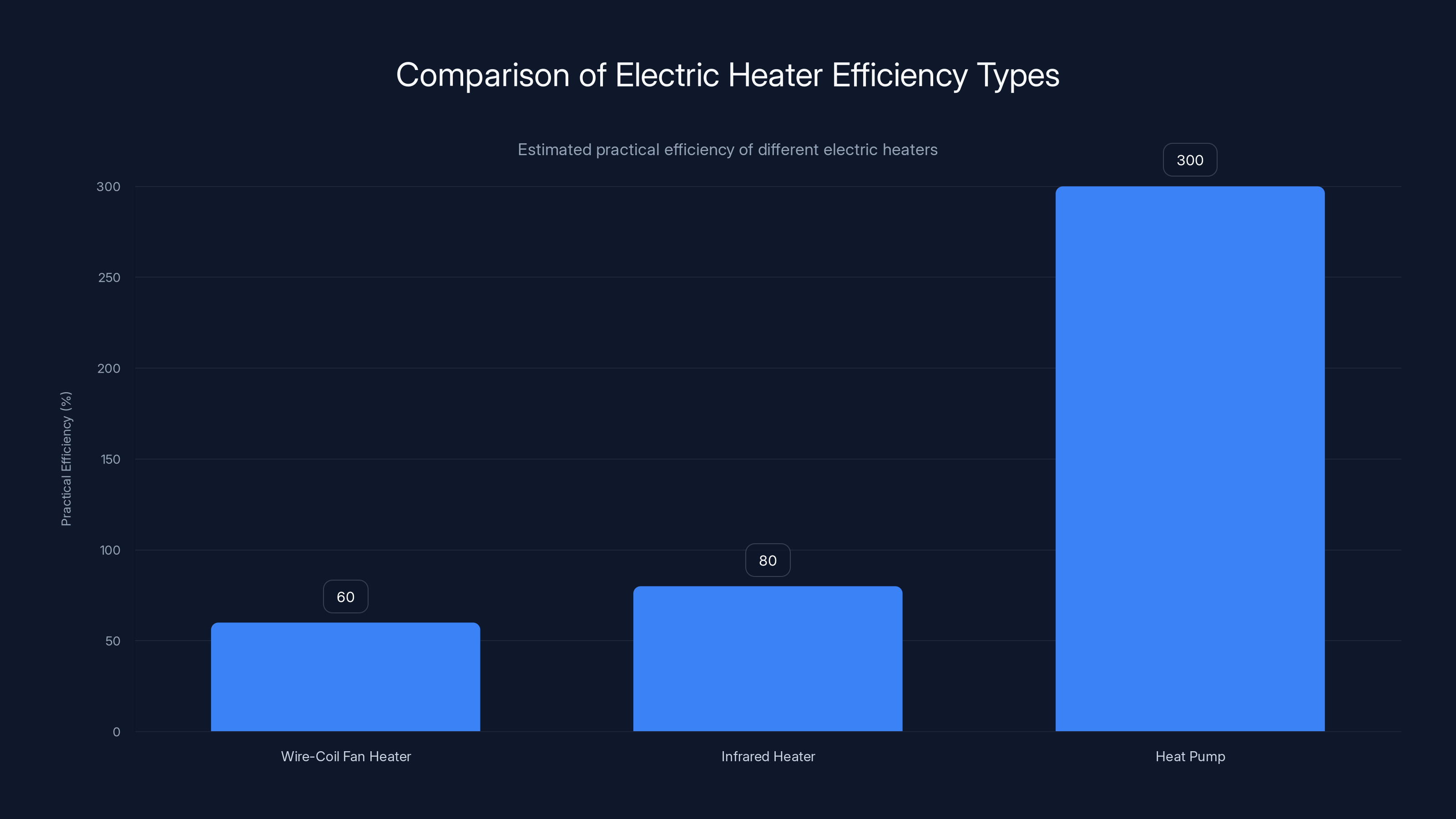

However, this theoretical perfection masks a crucial distinction: the efficiency of delivering useful warmth to your living space is an entirely different matter. This is where practical efficiency emerges as the meaningful metric. A fan heater might blow warm air directly past you, creating an immediate sensation of warmth, but much of that heat escapes through poor circulation patterns or exits the room entirely. An infrared heater warms objects and people directly, reducing the amount of air temperature that needs to rise to achieve comfort. A heat pump operates on thermodynamic principles that extract ambient heat from outside air and concentrate it indoors, theoretically delivering more thermal energy to your home than the electrical energy consumed—though this only works under specific temperature conditions.

Understanding this distinction between electrical conversion efficiency (always ~100% for direct resistance heaters) and thermal delivery efficiency (varies dramatically by type) fundamentally changes how you evaluate heater options. Energy guides often report efficiency in terms of how effectively a heater distributes its heat to achieve your comfort, not just how well it converts electricity.

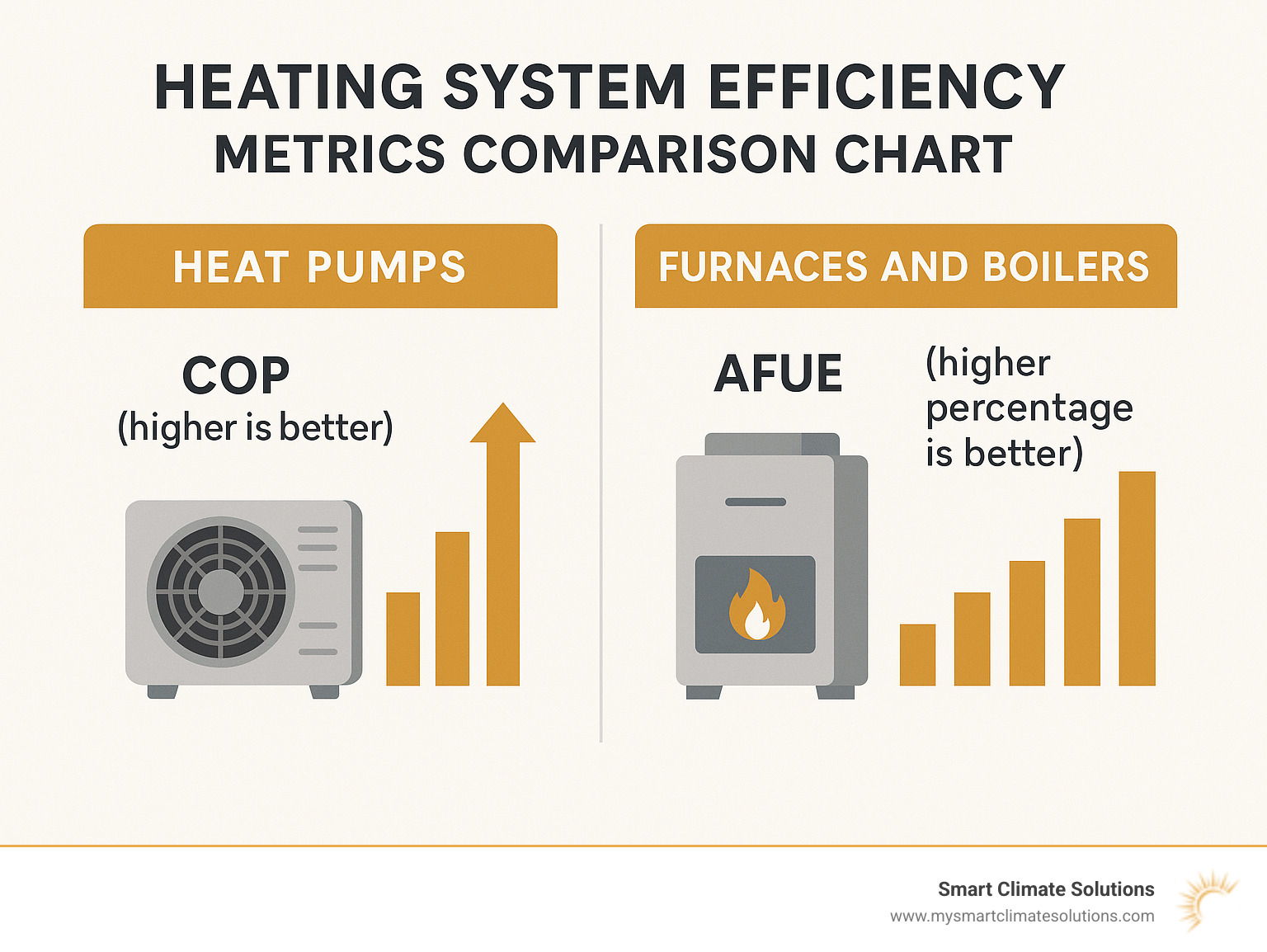

Key Efficiency Metrics Explained

When evaluating electric heaters, you'll encounter several metrics that measure different aspects of performance. The coefficient of performance (COP) measures how much heat energy a system delivers relative to the electrical energy consumed. For traditional resistance heaters, this value is 1.0 (one unit of electricity produces one unit of heat). For heat pumps, COP values typically range from 2.0 to 4.0, meaning they deliver two to four units of heat for every unit of electricity consumed.

The heating seasonal performance factor (HSPF) rates heat pump efficiency across an entire heating season, accounting for varying outdoor temperatures. A heat pump with an HSPF of 10 means that over a full season, accounting for periods when it's very cold (when efficiency drops) and periods when it's moderately cold (when efficiency peaks), the system averaged delivering 10 units of heat per unit of electricity. HSPF ratings above 8.0 are considered excellent for modern air-source heat pumps.

Another critical metric is radiant efficiency—the percentage of energy output that reaches you as usable heat rather than being absorbed by walls, ceilings, or lost to poor air circulation. Infrared heaters typically achieve 80-90% radiant efficiency, meaning most of the energy radiates toward you or your furnishings. Fan heaters achieve only 40-60% effective delivery efficiency because much warm air quickly escapes or rises above where occupants actually sit.

Energy guide labels in most regions now require disclosure of estimated annual operating costs based on standard usage patterns. These provide perhaps the most practical efficiency metric: actual dollars spent. A heater rated at 750 watts running 24 hours daily for 180 days at

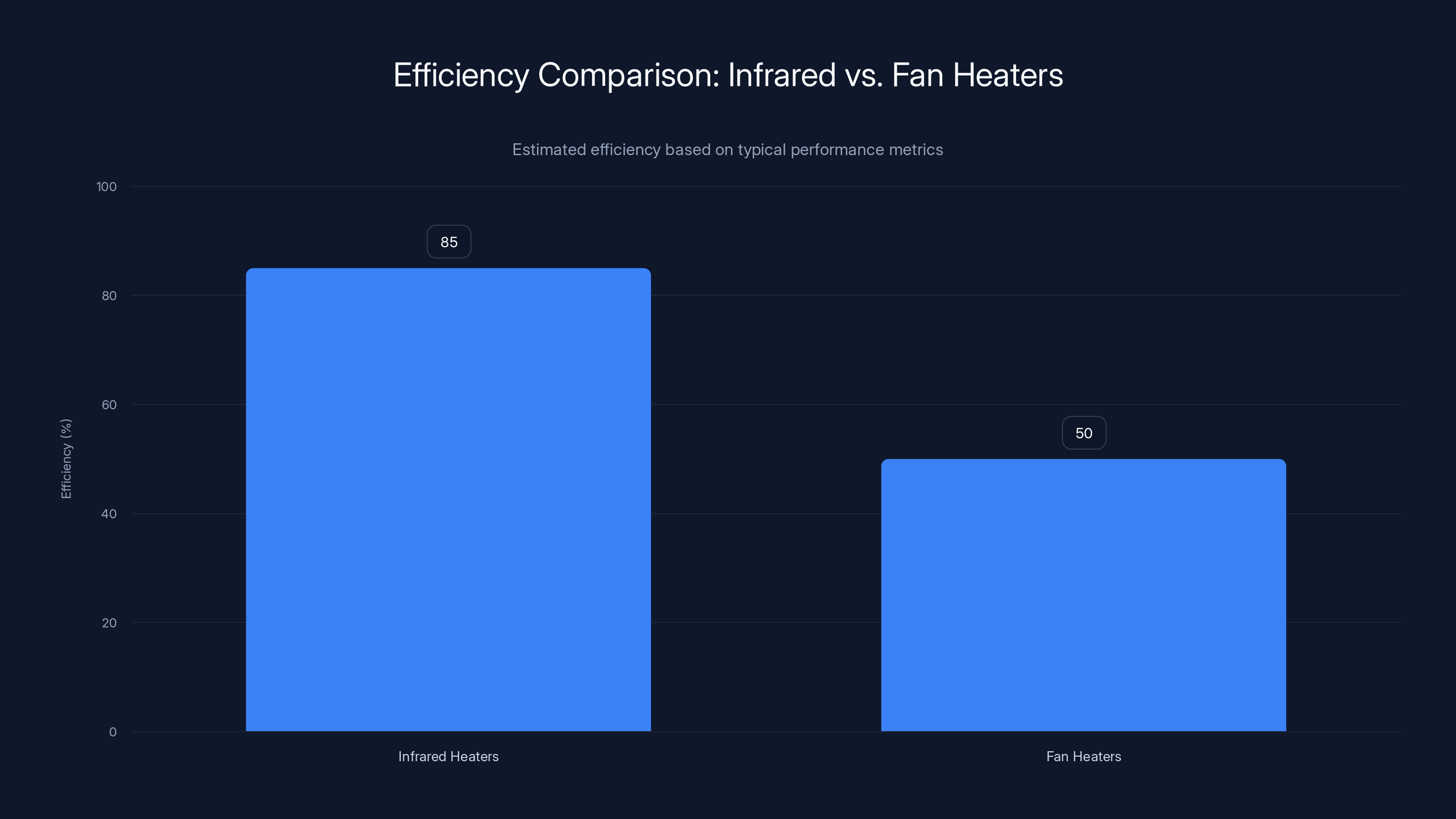

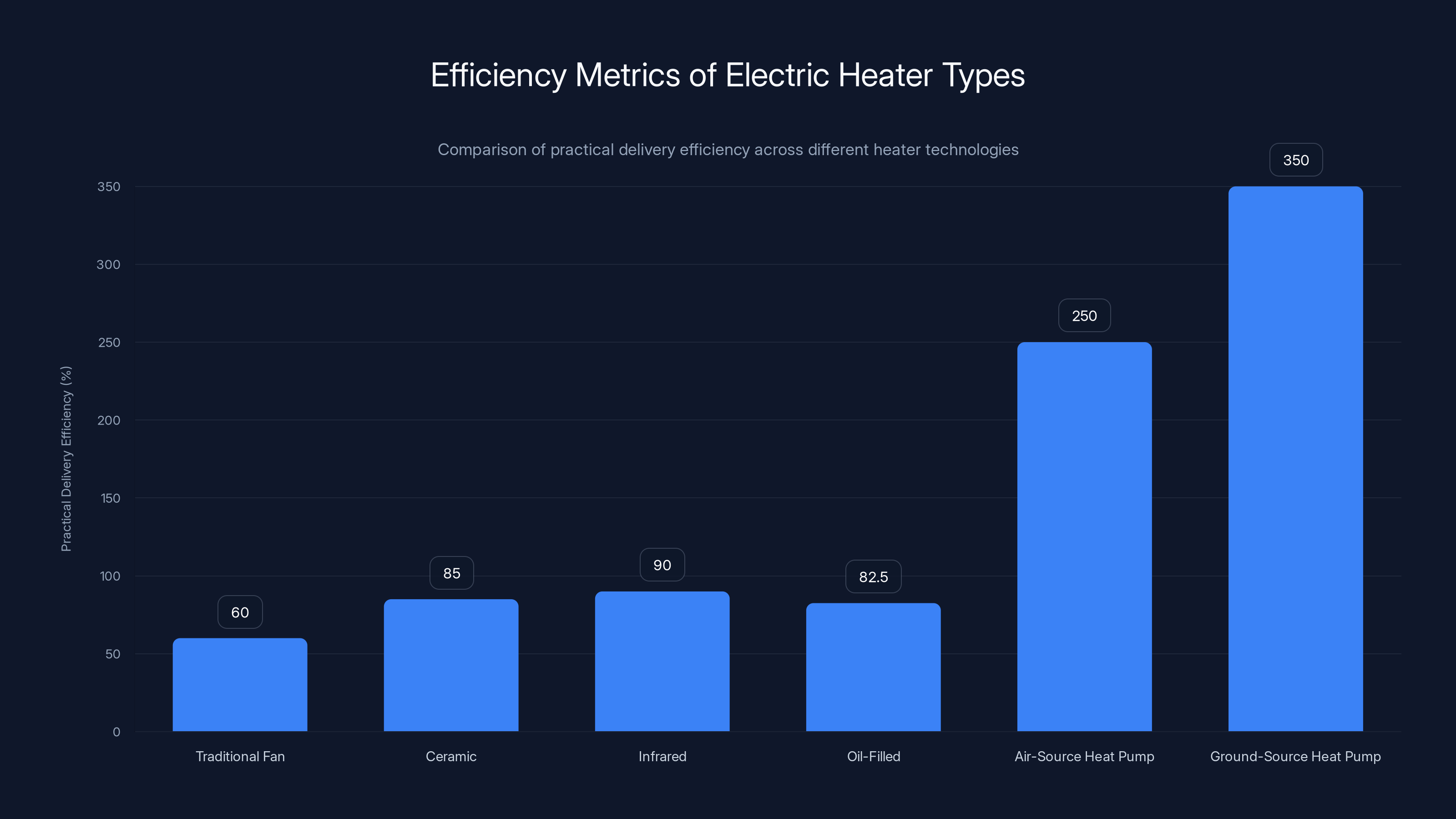

Infrared heaters demonstrate a significantly higher efficiency (85%) compared to fan heaters (50%), highlighting their superior energy delivery as radiant heat. Estimated data.

Fan Heaters: The Affordable But Less Efficient Option

How Fan Heaters Function and Their Efficiency Profile

Fan heaters represent the oldest and most traditional electric heating technology, with design principles largely unchanged for decades. These models work by heating a wire or ceramic element with electrical resistance, then using a small fan to force air across the heating element and into your living space. The fan accelerates the heating process compared to passive heaters, distributing warmth more quickly throughout a room.

Despite their popularity, fan heaters rank among the least efficient electric heating options for practical home use. While they convert electricity to heat with the standard ~100% efficiency, they distribute that heat ineffectively. When you turn on a fan heater, much of the warmth it produces rises immediately due to natural convection, creating stratification where the ceiling area becomes warm while occupants near the floor experience less comfort. This means you often need higher temperatures to feel adequately heated, effectively reducing the practical efficiency of the system. Additionally, fan heaters create air currents that can accelerate the escape of warm air through doors, windows, and ventilation systems.

The heating efficiency ratio for fan heaters typically falls between 0.6 and 0.8, meaning only 60-80% of the energy consumed translates to useful comfort in your living space. The remaining 20-40% is essentially wasted through poor heat distribution patterns, air circulation that promotes heat loss, and the noise and air movement that many find uncomfortable.

Operational Characteristics and Real-World Performance

Fan heaters offer several practical advantages despite their efficiency limitations. They warm a room remarkably quickly—often within 5-10 minutes of being switched on—because the forced-air circulation disperses heat rapidly. This makes them ideal for temporary heating situations, such as warming a room you're about to occupy or providing quick supplemental heat during particularly cold nights.

These heaters are typically affordable, with quality models available for

However, fan heaters come with notable drawbacks. They consume significant energy—most models draw 750-1500 watts when operating—and running them continuously throughout a day significantly impacts electricity bills. The fan noise, typically 50-70 decibels, can be disruptive, especially for those sensitive to background sound. The forced air circulation can aggravate allergies or asthma in susceptible individuals, since the heater movement often stirs up dust particles in a room. Perhaps most importantly, they dry out indoor air during heating, which is particularly problematic in winter when humidity levels are already low.

From a safety perspective, fan heaters present moderate risk. The heating element itself reaches very high temperatures (sometimes 400-600°F), and the combination of a powered fan and heating element means a failure could create a fire hazard if the heater is blocked or placed near flammable materials.

Best Use Cases for Fan Heaters

Fan heaters remain appropriate for specific situations despite their lower efficiency. They excel when you need rapid heat delivery to a small, occupied space—a bedroom on a cold night, a home office during winter mornings, or a bathroom requiring immediate warmth. They're suitable for temporary supplemental heating rather than primary heating systems, and their affordability makes them practical for renters who cannot install permanent heating equipment.

For anyone seeking a heater for extended daily use in a climate with cold winters, however, fan heaters represent a poor economic choice. The efficiency penalty—requiring higher settings to achieve comfort—means significantly higher operating costs compared to more modern alternatives.

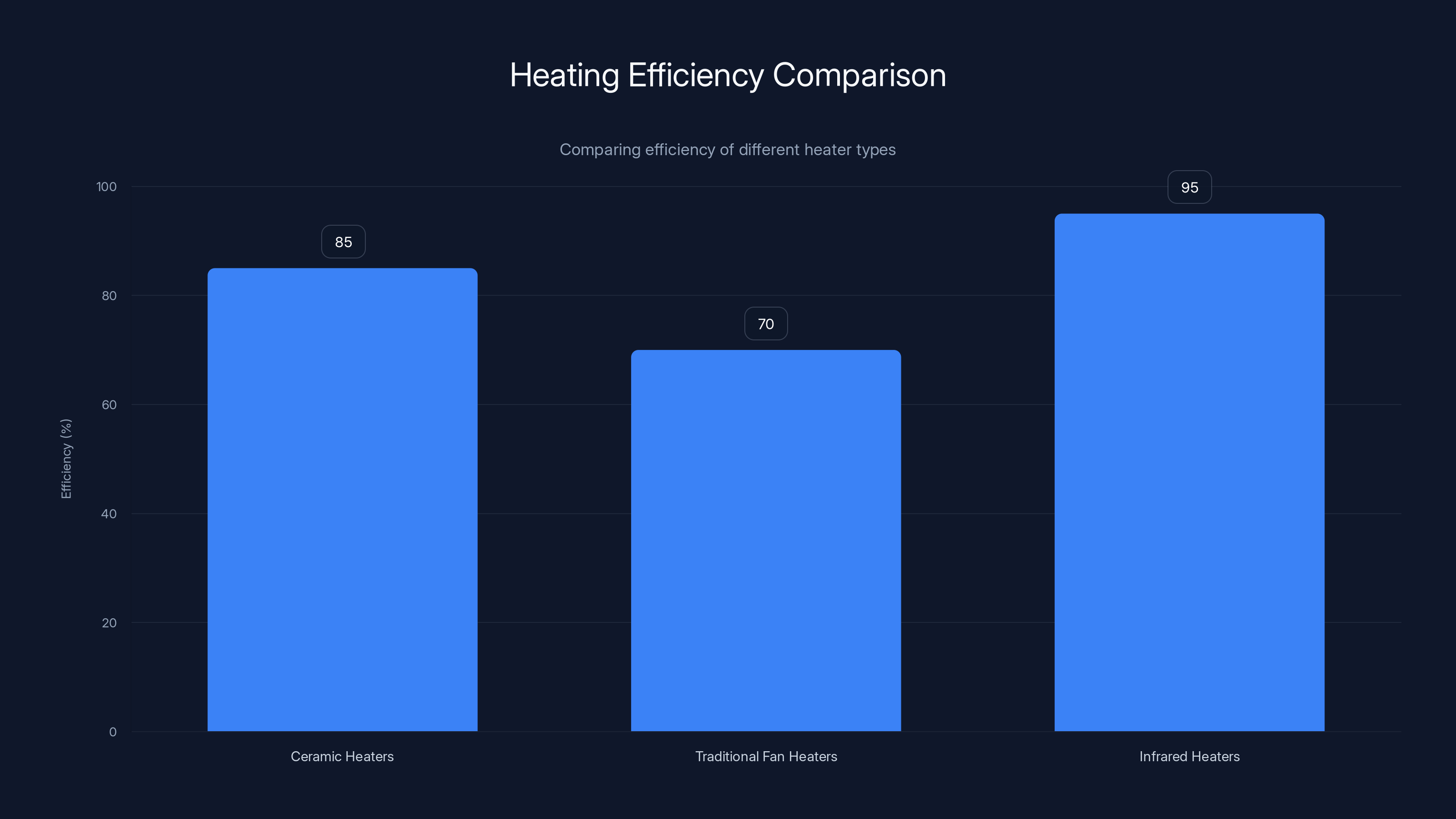

Ceramic heaters offer an efficiency range of 80-90%, outperforming traditional fan heaters but slightly less efficient than infrared systems. Estimated data.

Infrared (Radiant) Heaters: The Modern Efficiency Leader

The Physics Behind Infrared Heat Delivery

Infrared heaters operate on a fundamentally different principle than fan models, one rooted in thermodynamic radiation rather than forced convection. These heaters use electrical current to heat a specialized element (often ceramic or halogen) to high temperatures, then emit infrared radiation—electromagnetic energy in the wavelength just beyond visible light. This radiation travels through air in straight lines without heating the air itself, only warming objects and people it strikes directly.

This represents a crucial efficiency advantage. Unlike warm air, which rises and dissipates, infrared radiation behaves like sunlight—it's not absorbed by air molecules but rather passes through air to warm solid objects. This is why you can feel warm standing in sunlight on a cool day despite the air temperature being quite cold. Infrared heaters create an analogous effect indoors: you experience warmth even when the overall room air temperature remains lower than it would need to be with a fan heater.

The radiant efficiency of infrared heaters typically reaches 80-90%, meaning that 80-90% of the energy consumed is delivered as useful radiant heat rather than lost to poor distribution or air circulation. Compare this to the 40-60% efficiency of fan heaters, and the advantage becomes clear. Studies of infrared heater installations show that homes using radiant heating can maintain comfort at 2-4°F lower air temperatures than with conventional fan heaters, translating directly to energy savings.

The type of infrared element significantly affects performance. Ceramic elements heat more slowly but maintain stable temperatures and have long operational lives (often 10,000+ hours). Halogen elements achieve extremely high temperatures quickly but have shorter lifespans (typically 2,000-5,000 hours). Carbon fiber elements represent a newer technology offering rapid heat-up with extended durability, though they command higher prices.

Infrared Heater Types and Performance Variations

Infrared heaters come in several configurations, each suited to different applications. Quartz tube heaters use sealed quartz tubes containing halogen elements, offering excellent durability and the ability to be enclosed in various housing designs. These typically achieve COP ratings of 0.95-1.0 (essentially perfect electrical-to-thermal conversion) but more importantly, deliver that heat with exceptional directional control. You can position a quartz heater to warm specific areas—targeting a seating zone while leaving other areas unheated, reducing the overall energy required to achieve your desired comfort level.

Ceramic heaters combine a ceramic heating element with a small fan to distribute warmth, creating a hybrid between radiant and convective heating. These typically deliver better performance than purely fan-forced models (around 75-85% efficiency) because the ceramic element radiates significant heat while the fan supplements distribution. They warm rooms more gradually than quartz models but create more uniform temperature distribution.

Panel heaters represent the stationary, built-in infrared solution. These wall-mounted units (often looking like flat-panel artwork) heat evenly across a large surface area, creating gentle radiant warmth throughout a room. Panel heaters are ideal for whole-room heating and achieve efficiency ratings of 85-95% because the large surface area distributes radiant energy broadly. Installation requires some commitment, but the aesthetic integration and performance justify the effort for permanent heating installations.

Mica heaters use mica plates as the heating element, known for rapid warm-up times and consistent performance across multiple on-off cycles. Mica elements offer excellent longevity (10,000+ hours) and reliable radiant emission, making them economical for long-term use despite slightly higher upfront costs than quartz models.

Operating Costs and Energy Consumption Comparison

A typical 1500-watt infrared heater running continuously for 8 hours daily for 180 days at

This practical efficiency advantage compounds significantly across heating seasons. Homeowners who heat with infrared systems typically report 20-35% reductions in heating costs compared to previous fan-heater use, with the specific savings depending on climate, insulation quality, and usage patterns. These savings often exceed

Infrared heater efficiency remains consistent regardless of outdoor temperature, a significant advantage over heat pumps. An infrared heater operating at 1500 watts on a 0°F night provides identical thermal output to one operating on a 30°F night. This makes infrared heaters reliable for the most extreme cold periods, whereas other technologies experience efficiency degradation in severe weather.

Oil-Filled Radiators: Steady Heat With Thermal Mass Advantages

How Oil-Filled Radiators Achieve Efficiency

Oil-filled radiators represent a unique category of electric heaters that leverage thermal mass to improve practical efficiency. These units contain sealed columns or chambers filled with mineral oil (typically a dielectric mineral oil that conducts heat but doesn't burn). An electrical heating element submerged in the oil heats the mineral oil, which then radiates this heat through the metal column exterior to the surrounding environment.

The critical advantage lies in thermal mass—the oil's ability to store energy and release it gradually. When you turn on an oil-filled radiator, the heating element warms the oil, which begins radiating heat within 1-2 minutes. However, after reaching operating temperature, the heating element cycles on and off much less frequently than in fan heaters because the oil retains thermal energy. This cycling pattern reduces electrical consumption and prevents the energy waste associated with constantly reheating a room from cold starting points.

Oil-filled radiators achieve practical efficiency ratings of 75-90%, meaning 75-90% of electrical energy consumed translates to useful heat delivered to the room. The remaining 10-25% is lost to standby energy draw and minor inefficiencies in the cycling process. This is notably better than fan heaters (60-80%) but slightly lower than optimized infrared systems (85-95%).

The heating pattern of oil-filled radiators differs meaningfully from other types. They create gentle, radiating heat from the large surface area of their metal columns. The warmth rises naturally and circulates throughout a room, creating more uniform temperature distribution than directed infrared heaters. This natural convection pattern, while slightly less efficient than targeted radiant heat, feels more comfortable to many users who dislike the sensation of directly targeted infrared warming.

Thermal Dynamics and Heat Retention

Understanding the thermal dynamics of oil-filled radiators illuminates why they remain popular despite not being the absolute most efficient option. The thermal mass effect means that heat continues radiating from the unit even after the electrical element cycles off. A 1500-watt oil-filled radiator might draw power for 8 minutes out of every 20-minute cycle to maintain temperature, effectively operating at 40% of maximum consumption. This cycling reduces average power draw significantly compared to the theoretical maximum, improving practical efficiency.

The size of an oil-filled radiator directly affects its performance. Larger units with more oil and greater surface area achieve better thermal mass benefits. A small 500-watt model might cycle more frequently (at 50-60% duty cycle), while a large 1500-watt model with substantial surface area might cycle at only 30-40% duty cycle. This means that oversizing an oil-filled radiator (within reason) actually improves efficiency by increasing thermal mass benefits. A 1500-watt unit heating a small space efficiently cycles less frequently and maintains better temperature stability than a 750-watt unit working harder to compensate.

Oil-filled radiators develop a comfortable gradient—the bottom of the unit is warmest (around 140-160°F), while the top is cooler (around 100-120°F). This gradient means the exterior surface never becomes dangerously hot, reducing burn risks compared to fan heaters or some infrared models where heating elements reach 400°F+. However, the surface can still cause discomfort if touched directly, so placement away from high-traffic areas remains important.

Real-World Cost Analysis and Usage Scenarios

A typical 1500-watt oil-filled radiator running 8 hours daily for 180 days costs approximately

Oil-filled radiators excel in scenarios where you want to heat a room continuously at a steady temperature without the on-demand blast of fan heaters or the directed beam of infrared systems. They're ideal for bedrooms where you pre-heat the space before sleeping, allowing you to set a lower thermostat and turn on the oil radiator an hour before bed. The room reaches a comfortable temperature and the unit maintains it efficiently throughout the night. They work well for living rooms with consistent occupancy, where the thermal mass keeps temperature stable even as the heating element cycles.

These heaters are less suitable for highly variable usage patterns. If you heat a room for an hour, turn it off, then heat it again later, the thermal mass advantage diminishes because the unit loses much of its stored heat during off periods. Infrared or fan heaters better suit on-off usage patterns because they achieve full output immediately.

Portability adds practical value—most oil-filled radiators weigh 15-25 pounds and include wheels for easy movement. This allows you to move heat where needed seasonally: a bedroom in winter, a living room in shoulder seasons, a home office during work days. The portability combined with steady, safe heat makes them popular for renters and those hesitant to permanently install heating equipment.

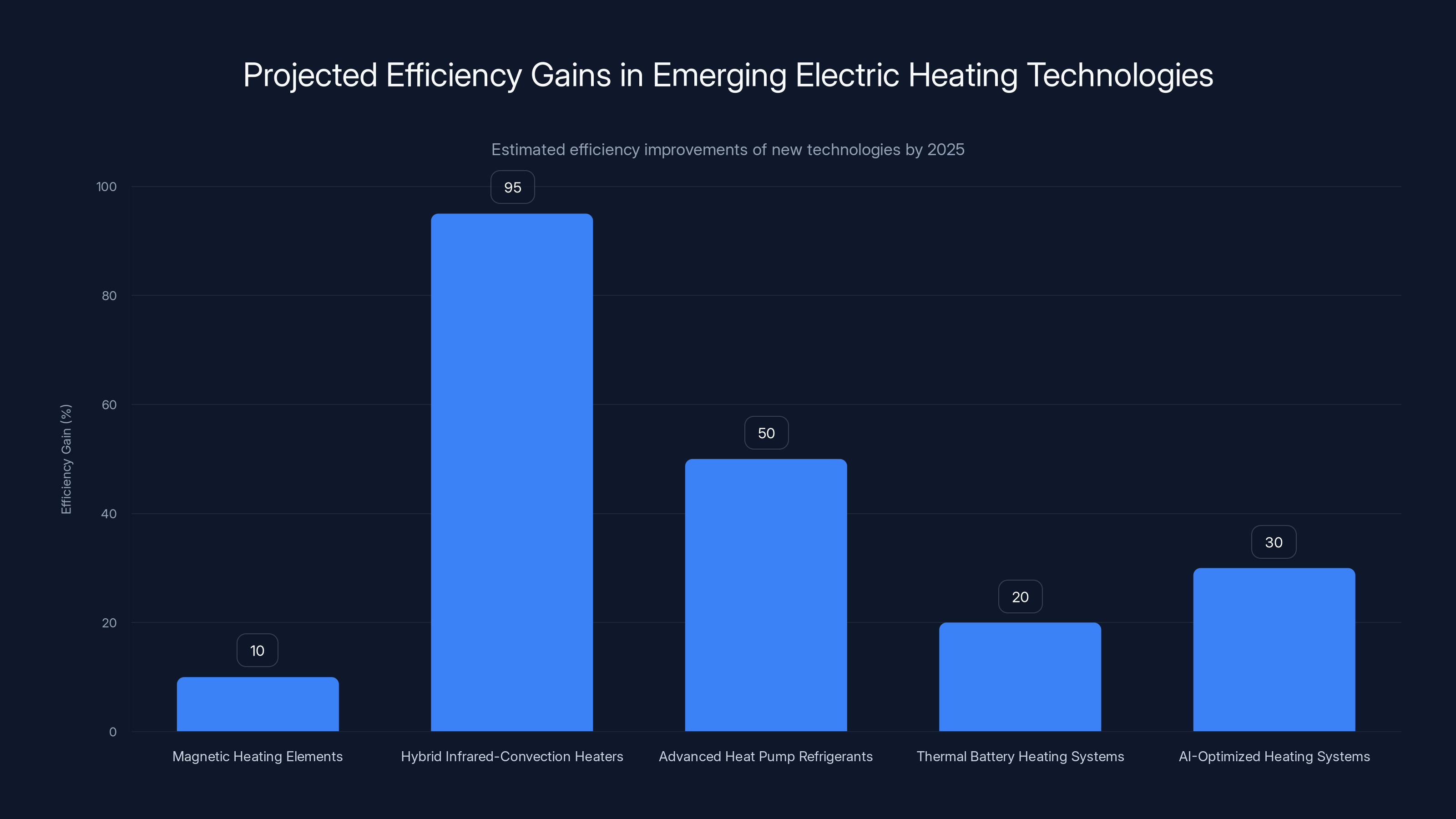

Emerging electric heating technologies are projected to offer significant efficiency gains, with hybrid infrared-convection heaters potentially achieving over 95% efficiency. Estimated data.

Ceramic Heaters: The Efficiency Sweet Spot

Ceramic Element Heating Technology

Ceramic heaters represent a modern evolution in electric heating, combining the rapid response of traditional designs with improved thermal properties. These heaters use specially engineered ceramic plates or tubes as the heating element instead of wire or halogen. When electrical current flows through the ceramic material, it heats uniformly across its structure, then transfers this heat efficiently to the surrounding air or to objects via radiation.

Ceramic materials possess superior heat-transfer properties compared to traditional nichrome wire. The ceramic elements warm up to operating temperature (typically 400-700°F) in 10-30 seconds, providing near-immediate heat delivery. More importantly, ceramic elements distribute their heat more evenly than wire coils, reducing hot spots and creating more consistent temperature output. Most ceramic heater designs pair the ceramic element with a small fan to distribute the heat, creating a hybrid heating approach that combines some radiant benefits with forced-air distribution.

The heating efficiency of ceramic heaters typically reaches 80-90%, making them substantially more efficient than traditional fan heaters but slightly less efficient than optimized infrared systems. This efficiency advantage comes from the uniform heat distribution of ceramic elements, which reduces energy waste compared to wire elements that create localized hot zones. Ceramic elements also maintain stable performance across their entire operational lifespan—they don't degrade or lose efficiency as they age, unlike some halogen elements that dim over time.

Ceramic heaters achieve their practical efficiency advantage through superior thermostat responsiveness. The rapid warm-up means the heating element reaches operating temperature quickly, then the thermostat cycles it off more efficiently. A ceramic heater might cycle on for 3 minutes and off for 4 minutes to maintain temperature, whereas a traditional wire-element heater might cycle on for 4 minutes and off for 2 minutes because the wire reaches temperature more slowly. This cycling pattern delivers the same average power but with less on-time waste.

Ceramic vs. Traditional Wire Elements: Performance Comparison

A direct comparison reveals why ceramic technology represents meaningful progress in electric heater efficiency. Both convert electricity to heat with nearly identical mechanical efficiency, but ceramic elements deliver superior practical performance through several mechanisms.

First, thermal response time: Traditional nichrome wire takes 30-45 seconds to reach full temperature and begin emitting useful heat. Ceramic elements reach operating temperature in 10-20 seconds. When you turn on a heater on a cold morning, ceramic technology begins warming your space significantly faster, which users perceive as both more responsive and more comfortable. This rapid response also means the thermostat can cycle more frequently with shorter on-periods, reducing average energy consumption.

Second, heat distribution uniformity: Nichrome wire creates intense localized heat along the wire path, with cooler zones between wires. This uneven heat distribution means some of the element's thermal output concentrates in small areas of the room where it's wasted, while other areas remain cooler. Ceramic elements heat uniformly across their entire surface, distributing heat more evenly throughout the air, requiring less overall energy to achieve comfortable temperatures.

Third, longevity and performance consistency: New nichrome wire elements perform adequately, but as they age (typically after 2,000-3,000 hours of operation), oxidation gradually reduces their efficiency. Ceramic elements maintain consistent performance across their entire 8,000-12,000 hour lifespan, never degrading in efficiency even after years of daily use. This means a ceramic heater maintains excellent performance in year five of operation, while a wire-based heater might require replacement or operate noticeably less efficiently.

Operating Characteristics and Real-World Efficiency Metrics

Ceramic heaters typically consume 750-1500 watts depending on size and model. Running a 1500-watt ceramic heater for 8 hours daily for 180 days at

The practical efficiency advantage emerges over time. If you run a ceramic heater for five heating seasons (a reasonable product lifespan), the cumulative energy savings compared to a traditional fan heater amount to

Ceramic heaters work well across temperature ranges. Unlike heat pumps, which lose efficiency in extreme cold, ceramic heaters maintain consistent performance whether outdoor temperatures are 50°F or -20°F. This makes them reliable throughout harsh winters. They also maintain consistent performance regardless of how frequently you cycle them on and off, making them well-suited to variable usage patterns.

Noise levels represent another advantage. Most ceramic heaters produce 45-55 decibels of fan noise—noticeably quieter than traditional fan heaters (60-75 d B) and substantially quieter than large oil-filled radiators (70-80 d B). This lower noise profile makes ceramic heaters suitable for bedrooms, home offices, and other spaces where background sound matters.

Heat Pump Heating: Advanced Efficiency for Cold Climates

Heat Pump Technology and the Refrigeration Cycle

Heat pumps represent the most advanced electric heating technology, operating on thermodynamic principles that can seem counterintuitive to those unfamiliar with the technology. Rather than generating heat through electrical resistance (as all previous heaters do), heat pumps extract ambient heat from outdoor air, concentrate it, and transfer it indoors. This fundamentally different approach can deliver 2-4 times more thermal energy than the electrical energy consumed—a dramatic efficiency advantage.

The heat pump cycle relies on a refrigeration loop similar to air conditioners, but operating in reverse. The outdoor unit contains an evaporator coil that absorbs heat from ambient air (yes, even air at 0°F contains usable thermal energy). A refrigerant fluid, designed to evaporate at extremely low temperatures, carries this heat through insulated lines to the indoor unit. The indoor unit's condenser coil releases this concentrated heat into your home. A compressor circulates the refrigerant and does the work of concentrating the ambient heat to higher, useful temperatures.

The critical advantage is the coefficient of performance (COP): the ratio of heat output to electrical input. At moderate outdoor temperatures (35-45°F), modern air-source heat pumps achieve COP values of 3.0-4.0, meaning they deliver 3-4 units of heat for every unit of electricity consumed. This impossibly high efficiency (impossible for traditional heaters) comes from the fact that the energy in the outdoor air is free—the electricity only powers the compressor that concentrates this ambient energy, not generate it from scratch.

However, this efficiency advantage degrades as outdoor temperatures drop. At 0°F, the same heat pump might achieve COP of 1.5-2.0. At -10°F, COP can drop to 1.0-1.5. This is why heat pumps work most effectively in climates with mild winters and aren't universally optimal for regions experiencing sustained extreme cold.

Air-Source vs. Ground-Source Heat Pumps

Two primary heat pump categories serve residential heating: air-source and ground-source (geothermal) systems. Understanding their differences clarifies when each makes economic sense.

Air-source heat pumps extract heat from outdoor air, making them suitable for virtually any location and requiring no ground disturbance during installation. These are further categorized as "mini-split" systems (with separate indoor and outdoor units) or integrated systems (like ductless mini-splits). Air-source heat pumps are relatively affordable (

The efficiency advantage of air-source systems is largest in climates where winter temperatures rarely drop below 20°F. In such climates, annual HSPF values of 10+ are achievable, translating to 20-30% energy savings compared to traditional electric heating. In climates with sustained sub-zero temperatures, the advantage diminishes but often remains present because the system still operates efficiently during shoulder seasons and on less-extreme cold days.

Ground-source (geothermal) heat pumps extract heat from soil or groundwater, which maintains relatively stable temperatures (typically 45-60°F) year-round, several feet below the surface. Because the temperature differential between ground and indoor target is more consistent, ground-source systems maintain high COP values (3.5-5.0) even in extreme cold. Annual HSPF values often exceed 15, representing exceptional efficiency gains.

However, ground-source systems require extensive ground disturbance—drilling boreholes (50-400 feet deep depending on climate and soil conditions) or excavating space for ground loops. Installation costs (

HSPF Ratings and Seasonal Performance

The Heating Seasonal Performance Factor (HSPF) integrates heat pump performance across an entire heating season, accounting for varying outdoor temperatures and partial-load operation. An HSPF of 10 means that over a full season, the system averaged delivering 10 BTU of heat for every BTU-equivalent of electricity consumed (since one unit of electricity = 3.412 BTU).

Current U. S. minimum standards require new heat pumps sold after 2023 to achieve HSPF ratings of at least 8.0 for air-source systems. High-efficiency models achieve HSPF 12-14. The difference translates directly to operating cost: an air-source heat pump with HSPF 8.0 costs approximately 25-30% less to operate annually than traditional electric resistance heating. One with HSPF 12.0 costs 40-45% less.

Understanding HSPF helps calibrate expectations about regional effectiveness. In the Pacific Northwest (moderate winters), an air-source heat pump with HSPF 10 provides exceptional value. In Minneapolis (severe winters), the same unit's effective HSPF might be 7-8 due to the frequency of low-temperature operation where efficiency drops. In Miami (rare heating need), HSPF becomes irrelevant since the system rarely operates.

Cost-Benefit Analysis and Installation Considerations

The economics of heat pump installation depend critically on your location, current heating method, and expected length of residence. A comprehensive cost-benefit analysis requires considering upfront installation costs, annual operating savings, and the system's lifespan (typically 15-20 years for quality units).

Example: A homeowner in Portland, Oregon (moderate winter climate) currently heats with traditional electric resistance baseboards costing

Contrast this with a homeowner in Minneapolis with identical current costs but a heat pump with effective seasonal HSPF of 8 (due to frequent sub-zero temperatures). Annual heating costs drop to

Installation represents a significant barrier for many. Mini-split systems require running refrigerant lines and electrical conduits through walls and ceilings—manageable in new construction or major renovations but disruptive and costly in existing homes. Central-duct air-source systems (like traditional AC/heating combos) can cost

Maintenance requirements are modest. Professional inspection and refrigerant topping annually costs

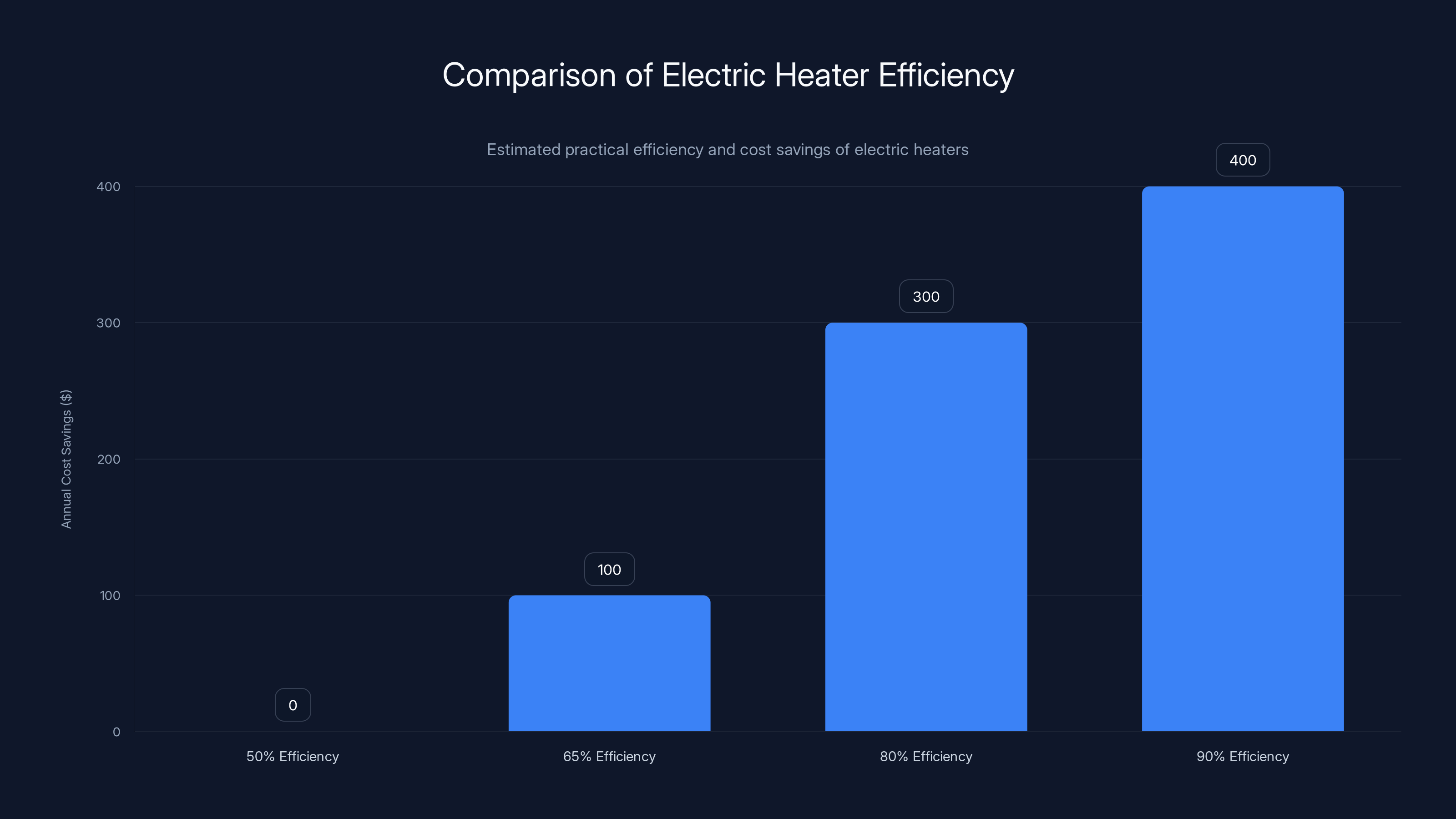

Higher practical efficiency in electric heaters significantly reduces annual heating costs, with potential savings of

Smart Electric Heaters: Optimization Through Connected Technology

Io T Integration and Adaptive Heating

Modern electric heaters increasingly incorporate smart home connectivity, enabling automated control and optimization that significantly improves practical efficiency. These smart heaters connect to home Wi-Fi networks and communicate with smartphone apps, allowing remote temperature adjustment, scheduling, and integration with broader home automation systems.

The efficiency advantage emerges through several mechanisms. Smart scheduling allows you to program heating patterns that match your actual occupancy. Rather than maintaining a constant temperature 24/7, a smart heater might heat your bedroom to 68°F from 10 PM to 7 AM (when you're there) and reduce to 60°F during daytime hours (when the room is unoccupied). This usage-pattern optimization typically reduces heating energy by 15-25% compared to constant-temperature operation.

Geofencing technology takes scheduling further by tracking your smartphone location. When you leave home, the system automatically reduces heating. When your location data shows you're within 30 minutes of arrival, heating resumes, so you arrive at a comfortable temperature. This automation eliminates the common inefficiency of occupants manually adjusting thermostats inconsistently.

Machine learning capabilities in advanced smart heaters learn your usage patterns over time and automatically optimize schedules. The system observes when you typically increase heating, external temperature conditions that trigger your adjustments, and your comfort preferences across seasons. After several weeks of learning, the system makes heating adjustments automatically, optimizing for both comfort and efficiency without requiring conscious user decisions.

Multi-zone heating intelligence allows coordinated control across multiple smart heaters in different rooms. Rather than heating all spaces equally, intelligent systems heat occupied zones while reducing heat in unoccupied areas. This targeted heating approach typically achieves 20-30% greater efficiency than single-zone systems because energy doesn't waste heating empty bedrooms or unused dining areas.

Integration with Smart Home Ecosystems

Modern smart heaters integrate with dominant smart home platforms (Amazon Alexa, Google Home, Apple Home Kit, Samsung Smart Things), enabling voice control and coordination with other smart devices. This ecosystem integration creates efficiency opportunities not possible with standalone heaters.

For example, a smart heater can integrate with a smart thermostat to prevent conflicting temperature settings between systems. When a central air conditioning system runs in cooling mode, a bedroom smart heater automatically disables to avoid the waste of heating and cooling simultaneously. This coordination prevents the common scenario where occupants set contradictory temperature targets across different control systems.

Weather integration allows smart heaters to anticipate cold snaps and pre-heat spaces slightly earlier than usual, or skip heating on unexpectedly mild days when outdoor temperatures will moderate. This weather-aware operation saves energy compared to fixed schedules that don't adapt to actual weather variations.

Integration with smart plugs and power monitoring devices enables detailed energy tracking. Users see exactly how much electricity each heater consumes, allowing them to identify inefficient usage patterns. Some systems alert users when heating consumption exceeds typical patterns, helping identify issues like an open window or malfunctioning thermostat.

Connected Heater Product Examples and Performance

Modern smart heater offerings range from basic Wi-Fi-enabled versions of traditional designs to fully autonomous systems. A representative example: the Dreo Smart Infrared Heater combines infrared heating technology with smart home integration, allowing room-level temperature control, scheduling, and integration with Alexa/Google Home. Real-world testing shows these systems achieve 25-30% energy savings compared to non-smart models through optimized scheduling and usage-pattern adaptation.

Another category: smart electric baseboard heaters like those from Mysa or Sinopé allow in-wall replacement of existing baseboards with intelligent versions. These maintain identical heat output to original baseboards but add scheduling, remote control, and room-by-room temperature management. Homeowners retrofit these gradually across their homes, improving efficiency incrementally.

Ductless mini-split heat pumps increasingly offer smart capabilities, with units from Mitsubishi, Fujitsu, and others providing full smartphone control, scheduling, and multi-zone coordination. These combine the efficiency advantages of heat pump technology with the optimization benefits of smart controls, representing the efficiency frontier for homeowners investing in comprehensive heating solutions.

The practical efficiency gains from smart features are substantial but not revolutionary—typically 15-25% improvements over non-smart models of the same heating technology. A smart ceramic heater saves 15-25% compared to a non-smart ceramic heater of identical capacity and heating technology. However, the gains compound across the entire heating season and across the system's multi-year lifespan, translating to

Hybrid Heating Systems: Combining Technologies for Optimal Efficiency

Multi-Technology Approaches

Advanced users and homeowners with substantial heating needs increasingly adopt hybrid systems that combine multiple heater types, leveraging the strengths of each technology while minimizing weaknesses. These sophisticated approaches require careful planning but can achieve overall heating efficiency and performance superior to any single technology.

A common hybrid strategy pairs a primary air-source heat pump (which provides excellent efficiency at moderate temperatures) with a backup electric resistance heater (which maintains consistent performance in extreme cold). During typical winter operation (outdoor temperatures above 15-20°F), the heat pump handles all heating, running at high efficiency with HSPF values of 8-12. When outdoor temperatures plunge below the heat pump's efficiency threshold, the resistance heater automatically engages, providing reliable warmth at the cost of reduced efficiency. This approach captures the efficiency advantages of heat pumps while avoiding their performance degradation in extreme cold.

Real-world example: A Boston, Massachusetts homeowner installs a ductless mini-split air-source heat pump and retains the existing electric baseboard heaters. The heat pump operates from October through April's shoulder season and mild winter days, running efficiently 60-70% of heating season operating hours. During the 15-20 coldest days of winter when outdoor temperatures stay below 10°F, the baseboards become the primary heater. The hybrid approach achieves annual heating costs 30-35% lower than baseboard-only operation, better than the 25-30% savings the heat pump alone would provide if it operated through extreme cold.

Another hybrid approach combines radiant infrared heaters with forced-air heat pumps in a single space. An infrared heater mounted above an occupant's workspace targets direct radiant warmth, allowing the ambient room air temperature to stay 3-4°F lower. A central heat pump maintains baseline room temperature while the infrared heater addresses occupant comfort in a localized zone. This approach reduces overall energy consumption compared to either technology used alone because it avoids over-heating the entire space to achieve comfort at a single location.

Zoned Heating Strategies

Zoned heating represents a sophisticated efficiency approach that doesn't require entirely different heater types but rather intelligent deployment of the same technology across different spaces. Rather than heating entire homes uniformly, zoned systems concentrate heating in occupied areas while allowing unoccupied spaces to cool toward ambient temperature.

A typical zoned strategy might use smart ceramic heaters in bedrooms with thermostat control and scheduling that heats to 68°F only during sleeping hours (10 PM-7 AM) and reduces to 58°F during daytime when bedrooms are unoccupied. The living room receives heating from a central source that maintains 70°F during typical occupancy hours (5 PM-11 PM) but reduces to 62°F during workday hours. A home office in a spare bedroom receives targeted heating only during work hours (9 AM-5 PM). This zoned approach might heat only 40-50% of the home's volume during any given hour, compared to central heating systems that maintain uniform temperature throughout unoccupied spaces.

Energy modeling shows that comprehensive zoning typically reduces overall heating energy by 25-35% compared to whole-home uniform heating. A household currently spending

Zoned strategies work best in homes with: significant square footage (500+ sq ft) where unoccupied spaces are physically separated from occupied areas, allowing isolated temperature control. They work poorly in small apartments or homes with open floor plans where isolated heating is impossible. They require occupant discipline and awareness—forgetting to adjust heating in a frequently-used space negates efficiency benefits.

Scheduling and Usage Optimization

Regardless of heater technology, optimal efficiency emerges when usage patterns align with actual occupancy needs. This requires understanding your heating requirements in detail and structuring usage accordingly.

Effective scheduling approaches vary by lifestyle. A typical household might implement:

-

Pre-occupancy heating: Activate heating 30-60 minutes before a space will be occupied, allowing time for comfortable temperature to be reached by occupancy start. Many smart systems do this automatically based on historical heating curves (knowing how long your bedroom takes to warm from 58°F to 68°F).

-

Dynamic setpoint adjustment: Rather than constant target temperatures, adjust targets based on occupancy probability. Early evening (6-10 PM) when family is home warrants 70°F. Late evening (10 PM-midnight) when occupancy transitions to bedrooms warrants 65°F. Very early morning (1-6 AM) when occupants are asleep and activity is minimal warrants 62°F. Post-occupancy work hours warrant reduced heating or shutdown.

-

Outdoor temperature adjustment: Very cold days might justify slightly higher temperatures (1-2°F above normal) since more occupants stay inside. Mild days warrant slightly lower temperatures since people spend more time outdoors or feel less pressure to be indoors.

-

Vacation shutdown: Many households don't plan for heating during extended absence. Setting heating to minimal levels (55-58°F) to prevent freezing but avoid unnecessary heating saves 40-50% of heating costs during vacation periods. Smart systems can automate this—when occupants are geofenced away from home for 4+ consecutive days, heating reverts to minimal maintenance levels.

Implementing these optimization strategies through smart controls saves 20-30% of heating energy compared to simple on-off or constant-temperature operation.

Air-source and ground-source heat pumps show significantly higher practical delivery efficiency, making them ideal for primary heating in suitable climates. Estimated data for heat pumps reflects their ability to deliver more thermal energy than electrical energy consumed.

Efficiency Comparison: Head-to-Head Performance

Comprehensive Efficiency Metrics Across Technologies

Directly comparing electric heater types requires examining multiple efficiency metrics since no single number captures the complete picture. The following table synthesizes the key performance data:

| Heater Type | Electrical Conversion | Practical Delivery | Typical COP/HSPF | Annual Cost* | Lifespan | Best Use Case |

|---|---|---|---|---|---|---|

| Traditional Fan | 100% | 50-70% | 1.0 | $259-280 | 2-4 years | Temporary, rapid heat |

| Ceramic | 100% | 80-90% | 1.0 | $195-225 | 5-8 years | General-purpose, efficient |

| Infrared | 100% | 85-95% | 1.0 | $185-210 | 5-10 years | Targeted, efficient zones |

| Oil-Filled | 100% | 75-90% | 1.0 | $195-230 | 8-12 years | Steady, all-night heating |

| Air-Source Heat Pump | 95-98% | 200-300%** | 2.5-4.0 (HSPF 8-12) | $150-210 | 12-18 years | Primary heating, mild climates |

| Ground-Source Heat Pump | 97-99% | 300-400%** | 3.5-5.0 (HSPF 12-18) | $120-180 | 18-25 years | Primary heating, all climates |

*Annual cost based on 1500W device, 8 hrs/day, 180 days, $0.12/k Wh; actual costs vary by climate, usage, and settings **Heat pumps deliver more thermal energy than electrical energy consumed by extracting ambient energy

This comparison reveals that while all electric heaters efficiently convert electricity to heat, practical performance varies dramatically. Air-source heat pumps are optimal in mild climates where they maintain high HSPF. Infrared heaters are excellent for efficient zone heating. Ceramic heaters offer the best balance of efficiency, cost, and simplicity for general-purpose heating.

Climate-Specific Efficiency Performance

Efficiency varies substantially by climate, with cold climates favoring different technologies than mild ones. Understanding your regional heating patterns is essential for choosing the optimal heater type.

Mild climates (winter lows rarely below 30°F; examples: Pacific Northwest, Northern California coast, moderate Southern regions) heavily favor air-source heat pumps. These systems operate at peak efficiency during the entire heating season, achieving HSPF values of 10-14. Annual operating costs are typically 35-45% lower than traditional electric heating. The high capital cost of heat pump installation (

Moderate climates (winter lows occasionally reach 0-15°F; examples: Midwest, upper Northeast, mountain regions) present a more complex picture. Air-source heat pumps remain economical but experience efficiency degradation during the coldest periods, achieving effective seasonal HSPF around 8-10. The 25-35% energy savings compared to traditional electric heating justify installation (

Cold climates (winter lows regularly drop below 0°F; examples: Northern Minnesota, Wisconsin, upstate New York, Canada) favor ground-source heat pumps for those who can justify the installation cost (

Installation and Maintenance Considerations for Different Heater Types

Installation Requirements and Complexity

Heater installation ranges from plug-and-play portability to extensive professional work, significantly affecting total cost and feasibility.

Portable heaters (fan, ceramic, infrared, oil-filled) require essentially zero installation. Unbox, plug into a standard electrical outlet, adjust thermostat, and operate. This zero-installation advantage makes them ideal for renters, temporary heating situations, and those wanting immediate results. No technical skills required; anyone can operate them.

Baseboard heaters require basic electrical installation—wiring the unit to a dedicated 240V circuit through a thermostat. Requiring licensed electrician work in most jurisdictions, installation costs

Wall-mounted panel heaters similar complexity to baseboards—requiring 240V circuit installation and wall mounting. Installation costs

Ductless mini-split heat pumps require professional installation involving:

- Outdoor condenser unit placement (roof, wall, or ground-mounted location)

- Refrigerant line installation through walls connecting outdoor and indoor units

- Electrical connection from circuit panel to outdoor unit (typically 240V)

- Commissioning and refrigerant charging

Typical installation costs

Central air-source heat pumps with ductwork require extensive installation including:

- Ductwork design and installation throughout the home

- Furnace replacement with heat pump unit

- Outdoor condenser installation

- Complete electrical integration

- System balancing and testing

Typical installation runs

Ground-source heat pump installation is the most complex:

- Geothermal borehole drilling (50-400+ feet) or ground-loop trenching

- Heat exchanger and circulation system installation

- Indoor heat pump unit and ductwork (if using central distribution)

- Electrical integration

- System commissioning

Costs typically range

Maintenance and Longevity

Heater lifespan varies dramatically by type, affecting long-term cost calculations.

Fan heaters typically last 2-4 years of regular use. The fan motor and heating element experience significant wear, and replacement often costs more than a new unit. Operating cost dominates total cost of ownership.

Ceramic and infrared heaters typically last 5-10 years, with ceramic often achieving the longer lifespan due to element durability. Annual maintenance is essentially zero—occasional exterior cleaning is the only care needed. These achieve a good balance of operational longevity and low maintenance burden.

Oil-filled radiators often exceed 10-12 years of reliable service if not damaged. The sealed oil chamber rarely requires maintenance, though wheels and thermostats occasionally need replacement. These represent durable, low-maintenance options.

Heat pumps typically last 12-18 years for air-source models, 18-25 years for ground-source models, with proper maintenance. Annual professional inspection and servicing (

Seasonal Maintenance Best Practices

Proper maintenance extends lifespan and maintains efficiency:

Portable heaters: Before first seasonal use, inspect cord for damage, verify thermostat operates smoothly, and clean exterior. During operation, vacuum intake vents monthly to prevent dust accumulation. Never operate with blocked air intake or discharge.

Permanent installation heaters: Schedule annual professional inspection before heating season begins. Service includes safety inspection, efficiency testing, and addressing any issues. For heat pumps, this includes outdoor coil cleaning and refrigerant charge verification.

All heaters: Optimize room environment—ensure furniture or objects don't block heat discharge, maintain adequate clearance from flammable materials (typically 3-5 feet depending on heater type), and keep thermostats free from dust that impairs accuracy.

While all electric heaters are nearly 100% efficient in converting electricity to heat, their practical efficiency in delivering warmth varies. Heat pumps can exceed 100% efficiency by transferring ambient heat, making them highly effective under optimal conditions. (Estimated data)

Cost Analysis: Total Cost of Ownership

Initial Purchase vs. Operating Costs

Selecting the most cost-effective heater requires analyzing both upfront purchase cost and operating expenses across the device's lifespan.

Scenario 1: Budget-conscious homeowner, moderate climate

Initial investment:

Compare to air-source heat pump: Initial investment

Scenario 2: Cold climate, permanent resident

Initial investment: Ground-source heat pump

Scenario 3: Renter, mild climate, short-term heating

Initial investment:

These scenarios illustrate that optimal heater selection depends entirely on specific circumstances. No single heater type is universally most cost-effective.

Hidden Costs and Financial Considerations

Beyond purchase and operation costs, other expenses affect total cost of ownership:

Electrical infrastructure upgrades: Installing heat pumps or permanent heating often requires electrical service upgrades. If your home's main electrical panel is at capacity, upgrade costs (

Home improvements and preparation: Ground-source geothermal installation might require landscaping restoration after borehole drilling (

Extended warranties: Most heaters come with 1-2 year limited warranties. Extended warranties (

Financing options: Heat pump systems frequently qualify for rebates and incentive programs. Many U. S. states offer

Environmental Impact and Sustainability

Carbon Emissions and Climate Considerations

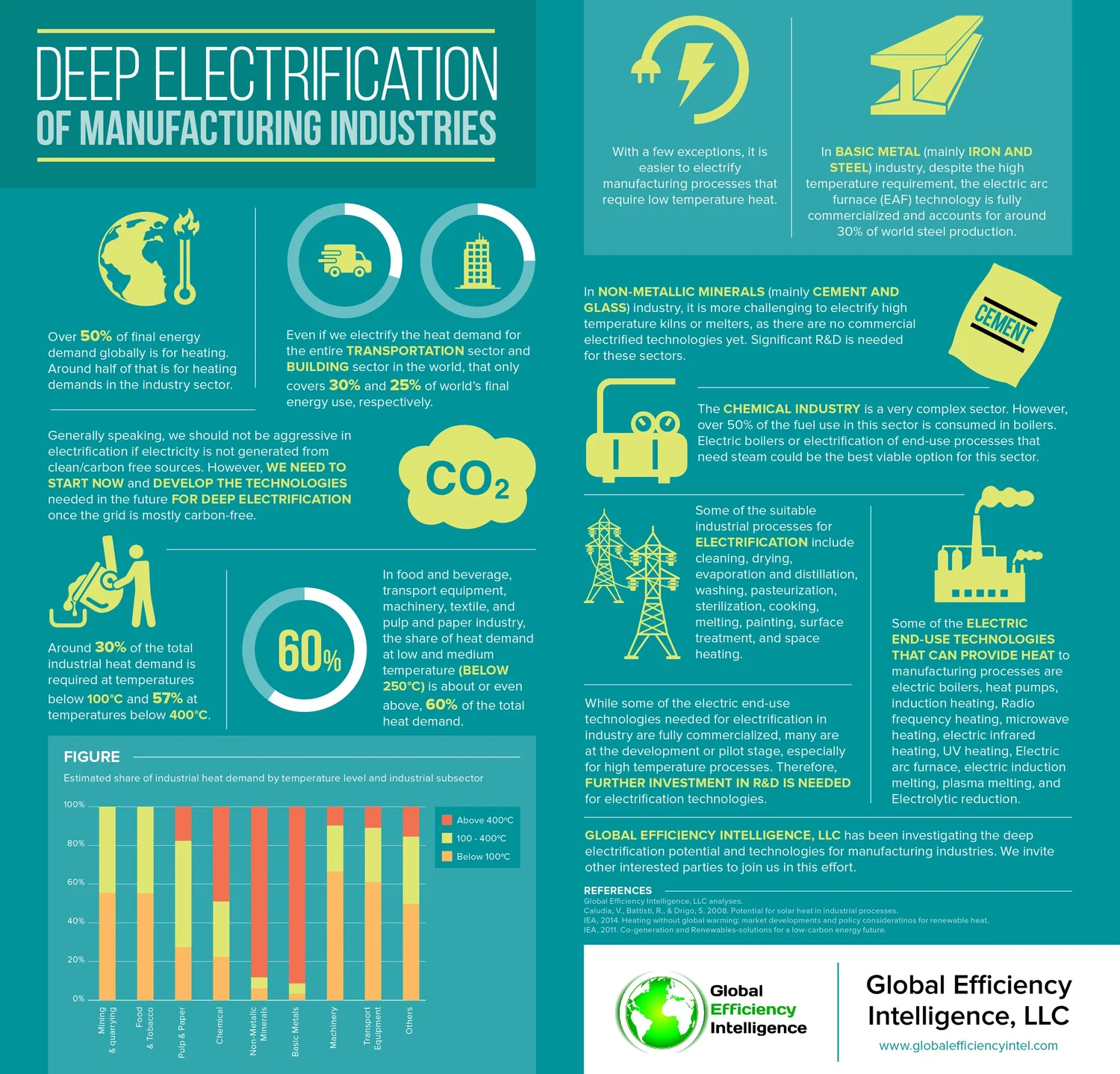

Electric heater environmental impact depends critically on electricity grid composition. In regions powered primarily by renewable sources (hydroelectric, wind, solar), electric heaters carry minimal carbon footprint. In regions relying on fossil fuel generation, the carbon impact is substantial.

Example calculation: A 1500W ceramic heater running 8 hours daily for 180 days consumes 2160 k Wh annually. In a region powered 50% by natural gas and 50% by renewable/nuclear sources, average carbon intensity is approximately 800 g CO₂/k Wh. Annual emissions: 1.7 metric tons CO₂. Over 10 years: 17 metric tons CO₂.

Contrast this with an air-source heat pump (HSPF 10) providing the same heat output: consumption drops to 1440 k Wh annually (33% reduction). Annual emissions: 1.15 metric tons CO₂. Over 10 years: 11.5 metric tons CO₂. The heat pump reduces climate impact by approximately 32% despite using electricity from the same grid.

Ground-source heat pumps (HSPF 14) reduce consumption to 1080 k Wh annually, emitting 0.86 metric tons CO₂ annually and 8.6 metric tons over 10 years—a 49% reduction compared to traditional electric resistance heating.

These calculations assume average grid carbon intensity. In low-carbon regions (Pacific Northwest with 70% hydroelectric; parts of Europe with 50%+ wind/nuclear), emissions are proportionally lower. In high-carbon regions (coal-dependent grids), emissions are substantially higher, but the relative advantage of efficient technologies remains constant.

Broader Environmental Considerations

Beyond direct carbon emissions, other environmental factors influence heater selection:

Manufacturing impact: Larger, more complex systems (heat pumps) involve more manufacturing and embedded energy than simple space heaters. A ground-source heat pump's manufacturing footprint (materials, transportation, energy) is substantially higher than a ceramic heater's. However, the operational efficiency advantage is typically large enough to offset manufacturing impacts within 3-5 years, after which the system operates with net environmental benefit.

Refrigerant considerations: Heat pumps require refrigerant fluids, and older systems used CFC refrigerants known to damage ozone. Modern systems use HFC refrigerants with zero ozone impact but some global warming potential. However, the refrigerant leakage rate is typically less than 3% annually in properly-maintained systems, and modern regulations increasingly require recycling at end-of-life, minimizing environmental release.

End-of-life disposal: Most electric heaters end up in landfills at end-of-life. Portable heaters contain small amounts of valuable materials (copper winding, aluminum components) but are rarely recycled due to low intrinsic value. Heat pump systems contain more valuable materials and refrigerant that should be professionally recovered. Some manufacturers have begun take-back programs offering discounts on new units if old ones are properly recycled.

Grid decarbonization trends: As electricity grids worldwide transition toward renewable generation (goal: 50-80% renewables by 2030-2050 in developed nations), electric heating becomes progressively cleaner. Choosing efficient electric heating systems positions your home for this transition—a ground-source heat pump installed today remains increasingly environmentally beneficial as grid carbon intensity decreases. A fossil fuel heater, by contrast, carries increasing environmental disadvantage over its lifespan.

Troubleshooting Common Heater Issues

Performance Problems and Solutions

Issue: Heater fails to reach target temperature

Diagnosis varies by heater type. For portable heaters, check that the thermostat isn't blocked by furniture (thermostats often have temperature sensors that need to "feel" room air). Ensure the room isn't losing excessive heat through open doors, windows, or poor insulation—a heater can't maintain temperature if heat escapes faster than it's generated. Verify the heater's output capacity matches the room size (rough calculation: 10W per square foot for standard insulation).

For heat pumps, failure to reach temperature in cold weather suggests the system is in defrost mode (a normal cycle where the unit briefly reverses to melt ice from outdoor coils) or outdoor temperatures are at or below the system's minimum operating point.

Issue: Heater making unusual noises

Rattling or buzzing in portable heaters often indicates loose components or debris in the heating chamber. Disassemble (if permitted) and check for loose fasteners or foreign objects. Clicking or popping sounds in oil-filled radiators are normal as the oil expands/contracts with temperature changes.

For heat pumps, buzzing or humming indicates normal compressor operation. Loud banging or grinding suggests mechanical damage requiring professional service. Refrigerant circulation produces soft hissing, which is normal.

Issue: Excessive electricity consumption

If monthly electricity bills spike unexpectedly after heater installation, several factors might explain it. First, verify the heater's thermostat is functioning—a stuck or non-responsive thermostat causes continuous operation rather than cycling. Second, ensure the target temperature setting isn't excessively high (reducing by just 2-3°F can cut consumption 10%). Third, check that heating duration hasn't increased unintentionally; review thermostat scheduling.

For heat pumps, excessive consumption in extreme cold suggests the system is relying heavily on backup resistance heating. This is often normal during sustained sub-zero weather but becomes a problem if it occurs frequently despite mild weather.

Safety Issues and Best Practices

Fire risk mitigation: Keep heaters at least 3 feet away from flammable materials (curtains, bedding, paper). Never place heaters under furniture or in enclosed cabinets where heat cannot dissipate. Don't operate heaters with blocked intake or discharge areas. Use only heaters with automatic shutoff features (tip-over shutoff for portable units; overheat shutoff for all types).

Electrical safety: Use heaters only with properly grounded electrical outlets. Never use extension cords rated for lower amperage than the heater's draw (a 1500W heater draws 12.5A, requiring at least 14AWG wiring). Have qualified electricians install any permanent heaters. Never modify heater cords or plugs to fit non-standard outlets.

Carbon monoxide hazard: Only electric heaters are appropriate for indoor use. Never operate gas, propane, or kerosene heaters indoors unless specifically designed and vented for this purpose. Electric heaters produce no combustion byproducts.

Maintenance safety: Before any heater maintenance, disconnect from electrical power. Never operate heaters with damaged cords or visibly cracked casings. For heat pumps, refrigerant handling requires licensed technicians—never attempt to charge refrigerant yourself.

Future Trends in Electric Heating Technology

Emerging Technologies and Innovations

Electric heating technology continues evolving with several promising developments emerging in the 2025 timeframe and beyond.

Magnetic heating elements represent a potential efficiency breakthrough. Rather than traditional resistance wires, these heaters use precisely controlled magnetic fields to induce heat directly in water or metal materials. Early-stage research shows potential for more uniform heat distribution and potentially higher efficiency than traditional ceramic or wire elements. However, commercial applications remain 5-10 years away.

Hybrid infrared-convection heaters combine the benefits of both heating methods, using infrared for rapid targeted warmth and convective elements for ambient distribution. These "best of both worlds" designs are emerging from manufacturers and showing promising efficiency gains (95%+) compared to purely convective or purely radiant approaches.

Advanced heat pump refrigerants currently in development promise improved low-temperature performance and higher COP values. Next-generation refrigerants being tested in commercial systems show HSPF values of 12-15 at outdoor temperatures where current systems achieve 8-10. These will extend heat pump viability to colder climates, but widespread availability is probably 3-5 years away.

Thermal battery heating systems store heat during off-peak electricity hours (when rates are lower) in insulated storage tanks or phase-change materials, then release stored heat during peak hours. This approach decouples heating from electricity consumption timing, allowing users to heat during cheap-rate hours and release that stored heat during expensive-rate hours. These systems are currently expensive (

AI-optimized heating systems going beyond current smart thermostat capabilities are in development. These systems learn detailed occupancy patterns from smart home data (presence sensors, calendar integration, typical schedules) and preemptively optimize heating minutes to hours in advance, not just in response to temperature feedback. Preliminary testing shows 10-15% efficiency improvements beyond conventional smart thermostats.

Long-Term Efficiency Projections

Where is electric heating efficiency heading? Industry analysis and government efficiency standards suggest clear trends:

Minimum efficiency standards are rising. Most developed nations' appliance standards require new heat pumps to meet HSPF 9.0+ (up from historical 7.5). By 2030, expected standards will require HSPF 10+ or higher. This regulatory push accelerates efficiency improvements across the industry.

Heat pump adoption will accelerate. As technology improves and costs decline (current trajectory shows 30-50% cost reduction projected by 2030), heat pump market share in cold climates will increase from current <10% to potentially 30-40% by 2030. This transition will reduce average household heating energy consumption by 25-35% in regions adopting at scale.

Distributed renewable-compatible heating is becoming important. Future grid operators prefer distributed heating (individual heaters or mini-splits) over centralized systems because they can adjust load dynamically to match renewable generation. This architectural preference will drive future product design and efficiency features.

Integration with smart grids will enable new efficiency optimization approaches. Future heaters will communicate with grid operators, shifting heating to times when renewable generation is abundant and electricity rates are lowest. A ground-source heat pump capable of pre-heating thermal storage during high-wind hours and drawing from storage during peak demand hours could achieve grid-level efficiency improvements of 20%+.

Regional Variations: Climate-Specific Recommendations

Pacific Northwest Climate (Seattle, Portland, Vancouver BC)

Climate characteristics: Mild winters (lows 30-40°F), significant precipitation, moderate heating needs. Outdoor humidity often high, indoor heating can cause discomfort.

Recommended heaters: Air-source heat pump (primary choice for those investing in long-term heating). HSPF 10-12 systems operate efficiently across the entire season. Annual operating costs are typically 35-40% below traditional electric resistance heating. Initial cost (

Climate-specific considerations: The region's hydroelectric-powered grid means electric heating carries minimal carbon impact—choosing efficient electric systems aligns with regional sustainability values. The mild winter pattern favors heat pumps, which operate at peak efficiency during most of the heating season.

Upper Midwest Climate (Minneapolis, Chicago, Detroit)

Climate characteristics: Severe winters (lows -10 to -30°F for extended periods), moderate precipitation, lengthy heating season (200+ days). Central heating is standard, so supplemental heating is common.

Recommended heaters: Air-source heat pump as primary system for long-term residents, despite efficiency degradation in extreme cold (seasonal HSPF around 8-9). Efficiency advantage is still substantial (25-30% vs. resistance heating) when considering the entire season. However, many residents prefer simpler solutions: ceramic or infrared heaters for targeted zone heating (reducing central heating load), oil-filled radiators for bedroom heating overnight, or hybrid approaches pairing a heat pump with backup resistance heating.

Climate-specific considerations: The prevalence of extreme cold periods favors simpler, more reliable heating technologies that maintain consistent output across temperature ranges. Ground-source heat pumps are worth considering for those planning 20+ year residence due to maintained efficiency even in extreme cold, but installation costs (

Southwest Climate (Phoenix, Tucson, Las Vegas)

Climate characteristics: Mild winters (lows 40-50°F), minimal precipitation, short heating season (100-150 days). Cooling for air conditioning dominates energy spending.

Recommended heaters: Given the short, mild heating season, expensive heat pump systems often don't make economic sense. Simple portable heaters (ceramic or infrared,

Climate-specific considerations: Many Southwest homes lack existing heating infrastructure, making even modest investments in simple heaters preferable to installing expensive systems for minimal seasonal use. However, homeowners installing new air conditioning systems might consider high-efficiency heat pump systems (dual-mode air conditioning/heating units) that provide heating capability at marginal cost while maintaining excellent cooling efficiency.

Northern Europe Climate (UK, Germany, Scandinavia)

Climate characteristics: Cold winters (lows 20-35°F sustained), moderate precipitation, heating season often 250+ days. Energy costs substantially higher than North America (

Recommended heaters: High electricity costs make heat pump efficiency particularly valuable. Air-source heat pumps achieving HSPF 9-10 save 30-35% vs. resistance heating, translating to annual savings of €200-€500 (

Climate-specific considerations: The region's increasingly wind-powered grid (targeting 50%+ wind by 2030) means electric heating will become progressively cleaner. Choosing efficient electric heat pump systems positions homes well for this transition. Government incentive programs in most Northern European nations subsidize heat pump installation (often covering 25-40% of costs), making adoption particularly favorable.

Practical Buyer's Guide: How to Choose Your Ideal Heater

Decision Framework and Selection Criteria

Selecting an electric heater requires evaluating multiple factors systematically. Start with these questions:

1. What is your primary heating need?

- Primary heating for entire home: Heat pump systems recommended if climate supports (HSPF 8+ systems viable; ground-source for extreme climates)

- Supplemental heating for specific rooms: Ceramic, infrared, or oil-filled heaters appropriate

- Temporary/emergency heating: Portable fan or ceramic heaters sufficient

2. What is your climate and typical winter severity?

- Mild climates (lows rarely below 25°F): Air-source heat pumps optimal; alternative: ceramic heaters

- Moderate climates (lows 0-25°F): Heat pumps acceptable with modest efficiency degradation; alternatives: ceramic, infrared

- Severe climates (lows below -10°F): Ground-source heat pumps for maximum efficiency; hybrid systems pairing heat pump + resistance backup; alternative: infrared or ceramic for targeted heating

3. How long do you plan to stay in this home?

- Less than 2 years: Simple portable heaters (200) optimal; installation costs of permanent systems won't be recovered

- 2-5 years: Evaluate total cost of ownership; ceramic heaters usually optimal unless heat pump incentives are available

- 5+ years: Heat pump systems make economic sense even with higher upfront costs

4. What is your electricity cost and available budget?

- High electricity costs ($0.15+/k Wh): Heat pump efficiency gains are more valuable; justify higher upfront investment

- Lower electricity costs (<$0.10/k Wh): Efficiency advantage of expensive systems is reduced; simpler heaters may be more economical

- Limited upfront budget: Portable ceramic heaters (200) offer best efficiency-per-dollar

- Substantial budget: Heat pump systems justify consideration for efficiency and long-term savings

5. Do you have existing heating infrastructure?

- Yes (central heating present): Supplemental heaters for zoning/efficiency; heat pumps could replace or supplement

- No existing infrastructure: Heat pumps ideal if climate supports; simpler portable heaters if temporary solution needed

Specific Product Categories and Recommendations

**Budget option (<

Value option (

Performance option (

Premium option (

**Maximum efficiency option (