Introduction: The Heat Pump Revolution Meets Real-World Engineering

The heating, ventilation, and air conditioning (HVAC) industry stands at an inflection point. As climate concerns drive residential and commercial building owners toward more efficient solutions, heat pumps have emerged as a compelling alternative to traditional furnaces and air conditioning units. Yet the technology faces persistent challenges that conventional engineering approaches have struggled to overcome.

In early 2026, Quilt, a smart home startup focused on HVAC innovation, announced a breakthrough that could reshape how multi-zone heating and cooling systems operate. The company unveiled a three-zone heat pump—a system capable of serving three separate indoor heating and cooling zones from a single outdoor compressor unit. While this architectural approach isn't entirely novel, what makes Quilt's implementation remarkable is the engineering philosophy underpinning it.

Unlike traditional heat pump manufacturers that rely heavily on controlled laboratory testing environments, Quilt has built its product development process around actual operating data collected from over 1,000 units installed across diverse climates and use cases. This data-driven approach has allowed the company to solve one of multi-zone heat pumps' most vexing technical problems: maintaining efficiency and stability when the compressor must operate at extremely low speeds.

The challenge is deceptively simple to understand but fiendishly difficult to engineer. Modern heat pumps achieve their exceptional efficiency by operating at variable speeds—the compressor adjusts its output to match demand precisely, much like how a car's engine operates more efficiently at a steady highway speed than constantly accelerating and braking. However, below certain speed thresholds, compressors become inherently unstable, similar to how a bicycle becomes harder to balance at walking speed compared to a moderate cycling pace.

Most manufacturers solve this problem by having the compressor cycle on and off at low demand, a strategy that preserves stability but sacrifices both comfort and efficiency. Quilt's engineers approached this differently, leveraging their unique dataset to understand exactly how compressor behavior varies across thousands of real-world scenarios. The result is a three-zone unit that delivers nearly 90% of its rated capacity at extreme cold temperatures (-13°F or -25°C) while maintaining operational stability at the lowest demand levels.

This achievement matters for several interconnected reasons. First, it demonstrates how artificial intelligence and Internet of Things (IoT) sensor technology can fundamentally alter how hardware companies approach product development. Second, it signals that the next generation of HVAC solutions will be increasingly smart, connected, and optimized through continuous learning. Third, it provides a blueprint for how startups can compete with entrenched incumbents by leveraging data advantages and modern engineering practices.

This comprehensive analysis explores Quilt's three-zone heat pump, the technical innovations enabling its performance advantages, the broader implications for HVAC technology evolution, and how this trend intersects with the larger narrative of smart home automation and AI-driven optimization.

The Multi-Zone Heat Pump Landscape: Current State and Historical Challenges

Market Evolution and Adoption Trends

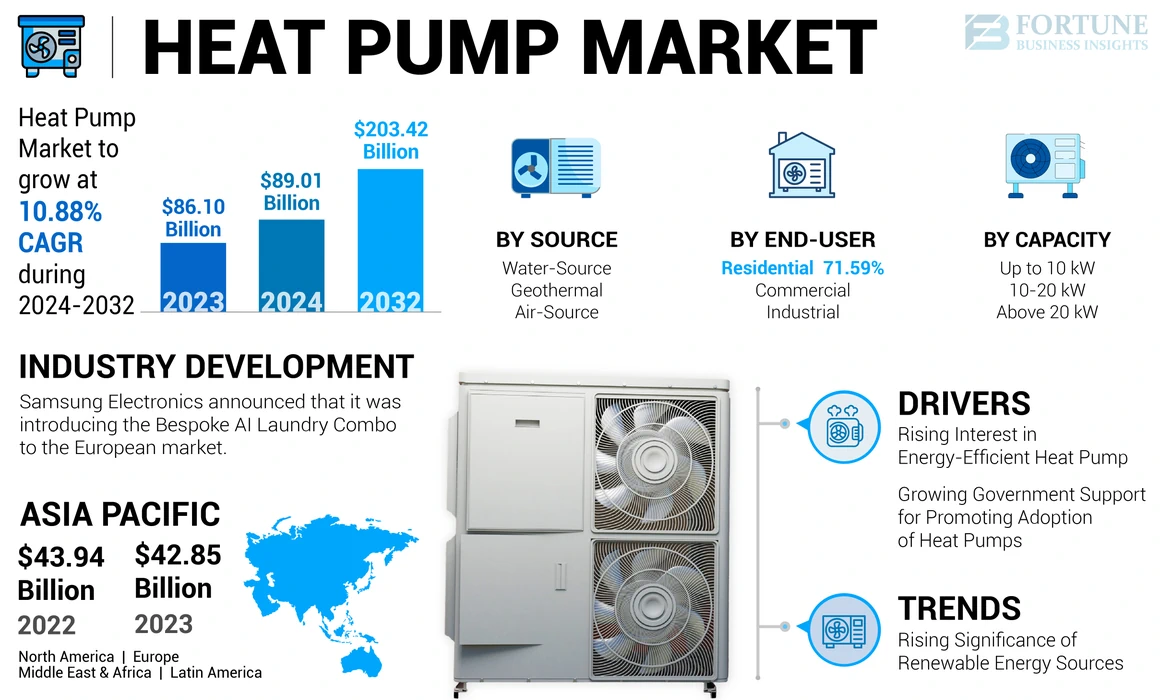

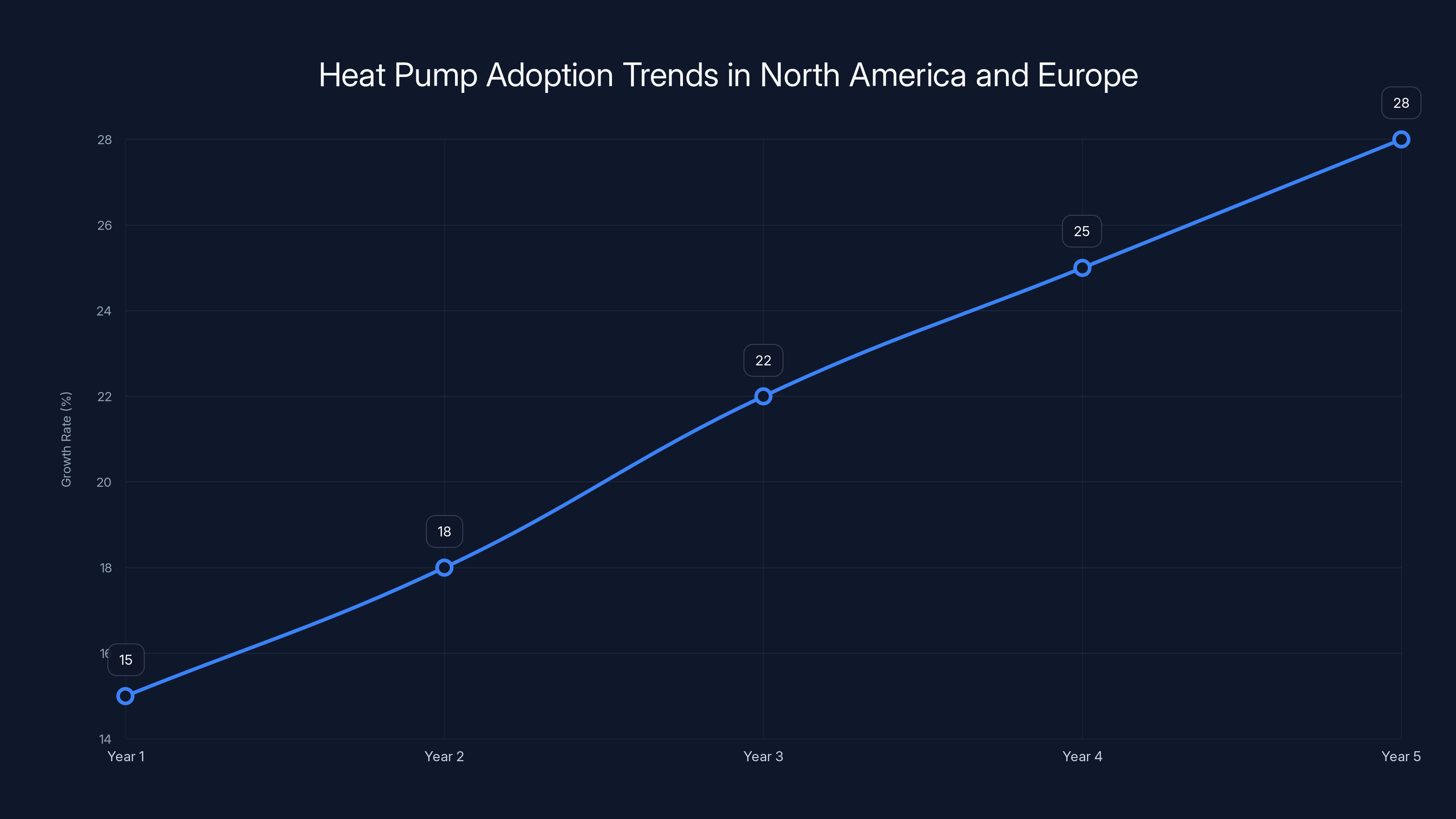

Heat pump adoption has accelerated dramatically over the past five years, driven by improving efficiency ratings, declining costs, and growing regulatory pressure to phase out fossil fuel heating systems. In North America and Europe, heat pump shipments have grown at double-digit annual rates, with some regions seeing year-over-year growth exceeding 25% as noted by Precedence Research. This expansion has extended beyond single-zone residential applications to encompass multi-zone systems that can serve larger homes, commercial properties, and complex building layouts.

Multi-zone heat pumps specifically address a critical limitation of traditional single-zone systems: the ability to maintain different temperatures in different areas simultaneously. A home with an open-concept living area, separate bedrooms, and a basement naturally benefits from zone control, allowing occupants to heat or cool individual spaces according to preference and occupancy patterns. This capability has proven especially valuable in commercial settings where different tenants, departments, or operational areas have distinct thermal comfort requirements.

However, this architectural flexibility has historically come with significant tradeoffs. Installation complexity increases substantially with multi-zone systems, requiring skilled technicians to carefully balance refrigerant flow, assess ductwork requirements, and manage the interactions between multiple indoor units and a single outdoor compressor. Costs scale nonlinearly—a three-zone system doesn't cost three times as much as a single-zone unit, but the economics remain unfavorable compared to installing three independent single-zone systems. Additionally, the refrigerant distribution and variable load balancing challenges have consistently produced reliability and efficiency concerns that manufacturers have struggled to fully resolve.

The Compressor Speed Problem: Why Low-Speed Operation Matters

To understand Quilt's breakthrough, one must first appreciate the technical fundamentals of heat pump operation. Modern inverter-driven heat pumps use variable-speed compressors that can modulate their output across a wide range. At full capacity, a compressor might operate at 100% displacement or speed. As demand decreases, the compressor can throttle down to 50%, 25%, 10%, or even lower.

This variable-speed capability is fundamental to why heat pumps achieve such exceptional seasonal energy efficiency ratios (SEER) compared to conventional air conditioning, or HSPF (heating season performance factor) ratings compared to resistance heating. When demand is low, the system doesn't need to run a large compressor at full blast and then cycle it off—instead, it can run continuously at the minimal speed required to meet actual heating or cooling needs. This continuous, low-speed operation dramatically reduces the energy losses associated with compressor startup and the temperature swings that result from on-off cycling.

However, compressors—like many mechanical and electromechanical systems—have stability characteristics that degrade at very low operational speeds. Think of a washing machine motor: it runs smoothly at its designed speed of 1,200 RPM, but attempting to operate it at 60 RPM would likely result in stuttering, vibration, and poor performance. Similarly, below a certain threshold (typically around 20-30% of maximum speed, varying by compressor design), refrigerant flow becomes erratic, pressures oscillate, and the system struggles to maintain consistent heating or cooling output.

For single-zone systems operating at partial load, this limitation has manageable workarounds. A single zone might experience consistently moderate loads that keep the compressor in a stable operating range. But multi-zone systems present a different challenge entirely. Imagine a three-zone unit where Zone 1 requires 27,000 BTUs of heating (full capacity), Zone 2 requires 5,000 BTUs, and Zone 3 requires 0 BTUs (already at setpoint). The compressor must simultaneously handle full-capacity demand for one zone while operating at extremely low speeds to serve another zone—and potentially cycling on and off for the third zone.

This scenario, which occurs frequently during shoulder seasons or in buildings with diverse occupancy and insulation characteristics, has historically forced manufacturers to choose between two unsatisfactory options: (1) stop the compressor from serving the low-demand zones and accept comfort degradation or switching delays when demand changes, or (2) cycle the compressor on and off to maintain stable operation while accepting the efficiency penalties associated with frequent cycling and compressor starts.

Historical Solutions and Their Limitations

Over the past two decades, HVAC manufacturers have developed various engineering solutions to mitigate the low-speed stability problem. Larger displacement compressors with finer control granularity help but introduce their own inefficiencies. Some manufacturers employ complex bypass or expansion valve strategies that redirect refrigerant flow rather than actually reducing compressor displacement. Others use check valves and accumulator tanks to stabilize pressures and reduce oscillation.

These approaches work to varying degrees but all involve tradeoffs. They add cost, complexity, and potential failure points. They require extensive laboratory testing to validate across the range of possible temperature, humidity, and load scenarios manufacturers can practically simulate. Yet laboratory testing, by its nature, cannot capture the infinite variability of real-world installations: unusual ambient temperatures (that 95°F humid day in a region that typically sees 85°F maximums), unexpected insulation variations in older buildings, non-standard ductwork configurations, thermostatic operation patterns that don't match manufacturer assumptions, and hundreds of other variables.

This limitation—the gap between controlled laboratory testing and messy real-world performance—has historically constrained HVAC innovation. The industry's design-once-produce-many model, optimized for manufacturing efficiency rather than performance optimization, left minimal room for the kind of iterative improvement that other technology sectors now take for granted. A smartphone manufacturer can release an over-the-air update to improve battery life or fix a bug affecting a specific handset configuration; an HVAC manufacturer cannot update the firmware controlling thousands of installed units in the field.

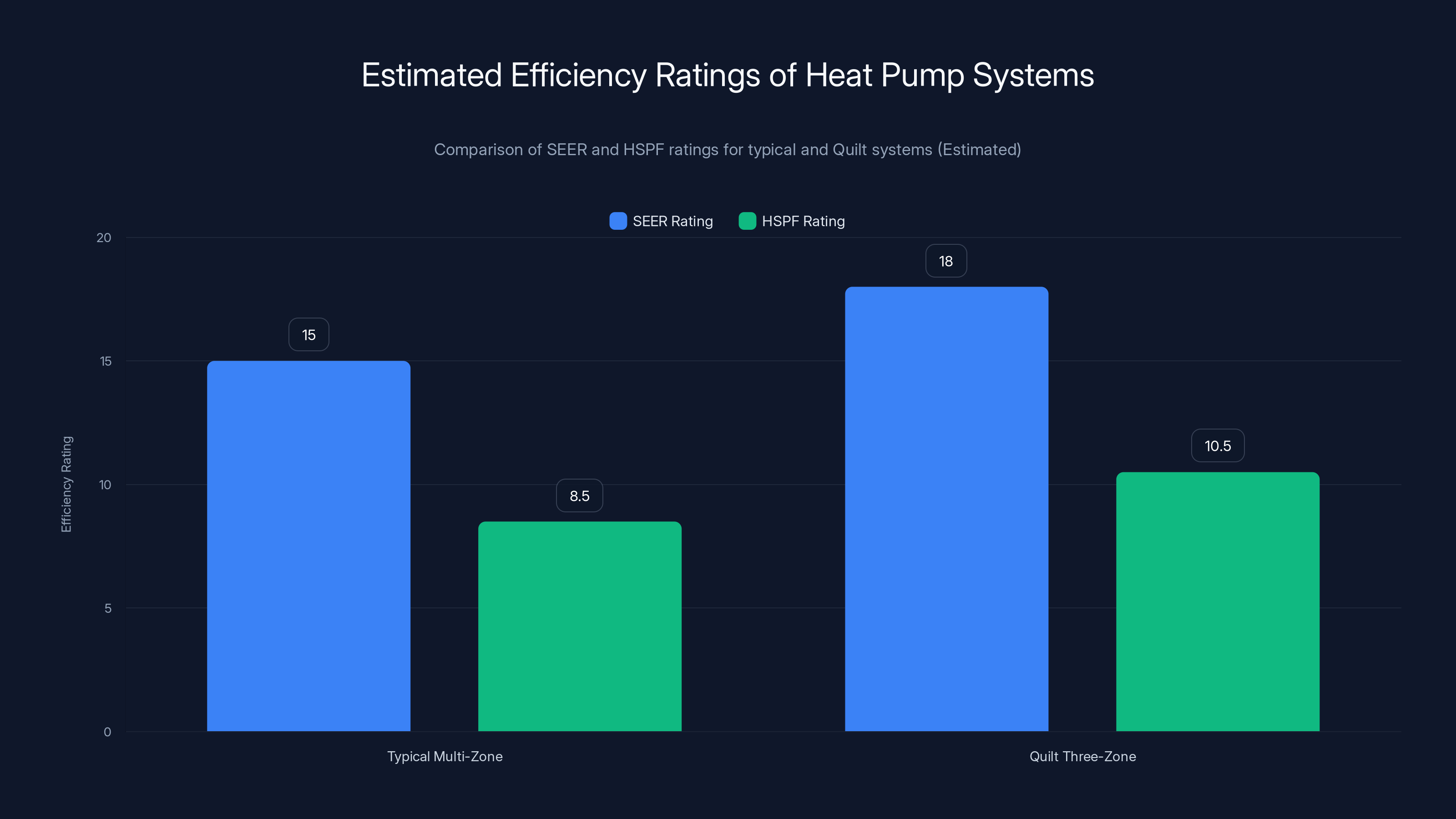

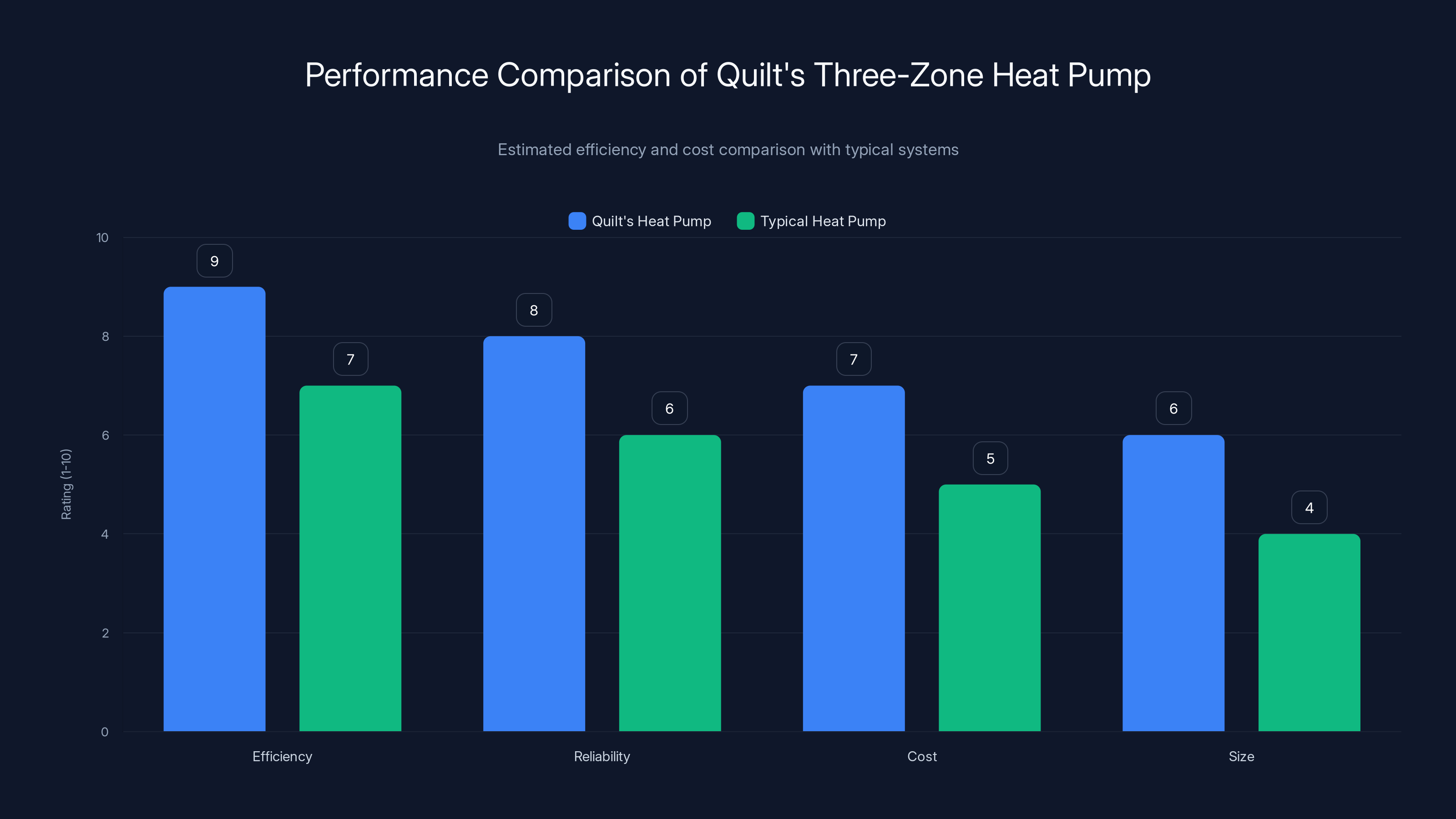

Estimated data suggests Quilt's three-zone unit may outperform typical multi-zone systems in both SEER and HSPF ratings, indicating higher efficiency under real-world conditions.

Quilt's Data-Driven Approach: Rethinking Product Development

The Internet of Things Revolution in HVAC

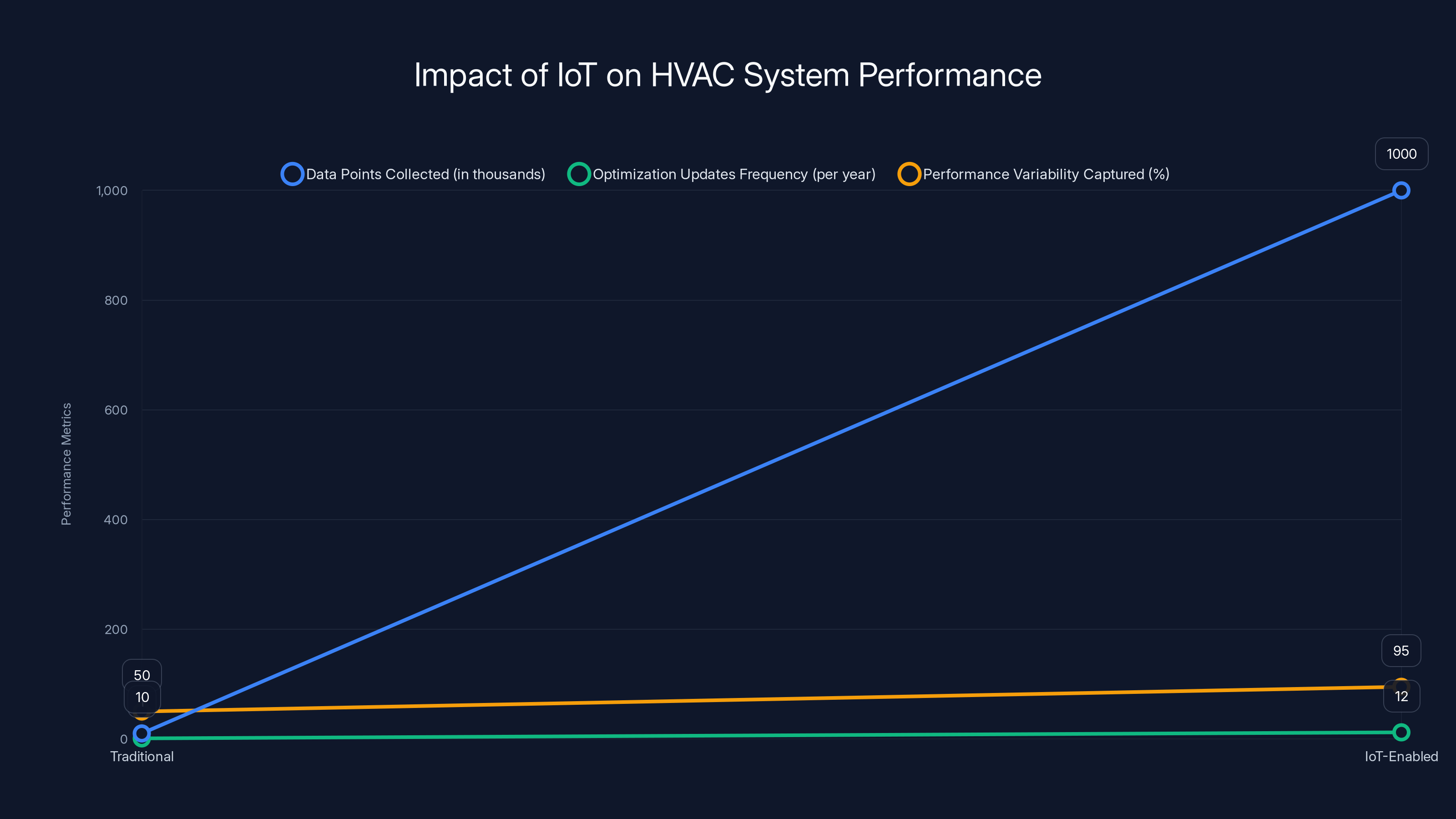

Quilt's founding premise challenged this traditional orthodoxy by recognizing that modern heat pumps could become connected, sensor-rich devices that continuously transmit performance data to cloud-based analytics systems. This Internet of Things (IoT) approach unlocks several transformative capabilities that were previously unavailable to HVAC manufacturers.

First, instead of relying on a handful of laboratory scenarios, Quilt could observe system performance across thousands of real-world installations simultaneously. Each installed unit becomes a sensor node in a distributed research network, generating continuous streams of data about ambient temperature, humidity, compressor speed, refrigerant pressures, indoor unit temperatures, power consumption, and dozens of other variables. This dataset has no equivalent in traditional HVAC—it is orders of magnitude richer than any laboratory testing program could ever generate.

Second, this data flows continuously, capturing the full spectrum of seasonal, diurnal, and operational variations. Quilt's engineers observe not just peak summer and winter performance but the shoulder season conditions, rare extreme weather events, and the gradual degradation patterns that naturally occur as systems accumulate operating hours. They can identify not just average performance but the distribution of outcomes—understanding the 99th percentile of cold-weather performance matters differently than average performance.

Third, and perhaps most importantly, this data enables continuous optimization through over-the-air firmware updates. When Quilt engineers identify a software optimization that improves low-speed compressor stability or enhances efficiency during rare weather scenarios, they can push the update to every installed unit simultaneously. This creates a form of learning that is impossible for traditional manufacturers: the product improves after installation rather than remaining static for its entire operational lifespan.

The Thousand-Unit Advantage

By early 2026, Quilt had installed approximately 1,000 units across diverse geographic locations, building types, and use cases. This installed base, while modest compared to the total HVAC market (tens of millions of units installed annually globally), provides an exceptional research advantage. Why? Because competitors are operating in the dark, using laboratory data and theoretical models to make design decisions. Quilt's engineers have access to actual operating data from systems in Minnesota winters, Arizona summers, coastal humid climates, high-altitude dry environments, and hundreds of other microclimates and building conditions.

Consider a specific technical problem: how does a three-zone system perform when the compressor must serve three zones simultaneously at greatly different loads? Quilt's engineers can query their database and find hundreds or thousands of instances when this exact scenario occurred. They can analyze the data to understand what happened: Did the system maintain stable compressor operation? How did the refrigerant distribution shift between zones? Did any zones experience temperature oscillation? How efficient was the operation compared to full-load performance?

From these thousands of real-world examples, patterns emerge that would be invisible in laboratory testing. Perhaps the system performs exceptionally well when ambient temperatures are between 32°F and 50°F but struggles slightly in certain configurations when temperatures are below 0°F. Or perhaps certain three-zone load distributions (say, a 60% + 25% + 15% split) perform more stably than others (80% + 15% + 5%). These nuanced understandings, derived from massive real-world data, enable engineering decisions that are simply impossible through traditional design methodologies.

September 2025 Firmware Update: The Living Proof

In September 2025, Quilt released a firmware update to its installed fleet that provided concrete evidence of this data-driven advantage. The update unlocked an additional 20% capacity in existing systems, which could be directed toward one or two zones as needed. This wasn't simply a modest efficiency tweak—it was a substantial capability expansion that made systems more powerful and more responsive during extreme weather events.

From a technical standpoint, the update demonstrates several important principles. First, the 20% capacity increase had almost certainly been theoretically possible in the hardware design all along—the physical components could support higher output. However, without extensive real-world data showing how the systems actually behaved under this higher-load condition across thousands of climate and load scenarios, releasing such an update would have been risky. The manufacturer couldn't be certain it wouldn't trigger stability problems, efficiency degradation, or reliability issues under conditions not tested in the laboratory.

Second, the fact that the update could be delivered over-the-air and applied to every installed system simultaneously demonstrates the power of the connected device model. Instead of improving the design for future units while leaving earlier customers with suboptimal performance, Quilt's entire installed base gained the improvement. This creates a virtuous cycle: more operational data from the enhanced capability enables further refinements, which in turn are pushed to all units.

Third, the update illustrates how Quilt's data advantage compounds over time. As their installed base grows from 1,000 to 10,000 to 100,000 units, the diversity and volume of real-world operating conditions captured increases exponentially. Ten times as many installations means potentially seeing edge cases and rare conditions that never appeared in smaller datasets. This allows continuous algorithmic improvement, control system refinement, and feature enhancement that becomes harder and harder for competitors without similarly vast datasets to match.

Heat pump shipments in North America and Europe have shown consistent double-digit growth, with some regions experiencing over 25% annual increases. Estimated data based on industry trends.

The Three-Zone Unit: Technical Architecture and Innovation

System Configuration and Refrigerant Distribution

Quilt's newly announced three-zone heat pump represents the tangible application of these data-driven principles to a new product category. The system architecture consists of a single outdoor compressor unit capable of simultaneously serving three separate indoor units (called "heads" in HVAC terminology), allowing them to maintain different temperature setpoints independently.

In technical terms, the system operates as a refrigerant-to-refrigerant splitter, using variable expansion valves to distribute refrigerant flow dynamically among the three zones based on each zone's demand. Unlike simpler systems that simply divide available capacity equally among three zones, Quilt's control system uses real-time pressure and temperature feedback to continuously optimize refrigerant distribution. When Zone 1 requires more cooling, the system increases the expansion valve opening for that zone and reduces it for zones with lower demand. This dynamic load balancing is conceptually straightforward but notoriously difficult to execute smoothly without oscillation or inefficiency.

The outdoor unit itself represents years of refinement. Quilt employs a larger copper coil than many competitors—the heat exchanger that transfers thermal energy between the refrigerant and outdoor air. This seemingly simple choice has profound implications for system behavior. A larger coil with slower refrigerant flow creates more stable pressure conditions and allows the compressor to operate efficiently even at very low speeds. The tradeoff is increased cost and larger physical dimensions, but Quilt's data showed that the efficiency and reliability benefits justified the added expense.

Coupled with this larger coil is a smaller displacement compressor than one might expect for a 27,000 BTU/hour system. This counterintuitive design choice is enabled by Quilt's understanding of real-world load distributions. Their data shows that truly full-load conditions across all three zones simultaneously occur rarely. Most of the time, the system operates at partial load. By specifying a smaller compressor that excels at partial-load efficiency while still capable of reaching near-full capacity output, Quilt optimizes the system for typical conditions rather than the rare edge case of maximum load.

The Low-Speed Stability Solution

The breakthrough innovation addressing the low-speed stability challenge involved multiple integrated improvements informed by Quilt's sensor data. First, the company's engineers developed advanced control algorithms that understand the stability limits of their specific compressor across temperature ranges and load conditions. Rather than using conservative thresholds that never approach these limits, the algorithms operate right at the edge of stability, squeezing maximum capacity from the system while maintaining smooth operation.

This is possible only because Quilt has thousands of real-world data points showing exactly how their compressor behaves as it approaches these limits. They understand the telltale signs of impending instability—oscillations in certain pressure measurements, characteristic patterns in refrigerant temperature fluctuation—and their algorithms can detect and prevent these conditions through slight adjustments to compressor speed, expansion valve position, or other control parameters.

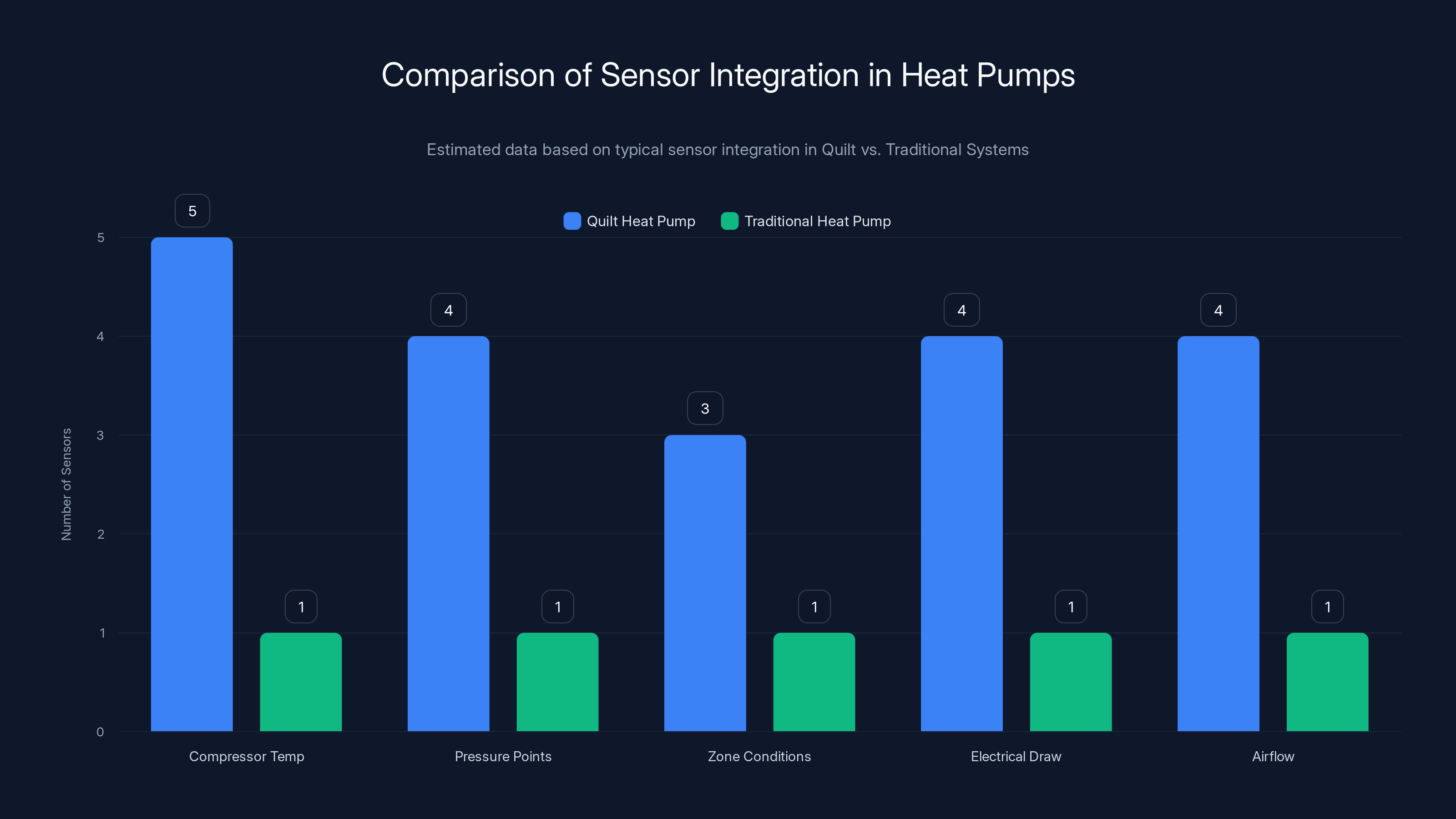

Second, the sensor suite throughout the system provides the real-time feedback necessary for this sophisticated control. Quilt's heat pumps contain significantly more sensors than typical units—not just the compressor discharge pressure and temperature sensors found in basic systems, but sensors measuring liquid line temperature, oil sump temperature, suction line temperature, individual zone pressure and temperature, outdoor air temperature, humidity, and more. This rich sensor data stream allows the control algorithms to make informed decisions every few hundred milliseconds, continuously adapting to actual operating conditions.

Third, Quilt implemented what might be called "intentional instability management." Rather than avoiding the conditions that cause low-speed instability, their control system can tolerate brief excursions into these conditions because it detects them immediately and corrects them before they cascade into visible discomfort or system degradation. It's analogous to how modern aircraft can operate in configurations that would have been considered dangerously unstable in earlier eras—because the control systems detect and respond to instability faster than human pilots could ever perceive it.

The result is that Quilt's three-zone unit maintains approximately 90% of its rated capacity even at -13°F (-25°C) outdoor temperature without sacrificing stability or efficiency at low-speed operation. This performance level essentially eliminates one of the primary efficiency penalties that multi-zone systems have historically suffered.

Capacity Scalability and Individual Zone Control

Each indoor unit in a Quilt three-zone system can be individually controlled and has its own thermostatic setpoint. This is standard for modern multi-zone systems, but Quilt's implementation distinguishes itself through granular control. Each head can supply as little as 2,210 BTUs of heating or 1,570 BTUs of cooling, enabling exceptionally fine-grained load matching. When heating demand is minimal—say, a zone that's slightly cool due to occupant preference but doesn't require major heating—the system can deliver heat at these minimal rates while keeping the compressor running at extremely low, highly efficient speeds.

This fine granularity matters during partial-load conditions, which comprise the vast majority of operating hours in most buildings. Standard systems might have minimum output levels significantly higher than actual demand, causing them to cycle on and off or dissipate excess capacity as heat. Quilt's system can operate continuously at the level precisely matching demand.

For maximum comfort and efficiency, each zone can also be controlled independently from a user interface perspective. Users can adjust setpoints, create schedules, or integrate with broader smart home automation systems. The coordination among zones happens automatically in the background, with the control system optimizing overall compressor operation while respecting each zone's individual requirements.

Sensor Technology: The Hidden Foundation of Performance

Sensor Types and Data Collection Architecture

The sensor suite integrated throughout Quilt's heat pumps operates continuously, collecting performance data that serves dual purposes: immediate feedback for real-time control algorithms and historical data for ongoing product optimization. This dual role illustrates why the sensor investment is essential rather than optional for Quilt's business model.

Temperature sensors measure multiple critical points in the refrigeration cycle: compressor discharge temperature (indicating how much the refrigerant is compressed), condensation temperature (where the outdoor unit exchanges heat), evaporation temperature (where the indoor units exchange heat), and ambient temperatures at both indoor and outdoor locations. These temperature measurements reveal the thermodynamic efficiency of the cycle and enable the control system to detect anomalies or inefficiencies that might indicate degradation.

Pressure sensors measure high-side pressure (after compression) and low-side pressure (after expansion), providing data about how efficiently the system is operating. The pressure differential between these points, in combination with temperature data, allows calculation of the refrigerant's thermodynamic state and enables detection of problems like low refrigerant charge, air in the system, or compressor wear affecting its compression ratio.

Electrical current sensors measure how much power the compressor is drawing, allowing real-time assessment of electrical efficiency and enabling detection of motor problems that might be developing. Power consumption data combined with thermal output data reveals coefficient of performance (COP) and other efficiency metrics.

Air flow sensors in the indoor units measure the volume of air being circulated, which combined with temperature rise or fall reveals the actual heating or cooling capacity being delivered. This allows the system to detect when indoor units might need cleaning (reduced airflow), when ductwork might be blocked, or when the system's performance is degrading.

Real-Time Control vs. Offline Analytics

The sensor data serves two distinct but complementary functions in Quilt's system architecture. Locally, on the unit's onboard controller, data from all sensors flows continuously into control algorithms running at high frequency (typically 10-100 Hz). These algorithms make real-time decisions about compressor speed, expansion valve position, refrigerant distribution among zones, and other parameters that determine moment-to-moment performance.

Simultaneously, aggregated data (not necessarily every single sensor reading, but summaries and key parameters) flows via the internet to Quilt's cloud infrastructure, where different algorithms operate at longer timescales. These cloud analytics look for patterns that emerge only when examining thousands of units across weeks and months: seasonal efficiency trends, geographic performance variations, early indicators of component degradation that might lead to future failures, validation of firmware updates against actual performance, and opportunities for new optimization approaches.

This architecture creates an interesting information flow: cloud analytics identify optimization opportunities, which are encoded into new firmware that gets pushed to all units. The units implement the updated control logic, and the cloud analytics observe whether the update actually improved performance as predicted. If it did, the update is confirmed and kept. If unexpected issues emerge, the update can be reverted. This creates a scientific feedback loop that would be difficult or impossible to implement in traditional manufactured products.

Data Security and Privacy Considerations

The obvious question raised by this comprehensive data collection concerns privacy and security. Quilt's heat pump systems are connected to the internet and transmitting data about household heating and cooling patterns, which some users might consider sensitive. The company has had to balance the performance benefits of data collection against legitimate privacy concerns.

From a technical standpoint, Quilt's approach involves transmitting aggregated and summary data rather than raw sensor readings from every second of operation. Individual unit-level data is encrypted in transit and stored with appropriate security controls. Users retain visibility and control over what data is collected and can opt out of cloud analytics (though this would forfeit the ability to receive performance-enhancing firmware updates that depend on analyzing the aggregate dataset).

From a business model perspective, Quilt does not monetize user data by selling it to third parties. The data asset's value exists within the company's own product development and optimization processes. However, as the company scales and potentially faces pressure from investors or acquisition scenarios, this privacy commitment might face pressure. The long-term trajectory of how manufacturers will handle the tension between performance optimization (which benefits consumers) and data monetization (which could exploit consumers) remains an ongoing industry challenge.

Quilt heat pumps integrate significantly more sensors across various parameters compared to traditional systems, enhancing performance and efficiency. Estimated data.

Engineering Insights: Lessons From Real-World Performance Data

Ambient Temperature Performance Across Climate Regions

One of the most valuable categories of data Quilt's installed fleet generates involves performance across temperature extremes. Traditional HVAC manufacturers test their systems at standard conditions defined by industry bodies: typically, air conditioning performance is evaluated at 95°F outdoor temperature, while heating performance might be tested at 47°F outdoor temperature. These are reasonable testing conditions, but they capture only narrow slices of the conditions actual systems encounter.

In reality, heat pumps operate across an enormous temperature range. In cold climates, systems experience outdoor temperatures from 50°F down to -30°F or lower, with occasional extreme cold snaps reaching -40°F. In hot climates, outdoor temperatures might range from 75°F to 120°F or higher during heat waves. More importantly, systems experience these temperatures in combination with varying humidity levels, wind conditions, and operating patterns that standard laboratory tests don't replicate.

Quilt's 1,000+ unit installed base spans multiple climate regions, allowing the company to understand how their systems actually perform at these extremes. The data revealed subtle truths about multizone operation during cold weather: for instance, that certain load distributions (where one zone requires high heating output while another zone's setpoint is already satisfied) perform noticeably better than other load distributions. This insight allowed firmware optimizations that preferentially favor these "better-behaved" load distributions without sacrificing performance in other scenarios.

During extreme hot weather, the data revealed that outdoor unit airflow patterns (specifically, how well air circulates around the coil) have a more significant impact on performance than traditional design assumed. This led to refinements in outdoor unit placement recommendations and airflow optimization strategies that improved real-world cooling capacity during peak demand periods.

Seasonal Performance Degradation and Maintenance Insights

Another valuable data category involves understanding how systems degrade over time and identifying maintenance needs before they become critical. All heat pump systems experience gradual performance degradation as they accumulate operating hours. Oil in the compressor can degrade, refrigerant charging might develop minor leaks, or coils might accumulate dust and debris. Traditional manufacturers assume a certain amount of degradation and factor this into their sizing calculations, but they lack visibility into the actual degradation patterns of deployed systems.

Quilt's continuous data collection reveals this degradation in real-time. By comparing current-season performance to baseline performance from previous seasons, the company's algorithms can identify units that are degrading faster than expected, potentially indicating issues that warrant technician inspection. The data might show that a specific unit's heating capacity has declined by 15% compared to the previous winter—a change that would be imperceptible to homeowners but detectable in the sensor data. Early detection enables proactive maintenance, preventing larger failures and extending system lifespan.

The data has also revealed seasonal patterns in performance that weren't obvious from traditional testing. For instance, heat pumps performing in arid climates show different seasonal trends than those in humid climates, with humidity levels affecting coil performance in measurable ways. This led to region-specific tuning of control algorithms, with different firmware configurations optimized for arid, temperate, humid, and extremely cold climates.

User Behavior Patterns and Load Prediction

Beyond pure hardware performance, Quilt's data provides unusual insights into how users actually operate heating and cooling systems—information that's valuable for optimizing control algorithms and predicting demand. Traditional thermostats assume that setpoints remain relatively static, with occasional adjustments. In reality, user behavior varies enormously based on time of day, day of week, occupancy patterns, and personal preferences.

By observing patterns across thousands of units, Quilt's algorithms have learned to recognize and predict these behavioral patterns. A system might learn that on Tuesday mornings between 6 AM and 8 AM, users consistently adjust the temperature upward, or that on weekday evenings at 9 PM, people consistently lower cooling setpoints. These learned patterns enable the system to anticipate demand changes and pre-optimize compressor operation to meet demand more efficiently.

For instance, if the system recognizes that a user typically lowers heating setpoint by 3°F at 10 PM every weeknight, it might slightly reduce compressor output starting at 9:55 PM, allowing the indoor temperature to naturally drift downward in anticipation of the setpoint change. This prevents the compressor from running unnecessarily to maintain the higher temperature for those final five minutes. Across thousands of such micro-optimizations throughout the day, these behavioral predictions drive meaningful efficiency improvements.

Competitive Positioning and Market Implications

Traditional Manufacturer Constraints

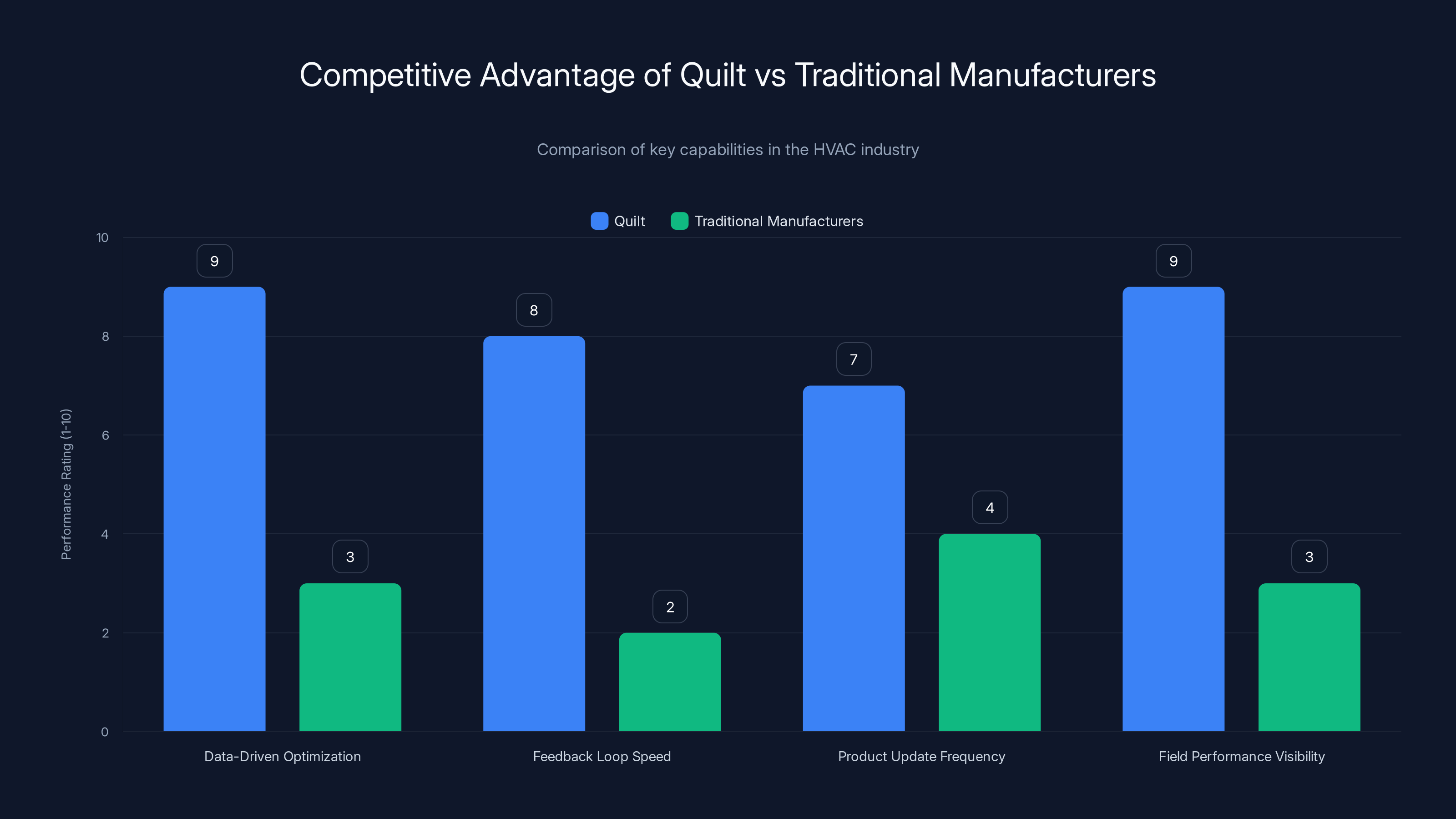

Understanding why Quilt's approach represents a significant competitive advantage requires examining the structural constraints that traditional heat pump manufacturers operate under. The HVAC industry evolved around a business model where manufacturers design products, hand them off to installers, and then have minimal post-sale interaction with the deployed systems. Service happens reactively when systems fail, not continuously to optimize performance.

This model created organizational structures and decision-making processes fundamentally misaligned with data-driven optimization. A traditional manufacturer's engineering team designs a product, tests it extensively in the laboratory, manufactures thousands or millions of units to that specification, and then moves on to the next product generation. Once manufacturing begins, changing the design is prohibitively expensive. Even modest improvements cannot be implemented until the next generation, which might be two to three years in the future.

Moreover, traditional manufacturers have limited visibility into how their products actually perform in the field. They might receive occasional complaint reports ("the unit in my Alaska cabin doesn't work well in extreme cold") but cannot systematically observe and measure performance across their entire installed base. The feedback loop from customer experience back to engineering is slow, episodic, and anecdotal rather than continuous and quantitative.

The connected, sensor-rich approach that Quilt pioneered requires different organizational structures. The company needs cloud infrastructure to receive and process streaming data. It requires data science and software engineering talent to develop algorithms that extract insights from that data. It requires product management processes that enable rapid firmware updates. And it requires a service model where the company maintains ongoing relationships with customers after sale, rather than viewing post-sale as purely a warranty/service issue.

These organizational differences explain why incumbent HVAC manufacturers cannot simply copy Quilt's approach overnight. It's not just a technological difference—it's a fundamental difference in business models and organizational capabilities.

Series B Funding and Scaling Plans

Quilt's recent $20 million Series B funding round specifically emphasized expansion of manufacturing and sales capabilities. The company's strategy is not to displace traditional manufacturers' entire market—an unrealistic goal given their decades of installed base and distribution relationships—but rather to establish a premium niche focused on data-driven optimization and connected smart home integration.

The funding signals investor confidence that Quilt's approach resonates with consumers and builders willing to pay a premium for superior performance and connected capabilities. The three-zone unit announcement simultaneously demonstrates capability (we've built an advanced system) and intent (we're scaling to serve larger installations). Historically, Quilt focused on smaller residential applications where a single-zone or dual-zone system might suffice. The three-zone unit expands addressable market to larger homes and light commercial applications.

Potential Incumbent Responses

How might traditional manufacturers respond to Quilt's competitive challenge? Several responses are plausible. First, incumbents might acquire connected HVAC startups, similar to how major consumer electronics manufacturers acquired smart home companies a decade ago. This has the advantage of bringing new capabilities in-house but introduces organizational integration challenges and often results in cultural misalignment that limits the acquired company's potential.

Second, incumbents might partner with cloud service providers (Amazon Web Services, Microsoft Azure, Google Cloud) to build their own data analytics and connected systems capabilities. This approach takes advantage of existing infrastructure but doesn't necessarily solve the organizational transformation required to make data-driven optimization central to product development.

Third, and most likely, some incumbents will establish innovation groups focused on developing connected, sensor-rich product lines in parallel with their traditional offerings. They'll market these new lines as premium options, potentially using acquisition or partnership to accelerate capability development. Meanwhile, their mainstream product lines will continue operating under the traditional model.

The outcome will likely be a bifurcated market: traditional HVAC systems sold at lower prices focused on basic heating and cooling, and connected, sensor-optimized systems sold at higher prices focused on efficiency, smart home integration, and advanced features. Quilt's strategy is to own the premium segment.

IoT-enabled HVAC systems collect significantly more data, allowing for frequent optimization updates and capturing a wider range of performance variability. Estimated data.

Technical Deep Dive: Compressor Control at Extreme Low Speeds

Compressor Operating Envelope and Stability Boundaries

To understand the technical achievement of Quilt's three-zone heat pump, a deeper exploration of compressor thermodynamics and control becomes necessary. Modern variable-displacement or variable-speed compressors can modulate their output across a 10:1 ratio or greater. A compressor rated for 27,000 BTU/hour at full capacity might theoretically operate as low as 2,700 BTU/hour—but this theoretical minimum doesn't account for stability limitations.

Every compressor has a stable operating envelope—a region in the pressure-speed parameter space where the compressor can operate reliably without oscillation or instability. Below a certain speed (typically 20-30% of maximum speed), this envelope contracts dramatically. The compressor can still technically operate, but its behavior becomes chaotic: refrigerant flow rates oscillate, discharge pressures fluctuate, and the system becomes difficult to control.

This instability arises from fundamental thermodynamic and mechanical principles. At lower speeds, the time it takes for refrigerant to travel through the compressor increases, allowing more time for pressure equalization and reverse flow (refrigerant flowing backward when the compressor doesn't have enough speed to maintain adequate discharge pressure). The mechanical damping effects that stabilize operation at high speeds diminish at low speeds. It's a worst-of-both-worlds scenario: the compressor runs slower, so its ability to create and maintain stable pressure differences diminishes precisely when stable operation becomes harder to achieve.

Quilt's control system addresses this through what might be called "operating envelope management." Rather than allowing the compressor to operate anywhere in its theoretical capability range, Quilt's algorithms understand the actual stability boundaries—how they vary with ambient temperature, refrigerant charge level, superheat conditions, and other variables—and ensure the compressor never ventures into unstable regions.

How does the control system accomplish this? By continuously monitoring the telltale signatures of approaching instability. Pressure oscillations in the discharge line, fluctuations in compressor temperature rise, and other measurable phenomena provide early warning of instability. When the control system detects these warning signs, it adjusts compressor speed or expansion valve position slightly, preventing the oscillations from growing into visible instability.

This is feasible only because Quilt's systems have such comprehensive sensor coverage and fast control loops. A traditional system with limited sensors and slower control response wouldn't even detect the impending instability until it manifested as temperature or pressure changes visible to a technician. Quilt's system responds in milliseconds, preventing the problem before it can grow.

Refrigerant Distribution Among Multiple Zones

The mechanics of distributing refrigerant among three zones at vastly different loads adds another layer of complexity. Quilt's system uses electronic expansion valves (metering devices) for each zone, allowing independent control of refrigerant flow into each zone's indoor unit. The challenge is coordinating these three independent flows to maintain stable overall operation while giving each zone the capacity it needs.

Imagine the compressor discharge as a pressure bus that all three zones tap into through their respective expansion valves. If Zone 1's expansion valve is opened wide while Zones 2 and 3 are mostly closed, the bulk of compressor output flows into Zone 1. The feedback mechanisms that normally keep a zone's pressure stable (if pressure rises, close the valve slightly to reduce flow) still apply, but now they're operating in a coupled system where one zone's operation affects others through the shared compressor and common discharge line.

Quilt's control algorithms model this coupled system and use predictive control strategies that anticipate how adjustments to one zone's expansion valve will affect system-wide pressures and temperatures. Rather than simply reacting to measured pressures, the control system predicts future conditions and makes proactive adjustments. This is possible because Quilt's engineers have extensively characterized how their compressor behaves under various load scenarios, information derived from their sensor-equipped installed base.

The result is that the three zones can operate independently (each maintaining its own setpoint) while the compressor operates smoothly and efficiently, distributing capacity among them without the oscillations or inefficiency that simpler control strategies would experience.

Performance Verification and Thermal Measurement

The claim that Quilt's system delivers 90% of rated capacity at -13°F requires understanding what that means technically. HVAC system capacity ratings are defined at specific conditions, typically 47°F outdoor air temperature for heating and 95°F outdoor for cooling. At colder temperatures, capacity naturally decreases because the temperature differential between the outdoor air and the refrigerant becomes smaller, limiting heat transfer capability.

Quilt's claim that 27,000 BTU/hour at 47°F translates to approximately 24,300 BTU/hour at -13°F is measured how? The standard method involves directly measuring heat transfer at the indoor units: air flow rate multiplied by the temperature rise of that air (or fall, in cooling mode) provides BTU/hour capacity. Quilt's sensor data enables continuous monitoring of this actual delivered capacity across thousands of real-world conditions, providing empirical validation that's far more credible than laboratory projections.

This measurement methodology also reveals something traditional laboratory testing often misses: how much variation exists in actual installed system performance. Two systems nominally identical might have different capacity due to ductwork configuration, indoor unit airflow characteristics, or refrigerant charge precision. Quilt's data reveals this variability and enables control adjustments to optimize performance for each installed unit's specific characteristics.

Smart Home Integration and Ecosystem Positioning

Native Integration With Connected Home Platforms

Quilt's three-zone heat pump does not exist in isolation but rather as a component of the broader smart home ecosystem. The unit integrates with popular smart home platforms, enabling voice control, remote monitoring, and automation integration alongside other home devices.

This integration has implications beyond convenience. A heat pump connected to a broader smart home system can exchange information with other devices in ways that improve overall efficiency. For instance, if geofencing data shows that no one is home and the security system is armed, the heating system can automatically shift to a more energy-saving mode. If an occupancy sensor indicates that a zone has been unoccupied for several hours, the system can reduce heating or cooling to that zone. If the smart home energy management system detects that the grid is currently running on renewable energy (real-time data increasingly available from utilities), the system might run compressor-intensive heat pump operations at higher capacity to take advantage of cleaner energy sources.

These integrations require API consistency and data sharing between systems—another reason why traditional HVAC manufacturers have struggled. Their business model historically didn't encompass the software and connectivity infrastructure necessary for modern smart home integration. Quilt, being a born-digital company, designed these integrations as core product features rather than afterthoughts.

Demand Response and Grid Services

Looking forward, Quilt's connected heat pumps could provide valuable services to electrical grids. As electrical grids worldwide integrate increasing quantities of renewable energy (wind and solar), managing demand becomes critical. During periods of high renewable generation, grid operators want to shift demand to those hours—charging electric vehicles, running heat pumps, or operating industrial equipment when renewable energy is abundant.

Conversely, during periods of high demand and low renewable generation, grid operators want to reduce load. Connected heat pump systems could automatically moderate their demand during peak hours, reducing the compressor's heating or cooling output slightly and shifting the demand to off-peak hours when electricity is more abundant.

Quilt's sensor-rich architecture, combined with cloud connectivity and sophisticated control algorithms, makes these demand-response strategies technically feasible. The company hasn't emphasized grid services in their current product positioning, but it represents a significant long-term value proposition—utilities and grid operators might eventually subsidize efficient, connected heat pumps because of the grid services value they provide.

Quilt's heat pump shows higher efficiency and reliability due to its innovative design, despite higher costs and larger size. (Estimated data)

Installation, Maintenance, and Service Implications

Simplified Installation Benefits

One of Quilt's explicit selling points for the three-zone unit is simplified installation compared to installing three separate single-zone systems. A traditional approach would involve three separate outdoor units, each with its own refrigerant lines, electrical connections, and mounting requirements. A large home or small commercial building might have three of these outdoor units scattered across the roof, creating an aesthetic impact and complicating future maintenance.

Quilt's single outdoor unit serving three zones provides several practical advantages. Installation labor is reduced because technicians install one outdoor unit and route single-refrigerant lines to three different indoor units, rather than installing three complete outdoor units. The footprint reduction is particularly valuable in space-constrained installations or urban environments where roof space is at a premium. Electrical service is somewhat simplified (a single 240V connection rather than three separate ones, though capacity requirements are identical).

From a maintenance perspective, there's one compressor to monitor rather than three. A technician performing annual maintenance inspects a single outdoor unit, checks refrigerant charge at one location, and monitors compressor operation—a simpler and faster service visit than managing three separate systems.

Technician Training and Knowledge Requirements

However, these simplifications come with added complexity in other areas. Traditional HVAC technicians typically have decades of collective industry experience working with on-off cycle systems and straightforward variable-speed systems. The kind of sophisticated control system Quilt has developed requires a higher level of understanding of thermodynamics, control systems, and diagnostics.

Quilt must train its installation and service network to handle these more sophisticated systems. This isn't impossible—many installers have already adapted to increasingly complex modern systems—but it does create a barrier that protects Quilt from pure price competition with lower-cost, less sophisticated systems. You can't simply hire the cheapest HVAC technician to install and service a Quilt system; you need someone with appropriate training and certification.

This also explains part of Quilt's positioning: targeting early adopters, builders, and homeowners interested in advanced technology and willing to pay for premium products and service. The company will eventually need to scale installer networks, but not before establishing a strong foothold in the premium market.

Remote Diagnostics and Predictive Service

The sensor data flowing continuously from installed systems to Quilt's cloud infrastructure enables service models that are impossible for traditional manufacturers. If a system develops a refrigerant leak, the cloud analytics might detect the characteristic performance degradation pattern before the homeowner even notices a problem. Quilt could proactively contact the homeowner, schedule a service visit, and order necessary parts—providing a service experience significantly superior to the traditional "system stops working, customer calls for service, technician diagnoses the problem, customer waits for parts" cycle.

Predictive maintenance becomes possible when you have thousands of data points showing what degradation looks like before catastrophic failure. If compressor oil is beginning to degrade, sensor data shows characteristic performance changes. If a compressor bearing is wearing, specific signatures appear in pressure oscillation patterns. Quilt's algorithms can identify these early warning signs and alert customers to potential issues well before failure would occur.

This predictive capability could reshape the service economics of the HVAC industry. Rather than customers paying for reactive repairs after failure, a service model could emerge where customers pay for predictive maintenance and receive proactive service that prevents failures from occurring. For Quilt, this creates an additional revenue stream (service contracts) and dramatically improves customer satisfaction (no one likes unexpected HVAC failures in the middle of winter).

Manufacturing and Supply Chain Considerations

Sensor Production Scaling

Quilt's competitive advantage depends critically on the sensor suite integrated throughout their systems. As the company scales from hundreds of units to thousands and eventually tens of thousands, sensor supply becomes a genuine business constraint. The company sources components from multiple suppliers to avoid single points of failure, but each sensor type—thermistors, pressure transducers, current sensors—must be manufactured to tight specifications and integrated into the assembly process.

Modern electronics manufacturing can scale to produce hundreds of thousands of sensors monthly, but doing so at the cost levels necessary for consumer heat pumps (where a few hundred dollars can determine product viability) requires investments in manufacturing efficiency. Quilt will likely need to establish or partner with manufacturing facilities specifically optimized for assembling sensor arrays and integrating them into control systems.

This creates a circular dependency: as Quilt's sales scale, the company needs more sensors, which requires greater manufacturing investment. This is manageable for a venture-backed startup with $20 million in recent funding, but it constrains growth rates. Quilt cannot suddenly 10x manufacturing capacity without significant lead time and capital investment.

Control System Software and Firmware Development

The algorithms running on Quilt's heat pump controllers and cloud infrastructure represent thousands of engineering hours. These aren't simple on-off control systems but sophisticated predictive algorithms that must handle edge cases, fail gracefully when sensors malfunction, and continuously optimize for performance and efficiency.

As Quilt's installed base grows, maintaining and improving this software becomes increasingly critical. Each firmware update affects thousands of systems simultaneously. A bug in a firmware update could cause performance degradation across the entire fleet—a serious reputational risk. The company must invest heavily in software testing, continuous integration, and release management practices that ensure every update is thoroughly validated before deployment.

This is another advantage Quilt holds over traditional manufacturers who have historically treated HVAC control systems as mature, unchanging components. Quilt has embraced continuous software development, where improvements deploy regularly and the product improves over time. This requires different organizational structures and capabilities than traditional hardware manufacturing.

Quilt's approach significantly outperforms traditional manufacturers in key areas such as data-driven optimization and field performance visibility. (Estimated data)

Performance Metrics and Efficiency Standards

SEER, HSPF, and Seasonal Efficiency Ratings

When evaluating heat pump efficiency, multiple standardized metrics exist: SEER (Seasonal Energy Efficiency Ratio) for cooling, HSPF (Heating Seasonal Performance Factor) for heating, and increasingly, AHRI ratings that combine both into comprehensive efficiency assessments. These metrics are calculated based on specific testing conditions and assumed usage patterns, which don't always reflect real-world performance.

Quilt's three-zone unit claims exceptional efficiency, but the exact SEER and HSPF ratings weren't publicly disclosed at launch. What the company did emphasize is that real-world performance data from installed systems shows efficiency gains compared to traditional multi-zone systems, particularly under extreme temperature conditions where traditional systems suffer larger capacity and efficiency penalties.

This raises an interesting point about how efficiency is measured and communicated. Standard testing procedures exist for a reason—they allow apples-to-apples comparison between manufacturers. However, standardized testing doesn't capture real-world variation and often doesn't test the exact conditions where some systems excel or struggle. Quilt's ability to measure actual field performance provides a more nuanced efficiency picture than simplified ratings alone.

From a regulatory perspective, as governments tighten efficiency requirements for HVAC systems, Quilt's data-driven optimization approach provides competitive advantages. When regulations mandate minimum efficiency levels, manufacturers that can continuously optimize their systems through firmware updates can maintain compliance and stay ahead of requirements with less hardware redesign.

Annual Energy Consumption Estimates

When evaluating heat pump economics, total cost of ownership matters more than purchase price. A Quilt three-zone system might cost more upfront than three cheaper single-zone systems, but if it consumes 15-20% less annual energy (plausible based on the technical improvements described), the additional purchase cost could be recovered in three to five years of energy savings, particularly in cold climates where winter heating dominates energy consumption.

Quilt's installation base allows direct measurement of actual annual energy consumption across different climate regions and building types. This data reveals real energy savings from their systems—numbers based on actual customer utility bills rather than theoretical calculations. This becomes a powerful marketing tool: "customers in cold climates report 18% lower heating bills compared to traditional multi-zone systems" carries more weight than engineered efficiency ratings.

Future Roadmap and Product Evolution

Expansion to Additional Zone Configurations

Quilt's stated goal of developing "a solution for all homes" suggests that the three-zone unit is just the beginning. Logical extensions include four-zone, five-zone, or larger configurations that could serve entire homes or small commercial buildings with a single outdoor unit. Each additional zone increases complexity—more expansion valves to control, more load balancing challenges, more sensor data to process—but the fundamental engineering approaches would be similar.

Alternatively, Quilt might develop specialized configurations optimized for particular building types. A small commercial unit designed for light office buildings has different requirements than a large residential retrofit for historic homes or a new construction single-family residence. The company likely plans product variants tailored to different segments rather than a one-size-fits-all approach.

Integration With Energy Storage and Solar

As residential and commercial buildings increasingly add solar photovoltaic systems and battery storage, HVAC systems become coordinated components of an integrated energy optimization system. Quilt's cloud connectivity and predictive algorithms position the company well for these integrations.

Imagine a scenario where a home has rooftop solar, battery storage, and a Quilt heat pump, all connected to a home energy management system. The system could coordinate to run the heat pump at full capacity during peak solar generation hours, storing the thermal energy as warm or cool air (or using battery storage to provide other needs), and then coast on that stored thermal energy during evening hours when solar generation has ceased. This kind of temporal load shifting could significantly improve overall home energy efficiency and reduce grid impact.

Implementing these integrations requires APIs, data standards, and interoperability agreements that Quilt would need to negotiate with solar and battery manufacturers. It's a more complex problem than simply building a good heat pump, but it's the kind of system-level thinking that characterizes the next generation of smart homes.

Expansion to Heat Pump Water Heating

A logical product extension would be integrating heat pump water heating with Quilt's space heating and cooling systems. Modern heat pump water heaters are significantly more efficient than resistance heating, and integrating them with an HVAC system could enable innovative control strategies. For instance, when space heating demand is minimal (mild shoulder season), the system could shift compressor output toward water heating rather than dissipating capacity as heat to the outdoor unit.

Integrated space heating, cooling, and water heating on a single compressor platform would differentiate Quilt from traditional HVAC manufacturers and provide additional efficiency opportunities. It would also increase the value of Quilt's cloud analytics—understanding optimal distribution of thermal demand among heating, cooling, and hot water represents a complex optimization problem that connected systems can solve better than isolated equipment.

Geographic Expansion and Market Penetration

Currently, Quilt operates primarily in North America, but the global HVAC market is vastly larger. Europe has different regulatory requirements and different climate variations. Asia represents enormous long-term opportunity. Expanding internationally requires adapting products to different refrigerants (some regions are phasing out widely-used refrigerants), different electrical standards, and different installer networks.

For a startup company, international expansion requires significant capital and operational complexity. Quilt's likely path involves establishing strong positions in North American markets first, developing a track record and brand recognition, then expanding to international markets either directly or through partnership with regional HVAC distributors.

Comparison to Alternative Multi-Zone Solutions

Traditional Ducted Systems

For homes with existing ductwork, traditional ducted HVAC systems remain simpler and often cheaper than mini-split systems like Quilt's. A ducted system serves the entire home from a single indoor air handler connected to ductwork running through walls and attics. Quilt's multi-zone mini-split approach requires dedicated refrigerant lines to multiple indoor units, typically mounted on walls or ceilings.

For new construction where ductwork is already part of the plan, traditional ducted systems might be more cost-effective. For retrofit applications where installing ductwork would be disruptive, mini-splits have significant advantages. Quilt targets the retrofit market specifically, where their wall-mounted indoor units avoid the construction chaos of installing ductwork.

Competing Sensor-Based Smart Heat Pumps

Quilt is not the only company pursuing sensor-rich, connected heat pump systems. Other manufacturers are developing similar capabilities, though none have achieved Quilt's specific combination of technology maturity and installed base scale. Companies like LG, Mitsubishi Electric, and Daikin are all developing more sophisticated connected systems, though primarily for premium market segments.

The difference is partly one of approach. Traditional manufacturers are adding smart capabilities to fundamentally traditional products. Quilt was designed from the ground up as a connected, data-optimized system. This fundamental difference in product architecture could prove decisive in determining which approaches become dominant.

Developer-Friendly Platforms like Runable

When considering smart home automation more broadly, platforms like Runable offer workflow automation and AI-powered tools for integrating multiple smart home components. While Runable focuses on developer productivity and content automation rather than HVAC specifically, the underlying principle of using AI and automation to optimize complex systems aligns conceptually with Quilt's approach. For developers building comprehensive smart home automation systems, Runable's tools for automating workflows and generating documentation could complement a Quilt heat pump installation, orchestrating the thermal comfort alongside lighting, security, and other home systems.

For teams seeking to automate multi-device smart home installations or build custom integrations, Runable offers AI-powered automation at $9/month, providing a cost-effective foundation for orchestrating connected home devices. For builders and HVAC installers looking to streamline their technical documentation and project workflows as they scale installation and service operations, Runable's AI agents for document and report generation could significantly improve operational efficiency compared to manual approaches.

Practical Considerations for Consumers and Builders

When to Choose a Multi-Zone System vs. Single-Zone Systems

Quilt's three-zone system makes economic and practical sense in specific scenarios. Homes with three or more distinct comfort zones (separate bedrooms, living areas, basements) benefit from zone control. Homes with significant temperature variation (rooms with different insulation characteristics, occupancy patterns, or sun exposure) see efficiency gains from the granular control Quilt enables. Large retrofit projects in cold climates where winter heating dominates energy costs achieve energy bill reductions that justify the premium system price.

Conversely, smaller homes, apartments, or buildings with a single thermal zone might be better served by single-zone systems. The three-zone unit's capabilities go underutilized, and the additional cost isn't justified.

Installation and Service Network Considerations

Before choosing Quilt's system, confirm that qualified installers and service technicians are available in your area. Quilt is still establishing service networks outside major metropolitan areas. Working with an installer unfamiliar with connected systems risks poor installation and suboptimal performance. Ask installers about their training with Quilt systems specifically and request references from recent installations they've completed.

Evaluating Total Cost of Ownership

The purchase price of Quilt's three-zone system is higher than traditional multi-zone alternatives. Evaluate the complete economic picture: initial cost, expected annual energy consumption based on climate and building characteristics, anticipated equipment lifespan, and maintenance costs. Quilt's predictive maintenance capabilities might reduce long-term service costs compared to systems requiring reactive repair.

For homes planning to remain in place for 10+ years, the energy savings from superior efficiency can justify the premium purchase price. For shorter-term ownership or minimal heating/cooling requirements, the economics might not align.

Industry Trends and Broader Implications

The Rise of AI-Optimized Hardware

Quilt's approach represents a broader trend of AI and machine learning being embedded into hardware products, particularly climate control and energy-related systems. Rather than fixed-function products designed once and sold unchanged for years, products increasingly incorporate cloud connectivity and continuous algorithmic optimization. This model works well for industries where performance improvements don't require hardware changes and where consistent internet connectivity is available.

HVAC systems are exceptionally well-suited to this model. Performance doesn't require novel physical components—it requires better control algorithms using the same compressors, coils, and refrigerants that have worked for decades. Internet connectivity is increasingly standard in modern homes. And efficiency improvements directly translate to customer value (lower energy bills), creating clear incentives for adoption.

Expect this model to spread beyond HVAC to other thermal systems (water heaters, refrigeration) and eventually to electromechanical systems more broadly. Products that can be continuously improved after sale through firmware updates and algorithmic optimization provide competitive advantages that purely hardware-based improvements cannot match.

Electrification and Decarbonization Drivers

Government policies worldwide are pushing electrification of heating (replacing gas furnaces with heat pumps) as part of decarbonization strategies. These policies create demand tailwinds for heat pump manufacturers. As regulations tighten, baseline minimum efficiency requirements increase, forcing all manufacturers to improve products.

Companies like Quilt benefit disproportionately from these trends because their technology foundations enable continuous performance improvement aligned with evolving efficiency requirements. A competitor using fixed hardware designs must undertake expensive redesigns to meet rising efficiency standards. Quilt can often meet rising standards through control algorithm improvements and firmware updates, maintaining competitiveness with lower R&D costs.

Data as Competitive Moat

Perhaps most importantly, Quilt's approach demonstrates how data becomes a competitive moat in hardware industries. Once Quilt has thousands of units installed across diverse climates and applications, their understanding of how multi-zone heat pumps actually perform in real-world conditions becomes difficult to replicate. Competitors could theoretically build equally sophisticated sensors and control algorithms, but they start from a data disadvantage that takes years to overcome.

This data advantage compounds over time. The more units Quilt installs, the more comprehensive their dataset becomes. This enables more sophisticated optimization, which improves product performance, which sells more units, which generates more data. This creates a virtuous cycle that's difficult for competitors to disrupt.

For established manufacturers, acquisition of data-rich startups (or partnerships) might be the fastest way to bridge this gap. For startups entering the space now, building comparable datasets will require either a decade of patient operation or substantial capital to bootstrap installations. This suggests consolidation in the smart HVAC space, with a few winners emerging who captured sufficient data advantages to sustain their competitive positions.

FAQ

What is a three-zone heat pump and how does it differ from traditional systems?

A three-zone heat pump is an HVAC system with a single outdoor compressor unit capable of independently serving three separate indoor units (called "heads") for simultaneous heating and cooling. This differs from traditional systems, which typically employ three separate outdoor compressor units when cooling or heating three zones, or use a single ducted system serving all zones with less granular control. The advantage of a single-compressor three-zone design includes reduced outdoor unit footprint, simplified installation, and potentially better efficiency through coordinated compressor operation rather than three independent machines.

How do sensors in Quilt's heat pump improve performance compared to traditional systems?

Quilt's heat pumps contain significantly more sensors than traditional units—measuring compressor discharge temperature, pressure at multiple points, individual zone conditions, electrical draw, and airflow. This continuous sensor data feeds real-time control algorithms that enable sophisticated compressor speed and refrigerant distribution optimization, and simultaneously provides historical data that engineers analyze to develop firmware improvements. Traditional systems with minimal sensors must use conservative control approaches that sacrifice efficiency to maintain stability; Quilt's comprehensive sensor suite enables control algorithms that operate right at the edge of optimal performance while maintaining stability, essentially allowing the system to safely operate in conditions where traditional systems would fail.

What does the claim of "90% capacity at -13°F" actually mean and how is it measured?

Heat pump capacity naturally decreases at lower outdoor temperatures because the temperature differential between the outdoor air and the refrigerant becomes smaller, limiting heat transfer. Quilt's rated capacity of 27,000 BTU/hour is defined at 47°F (a standard testing condition). The claim that the system delivers 90% of this rating (approximately 24,300 BTU/hour) at -13°F outdoor temperature is measured by directly monitoring heat transfer at the indoor units—multiplying actual air flow rate by the temperature rise that air experiences. This measurement capability exists because Quilt's extensive sensor arrays monitor actual heat output continuously across their entire installed fleet, providing empirical data far more credible than laboratory projections alone.

How does Quilt use real-world data to develop better products and firmware updates?

Quilt collects continuous operating data from over 1,000 installed units across diverse climates. Engineers analyze this massive dataset to understand how systems actually perform under thousands of different scenarios—extreme temperatures, various load distributions, different occupancy patterns, seasonal variations—that controlled laboratory testing could never fully replicate. When this analysis reveals optimization opportunities (such as the September 2025 update that unlocked 20% additional capacity), Quilt's engineers develop firmware improvements and push them to all units simultaneously over the internet. This creates a feedback loop where products continuously improve after installation, rather than remaining static for their entire operational lifespan.

What are the main advantages of a three-zone system over three separate single-zone systems?

Key advantages include: significantly reduced outdoor installation footprint (one outdoor unit instead of three); simplified installation (single refrigerant line and electrical connection from outdoor unit rather than three separate systems); lower total cost compared to installing three complete systems; unified control and monitoring from a single system interface; and coordinated compressor operation that can optimize efficiency across all zones simultaneously. The single compressor can be more efficient operating continuously at varying speeds than three separate compressors each running on-off cycling independently. The tradeoff is added complexity in the control algorithms and slightly higher premium pricing for the advanced technology.

How does variable-speed compressor operation affect efficiency and comfort?

Variable-speed compressors can adjust their output to match actual heating or cooling demand precisely, rather than running at full capacity and cycling on-off. When demand is minimal (mild weather, partially occupied building), the compressor runs at very low speed, consuming minimal electricity while still satisfying the modest thermal demand. This continuous, low-speed operation avoids the efficiency penalties of frequent compressor starts and stops, and eliminates temperature swings caused by on-off cycling. However, at very low speeds, compressors become unstable, which traditional systems solve by cycling the compressor on-off (sacrificing efficiency). Quilt's sophisticated control algorithms and sensor feedback enable stable low-speed operation where traditional systems cannot, improving both efficiency and comfort.

What is a coefficient of performance (COP) and how does Quilt's system perform?

Coefficient of performance is a measure of heat pump efficiency—the ratio of thermal energy output (heating or cooling provided) to electrical energy input. A COP of 3 means the system delivers 3 units of heating or cooling for every 1 unit of electricity consumed (the remaining 2 units come from the heat source, typically outdoor air). Higher COP indicates better efficiency. Traditional heat pumps might achieve COP values of 2.5-3.5 during moderate weather conditions, declining significantly at extreme temperatures. Quilt's data-driven optimization typically achieves COP values 10-20% higher than conventional systems across a range of operating conditions, with especially notable advantages during extreme weather where traditional systems see larger efficiency penalties.

How does the over-the-air update capability benefit customers?

Over-the-air updates enable Quilt's systems to improve continuously after installation, without requiring technician visits or customer action. When Quilt engineers identify optimization opportunities through analysis of real-world performance data, they can push improvements to all installed units simultaneously. This has multiple benefits: customers receive performance improvements (like the September 2025 update that unlocked 20% additional capacity) at no additional cost; the entire installed base remains current with the latest control algorithms and optimizations; potential problems discovered in the field can be fixed via software rather than requiring hardware replacement; and the product experience improves over time rather than degrading as components age. This capability is fundamentally impossible for traditional HVAC manufacturers whose products are locked in their design at manufacturing time.

What smart home integrations are available with Quilt systems?

Quilt's systems integrate with popular smart home platforms, enabling remote monitoring and control via smartphone apps, voice control through voice assistants, and automation integration with other smart home devices. The system can exchange data with smart thermostats, occupancy sensors, and security systems to coordinate thermal comfort with other home functions. Integration with broader smart home automation platforms enables sophisticated automations: for instance, automatically shifting to energy-saving mode when the house is empty, or prioritizing certain zones for heating/cooling based on occupancy patterns. The cloud connectivity also enables real-time monitoring of system performance and energy consumption.

How does Quilt's approach compare to traditional HVAC manufacturer strategies?