The Samsung 20,000 mAh Battery Breakthrough: Separating Fact from Fiction

Smartphone battery technology has been one of the most frustrating aspects of mobile device evolution. While processors double in speed and cameras multiply in megapixels, battery capacity improvements have felt glacially slow. Samsung's reported testing of 20,000 mAh batteries represents a potential game-changer in this stagnant landscape, yet the reality of when—and how much—this technology will transform your daily smartphone experience is far more nuanced than headlines suggest.

The significance of this development cannot be overstated. Current flagship smartphones like the Samsung Galaxy S25 Ultra ship with approximately 5,000 mAh batteries, meaning a 20,000 mAh capacity would represent a 400% increase in raw storage capacity. For context, this would be equivalent to the difference between owning a compact car with a 12-gallon tank and suddenly receiving one with a 48-gallon tank. The theoretical implications are revolutionary: multi-week battery life instead of single-day endurance, elimination of anxiety around finding charging ports, and a fundamental shift in how users interact with their devices.

However, Samsung's own roadmap suggests consumers shouldn't expect this technology to revolutionize the Galaxy S26 Ultra upon arrival. The distinction between testing battery technology in laboratory conditions and integrating it into a consumer device that must pass rigorous safety certifications, fit within ergonomic dimensions, and maintain profitability is substantial. The company's cautious messaging indicates a phased approach to deployment, with larger capacity batteries likely appearing first in less size-constrained device categories before trickling down to premium flagships.

This article explores the technical realities behind Samsung's 20,000 mAh battery development, examines the genuine limitations that prevent immediate implementation, analyzes what consumers might realistically expect from the Galaxy S26 Ultra and subsequent generations, and provides context on how this advancement fits into the broader smartphone evolution narrative. Understanding the gap between laboratory achievements and consumer reality is essential for setting reasonable expectations about smartphone longevity.

Understanding Battery Capacity Measurements and Real-World Performance

What Does 20,000 mAh Actually Mean?

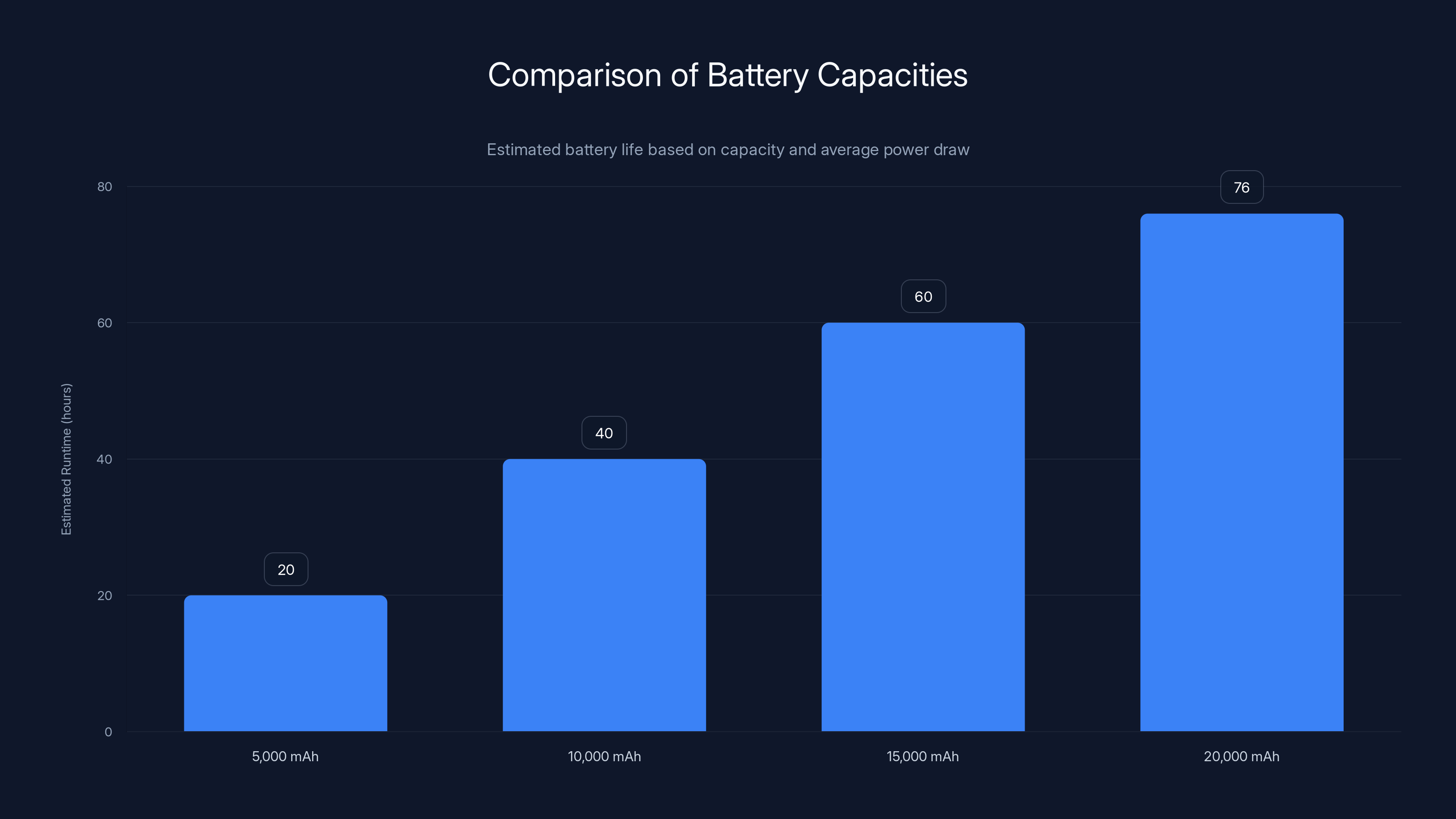

Milliampere-hours (mAh) measure electrical charge—specifically, the amount of current a battery can supply over time. A 20,000 mAh battery can theoretically deliver 1 amp of current for 20 hours, or 2 amps for 10 hours. This is raw capacity, not actual device runtime. The confusion between capacity and usable performance lies at the heart of why consumers often feel deceived by battery specifications.

Current flagship devices use batteries with capacity between 4,500-5,500 mAh. The iPhone 16 Pro Max contains a 4,685 mAh battery, while the Galaxy S25 Ultra features a 5,000 mAh unit. These seem modest compared to Samsung's reported 20,000 mAh testing figure, but capacity alone doesn't determine how long your phone lasts. A 5,000 mAh battery paired with efficient processors, optimized software, and low-power display technologies can outperform a 6,500 mAh battery in an older device with power-hungry components.

The relationship between capacity and runtime follows the equation: Runtime (hours) = Battery Capacity (mAh) × Energy Density (Wh) ÷ Average Power Draw (mA). This means that while a 400% increase in capacity sounds transformative, a 50% improvement in processor efficiency, a 30% reduction in display power consumption, and a 40% boost in battery energy density would collectively deliver results approaching a 20,000 mAh equivalent effect without requiring such a massive physical battery.

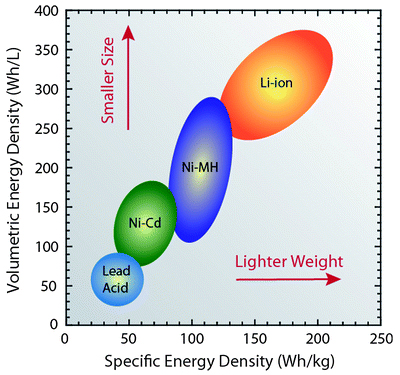

Energy Density vs. Raw Capacity: The Physics Constraint

Energy density measures how much energy a battery stores per unit of volume or weight, typically expressed in watt-hours per liter (Wh/L) or watt-hours per kilogram (Wh/kg). Samsung's 5,000 mAh battery in the Galaxy S25 Ultra delivers approximately 19.95 Wh of energy, working out to roughly 3.99 Wh per 1,000 mAh.

If Samsung simply increases capacity to 20,000 mAh without improving energy density, the battery would deliver approximately 79.8 Wh—nearly four times the energy. A standard lithium-ion battery cell measures roughly 65mm × 35mm × 8mm (approximately 18,200 cubic millimeters). Scaling this four-fold would create a battery roughly the size of two standard AA batteries stacked together, which would make holding the device extremely uncomfortable and potentially unsafe due to thermal concerns.

This is where energy density improvements become critical. Samsung's testing likely focuses on new chemistry combinations, such as lithium-metal, solid-state, or lithium-sulfur variants that could deliver 25-50% higher energy density than current lithium-ion formulations. A 40% density improvement would allow a 20,000 mAh battery to fit into a package only marginally larger than today's 5,000 mAh cells.

The challenge is manufacturing reliability. Lithium-metal batteries can deliver higher energy density but exhibit stability issues, particularly around cycle life and thermal management. Solid-state batteries promise revolutionary improvements but require solving complex production problems, including electrolyte interface engineering and dendrite formation prevention. These aren't theoretical barriers—they're active areas of global battery research, with companies like Toyota, QuantumScape, and Samsung investing billions annually.

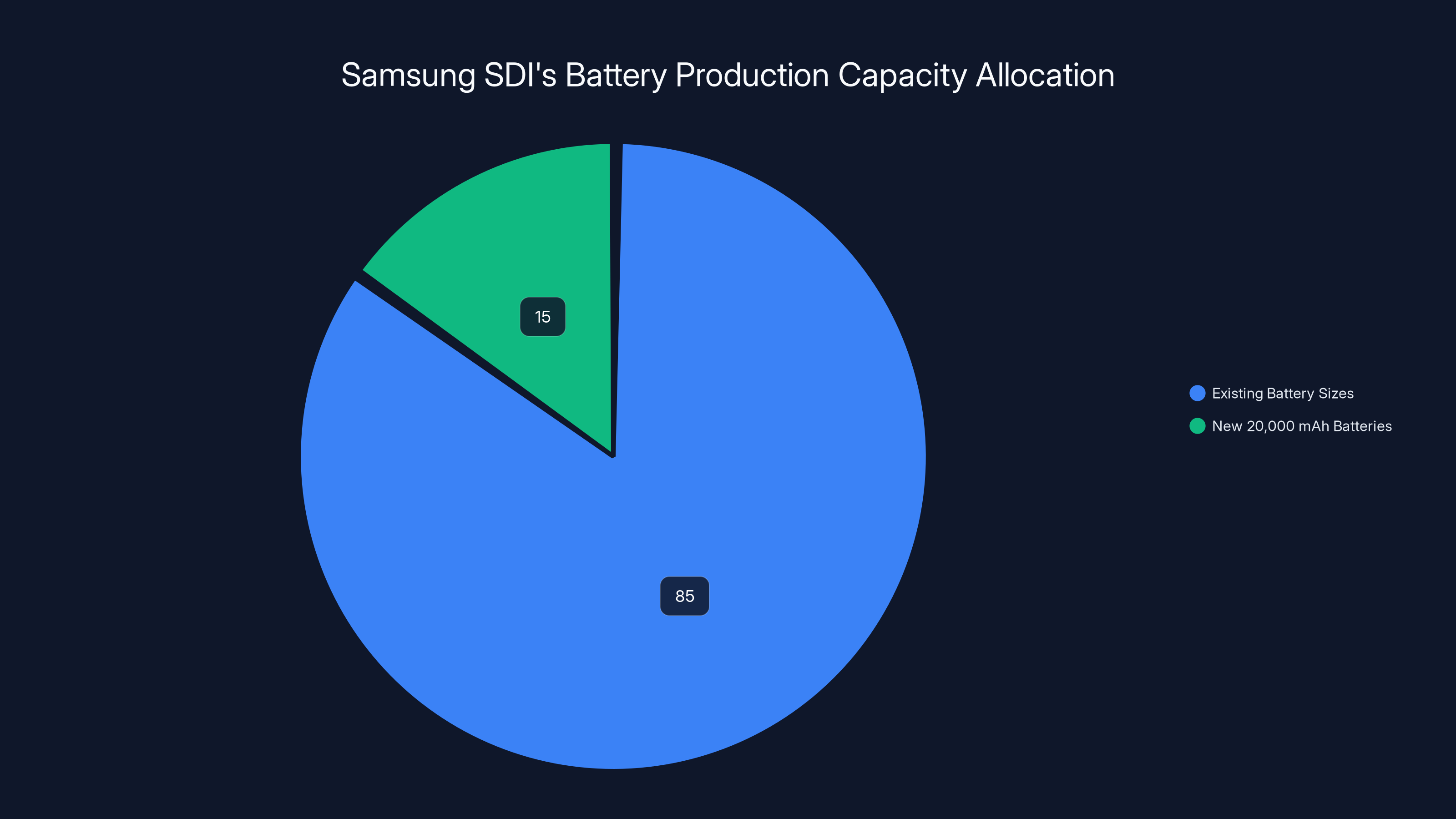

Estimated data: Introducing 20,000 mAh batteries could require allocating 15% of Samsung SDI's production capacity, impacting existing battery production.

Samsung's Battery Development Timeline and Technology Platform

Current Battery Testing Specifications

Samsung's reported 20,000 mAh battery testing represents an extension of the company's silicon-graphite anode research program, which has quietly progressed over the past five years. Samsung's Battery division has published papers describing porous silicon-graphite composite anodes that theoretically enable 50% higher energy density compared to conventional graphite-only anodes. The silicon component provides higher specific capacity (approximately 3,572 mAh/g versus graphite's 372 mAh/g), while the graphite matrix provides structural stability and cycle life.

The 20,000 mAh figures in Samsung's testing likely refer to batteries using these next-generation anode materials combined with nickel-rich layered oxide cathodes (NCA or NCMA chemistries) and potentially novel solid electrolytes in prototype form. Laboratory prototypes are testing different configurations: some optimizing for maximum energy density, others prioritizing thermal stability, and still others balancing cycle life with fast-charging capability.

What Samsung hasn't confirmed—and what industry analysts suspect—is whether these 20,000 mAh prototypes achieve the cycle life and thermal characteristics necessary for consumer electronics. A battery that delivers impressive capacity but requires replacement after 300 charge cycles (versus the 1,000+ cycles expected from smartphone batteries) would be commercially unviable. Similarly, batteries that operate safely only within narrow temperature ranges or require specialized cooling systems add complexity incompatible with mainstream consumer devices.

Manufacturing Scale and Production Challenges

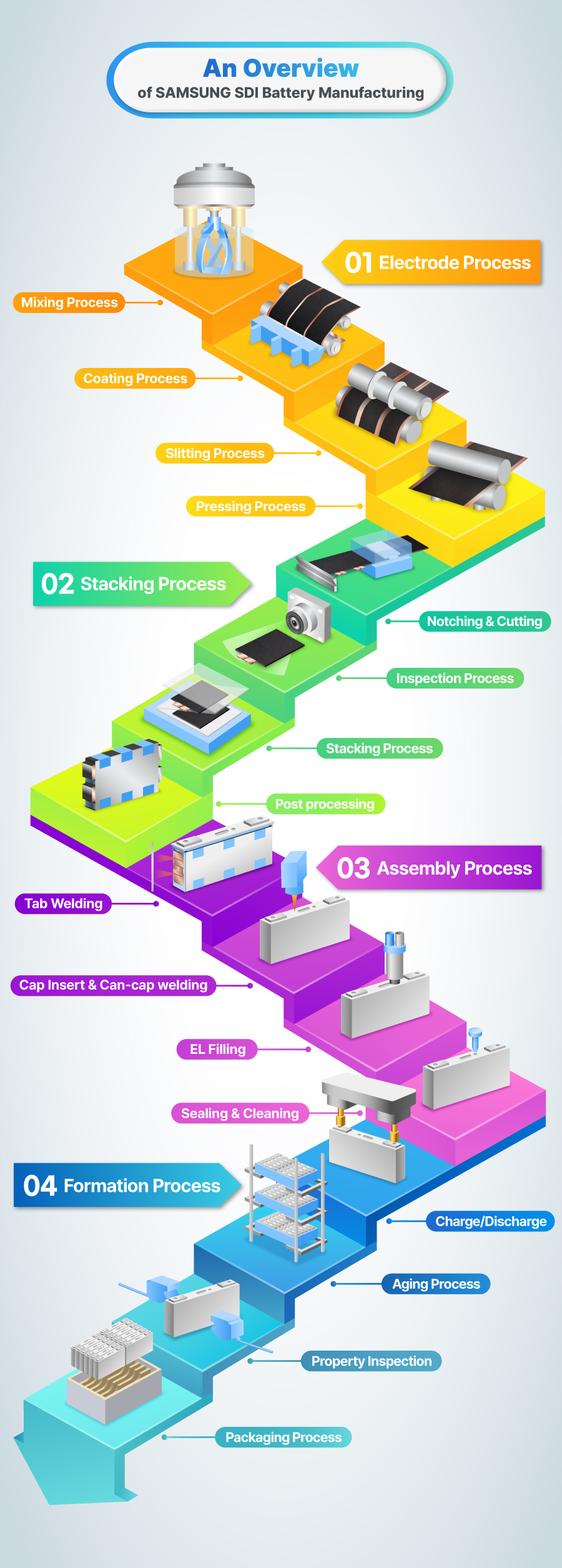

Moving from laboratory prototypes to commercial manufacturing represents a quantum leap in complexity. Samsung operates multiple battery fabrication facilities globally, with annual production capacity of over 200 GWh (gigawatt-hours). However, integrating new chemistry variants into existing production lines requires substantial capital investment, process development, and quality control certification.

Each new battery chemistry demands proprietary manufacturing sequences: precise anode coating processes, specific cathode sintering temperatures, customized electrolyte dispensing systems, and novel cell encapsulation techniques. Samsung must validate that new chemistry batteries can be manufactured at scale with >98% yield rates (industry standard), meeting strict specifications across millions of units. A 1% failure rate across 50 million devices annually means 500,000 defective units—an unacceptable outcome for a premium device.

The company has provided hints about its timeline through investor presentations. Samsung SDI (the division handling advanced battery R&D) indicated that solid-state battery mass production could begin in the 2027-2028 timeframe, with initial deployment in non-smartphone applications (vehicles, energy storage) before trickling down to mobile devices. This suggests the 20,000 mAh batteries currently in testing represent intermediate technology—an improvement over today's lithium-ion but not yet the revolutionary solid-state platform.

Physical Design Constraints: Why Larger Batteries Can't Simply Fit

Dimensional and Weight Considerations

The Samsung Galaxy S25 Ultra measures 162.8 × 77.8 × 8.2 mm and weighs 218 grams. This form factor represents an optimization between screen real estate, handling comfort, and pocket-ability. A larger battery introduces competing design pressures.

Batteries occupy roughly 25-30% of the internal volume of a smartphone, with the remainder dedicated to processors, display panels, antennas, thermal management systems, and mechanical structures. The Galaxy S25 Ultra's 5,000 mAh battery occupies approximately 1,150 cubic centimeters of the device's internal space. Scaling to 20,000 mAh with only modest energy density improvements would require battery volume approaching 3,500-4,000 cubic centimeters.

Achieving this within Samsung's design aesthetic requires either:

- Increased thickness: Growing from 8.2mm to approximately 11-12mm (50% thicker)

- Increased length or width: Proportionally scaling the device larger

- Dual-battery configuration: Splitting capacity across multiple cells positioned differently within the chassis

- Significant energy density improvements: Requiring next-generation chemistry

Weight becomes a secondary concern. Lithium-ion batteries weigh approximately 0.15-0.18 kg per kilowatt-hour. A 20,000 mAh battery (roughly 76 Wh) would weigh approximately 12-14 grams, compared to today's 5,000 mAh batteries at roughly 3-3.5 grams. While this 10-gram increase seems modest, it's meaningful in devices where precision engineering keeps total weight at 200-220 grams. This shifts the weight distribution, potentially affecting ergonomics or requiring structural redesign.

Thermal Management and Safety Requirements

Larger batteries generate more heat, particularly during fast charging or intensive gaming sessions. Smartphone thermal management relies on passive heat dissipation through graphite sheets, copper layers, and aluminum frames. A battery quadrupling in capacity increases peak heat generation proportionally unless cycle efficiency improves dramatically.

Samsung's current flagship phones use 15W-25W wireless charging and support fast-wired charging up to 45W. Charging a 20,000 mAh battery at 45W would take approximately 1.5 hours from empty to full (assuming 85% charging efficiency and accounting for power delivery overhead). However, maintaining rapid charging speeds on larger batteries risks thermal stress that compromises long-term battery health.

This creates an engineering paradox: larger batteries promise longer runtime, but rapid charging of those larger batteries generates heat that accelerates battery degradation. Samsung's realistic approach involves slower charging profiles for these massive capacity batteries, potentially requiring 2-3 hours for a complete charge despite the increased energy storage. This somewhat defeats the psychological appeal of a 20,000 mAh battery, though longer runtime between charges would likely outweigh slower charging speeds for most users.

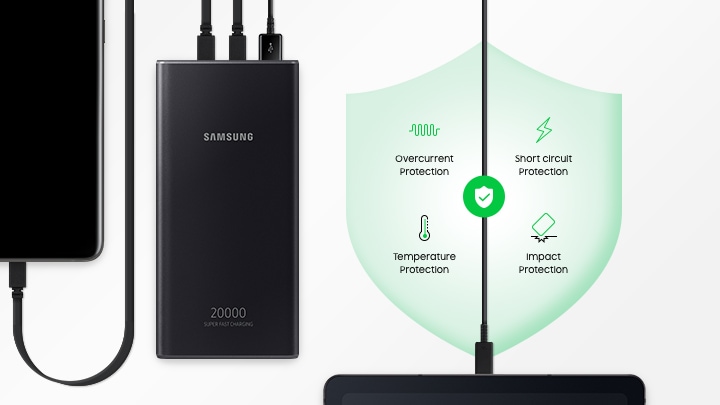

Safety standards like IEC 62619 (secondary batteries for portable sealed apparatus) and UN 38.3 (transportation of dangerous goods) impose strict limits on battery energy content, thermal limits, and abuse testing. A 20,000 mAh battery pushes against these regulatory boundaries, requiring certification testing that adds months to device development timelines.

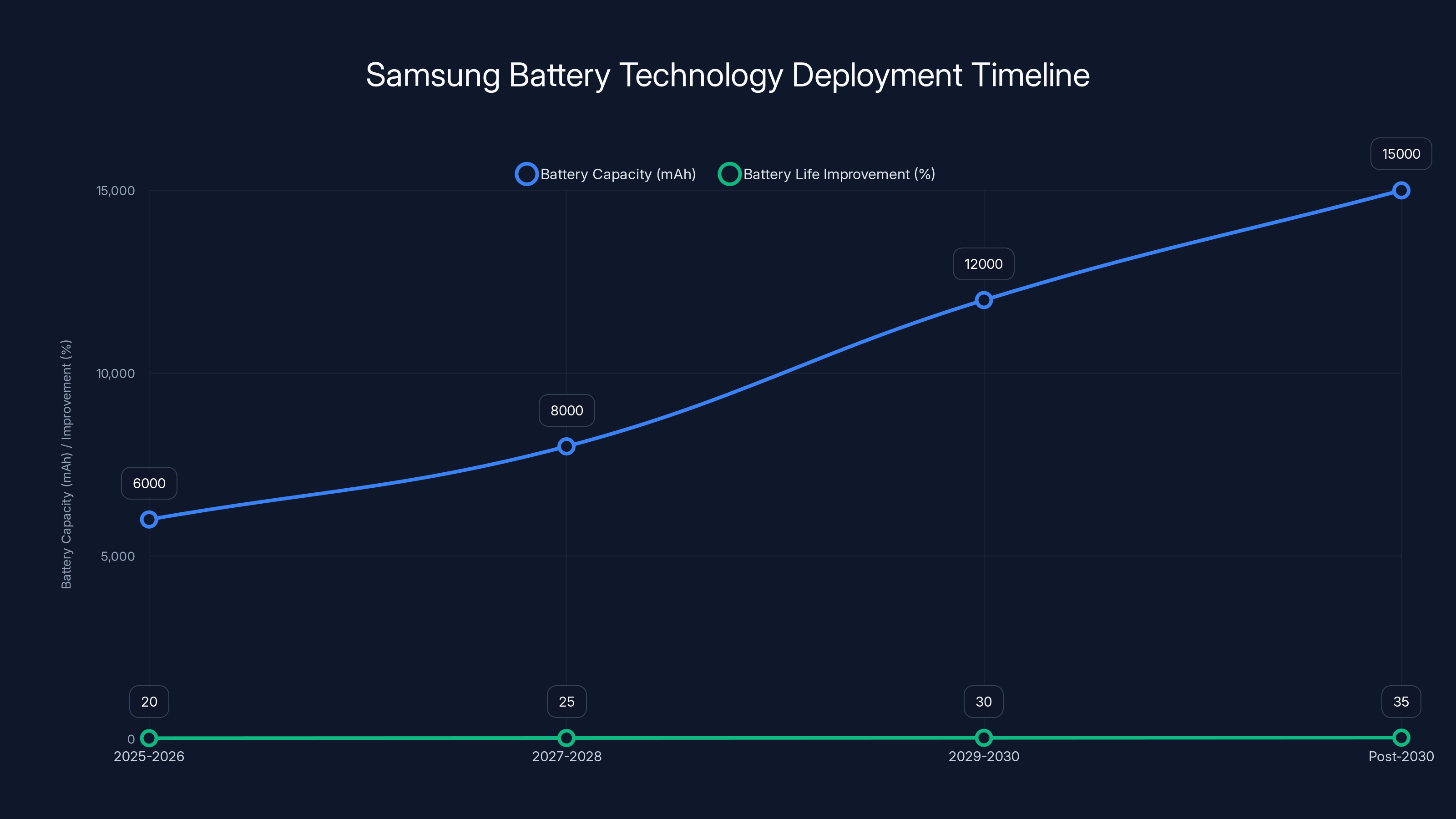

The timeline shows projected advancements in Samsung's battery technology, with significant capacity and efficiency improvements expected by 2030. Estimated data.

Chemistry Innovation: Next-Generation Battery Materials

Silicon-Dominant Anode Technology

Silicon anodes represent perhaps the most promising near-term path to higher energy density. While graphite dominates current anodes due to proven cycle life and manufacturing maturity, silicon offers superior specific capacity. Pure silicon delivers approximately 3,570 mAh/g, roughly 10 times graphite's capacity. However, silicon expands and contracts dramatically during charging and discharging—up to 300% volume change—which causes mechanical stress, electrolyte decomposition, and rapid capacity fade.

Samsung's silicon-graphite composite approach mitigates these issues by using graphite as a structural matrix that accommodates silicon expansion while maintaining electron pathways. Laboratory results published by Samsung indicate 50% higher energy density compared to pure graphite anodes while maintaining 90%+ capacity retention after 1,000 cycles. The breakthrough involves precisely engineered porous structures at the nanometer scale, which require specialized manufacturing techniques like atomic layer deposition (ALD) or chemical vapor deposition (CVD).

Moving this technology from laboratory prototypes to consumer devices requires solving manufacturing complexity. Each anode layer must achieve consistent porosity, uniform silicon distribution, and reliable electrical connectivity across millions of cells. Current production yields likely remain in the 70-85% range, meaning 15-30% of manufactured cells fail quality checks. Before commercial deployment, Samsung needs to push yields above 98-99%, a process typically requiring 3-5 years of iterative refinement.

Cathode Material Evolution

The cathode (positive terminal) equally influences battery performance. Current flagships predominantly use NCA (nickel-cobalt-aluminum oxide) or NCM (nickel-cobalt-manganese oxide) chemistries. Samsung's development roadmap increasingly focuses on NCMA (nickel-cobalt-manganese-aluminum) and high-nickel variants that increase energy density by reducing cobalt content (which is expensive and ethically problematic to source).

High-nickel cathodes (where nickel comprises 80%+ of the transition metals) deliver approximately 15-20% higher energy density than conventional formulations. However, they exhibit increased reactivity with electrolytes, higher oxygen loss at elevated temperatures, and reduced cycle life. Samsung's research has demonstrated that doping these high-nickel cathodes with elements like magnesium or zinc, combined with specialized surface coatings, substantially improves stability while maintaining the energy density benefits.

The next frontier involves layered lithium-rich cathodes and LMFO (lithium manganese iron oxide) variants that theoretically deliver energy densities 25-30% higher than current standards. However, these materials suffer from voltage fade (capacity loss over cycles) and irreversible reactions with conventional electrolytes. Samsung's chemistry teams are investigating novel electrolyte formulations that stabilize these high-capacity cathodes, representing a coordinated materials science effort rather than a single breakthrough.

Electrolyte Innovation and Solid-State Progress

The electrolyte (the chemical medium enabling ion transport) might represent the most critical bottleneck. Current lithium-ion batteries use organic liquid electrolytes based on lithium salts dissolved in carbonate solvents. These proved reliable over decades but impose fundamental performance limits related to electrochemical stability windows and thermal safety.

Solid-state electrolytes—ceramic or polymer materials replacing liquid electrolytes—promise revolutionary improvements: wider operating temperature ranges, higher energy density (enabling lithium-metal anodes), improved cycle life, and enhanced safety. Samsung has invested heavily in solid-state research through its advanced battery division, with public timelines suggesting late 2020s commercialization.

The technical barriers are formidable. Solid electrolytes must conduct lithium ions efficiently (competitive with liquid electrolytes), withstand manufacturing and assembly stresses, maintain contact with electrodes through hundreds of charge cycles despite volume changes, and be manufacturable at scale using existing or slightly modified production infrastructure. Samsung's approach uses ceramic-based sulfide electrolytes with polymer binders, attempting to combine ceramic stability with polymer manufacturability. Laboratory prototypes show promise, but moving to production-ready cells requires solving interface engineering problems that have resisted solution for 15+ years.

Galaxy S26 Ultra Expectations: What's Realistic for 2025-2026

Current Timeline and Development Cycles

Samsung operates on predictable annual development cycles. The Galaxy S26 Ultra will likely launch in early 2026, with development finalized by mid-2025. The company's battery research operates on longer timescales than annual product cycles—battery technology decisions must be finalized 18-24 months before consumer launch to allow for supply chain setup, certification testing, and production ramp.

If Samsung is currently testing 20,000 mAh batteries (as of 2024-2025), the timeline for integrating this technology into the S26 Ultra is extremely compressed. Industry sources suggest Samsung would need 18 months of optimization work post-prototype to achieve manufacturing readiness for a flagship device. This leaves a narrow window for the S26 Ultra to incorporate preliminary versions of this battery technology.

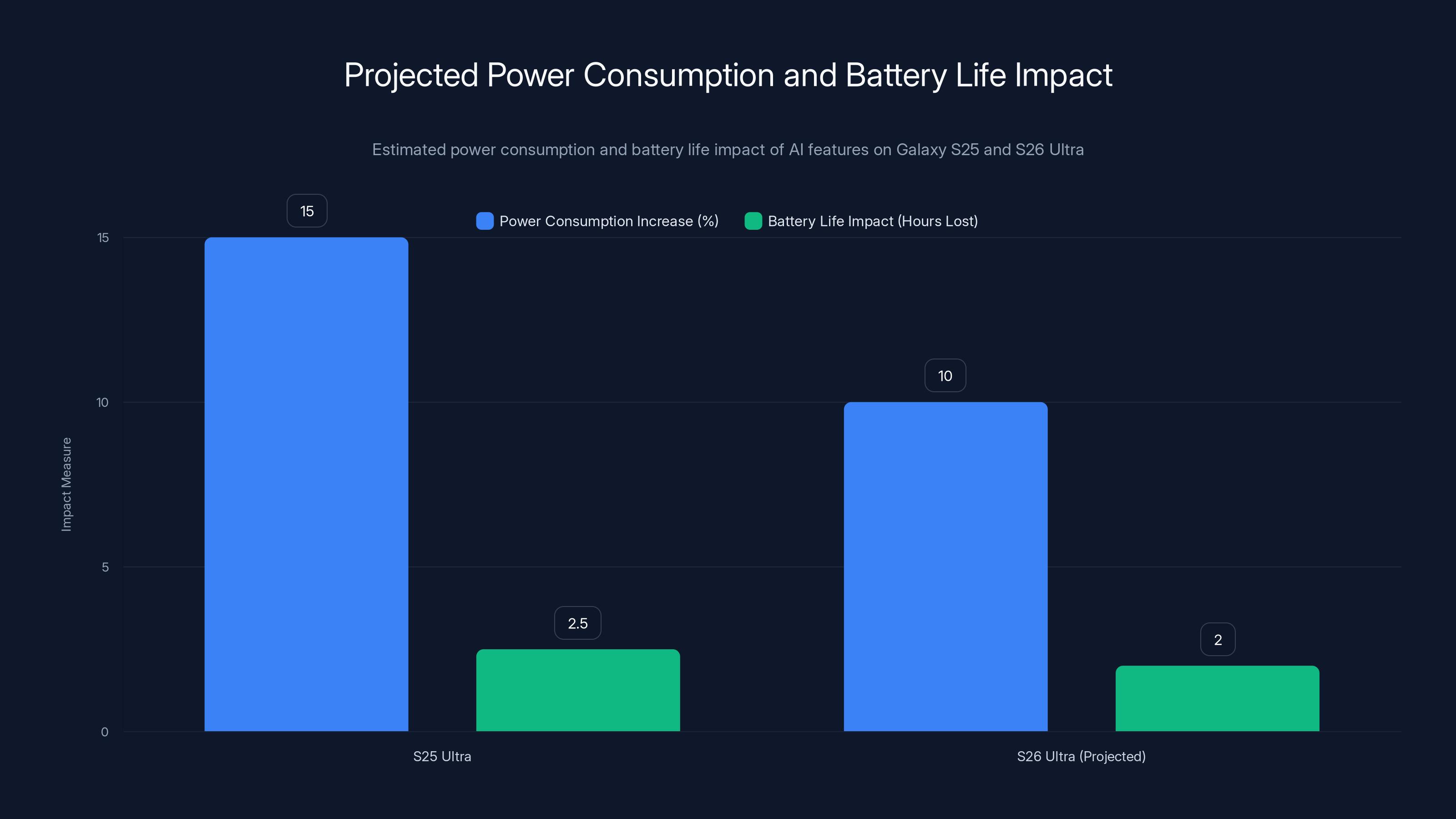

More realistically, Samsung will likely include incremental improvements to the Galaxy S26 Ultra's battery: possibly increasing capacity from 5,000 mAh to 5,500-6,000 mAh through refined silicon-graphite anodes and optimized cathode materials, improving energy efficiency through processor and display optimizations, and potentially implementing faster charging protocols. These enhancements might deliver 15-20% longer battery life compared to the current generation—meaningful but evolutionary rather than revolutionary.

The more transformative 20,000 mAh batteries would appear in subsequent generations, possibly in the Galaxy S27 Ultra (2027) or dedicated ultra-premium variants (potentially an S Ultra Max) that prioritize battery life above traditional premium features like thinness. Samsung has precedent for this strategy: the Galaxy Note series historically prioritized size and battery capacity over the mainstream S series.

Realistic Battery Life Projections for S26 Ultra

Current Galaxy S25 Ultra delivers approximately 22-24 hours of typical usage with mixed activities (social media, email, light gaming, photography). With a 6,000 mAh battery (assuming conservative S26 upgrades) and 10% efficiency improvements across processor and display, the S26 Ultra might achieve 28-32 hours of usage on a single charge.

This represents meaningful progress but falls far short of the weeks-long battery life that consumer imagination attaches to 20,000 mAh batteries. The gap reflects physical reality: software and hardware efficiency improvements follow diminishing returns, and processor power demands inevitably increase with new capabilities (enhanced AI features, ray-tracing gaming, computational photography).

Fast charging would likely remain in the 45-65W range rather than seeing revolutionary improvements. Faster charging generates heat that stresses batteries; Samsung balances charging speed against long-term battery health, knowing that warranty claims spike if devices ship with batteries that degrade to 80% capacity within 18 months.

Design Implications for S26 Ultra

If Samsung increases battery capacity modestly (to 5,500-6,000 mAh) while maintaining or even slightly reducing thickness, this requires aggressive energy density improvements. The physics works out: a 7-10% thickness reduction to maintain current form factor, combined with 10-15% energy density improvements, enables roughly 5% additional capacity without thermal concerns.

Samsung's historical approach involves reallocating internal space through processor optimization and component consolidation. The Snapdragon 8 Elite and equivalent Samsung processors are becoming increasingly efficient, consuming less power per computational operation. This creates budget for slightly larger batteries while managing thermal profiles.

Design-wise, the S26 Ultra will likely maintain continuity with the current generation: premium materials (glass/metal), refined camera module design, and possibly slightly improved water resistance (moving from IP68 to potentially IP69K). The battery will remain invisible to users, with Samsung hiding its advances in internal engineering rather than external form factor changes.

Comparative Analysis: Battery Technology Across Competitors

Apple's Battery Approach and iPhone 16 Pro Max Performance

Apple ships the iPhone 16 Pro Max with a 4,685 mAh battery delivering approximately 19.5 Wh of energy. This capacity seems modest compared to Android flagships, yet the iPhone 16 Pro Max consistently achieves comparable battery life through aggressive optimization. The A18 Pro processor, manufactured on 3nm process technology, delivers exceptional efficiency. Apple's control over hardware-software integration enables fine-tuned power management that third-party Android manufacturers struggle to match.

Apple's approach to battery scaling differs philosophically from Samsung's. Rather than pursuing massive capacity increases, Apple invests in efficiency gains that reduce power consumption to the point where smaller batteries suffice. This strategy keeps devices thin and light—qualities Apple marketing emphasizes—while maintaining competitive battery life.

However, Apple faces criticism from users demanding larger batteries. The company's physics-first approach (smaller, more efficient batteries rather than larger packs) works well for many users but frustrates power users expecting all-day gaming and photography without charging. Apple's reported interest in lithium-metal anodes and potential solid-state batteries by 2028-2030 suggests the company recognizes that efficiency alone won't sustain competitive battery life as processors become more powerful and AI features more demanding.

Google Pixel 9 Pro XL and Optimization Philosophy

Google's Pixel 9 Pro XL carries a 5,550 mAh battery (approximately 21.0 Wh), positioning between Samsung and Apple. Google's Tensor processor, while not matching Apple's efficiency metrics, benefits from extensive software optimization. The Pixel's pure Android experience, without Samsung's One UI overlay, reduces background processing and enables more aggressive power management.

Google's strategy emphasizes adaptive battery algorithms that learn user patterns and preemptively manage power consumption. Rather than pursuing absolute capacity leadership, Google focuses on intelligent power allocation, a philosophy that differentiates the Pixel from competitors. However, raw battery capacity remains competitive with Samsung, suggesting Google views capacity increases alongside efficiency as necessary for premium positioning.

Google has not publicly disclosed advanced battery research comparable to Samsung's. The company likely relies on battery suppliers' roadmaps rather than developing proprietary battery chemistry, a strategic difference reflecting different organizational capabilities and market focus.

Xiaomi and OnePlus: Aggressive Capacity Strategies

Xiaomi's flagship devices push battery capacity to extremes: the Xiaomi 14 Ultra features a 5,300 mAh battery, while rumors suggest upcoming Xiaomi models will approach 6,000 mAh or higher. OnePlus similarly pursues larger batteries, with the OnePlus 12S carrying a 5,400 mAh pack. These manufacturers prioritize capacity over form factor considerations, resulting in slightly thicker devices that consumers increasingly accept.

This strategy creates a market segmentation: premium brands (Apple, Samsung in their S-series positioning) emphasize thinness and material quality, while manufacturers competing on value proposition (Xiaomi, OnePlus) lean into battery capacity. Consumers choosing between a 7.8mm iPhone and a 8.8mm Xiaomi increasingly favor the Xiaomi's substantial battery advantage for the marginal thickness cost.

Samsung risks being positioned between these extremes: unwilling to match Xiaomi's capacity-first approach, yet facing pressure to demonstrate battery leadership against competitors. The 20,000 mAh testing signals Samsung's intent to reclaim battery technology leadership, though product execution will determine whether this translates to consumer advantage.

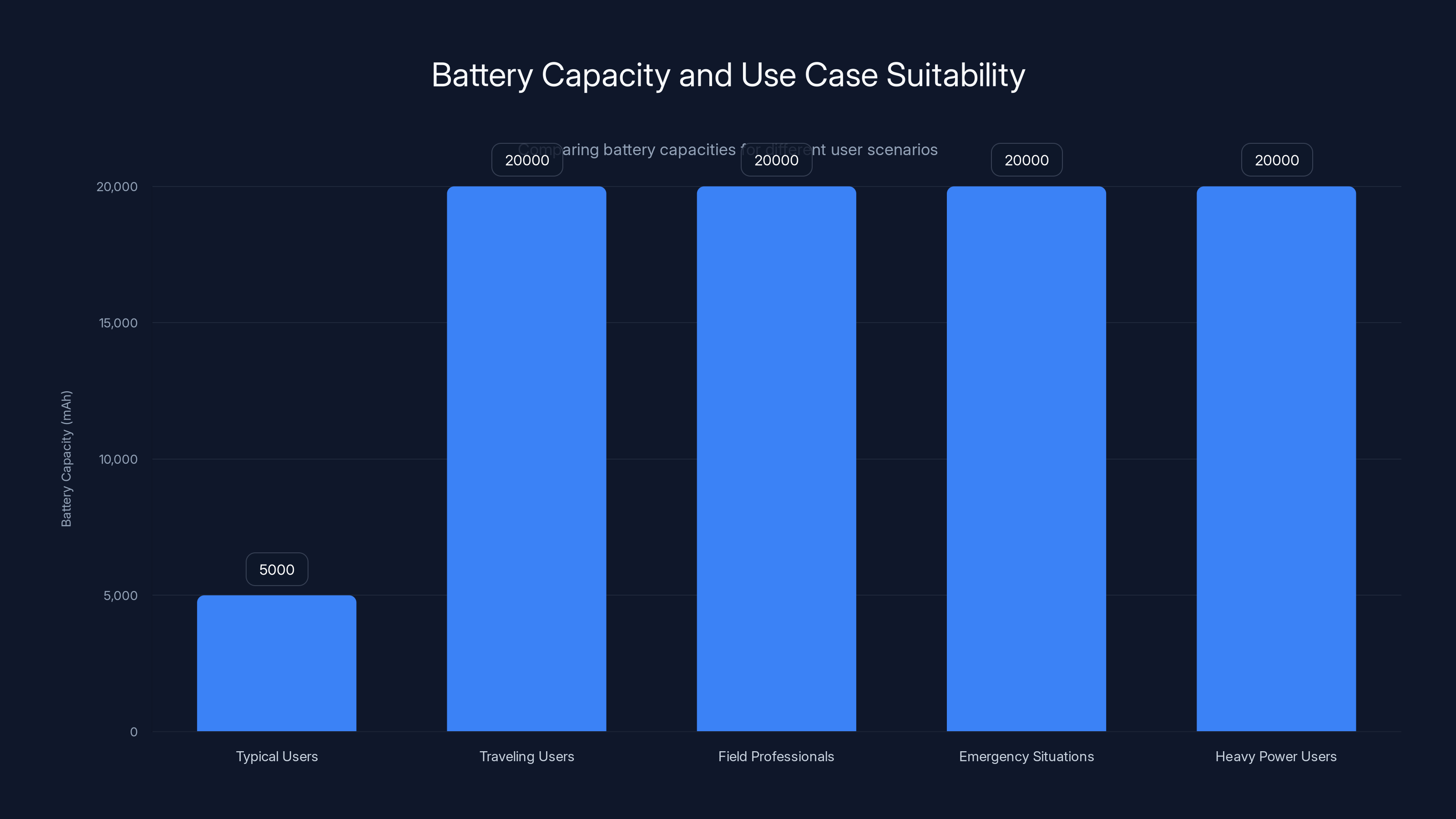

A 20,000 mAh battery is essential for traveling users, field professionals, emergency situations, and heavy power users, offering 3-5 days of usage without charging. Estimated data.

The Science of Battery Efficiency: Why Capacity Alone Is Insufficient

Power Management and Software Optimization

A battery's subjective performance depends on two variables: capacity and power consumption. A 5,000 mAh battery in a power-efficient device can outperform a 6,000 mAh battery in a power-hungry device. This is where software optimization and processor architecture become critical.

Processor power consumption follows the equation: P = CV²f, where C is capacitance, V is voltage, and f is frequency. Modern chips reduce power consumption through lowering V (voltage) and f (clock frequency) during idle periods, increasing transistor count for more efficient processing at lower frequencies, and using specialized processing units (AI accelerators, encryption engines) that consume less power than general-purpose computation.

Samsung's Exynos processors and licensed Snapdragon chips have historically lagged Apple's A-series in efficiency metrics. This gap reflects manufacturing process node differences (Apple typically leads by one generation) and architectural philosophy. However, the efficiency gap is narrowing: the latest flagship processors from Samsung and Qualcomm are achieving 60-75% of Apple's efficiency (measured in performance per watt), a substantial improvement from previous generations at 40-50%.

This efficiency convergence is crucial to understanding battery outlook. If Samsung can match Apple's efficiency through next-generation processors and optimized software (One UI refinements), 5,500 mAh batteries would deliver battery life comparable to 6,500 mAh batteries in competitors' phones. The path to substantially longer battery life doesn't require 20,000 mAh batteries—it requires synchronized improvements across processor efficiency, display optimization, and software power management.

Display Technology Impact on Overall Power Consumption

Display power consumption typically accounts for 30-40% of total device energy consumption during active use. The Galaxy S25 Ultra uses 2K AMOLED technology with 120 Hz refresh rate, consuming approximately 4-6 watts at moderate brightness. This is acceptable but represents significant power draw compared to the processor's 3-5 watts peak consumption.

Next-generation displays offer efficiency gains:

- LTPO (Low-Temperature Polycrystalline Oxide) technology: Dynamically adjusts refresh rates between 1 Hz and 120 Hz based on content, reducing power consumption during static displays by 15-25%

- Improved OLED efficiency: New organic materials and pixel designs could deliver 20-30% power reduction while maintaining brightness

- Micro-LED exploration: Samsung is researching micro-LED displays that could deliver 40-50% better efficiency than current OLED, though mass production remains 3-5 years away

The realistic scenario for the Galaxy S26 Ultra involves adopting refined LTPO technology and optimized OLED materials, delivering approximately 10-15% lower display power consumption. Combined with processor efficiency improvements (another 8-12% reduction) and software optimization (5-8% reduction), total device power consumption could decrease by 25-35% without increasing battery capacity. Alternatively, maintaining power consumption while increasing capacity to 5,500-6,000 mAh would deliver 35-50% longer battery life—genuinely transformative without requiring revolutionary battery chemistry.

Thermal Efficiency and Heat Dissipation

Battery efficiency degrades with temperature. Lithium-ion batteries operate optimally between 15-35°C. At 40°C, charging efficiency drops by approximately 3-5%, and discharge efficiency diminishes by similar percentages. At 50°C, capacity loss becomes substantial, and cycle life degradation accelerates. This is why thermal management—maintaining optimal operating temperature—directly impacts battery longevity and effective capacity.

Samsung's thermal management approach uses graphite sheets, copper layers, vapor chambers, and phase-change materials to distribute heat from the battery and processor to the aluminum frame, where it dissipates through radiation and conduction to the environment. More sophisticated thermal designs can reduce internal temperatures by 5-10°C under peak load, which translates to 3-5% efficiency improvements and 10-15% longer cycle life.

The Galaxy S26 Ultra will likely feature incrementally improved thermal management—possibly more extensive copper layers, optimized vapor chamber design, or novel phase-change materials—delivering measurable efficiency gains without requiring revolutionary technology.

Manufacturing and Supply Chain Implications

Battery Cell Production Capacity and Sourcing

Samsung SDI, the company's battery division, operates production facilities in South Korea, China, and Hungary, with combined annual capacity exceeding 200 GWh. This production capacity serves Samsung's internal demands (smartphone, tablet, wearable divisions) and third-party customers (automotive, energy storage). Introducing 20,000 mAh batteries into production would require substantial capacity allocation and process line modifications.

Battery cell production follows a simplified process: electrode coating, cell assembly, electrolyte filling, formation cycling, and quality testing. Each stage requires precise environmental control, equipment calibration, and consistency verification. Introducing new chemistry batteries necessitates:

- Equipment retrofitting: Coating machines optimized for silicon-graphite anodes, electrolyte dispensing systems calibrated for new electrolyte formulations

- Process validation: Extended test runs confirming yield rates, performance consistency, and safety across batches

- Supply chain development: Sourcing silicon powder (or composite materials), novel cathode materials, and specialized electrolytes from qualified suppliers

- Quality assurance: Implementing new testing protocols, failure mode analysis, and customer satisfaction metrics for novel battery chemistries

Historically, introducing new battery chemistry requires 12-24 months of production ramp-up before achieving target yield rates. Samsung would need to allocate significant capacity (potentially 10-20% of total production) to 20,000 mAh batteries. This has supply chain ripple effects: reduced capacity for existing battery sizes, potential allocation issues during shortage periods, and higher product cost due to new process overhead.

Raw Material Sourcing and Cost Implications

Battery material costs constitute 40-50% of total battery production cost, with pricing sensitive to commodity markets and supply chain disruptions. Key materials affected by 20,000 mAh battery deployment:

Lithium: Current price approximately

Nickel: High-nickel cathodes increase nickel content. Current nickel pricing (~

Silicon: If silicon-graphite anodes become standard, silicon supply becomes critical. Currently, silicon powder production is supply-constrained. A 20,000 mAh battery might incorporate 2-4 grams of refined silicon, adding $0.40-0.80 per battery in raw material cost. Mass adoption by Samsung and competitors could strain silicon supply, driving prices higher.

Cobalt: Controversially sourced from Central Africa with ethical and environmental concerns, cobalt represents a sustainability liability. Samsung's move toward cobalt-free or cobalt-reduced chemistries (NCMA, NCA variants with reduced cobalt) aligns with corporate responsibility goals, but alternative cathode materials haven't yet demonstrated equal cycle life and manufacturing maturity. This represents a genuine tension between material cost, performance targets, and corporate values.

Combining material cost increases across lithium, nickel, and silicon, a 20,000 mAh battery would cost approximately

Real-World Battery Degradation and Longevity Expectations

Cycle Life and Capacity Retention Over Time

Battery degradation follows predictable patterns. A smartphone battery typically retains 80% of original capacity after 500-1,000 complete charge cycles, depending on chemistry, thermal management, and usage patterns. Users typically achieve this degradation threshold within 18-24 months of typical use (roughly 1-2 charge cycles daily).

A 20,000 mAh battery faces identical degradation rates, meaning after 18-24 months, it would retain approximately 16,000 mAh of capacity—still substantially larger than today's fresh 5,000 mAh batteries. This suggests that even after significant degradation, 20,000 mAh batteries would maintain usable performance advantages.

However, manufacturers must factor degradation into warranty terms and reliability expectations. Samsung's current batteries carry an implicit expectation of 80%+ capacity retention after 18 months. Introducing 20,000 mAh batteries with worse degradation characteristics would damage consumer satisfaction. Therefore, Samsung's chemistry development must achieve degradation rates matching or exceeding current standards—a constraint that complicates new material development.

Fast charging significantly accelerates degradation. Batteries charged at 45W experience 15-20% more capacity loss over 500 cycles compared to 20W charging. This creates strategic tension: larger batteries enable longer usage, but rapid charging of those larger batteries accelerates degradation. Realistic deployment might involve slower charging recommendations (or automatic 25W charging caps) for 20,000 mAh batteries, mitigating thermal stress and extending lifespan.

Environmental Factors and Real-World Performance

Laboratory battery ratings assume room temperature (20-25°C) operation. Real-world conditions diverge substantially. In summer heat (particularly in phones left in sunlight), internal temperatures exceed 45-50°C, reducing battery efficiency and accelerating degradation. Winter cold (below 5°C) temporarily reduces available capacity—cold batteries cannot discharge as rapidly, manifesting as sudden power-offs despite reported charge remaining.

A 20,000 mAh battery faces identical environmental challenges. A phone charged to 100% in winter conditions might exhibit only 85-90% usable capacity until warmed to operating temperature. Users in hot climates (common in India, Middle East, Africa) would experience accelerated degradation. This isn't a technology problem but a physics reality that no engineering can eliminate.

Samsung's device design must account for these factors. Improved thermal management (discussed earlier) helps, but cold-start performance and summer degradation mitigation requires software contributions: disabling fast charging below certain temperatures, throttling processor performance in high-temperature conditions, and conservative capacity reporting in thermal extremes.

The Galaxy S26 Ultra is projected to have a 10% power consumption increase due to AI features, with an estimated 2-hour battery life reduction. Estimated data.

Integration With AI Features and Emerging Workloads

AI Processing Demands and Power Profiles

Smartphone AI capabilities have expanded dramatically with machine learning accelerators built into modern processors. The Galaxy S25 features the Exynos 2500 (or Snapdragon 8 Elite) with dedicated neural processing units (NPUs) enabling on-device AI operations. These accelerators are highly efficient (consuming 1-3 watts for inference operations), but aggregate AI workload demands have increased.

New features like on-device transcription, real-time language translation, computational photography (image upscaling, noise reduction), and AI assistant interactions collectively consume significant power. A typical user activating these AI features might increase average power consumption by 10-20% compared to 2024 devices. Over a day, this translates to equivalent loss of 2-3 hours of battery life without corresponding capacity increases.

A 20,000 mAh battery addressed to this problem would absorb AI workload increases, enabling users to employ these features without battery anxiety. However, the timeline is important: Samsung's AI ambitions are accelerating faster than battery development. If Samsung ships S26 Ultra with substantially expanded AI features but only modestly larger batteries (5,500 mAh), battery life might actually decrease relative to S25 Ultra despite larger capacity.

Realistic expectations: The S26 Ultra will ship with slightly larger batteries and enabled AI features, with net battery life approximately equal to or 10-15% improved versus S25 Ultra. Genuinely transformative battery life (truly all-day heavy use with AI features maximized) likely requires the combination of:

- Larger batteries (6,000+ mAh through 2026 technology)

- More efficient AI processors (NPUs consuming 30-40% less power)

- Optimized software (smarter feature throttling, scheduled processing)

- Improved thermal efficiency (allowing processors to maintain performance longer)

Samsung is pursuing all four vectors simultaneously, but they're all progressing on different timelines. The intersection of all four reaching maturity simultaneously would represent the most favorable scenario for battery life improvement.

Always-On Display and Ambient Computing Impact

Always-on displays (showing time, weather, notifications without full screen activation) have become standard in premium devices. Samsung's Dynamic AMOLED 2X displays enable always-on functionality with minimal power consumption (0.2-0.5 watts compared to 5-6 watts for full brightness operation). However, cumulative power consumption of always-on features (always-listening microphones for voice commands, location services, synchronization background tasks) creates a baseline power draw even when the device appears idle.

A modern smartphone in pure standby mode (screen off, no user interaction) consumes approximately 50-150 mW of power—enough to drain even a 20,000 mAh battery over 50-100 days without user intervention. This explains why older phones sometimes seem to discharge overnight: accumulated background tasks and ambient computing features consume power even in apparent standby.

Samsung's software optimization roadmap includes aggressive background task management, potentially reducing baseline power consumption by 20-30%. Combined with larger batteries, this would meaningfully extend stand-by duration and reduce the psychological impact of devices appearing drained after a few days of light use.

Regulatory and Safety Certification Challenges

International Battery Standards and Testing

Batteries must comply with numerous international standards before reaching market:

IEC 62619: Specifies testing for secondary batteries used in portable sealed apparatus. Requires verification of voltage stability, self-discharge rates, capacity measurements, and cycle life testing. A battery passing IEC 62619 is certified safe for consumer electronics.

UN 38.3: Addresses transportation safety for batteries containing hazardous materials. Lithium-ion batteries pose fire risk if damaged or short-circuited. Batteries destined for air transport must pass rigorous testing including thermal testing (heating to 20°C above max operating temperature), vibration testing (simulating shipping stresses), and short-circuit testing.

UL 2054: The Underwriters Laboratories standard for batteries used in consumer electronics. Mandates safety margins, thermal abuse testing, external short-circuit testing, and mechanical shock testing. Non-compliance can result in product recalls and manufacturer liability.

Introducing new battery chemistry—particularly silicon-dominant anodes or solid-state electrolytes—requires extensive certification testing. A 20,000 mAh battery with novel materials might require 6-12 months of dedicated testing to achieve compliance with all standards. This cannot be parallelized with product design (the battery must be certified before final device design can lock specifications), creating critical path compression in Samsung's S26 Ultra development.

Thermal Runaway and Safety Margins

Lithium-ion batteries can experience thermal runaway if internal temperature exceeds critical thresholds. A separator (porous plastic layer between anode and cathode) melts at approximately 130-150°C, collapsing the cell structure, short-circuiting electrodes, and generating intense heat. If internal shorting causes temperatures to exceed 200°C, chemical decomposition of the electrolyte initiates exothermic reactions, potentially causing fire or explosion.

Safety devices in modern batteries—such as positive temperature coefficient (PTC) resistors and thermal fuses—disconnect the battery if temperature exceeds safe thresholds. However, these safety mechanisms are imperfect and operate with response delays. Batteries designed with larger capacity and higher energy density inherently contain more energy capable of being released in a failure scenario. A 20,000 mAh battery represents approximately 4 times the stored energy of a 5,000 mAh battery, meaning potential thermal runaway energy release is proportionally larger.

Samsung must ensure that safety mechanisms for 20,000 mAh batteries operate with equivalent reliability (or better) compared to existing designs. This might require design improvements:

- Larger separator materials with higher melting point stability

- Multiple thermal fuses positioned across the battery to ensure cascade failure doesn't propagate

- Improved electrode materials that are chemically stable at higher temperatures

- Enhanced electrolyte formulations with wider electrochemical stability windows

These improvements increase manufacturing complexity and cost, contributing to the reason why 20,000 mAh batteries haven't yet reached mass production.

Alternative Battery Chemistries Beyond Lithium-Ion

Lithium-Metal Anode Advantages and Challenges

Lithium-metal anodes replace the graphite structure with pure lithium foil, eliminating the need for lithium ions to intercalate into graphite. This fundamentally improves energy density: a lithium-metal battery delivering the same energy density as graphite would weigh 20-30% less, or deliver 20-30% more energy at equivalent weight.

However, lithium metal exhibits severe stability challenges. During charging, lithium ions plate onto the anode surface in non-uniform crystalline formations called dendrites. These dendrite structures eventually reach the separator, short-circuiting the cell and causing catastrophic failure. Simultaneously, lithium metal reacts with conventional organic electrolytes, forming unstable surface layers that increase internal resistance and prevent normal ion transport.

Samsung's lithium-metal battery research focuses on electrolyte engineering to suppress dendrite growth. The company has published research on solid polymer electrolytes and ceramic-based electrolytes that physically prevent dendrite propagation while maintaining ionic conductivity. Laboratory prototypes have demonstrated dendrite-free operation across 500+ charge cycles, a major breakthrough. However, scaling this to commercial manufacturing remains unsolved: producing separator-less solid-state cells at the precision and yield rates necessary for billions of devices annually requires innovations in coating, lamination, and cell assembly that don't yet exist.

Lithium-Sulfur and Lithium-Air Concepts

Theoretically superior battery chemistries exist on research timelines:

Lithium-sulfur: Uses sulfur (an abundant, low-cost element) as the cathode material. Sulfur has exceptionally high theoretical energy density—approximately 2,600 Wh/kg—compared to lithium-ion at roughly 250-300 Wh/kg. A lithium-sulfur battery could theoretically deliver 8-10 times the energy density.

Practical barriers are substantial. Sulfur cathodes suffer from polysulfide dissolution—sulfur reacts with the electrolyte, forming molecules that migrate to the anode and decompose, causing rapid capacity loss. Lithium-metal anodes (required for lithium-sulfur chemistry) face the dendrite challenges mentioned above. Current laboratory prototypes achieve only 100-300 charge cycles before capacity drops below usable thresholds, compared to the 1,000+ cycles required for consumer devices.

Lithium-air: Uses oxygen from ambient air as the cathode reaction partner, theoretically enabling energy densities exceeding 1,000 Wh/kg—revolutionary by current standards. However, ambient oxygen introduces atmospheric moisture and contaminants into the battery, severely compromising performance and safety. Practical lithium-air batteries require complex air filtration and oxygen management systems that negate many theoretical advantages.

Both lithium-sulfur and lithium-air remain firmly in the research phase, likely 5-10+ years from commercial viability. Samsung's roadmap focuses on near-term improvements (lithium-metal, solid-state) rather than speculative far-future chemistries.

A 20,000 mAh battery can theoretically provide up to 76 hours of runtime, assuming a 1-watt power draw, highlighting the significant increase in potential device usage time with higher capacities. Estimated data.

Market Impact and Consumer Adoption Timeline

Realistic Deployment Expectations

Based on Samsung's disclosed roadmap, battery technology development timelines, and manufacturing constraints, here's a realistic deployment schedule:

2025-2026 (Galaxy S26 era): Incremental improvements—battery capacity increasing to 5,500-6,000 mAh, energy density improving 8-12% through refined silicon-graphite anodes and optimized cathodes. Battery life improvement: 15-25% relative to S25 Ultra. No fundamental chemistry changes.

2027-2028 (Galaxy S27-S28 era): Introduction of lithium-metal anode batteries in initial production runs, initially deployed to selected markets or configurations. Capacity potentially reaching 7,000-8,000 mAh with equivalent or slightly improved dimensions. Manufacturing yields still ramping, product cost premium substantial ($30-50 per device). Solid-state battery initial production announcements, likely limited to early adopter segments.

2029-2030 and beyond: Widespread deployment of solid-state lithium-metal batteries, capacity potentially reaching 10,000-12,000 mAh with substantial efficiency and form-factor improvements. Manufacturing scaled to mainstream production volumes, pricing competitive with conventional lithium-ion. True multi-day battery life becomes standard in flagship devices.

Post-2030: Alternative chemistries (lithium-sulfur, advanced lithium-air) potentially reaching niche commercial deployment, primarily in specific use cases (aviation, extreme durability applications) rather than mainstream smartphones.

The 20,000 mAh batteries Samsung is currently testing likely represent a target state for the 2028-2029 timeframe, with earlier commercial deployments featuring 10,000-15,000 mAh capacity. The lag between prototype development and consumer availability reflects not just technical challenges but manufacturing, supply chain, and certification complexities that consume years even after laboratory viability is demonstrated.

Competitive Responses and Market Dynamics

If Samsung successfully deploys 20,000 mAh batteries (or equivalent energy density improvements through alternative chemistries), competitors will respond:

Apple might maintain philosophical consistency, prioritizing efficiency over capacity, but would likely introduce solid-state batteries or lithium-metal variants in the 2028-2030 range to maintain energy density competitiveness.

Google would likely adopt Samsung battery technology through supply agreements, avoiding the R&D investment while maintaining feature parity.

OnePlus and Xiaomi would aggressively pursue large-capacity 20,000+ mAh batteries, marketing capacity as a core differentiator and accepting increased thickness.

This competitive response creates a virtuous cycle: larger capacity batteries become normalized, manufacturing scales up, costs decrease, and adoption accelerates. By 2030, 8,000+ mAh smartphone batteries could become standard even in mid-range devices, fundamentally shifting battery expectations.

Cost-Benefit Analysis: When Do Massive Batteries Make Sense?

Use Cases Where 20,000 mAh Becomes Necessary

For typical users with daily charging access, current 5,000 mAh batteries are fundamentally adequate. Even 5,000 mAh plus efficiency improvements delivering 30-40% longer life (roughly 30-35 hours usage) exceeds most daily requirements. A 20,000 mAh battery becomes genuinely valuable for:

Traveling users: Business travelers, digital nomads, or people in regions with unreliable power infrastructure benefit from 3-4 day battery life without charging access. A 20,000 mAh battery enabling this use case justifies device cost premium.

Field professionals: Construction workers, outdoor photographers, researchers in remote locations face charging difficulties. Devices lasting 4-5 days in harsh conditions represent genuine productivity advantages.

Emergency situations: Natural disasters, power outages, or emergency response scenarios where charging infrastructure is unavailable. Extended battery life becomes a safety feature.

Heavy power users: Mobile gamers playing for 6-8 hours daily, content creators running intensive editing software, or users maximizing AI features benefit from larger batteries. Current flagships approaching capacity limits for these users.

For these specific use cases, a 20,000 mAh battery would command premium pricing—potentially $100-200 additional—without resistance. The mass market of typical users (2-3 hour daily phone usage with convenient charging) would likely prefer thinner, lighter devices with 6,000 mAh batteries over thicker devices with 20,000 mAh capacity.

![Samsung's 20,000 mAh Battery Innovation: Galaxy S26 Ultra Implications [2025]](https://tryrunable.com/blog/samsung-s-20-000-mah-battery-innovation-galaxy-s26-ultra-imp/image-1-1767006801788.jpg)