The $7,999 Laundry Robot Problem: Why AI Isn't Ready Yet

Imagine paying nearly eight grand for a robot that folds your laundry. Sounds great, right? You dump a load in, walk away, and boom—perfectly folded clothes waiting for you later. Except there's a catch. Actually, there are several catches.

Weave's Isaac 0 robot launched with serious limitations. It can't handle large blankets, fitted sheets, or clothes that are inside out. It takes 30 to 90 minutes to fold a single load. And despite being marketed as "autonomous," it still needs human teleoperators to jump in and fix folds it messes up.

This isn't a failure of engineering alone. It's a window into why household robots are way harder to build than anyone thought. We've been promised home robots for decades. Boston Dynamics shows us videos of robots doing backflips. Tesla talks about humanoid servants becoming as common as dishwashers. But when it comes to actually doing laundry in your house, we're stuck with machines that need a human babysitter.

So what's actually going on with laundry robots? Why is folding clothes still such a nightmare for artificial intelligence? And should you seriously consider dropping eight thousand dollars on this thing?

Let's break it down.

TL; DR

- Isaac 0 costs $7,999 but can only fold certain clothing items and requires human teleoperator assistance

- Current laundry robots can handle maybe 60-70% of real-world laundry situations, making them impractical for most households

- The fundamental problem is complexity: fabric types, wrinkles, inside-out garments, and edge cases require dexterity and problem-solving that AI hasn't mastered

- Human teleoperators add significant ongoing costs to these systems, undermining the "automation" value proposition

- The market is exploding anyway: LG, Switch Bot, and other major players are racing to launch laundry robots despite these limitations

- Real household adoption will require 85%+ success rates, which we're probably 3-5 years away from achieving

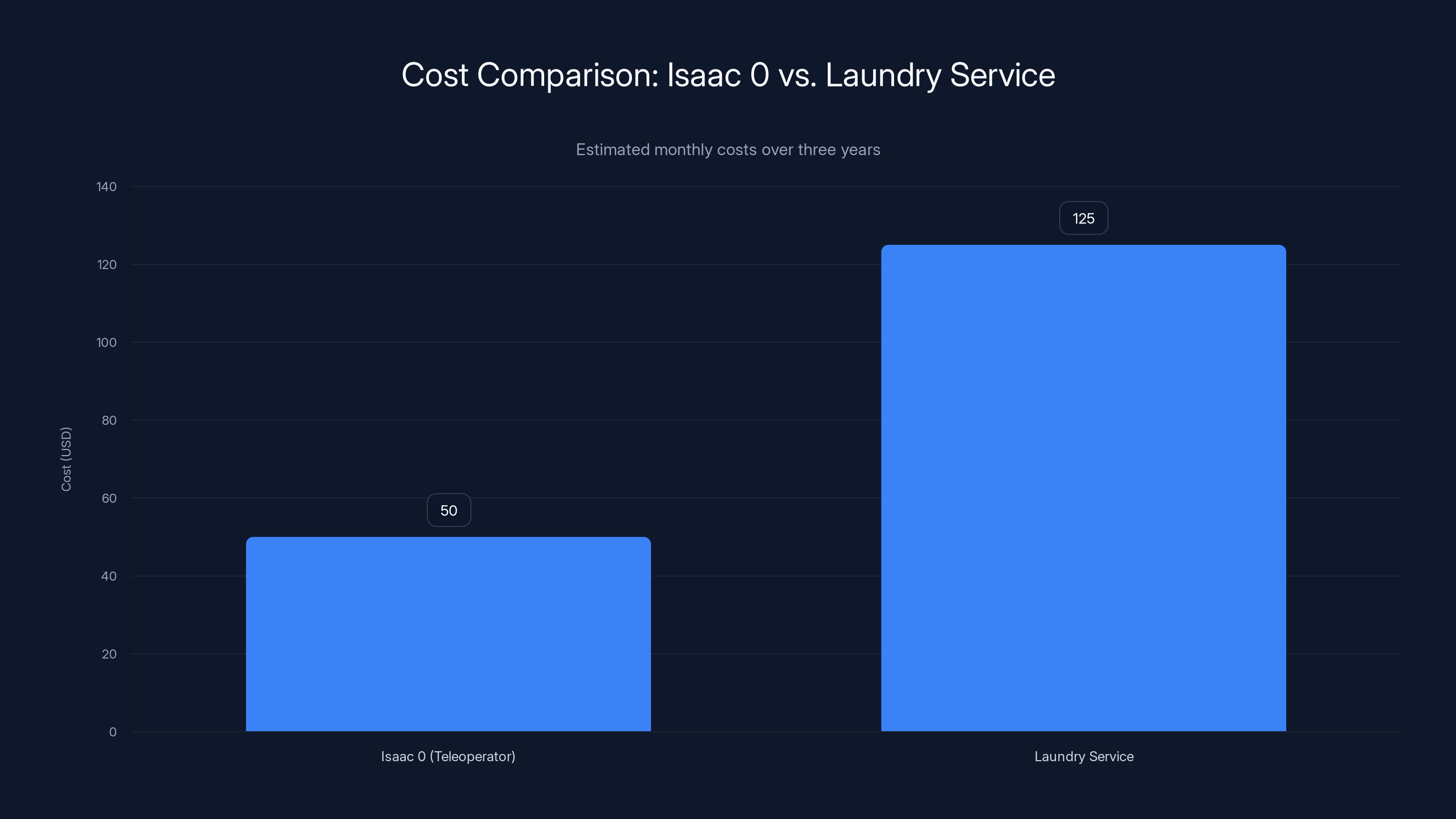

Isaac 0's teleoperator service costs an estimated

What Is Isaac 0, Really?

Weave's Isaac 0 isn't some sleek humanoid robot wandering around your laundry room. It's stationary. It sits on your counter or table, plugs into a regular wall outlet, and does one specific job: folds clothes that humans feed it.

Think of it as a precision machine with a very narrow skill set. The robot has a single arm with multiple end-effectors (fancy word for grippers and manipulation tools). It uses vision systems to identify fabric, detect edges, and plan folds. On the software side, it's running computer vision algorithms trained to recognize clothing types and determine optimal folding sequences.

Weave claims the robot can handle t-shirts, socks, pants, towels, and light jackets. The company says it'll fold a basket of laundry in 30 to 90 minutes, depending on fabric types and complexity. For comparison, a human folds the same load in about 15-20 minutes, working at a leisurely pace while watching Netflix.

But here's what makes Isaac 0 interesting from a technical standpoint. The robot isn't trying to be a general-purpose humanoid. It's purpose-built. Weave designed it specifically for one task, optimizing every sensor and actuator for that mission. This focused approach makes more sense than trying to build a robot that does everything poorly.

The catch? Even with this singular focus, the robot still needs babysitting. Weave employs teleoperators who monitor the robot's work and take over when things get weird. A sheet starts bunching up. The robot gets confused. A human jumps in, straightens things out, and the robot learns. Over time, the company says performance improves.

This teleoperator model is crucial to understand. It's not fully autonomous. It's not plug-and-play. It's semi-autonomous, which is a polite way of saying "a human is fixing the robot's mistakes in real time."

The Fabric Problem: Why Clothes Are Harder Than Robots

Let's talk about why folding laundry breaks robots. On the surface, it seems simple. Pick up fabric, identify the pattern, fold along certain lines, smooth it out. A toddler can do it. So why can't a multi-million-dollar robot company solve this?

Fabric is deceptively complex. Unlike hard objects like boxes or books, fabric is deformable. It stretches, wrinkles, clings to itself, and moves in unpredictable ways. When you fold a shirt, you're constantly adjusting for fabric behavior. You feel tension. You anticipate how the material will collapse. You correct course mid-fold based on real-time feedback.

Robots struggle with this. Computer vision alone isn't enough. The robot needs to understand fabric properties, predict how material will move, and adjust grip strength and arm position in real time. Current systems can't do all three simultaneously with high reliability.

Then there's the variety problem. Your laundry isn't uniform. You've got cotton t-shirts, silk blouses, stretchy athletic wear, stiff jeans, delicate lingerie, thick towels, and weird-shaped underwear. Each material behaves differently. A grip pressure that works for jeans will tear a silk shirt. The tension needed to fold a thick towel won't work on a t-shirt.

Isaac 0 handles this by being selective. It works with specific fabric types it's been trained on. It refuses harder items. This is honest, at least. Better to admit limitations than pretend the robot can handle everything.

But it also highlights the real barrier to consumer adoption. Most people want a robot that handles their entire laundry load. Not most of it. All of it. The moment a robot fails on one item in a basket, it becomes less useful than just folding the clothes yourself.

Here's another wrinkle: inside-out garments. When clothes come out of the dryer, some items are inverted. A robot needs to detect this, manually flip the garment, and then fold it. This requires understanding 3D spatial relationships, predicting how fabric will move when inverted, and executing the flip without tangling. Isaac 0 can't do it. The robot just skips inside-out items and leaves them for humans.

Large items are equally problematic. Fitted sheets, king-size blankets, and oversized comforters require a working surface the robot doesn't have. Weave's solution? Don't try. The company explicitly says Isaac 0 won't tackle these items. Which means if you have a standard household with standard bedding, this robot handles maybe 65-70% of your laundry load, leaving you to fold the rest anyway.

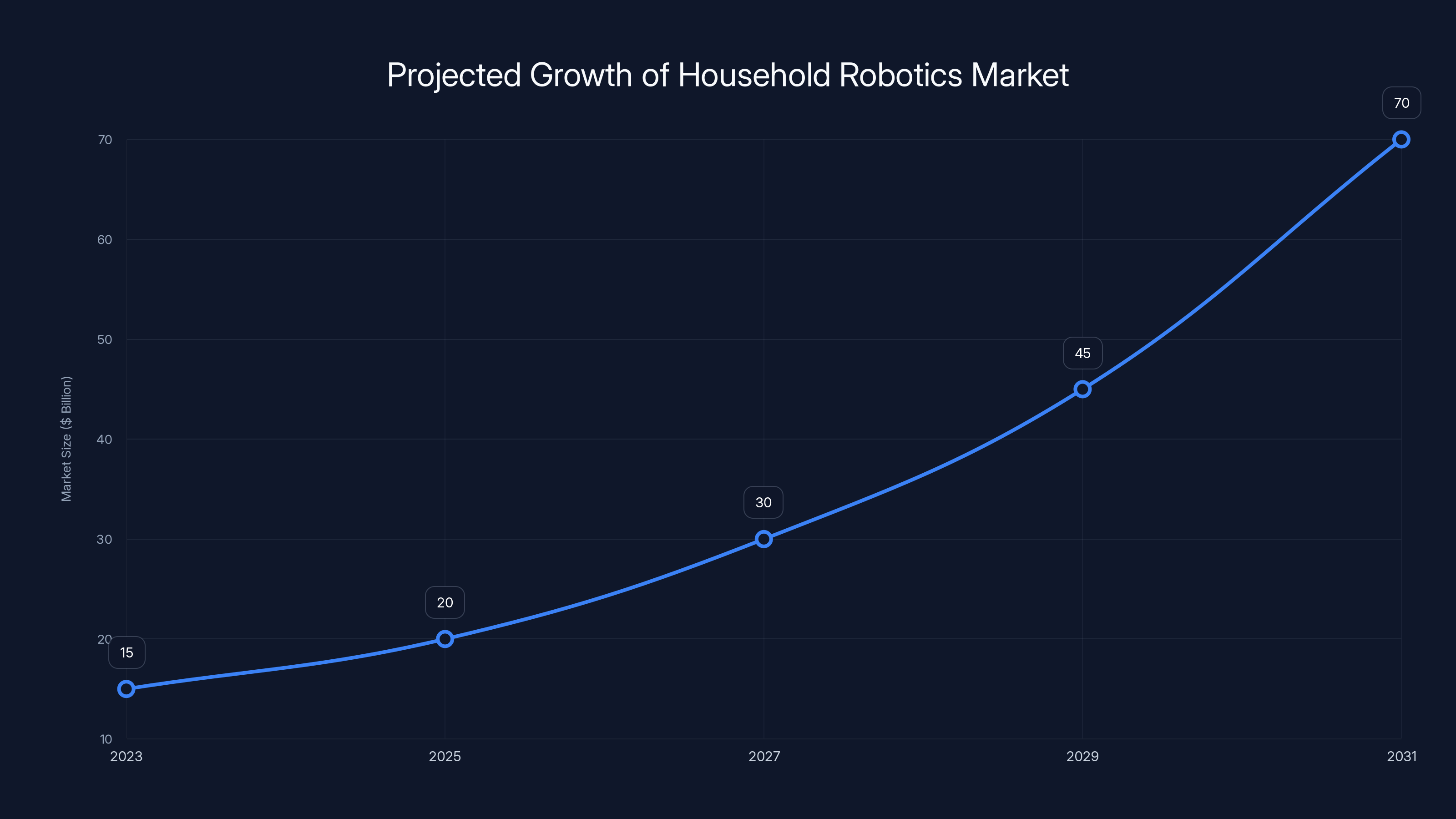

The household robotics market, including laundry robots, is projected to grow significantly, reaching $70 billion by 2031, driven by technological advancements and decreasing costs. Estimated data.

The Dexterity Gap: What We're Missing

Human hands are absurdly good at fine motor tasks. We have 27 bones in each hand, intricate tendon systems, and millions of sensory receptors feeding real-time feedback to our brains. We can feel the weight of fabric, detect folds forming, sense wrinkles, and adjust pressure unconsciously.

Robots have grippers. These are blunt instruments. Even advanced robotic grippers can't replicate the sensitivity of human touch. They can't feel fabric texture the way your fingers can. They can't make the micro-adjustments that separate a neat fold from a wrinkled mess.

Weave's Isaac 0 uses vision-based control, meaning it relies entirely on cameras to understand what's happening. If a fold is off by an inch, the vision system might miss it. By the time the next fold happens, the error compounds. What started as a small mistake becomes a noticeably bad fold.

This is why the teleoperators are essential. When the robot struggles, a human takes over, applies dexterity, fixes the issue, and lets the system learn. It's a hybrid model that basically admits: "Our robot alone isn't good enough."

The dexterity gap extends beyond folding. Hanging clothes on hangers, organizing folded stacks, and handling delicate items all require capabilities that current robots simply don't have. This is why you'll see laundry robots marketed for "assistance" rather than "replacement." They're not designed to eliminate laundry work entirely. They're designed to reduce it.

But here's the thing: consumers don't want 30% reduction. They want elimination. They want to toss laundry into a machine and forget about it for an hour. That's what washing machines and dryers do. A laundry robot that does 65% of the work is still a disappointment.

The Economics Don't Work (Yet)

Let's do the math on Isaac 0's actual cost of ownership.

Initial purchase: **

But that's not the full picture. Weave's teleoperator service isn't free. The company hasn't publicly stated pricing for ongoing support, but industry estimates suggest similar services run $30-100 per month, depending on usage.

That means if you own Isaac 0 for three years, you're paying roughly:

Over three years, assuming you save an average of 2 hours per week (folding time eliminated), that's:

104 weeks × 2 hours = 208 hours saved

At that math, you'd need to value your time at nearly $50 per hour for this to make financial sense. Most people don't value their leisure time that highly (at least not consciously).

For comparison, hiring a laundry service to pick up and fold your clothes typically costs

This is the core issue with early-stage home robotics. The economics don't pencil out yet. You're paying a premium for novelty and the promise that costs will decline as adoption scales. But that promise is speculative.

Weave will likely lower prices as production volume increases, just like every consumer electronics company does. But the fundamental cost structure of teleoperator support is hard to optimize away. You need people to monitor machines. People cost money. Until robots achieve significantly higher autonomy, this is a permanent cost.

That said, if you're in the early adopter category and have genuine mobility limitations that make laundry a physical burden, the calculus changes. For someone with arthritis, back pain, or other conditions that make standing and folding painful, $7,999 might be worth it immediately. The robot doesn't need to be perfect. It just needs to reduce your pain and burden.

But for a typical household looking for convenience? Hard pass right now.

CES 2025: The Laundry Robot Arms Race

Despite these limitations, the laundry robot market is exploding. Every major consumer electronics company is jumping in.

LG's CLOi D system uses a cabinet design where you load laundry into a chamber, close the door, and the robot handles it internally. Switch Bot's Onero H1 is a portable robot arm designed to work with laundry baskets. Electrolux announced plans for a fully integrated laundry solution. Even startups like Airsense are working on specialized systems.

Why the rush? Two reasons. First, laundry is genuinely painful. It's a problem with a large addressable market. Second, CES showcases tech that's years away from consumer availability. Companies use these announcements to generate buzz, attract investors, and test public reactions.

The demos you see at CES are optimized. The laundry is pre-sorted. The room is climate-controlled. The lighting is perfect. Real homes are messier. Dryers generate lint. Clothes tangle. Rooms vary in temperature and humidity. What works in a demo doesn't always work at scale.

But there's also genuine progress happening. Computer vision is improving rapidly. Soft robotics (robots made with flexible materials) are getting better at handling delicate items. Machine learning models trained on millions of images of folded clothes are improving accuracy.

Within 5 years, we'll probably see laundry robots that handle 80%+ of typical household loads. Maybe in 10 years, they'll handle 95%. At that point, the economics shift dramatically. A robot that eliminates 95% of laundry work is genuinely valuable, even at $8,000.

But we're not there yet.

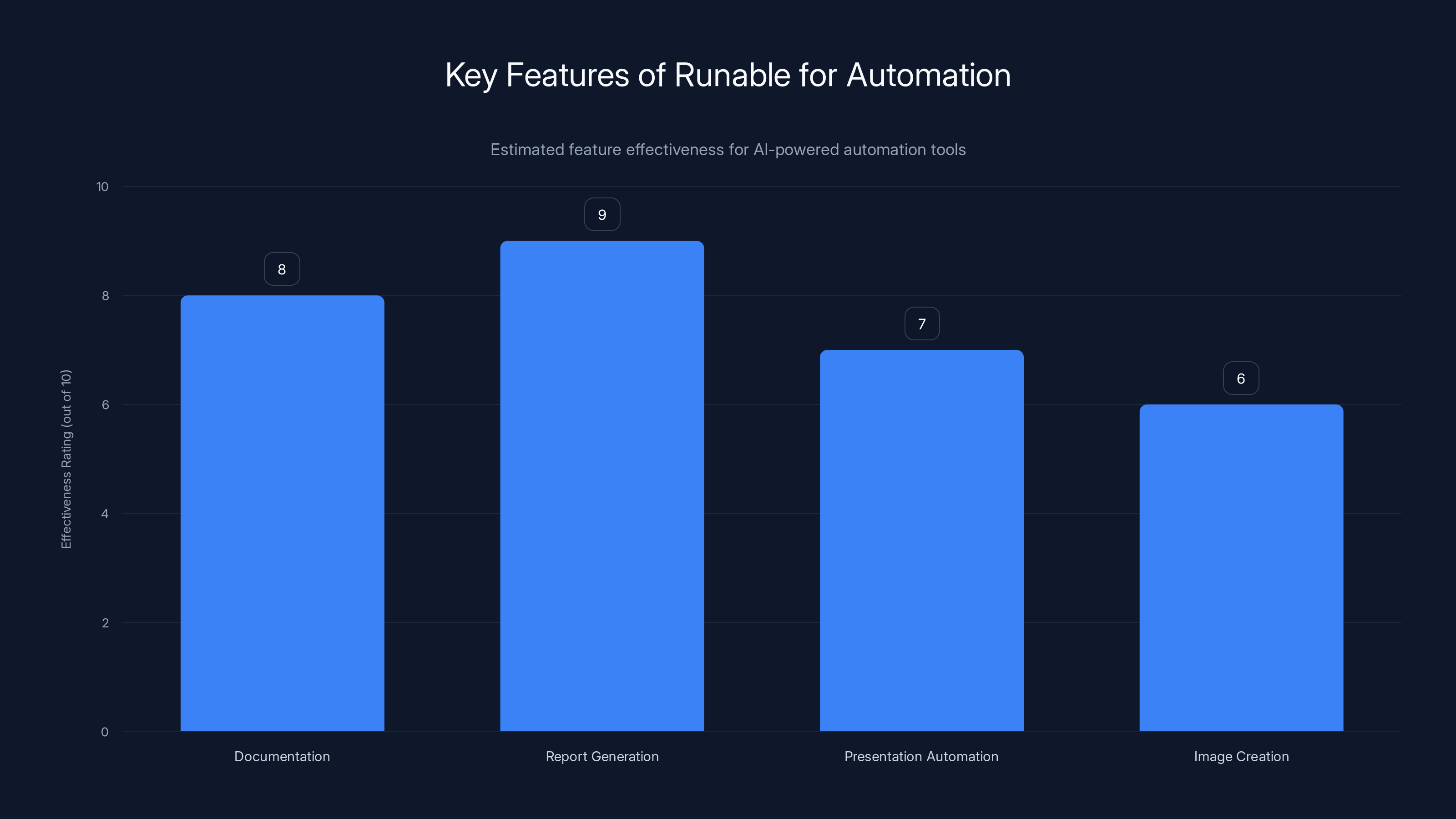

Runable offers robust AI-powered automation features, with report generation rated highest for effectiveness. Estimated data.

The Teleoperator Model: A Band-Aid Solution

Weave's reliance on teleoperators is fascinating because it reveals the current state of robotics. The company is basically admitting: "Our software isn't good enough yet, so we're hiring humans to help."

This isn't a long-term business model. It's a scaling problem. If Isaac 0 becomes popular, Weave would need to hire hundreds or thousands of teleoperators worldwide. Labor costs would skyrocket. The business becomes unsustainable.

But it's also clever. Instead of shipping a half-baked robot and hoping for the best, Weave uses humans to patch the gap. This improves the customer experience today while the company trains machine learning models on every teleoperator interaction. That data is gold. It teaches the AI exactly what humans do when the robot gets confused.

Over time, the AI learns. It handles more scenarios autonomously. Fewer teleoperator interventions are needed. Eventually, the teleoperator cost might drop from

This is a realistic path to profitability. But it requires patience. Investors get antsy when a company is paying humans to fix robot mistakes. But it's actually the most pragmatic approach available right now.

The alternative is shipping a fully "autonomous" robot that fails silently, producing terrible folds and damaging customer trust. Weave chose transparency instead, which is refreshing.

Fabric Recognition and Computer Vision

Under the hood, Isaac 0 relies on sophisticated computer vision systems. The robot uses multiple cameras to build a 3D model of the garment, identify fabric type, detect edges, and plan a folding sequence.

Fabric recognition is harder than it sounds. A camera sees color and texture, but fabric behavior depends on material properties the camera can't directly observe. Cotton folds differently than polyester. Silk drapes differently than denim. A vision system needs to infer these properties from appearance alone.

Weave has likely trained deep learning models on thousands of images of different fabrics. These models learn to classify materials with reasonable accuracy. But there are always edge cases. A blend fabric (50% cotton, 50% polyester) behaves like neither material alone. New fabrics hit the market constantly. Seasonal colors or patterns the model hasn't seen before create uncertainty.

The folding sequence planning is equally complex. The robot needs to decide: which corner to grab first? How to orient the garment? What sequence of folds leads to a compact, neat result? This is a planning problem in a high-dimensional space. Small errors compound.

Humans solve this by intuition. We've folded thousands of garments. We've developed heuristics that work "well enough." We don't optimize globally; we just make locally sensible decisions. Robots need explicit rules or learned patterns.

One approach gaining traction is learning from demonstration. Researchers show the robot how humans fold clothes, capture every movement, and have the AI learn the pattern. With enough examples, the model generalizes to new garments.

Weave is likely using a combination: pre-programmed rules for common garments, learned patterns from human demonstrations, and real-time vision feedback. The teleoperators add a fourth layer: human correction that becomes training data.

The Market for Laundry Robots

Who's actually buying these things?

Right now, it's early adopters, tech enthusiasts, and people with genuine mobility constraints. The

But the market potential is enormous. Laundry is a universal problem. Everyone with clothes does laundry. If robots can achieve 85%+ reliability at sub-$3,000 price points, adoption could be substantial.

Consumer research suggests people value their time highly in casual surveys but don't actually spend on conveniences in real purchasing behavior. Ask someone if they'd pay for laundry automation, and many say yes. Ask them if they'll actually buy an $8,000 robot, and the answer is usually no.

This is called the attitude-behavior gap. It means market research can be misleading. Real demand might be much lower than surveys suggest.

That said, the market is growing. As robots improve and prices fall, adoption will accelerate. In 5 years, laundry robots might be as common as dishwashers or robotic vacuums. But we're in the early innings now.

For Weave and competitors, this is high-risk, high-reward. They're betting that home robotics eventually become a $10+ billion market. If they succeed, early players capture outsized value. If robotics progress stalls, they're betting on a dud.

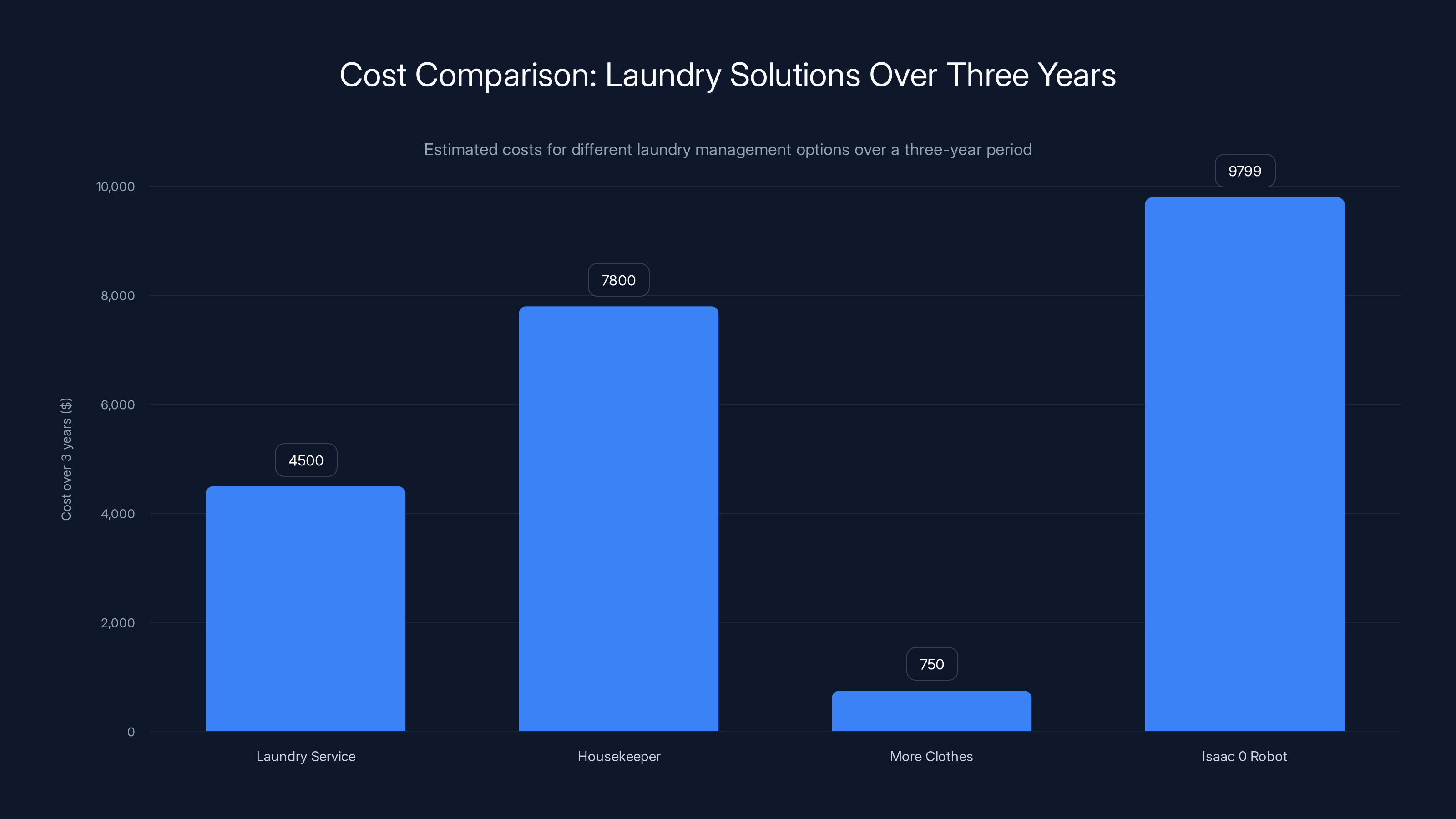

Estimated data shows that while the Isaac 0 Robot is the most expensive option, laundry services and housekeepers also incur significant costs over three years. Buying more clothes is the least costly option.

Design Constraints and Real-World Friction

Isaac 0's limitations don't come from stupidity or poor engineering. They come from real physical constraints.

Design constraint 1: Size. Isaac 0 is stationary because a mobile robot capable of folding laundry would need significant power, processing, and structural support. That adds weight, complexity, and cost. A stationary design is simpler.

Design constraint 2: Power. The robot needs enough grip strength to handle heavy items like jeans and thick towels, but fine enough control for delicate fabrics. Achieving both with current actuator technology is hard. Weave's solution: skip the heavy items.

Design constraint 3: Manufacturing speed. Folding a load of laundry in 30-90 minutes is slow compared to humans, but folding individual garments faster would require a larger robot or more arms, which increases cost exponentially.

Design constraint 4: Generalization. Building a robot that handles all garment types with all possible edge cases requires either massive over-engineering or AI so advanced it doesn't exist yet. Weave chose selective functionality.

These aren't problems with poor execution. They're fundamental tradeoffs. Any laundry robot company faces them. The question is how to balance capability, cost, speed, and complexity.

Weave's answer: focus on the core 60-70% of laundry that's straightforward, be transparent about limitations, and use humans to bridge the gap while the AI improves. It's not perfect, but it's an honest approach.

Other companies might make different tradeoffs. LG's cabinet design, for example, works with fixed geometry. That simplifies some problems (the robot knows exactly where items are) but creates others (the cabinet must accommodate all garment sizes).

Ongoing Support and the Service Model

Here's something important that often gets overlooked: consumer robotics require ongoing support.

Your washing machine works for 10 years with maybe one service call. Your robot? It needs software updates, customer support, and potentially hardware repairs. The more complex the robot, the more support is needed.

Weave's model includes teleoperator support, which suggests they're planning an ongoing service relationship with customers. This is more like cloud software than traditional appliances. You're not buying a product; you're buying a service.

This changes the relationship. If something breaks, you don't just troubleshoot it yourself. You contact support. There might be downtime. There might be delays if the company is overwhelmed. For something as mundane as laundry folding, that's annoying.

But it also means Weave has visibility into how the robot is being used. The company sees which folds fail most often. It sees which garment types cause problems. It gets real-world data that informs product improvements.

Over time, this service-based model could become genuinely valuable. Weave might offer additional services: laundry pickup, sorting assistance, professional folding techniques. The robot becomes the foundation of a broader laundry service platform.

But that's speculation. Right now, it's a $7,999 robot with ongoing support costs, and most consumers aren't ready for that commitment.

Comparison: Robots vs. Alternatives

Let's be honest about the alternatives.

Option 1: Laundry service. Pick up, wash, fold, and deliver for

Option 2: Hire a housekeeper. Many people hire cleaners for 2-4 hours per week at

Option 3: Reduce laundry volume. Buy more clothes so you wash less frequently. Eliminates the urgency. Cost: one-time clothing investment ($500-1,000). Disadvantage: requires more closet space, doesn't actually eliminate laundry.

Option 4: Isaac 0. Cost: $9,799+ (including teleoperator support). Handles 60-70% of laundry autonomously. Requires space and electricity. Disadvantage: still doesn't eliminate all work, premium price, needs support.

For most people, options 1 or 2 are more cost-effective and less hassle than a robot. The robot makes sense if you want to own a cutting-edge device, enjoy tinkering with technology, or have specific needs (mobility issues, space constraints that make hiring someone difficult).

But we're clearly in the wrong phase of the market for mainstream adoption.

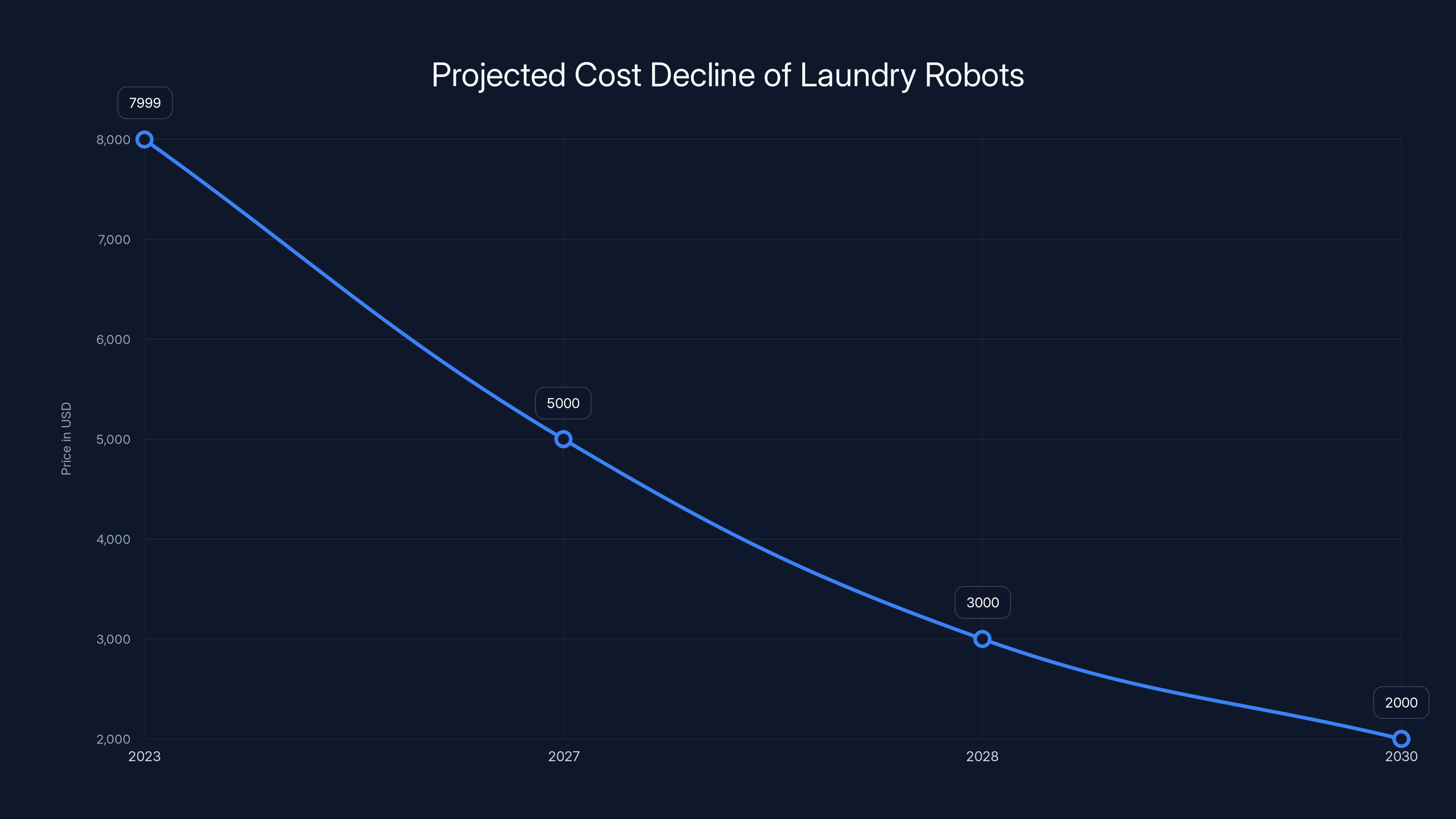

The price of Isaac 0 is projected to decrease significantly by 2030+, reaching a range of

The Path Forward: What Needs to Happen

For laundry robots to become truly mainstream, several things need to change.

Better dexterity. Current grippers are crude. We need soft robotics, better sensors, and more sophisticated control algorithms. Companies are working on this. MIT's Distributed Robotics Lab is researching modular grippers. Soft robotics startups are making progress. Give this 3-5 years.

Broader autonomy. Robots need to handle more fabric types, edge cases, and garment shapes. This requires more training data and better AI models. With each new product generation, autonomy improves. Give this 3-5 years as well.

Lower costs. Manufacturing efficiency and competitive pressure will drive prices down. What costs

Reduced teleoperator dependency. As AI improves, the need for human interventions drops. Teleoperator costs decline. The business model becomes sustainable. Give this 3-5 years.

Integration with smart homes. Robots that connect with washing machines, dryers, and storage systems will be more valuable. Automation that schedules laundry work, coordinates with other household tasks, and learns your preferences will justify higher prices. Give this 2-4 years.

If all of this happens, laundry robots could be a standard household appliance by 2030. That's plausible, maybe even likely.

But we're not there yet. We're in the "interesting prototype" phase. Isaac 0 is a real product, but it's not a complete solution. It's a stepping stone.

Industry Context: Where Other Companies Stand

Weave isn't alone. The laundry robot space is getting crowded.

LG's CLOi D is a cabinet system where laundry is loaded, the door closes, and robotics handle everything inside. LG hasn't publicly released pricing or availability, but expect it to be premium (probably $5,000-10,000). The advantage: contained environment, integrated with LG's appliance ecosystem. The disadvantage: requires space, less portable than Isaac 0.

Switch Bot's Onero H1 is a portable robotic arm designed to work with standard laundry baskets. It's more flexible than Isaac 0 because it can be repositioned, but it's also more complex. Expected pricing is similar to Isaac 0 ($7,000-9,000). Advantages: mobility, flexibility. Disadvantages: takes up space, requires setup.

Electrolux's initiative is focused on end-to-end laundry solutions, potentially integrating washers, dryers, and folding systems. They're not rushing to market, preferring to develop a complete ecosystem. This approach takes longer but could result in a superior product.

Chinese startups like Airsense are focusing on cost optimization. They're building laundry robots at lower price points ($4,000-6,000) with simpler functionality. As Chinese manufacturing scales, these competitors could drive market prices down significantly.

The pattern is clear: everyone sees opportunity in household robotics. Everyone is investing heavily. Within 3-5 years, we'll have multiple viable laundry robot options at various price points and capability levels.

Weave's first-mover advantage is significant, but it's not insurmountable. The company needs to continue improving the product, reduce costs, and build customer loyalty through good support. That's achievable, but it's also competitive.

The Deeper Problem: Why Home Robotics Is So Hard

Let's zoom out. Laundry is just one example of a broader problem: home robotics is genuinely difficult.

Consider what a robot needs to do in a home:

- Operate in an unpredictable environment with varied lighting, temperatures, and layouts

- Handle thousands of different object types with different properties

- Make sense of human preferences and adapt accordingly

- Recover gracefully from failures

- Interact safely with humans and pets

- Provide value that justifies the cost

Each of these is a research-level problem. Even Google and Amazon, with unlimited resources, haven't solved household robotics. Google's robot arms can flip pancakes, but they're not in homes yet. Amazon's robot is still in limited beta testing.

The issue is scale and generalization. A robot that works in a controlled lab environment might fail spectacularly in the real world. Homes vary. People vary. Laundry varies.

Weave's approach—focusing narrowly on laundry folding, being transparent about limitations, and using human assistance—is actually a smart way to make progress. Rather than trying to build a general-purpose robot, build a special-purpose one. Perfect it. Improve the AI gradually. Then expand scope.

This is the opposite of the Tesla Optimus approach (build a general-purpose humanoid). Both approaches have merit. But for a startup with limited resources, narrow focus makes sense.

Laundry robots are expected to become more affordable, with prices potentially dropping to

Should You Buy Isaac 0?

Let's be direct. Here's the decision framework:

Buy if:

- You have mobility constraints that make laundry painful

- You value time extremely highly (earning $50+/hour)

- You're genuinely interested in technology and willing to accept limitations

- You have space for a stationary robot

- You live in an area with good customer support

Don't buy if:

- You want to eliminate laundry entirely (you can't yet)

- You're looking for cost-effectiveness

- You need the robot to handle all garment types

- You prefer low-maintenance appliances

- You're price-sensitive

For most households, waiting 2-3 years for improved products at lower prices is the rational choice. The technology is advancing quickly. Prices will fall. By 2027-2028, you'll have better options.

But if you're in the early adopter camp and can afford the premium, Isaac 0 is a legitimate product that does what it claims (with caveats). It won't revolutionize your life, but it will fold some of your laundry.

The Broader Vision: Where This Is Heading

Weave isn't just building a laundry robot. The company is building toward something bigger: a home that helps with chores.

Today, it's laundry. Tomorrow, it might be: other cleaning tasks, organization, even meal preparation. The core technology—robotics, vision, planning, human collaboration—transfers across domains.

If Weave successfully scales laundry robots, the company has a platform. The customer relationship is established. The manufacturing know-how exists. Adding new tasks is easier.

This is the thesis that investors find appealing. Weave isn't a laundry robot company. It's a household robotics company. The laundry robot is the beachhead.

Over the next decade, we'll likely see a consolidation in home robotics. Some startups fail (can't raise enough capital, tech doesn't advance fast enough). Others get acquired by appliance makers or tech giants. A few become independent powerhouses.

Weave's goal is probably to be one of the survivors, either independently or as part of a larger ecosystem. Achieving that requires continuous improvement, customer satisfaction, and market growth.

For now, that means shipping Isaac 0, supporting customers, gathering data, improving the AI, and gradually reducing the need for human teleoperators. It's unglamorous, but it's the right strategy.

Common Misconceptions About Home Robotics

Let's clear up some myths.

Myth 1: "AI will eventually solve this."

True, in the very long term. But "AI" isn't magic. It's a tool that requires training data, computational resources, and time. The bottleneck isn't usually intelligence; it's embodied skill. A robot needs to develop real-world competence through practice. That takes time, not just better algorithms.

Myth 2: "Robots will be cheaper than humans in 5 years."

Maybe someday, but not 5 years. Human labor in developed countries costs $15-25/hour. A robot that matches human performance needs to be amortized over thousands of hours of use to make economic sense. That requires either high reliability, long lifespan, or both. We're not there yet.

Myth 3: "Robotics is mature; it's just a scaling problem."

Incorrect. Robotics is still in the research phase in many domains. We haven't solved robust manipulation, real-world perception, or safe human-robot interaction at a consumer level. Yes, there are amazing robots in research labs. But consumer products are much less capable. There's still significant development work ahead.

Myth 4: "Home robots will eliminate jobs."

Probably not in the near term. We're decades away from robots that can do everything a housekeeper does. And even when that happens, the economics might favor human labor in some contexts. Robots are capital-intensive; humans are flexible. There's room for both.

Myth 5: "Big tech companies should just solve this."

They could, in theory. But corporate robotics teams move slowly. There's less tolerance for failure. The economics need to pencil out before launch. Startups can take risks that big companies can't. Sometimes the risk pays off. Sometimes it doesn't.

Looking at Specific Use Cases

Let's talk about when Isaac 0 (and robots like it) actually make sense.

Use case 1: Someone with severe arthritis. Folding laundry causes pain. An expensive robot beats pain. The ROI is health, not time. This makes sense immediately.

Use case 2: Large families. 8+ people generating 15+ loads per week. At this volume, the per-load cost of a robot improves. If it saves 2 hours per week, that adds up. Still marginal at $8,000, but less obviously ridiculous.

Use case 3: Tech companies and innovation offices. Some organizations buy robots for research and marketing purposes. The actual utility is secondary to the innovation signal.

Use case 4: Accessibility centers. Places that help people with disabilities might buy robots to demonstrate technology. Helps the organization, helps clients envision possibilities.

Use case 5: Luxury hotels or laundry services. A hotel that processes 100+ loads per day could benefit from a robot that handles most of the work. The per-load economics improve dramatically at scale.

For typical homeowners? The ROI is marginal at best. You're paying for the privilege of owning cutting-edge technology, not for practical savings.

Cost Projections: Will It Get Cheaper?

Yes, but not as fast as you might hope.

Let's project Isaac 0's price trajectory:

- 2025 (now): $7,999 Launch pricing with limited supply

- 2026: $6,500-7,000 Increased production, minor competition pressure

- 2027: $4,500-5,500 Scale economies kick in, more competitors enter

- 2028: $2,500-3,500 Serious competition, manufacturing optimized

- 2030+: $1,500-2,500 Market saturation, price wars, commodity pricing

This trajectory is rough, but it's plausible based on how other consumer electronics have evolved. Robotics might move slower than smartphones because manufacturing is more complex and volumes are lower.

Note the trajectory: even at

The inflection point comes when robots hit the $1,000-2,000 price range and can handle 90%+ of typical laundry. At that point, they become genuinely appealing. We're probably 4-6 years from that scenario.

The Role of Machine Learning and Training Data

Here's something that rarely gets discussed: the laundry robot market will be shaped by which company accumulates the best training data.

Each Isaac 0 unit in the field generates data. Every time a teleoperator steps in to help, the system learns. Every fold, every garment type, every edge case becomes training data.

Weave is likely aggregating this data and using it to improve the core folding models. In six months, Isaac 0 might require human intervention 30% of the time. In a year, maybe 20%. Over three years, possibly <5%.

Companies with more units in the field accumulate data faster. This creates a network effect. Weave's early adoption becomes an advantage, not just in market share, but in data advantage.

This is why the race matters. If Weave ships 10,000 units while competitors ship 1,000, Weave trains its AI on 10x more real-world data. That compounds over time.

Switch Bot, LG, and others understand this. They're not trying to beat Weave on the first product. They're trying to build data moats for the second-generation robot.

By 2028, the company with the best training data, the most refined algorithms, and the most efficient manufacturing will likely dominate. It might be Weave. It might be a larger player that acquired them. Either way, data matters.

Regulatory and Safety Considerations

We haven't talked much about regulation, but it matters.

In the US, there's limited regulation of household robots. Consumer product safety standards apply (the robot can't electrocute you, start fires, etc.), but there's no specific robotics regulation. This allows faster iteration.

But as robots become more common, regulation will likely increase. Questions will emerge:

- What happens if a robot damages clothes?

- What if it injures someone?

- Who's liable?

- What data can manufacturers collect?

- How is that data used and stored?

Weave's teleoperator model creates additional questions. If a teleoperator in another country is controlling a robot in your home, what privacy protections apply? How is video data from your laundry room handled?

These are solvable problems. Most robotics companies have strong privacy practices. But as the market scales, regulators will want to understand these systems better.

Small startups like Weave might find regulation burdensome. Big companies with compliance departments will handle it more easily. This could be a moat for larger competitors eventually.

The Human Element: Why Teleoperators Matter

Weave's teleoperator model is worth understanding deeply because it reveals something important about AI's current state.

The robot can't solve every problem. So Weave hired humans to bridge the gap. But more importantly, the humans teach the AI.

Every time a teleoperator takes over, they're essentially saying: "Here's how I'd solve this." The system records that solution and learns from it. Over thousands of interventions, patterns emerge. The AI discovers heuristics it wouldn't have discovered alone.

This is called learning from human feedback, and it's becoming a core machine learning technique. OpenAI uses it to train Chat GPT. Tesla uses it to improve its driving models. Weave is using it to improve its folding models.

The teleoperator isn't a failure of the robot. It's a component of the learning system. Yes, it's expensive. Yes, it's not scalable indefinitely. But it's a proven path to improvement.

Over time, as the AI becomes more capable, fewer teleoperator interventions are needed. The cost drops. The business becomes more efficient.

This is patient capital work. It requires investors comfortable with multi-year timelines and increasing costs before profitability. Not every company can do this. Startups with limited runway can't afford it. This is why Weave likely raised significant funding before launching.

Conclusion: The Bottom Line on Laundry Robots

Isaac 0 is a real product that does what Weave claims. It folds clothes. It's expensive. It has limitations. It needs human help sometimes. But it works.

It's also a preview of a future that's coming. In 5-10 years, household robotics will be much better, much cheaper, and much more common. By 2035, laundry robots might be as unremarkable as dishwashers.

But we're not there yet. We're in the phase where home robotics is expensive, limited, and somewhat disappointing relative to hype. This is normal. Every major technology went through this phase.

Smartphones were expensive and limited in the early 2000s. Dishwashers were luxuries in the 1950s. Electric cars were toys until recently. The pattern repeats: expensive early versions, gradual improvement, eventual ubiquity.

Laundry robots are following the same curve. Isaac 0 is toward the beginning. Better products will come. Prices will fall. Eventually, it will be a commodity.

If you can afford it and want to be an early adopter, go ahead. You're paying for the privilege of exploring cutting-edge technology. The value is partly practical (some laundry folded) and partly aspirational (you own a robot).

If you're pragmatic, wait 2-3 years. The technology will be better. The prices will be lower. Your experience will be significantly improved.

Either way, laundry robots represent something important: the slow, unglamorous march of technology into everyday life. It's not as flashy as AI breakthroughs or space exploration. But it's real, and it's happening.

The future of the home is robotic. It's just arriving slower than we thought.

FAQ

What is Isaac 0?

Isaac 0 is a stationary laundry folding robot made by Weave that costs

How does Isaac 0 fold clothes?

The robot uses multiple cameras to create a 3D image of a garment, identifies its type through machine learning models, plans a folding sequence, and executes the folds using precision robotic arms with specialized grippers. When the system encounters challenges it can't solve, a human teleoperator takes remote control to complete the fold, and the system learns from that intervention.

What are the main limitations of Isaac 0?

Isaac 0 cannot handle large blankets, fitted sheets, or clothes that are inside-out. It takes 30-90 minutes to fold a standard load (compared to 15-20 minutes for a human). It also still requires human teleoperator support for roughly 20-30% of folding tasks, adding ongoing monthly costs on top of the $7,999 purchase price.

How much does Isaac 0 actually cost per year?

Beyond the initial

Will laundry robots become cheaper in the future?

Yes, projections suggest laundry robots will decline to

How does Isaac 0 compare to alternatives like laundry services or hiring help?

A laundry service costs

Should you buy a laundry robot right now?

Buying makes sense if you have mobility constraints that make laundry painful, earn $50+ per hour and highly value your time, are an early technology adopter, or have sufficient space and reliable customer support access. For most households, waiting 2-3 years for improved products at lower prices is more rational, as the technology is advancing rapidly and the next generation will be significantly better.

Looking Further: Runable for Automation

While discussing the future of household robotics and automation, it's worth noting that many of these emerging robot companies rely on AI-powered workflow automation for their internal operations. For teams building the next generation of products like laundry robots, platforms like Runable offer AI-powered automation at $9/month that can help with documentation, report generation, presentation automation, and image creation for product launches and marketing. As home robotics companies scale, they need efficient internal processes just as much as groundbreaking products.

Use Case: Automate your product development workflow by generating documentation, creating presentation decks from robot performance data, and generating reports on customer feedback and AI improvement metrics.

Try Runable For FreeKey Takeaways

- Isaac 0 costs 9,799, equivalent to $47/hour of laundry time saved

- Current laundry robots can only handle 65-75% of typical household loads, unable to manage sheets, large blankets, or inside-out garments

- The fundamental limitation isn't stupidity but physics: fabric is deformable and unpredictable, requiring dexterity current robotic grippers cannot match

- Human teleoperators aren't a failure but a feature, providing real-time assistance while generating AI training data that improves future versions

- Prices are projected to decline 50-80% by 2030 as manufacturing scales and competition intensifies; waiting 2-3 years likely yields significantly better products at lower costs

- The teleoperator model is unsustainable long-term but allows Weave to ship a useful product today while advancing AI capabilities gradually

- At least 5-10 companies (LG, SwitchBot, Electrolux, Airsense) are developing competing laundry robots, suggesting the market sees genuine opportunity despite current limitations

Related Articles

- Apple HomeKit Migration: Complete Guide to the February 2026 Shutdown [2026]

- IKEA Smart Switches Guide: Why Budget-Friendly Home Automation Wins [2025]

- Apple's Home App Mandatory Update: What You Need to Know [2025]

- Argos Big Red Sale: Best Tech Deals Up to 50% Off [2025]

- Lifx Matter Smart Bulbs: The Complete Buyer's Guide [2025]

- Jackery HomePower 3600 Plus: Complete Guide to Whole-Home Backup Power [2025]

![The $7,999 Laundry Robot Problem: Why AI Isn't Ready Yet [2025]](https://tryrunable.com/blog/the-7-999-laundry-robot-problem-why-ai-isn-t-ready-yet-2025/image-1-1770901635594.jpg)