The Volvo EX60 Changes the Electric SUV Game

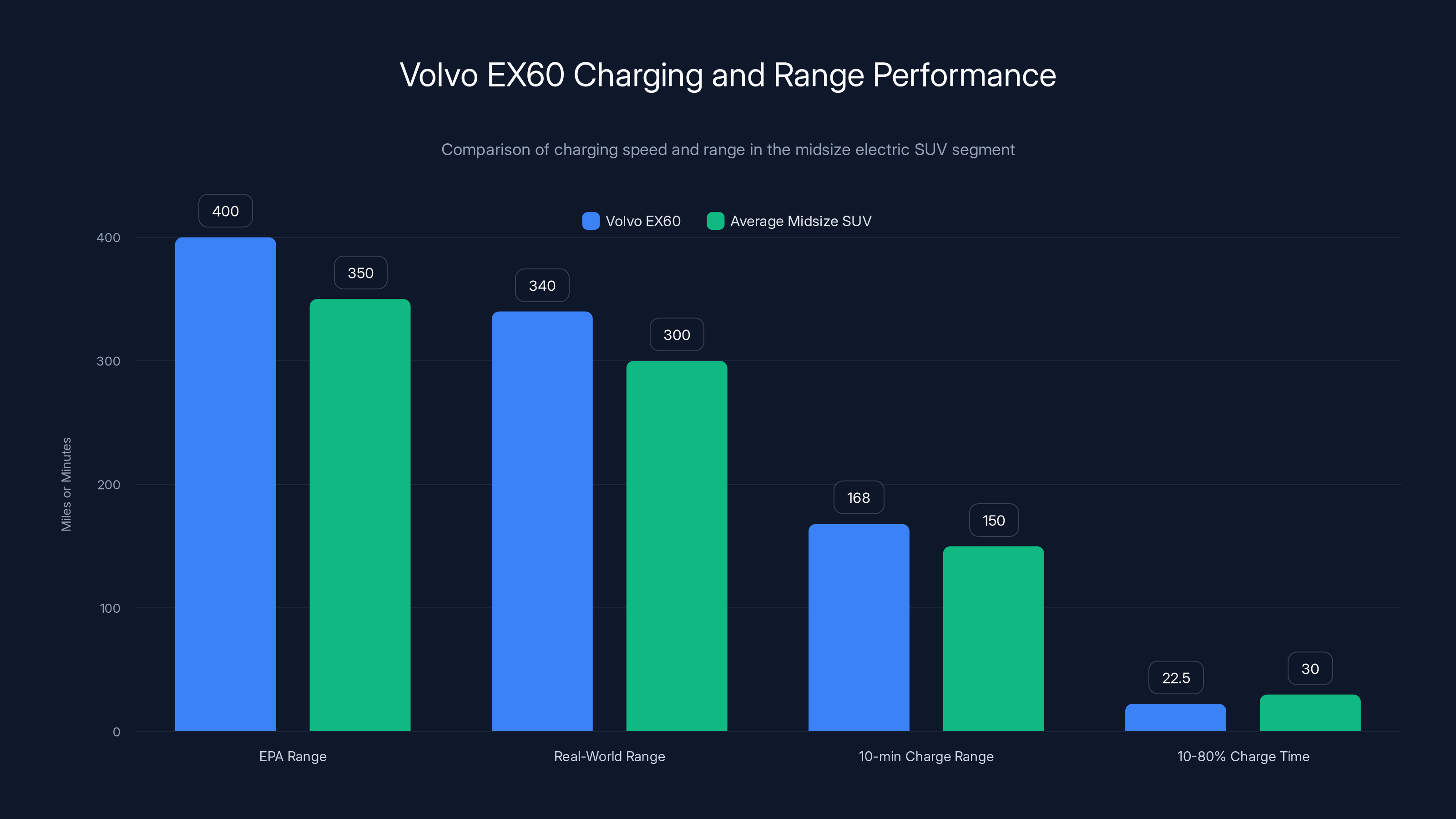

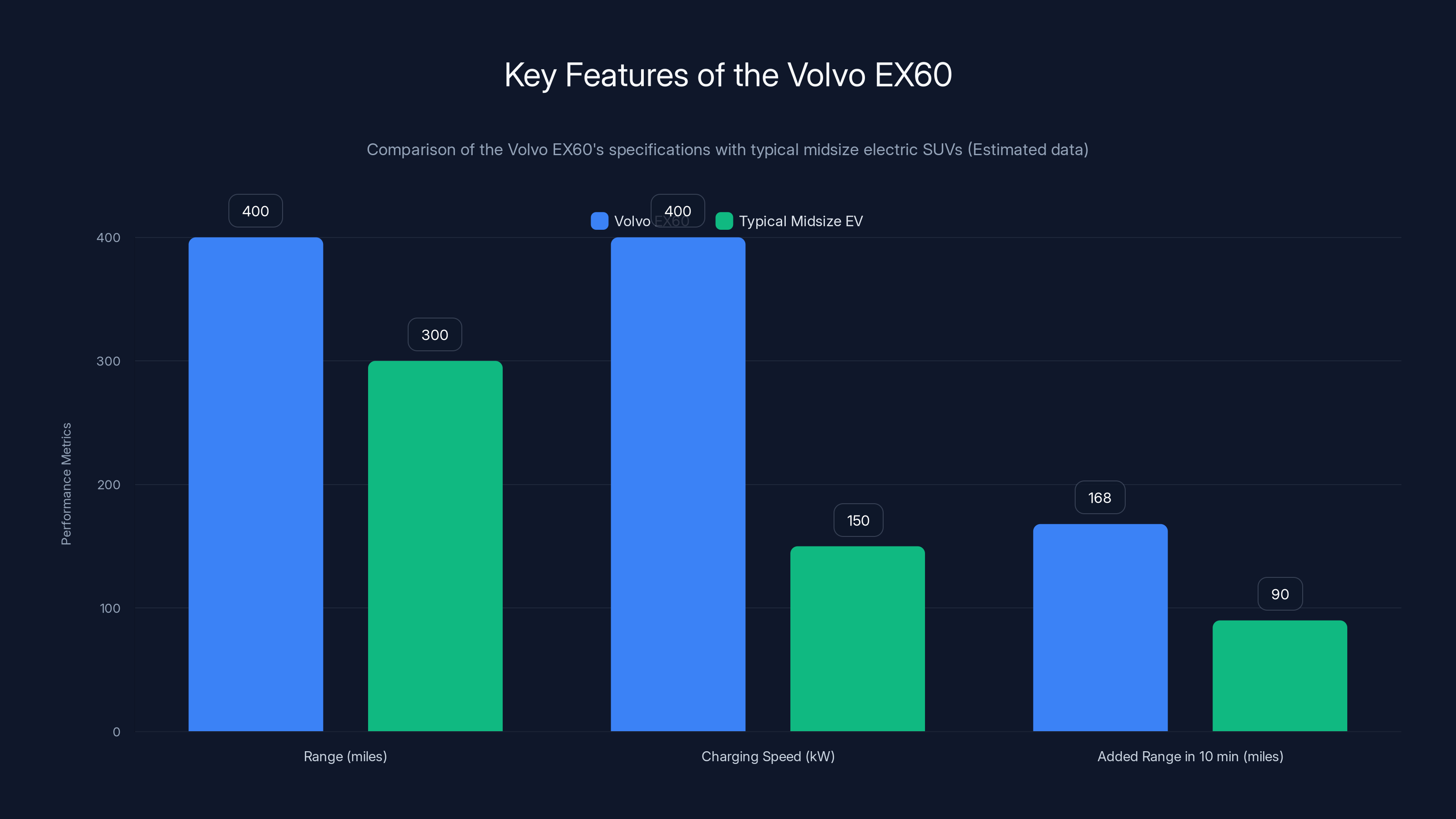

Volvo's about to shake up the midsize electric SUV segment with the all-new EX60, and honestly, the specs are impressive enough to make you pay attention. We're talking about a vehicle that promises 400 miles of EPA-estimated range, charges at speeds up to 400 kilowatts, and supposedly adds 168 miles of driving distance in just 10 minutes. That's not hype—that's a genuine reset on what midsize electric vehicles should deliver.

But here's where it gets interesting. The EX60 isn't just throwing bigger batteries and faster chargers at the problem. Volvo engineered this from the ground up using modern EV architecture that most legacy automakers are still figuring out. The company used structural battery packs, massive single-piece castings, and in-house motor designs to cut weight and maximize efficiency. The result? A vehicle that addresses the two biggest concerns keeping people away from electric cars: range anxiety and charging time.

The official unveiling happened in January 2026, but Volvo already released enough technical details to understand why this car matters. It's not just another luxury SUV competing in a crowded market. The EX60 is positioned directly between Volvo's smaller EX30 and its larger EX90, filling a gap that the Swedish automaker desperately needed to address, especially after sales took a hit in traditional markets like Europe and China during 2025.

What makes the EX60 particularly relevant right now is the timing. The EV market is accelerating rapidly, battery technology has matured significantly, and charging infrastructure is finally catching up. Volvo's bet on this specific combination of features—exceptional range, rapid charging, lightweight construction, and efficient motors—reflects where the industry is headed. This isn't a car designed for 2020. It's built for 2026 and beyond.

Understanding the 400-Mile Range Achievement

Let's break down what 400 miles actually means and how Volvo achieved it. The EPA test cycle is standardized, which makes the claim meaningful. You're not comparing apples to oranges when a manufacturer says 400 miles EPA-estimated. It means the vehicle was tested under controlled conditions on a dynamometer using a specific driving pattern that roughly simulates real-world driving.

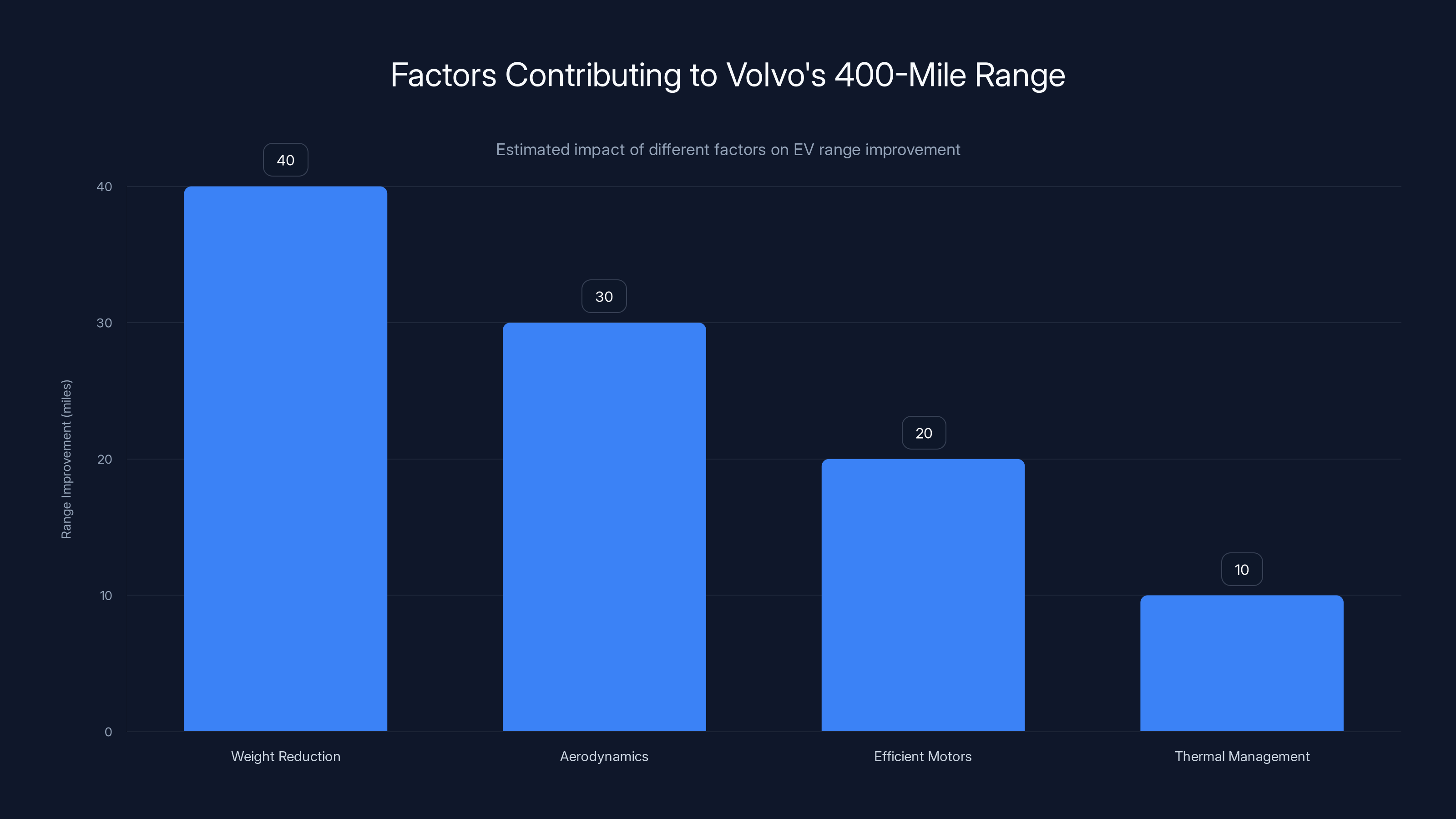

But here's the thing: getting to 400 miles isn't just about packing a massive battery into the car. If that were the case, every EV would weigh 5,000 pounds and cost $150,000. Volvo solved this problem by reducing vehicle weight, improving aerodynamics, and designing more efficient motors. All three factors matter equally.

The structural battery pack is the foundation here. Traditional EV designs bolt a battery pack underneath the floor with separate structural components below that. Volvo's approach integrates the battery itself as a structural element—it supports the vehicle's weight and absorbs crash forces. This eliminates redundancy and saves hundreds of pounds. Weight reduction is one of the most underrated ways to improve electric vehicle range and efficiency.

Let's do the math. A 10% weight reduction typically translates to roughly 7-10% improvement in range, assuming the same battery size. If Volvo saved 500 pounds through structural optimization and material science, that's potentially 35-50 extra miles of range right there. Add in more efficient motors, better aerodynamics, and thermal management, and suddenly 400 miles becomes achievable without a battery that costs $25,000.

Volvo hasn't officially announced the EX60's battery capacity yet, but industry analysts predict it's likely in the 100-115 kWh range for the long-range variant. Compare that to competitors like the Tesla Model Y Long Range (82 kWh usable) or the BMW iX xDrive 50 (130 kWh), and you get a sense of where Volvo is positioning itself. The EX60 appears to be hitting that sweet spot of capacity without excessive weight penalty.

The motor design matters too. Volvo developed the EX60's motors in-house, which means they optimized every component for this specific vehicle rather than using off-the-shelf units. In-house motor development allows engineers to balance power delivery, efficiency, and thermal characteristics for the exact weight distribution, aerodynamics, and intended use case of this SUV. It's more expensive than buying motors from a supplier, but it pays dividends in real-world performance.

Another critical factor is thermal management. Electric motors waste less energy than internal combustion engines, but they still generate heat. The EX60 needs sophisticated cooling systems to keep battery and motor temperatures within optimal ranges across different climates. A battery operating at 85 degrees Fahrenheit is far more efficient than one running at 100 degrees. Volvo's engineers spent significant resources on this unsexy but essential component.

The Volvo EX60 leads with an EPA-estimated range of 400 miles and fast charging capabilities, adding 168 miles in 10 minutes. Estimated data for real-world range and charging times.

The Mega-Casting Strategy: Weight Reduction Through Manufacturing Innovation

Mega castings sound like something straight out of science fiction, but they're actually one of the most practical manufacturing innovations in modern automotive engineering. Instead of assembling a component from hundreds of individual parts through welding, riveting, and fastening, Volvo pours molten aluminum into a mold and gets a single piece.

Take the EX60's rear floor. Traditionally, a vehicle floor is built from multiple stamped steel panels, welded together and reinforced with additional substructures. That process creates weak points at every weld and requires hundreds of fasteners. A single mega casting replaces all of that. The rear floor becomes one unified piece of aluminum that's stronger, lighter, and more rigid than the welded alternative.

The weight savings are significant. A traditional floor assembly might weigh 150-200 pounds. A mega-cast rear floor could weigh 110-130 pounds. Multiply that across multiple mega castings (front structure, seat frame supports, battery housing reinforcements) and you're looking at 500+ pounds of weight reduction. That's roughly a 7-8% weight saving on a midsize SUV.

But mega castings require capital investment and engineering precision that few manufacturers possess. Tesla pioneered this approach with the Model Y and Model 3, developing custom mega-casting machines that cost tens of millions of dollars each. Volvo, being part of the Geely-Volvo family (which also owns Polestar and Geely), has access to manufacturing expertise and capital that allows them to implement this technology competitively.

The trade-off is complexity. If something goes wrong with a mega casting during manufacturing, you can't fix it with a welder. The entire piece is scrap. Quality control becomes absolutely critical. Volvo has invested in advanced inspection systems, including AI-powered visual inspection and dimensional measurement, to catch defects before castings leave the production line.

Maintenance and repair also change with mega castings. If you damage the rear floor of a traditional vehicle, a body shop can cut out the damaged section and weld in a replacement panel. With a mega casting, that option doesn't exist. You're replacing the entire component, which is more expensive upfront but less labor-intensive than traditional repair.

The Volvo EX60 leads with a 400-mile range, 400 kW charging speed, and 168 miles added in 10 minutes, setting new benchmarks in the midsize electric SUV market. Estimated data for typical midsize EVs included for comparison.

Fast Charging: Understanding 400 kW and 10-Minute Reality

The headline numbers are compelling: 400 kilowatts of charging power delivering 168 miles of range in 10 minutes. That's genuinely fast. But let's unpack what that actually means in practice and why the entire charging curve matters more than any single headline number.

Charging isn't linear. When you plug an EV into a DC fast charger, the car doesn't accept the same amount of power the entire time. Power delivery follows a curve that starts high when the battery is depleted and gradually tapers down as the battery reaches higher states of charge. This is physics, not a limitation. Lithium-ion batteries heat up when charged at maximum power. At 10% charge, a battery can dissipate heat relatively easily. At 80% charge, thermal management becomes critical. Exceed safe temperature thresholds, and you risk degradation.

So yes, the EX60 might accept 400 kW when you're starting at 10% charge, but that power delivery probably drops to 300 kW by 20% charge, 200 kW by 50%, and significantly lower by 80%. Volvo hasn't released the complete charging curve yet, so we don't know the exact power profile. But we do know that 168 miles in 10 minutes represents an average power delivery of roughly 230-240 kW throughout that window. That's still extremely rapid.

For context, most fast chargers in the U.S. top out at 150-180 kW. The EX60's 400 kW capability requires specialized ultra-fast charging infrastructure that currently exists in limited numbers, mostly in Europe and parts of Asia. In North America, you'll find 350 kW chargers at Electrify America and Tesla Supercharger V3 stations (which deliver up to 250 kW). The 400 kW capability is future-proofing—infrastructure to match it is coming, just not everywhere yet.

The 10-minute claim assumes several factors. First, you're starting from significantly depleted charge levels. Adding 168 miles from a 400-mile-total-range vehicle means going from roughly 42% charge to 84% charge (simplifying for illustration). That's the sweet spot of the charging curve where power delivery is high and battery thermal stress is manageable.

Second, you're using a charger that actually delivers 400 kW. Most current installations don't. Third, ambient temperature matters. Charging in 40-degree weather is easier than charging in 100-degree heat. The car's thermal management system works harder to keep the battery cool during rapid charging in hot climates, which might reduce power delivery to protect the battery.

The engineering challenge is substantial. Accepting 400 kW means the EX60's high-voltage architecture needs to handle enormous currents. The battery management system, cooling loops, and electrical connections all require oversizing to safely manage this power. Weight increases, cost increases, and complexity increases. But the end result is transformative: 10 minutes to charge enough range for a 3-hour drive is a game-changer for road trips and daily commuting anxiety.

One detail Volvo hasn't clarified yet is the 10-80% charging time. That's the metric that actually matters for most driving situations. You rarely drain a battery to 0% or charge to 100% on a daily basis. Getting from 10% to 80% is the charging scenario that most EV owners experience. Current information suggests the EX60 handles this range in 20-25 minutes, which is faster than competing offerings.

Cell-to-Body Architecture: Why It Matters More Than You Think

Cell-to-body architecture represents a fundamental shift in how EVs are engineered. Traditional vehicles have a body structure and a separate battery pack mounted underneath. The cell-to-body approach integrates battery cells directly into the vehicle's structural members.

This isn't just clever packaging. It's a different philosophy. Instead of designing a car and then fitting a battery underneath, Volvo designed the battery first and integrated the vehicle structure around it. The battery cells become load-bearing members that support the vehicle's weight, handle crash forces, and provide torsional rigidity.

The advantages are numerous. First, space efficiency improves dramatically. Every cubic centimeter can be used for actual battery capacity rather than wasted on structural components. A midsize SUV might gain 10-20 liters of battery volume, translating directly to increased capacity without growing the vehicle's footprint.

Second, weight optimization becomes much more effective. A traditional battery pack has its own casing and structural reinforcement. The vehicle body has separate support structures above and below the battery. Cell-to-body eliminates this duplication. You're supporting the weight with one integrated system instead of two separate ones.

Third, crash performance actually improves. Battery cells are surrounded by structural reinforcement in the most critical impact zones. Energy absorption characteristics are engineered into the battery pack itself, not bolted on afterward. Volvo's testing likely shows that the integrated approach distributes crash forces more evenly than traditional separate-pack designs.

The manufacturing complexity increases substantially. You can't service or repair a cell-to-body battery like you would a traditional pack. If cells are damaged, you need to replace large structural sections. From a manufacturer's perspective, quality control becomes absolutely critical because failures are more expensive and complicated to address.

Volvo's implementation appears to follow the playbook developed by Chinese EV makers, particularly BYD's blade battery technology. The company's leverage of Geely manufacturing expertise allows them to implement this architecture more rapidly than some Western competitors who are still transitioning from traditional designs.

Estimated data shows weight reduction as the largest contributor to achieving a 400-mile range, followed by aerodynamics and motor efficiency improvements.

How Volvo Designed Motors In-House for Superior Efficiency

Motor design is where engineering meets mathematics. The efficiency difference between a mediocre motor and an optimized one can represent 5-10% of total vehicle range. For the EX60, that could mean 20-40 miles of difference. Volvo's decision to develop motors in-house signals a serious commitment to efficiency.

In-house motor development allows for optimization specific to this vehicle's needs. Weight distribution, power requirements for desired acceleration, the aerodynamic drag profile, and intended use cases all inform motor design. An off-the-shelf motor is a compromise designed to work adequately in multiple vehicles. A custom motor is built for one specific purpose.

Modern EV motors are typically permanent magnet AC motors or induction motors. Permanent magnet motors are more efficient but require rare earth materials and cost more upfront. Induction motors are cheaper but slightly less efficient. Volvo likely chose permanent magnet technology for the EX60 given the focus on range and efficiency.

The motor's efficiency curve matters as much as its peak efficiency. A motor might be 92% efficient at peak power but only 75% efficient at partial loads. Since most driving happens at partial loads, overall efficiency depends heavily on how the motor performs across its entire operating range. Volvo's engineers optimized the motor windings, rotor design, and magnetic field configuration to maintain high efficiency across different power outputs.

Thermal management of the motor is crucial. An inefficient motor generates excess heat, which requires bigger cooling systems, which adds weight. An optimized motor generates less heat, reducing cooling requirements and saving weight throughout the vehicle. It's a cascading effect where motor efficiency improvements ripple through the entire design.

Volvo also designed the motor controller, which manages power delivery and efficiency. The controller adjusts how current flows through the motor windings to match the instantaneous power demand. A sophisticated controller can squeeze an additional 2-3% of efficiency compared to basic designs, but it requires more processing power and advanced thermal management.

Structural Battery Pack: Maximizing Volume and Minimizing Weight

The structural battery pack works because modern lithium-ion battery cells are surprisingly strong. A single cylindrical cell (like the 2170 or 4680 format) can handle compression, tension, and torsional loads. When you arrange thousands of cells in a structured pattern and surround them with a rigid casing, you've created a component stronger than many traditional structural materials.

Volvo's structural battery pack likely uses a sandwich construction with cells arranged in precise patterns, surrounded by aluminum extrusions and composite materials. The outer structure provides crash protection and load distribution. The inner arrangement optimizes electrical connections and cooling paths.

Space utilization improves dramatically compared to traditional designs. A conventional battery pack bolted under a vehicle wastes roughly 15-25% of its volume on protective casing and mounting structure. A structural pack eliminates most of this waste. That's equivalent space for an additional 8-12 kWh of battery capacity at no additional weight cost.

Manufacturing tolerances become critical. Every cell must fit precisely into its designated spot. Any gap reduces load-bearing capacity and efficiency. Volvo's manufacturing process likely includes extensive robotics, vision systems, and automated alignment equipment to ensure consistency across thousands of units.

The longevity question arises. If the battery structure is also supporting vehicle weight, does it degrade differently than a non-structural pack? Preliminary data suggests it doesn't—structural loads on a battery pack are minimal compared to the electrochemical stresses from charging and discharging. But long-term data will take years to accumulate.

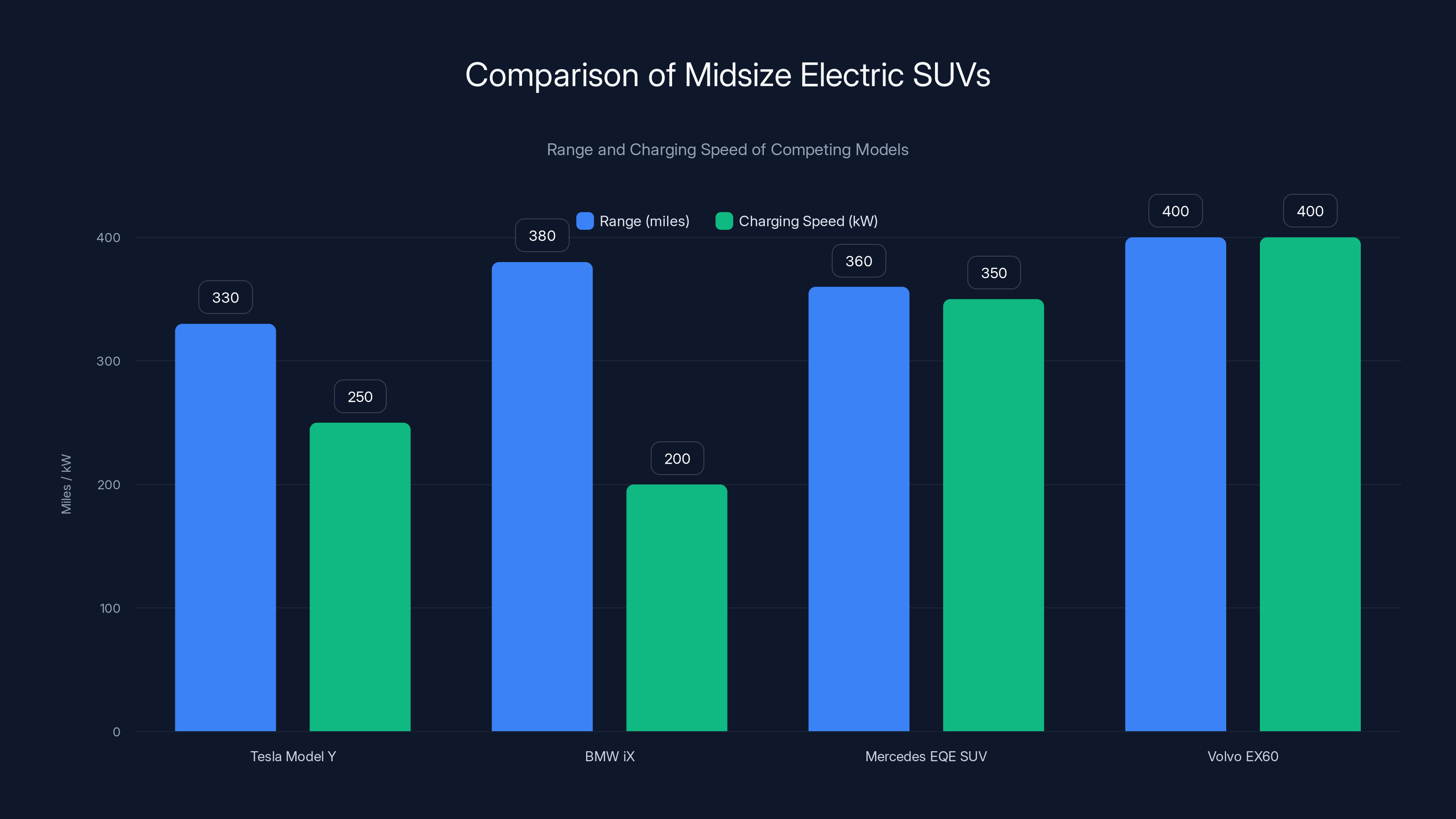

The Volvo EX60 leads in both range and charging speed among midsize electric SUVs, offering 400 miles of range and a 400 kW charging capability, surpassing its competitors.

Comparison With Competing Midsize Electric SUVs

Where does the EX60 stand against competitors? Let's look at the landscape. The Tesla Model Y, while technically smaller, competes in the same price range and customer segment. The BMW iX, the Mercedes-Benz EQE SUV, and the Audi Q6 e-tron are more direct competitors in terms of size and positioning.

Range comparisons are tricky because EPA, WLTP (Europe), and Chinese standards use different testing methods. The Model Y Long Range manages roughly 330 EPA miles. The BMW iX with the 130 kWh battery achieves around 380 EPA-estimated miles on the newest version. The Mercedes EQE SUV manages around 360 miles EPA-estimated.

So a claimed 400 miles puts Volvo at the top of the midsize SUV segment. That's a meaningful advantage, roughly 30-70 miles more than competitors. In real-world driving, that difference might shrink to 20-40 miles after accounting for variations in driving style and conditions. Still significant.

Charging speed comparison: Tesla Supercharger V3 delivers up to 250 kW. Electrify America's latest stations deliver 350 kW. BMW iX charging tops out at around 200 kW with current infrastructure. A 400 kW capability puts the EX60 ahead of current infrastructure availability, future-proofing for when chargers catch up.

Pricing isn't officially confirmed yet, but Volvo typically positions vehicles 10-15% below German luxury competitors. If the iX starts around

Why Volvo Needed a Midsize Option: Market Context and Sales Performance

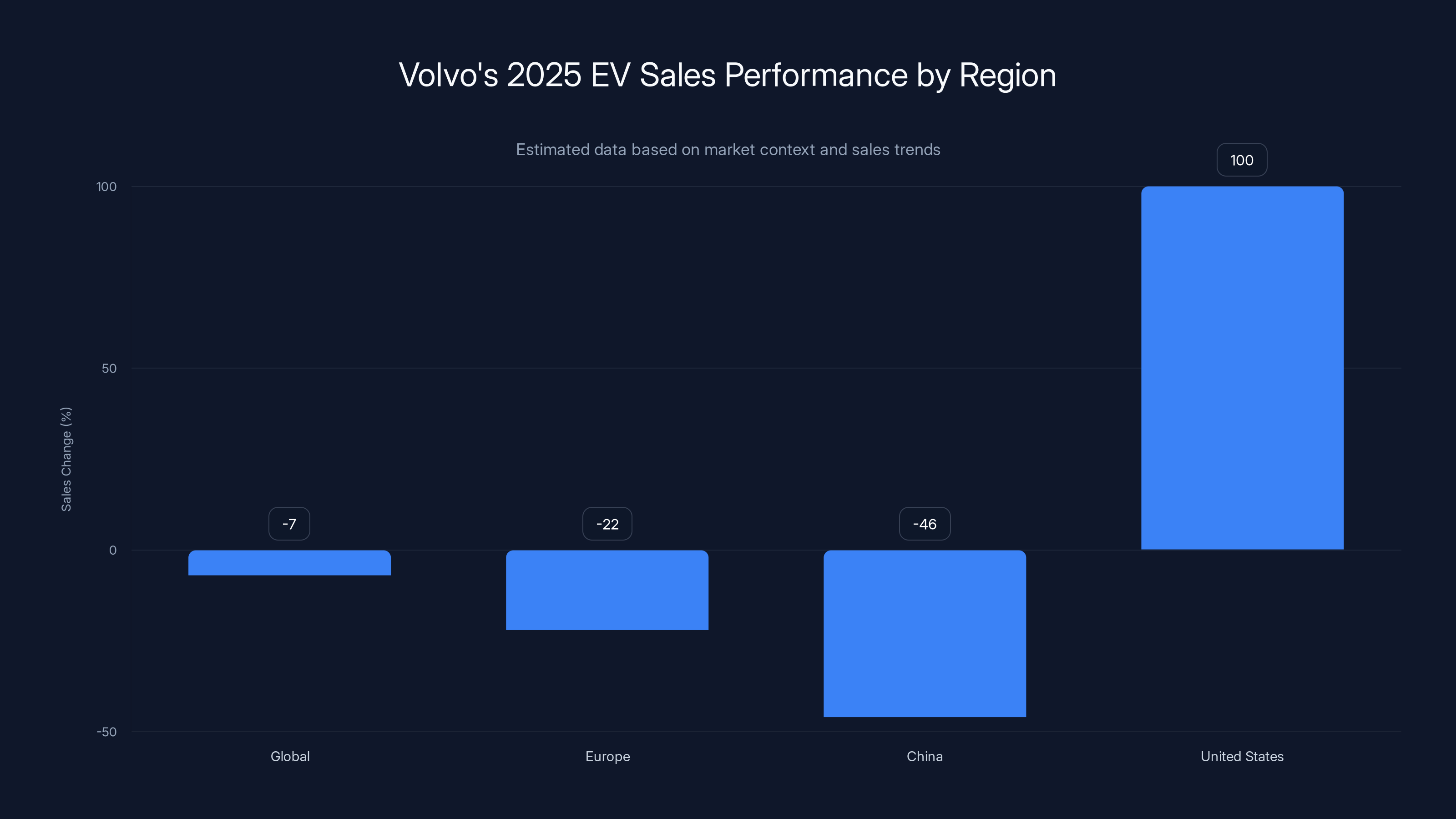

Let's talk about why the EX60 exists. Volvo's 2025 was rough. Global sales fell 7% year-over-year, but the really concerning numbers were in EV sales specifically. Europe saw a 22% decline in EV sales. China, the world's largest EV market, saw Volvo's EV sales drop 46%. That's catastrophic in an industry betting everything on electrification.

The bright spot? The United States. Volvo doubled its EV sales in the U.S. in 2025 compared to 2024, driven primarily by the EX30 (small, affordable) and EX90 (large, luxury). But there was a gap in the middle. Customers wanting something between the compact EX30 and the flagship EX90 had no options. The EX60 fills that gap.

This positioning reflects broader market trends. Consumers want choice in size and price. The EX30 targets younger buyers and budget-conscious customers. The EX90 targets luxury and performance enthusiasts. The EX60 targets families and practical buyers who want something larger than compact but don't need the EX90's premium positioning or flagship price.

Geographically, this strategy matters differently in different markets. In North America, the midsize SUV is the heart of the market—this is where sales volume lives. In Europe, premium midsize vehicles do well but face competition from different angles (taxes and charging infrastructure). In China, Volvo is fighting for relevance against domestic brands that have profound cost and technology advantages.

The performance issues in 2025 also reflect the increasing competitiveness of the EV market. Every manufacturer is launching EVs. Prices are dropping. Consumers have real choice for the first time. Volvo's traditional brand cachet—Swedish engineering, safety focus, luxury positioning—resonates with some buyers but doesn't automatically guarantee sales in a crowded marketplace.

Introducing the EX60 with exceptional range and charging speed is Volvo's attempt to compete on substance rather than heritage. The messaging is clear: we're not resting on history; we're building better EVs right now.

Volvo's EV sales in 2025 saw a global decline, with significant drops in Europe and China. However, the U.S. market showed a positive trend, doubling sales, highlighting the need for a midsize option like the EX60. Estimated data.

The Cell-to-Body Manufacturing Process: Complexity and Quality Control

Manufacturing a cell-to-body vehicle represents a complete rethinking of assembly line processes. Traditional vehicle manufacturing evolved over a century. Hundreds of stamped panels are welded together. A separate battery pack is bolted underneath. Seats, door panels, and interior trim are installed into this structure.

Cell-to-body flips this sequence. The battery structure goes into the press first. It becomes the foundation for everything else. The upper body structure mounts onto it. This requires different tooling, different assembly sequences, and different quality control checkpoints.

Volvo's Ghent plant in Belgium produces the EX90 and will handle EX60 production. The company has invested substantially in robotics and automation to handle the precision required for structural battery integration. Vision systems check cell positioning. Load testing validates structural integrity before vehicles progress to the next assembly stage.

One manufacturing advantage is flexibility. A structural design that integrates the battery also integrates wiring, cooling, and power management. These components don't need separate assembly steps—they're built in from the start. Line efficiency theoretically improves compared to traditional designs where battery installation is a separate process.

Quality control challenges are different but not necessarily harder. Instead of checking that a bolt is tightened to specification, you're checking that battery cells are positioned correctly and that structural interfaces are clean and precise. Automated systems handle most of this, reducing human error.

Thermal Management Systems: The Unsexy Engineering That Makes Everything Work

Battery thermal management might be the most important engineering system you never think about. It's why your phone gets warm during charging. It's why electric cars need sophisticated cooling systems. And it's absolutely critical to the EX60's ability to deliver 400 miles and charge at 400 kW.

Lithium-ion batteries generate heat when charged, discharged, or operated at high power. Ideal operating temperature for most lithium-ion batteries is 20-35 degrees Celsius (68-95 Fahrenheit). Below that range, internal resistance increases and the battery can't deliver peak power. Above that range, degradation accelerates and safety risks increase.

The EX60 needs a thermal management system that maintains battery temperature within optimal ranges across extreme conditions. In Arizona summer heat, the system must cool the battery. In Canadian winter, it must warm the battery. During rapid charging at 400 kW, thermal management must prevent the battery from overheating while maintaining power delivery.

This isn't a simple coolant loop. Modern EV thermal systems are integrated networks with multiple temperature zones, bypass valves, and intelligent control. Some cells might be cooled more aggressively than others based on localized heat generation. The motor cooling loop and battery cooling loop might be separate or integrated depending on operating conditions.

Volvo likely uses a combination of liquid cooling (for high-power heating/cooling demands) and phase-change materials (for passive thermal buffering). Phase-change materials absorb heat when battery temperature rises and release heat when temperature drops, smoothing out temperature swings and reducing the load on active cooling systems.

Control logic is handled by the battery management system. This computer monitors temperature sensors throughout the battery pack, predicts thermal behavior based on current operating conditions, and adjusts cooling delivery. It's essentially a cruise control for temperature, keeping the battery in its happy zone as much as possible.

The efficiency implications are significant. Every watt of energy used for thermal management is a watt not used for propulsion. Optimizing thermal management might save 50-100 watts during normal driving, adding 10-15 miles of range. During rapid charging, efficient thermal management allows sustained high-power delivery rather than throttling back when temperatures rise.

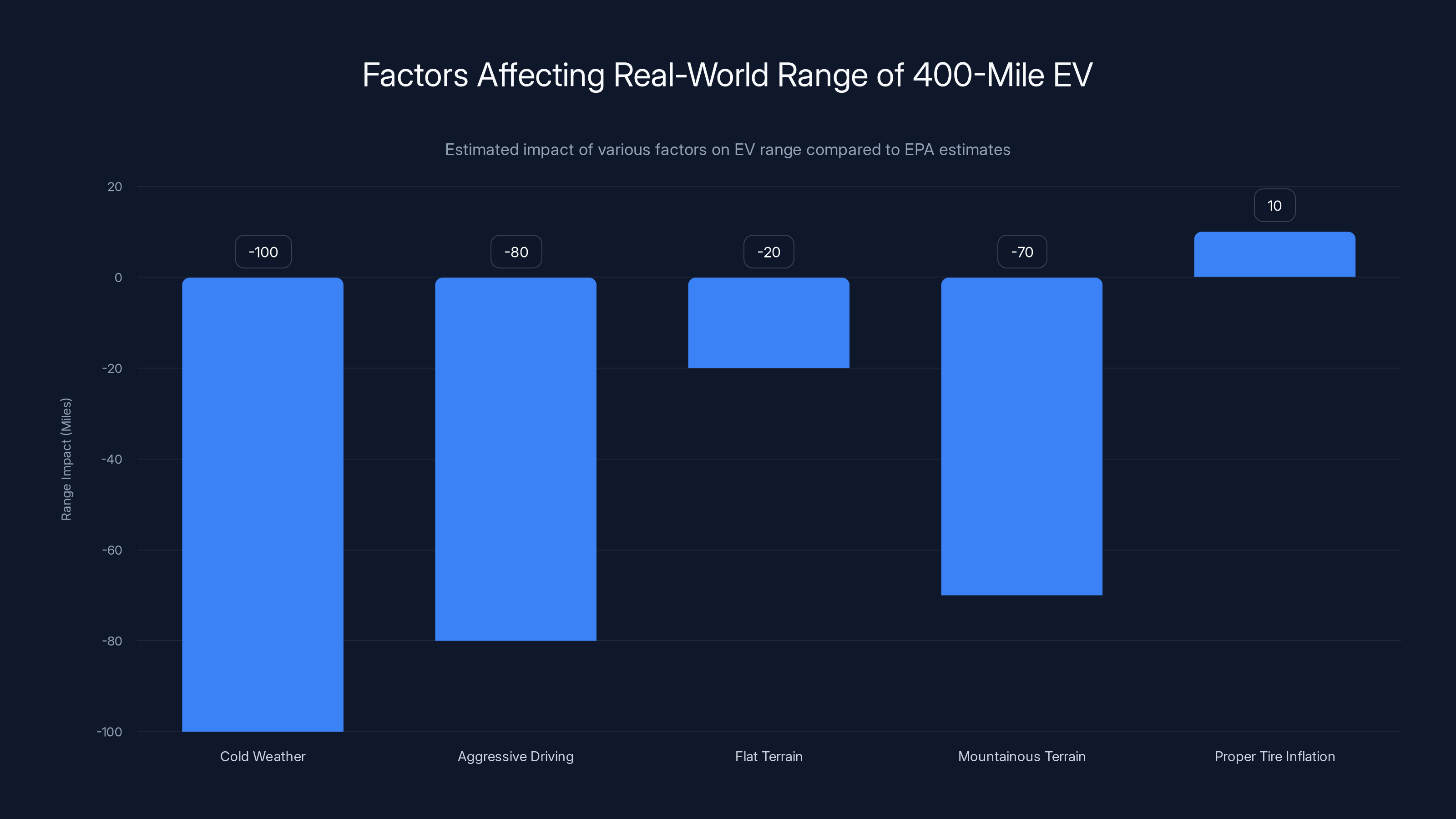

Estimated data shows cold weather and aggressive driving can significantly reduce EV range, while proper tire inflation slightly improves it.

Real-World Range Expectations: What 400 Miles Actually Means

Here's where the rubber meets the road—literally. EPA range estimates, while standardized, don't perfectly predict real-world driving. Several factors cause deviation.

Temperature is the biggest variable. Cold weather reduces range significantly. A battery operating at 40 degrees Fahrenheit has higher internal resistance than one at 70 degrees. The motor needs more power to overcome this resistance. And battery heating (warming the battery to optimal operating temperature) requires energy. Combine these factors and cold-weather range might be 20-30% lower than EPA estimates.

Driving style matters enormously. Aggressive acceleration drains the battery faster. Highway driving at 75 mph uses more energy than city driving at 35 mph. Regenerative braking doesn't recover as much energy during highway driving. An efficient highway driver might see range 10-15% above EPA estimates. An aggressive driver might see 15-20% below.

Terrain and elevation change affect range. Mountains demand more energy climbing and less energy descending (depending on regenerative braking efficiency). A 400-mile EPA-rated vehicle might achieve 380 miles on flat terrain and 330 miles through mountainous regions.

Tire pressure significantly impacts rolling resistance. Under-inflated tires waste energy. Properly inflated tires optimized for efficiency (higher pressure than comfort-oriented specs) can improve range by 2-3%.

Payload and aerodynamic drag matter. A fully loaded vehicle with roof-mounted cargo achieves less range than an empty one. Volvo likely designed the EX60 with excellent aerodynamics (coefficient of drag probably around 0.23-0.25 Cd), but aftermarket modifications reduce efficiency.

A realistic range expectation for the EX60 in mixed driving:

- Cold weather (below 40°F): 340-360 miles

- Temperate weather (50-75°F): 380-400 miles

- Hot weather (above 85°F): 360-380 miles

- Highway driving (70 mph sustained): 340-370 miles

- City driving (mixed speeds): 400-420 miles

These estimates assume decent driving habits, properly maintained tires, and typical loading. Your mileage will vary, as the EPA always says.

Charging Infrastructure Reality: Where 400 kW Chargers Actually Exist

This is the practical limitation. The EX60 can accept 400 kW, but current charging infrastructure is limited.

In North America, Electrify America has deployed 350 kW chargers at select locations. Tesla Supercharger V3 tops out at 250 kW for most vehicles. These networks are expanding, but coverage is concentrated around major highways and urban centers.

Europe has better ultra-fast charging infrastructure. Companies like Ionity and Allego operate 350-400 kW chargers across major European highways. Volvo's home market is well-positioned for this technology.

China has the most extensive ultra-fast charging network. By the time the EX60 launches there, many cities will have 400+ kW chargers available.

The practical implication: the EX60's 400 kW capability is genuine but won't be fully utilized by most owners most of the time. When you encounter a true 400 kW charger, the EX60 will leverage it. When you charge at more common 150-200 kW stations, you'll get slower charging than the headline specs suggest. This is normal and expected as infrastructure evolves.

Volvo's decision to support 400 kW is future-proofing. The EX60 will be sold for 5-7 years. Charging infrastructure will improve every year. A vehicle rated for 400 kW can take advantage of newer infrastructure that didn't exist when the car launched.

The Competitive Landscape in 2026 and Beyond

What does Volvo face from competitors launching similar vehicles? Tesla's Model Y refresh might include improved range. BMW will update the iX. Mercedes will refine the EQE. Audi will launch new variants of the Q6 e-tron.

The advantage Volvo has right now is momentum. The EX60 launches with serious specifications and modern engineering. It's not a refresh of an old platform. It's built from scratch using current best practices in EV design.

Cost is another advantage. Volvo's manufacturing capabilities and platform sharing with Geely/Polestar allow competitive pricing. The EX60 will likely undercut equivalent luxury competitors by several thousand dollars while matching or exceeding their capabilities.

The weakness is brand perception in some markets. In the U.S., Volvo is known for safety and reliability but not for cutting-edge technology or performance. The EX60 will need strong marketing to overcome this perception.

Volvo's strategy appears to be building momentum through product competitiveness, then leveraging that momentum to increase brand value. The EX30 proved affordable EVs work. The EX90 proved luxury EVs work. The EX60 proves mid-market EVs work. By the time Volvo refreshes its entire lineup in 2027-2028, the brand will have multiple successful EV generations and a reputation for delivering on technical promises.

Technical Specifications Summary and What They Reveal

Let's aggregate what we know about the EX60's technical package:

Performance Metrics:

- 400 miles EPA-estimated range

- 168 miles in 10 minutes charging (at 400 kW)

- 400 kW maximum charging power

- In-house designed motors for efficiency

- Structural battery pack integration

- Mega-cast rear floor and likely front structure

- Cell-to-body battery architecture

Engineering Priorities (revealed by choices):

- Weight efficiency is paramount (justified by mega castings and structural integration)

- Motor efficiency is critical (in-house design signals high priority)

- Thermal management is sophisticated (required for 400 kW charging)

- Structural integration is fundamental (battery pack isn't bolt-on, it's built-in)

Market Positioning:

- Premium but not ultra-luxury

- Practical rather than performance-focused

- Technology-forward without excessive complexity

- Range and charging as primary selling points

These choices reveal that Volvo is targeting practical buyers who care about capability and efficiency. They're not trying to out-performance Tesla with 0-60 times. They're not trying to out-luxury Mercedes with hand-stitched interiors. They're trying to out-engineer everyone with thoughtful design that delivers on real customer needs.

What the EX60 Launch Means for Volvo's Future

The EX60 isn't just a new product. It's a statement about Volvo's commitment to electric vehicles and modern engineering. The Swedish automaker is betting significant resources on this vehicle succeeding in multiple markets.

Success in North America is crucial. The U.S. market is essential to profitability. If Volvo can capture meaningful market share in the midsize premium SUV segment, it funds investment in future products. The EX60 is the vehicle that proves Volvo can compete on technology and capability, not just heritage and safety.

For customers considering the purchase, the EX60 represents a genuine alternative to established competitors. You're not buying yesterday's platform with modern batteries bolted on. You're buying a vehicle engineered from the ground up as an EV. Every component reflects modern best practices in electric vehicle design.

The longer-term implications are about platform leverage. The EX60's platform and architecture will likely underpin future Volvo vehicles. A smaller variant might become the next-generation EX30. A larger variant might replace the EX90. Geely and Polestar will probably use similar or identical platforms for their own models. One successful platform design generates multiple successful vehicles.

Key Takeaways From the EX60's Technical Achievement

The Volvo EX60 represents a genuine leap forward in midsize electric SUV engineering. The combination of 400-mile range, 400 kW charging, structural battery integration, and mega-cast construction isn't flashy, but it's genuinely impressive.

Range anxiety finally becomes a non-issue for most drivers. Four hundred miles covers 90% of real-world driving needs. Charging at meaningful speeds (168 miles in 10 minutes) makes road trips viable without extensive planning.

The engineering choices—mega castings, cell-to-body architecture, in-house motor design, thermal management—reveal that Volvo is serious about efficiency and cost optimization. These aren't luxury features. They're practical engineering that benefits every owner.

For the EV market broadly, the EX60 signals that technology has matured. Automakers aren't struggling to hit 200-mile range anymore. They're competing on 350-400 mile range. They're not just accepting slow charging. They're building fast-charging into the DNA of new platforms. The EV transition isn't coming—it's here. The EX60 is proof that mature, practical electric SUVs are now the default, not the exception.

FAQ

What is the Volvo EX60's EPA-estimated range?

Volvo claims the EX60 will achieve 400 miles of EPA-estimated range, making it class-leading in the midsize electric SUV segment. This range is achieved through a combination of structural battery integration, efficient in-house-designed motors, mega-cast construction for weight reduction, and optimized aerodynamics. Real-world range will vary based on driving conditions, temperature, terrain, and driving style, typically landing 10-20% lower in demanding conditions like cold weather or highway driving.

How fast does the Volvo EX60 charge?

The EX60 can accept up to 400 kilowatts of charging power at compatible ultra-fast chargers. This allows it to add approximately 168 miles of range in 10 minutes under optimal conditions. However, actual charging speed varies across the charging curve, with maximum power delivery typically occurring at lower state-of-charge and tapering as the battery reaches higher charge levels. The 10-80% charging time (more representative of typical usage) is estimated at 20-25 minutes with 400 kW infrastructure.

What is cell-to-body battery architecture and why does it matter?

Cell-to-body architecture integrates the battery pack as a structural member of the vehicle, rather than as a separate component bolted underneath. This approach allows the battery cells to support vehicle weight, absorb crash forces, and provide structural rigidity, eliminating redundant structural components. The benefits include improved space efficiency (more volume for actual battery capacity), weight reduction (fewer structural components needed), enhanced crash performance (integrated energy absorption), and better packaging efficiency.

How do mega castings improve the EX60?

Mega castings replace multiple stamped metal parts and welded assemblies with single-piece aluminum castings. The EX60's rear floor is a single mega casting instead of multiple welded panels. Benefits include significant weight reduction (potentially 500+ pounds across the vehicle), improved structural rigidity, elimination of weak points at welds, and simplified manufacturing processes. The trade-off is increased tooling cost and more complex quality control requirements.

What does it mean that Volvo designed the EX60's motors in-house?

In-house motor design allows Volvo to optimize every aspect of motor performance specifically for the EX60's weight distribution, aerodynamic profile, and power requirements. This results in better efficiency across the motor's operating range, improved thermal characteristics, and better integration with the vehicle's overall efficiency strategy. Custom motors are more expensive than off-the-shelf components but deliver measurable improvements in range and performance.

How does the EX60 compare to Tesla Model Y and BMW iX in range and pricing?

The EX60's claimed 400-mile EPA range exceeds the Model Y Long Range (approximately 330 miles) and is competitive with the newest BMW iX variant (approximately 380 miles). Pricing hasn't been officially confirmed, but Volvo typically positions vehicles 10-15% below German luxury competitors. If the BMW iX starts around

Will the EX60 have sufficient charging infrastructure for 400 kW charging?

Current charging infrastructure is limited. Electrify America has deployed 350 kW chargers at select locations. Tesla Supercharger V3 tops out at 250 kW. The EX60's 400 kW capability is future-proofing—the vehicle will remain relevant as infrastructure improves over its 5-7 year sales cycle. In most of North America today, owners will charge at 150-350 kW networks, receiving substantial but not maximum charging speeds.

What thermal management systems does the EX60 use?

The EX60 requires sophisticated thermal management to maintain optimal battery temperature across extreme conditions. This likely includes liquid cooling loops for active thermal management, phase-change materials for passive thermal buffering, separate cooling circuits for battery and motor, and intelligent control logic via the battery management system. Thermal management is critical for both achieving 400-mile range (cold batteries are less efficient) and supporting 400 kW charging speeds.

Why did Volvo create the EX60 between the EX30 and EX90?

Volvo's 2025 sales showed strong U.S. performance with the EX30 and EX90, but a gap in the midsize segment. The EX60 targets practical buyers wanting something larger than compact but not requiring EX90's premium positioning or flagship pricing. This strategy reflects broader market trends where consumers want choices in size and price. The EX60 also addresses Volvo's weak performance in Europe and China by offering a product optimized for global markets with strong range and charging capabilities.

How does cold weather affect the EX60's range and charging speed?

Cold weather reduces EV range and charging speed through multiple mechanisms. Cold batteries have higher internal resistance, reducing power delivery. Battery heating (warming the battery to optimal operating temperature) consumes energy. Cold air reduces motor efficiency. Combined, these factors typically reduce range by 20-30% in temperatures below 40°F. Charging speed may reduce 20-40% in cold conditions because the thermal management system prioritizes battery warming over charging power. Volvo's system likely includes battery preheating for cold climates to mitigate these effects.

When will the Volvo EX60 be available for purchase?

Volvo unveiled the EX60 in January 2026, with official specifications and availability details released at that time. Production and customer deliveries are typically expected within 3-6 months of a major unveiling, suggesting EX60 availability likely in Q2-Q3 2026. Specific availability dates and market rollout vary by region, with North America, Europe, and China potentially having staggered launch schedules.

Related Articles

- Samsung Galaxy S26 Rumors and Expected Features [2025]

- Samsung Galaxy S26 Launch Date & Price Predictions [2025]

- CES 2026 Day 1: The 11 Best Tech Gadgets Revealed [2025]

- LG xBoom Speakers 2026: AI EQ, Smart Lighting, and Design Innovation [CES]

- Best Phones 2025: Why Folding Devices & Design Innovation Matter [2025]

![Volvo EX60: 400-Mile Range and 400 kW Charging Explained [2025]](https://tryrunable.com/blog/volvo-ex60-400-mile-range-and-400-kw-charging-explained-2025/image-1-1767861426111.jpg)