China's Hidden Car Door Handle Ban: The Safety Crisis Reshaping Electric Vehicles

Imagine being trapped in your own car during an emergency because the door won't open. It's not a hypothetical scenario. It's happened dozens of times, and it's infuriating enough that China's government decided to ban the feature causing it.

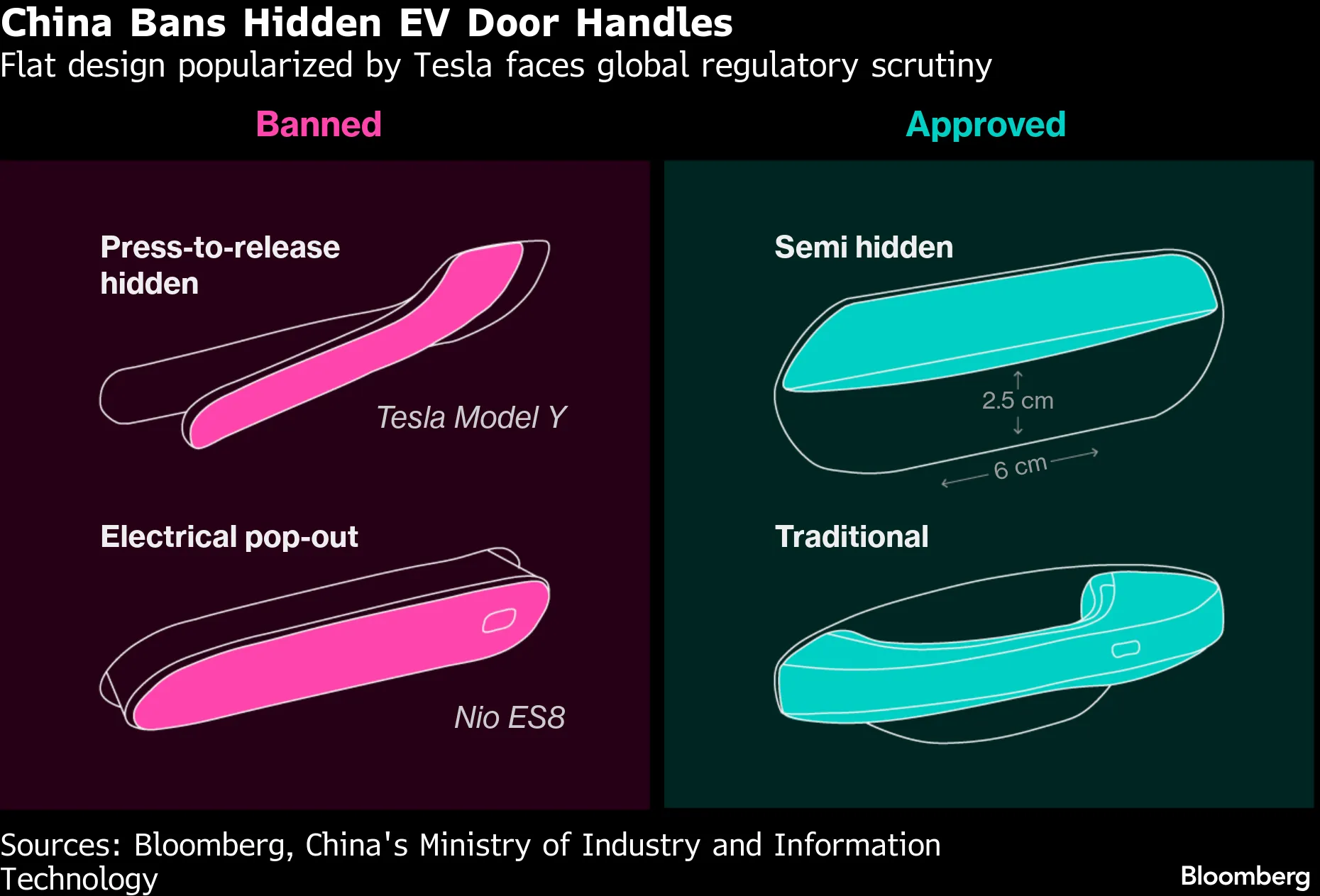

On January 1, 2027, a new safety regulation took effect across China. Every new vehicle sold in the country must have a mechanical, manually-operated door handle that doesn't rely on electronics. This seemingly small technical requirement represents something far bigger: the first major government pushback against design trends that prioritize sleekness over survival, as reported by Bloomberg.

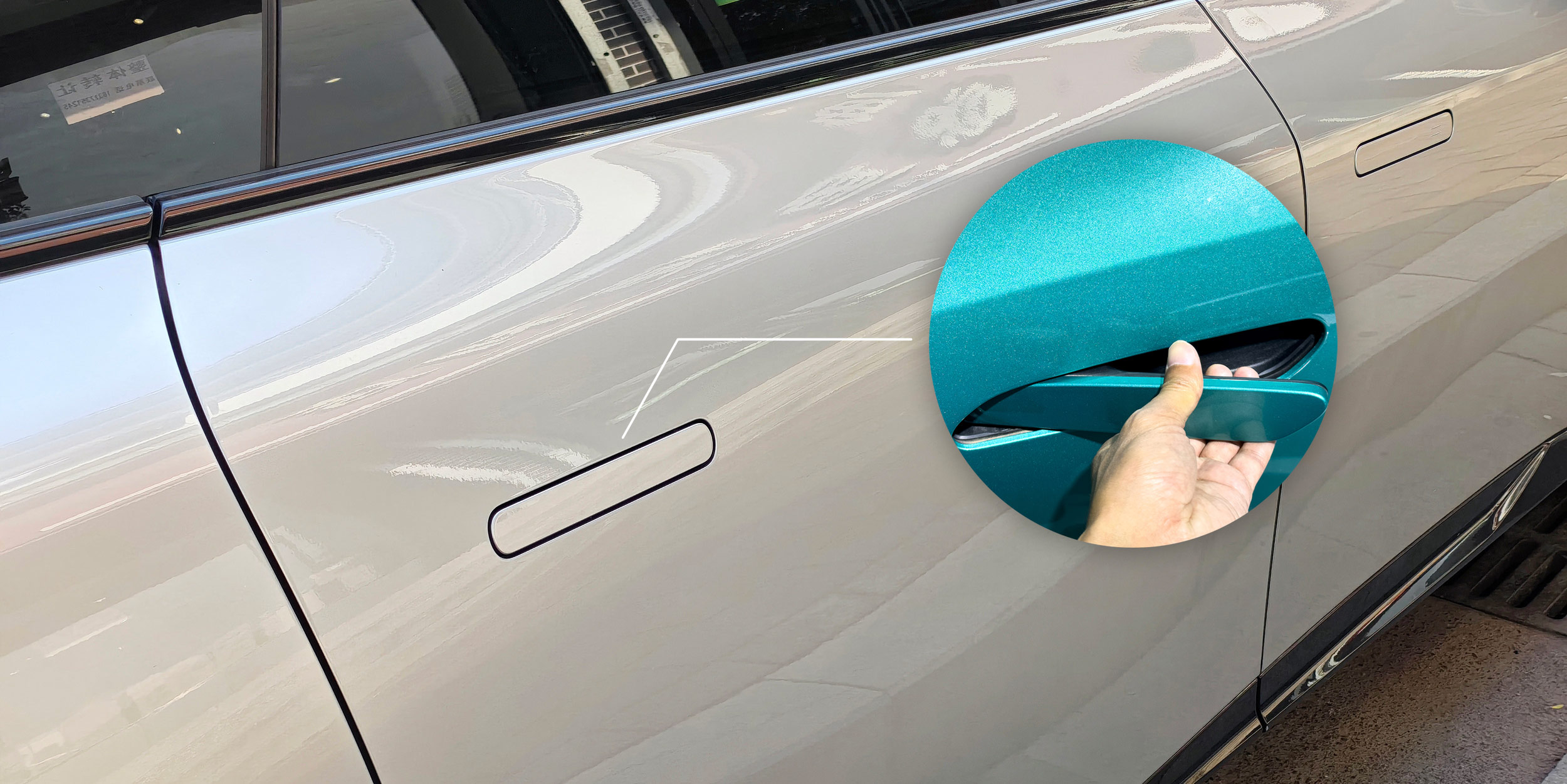

The rule targets a specific innovation that Tesla popularized and that's now spread to nearly every electric vehicle maker. Hidden, flush-mounted door handles that pop out electronically. They look incredible in marketing photos. They reduce drag, save weight, and create that seamless, minimalist aesthetic that EV companies have been obsessed with for years. But they also create a critical failure point. When your battery dies, your door handle dies with it. When the electronic system glitches, you're stuck.

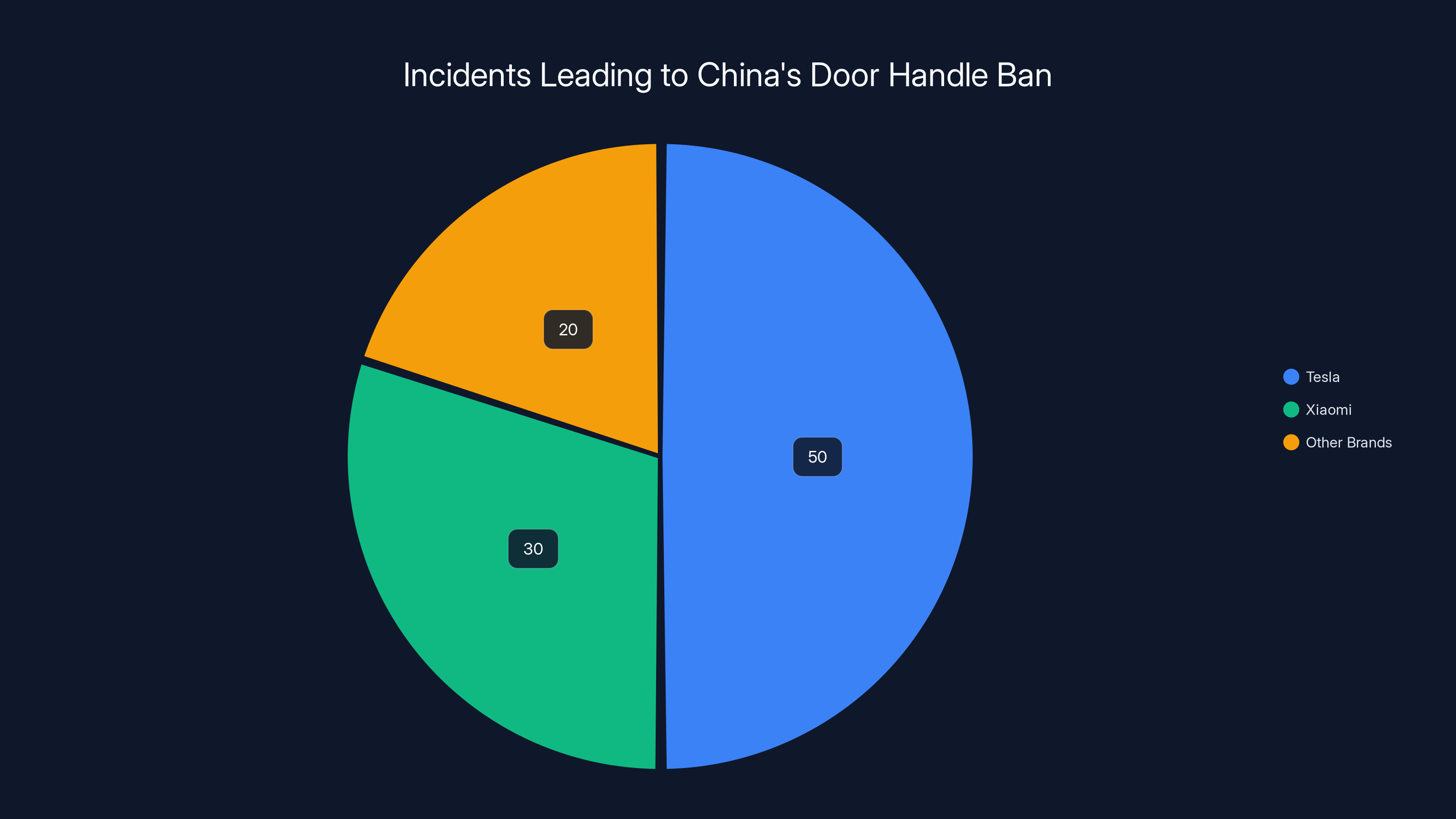

China didn't make this decision in a vacuum. Multiple fatal crashes pushed regulators to act. A Xiaomi SU7 crash. A Tesla incident. Stories of occupants trapped while emergency responders couldn't reach them. Stories of children unable to find the manual override because it was hidden and unmarked. These weren't edge cases. They were warnings that the industry ignored, as noted by Consumer Reports.

This article breaks down what the ban actually means, why it happened, how it'll reshape the EV industry, and what it tells us about the future of automotive safety and design.

TL; DR

- New Regulation: China's government banned electronic-only door handles effective January 1, 2027, requiring mechanical releases on all vehicle doors

- The Problem: Hidden electronic door handles fail during power loss, trapping occupants in vehicles during emergencies

- Fatal Context: Multiple crashes in China, including a Xiaomi SU7 incident, exposed the danger and prompted regulatory action

- Industry Impact: Tesla, BYD, Xiaomi, and over 40 other manufacturers must redesign vehicles to comply

- Global Ripple: The U.S. is investigating similar issues; other countries may follow China's lead

- Bottom Line: Sleek design lost to survival. Every EV sold in China now needs a way to open from the inside, no electricity required

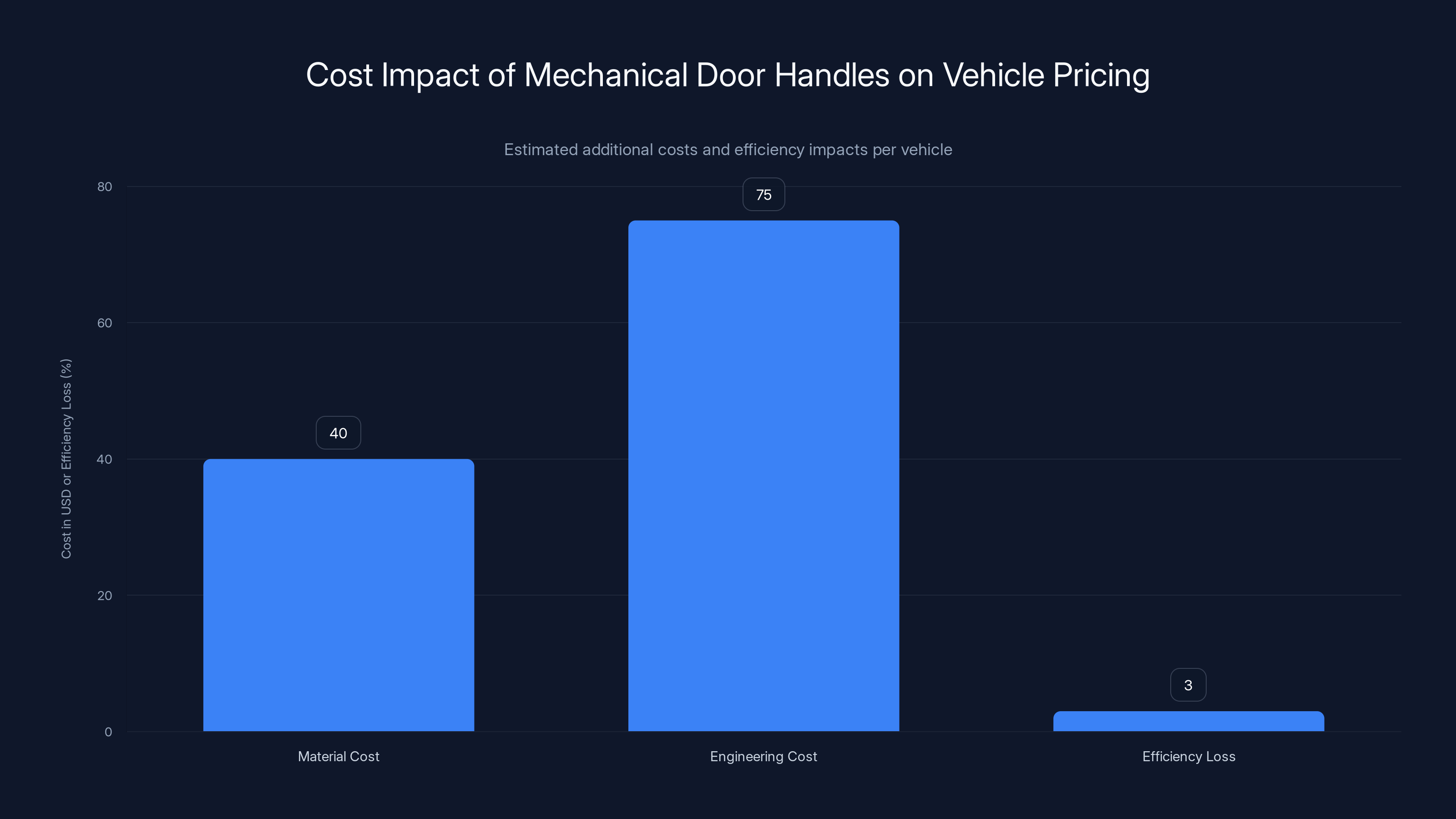

Estimated additional costs per vehicle include

Why Hidden Door Handles Became a Problem

When Tesla introduced flush-mounted, electronically-actuated door handles on the Model X in 2015, it was brilliant theater. The doors would pop out like something from a sci-fi film. It reduced wind resistance. It eliminated the mechanical complexity of traditional external door handles. From an engineering and marketing perspective, it was genius.

The problem? Nobody accounted for what happens when the system fails.

Electric vehicles rely entirely on battery power for almost everything. Your door handle, your locks, your window motors, your climate control. All electronic. Most of the time, this works flawlessly. But when it doesn't, the consequences are immediate and severe.

A car's battery can fail in several ways. A crash can damage the electrical system. A software glitch can lock out the door mechanism. Extreme cold can drain power faster than expected. And in rare but critical moments, the battery can become completely depleted before the vehicle shuts down properly, as highlighted by KNOP News.

When any of these happen, and your door handle is entirely electronic with no mechanical backup, you have a problem. You're physically trapped inside a vehicle. Your options are limited. Call for help. Wait for a technician. Break a window. Pray the manual override you didn't know existed actually works.

For emergency responders, the situation is even worse. If they don't know about the manual release, or if it's located somewhere unintuitive, they can't quickly extract trapped occupants. In a fire, in a flood, in any time-critical emergency, seconds matter. Hidden door handles cost seconds.

Tesla does include manual releases inside its vehicles. But they're often small, unmarked, and many owners are completely unaware they exist. Some are positioned in difficult-to-reach locations. Children might not have the strength to use them. First responders arriving at an accident scene have no way to know where these hidden releases are without instruction.

The design philosophy was clear: optimize for aesthetics and aerodynamics at the cost of redundancy and fail-safe design. It's a trade-off the auto industry has made countless times. Usually, it works out. Sometimes, it costs lives.

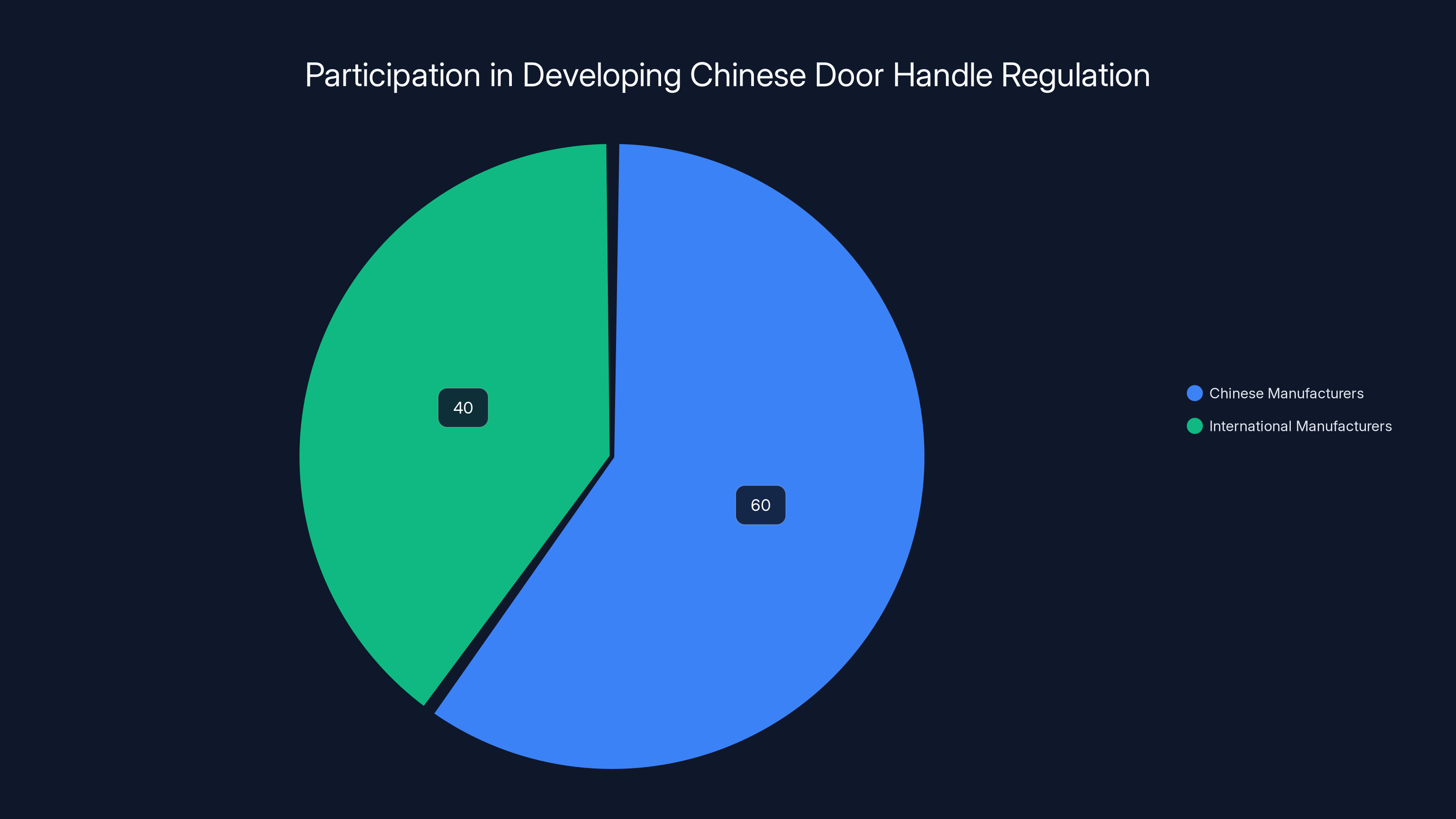

Estimated data shows that 60% of the manufacturers involved in developing the Chinese door handle regulation were Chinese, while 40% were international. This highlights the collaborative effort to enhance vehicle safety.

The Fatal Incidents That Triggered Regulation

Regulation rarely happens without tragedy to drive it. China's ban on electronic door handles was no exception.

The specific incident that seems to have tipped the scales was a crash involving a Xiaomi SU7, Xiaomi's first electric sedan. The incident exposed what happens when occupants become trapped in a vehicle and can't escape. The implications were clear and terrifying to Chinese regulators, as detailed by Bloomberg.

This wasn't isolated. Across China, multiple incidents surfaced where occupants or first responders couldn't open vehicle doors due to electronic failures. Each story added pressure. Parents concerned about their children. Emergency workers frustrated by design decisions that actively hindered rescue efforts. News coverage amplifying the danger.

Meanwhile, in the United States, Bloomberg's investigative journalism uncovered similar problems. An investigation into Tesla vehicles found that the concealed door handles could fail during crashes when the battery system wasn't providing adequate power to the door actuators. The electronic locks would engage, trapping people inside. The manual releases, when occupants could find them in the chaos of a crash, sometimes worked. Sometimes they didn't.

The U.S. National Highway Traffic Safety Administration took notice. They opened a formal defect investigation into certain Tesla Model Y and Model 3 vehicles. Investigators noted that the manual releases inside Tesla vehicles are often difficult for children to locate and access. Many owners don't even know the releases exist. The design created a knowledge gap that could be fatal, as reported by Repairer Driven News.

Some U.S. lawmakers proposed regulations requiring manual door releases in all new vehicles, similar to what China eventually implemented. But the U.S. moved slowly. China moved decisively.

China's government and regulators looked at the evidence. They saw a pattern. A design trend that prioritized appearance and aerodynamic efficiency over safety redundancy. A failure mode that was rare but catastrophic. An industry that wasn't voluntarily fixing the problem because the aesthetic benefit and engineering simplification were too valuable to abandon.

The decision was made. Starting January 1, 2027, this ends.

The Chinese Government's Safety Technical Requirements for Automobile Door Handles

China didn't rush this regulation. The government took a methodical approach that involved the entire automotive industry.

In May 2025, the Chinese government began the formal standards development process. Over 40 domestic vehicle manufacturers, parts suppliers, and testing institutions participated. The scope was massive. BYD, one of the world's largest EV makers. Geely Holdings, a major Chinese automaker. SAIC, another domestic manufacturer. Xiaomi, the electronics giant entering the EV market. NIO, XPeng, Li Auto, and dozens of others all had a seat at the table.

But international manufacturers were invited too. General Motors, Ford, Hyundai, Nissan, Porsche, Toyota, Volkswagen. They had a voice in shaping the standard because they all sell vehicles in China and would all need to comply.

One notable absence? Tesla was not listed as an official "drafter" of the regulation on the Chinese government's standards agency website. This is significant. Tesla has enormous influence in China. The company builds vehicles there, sells them there, and has deeply embedded relationships with Chinese government agencies. Yet Tesla didn't participate in drafting the rule that would most directly affect its design philosophy.

More than 100 industry experts held multiple rounds of discussions. Engineers from battery manufacturers debated the requirements with suspension specialists. Safety engineers discussed what a mechanical release needed to withstand. Testing professionals outlined how to verify compliance. Discussions covered edge cases. What if someone's hand is injured? What if a child is trying to escape? What about people with limited strength?

The resulting standard was released as the "Safety Technical Requirements for Automobile Door Handles." The key requirement is simple but comprehensive: each door (excluding the tailgate) must be equipped with a mechanically released external door handle. Vehicles must also have a mechanical release on the interior of the vehicle. That means no electronic-only systems. No flush-mounted pop-out handles without a mechanical backup. No design where the door handle disappears into the body panel with zero fallback.

It's a straightforward requirement that has been standard in automobiles for more than a century. Hidden, electronic-only door handles represent a deviation from this baseline safety feature. China's regulation brings the industry back to that baseline, but with modern vehicles.

The regulation goes into effect January 1, 2027. For manufacturers already producing vehicles with electronic-only door handles, this creates a significant design challenge. Every vehicle sold in China after that date needs a redesign.

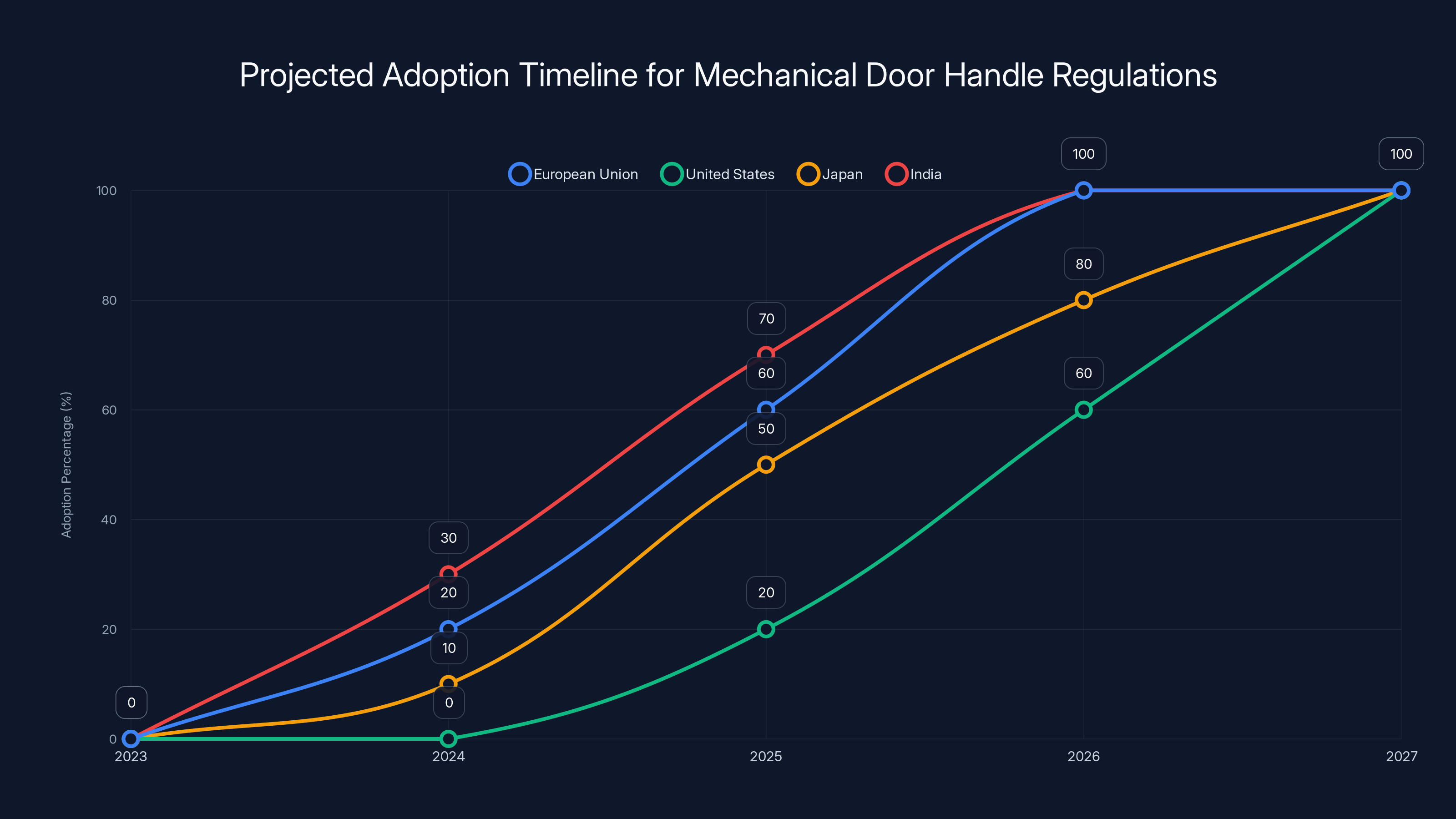

Estimated data shows that the EU may adopt mechanical door handle regulations within 2-3 years, followed by the U.S. in 4-5 years. Other markets like Japan and India are expected to follow closely.

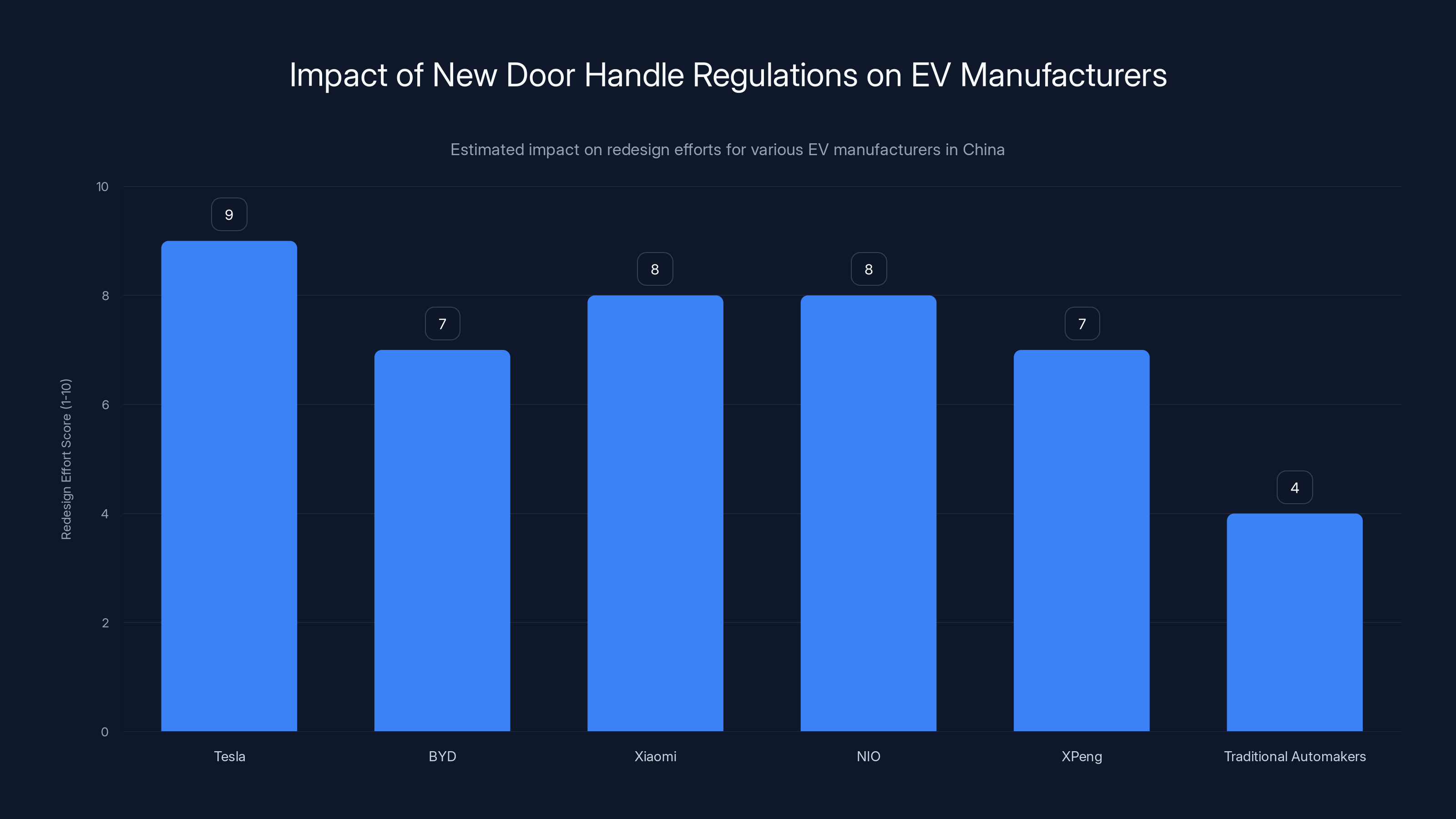

The Impact on Tesla and the Global EV Industry

Tesla's door handle design became iconic. The Model X, Model Y, and Model 3 all feature electronic pop-out handles. They're recognizable. They're futuristic. They're deeply embedded in Tesla's brand identity. And as of January 1, 2027, they're no longer allowed in China.

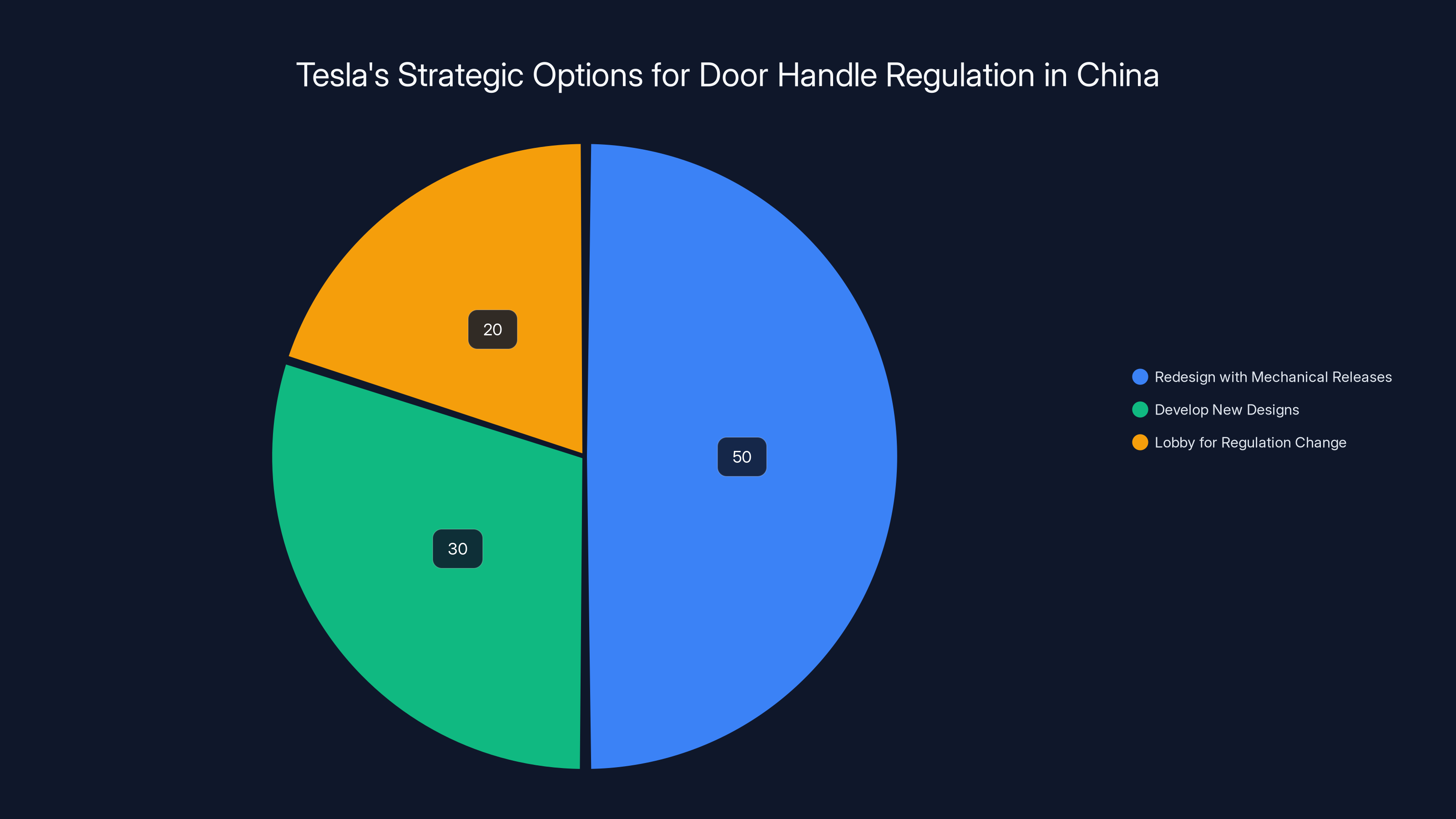

For Tesla, this means a complete redesign of the exterior door handle system for Chinese vehicles. The company could add mechanical releases that work alongside the electronic system, creating redundancy. They could redesign the handles to be partially mechanical with electronic assistance. They could revert to traditional mechanical handles with electronic locks, sacrificing the minimalist aesthetic for compliance and safety, as discussed by Electrek.

Each option involves engineering effort, tooling costs, and supply chain changes. It also involves accepting that the iconic flush-mounted pop-out handle won't exist on Chinese Teslas anymore. The visual identity changes. The aerodynamic efficiency is affected. The weight might increase slightly.

But Tesla isn't alone. Every EV maker in China faces the same requirement. BYD, already the world's largest EV manufacturer by sales volume, must redesign its door handles. Xiaomi must redesign its SU7. NIO, XPeng, Li Auto, Geely, SAIC all must comply. And the international manufacturers selling in China, including General Motors, Volkswagen, and Porsche, must redesign their Chinese market vehicles.

For some manufacturers, this might be less disruptive. Traditional automakers never fully embraced electronic-only door handles the way Tesla did. Many EV models still use conventional external door handles with electronic locks. The mechanical release is already there. Adding an interior mechanical release might only require labeling or design modification.

For others, especially startups and brands that built their identity around the electronic handle aesthetic, the impact is more significant.

The regulation also creates a fragmented market. A Tesla Model Y sold in China will have different door handles than one sold in the U.S. European cars sold in China will differ from the same models sold in Europe. Manufacturers now manage multiple vehicle variants across regions based on local safety standards.

This fragmentation has costs. Higher engineering complexity. More stock-keeping units in supply chains. Different training for service technicians. But it also has a benefit: it proves that the electronic-only design isn't essential. Manufacturers can build world-class electric vehicles with mechanical door handles. The assumption that this feature is non-negotiable for performance or image turns out to be wrong.

Why the U.S. Hasn't Acted (Yet)

The contrast between China and the United States is striking. China identified a safety problem, involved its industry, developed a standard, and implemented it in approximately 18 months. The U.S., despite evidence of the same problem, hasn't mandated similar changes.

This isn't because Americans don't care about safety. It's about how regulatory agencies work. The National Highway Traffic Safety Administration opened a defect investigation into Tesla's door handles. NHTSA has the authority to require recalls if it finds a defect. But a recall addresses existing vehicles. A ban addresses future vehicles.

Banning a feature entirely requires rulemaking. NHTSA would need to propose a new standard, accept public comments, conduct research, and finalize the rule. The process takes years. During that time, manufacturers lobby. They argue that the problem is rare. They claim the technology is safe if designed correctly. They propose alternatives like improved software or better training.

Tesla, with its significant political and economic influence, actively participates in the rulemaking process. The company has engineers, safety experts, and representatives involved in every regulatory discussion. They can advocate for their design choices.

Some U.S. lawmakers have proposed legislation requiring manual door releases in all new vehicles. But proposals don't automatically become law. They need to pass both houses of Congress, survive lobbying pressure, and be signed by the president. The political capital required to push a niche safety feature through Congress is substantial, as noted by Autoblog.

Meanwhile, the auto industry argues that the feature is becoming increasingly uncommon as technology improves. Software updates can address issues. Better power management means battery depletion is less likely. The problem, they argue, is being solved through engineering rather than regulation.

China's approach was different. Regulators looked at the evidence and acted directly. They didn't wait for the problem to become more common. They didn't rely on manufacturers to voluntarily improve. They set a requirement and gave manufacturers a clear deadline to comply.

The U.S. may eventually follow. Congressional pressure is building. Safety advocates are vocal. The evidence is clear. But American regulatory processes move slowly. By the time the U.S. implements a similar requirement, China will have already proven that the industry can adapt.

Tesla faces the highest redesign effort due to its reliance on electronic-only door handles, while traditional automakers face less disruption. Estimated data based on industry analysis.

What the Regulation Means for Vehicle Design Philosophy

China's door handle ban signals something broader: a shift in how regulators view innovation in safety-critical systems.

For decades, automotive innovation has often meant removing redundancy. Reducing mechanical complexity. Replacing passive safety features with active electronic systems. Electronic stability control is safer than mechanical anti-lock brakes. Airbags are better than lap belts. Crumple zones are superior to rigid frames. The trend has been toward sophisticated electronics that work better than mechanical alternatives when everything functions as designed.

But the design philosophy has been consistent: introduce new technology, but maintain a mechanical fallback. Brakes have both electronic and hydraulic systems. Steering has both electronic and mechanical components. Most systems have failsafes.

Electronic door handles violated this principle. They were designed as a complete replacement for mechanical handles, not an enhancement of them. There was no redundancy. When the technology failed, there was no backup.

China's regulation reasserts the importance of redundancy in safety-critical systems. It says: your innovation can't come at the cost of a fundamental fail-safe. You can have electronic door handles. You can have flush-mounted handles. You can have all the aesthetic and aerodynamic benefits. But you must maintain a way to open the door if the electronics fail.

This principle will likely extend to other systems. Battery management systems need mechanical overrides. Emergency braking needs redundant systems. Power steering needs a mechanical alternative. The lesson from this regulation is that in safety-critical automotive systems, mechanical backup is not optional. It's required.

For manufacturers, this means design philosophy shifts. Instead of replacing mechanical systems with electronic alternatives, they need to augment mechanical systems with electronic enhancements. Add electronic locks to mechanical handles instead of replacing mechanical handles with electronic ones. This is more complex and sometimes heavier. But it's safer.

Designers and engineers will need to accept that some aesthetic and efficiency goals must be sacrificed for safety. The flush-mounted minimalist handle might not be achievable if a mechanical release is required. But that's the trade-off society is making. Safety redundancy beats pure aesthetics.

The Ripple Effect: Will Other Countries Follow?

China's regulation sets a precedent. When the world's largest automotive market makes a requirement, other governments pay attention.

The European Union has a history of adopting safety standards that are at least as strict as China's. European regulations already require certain safety features that the U.S. doesn't mandate. If China has a mechanical door handle requirement, EU regulators will likely consider adopting the same standard. The engineering is straightforward. The safety benefit is clear.

European automakers are already adapting their vehicles for the Chinese market. Adding a parallel compliance pathway for European regulations wouldn't be significantly more complex. The same mechanical handles could meet both standards.

The United States faces more political obstacles. But the combination of NHTSA's investigation, congressional pressure, and consumer advocacy might eventually push the U.S. toward a similar requirement. Safety advocates will point to China's experience. Regulators will cite evidence of the danger. The momentum could build.

Other markets may follow suit. Japan has a rigorous safety standard development process. India's automotive safety regulations are rapidly evolving. Once mechanical door handles become a baseline requirement in major markets, manufacturers will simply adopt them globally. It becomes easier to make all vehicles the same than to manage variants.

The timeline varies by country. The EU might move within 2-3 years. The U.S. might take 4-5 years. Smaller markets might adopt standards almost immediately. But the direction is clear. China has shown that the industry can adapt to this requirement. Other regulators will likely follow.

For manufacturers, this means planning. Tesla is already adjusting its designs. Other EV makers are reconsidering their door handle strategies. By the time most major markets have similar requirements, the industry will have largely adapted. The flush-mounted electronic-only handle will become a historical curiosity.

Estimated data suggests Tesla is most likely to focus on redesigning vehicles with mechanical releases (50%), followed by developing new designs (30%), and lobbying for regulation changes (20%).

Engineering Solutions: How Manufacturers Are Adapting

When faced with the Chinese regulation, manufacturers have several options. Each involves different trade-offs.

Option one is the simplest: add a mechanical backup to the existing electronic system. Keep the flush-mounted pop-out handle, but add a mechanical release that works even if electronics fail. The button pops out, but it's now mechanically connected to a latch inside the door frame. If power is lost, you can still open the door by engaging the mechanical linkage.

This solution requires engineering work. The handle needs to be redesigned to accommodate both electronic actuation and mechanical release. The interior linkage must be added. Testing must verify that both systems work independently. But it maintains the flush-mounted aesthetic that manufacturers invested in. The engineering cost is moderate. The time to implement is several months.

Option two is a hybrid approach. Replace the flush-mounted pop-out handle with a mechanical handle that includes electronic enhancement. Think of a traditional external door handle where you push or pull to open it. Add electronic locks that prevent opening until the door is unlocked. The mechanical system provides the fail-safe. The electronics add convenience.

This solution reduces the "futuristic" aesthetic. The handle is visible on the vehicle rather than flush with the body. Some aerodynamic efficiency is lost. But the system is simpler, more reliable, and requires less redesign. Manufacturers can implement this relatively quickly because traditional door handle engineering is mature and well-understood.

Option three is a complete redesign. Some manufacturers are exploring entirely new approaches. Motorized mechanical handles that combine electronic actuation with mechanical redundancy. Handles that can be manually operated if power is lost. Innovative designs that try to maintain some aesthetic appeal while meeting safety requirements.

These novel approaches require more development. They need extensive testing. But they potentially offer the best of both worlds: modern technology with mechanical safety.

Each manufacturer will choose based on their priorities. Tesla is likely exploring options one or three to maintain its brand identity. Traditional automakers might choose option two since they have existing mechanical handle designs. New startups might develop novel solutions.

The common thread is that mechanical door handles are returning to electric vehicles. The flush-mounted pop-out handle as the only way to open a car door is becoming extinct. Manufacturers will adapt because they have no choice. And the industry will discover that vehicles can be safe, elegant, and functional without sacrificing mechanical redundancy.

The Broader Context: Why Interior Mechanical Releases Matter

China's regulation requires both external mechanical releases and interior mechanical releases. The interior requirement is particularly important because it addresses the scenario where someone is trapped inside the vehicle.

In traditional vehicles, the interior door release is simple. A handle or button that disengages the latch, allowing the door to open. You don't need to think about it. You just use it. Children learn to operate it instinctively.

In some electric vehicles, the interior release is obscure. It's small. It's unmarked. It's in an unexpected location. Many owners don't know it exists. If a vehicle loses power and traps occupants inside, those trapped people might not find the release mechanism.

China's regulation mandates that interior mechanical releases exist and are accessible. This means they must be functional regardless of battery power, clearly marked or discoverable, and within reach of a person of average size and strength. It rules out hidden releases that require knowledge or special effort to access.

This requirement protects occupants in several scenarios. If power is lost during an accident. If a vehicle is trapped in a flooded area. If a child is locked inside. If a person with limited mobility needs to exit. The interior mechanical release becomes a critical safety feature.

Manufacturers are responding by making interior releases more prominent and accessible. Some are adding redundant release mechanisms. Others are improving labeling and visibility. The trend is toward making the mechanism obvious and intuitive.

This has downstream effects on vehicle design. Interiors must accommodate clearly accessible release mechanisms. Engineering teams must design them to withstand typical wear and abuse. Service manuals must document the system clearly.

But the benefit is clear. It dramatically improves safety for occupants in emergency situations. No trapped people in non-responsive vehicles. No first responders unable to extract casualties. No scenarios where design choices actively harm people.

Estimated data suggests Tesla and Xiaomi incidents were significant contributors to the decision to ban electronic door handles in China.

Cost Implications: What This Means for Vehicle Pricing

Adding mechanical door handle systems to vehicles that were designed without them has costs. The question is how significant those costs are.

Engineering and redesign are the largest expenses. Each vehicle model needs door handle components redesigned, tested, and validated. Supply chains need to be established for mechanical components that some manufacturers have been phasing out. Manufacturing processes need to accommodate new parts. These costs are real but one-time for most manufacturers.

Material costs are generally modest. A mechanical door handle and latch system isn't expensive. Metals, plastics, springs. It's mature technology. The materials for a traditional door handle system cost maybe

The larger question is whether adding the mechanism affects vehicle weight, drag coefficient, or other performance characteristics. A visible external handle adds a bit of weight and slightly increases drag. A vehicle designed around the electronic handle might lose some aerodynamic efficiency when a mechanical handle is added. For EV ranges, this could translate to a 1-3% reduction in efficiency, depending on design.

For a vehicle with a 300-mile range, a 1-3% reduction is 3-9 miles of range. That's noticeable but not catastrophic. Most owners would trade this for the safety benefit of not being trapped in their vehicle.

Manufacturers will likely absorb most of the cost rather than passing it to consumers. A

So the economic impact is real but manageable. It's not going to make electric vehicles unaffordable. It might reduce profit margins slightly. It will force manufacturers to be more thoughtful about design. But the industry will adapt, and consumers will get safer vehicles.

What This Means for Tesla's Future in China

Tesla's relationship with China is complicated and crucial. The company manufactures vehicles there. Tesla's Shanghai Gigafactory is one of the most productive auto plants in the world. China is Tesla's second-largest market after the United States.

The door handle regulation is specifically challenging Tesla's design identity in the most important foreign market. The company must choose between maintaining its aesthetic philosophy and complying with Chinese law. There's no middle ground. Every vehicle sold in China after January 1, 2027 must comply.

Tesla has several paths forward. First, the company could redesign its Chinese vehicles to include mechanical releases while maintaining electronic pop-out handles. The aesthetic remains similar. The safety redundancy is added. This is the most likely approach.

Second, Tesla could develop completely new door handle designs specifically for the Chinese market. Different handles for Chinese vehicles than for American or European vehicles. This increases complexity but allows Tesla to maintain its design philosophy where possible.

Third, Tesla could fight the regulation. The company could lobby Chinese government officials, arguing for exemptions or delays. Given Tesla's economic importance and technical expertise, the company has influence. But fighting appears unlikely. Tesla typically accepts regulatory requirements and adapts engineering to meet them. The company has done this with emissions standards, safety standards, and numerous other requirements across different markets.

Most likely, Tesla will adapt. The company will announce that it's developing a new mechanical door handle system that meets Chinese requirements while maintaining the design integrity of its vehicles. Engineering teams will spend the next months redesigning the door system. By January 2027, Chinese Teslas will have mechanical releases.

The long-term impact on Tesla's brand is minimal. The flush-mounted pop-out handle is iconic, but it's not the reason people buy Teslas. Range, performance, technology, and Supercharger network are much more important. A mechanical door handle added to the system won't change the fundamental appeal of the vehicle.

But it does establish that design choices, even signature ones, can be overridden by safety requirements. It demonstrates that regulators can force changes that manufacturers would prefer not to make. And it shows that once major markets implement a requirement, global manufacturers must adapt, even if they don't like it.

Safety Standards: How This Fits Into the Global Regulatory Landscape

Automotive safety standards are typically developed by international organizations or adopted by national regulatory bodies. NHTSA sets standards in the United States. The EU has its own body of safety regulations. Japan, China, India, and other major markets all have national standards.

These standards don't always align. A vehicle sold in the U.S. might not meet European requirements without modification. A European car might not comply with Chinese safety rules. Manufacturers manage this through vehicle variants. Different versions for different markets. Different door handles, different bumpers, different safety systems.

This fragmentation is expensive and inefficient. The automotive industry would prefer global harmonization where one set of standards applies everywhere. But safety priorities differ by country. Risk tolerance differs. Cultural attitudes toward regulation differ.

China's door handle regulation is an example of a market-specific requirement that creates fragmentation. It exists because China prioritized this particular safety feature and was willing to require industry adaptation.

The interesting question is whether other markets will adopt the same standard. If the EU, U.S., and Japan all implement similar requirements, then it's effectively global. Manufacturers would integrate mechanical door handles into all vehicles because compliance with multiple major markets requires it.

We might be seeing the beginning of that process. China sets the requirement. Other regulators notice and consider similar rules. Within a few years, it becomes standard practice globally. The automotive industry will have adapted not because of a global mandate but because multiple major markets independently required it.

This is how safety standards often evolve. A country leads. Others follow. Eventually, it becomes normal. Seat belts, airbags, antilock brakes, electronic stability control. All of these became standard not through global coordination but through a combination of national regulations and market forces.

The door handle requirement may follow the same path. China's January 2027 deadline is just the beginning.

Looking Forward: Will Electronic Door Handles Disappear Entirely?

The regulation doesn't ban electronic door handles. It requires mechanical releases alongside electronic systems. This allows for continued use of electronic enhancement and control.

So electronic door handles probably won't disappear. Instead, they'll exist as part of a redundant system. The door opens electronically when power is available. The door opens mechanically when power is lost. Both systems serve their purpose.

This is similar to other automotive systems. Brakes combine electronic ABS with hydraulic fundamentals. Steering combines electronic power steering with mechanical control. Climate control combines electronic precision with mechanical override. Redundancy is the future of automotive design, not elimination of technology.

For manufacturers, this means embracing dual-system design. Electronic enhancement layered on top of mechanical fundamentals. It's more complex than pure electronic systems. But it's safer. And increasingly, safety is what regulators require.

The aesthetic implications are significant. The flush-mounted pop-out handle becomes less common. Visible mechanical elements return to vehicle exteriors. Cars look slightly more conventional as a result. But this is a feature, not a bug. It signals that safety is paramount. Design must accommodate survival, not just style.

Electronic door handles will continue evolving. They'll become faster, more reliable, more integrated with vehicle systems. But they'll always have a mechanical backup. That's the lesson of China's regulation.

The Regulatory Precedent: What Comes Next?

China has demonstrated that when safety concerns are serious enough, rapid regulatory action is possible. The government identified a problem, involved industry, developed a standard, and implemented it in roughly 18 months. That's remarkably fast by regulatory standards.

This suggests that other safety issues might receive similar treatment. If regulators become concerned about battery thermal management, they might implement similar requirements. If data privacy in vehicles becomes a concern, regulation might follow quickly. The door handle ban establishes a model for rapid response to safety threats.

It also demonstrates China's regulatory authority and willingness to override industry preferences. Tesla wasn't consulted as an official drafter. Yet Tesla must comply. This is regulatory authority exercised directly, without negotiation. Other manufacturers understand the message.

Manufacturers should expect more requirements that challenge their preferred designs. As EV technology becomes more complex, more potential failure modes emerge. Regulators will likely become more active in identifying and addressing these failure modes through rulemaking.

The strategic implication for manufacturers is clear: include mechanical backup systems in safety-critical components. Don't design systems that fail entirely if electronics fail. Build redundancy into your engineering from the start. This makes regulatory action less likely because the systems are already safe.

For safety advocates and regulators, the door handle ban proves that action is possible. If you see a safety concern and the industry isn't addressing it, regulation might be the answer. China showed the way.

FAQ

What is the Chinese door handle regulation?

The Chinese government's "Safety Technical Requirements for Automobile Door Handles" regulation, effective January 1, 2027, requires all vehicles sold in China to have mechanical door handle releases that function without electronic power. Each door must have an external mechanical release and the vehicle must have an interior mechanical release mechanism. This targets electronic-only door handles that trap occupants when power is lost.

Why did China ban electronic-only door handles?

Multiple fatal crashes, including incidents involving a Xiaomi SU7 and Tesla vehicles, exposed the danger of electronic-only door systems. When vehicle batteries lose power, occupants become trapped inside. Emergency responders couldn't locate hidden mechanical overrides. Children couldn't operate sophisticated releases. The regulation was developed after industry consultation and represents a safety priority over design aesthetics.

How does the regulation affect Tesla?

Tesla's iconic flush-mounted pop-out door handles are no longer compliant in China after January 1, 2027. Tesla must redesign its vehicles to include mechanical releases alongside the electronic system. The company can maintain the electronic pop-out feature but must add a mechanical backup that works without power. This requires engineering changes, new tooling, and supply chain adjustments, but is achievable for a manufacturer of Tesla's resources.

What about other EV manufacturers in China?

Over 40 manufacturers participated in developing the standard, including BYD, Geely, SAIC, Xiaomi, and international companies like General Motors, Ford, Volkswagen, and Porsche. All must comply for vehicles sold in China after the deadline. Most are implementing similar solutions: adding mechanical releases to vehicles previously designed with electronic-only systems. Traditional automakers with existing mechanical handles face smaller engineering challenges.

Will the United States implement similar requirements?

The U.S. National Highway Traffic Safety Administration opened a defect investigation into Tesla's door handles and found similar problems. Some U.S. lawmakers proposed legislation requiring mechanical releases in all vehicles. However, American regulatory processes move slowly compared to China. Implementation in the U.S. may take 4-5 years or longer. The U.S. likely will eventually adopt similar requirements as evidence accumulates and pressure builds.

What are the cost implications of the regulation?

The material cost of adding mechanical door handle systems is modest, typically $30-50 per vehicle. Engineering and redesign costs are one-time expenses that manufacturers absorb. The primary impact is on vehicle weight and aerodynamic efficiency, potentially reducing range by 1-3%. Most manufacturers will absorb costs rather than pass them to consumers, as competitive pressure prevents price increases. The safety benefit is considered worth the modest economic impact.

Can vehicles still have electronic door handles under the new regulation?

Yes, electronic door handles are not banned. The regulation requires mechanical releases alongside electronic systems. Vehicles can have electronic pop-out handles, electronic locks, and electronic control, as long as a mechanical override works without power. This redundancy approach is becoming standard in safety-critical automotive systems globally.

What is the timeline for vehicle redesign?

The regulation takes effect January 1, 2027. Manufacturers have roughly 18-24 months from the rule announcement to redesign vehicles and validate compliance. Most manufacturers have already begun engineering work. New models introduced after the deadline must comply. Existing vehicles in production at the time of the regulation must transition to compliant designs relatively quickly.

Will other countries follow China's lead?

The European Union is likely to adopt similar requirements within 2-3 years. Japan and India may follow. The United States will take longer due to regulatory processes. Once major markets implement the requirement, global manufacturers will likely standardize on mechanical releases for all vehicles worldwide. This turns a Chinese regulation into a global de facto standard within 3-5 years.

What does this mean for vehicle design philosophy going forward?

The regulation reasserts the importance of mechanical redundancy in safety-critical systems. Design innovations can no longer eliminate fail-safe mechanisms. Electronic enhancements must layer on top of mechanical fundamentals rather than replace them. This affects not just door handles but also braking systems, steering, and emergency systems. The era of purely electronic, redundancy-free safety systems is ending. Manufacturers must embrace dual-system design where mechanical and electronic systems both function independently.

Conclusion: Safety Over Aesthetics

The story of China's door handle regulation is ultimately a story about priorities. For years, the automotive industry prioritized minimalist design and aerodynamic efficiency. Hidden, electronic-only door handles served those priorities perfectly. They were elegant. They reduced drag. They simplified engineering in some respects.

But when the first person got trapped in a vehicle because the electronic system failed, priorities shifted. The industry didn't shift fast enough. Manufacturers continued selling vehicles with electronic-only door handles even as evidence of danger accumulated. Safety advocates pressed for change. Regulators investigated.

China took action. Not with hesitation or compromise. Not with industry input about how disruptive the change would be. Just a straightforward requirement: mechanical releases, or don't sell in China. The deadline was clear. The requirement was simple. Compliance was mandatory.

This is how safety regulation should work. Identify a danger. Develop a solution. Require implementation. Let manufacturers figure out the engineering. Don't accept "but our design identity requires electronic-only handles." Design identity can be adapted. Safety cannot be compromised.

The broader lesson extends beyond door handles. Every vehicle system that can fail should have a fallback. Every safety-critical function should have redundancy. When regulations force this principle, manufacturers find ways to implement it. The industry adapts. Consumers get safer vehicles.

Tesla and other EV makers will survive this regulation. Vehicles will still be sleek, efficient, and technologically advanced. But they'll also be safer. People won't be trapped in non-responsive vehicles. First responders will be able to extract casualties. Children will be able to escape emergencies.

The door handle ban represents a decision that safety matters more than seamless design. It's a decision that redundancy is worth the minor engineering and efficiency costs. It's a decision that living through a crash is more important than reducing wind resistance by a fraction of a percent.

China made that decision. Other countries are likely to follow. And the automotive industry, for all its resistance to change, will adapt because adaptation is what the industry does. By 2030, mechanical door handles will be standard on every electric vehicle globally. The flush-mounted pop-out handle will be remembered as a bold design experiment that ultimately couldn't survive the test of safety and survival.

In the end, humans beat elegance. Safety beats aesthetics. And regulators who are willing to act beat manufacturers who hope nobody notices the danger. That's the real story of the hidden car door handle ban.

Key Takeaways

- China's new regulation requires mechanical door handle releases on all vehicles effective January 1, 2027, eliminating electronic-only designs popularized by Tesla

- Multiple fatal crashes where occupants couldn't escape trapped vehicles due to electronic system failures prompted the regulatory action after 18 months of industry consultation

- Tesla and 40+ other manufacturers must redesign vehicles to include mechanical backup systems while maintaining electronic convenience features

- The regulation establishes a global precedent: the EU will likely adopt similar requirements within 2-3 years, with the U.S. following within 4-5 years

- Mechanical redundancy in safety-critical systems is becoming the baseline design principle for automotive engineering, replacing pure electronic innovation

![China's Hidden Car Door Handle Ban: The Safety Crisis Reshaping EVs [2025]](https://tryrunable.com/blog/china-s-hidden-car-door-handle-ban-the-safety-crisis-reshapi/image-1-1770069987803.jpg)