Introduction: The Plastic Bag Problem Nobody Talks About

You know that drawer under your sink? Or maybe it's a cabinet, a closet, or a tangled nest shoved behind the kitchen door. Most households have one: a growing collection of plastic bags that started with good intentions but somehow multiplied into something resembling a small landfill.

They're everywhere. Every grocery trip adds more. Every online delivery brings reinforcements. You tell yourself you'll reuse them, recycle them, or find some crafty purpose. But realistically? They accumulate. Studies suggest the average American household contains between 50 to 100 plastic bags at any given time, with many people admitting they have no idea what to do with them.

Here's the uncomfortable truth: most recycling programs won't accept soft plastics. Your blue curbside bin rejects them. The machines jam. The whole sorting facility gets disrupted. So these bags sit in homes, get buried in landfills, or worse, wind up in oceans where they suffocate marine life for decades. A single plastic bag can take 20 years to decompose.

This isn't a new problem, but it's becoming impossible to ignore. Plastic production has tripled since 2000, and soft plastics account for roughly 40% of all plastic waste generated globally. Yet infrastructure to handle them remains fragmented and underdeveloped. Recycling facilities simply weren't designed for the volume and complexity of soft plastics flooding the system.

Enter Clear Drop. At CES 2026, the company unveiled something that looked almost too simple to work: a home compactor that converts your bag collection into solid, shippable bricks. It's a pre-recycler. It's a physical manifestation of finally doing something about that drawer. And it represents a growing shift in how innovators think about the end-of-life cycle for plastics most people have given up on recycling.

This article explores the Clear Drop Soft Plastic Compactor in depth, examines why soft plastics pose such a unique recycling challenge, evaluates whether home compaction is a viable solution, and considers what this technology means for the future of household waste management.

TL; DR

- Clear Drop compacts soft plastics into 8x 12x 4-inch bricks that can be shipped to specialized recycling facilities

- The problem is real: Most municipal recycling won't accept soft plastics, leaving households with few options

- The price is steep: At $1,400 over two years, the device works best for environmentally committed households

- Infrastructure matters: Success depends on building partnerships with recycling facilities and eventually municipal programs

- This is a start, not a complete solution: Technology alone can't fix systemic recycling gaps without supporting infrastructure

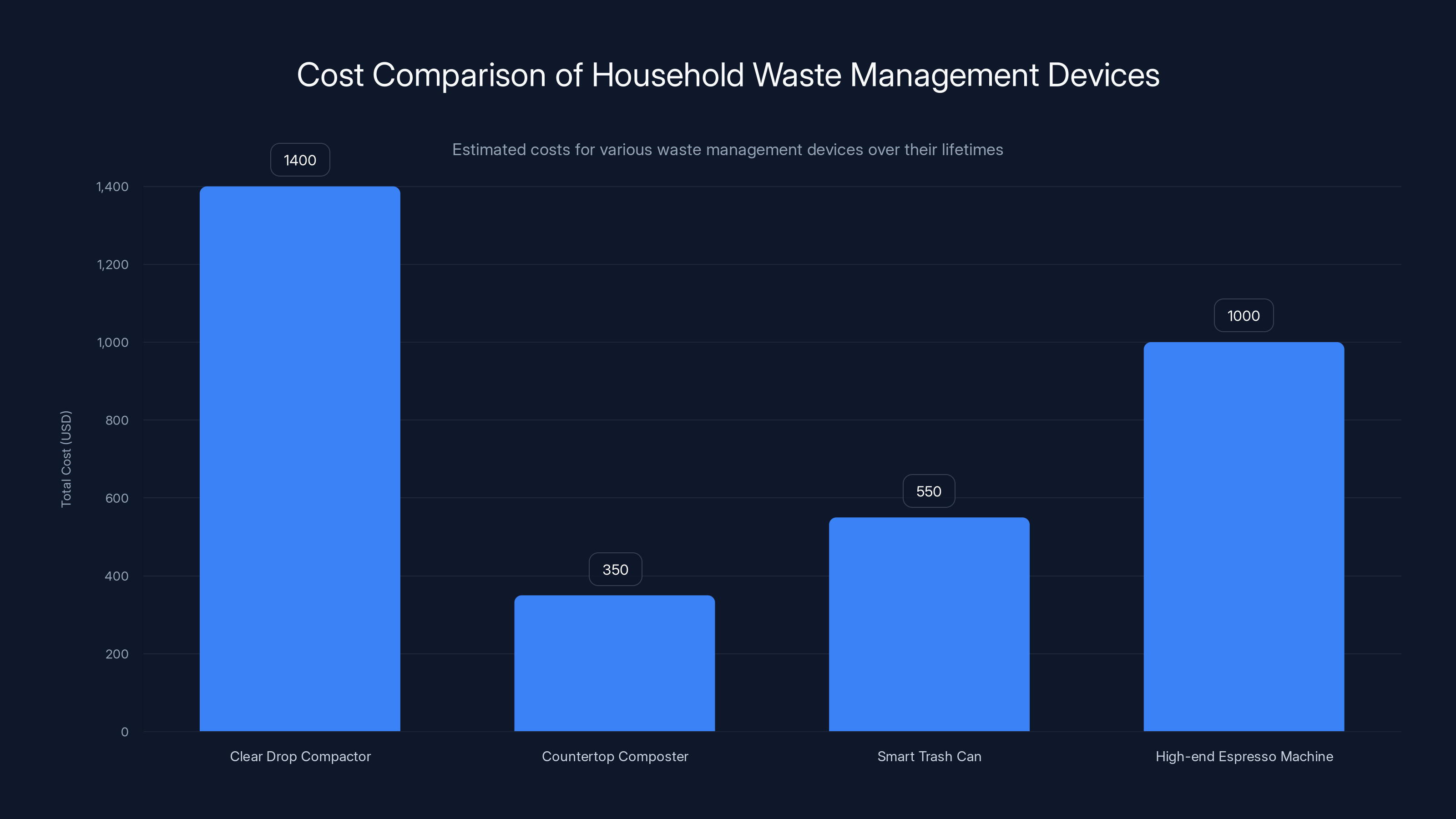

The Clear Drop compactor costs significantly more than other waste management devices, with an estimated total cost of $1,400 over its lifetime. This positions it as a premium choice for environmentally conscious households.

The Soft Plastic Crisis: Why Your Bags Can't Go in the Recycling Bin

Understanding Soft Plastics vs. Hard Plastics

Most people assume all plastic is created equal. It isn't. The recycling industry divides plastics into two distinct categories, and soft plastics represent the problem child that nobody wants.

Hard plastics include rigid containers like milk jugs, water bottles, detergent bottles, and yogurt containers. These materials have defined shapes. They're consistent. Recycling equipment designed decades ago actually works with hard plastics. They tumble through conveyor belts, get sorted by type and color, and can be processed into new products relatively efficiently.

Soft plastics are the opposite. Grocery bags, plastic film, bubble wrap, ziplock bags, product packaging, dry cleaning bags, bread bags, and candy wrappers all belong to this category. They're flexible, slippery, and clingy. That's exactly what makes them impossible for most recycling facilities to handle.

Why Recycling Machines Jam and Fail

When soft plastics enter a traditional recycling facility, they cause immediate problems. The bags wrap around conveyor belt rollers, tangling machinery designed to separate metals, glass, and hard plastics. A single grocery bag can bring an entire sorting line to a halt. Workers must stop everything and manually untangle the mess, which costs time and money.

Facilities estimate that soft plastics cause machinery shutdowns up to 10 times per day on average. Some operations lose 30 to 45 minutes per incident. Over a year, that adds up to hundreds of thousands of dollars in lost productivity and maintenance costs. No wonder they refuse to accept soft plastics through curbside collection.

The mechanical sorting equipment simply predates the modern soft plastic explosion. When municipal recycling infrastructure was built in the 1980s and 1990s, single-use plastic bags were far less prevalent. Equipment was optimized for glass bottles and aluminum cans. Today's volume of soft plastics wasn't anticipated, and retrofitting entire facilities is prohibitively expensive.

The Scale of the Soft Plastic Problem

There are approximately 130 million tons of plastic waste generated globally each year. Roughly 40% of that is soft plastic film and flexible packaging. The United States alone generates 35 million tons of plastic waste annually, and only about 9% gets recycled overall. For soft plastics specifically, the recycling rate hovers around 5%.

This means 95% of soft plastics end up in landfills or the environment. They persist for 20 to 30 years before breaking down into microplastics. They tangle around tree branches, get caught in animal digestive systems, and accumulate in ocean gyres forming patches of floating garbage.

Innovators have been trying to solve this problem for years. Some companies developed separate soft plastic collection programs. Others created new equipment designed specifically for film materials. But these solutions never achieved mainstream adoption because they require coordination across municipalities, investment in new infrastructure, and consumer participation in separate collection streams.

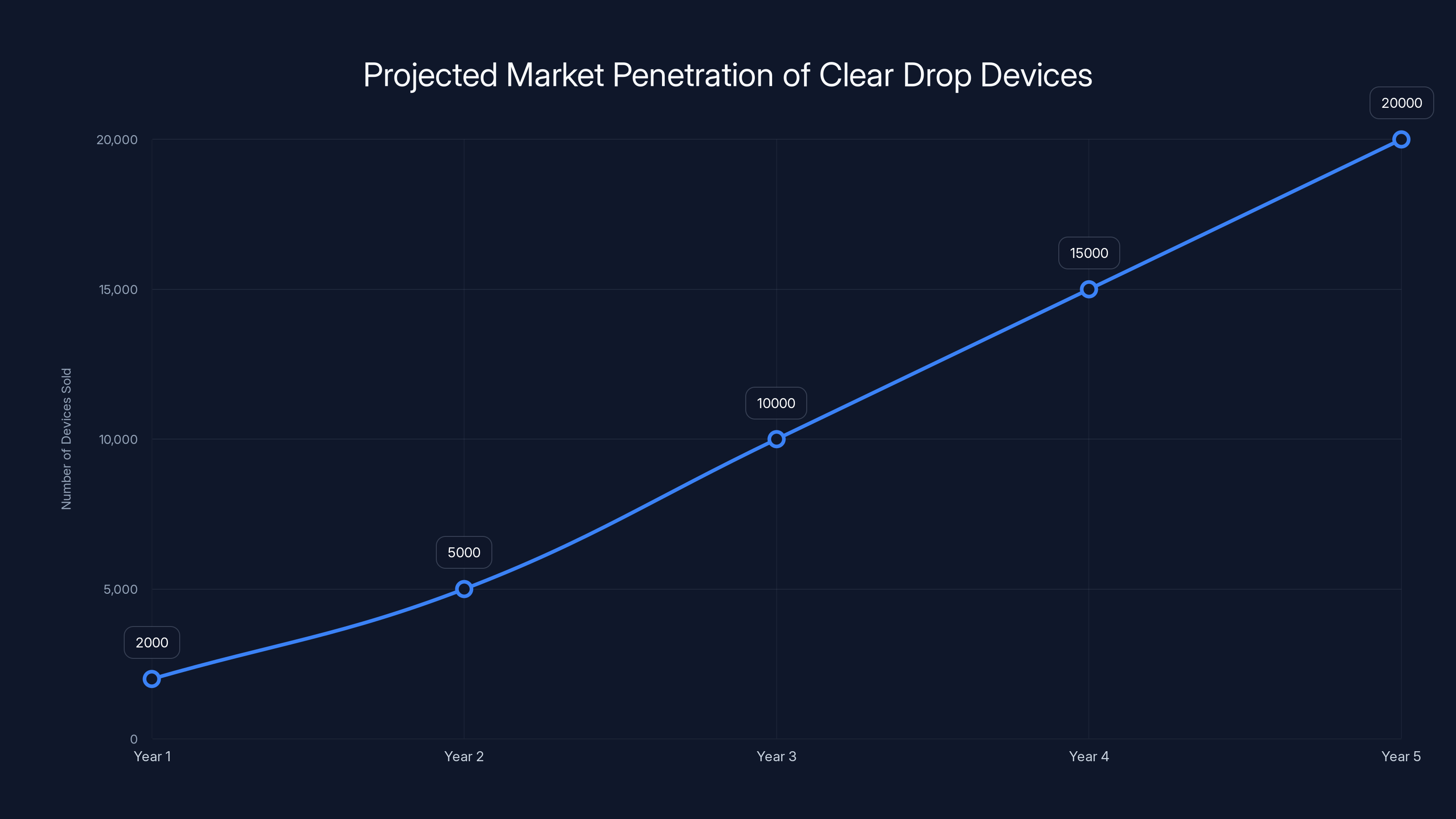

Estimated data suggests Clear Drop could sell 20,000 devices in five years, achieving 1% market penetration in the US. This projection assumes steady growth among environmentally conscious consumers.

How the Clear Drop Soft Plastic Compactor Works

The Technology Behind the Compression

Clear Drop's approach is elegant in its simplicity. Rather than trying to fix the entire recycling infrastructure (an impossible task for a single company), they built a device that transforms the problem material into something easier to handle: a dense brick.

The compactor uses a combination of mechanical compression and thermal heating. When you feed soft plastics into the slot on top, the machine pulls them into an internal chamber. Rollers compress the material while heating elements warm the plastic to its melting point, causing it to fuse together. The process doesn't actually melt the plastic into a liquid but rather softens it enough that multiple materials bond together into a single solid form.

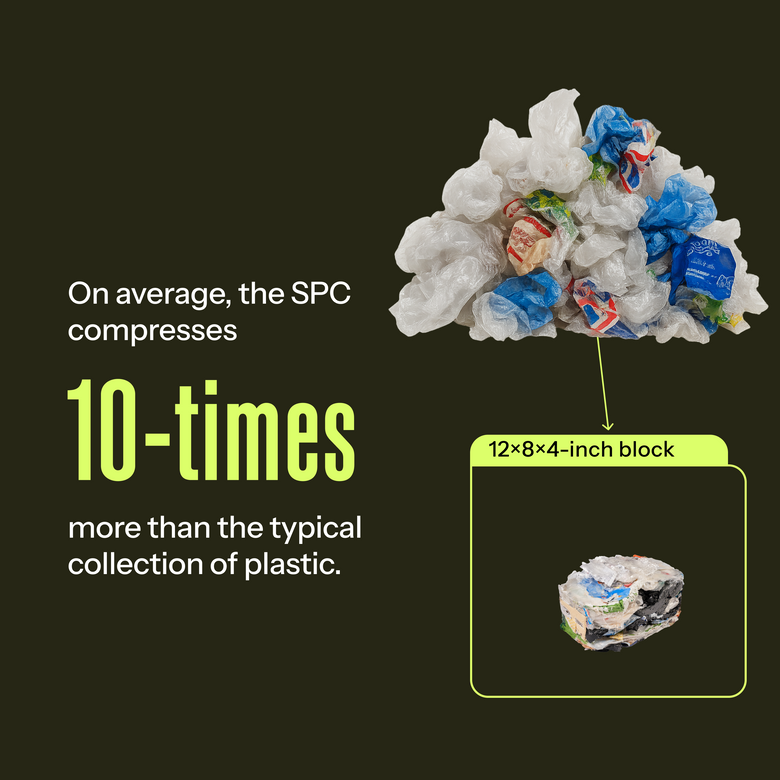

The resulting brick measures eight inches by twelve inches by four inches and weighs approximately four to five pounds. This density and shape makes the material stackable, shippable, and far easier to handle than loose plastic bags. You can't throw it in your trash because it wouldn't compress further. You can't throw it in regular recycling because it would jam machines. But you can put it in a box and ship it somewhere designed to handle it.

What Materials the Machine Accepts

Clear Drop designed the compactor to handle approximately 95% of soft plastics found in households. This includes:

- Grocery bags and produce bags

- Plastic film and packaging wrap

- Bubble wrap and protective packaging

- Ziplock bags and food storage bags

- Bread bags and cereal liners

- Dry cleaning bags

- Candy and snack wrappers (plastic components)

- Plastic stretching wrap

- Plastic envelopes and mailers

- Cling film and food wrap

The machine rejects a few materials: ping pong balls, IV bags, camera film, and certain specialized plastic types. The reasoning is safety and purity. IV bags might contain biological material. Camera film requires different processing. Ping pong balls are made from celluloid, which behaves completely differently when heated. The company tested extensively to understand which materials would safely compress without creating fumes or structural problems.

The Compaction Process and Timeline

Clear Drop estimates that the average household generates enough soft plastic to fill one brick approximately once per month. This translates to around 30 gallons of loose plastic bags compressed into a single four-pound brick. The machine doesn't require any special preparation. You don't need to wash bags or remove residue. You don't need to separate materials by type or color. You feed mixed soft plastics into the slot, and the machine handles everything.

The compactor is designed for a family of four generating typical plastic waste. Larger households or those who consciously collect soft plastics might fill a brick faster. Smaller households or those vigilant about using reusable bags might take six weeks instead of four.

Safety Considerations and Emissions

When the company demonstrated the compactor at CES, they didn't activate the heating element publicly. This led to some skepticism about what the device actually does when it operates. Does it create fumes? Does it smell bad? Is it safe to run in a home environment?

Clear Drop conducted extensive safety testing. The company claims that any plastic smell produced during operation is minimal and that the machine underwent rigorous testing to ensure it doesn't create harmful emissions or off-gas toxic chemicals. The heating reaches temperatures that soften plastic without breaking down the polymer chains into volatile organic compounds.

However, the company recommends running the compactor in a well-ventilated area and suggests not operating it in tight closets or sealed rooms. This is prudent practice for any appliance involving heat and plastic, though it's worth noting that the company positions the device as safe for typical home kitchen environments.

The Recycling Infrastructure Challenge: From Brick to Facility

How Pre-Paid Shipping and Drop-off Works

Once you've created a brick, you can't simply throw it away. Clear Drop provides pre-paid USPS shipping envelopes with every compactor. The brick fits in a standard Priority Mail box. You schedule a USPS pickup, and the package goes to one of Clear Drop's partner recycling facilities.

This is where the business model becomes slightly complicated. The device isn't just a home appliance; it's part of a closed-loop system. Clear Drop maintains relationships with specialized recycling facilities that can actually process these bricks. The company doesn't operate the facilities themselves but rather coordinates logistics and ensures quality control.

Clear Drop audits their partner facilities to verify that bricks are genuinely being recycled and not simply moved to another landfill. This transparency is crucial because the entire value proposition collapses if materials aren't actually recycled.

Current Recycling Partner Network

As of early 2025, Clear Drop works with multiple US-based recycling facilities specifically equipped to handle soft plastics. The company doesn't publicly name all partners, likely due to competitive considerations, but they've confirmed partnerships with facilities in several regions including California, Texas, and the Northeast.

These specialized facilities use different processing methods than traditional recycling centers. Some use thermal processing to create plastic lumber or composite materials. Others grind and re-pelletize the plastic for manufacturing new products. A few are developing chemical recycling methods that break plastics down to molecular components for more applications.

The challenge is that these facilities remain niche operations serving a small percentage of national plastic waste. Scaling them up requires capital investment, which requires demand, which requires more compactors. It's a chicken-and-egg problem that most new waste technologies struggle with.

The Problem of Distributed Recycling

Here's what bothers environmental critics most: you're creating a brick in your home, boxing it up, paying for shipping, and sending it across the country. The environmental cost of transportation could theoretically offset some benefits of recycling. A brick shipped from California to Texas on a diesel truck generates emissions that might not be worth the value gained from recycling 4 pounds of plastic.

Clear Drop acknowledges this concern. They're working to expand the partner network so that most users can access a nearby facility, reducing shipping distances. The ultimate goal is to create infrastructure that eventually integrates with municipal recycling systems, eliminating the shipping step entirely.

But that's a future scenario. Today, shipping is part of the system. Whether you consider that acceptable depends on your environmental philosophy and whether you believe that recycling these materials at all is better than landfilling them.

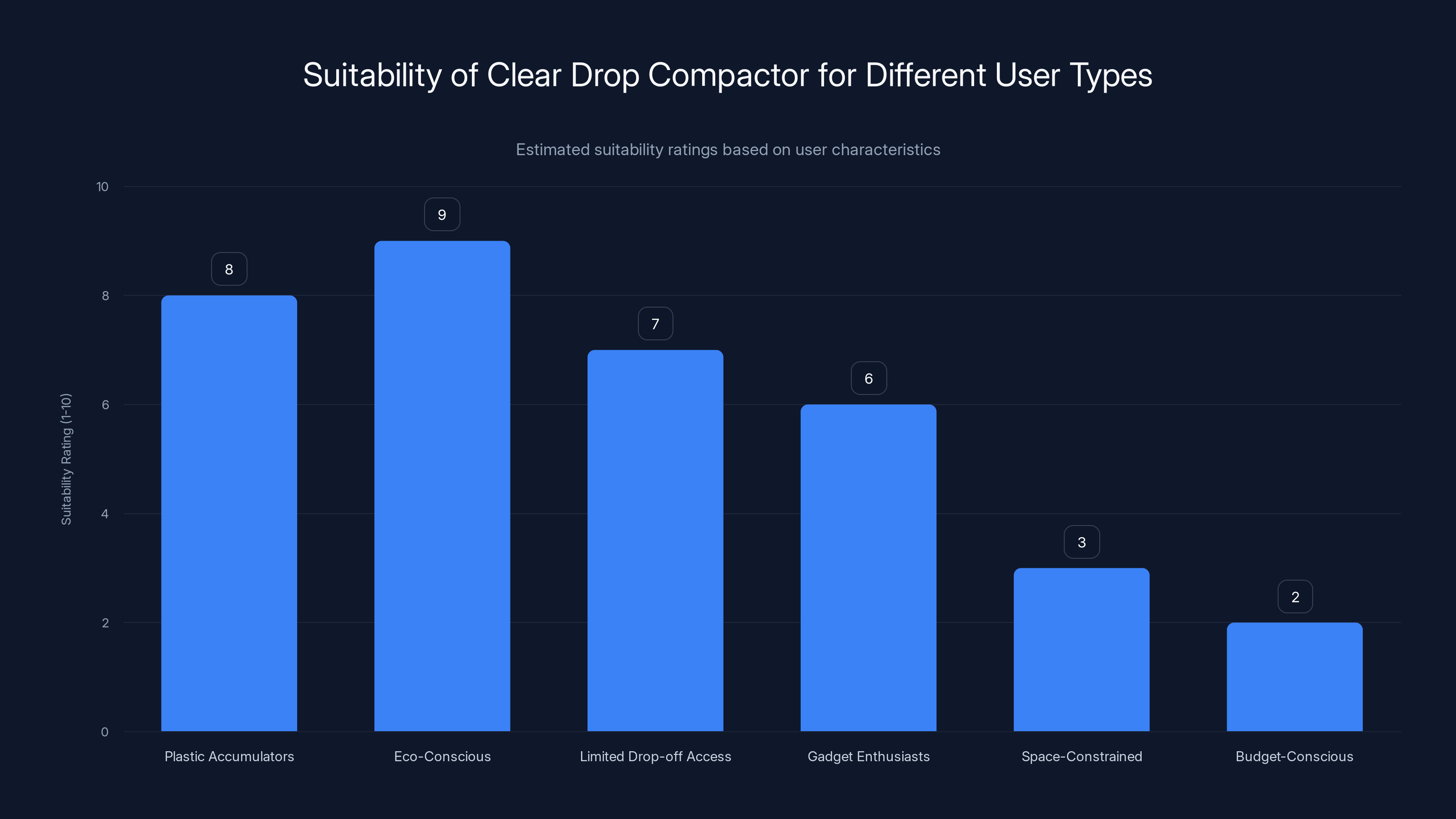

The Clear Drop Compactor is most suitable for eco-conscious users and those with limited access to recycling programs, while less suitable for space-constrained or budget-conscious households. (Estimated data)

The Economics: Is $1,400 Worth It for Your Household?

Understanding the Pricing Model

Clear Drop doesn't charge a single lump sum. Instead, they structure pricing over 24 months, making the device more accessible than quoting the full $1,400 upfront. But the total cost is significant either way. That's the price of a decent laptop or a good monitor.

For context, other home waste management devices offer different pricing structures. Countertop composters range from

This puts the device in a specific market segment: not quite luxury appliance pricing, but far beyond impulse purchase territory. Clear Drop is betting that environmentally conscious households will justify the expense through guilt reduction or alignment with values.

Cost Per Brick and Total Lifetime Value

If the device creates one brick per month for five years (the typical lifespan before needing replacement), a household would generate 60 bricks. The cost per brick works out to roughly $23, not accounting for electricity.

The electricity cost is minimal. The compactor probably draws 500-800 watts during operation and runs for 10-15 minutes per brick. At average US electricity rates of 14 cents per kilowatt-hour, each compaction costs roughly

So the effective cost per brick is closer to $24 all-in. Is that reasonable? That depends on whether you believe the environmental value justifies the expense and whether you'd otherwise be actively recycling these materials through alternative channels.

Comparing to Alternative Waste Management Approaches

Most households generate plastic bag waste but do nothing specific with it. They accumulate in drawers, eventually get tossed in regular garbage, and go to landfills. The Clear Drop compactor is an alternative to this baseline.

Other alternatives include:

- Store drop-off programs: Some grocery stores accept soft plastics at customer service desks. You'd need to drive there regularly, which generates its own emissions.

- Specialized recycling pickup services: A few regions offer special collection days for soft plastics. You'd need to wait for scheduled events.

- Using bags for other purposes: Reusing them as trash liners, litter box liners, or pet waste bags delays disposal but doesn't prevent eventual landfilling.

- Donating to animal shelters: Shelters use plastic bags for litter and waste, but this just postpones the problem.

For many households, Clear Drop represents the most proactive available option, which is why the price might seem justified despite the significant upfront investment.

Environmental Impact: Does the Math Actually Work?

The Landfill Diversion Calculation

To evaluate whether Clear Drop actually helps the environment, we need to consider several factors:

Materials diverted from landfills: Clear Drop claims the average household could divert 48-60 pounds of soft plastic annually using their device. This assumes monthly brick generation with average plastic density.

Lifespan impact: Soft plastics in landfills persist for 20-30 years. If Clear Drop enables recycling instead of landfilling, and if those materials are genuinely processed into new products, you're preventing decades of environmental impact.

Transportation emissions: The shipping cost in carbon terms depends on destination distance. A brick shipped 1,000 miles generates roughly 0.5 pounds of CO2. If the recycled plastic prevents new petroleum extraction for virgin plastic (which requires significant energy), the net impact could be positive.

Water and chemical savings: Producing new plastic from petroleum requires water, generates chemical waste, and depends on fossil fuel extraction. Recycled plastic avoids these impacts, though the exact savings vary by recycling method.

The calculation is complex. Environmental economists generally agree that recycling soft plastics beats landfilling them, even accounting for transportation. But the margin isn't enormous. It's not like hard plastic recycling where the energy savings are significant.

The Role of Consumer Psychology

Here's something often overlooked in environmental impact discussions: behavioral change.

Owning a Clear Drop compactor might make you more conscious about plastic consumption generally. You see the bricks accumulating. You become aware of how much soft plastic you generate. This psychological effect could lead to behavioral changes that have larger environmental impact than the device itself.

You might start using reusable bags more consistently. You might choose products with less plastic packaging. You might request your workplace implement similar systems. The device becomes a reminder that soft plastic waste is a problem worth addressing.

Conversely, you might convince yourself that owning a recycler gives you permission to generate more plastic guilt-free. This is the "ethical consumption under capitalism" paradox. You feel like you're doing something good, so you're less motivated to address root causes.

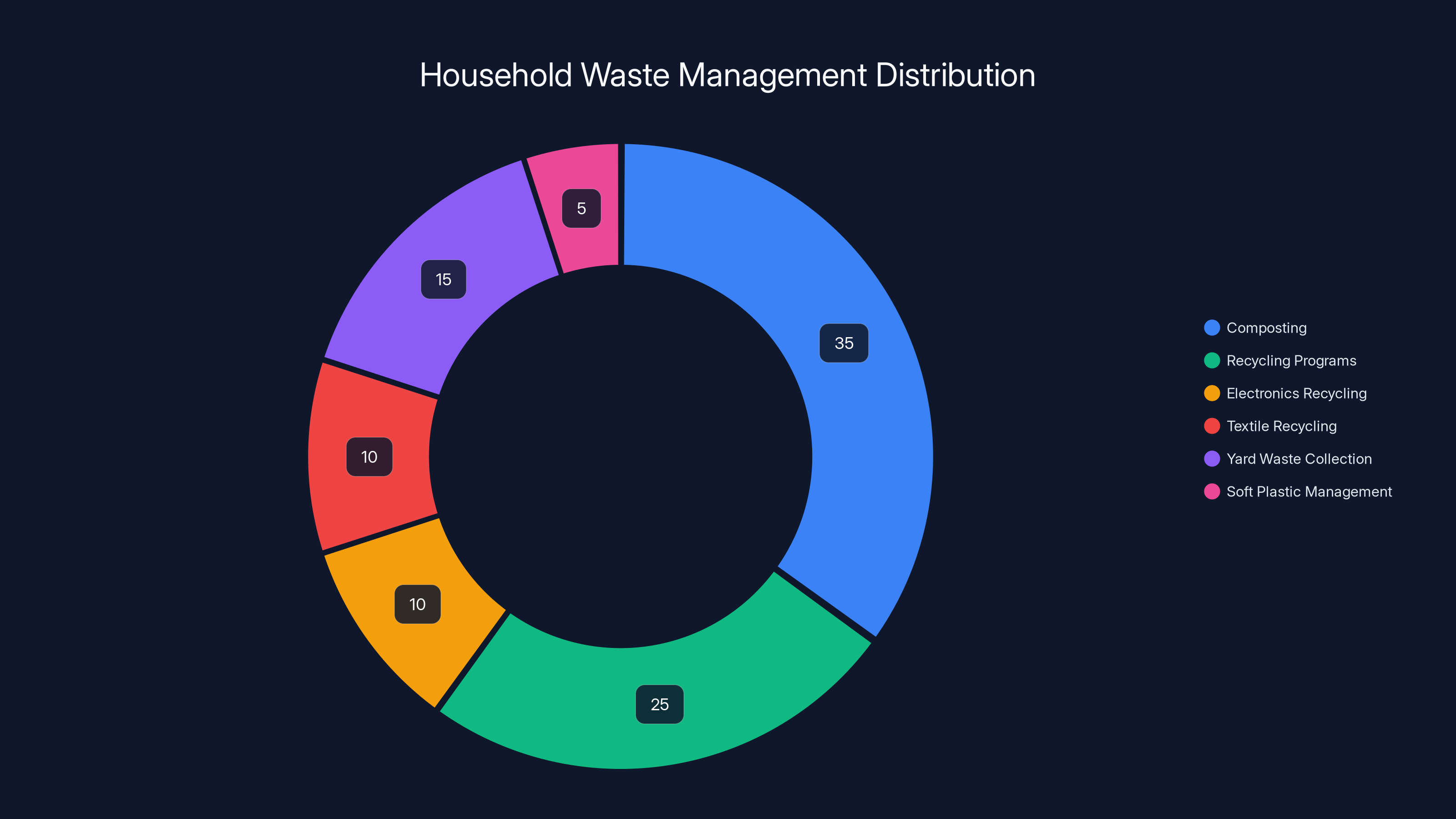

Estimated data shows composting and recycling programs handle the majority of household waste, with soft plastic management being a smaller, yet crucial component.

The Future of Household Plastic Compaction

Municipal Integration and Infrastructure Development

For Clear Drop's business to scale significantly, they need municipal governments to eventually accept bricks through local waste streams. This would eliminate shipping and make the system far more practical.

Some cities are exploring this. A few California municipalities have begun pilot programs with soft plastic pre-recycling. But widespread adoption requires regulatory changes, facility upgrades, and coordinated planning across hundreds of individual waste management agencies.

This is a "wait and see" situation. Clear Drop is working toward this future, but it's not guaranteed to arrive. Municipal recycling infrastructure moves slowly because it requires public funding and political coordination.

Technological Improvements and Next-Generation Devices

The current compactor is a first-generation product. Future iterations will likely improve efficiency, reduce size, lower costs, and expand capabilities.

Potential improvements include:

- Faster operation: Current models take several minutes per compaction. Improvements could reduce this to seconds.

- Quieter operation: Compression machinery generates noise. Better insulation and design could reduce this.

- Smaller footprint: A countertop model could serve apartments and smaller households.

- Chemical processing: Instead of pure compression, devices could partially break down plastics, creating material with different properties.

- Integration with smart home systems: Sensors could track how much plastic you're generating and estimate when bricks will be ready for shipping.

Clear Drop has patent applications for various improvements, suggesting the company is invested in innovation rather than resting on the current design.

Competitive Landscape and Market Expansion

Clear Drop isn't alone in recognizing this opportunity. Other companies are exploring soft plastic solutions:

- Recycle Technologies focuses on mechanical recycling of soft plastics at scale.

- Various startups are developing collection services that compete with Clear Drop's shipping model.

- Established waste management companies are beginning to invest in soft plastic infrastructure.

Competition is healthy. It drives innovation, lowers prices, and pushes the entire market toward better solutions. Clear Drop's advantage is first-mover awareness and brand recognition from their CES debut, but this advantage won't last forever.

Real-World User Considerations and Trade-Offs

Who Should (and Shouldn't) Buy a Clear Drop Compactor

The device isn't universally appropriate for every household. Consider whether it makes sense for you:

Good candidates for ownership:

- Households that accumulate significant plastic bags and actively want to address it

- Environmentally conscious consumers willing to pay premium prices for values alignment

- Areas without convenient soft plastic drop-off programs

- Families that use the compactor as part of broader waste reduction initiatives

- People who enjoy gadgets and are willing to experiment with new sustainability tools

Poor candidates for ownership:

- Households that already minimize plastic bag generation through reusable bags

- Renters in temporary housing situations

- Apartments with space constraints

- Budget-conscious consumers (nearly $1,400 is substantial)

- People skeptical about recycling effectiveness in general

- Households without reliable internet for scheduling USPS pickups

Installation, Space, and Maintenance Requirements

Unlike some appliances, Clear Drop is relatively straightforward to set up. The device doesn't require special plumbing, electrical connections, or ventilation ducting. It needs a standard 110-volt outlet and adequate space (roughly the size of a mini fridge based on CES demonstrations).

Maintenance appears minimal. There are no filters to replace or moving parts to lubricate. The company recommends occasional inspection to ensure the slot remains clear, but that's about it. Estimated maintenance costs are negligible over the device's lifespan.

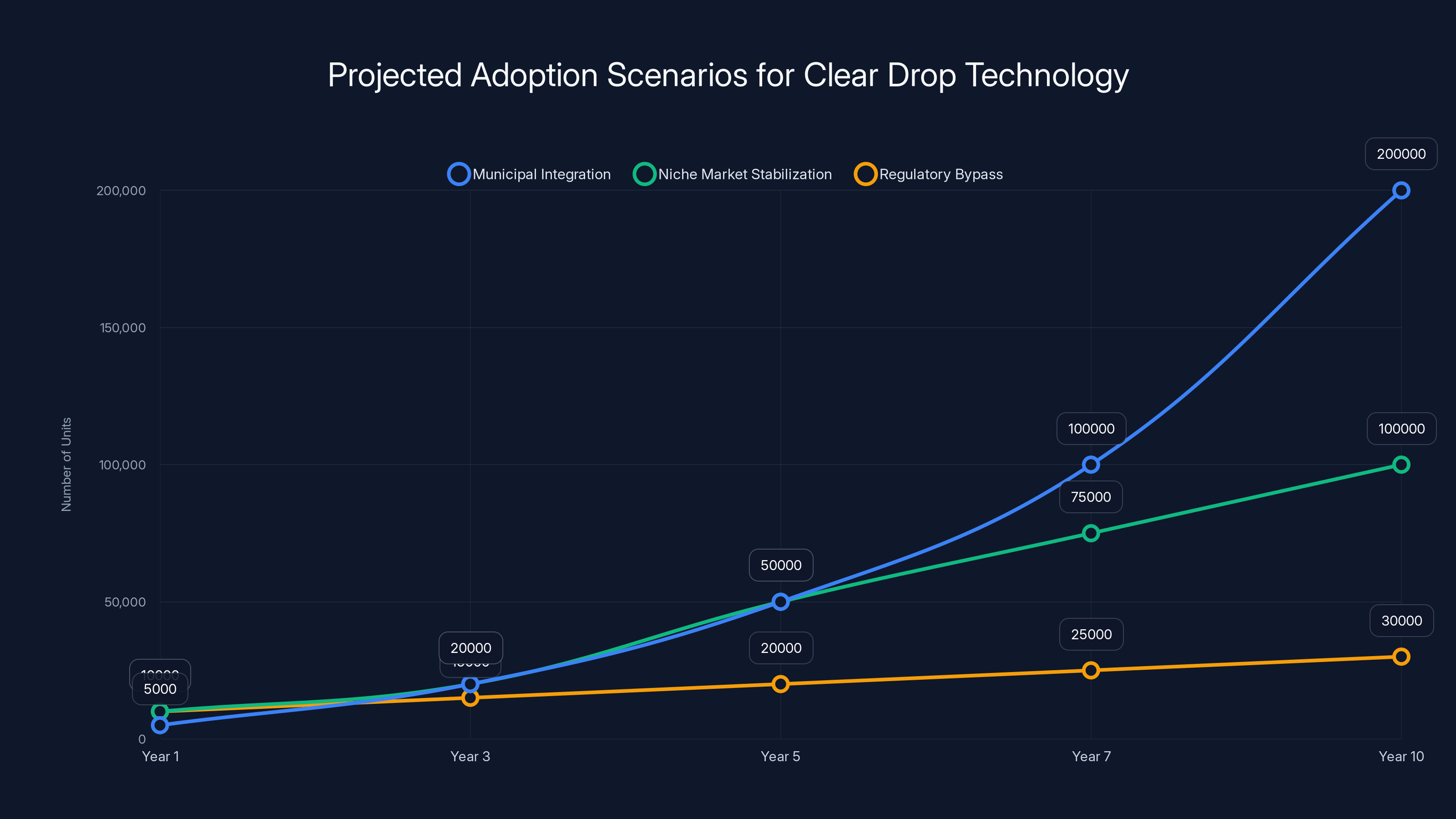

The 'Municipal Integration' scenario predicts widespread adoption, with Clear Drop becoming a standard household appliance. The 'Niche Market Stabilization' scenario sees moderate growth, while 'Regulatory Bypass' results in minimal adoption due to reduced need. Estimated data.

The Broader Waste Management Ecosystem

How Clear Drop Fits Into Comprehensive Home Waste Solutions

No single product solves all household waste challenges. Clear Drop addresses one specific problem: soft plastic accumulation. But comprehensive waste management involves multiple streams.

A household using Clear Drop might also use:

- Composting systems for organic waste (reducing landfill by 30-40% for typical households)

- Recycling programs for cans, bottles, and paper (already mainstream)

- Electronics recycling for computers and phones

- Textile recycling for old clothing

- Yard waste collection for grass clippings and leaves

Clear Drop completes a gap that's been ignored: soft plastics. It's one piece of an integrated waste reduction strategy rather than a complete solution.

The Psychology of Waste Reduction vs. Waste Management

Ecologists emphasize a hierarchy: Reduce, Reuse, Recycle, in that order. Clear Drop addresses the "recycle" tier. But arguably, the most important tier is "reduce."

If you stopped generating plastic bags entirely through aggressive use of reusables, you wouldn't need a compactor. The device is a helpful tool for people who generate plastic waste but want to handle it responsibly. It's not a replacement for actually reducing consumption.

This is worth keeping in mind. Clear Drop solves a real problem, but the ideal solution is preventing the problem in the first place. A

Regulatory and Policy Implications

Current Regulations and Why Soft Plastics Fell Through the Cracks

Recycling regulations developed in the 1990s and 2000s assumed a particular mix of waste materials. Hard plastics, metals, and paper were the focus. Soft plastics were either rare or considered uneconomical to process, so they were excluded from municipal programs.

As soft plastic consumption exploded with e-commerce and convenience packaging, regulations never updated to match reality. Policymakers assumed existing infrastructure would adapt, but it didn't because adapting is expensive and technically challenging.

Now we have a regulatory gap. Most municipalities legally prohibit soft plastics in curbside bins. Yet these materials are generated in massive quantities and have no designated disposal path. This is exactly the kind of problem that creates room for innovative solutions like Clear Drop.

Potential Regulatory Changes and Extended Producer Responsibility

Extended Producer Responsibility (EPR) is a policy approach where manufacturers are financially responsible for their products' end-of-life disposal. Some states are beginning to implement EPR for packaging, which could dramatically change the soft plastic landscape.

If a manufacturer knows they'll pay for soft plastic disposal, they'll have strong incentives to use less of it. This addresses the root problem rather than just creating better recycling infrastructure. A few states including California have begun pilot EPR programs for packaging.

Clear Drop could become less relevant if EPR policies actually reduce soft plastic generation. Or Clear Drop could become essential infrastructure for managing the transition period. Either way, the regulatory environment will shift over the next 5-10 years in ways that affect the device's value proposition.

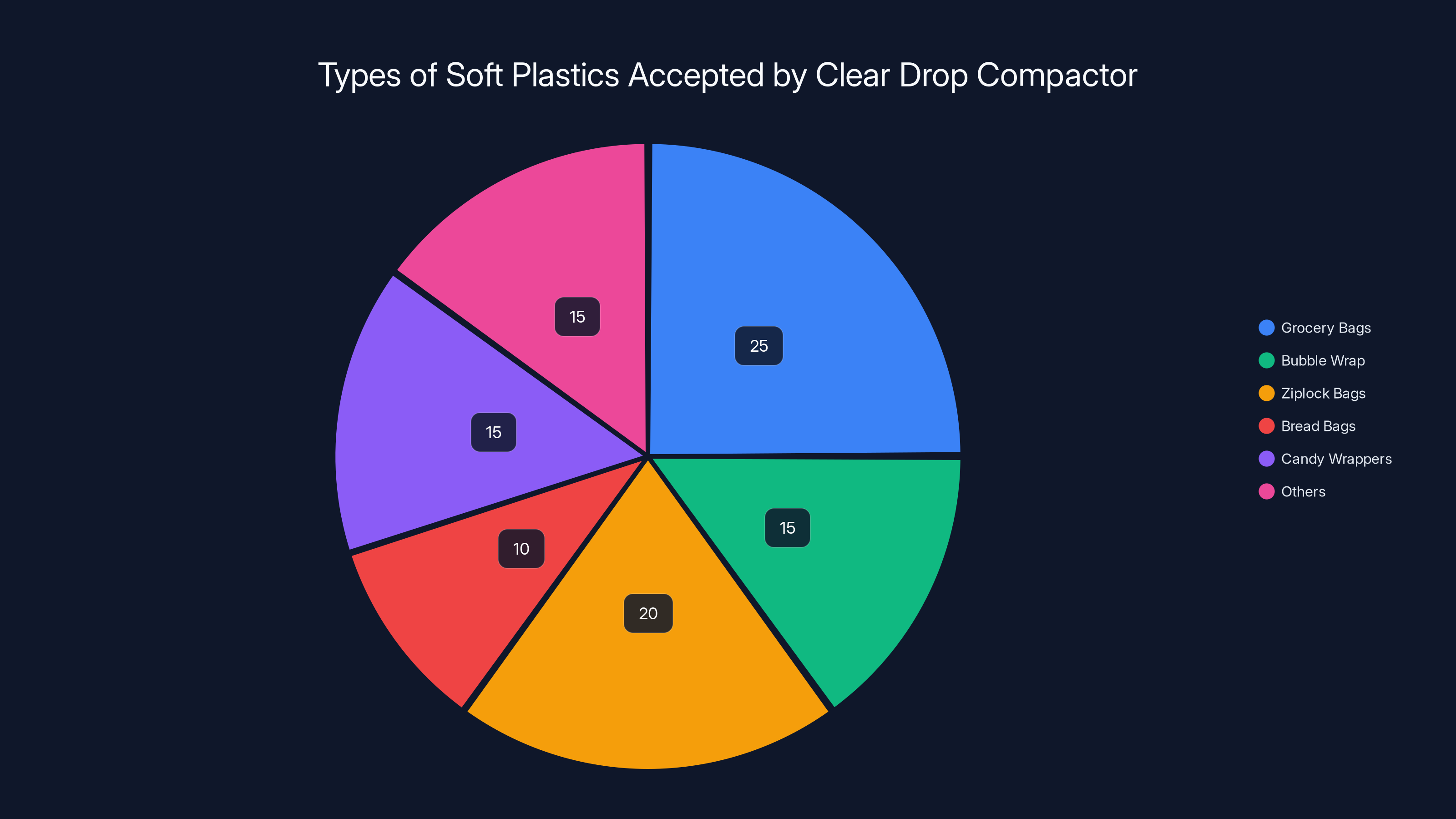

Estimated data shows that grocery bags and ziplock bags make up the largest portion of soft plastics processed by the Clear Drop Compactor.

Manufacturing and Materials Science Behind the Innovation

Polymer Chemistry and Why Heating Works

Understanding why Clear Drop can create solid bricks from diverse plastic types requires basic polymer chemistry. Soft plastics are made from long-chain hydrocarbons twisted into coiled configurations. When heated to specific temperatures (typically 250-350 degrees Fahrenheit depending on plastic type), these chains become flexible and can bond with adjacent chains.

Clear Drop's heating approach is clever because different soft plastics melt at different temperatures. Rather than heating to a single specific point, the device heats to a range where most soft plastics become adhesive without fully melting. This allows mixed materials to bond together.

The result isn't a chemical change where plastics combine into new compounds. It's more like pressing together hot glue. The molecules remain chemically what they were, but they're now fused into a solid form through physical proximity and adhesion.

Quality Control and Material Consistency

For recycling facilities to accept Clear Drop bricks reliably, the bricks need consistent properties. Density, composition, and structural integrity matter. A brick that crumbles during shipping is worthless.

The device likely uses pressure sensors and temperature monitoring to ensure consistency. Different batches of soft plastic might compress differently based on material composition. The machine might adjust compression force or heating duration based on feedback to maintain quality.

This is invisible to users but crucial to the business model. If facilities reject batches due to inconsistent quality, the entire recycling loop breaks.

Case Studies and Early Adoption Stories

CES Attendees and Early Testers

At CES 2026, Clear Drop made demonstrations and took pre-orders or expressions of interest. Early adopters tend to be environmentally conscious tech enthusiasts willing to experiment with new solutions. They're the people who already use composters, shop carefully for sustainable products, and view their purchasing decisions as votes for the world they want.

Early feedback has been mixed. Enthusiasm centers on finally having an option for soft plastics. Skepticism focuses on the price, the shipping requirement, and uncertainty about whether bricks are actually recycled.

The company is likely gathering data from early users about real-world plastic generation, shipping frequency, and customer satisfaction. This data will be crucial for improving the device and refining the business model.

Projections for Scale and Adoption

Clear Drop hasn't released official adoption projections, but industry analysts estimate that premium waste management devices appeal to roughly 2-3% of households in developed countries. That's roughly 2-3 million potential US customers.

If the company achieves even 1% market penetration over five years, that's 20,000 devices sold. At

But scaling beyond early adopters requires either dramatic price reductions or broader behavioral change around recycling consciousness. Neither is guaranteed.

Comparing Clear Drop to Alternative Solutions

Grocery Store Drop-Off Programs

Many supermarket chains including Walmart, Target, and Kroger accept soft plastics at customer service desks. These programs are completely free and don't require purchasing equipment. Many households already have this option available.

The trade-off is convenience. You need to save bags, drive to the store, remember to bring them, and find a customer service counter. Most people find this friction too high and never actually do it.

Clear Drop eliminates friction by moving the process into your home. You feed bags whenever you generate them, and Clear Drop handles shipping. The trade-off is the $1,400 investment upfront.

Curbside Soft Plastic Collection Pilots

A few cities including Santa Cruz, California, and some regions in the Pacific Northwest have launched separate soft plastic curbside collection. These programs treat soft plastics like a distinct waste stream, similar to yard waste.

Where these exist, they're the ideal solution: free, convenient, and integrated into existing municipal infrastructure. If you have access to such a program, Clear Drop becomes unnecessary.

The problem is that 95% of North American households lack this option. It exists only in early-adopter regions. Scaling it nationally would require massive infrastructure investment and regulatory coordination.

DIY Approaches and Waste Reduction

The most environmentally responsible approach remains the simplest: generate less soft plastic in the first place. Using reusable bags, choosing products with minimal packaging, and refusing plastic options whenever possible eliminates the problem rather than solving it.

Clear Drop acknowledges this. The company positions their device as a solution for households "doing everything right" who still generate some soft plastic unavoidably. It's a solution for the margin, not the core problem.

The Skeptic's Perspective: Valid Criticisms

Greenwashing Concerns

Critics worry that Clear Drop enables greenwashing: the practice of appearing environmentally responsible without making substantial impact. Buy a $1,400 compactor, feel virtuous, and continue consuming plastic products guilt-free.

This is a legitimate concern. Any tool designed to help people manage waste rather than reduce consumption carries this risk. The device needs to be paired with broader lifestyle changes to actually provide environmental benefit.

Questions About Actual Recycling

Without third-party verification, there's legitimate skepticism about whether Clear Drop bricks are actually recycled or just relocated to different landfills. The company claims to audit facilities, but this isn't independently verified by environmental organizations.

Transparency would help. If Clear Drop published detailed audits, tracked bricks through the entire recycling process, or partnered with established environmental nonprofits, skepticism would diminish.

Cost-Benefit Skepticism

A rigorous life-cycle assessment comparing Clear Drop's environmental impact to cost hasn't been published by independent researchers. The environmental benefit per dollar spent might not be optimal. You could theoretically donate $1,400 to established environmental organizations and create more measurable impact than buying a compactor.

This is a fair point. Whether Clear Drop is the best use of environmental resources depends on your priorities and values.

Future Scenarios: Where This Technology Goes

Scenario One: Municipal Integration and Mainstream Adoption

In this scenario, Clear Drop (or similar devices) become so popular that municipalities feel pressure to accept bricks through waste collection systems. Regional facilities expand capacity to process soft plastics. Within 10 years, home plastic compaction is a standard part of comprehensive waste management alongside traditional recycling.

Price drops to $400-600 as production scales. The device becomes a standard appliance like composters, expected in every home serious about waste reduction. Regulatory changes make soft plastic reduction mandatory for manufacturers, reducing generation overall.

This is the best-case scenario for Clear Drop and for environmental outcomes. It requires consumer demand, regulatory will, and infrastructure investment, but it's technically achievable.

Scenario Two: Niche Market Stabilization

Alternatively, Clear Drop remains a niche product for environmentally committed affluent households. The market reaches 50,000-100,000 units in North America but never scales beyond that. The device persists as a premium option for people willing to pay for values alignment.

Meanwhile, traditional recycling improves incrementally. Some cities implement EPR. Some manufacturing companies voluntarily reduce soft plastic packaging. Progress happens without requiring home compactors.

Clear Drop survives as a business but never becomes mainstream. It's like premium composters: not in every home, but accessible for people who prioritize them.

Scenario Three: Regulatory Bypass and Irrelevance

In this scenario, Extended Producer Responsibility regulations force manufacturers to reduce soft plastic packaging dramatically. The amount of soft plastic in homes decreases by 60-70%. Clear Drop becomes less relevant because the problem is partially solved at the source.

Companies shift to reusable or durable packaging to avoid EPR fees. Materials science improves, and soft plastics are replaced by alternatives that are recyclable through existing infrastructure.

This is actually the ideal outcome for the environment overall. Clear Drop becomes unnecessary because the problem is addressed at its source rather than in homes. The company either pivots to other waste management problems or becomes a historical footnote.

Practical Buying Guide and Decision Framework

Step-by-Step Decision Process

If you're seriously considering Clear Drop, work through these steps:

Step 1: Assess your local options. Research whether your city offers soft plastic drop-off programs or upcoming curbside collection. Call local recycling facilities and ask directly. Check Earth 911.com or Recycle Search.org for soft plastic options.

Step 2: Quantify your plastic generation. Spend 30 days collecting soft plastic bags without any special effort. Measure the volume. Is it truly a problem warranting $1,400 investment? Or is it manageable?

Step 3: Calculate true costs. Beyond the $1,400 device, factor in electricity costs, the cost per brick to ship (if pre-paid shipping runs out), and your time to schedule pickups.

Step 4: Evaluate alternatives. If your city has free drop-off programs, could you commit to visiting monthly? Could reusable bag discipline reduce generation below 1 brick monthly?

Step 5: Consider values alignment. Be honest about whether owning this device would be symbolic (making you feel good) or practically consequential (meaningfully reducing landfill impact).

Step 6: Start small. If available, test participation in free drop-off programs for 90 days. Confirm you'd actually maintain the habit before investing in equipment.

Red Flags That Suggest Waiting

Don't buy Clear Drop if:

- You haven't confirmed your region actually has soft plastic generation problems

- You're expecting the device to solve your guilt about consumption rather than reduce consumption

- Your city just announced curbside soft plastic collection coming next year

- You have space constraints or rent (making a $1,400 investment in rented housing questionable)

- You can't honestly commit to scheduling monthly pickups

Conclusion: Clear Drop as Part of a Larger Conversation

Clear Drop's Soft Plastic Compactor represents an important but limited response to a significant waste management problem. For a decade, soft plastics have been treated as a problem for someone else to solve. Households couldn't recycle them. Recycling facilities couldn't process them. Manufacturers had no incentive to reduce them because there were no economic consequences.

Clear Drop doesn't solve this system-level problem. But it does provide individuals with a tool for taking responsibility within their own homes. If you're already doing everything right on consumption, this device offers a way to handle unavoidable plastic waste responsibly.

The real question is whether solutions like Clear Drop are enough, or whether we need simultaneous action on multiple fronts: regulatory changes forcing manufacturers to use less plastic, infrastructure investments to handle soft plastics municipally, consumer behavior shifts toward reusable alternatives, and materials science innovation creating plastic-free packaging.

The answer is probably all of the above. Clear Drop isn't a replacement for these other changes. It's a bridge solution for the transition period. Whether it becomes truly mainstream depends on factors beyond the company's control: regulatory environment, municipal infrastructure investment, and whether consumers view the $1,400 price as justified.

For now, it stands as proof that innovation can address even stubborn waste management problems. Whether that innovation is necessary or simply convenient depends entirely on your circumstances and values.

FAQ

What is the Clear Drop Soft Plastic Compactor?

The Clear Drop Soft Plastic Compactor is a home appliance that mechanically compresses and heats soft plastics (bags, bubble wrap, film packaging) into solid bricks approximately 8x 12x 4 inches. These bricks can be shipped to specialized recycling facilities for processing, offering an alternative to landfilling soft plastics that municipal recycling programs won't accept.

How does the Clear Drop Compactor work?

The device uses a combination of mechanical compression and thermal heating to fuse soft plastics together. When you feed plastic bags into the slot on top, the machine pulls them into an internal chamber where rollers compress the material while heating softens the plastic enough for different types to bond together. The result is a dense, shippable brick that's easier to handle than loose bags.

Why can't I put soft plastics in my regular recycling bin?

Soft plastics jam the machinery at recycling facilities designed for hard plastics, metals, and paper. A single plastic bag can wrap around conveyor belt rollers and shut down an entire sorting line. Facilities estimate soft plastics cause 10+ machinery shutdowns daily, leading to hundreds of thousands of dollars in lost productivity and maintenance costs annually. This is why municipalities prohibit them from curbside bins.

What soft plastics can the compactor accept?

The Clear Drop accepts approximately 95% of household soft plastics including grocery bags, bubble wrap, ziplock bags, bread bags, candy wrappers, plastic film, dry cleaning bags, and protective packaging. It cannot accept ping pong balls, IV bags, camera film, or certain specialized plastics that behave differently when heated.

How much plastic does one brick represent?

A single brick typically represents about 30 gallons of loose plastic bags compressed into a 4-5 pound solid form. The average household generates one brick approximately monthly, translating to 48-60 pounds of soft plastic diverted from landfills annually.

Is the compactor safe to use in my home?

Clear Drop conducted safety testing to verify that the device doesn't create harmful emissions or off-gas toxic chemicals. The company recommends operating the compactor in well-ventilated areas (not sealed closets) and claims minimal plastic smell is produced. However, independent third-party verification of safety claims would provide additional confidence.

What does the compacted brick do after I send it to Clear Drop?

Clear Drop ships bricks to partner recycling facilities that specialize in soft plastic processing. These facilities use various methods including thermal processing to create plastic lumber and composite materials, grinding and re-pelletizing for new manufacturing, or developing chemical recycling to break plastics down to molecular components. Clear Drop claims to audit facilities to ensure bricks are actually recycled.

Is the Clear Drop worth the $1,400 cost?

Whether Clear Drop justifies its price depends on your household's plastic generation, your access to alternative soft plastic recycling options, your environmental values, and your willingness to pay a premium for values alignment. If you generate multiple bricks monthly and have no free local recycling options, the cost becomes more economical per brick. If you generate minimal soft plastic or have access to free drop-off programs, the investment is harder to justify.

Are there cheaper alternatives to the Clear Drop Compactor?

Yes. Many grocery stores including Walmart and Target accept soft plastics free at customer service desks. Some cities offer free curbside soft plastic collection through pilot programs. The trade-offs involve convenience and accessibility. Store drop-off requires driving and remembering to bring bags. Clear Drop eliminates friction but requires significant upfront investment.

What's the environmental impact of shipping bricks across the country?

Clear Drop acknowledges transportation concerns. Shipping a brick 1,000 miles generates roughly 0.5 pounds of CO2 emissions. Whether this offsets the environmental benefit of recycling depends on the recycling method and what virgin plastic production would otherwise occur. The company is working to expand facility partnerships to reduce average shipping distances, and the ultimate goal is municipal integration that would eliminate shipping entirely.

Will Clear Drop work with my municipal waste collection in the future?

Clear Drop is actively working with municipalities to eventually integrate bricks into standard waste collection systems. However, this remains aspirational rather than confirmed. Current infrastructure doesn't exist to handle bricks at scale. Whether this integration happens depends on regulatory environment changes, facility expansion, and municipal coordination that Clear Drop cannot control.

Ready to take control of your household soft plastic waste? The decision to invest in a Clear Drop Compactor is personal, but it should be informed by your local options, plastic generation reality, and environmental priorities. Start by researching what recycling options already exist in your area. Then, if Clear Drop still makes sense, it offers a genuine solution to a problem that's been ignored for far too long.

Key Takeaways

- Clear Drop compacts soft plastics into shippable bricks because 95% of municipal recycling facilities can't process them without jamming machinery

- The device costs 24 per brick when accounting for typical household generation rates

- Soft plastics achieve only 5% recycling rates versus 35% for hard plastics, representing a major gap in waste management infrastructure

- Transportation emissions from shipping bricks is a valid concern, though recycling still beats landfilling even with shipping costs factored in

- Clear Drop works best for environmentally committed households with no free local soft plastic drop-off alternatives who can afford the premium price

Related Articles

- Warner Bros. Discovery Rejects Paramount Skydance Bid: Why Netflix Won [2025]

- Best Gaming TV for PS5 & Xbox Series X [2025]: Complete Buyer's Guide

- Best Wi-Fi Extenders 2025: Complete Buyer's Guide [Updated]

- Netflix 2026: Complete Guide to Blockbuster Releases [2025]

- Apple Watch Series 11: Complete Guide, $100 Off Deal & Features [2025]

- Anker 45W Nano Charger with Smart Display [2025]

![Clear Drop Soft Plastic Compactor: A Home Solution to Plastic Waste [2025]](https://tryrunable.com/blog/clear-drop-soft-plastic-compactor-a-home-solution-to-plastic/image-1-1767796846840.jpg)