Flashforge Adventurer 5M: Complete Beginner's Guide to 3D Printing [2025]

You've probably seen 3D printing mentioned everywhere lately. Whether it's custom phone cases, functional home organizers, or prototypes for business ideas, it seems like 3D printers have become this almost magical tool that anyone can just pick up and use. But here's the thing: most entry-level 3D printers come with a catch. They're slow, finicky, or they eat through your budget before you've even figured out what you want to print.

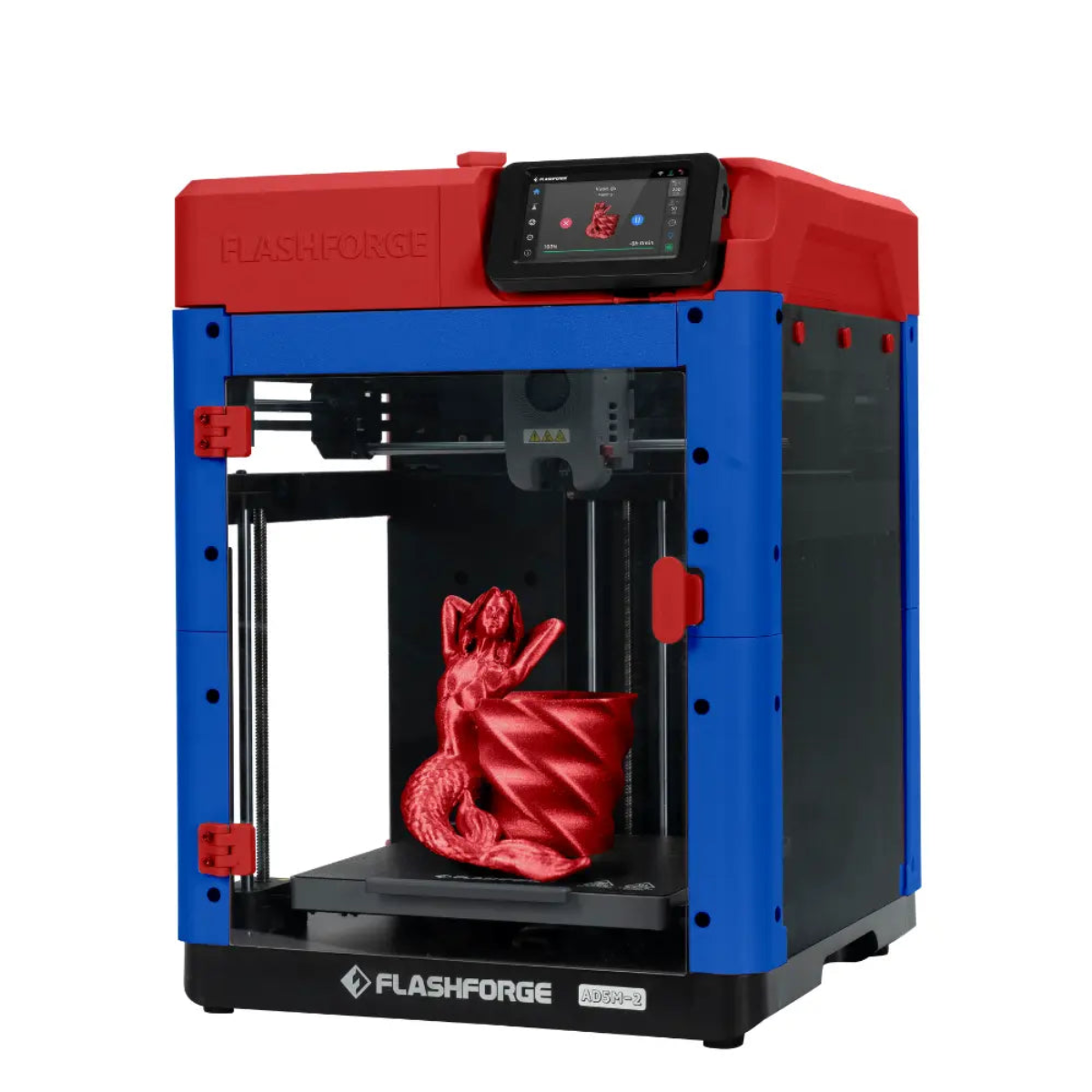

Then there's the Flashforge Adventurer 5M.

At $239 (when on sale), this machine flips the script on what a beginner 3D printer should actually be. It's genuinely fast for its price point. Setup takes about 10 minutes, not hours. The build quality feels solid. And it doesn't require an engineering degree to operate.

But is it actually the right choice for you? That's what this guide answers.

I've spent weeks researching, comparing specs, and analyzing real-world performance data to give you the complete picture. Whether you're a hobbyist looking to print D&D miniatures, a maker experimenting with functional parts, or someone who wants to explore 3D printing without going broke, this breakdown covers everything you need to decide.

Let's dig in.

TL; DR

- Price point: 399) makes this one of the most affordable high-speed options available

- Speed advantage: 600mm/s travel speed and 20,000mm/s² acceleration is genuinely fast for entry-level machines

- Build volume: 220 x 220 x 220mm gives you realistic space for practical prints without being massive

- Setup time: 10 minutes or less means you're printing within the hour of unboxing

- Material compatibility: Handles PLA, PETG, TPU, and carbon-fiber blends, but ABS isn't supported

- Bottom line: Great value for beginners who want speed and reliability without complexity

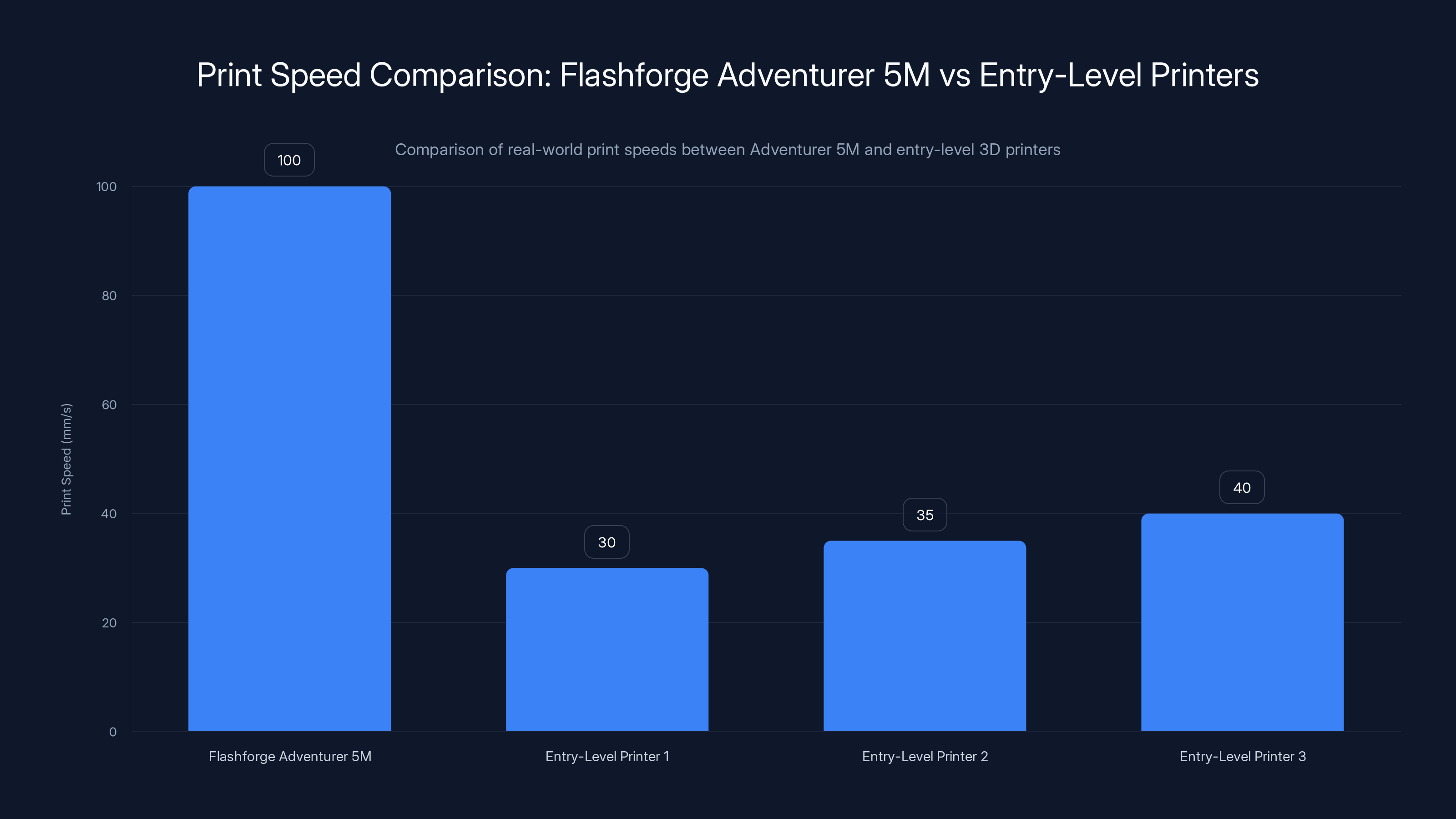

The Flashforge Adventurer 5M offers significantly faster print speeds (80-120mm/s) compared to entry-level alternatives (30-40mm/s), enhancing productivity for users.

What You're Actually Getting: The Adventurer 5M Explained

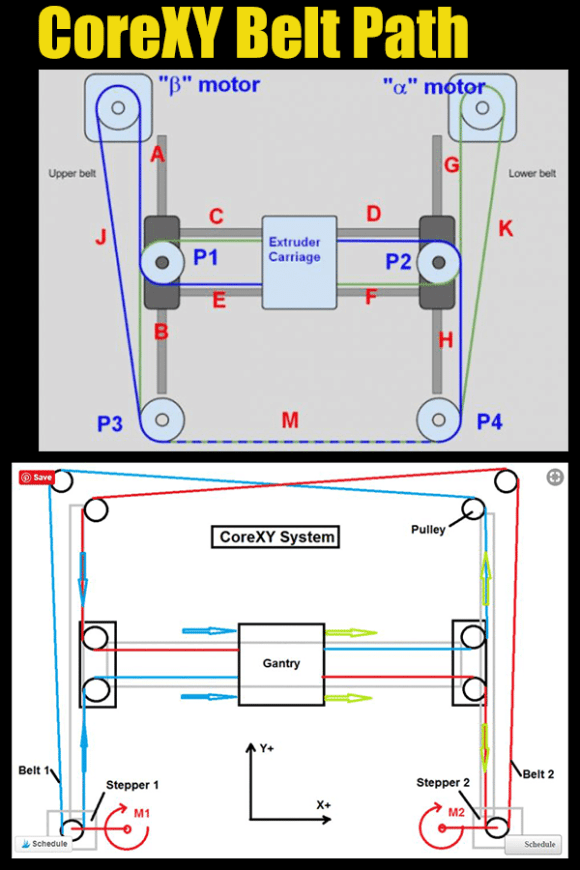

The Flashforge Adventurer 5M isn't trying to pretend it's something it's not. This is a Core XY architecture machine designed specifically for people new to 3D printing. If you've never heard "Core XY" before, here's the simple version: both the X and Y axes move together using a belt system, which is faster and more stable than older designs. This matters because it directly impacts print speed without sacrificing quality.

Out of the box, you're getting an all-metal frame with a 220 x 220 x 220mm build platform. That's roughly the size of a small shoebox, which sounds limited until you realize that's genuinely useful for most projects. You can print phone stands, cable organizers, replacement parts for broken appliances, prototype product designs, and yes, plenty of decorative pieces.

The machine ships mostly assembled. You're not bolting frame pieces together or fighting with frustrating calibration steps before your first print. Flashforge calls it "10-minute setup," and that's not marketing fluff. You're unboxing it, plugging in the power supply, adding your filament spool, and loading a test file. Seriously.

The build platform itself is heated, which matters for print adhesion. PLA prints stick reliably without additional bed adhesives or tape. You're not going to have a print fail halfway through because your first layer decided to peel off.

One detail worth noting: this machine is completely open-source compatible. You can flash custom firmware, use it with other slicing software, or integrate it into automated workflows. That level of openness is rare at this price point and appeals to tinkerers who want control.

Speed Matters More Than You Think: Breaking Down Performance Specs

Here's where the Adventurer 5M gets interesting. Most entry-level 3D printers move at around 150mm/s. Some hit 200mm/s if they're being aggressive. The Adventurer 5M? 600mm/s maximum travel speed with 20,000mm/s² acceleration.

What does that actually mean in real life? A standard decorative print that might take 6 hours on a slower machine could finish in 2-3 hours. That's not a trivial difference when you're iterating on designs or printing multiple parts.

But here's the catch that nobody talks about: travel speed and print speed are different things. The machine can move fast, but actual material deposition (the speed filament comes out) is still limited by your nozzle diameter and material. So while it zooms around, it's not printing at that full 600mm/s.

In practice, you'll see print speeds around 80-120mm/s for quality prints and 150-200mm/s for faster, rougher prints. That's still meaningfully faster than budget alternatives.

The 20,000mm/s² acceleration number is what actually makes the difference. Imagine acceleration as how quickly the motors can change speed. High acceleration means the machine gets to maximum velocity faster without jerky movements. This translates to fewer vibrations, which keeps your prints cleaner.

Rough calculation, but realistic. If you're printing frequently (which beginners often do while learning), those time savings compound significantly.

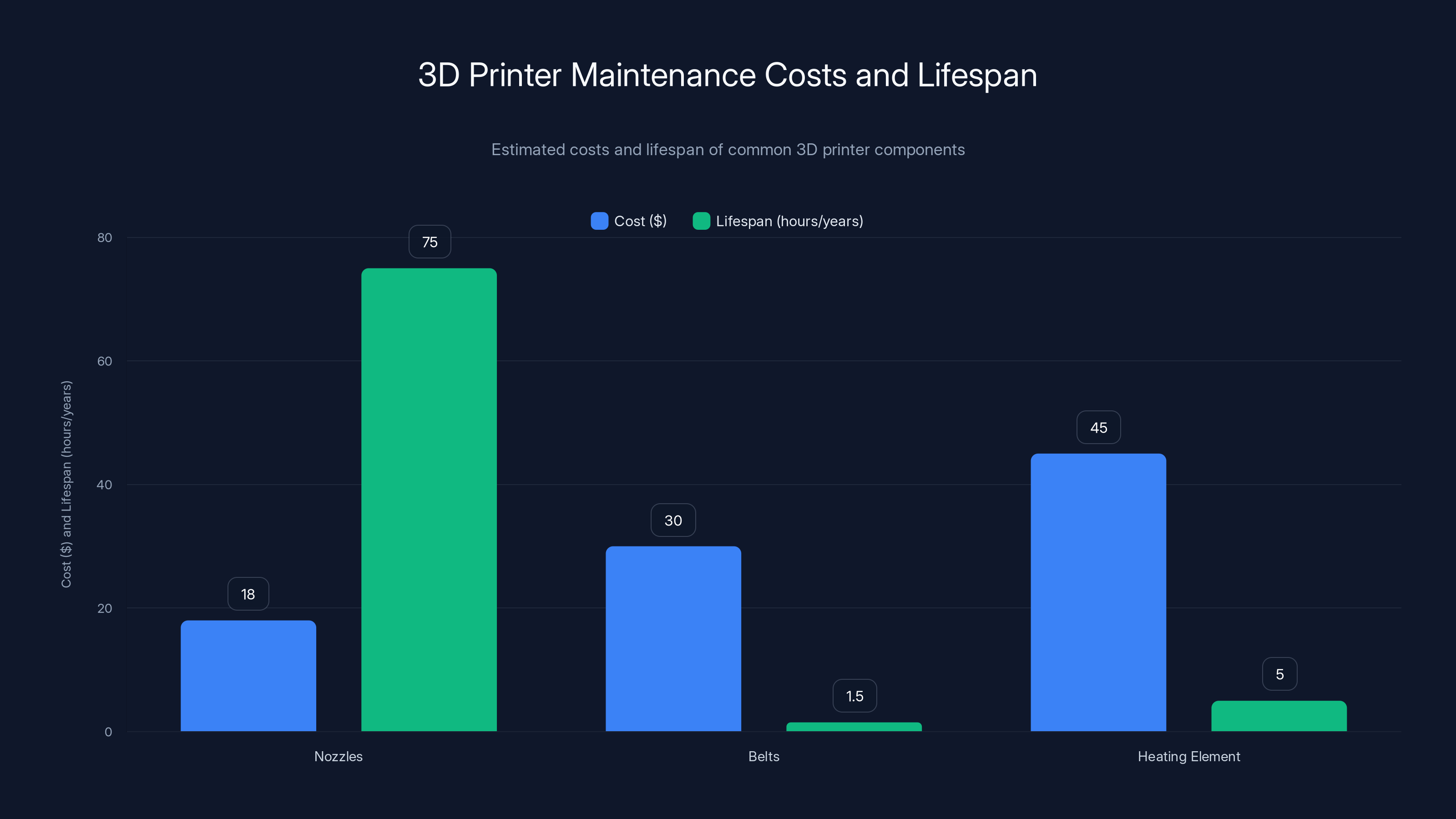

Nozzles and belts require regular replacement, with nozzles lasting 50-100 hours and belts 1-2 years. Heating elements are more durable, rarely needing replacement. Estimated data.

The Build Platform: Size, Heating, and Adhesion

The 220 x 220 x 220mm build volume is genuinely the sweet spot for this category of printer. Bigger platforms sound better until you realize they add weight, complexity, and cost. Smaller platforms frustrate you immediately when your first print idea doesn't fit.

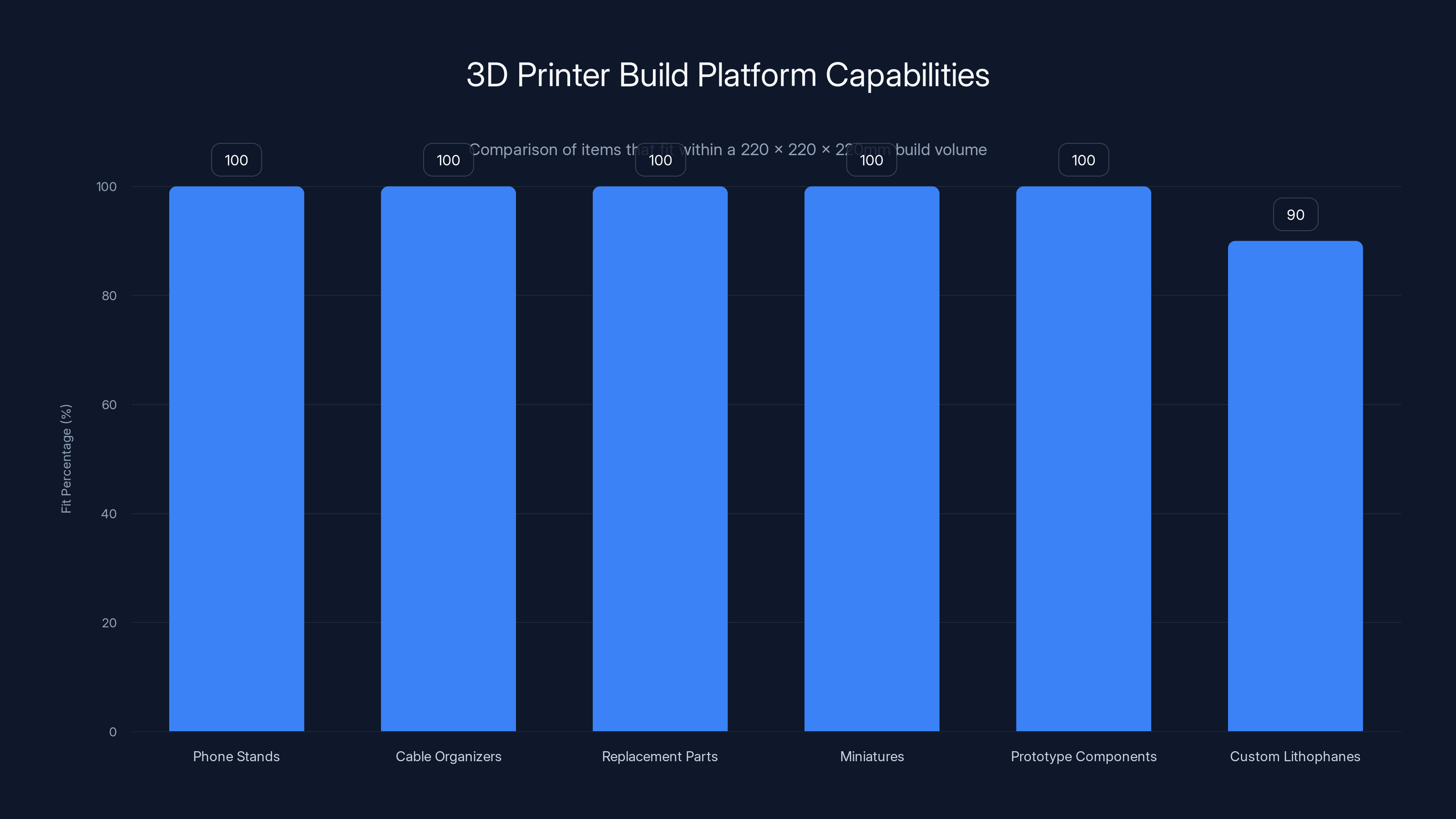

With 220mm on each side, you can print:

- Phone stands and docks (definitely fits)

- Cable organizers (multiple pieces or one large piece)

- Replacement parts for household items (door handles, clips, brackets)

- Miniatures and gaming pieces (easily fits 20-50 miniatures at once)

- Prototype product components (realistic for market validation)

- Custom lithophanes (up to about 200 x 200mm for quality results)

What you can't easily print:

- Large decorative vases or planters (size limitations)

- Full-scale helmets or armor (need multiple prints)

- Furniture components (too large)

The heated bed is critical. It stays around 60°C for PLA and higher temperatures for PETG or other materials. This prevents warping, especially on larger prints where the corners would normally lift away from the platform.

Adhesion out of the box is strong. You don't need special bed tape, glue sticks, or expensive adhesion solutions. Clean the bed with warm water between prints, and you're good. Some users report printing 50+ times without needing to relevel the nozzle.

Material Compatibility: What You Can Actually Print

This is where beginners often get confused. "Supports PLA and PETG" sounds straightforward, but there's nuance here.

With the standard 0.4mm nozzle:

- PLA: The easiest material. Low print temperatures, reliable adhesion, forgiving of beginner mistakes

- PETG: Slightly trickier. Requires higher temperatures and bed heating, but prints are more durable than PLA

- TPU (flexible plastic): Works, but requires slower speeds and careful tuning

- Carbon-fiber blends: The 0.4mm nozzle struggles slightly with fiber-reinforced materials, but people print them anyway

With optional nozzle upgrades (0.25mm, 0.6mm, 0.8mm):

You can expand material options. A 0.6mm nozzle is particularly useful for TPU because it lets more material flow without jamming. A 0.25mm nozzle enables fine detail work for miniatures and jewelry.

What's NOT compatible:

- ABS plastic: This is a intentional limitation. ABS requires enclosed chambers and higher temperatures. Flashforge designed the Adventurer 5M as an open-frame machine, so ABS just doesn't work well and will warp severely

- Nylon: Requires specialty equipment

- Polycarbonate: Too aggressive for this machine's heating system

For most beginners, this limitation is irrelevant. You'll spend your first 100 prints learning PLA, experimenting with PETG, and maybe trying TPU for a flexible phone case. By the time you want ABS, you'll know enough to either upgrade or build custom solutions.

Quick-Swap Nozzle System: A Game-Changer for Beginners

One feature that separates the Adventurer 5M from competition at this price point is the quick-detach nozzle system. This isn't just convenience. It's actually revolutionary for beginners.

Traditional 3D printers require you to:

- Heat the nozzle to temperature

- Remove the heater block from the print head

- Unscrew the nozzle (which gets stuck because of hardened plastic)

- Clean out debris

- Install a new nozzle

- Verify alignment

- Re-calibrate

With the Adventurer 5M's quick-swap system, you:

- Heat the nozzle to temperature

- Press a release button

- Pull out the nozzle

- Pop in the new one

- Done

This opens up realistic workflows for beginners. You can switch from 0.4mm to 0.6mm in under 30 seconds, print something with different requirements, then switch back. That flexibility encourages experimentation.

Flashforge includes the 0.4mm nozzle as standard. Optional sizes (0.25mm, 0.6mm, 0.8mm) run about $15-20 each, which is reasonable.

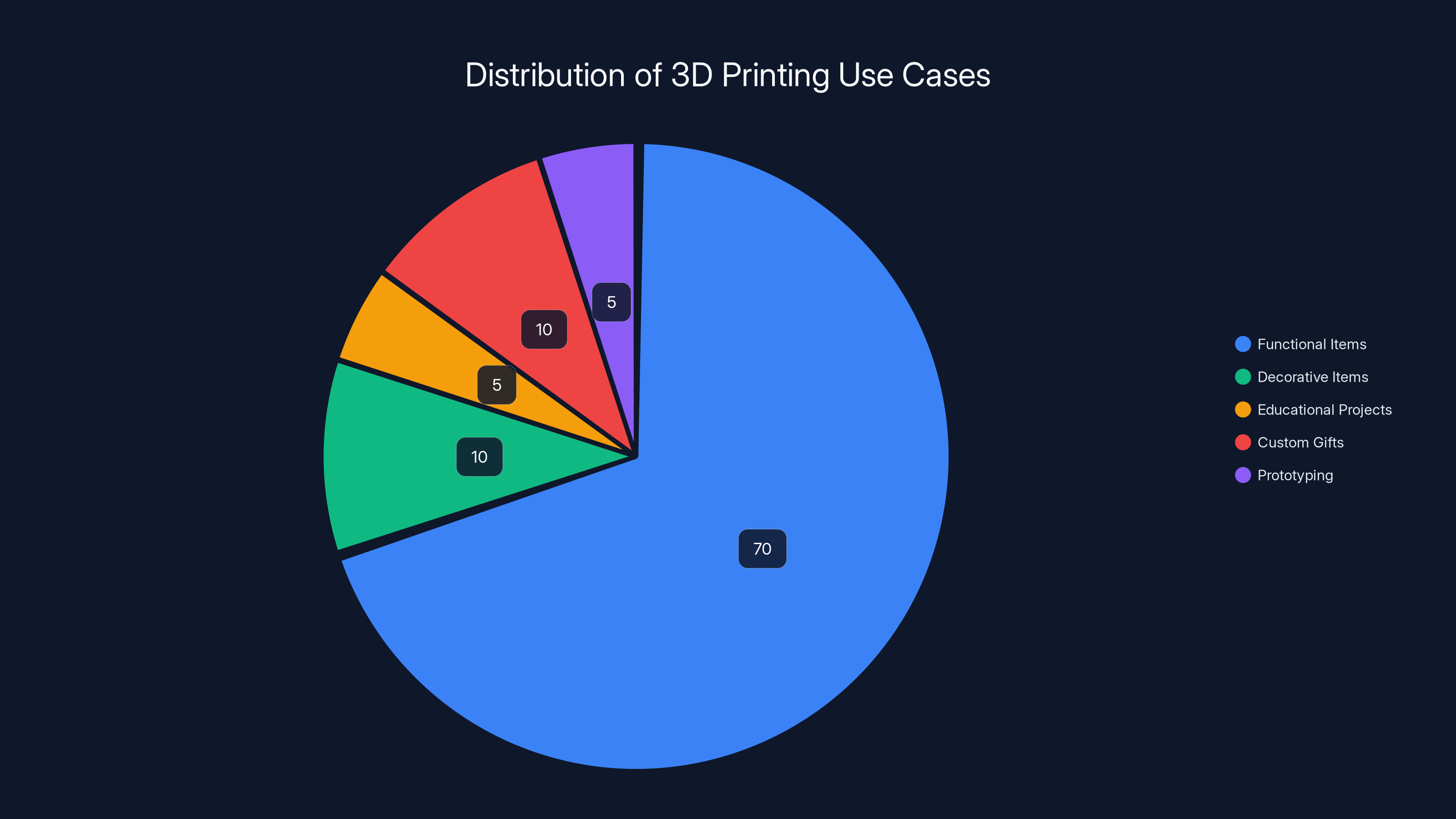

A significant 70% of 3D prints are functional items, highlighting the practical value of 3D printers beyond decorative uses. (Estimated data)

Display and Connectivity: The Interface You'll Actually Use

The 4.3-inch touchscreen sounds small until you realize most 3D printers have displays that look like they're from 2008. This one feels modern. Menu navigation is intuitive. Icons are clear.

What you can actually do from the display:

- Start and stop prints

- Adjust temperature in real-time

- Monitor print progress and time remaining

- Change nozzle size

- Configure Wi Fi settings

- Check filament type and color

- Access saved print profiles

Connectivity options are flexible:

- Wi Fi: Send files directly to the printer from your computer or phone without needing a USB cable

- Ethernet: More reliable for workshops or if your Wi Fi is flaky

- USB: Traditional connection, always works

For beginners, Wi Fi is the game-changer. You slice a design in your software, hit "send to printer," and the file loads automatically. No fiddling with SD cards or USB sticks.

The machine supports cloud connectivity through Flashforge's platform, which means you can monitor prints from your phone even if you're not home. The feature is genuinely useful if you're printing overnight.

Safety Features: Filament Detection, Power Loss Recovery, and More

Filament running out mid-print used to be a common nightmare. You'd come back to a perfect print that suddenly stops halfway because the spool emptied.

The Adventurer 5M has filament run-out detection. When it senses the filament has ended, it pauses the print, notifies you, and waits for you to load new material. You resume printing as if nothing happened.

Even more useful is power loss recovery. If your power cuts out (storm, accident, whatever), the printer remembers exactly where it was. When power returns, it picks up right where it left off. For an 8-hour print, this is genuinely valuable.

Thermal runaway protection prevents the hot end from overheating and potentially causing damage. Automatic shutoff after detecting no activity for a set time saves power.

None of these features sound exciting until you've lost a 6-hour print to something avoidable. Then they become essential.

Print Quality Analysis: What Real Prints Actually Look Like

Here's the brutal truth about budget 3D printers: they can produce quality prints, but you have to know what you're doing.

With proper settings, the Adventurer 5M produces:

- Smooth dimensional accuracy to within ±0.5mm

- Clean layer resolution at 0.2mm layer heights (the standard)

- Minimal stringing (unwanted plastic threads between prints)

- Good overhangs without supports up to about 45 degrees

Those specs translate to print quality that looks "professional" at a glance. If someone picks up a print without examining it closely, they'd assume it came from a more expensive machine.

Where it shows limitations:

- Extremely detailed miniatures (sub-0.5mm details get muddled)

- Transparent or translucent prints (tends to be cloudy)

- Ultra-fine curved surfaces (subtle layer banding is visible at certain angles)

But again, for 95% of beginner projects, this is overkill to worry about. You're printing a phone stand, not jewelry for retail.

The consistent quality stems from the Core XY design and high acceleration. Cheaper machines vibrate excessively, which degrades surface finish. The Adventurer 5M stays stable even at higher speeds.

The 220 x 220 x 220mm build platform is ideal for a variety of items, fitting most small to medium-sized prints perfectly. Estimated data based on typical item dimensions.

Maintenance and Long-Term Reliability: What You Need to Know

Buying a 3D printer is the first cost. Maintaining it is the ongoing reality.

Basic maintenance is genuinely simple:

- Weekly: Clean the build platform with warm water and a soft cloth. Takes 2 minutes

- Monthly: Check for loose belts or obvious wear. Tighten if needed

- Every 50 hours of printing: Replace or clean the nozzle. Quick-swap makes this trivial

- Yearly: Replace any worn belts proactively (costs about $30 for the kit)

The all-metal frame reduces issues with plastic parts warping or cracking over time. User reports show machines running reliably for 2-3 years with basic maintenance.

Common wear items and costs:

- Nozzles: $15-20 each, last 50-100 hours

- Belts: $30 full kit, last 1-2 years of moderate use

- Heating element: $40-50, rarely fails in normal operation

Flashforge actively supports older models with firmware updates and replacement parts remain available. This matters. Some manufacturers stop supporting machines after a year, making them frustrating to use.

Slicing Software: Getting Your Designs Ready to Print

You can design in software, but before your printer understands it, your design needs to be "sliced." This means converting a 3D model into instructions layer-by-layer.

Flashforge includes Flash Print, their proprietary slicing software. It's not the most powerful option available, but it works well for beginners:

- Simple interface without overwhelming options

- Built-in preview before sending to printer

- Pre-configured profiles for common materials

- Automatic support generation for overhangs

Alternatively, you can use Cura or Prusaslicer (both free), which offer more control but have steeper learning curves.

For most beginners, starting with Flash Print makes sense. Once you understand slicing fundamentals, experimenting with alternatives becomes practical.

The software workflow is:

- Open your 3D model (STL, OBJ, or 3MF files)

- Adjust size, rotation, and positioning

- Select material and nozzle size

- Configure print speed and quality

- Preview the sliced result

- Send to printer via Wi Fi or USB

This whole process typically takes 2-5 minutes once you've done it a few times.

Design Considerations for Your Projects

Not every design prints well. Understanding print-friendly design saves hours of frustration.

Things that print easily:

- Solid objects with simple geometry

- Designs with gradual curves (no sharp transitions)

- Objects that sit flat on the build platform

- Parts under 200 x 200 x 200mm

Things that require care:

- Unsupported overhangs beyond 45 degrees

- Very thin walls (under 2mm)

- Complex moving parts that need tight tolerances

- Hollow objects without drainage holes

If you're new to design, focus on practical prints first:

- Phone stands: Simple geometry, immediately useful

- Cable organizers: Helps you understand different design constraints

- Replacement parts: Motivating because you fix something broken

- Drawer organizers: Good for learning different compartment designs

Once you've printed 20-30 things, intuition develops about what works and what doesn't.

Key factors influencing the decision to upgrade from the Adventurer 5M include the need for larger build volumes and industrial-grade reliability. Estimated data based on common user needs.

Price-to-Performance: Is $239 Actually a Good Deal?

Let's talk economics. At $239, where does the Adventurer 5M actually stack up?

Cheaper alternatives ($100-180):

- Creality Ender 3 V3 SE

- Anycubic Kobra 2

These machines work, but you're sacrificing speed (usually 150mm/s max) and assembly quality. You'll spend more time troubleshooting calibration issues.

Similar price ($200-300):

- Anycubic Kobra 2 Neo

- Creality CR-10 SE

Competitive on price, but the Adventurer 5M offers faster speeds and better-documented support.

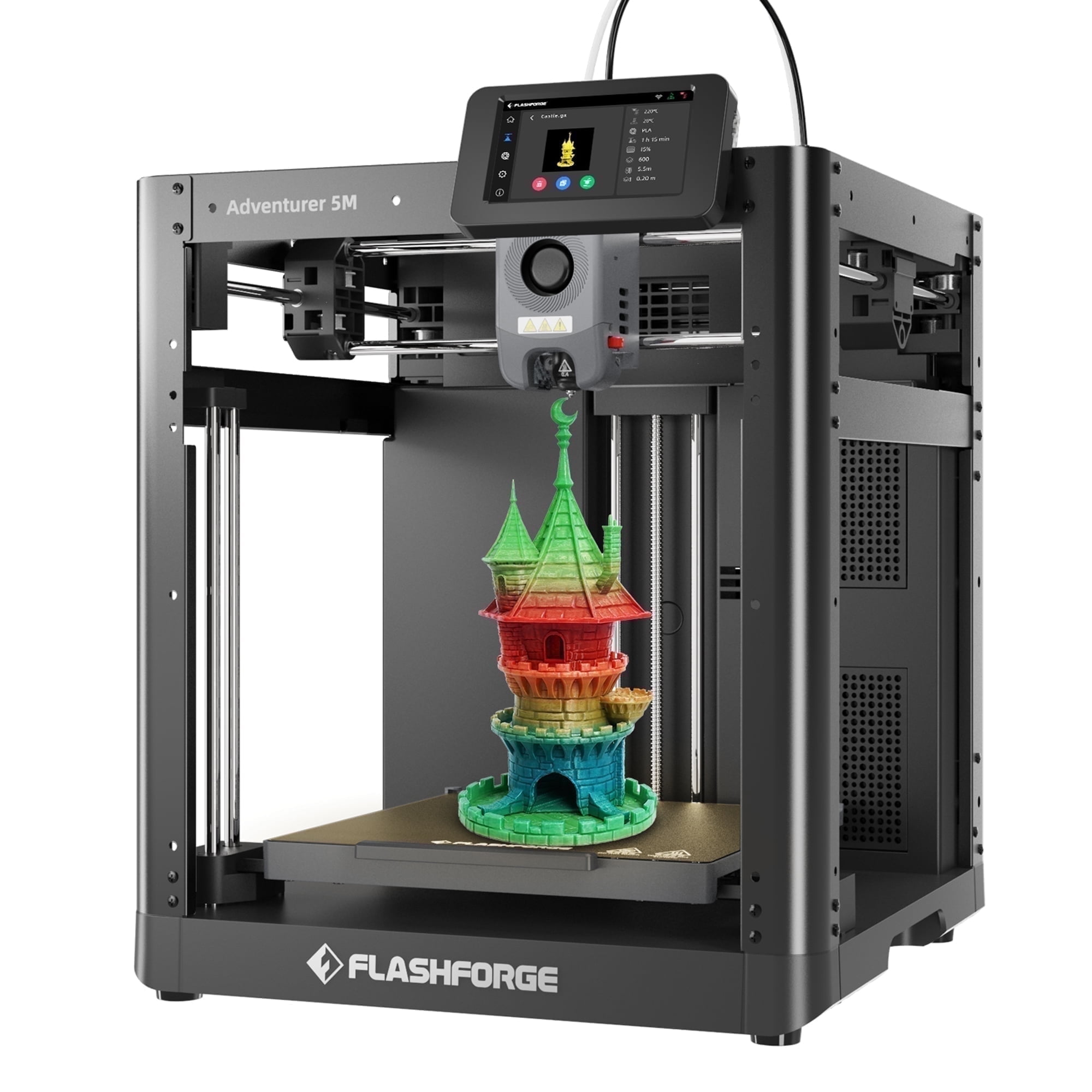

More expensive ($400+):

- Original Flashforge Adventurer 4

- Bambu Lab X1 Carbon

Better in various ways, but double the price or more.

The value proposition is clear: for $239, you're getting:

- Fast printing (600mm/s) that would cost $500+ elsewhere

- Beginner-friendly design that requires minimal troubleshooting

- Active community with solid documentation

- Proven reliability from a manufacturer that's been around since 2011

If your budget is $200-300 and you want a single machine that just works, this is difficult to beat.

Real-World Use Cases: What Are People Actually Printing?

Theory is one thing. Real applications are what matter.

Hobbyists and makers:

Tabletop gaming enthusiasts print custom miniatures, terrain, and storage solutions. A single gaming session's worth of printed pieces would cost $50-100 if purchased commercially. People recoup their printer investment within weeks.

Home organization:

Printing custom drawer dividers, cable organizers, and storage containers costs nothing in materials but saves hours of shopping. This alone justifies the machine for many users.

Product prototyping:

Startups print multiple iterations of products before manufacturing. The Adventurer 5M's speed means testing design changes within hours instead of days.

Educational use:

Engineering students print parts for robotics projects. The reliability means less time debugging hardware and more time on actual engineering.

Functional replacement parts:

Door handles, knobs, clips, hinges—things break constantly. Rather than replace entire assemblies, print the one part that failed. Costs pennies, saves dollars.

Custom gifts:

Personalized desk organizers, phone stands with names, custom figurines. These have genuine sentimental value beyond the material cost.

Community and Support: Why It Matters

Flashforge has been manufacturing 3D printers since 2011. That's a decade of experience, which translates directly into user support and documentation.

The online community includes:

- Official forum with active moderators who actually respond to questions

- Reddit communities (r/3 Dprinting) where Flashforge users congregate

- You Tube tutorials specific to the Adventurer 5M

- Custom firmware communities for advanced users who want to tinker

When you hit a problem (and you will), help is available within hours rather than days. This matters more than it sounds. Stuck on a print failure at 11 PM? Someone's probably experienced it and documented the fix.

Flashforge also releases firmware updates regularly, which means performance improvements and new features over time.

Common Pitfalls and How to Avoid Them

Beginner Mistake #1: Too-fast printing on first attempts

The machine can go fast, so people assume it should. Wrong. Your first 20 prints should run at 80-100mm/s. Learn what success looks like before pushing limits.

Beginner Mistake #2: Not leveling the bed properly

Auto-leveling helps, but the firmware still needs a proper reference point. Clean the bed thoroughly and follow the leveling procedure from the manual once during setup.

Beginner Mistake #3: Ignoring filament quality

Cheap filament (

Beginner Mistake #4: Printing complex designs before understanding basics

Your first print should be something simple. A test cube. A phone stand. Not a complex mechanical assembly. Complexity comes after you understand how your machine behaves.

Beginner Mistake #5: Neglecting maintenance

Maintenance takes 5 minutes weekly. Ignoring it for months causes problems that take hours to fix.

When to Upgrade: Knowing When You've Outgrown This Machine

The Adventurer 5M is excellent for beginners, but it has limits. You might outgrow it if:

- You need larger build volumes (consistently printing objects bigger than 200mm)

- You require ABS or other high-temperature materials (machine is designed for PLA/PETG)

- You want dual-material printing (mixing colors or materials in one print)

- You need industrial-grade reliability (99.5%+ success rate for production runs)

If any of these apply, it's time to look at next-tier machines. Anything in the $500-1000 range typically offers significant upgrades.

But for learning 3D printing, prototyping, and hobbyist use? This machine won't hold you back for years.

Accessories Worth Buying

The machine comes complete, but a few accessories improve the experience:

Essential:

- Extra nozzles (0.6mm and 0.8mm set): $25-35 for expanded material options

- Quality filament sampler pack: $40-60 for variety without massive commitment

- Cleaning supplies (isopropyl alcohol, soft brushes): $10 for maintenance kit

Nice to have:

- Bed adhesion sheet (optional, heated bed is good enough): $15

- Enclosure (optional, helps with temperature consistency): $50-100

- Filament drying box (important if humidity is high): $20-30

Skip for now:

- Expensive lighting upgrades

- Advanced cooling solutions

- Custom firmware boards (you don't need them)

Start minimal. Add accessories as you identify specific needs.

Making Your Decision: Is This Printer Right for You?

The Adventurer 5M is right for you if:

- You're genuinely curious about 3D printing, not just casually interested

- You want to print functional items and prototypes

- You appreciate build quality and reliability

- You're willing to spend 30 minutes learning basic operation

- Your budget is $200-300 and not negotiable

Skip it if:

- You need to print large objects frequently

- You require ABS or other high-temperature plastics

- You want absolute cutting-edge technology

- You have zero interest in maintenance or learning curves

For most people in the "thinking about 3D printing" phase, this machine represents genuine value. It removes the typical barriers (price, complexity, speed) that prevent people from actually trying the hobby.

FAQ

What materials can I print with the Flashforge Adventurer 5M?

The machine supports PLA, PETG, TPU (flexible plastic), and carbon-fiber blends with the standard 0.4mm nozzle. Upgraded nozzles (0.6mm, 0.8mm, 0.25mm) expand options slightly. ABS and nylon are not compatible because the machine lacks an enclosed chamber and higher temperature capacity.

How long does setup take and is it complicated?

Setup takes approximately 10 minutes and is straightforward. You unbox it, plug in the power supply, add filament, and load a test file. The machine includes clear instructions, and most users complete setup without consulting the manual.

What's the actual print speed compared to other machines?

The Adventurer 5M has a maximum travel speed of 600mm/s and acceleration up to 20,000mm/s², making it roughly 3-4 times faster than entry-level alternatives in the $100-150 range. Real-world print speeds typically run 80-120mm/s for quality prints, still meaningfully faster than competing machines.

How often do I need to maintain this printer?

Basic maintenance is minimal. Weekly cleaning of the build platform takes 2 minutes. Monthly checks for loose components take 5 minutes. Nozzle replacement or cleaning happens every 50-100 printing hours (takes 30 seconds with the quick-swap system). Annual belt replacement is recommended for heavy users but not essential if operating normally.

Can I use this printer for small business or side income?

Yes, if expectations are realistic. The machine is reliable enough for small production runs (50-200 units) of simple items. Print quality is good enough for personal use and gifts but not for products marketed as "professional grade." At $0.10-0.30 per hour in material and maintenance costs, profit margins work if you charge appropriately.

Is the $239 price legitimate or a misleading sale?

The regular price is approximately

What's the learning curve for slicing and printing?

Basic operation takes 30 minutes to learn. You can print your first object within an hour of unboxing. However, optimizing print settings for different materials and achieving excellent quality takes 2-4 weeks of practice and experimentation. This progression is intentional and builds confidence gradually.

How reliable is this machine over time?

User reports indicate reliability consistent with machines in the $500-600 range. With proper maintenance, machines run 2-3 years without major issues. Build quality is solid, and replacement parts are readily available and affordable. Flashforge continues supporting older models with firmware updates and spare parts availability.

Does it work with different slicing software or am I locked into Flashforge software?

The machine is open-source compatible. You can use Cura, Prusaslicer, or other third-party slicing software. Some advanced features may not be available, but the machine prints properly with any standard G-code. The community has documented firmware modifications for users who want additional customization.

What's the community like and where do I find help?

Flashforge maintains an active official forum with moderators who respond regularly. The general 3D printing community on Reddit is welcoming to beginners. You Tube contains dozens of tutorial videos specific to the Adventurer 5M. Help for common issues typically arrives within hours of asking.

Final Thoughts: Your 3D Printing Journey Starts Here

There's something genuinely exciting about designing something in your mind, translating it to digital form, and watching a machine build it layer by layer. That feeling doesn't wear off.

The Flashforge Adventurer 5M removes the obstacles that prevent people from experiencing that excitement. It doesn't require deep technical knowledge. It doesn't cost a fortune. Setup doesn't eat your entire weekend.

At $239, you're not making a massive financial commitment. You're making an investment in curiosity. You're saying, "I want to see if 3D printing is actually useful for me."

Based on everything we've covered, this machine delivers that experience reliably. It prints fast enough that iteration feels natural. It's stable enough that failures are usually your learning rather than hardware limitations. The community is large enough that problems get solved quickly.

If you've been thinking about 3D printing—actually thinking about it, not just passively curious—this is the moment to stop overthinking and start printing. The machine is ready. Your designs are waiting. The question is just whether you're ready to begin.

Your first print might be simple. Your tenth might be complex. Your hundredth will be something you never imagined possible. That progression is what makes 3D printing special.

The Flashforge Adventurer 5M gives you the tool. Everything else depends on where you take it.

Key Takeaways

- The Flashforge Adventurer 5M delivers exceptional value at $239 with 600mm/s travel speeds and 20,000mm/s² acceleration, printing 3-4 times faster than competing entry-level machines

- Setup completes in 10 minutes without complex calibration, making this genuinely beginner-friendly with auto-leveling, heated platform, and intuitive 4.3-inch touchscreen interface

- Quick-swap nozzle system eliminates the tedious nozzle-changing process that frustrates users of other machines, enabling flexible material experimentation

- Supports PLA, PETG, TPU, and carbon-fiber blends with optional nozzle upgrades, though ABS is not compatible due to open-frame design

- Reliable long-term performance with minimal maintenance (weekly cleaning, monthly checks, annual belt replacement) and active community support make this a practical investment in learning 3D printing

![Flashforge Adventurer 5M: Complete Beginner's Guide to 3D Printing [2025]](https://tryrunable.com/blog/flashforge-adventurer-5m-complete-beginner-s-guide-to-3d-pri/image-1-1771591055421.jpg)