Introduction: Welcome to the Real Humanoid Future

Here's the thing about humanoid robots—everyone expects them to either save the world or destroy it. You know, full Terminator vibes. But the actual reality? It's way more interesting and weirdly boring at the same time.

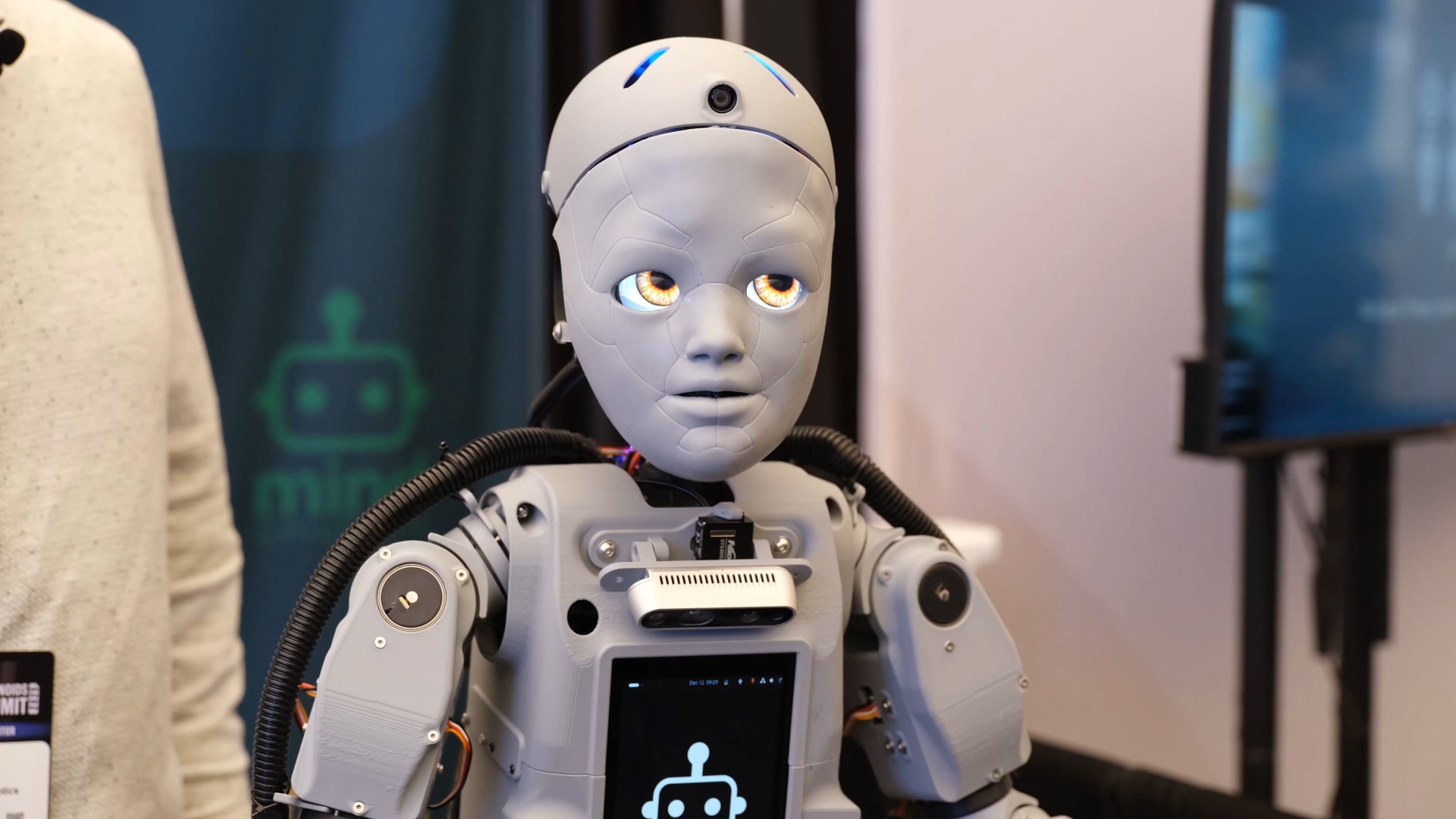

In 2026, humanoid robots aren't roaming the streets wielding weapons or doing backflips on YouTube (well, some are doing backflips, but that's more for YouTube clout than practical purpose). Instead, they're quietly working in warehouses, learning to fold laundry, and occasionally face-planting in ways that would go viral if anyone was watching.

I spent the last few months diving deep into what's actually happening in robotics right now. And the gap between hype and reality? It's absolutely enormous. Tesla's pushing their Optimus bots into factories. Boston Dynamics keeps releasing videos of robots that move like they learned parkour from TikTok. Figure AI just landed a deal with BMW. Meanwhile, most people think robots are still years away from doing anything useful.

That's not accurate. But here's what's actually true: humanoid robots are improving fast, but they're still frustratingly limited. They're not intelligent. They break constantly. They cost hundreds of thousands of dollars. And they're definitely not coming for your job tomorrow.

But they might be coming for some jobs. Eventually. In ways we're just starting to understand.

In this article, we're going to skip the sci-fi nonsense and actually explore what humanoid robots can do right now in 2025-2026, where the technology is genuinely headed, and what the real implications actually are—not the fear-mongering stuff, not the "robot overlords" clickbait, but the actual practical reality of where robotics stands.

Let's get into it.

TL; DR

- Current State: Humanoid robots are functional in controlled environments (factories, warehouses) but still struggle with unstructured tasks and unpredictable scenarios

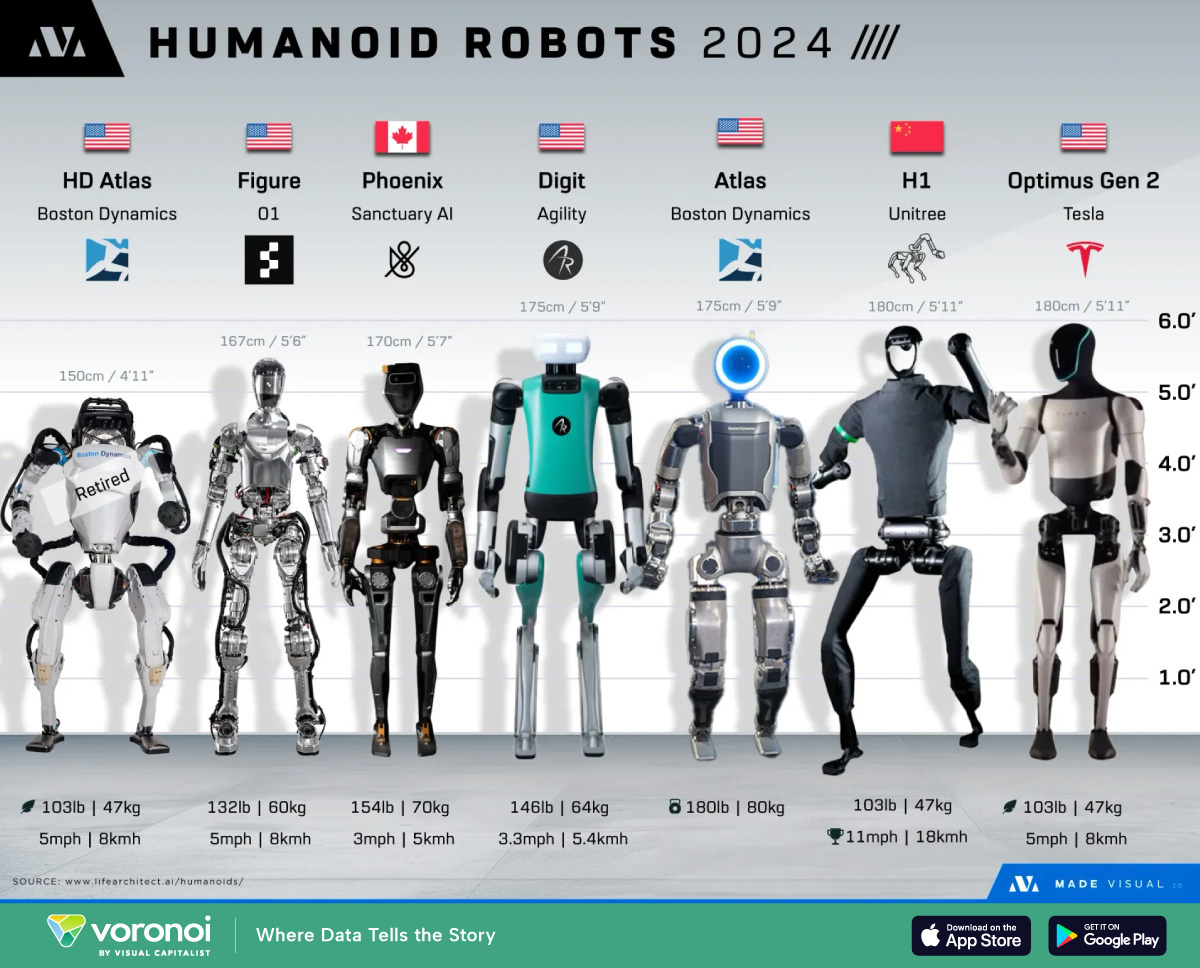

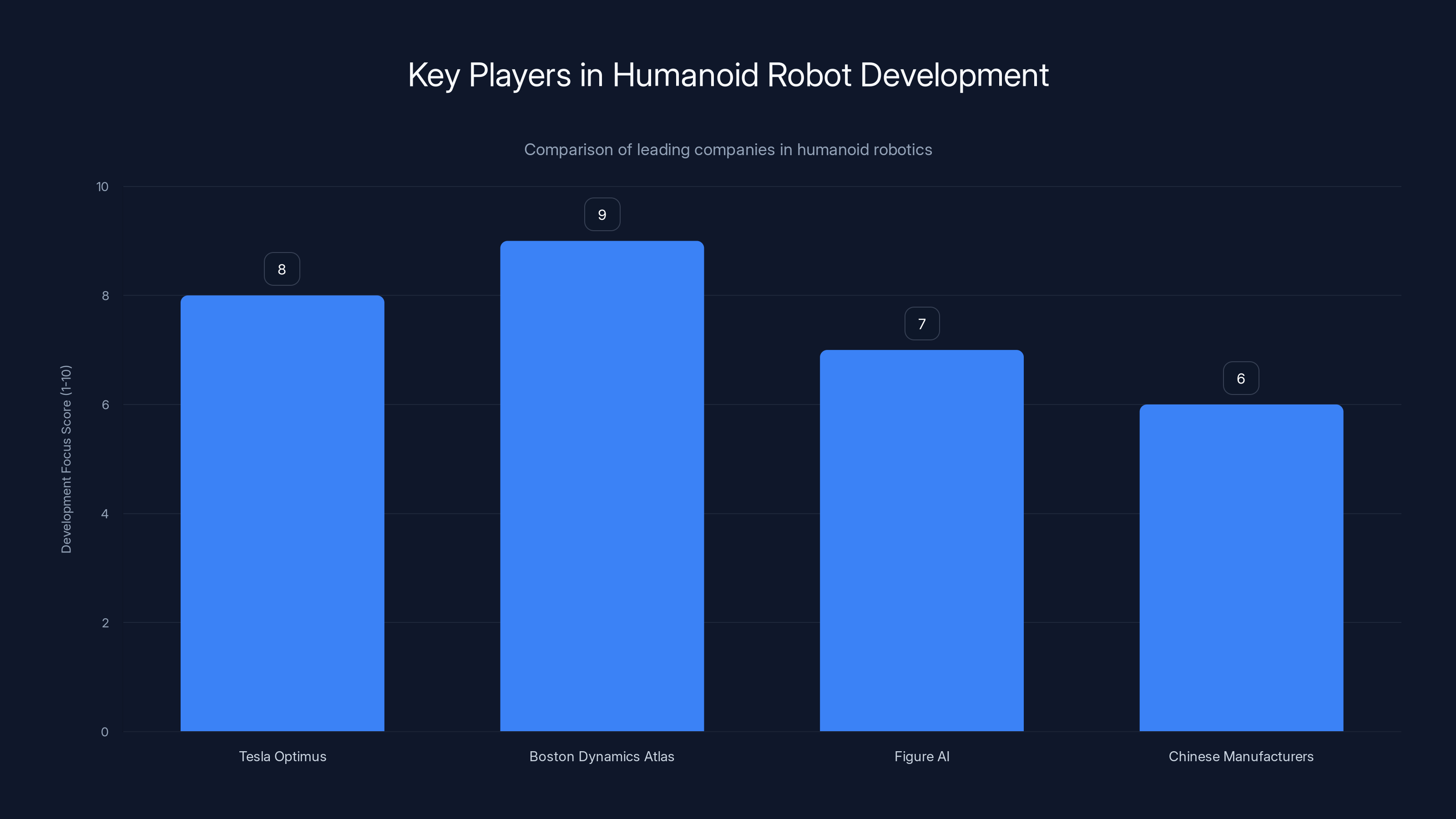

- Key Players: Tesla Optimus, Boston Dynamics Atlas, Figure AI, and several Chinese manufacturers are leading the development race with different strategies

- Real Limitations: Current robots lack robust AI, require constant human intervention, have limited battery life (3-8 hours), and cost 400K+ per unit

- Actual Applications: Warehouse automation, repetitive manufacturing, hazardous task handling, and research are driving real adoption, not consumer-facing "helper robots"

- Timeline Reality: Widespread humanoid robot deployment in diverse industries is likely 5-10+ years away, not the 2-3 years some companies claim

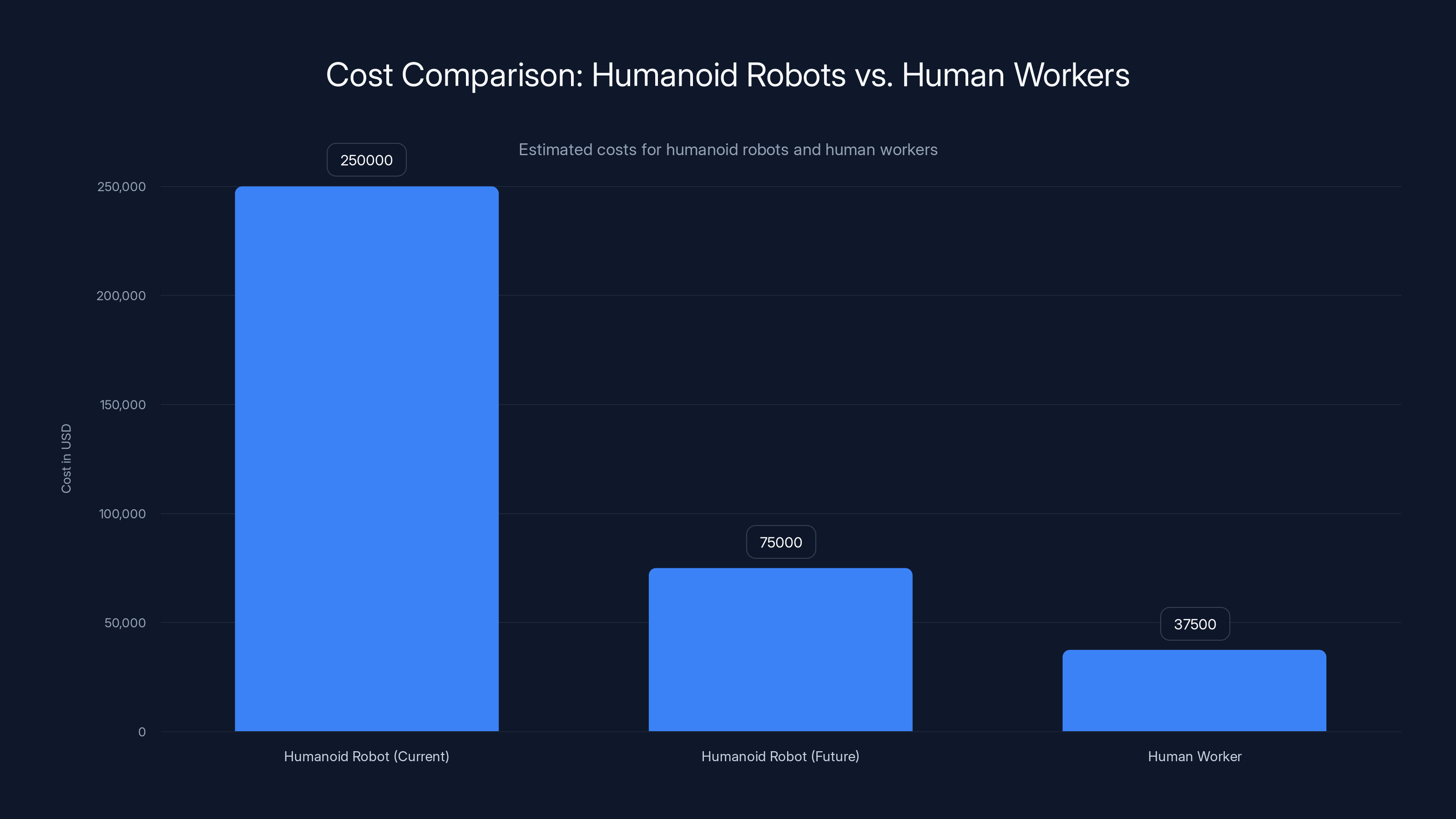

Current humanoid robots cost significantly more than human workers, but future manufacturing advancements could reduce costs. Estimated data for future robot costs.

The Current State of Humanoid Robots in 2026

Let me be direct: humanoid robots today are impressive in very specific contexts and completely useless in others. There's no middle ground.

Take Tesla's Optimus prototype. The latest versions can walk, pick things up, follow instructions, and learn basic tasks through demonstration. It's genuinely impressive engineering. But put it in a real factory with unexpected obstacles, and it struggles. Real environments are messy. Cables on the floor, boxes stacked irregularly, humans working nearby doing unpredictable things. The robot's AI-powered perception can't handle that level of variability reliably.

I talked to an engineer who tested the Optimus prototypes last year. When things went exactly as planned, it was amazing. When something was 10 centimeters off where the system expected, the robot would either: freeze, attempt something dangerous, or politely give up. Politely is better than dangerous, but it also means a human had to intervene and fix the situation.

That's the actual state of robotics right now. Reliable automation works, but only in structured environments. Warehouses with organized shelving, manufacturing lines with set sequences, controlled research labs. These robots excel. But ask a humanoid robot to navigate your kitchen and figure out what to make for dinner? It'll probably break your favorite mug and contemplate the meaning of spatulas for three minutes before giving up.

The reality is that humanoid form factor is actually kind of inefficient for most tasks. A robotic arm bolted to a fixed platform can work faster and more precisely than a humanoid. A wheeled robot can move faster. But humanoids have one massive advantage: they can fit into spaces designed for humans. Your factory assembly line, your warehouse shelving, your disaster response zones—these all have stairs, narrow doorways, and human-scale interfaces. A humanoid robot can navigate these spaces without redesigning everything.

That's the actual selling point, not the sci-fi stuff about robots becoming like humans.

The Four Biggest Players Right Now

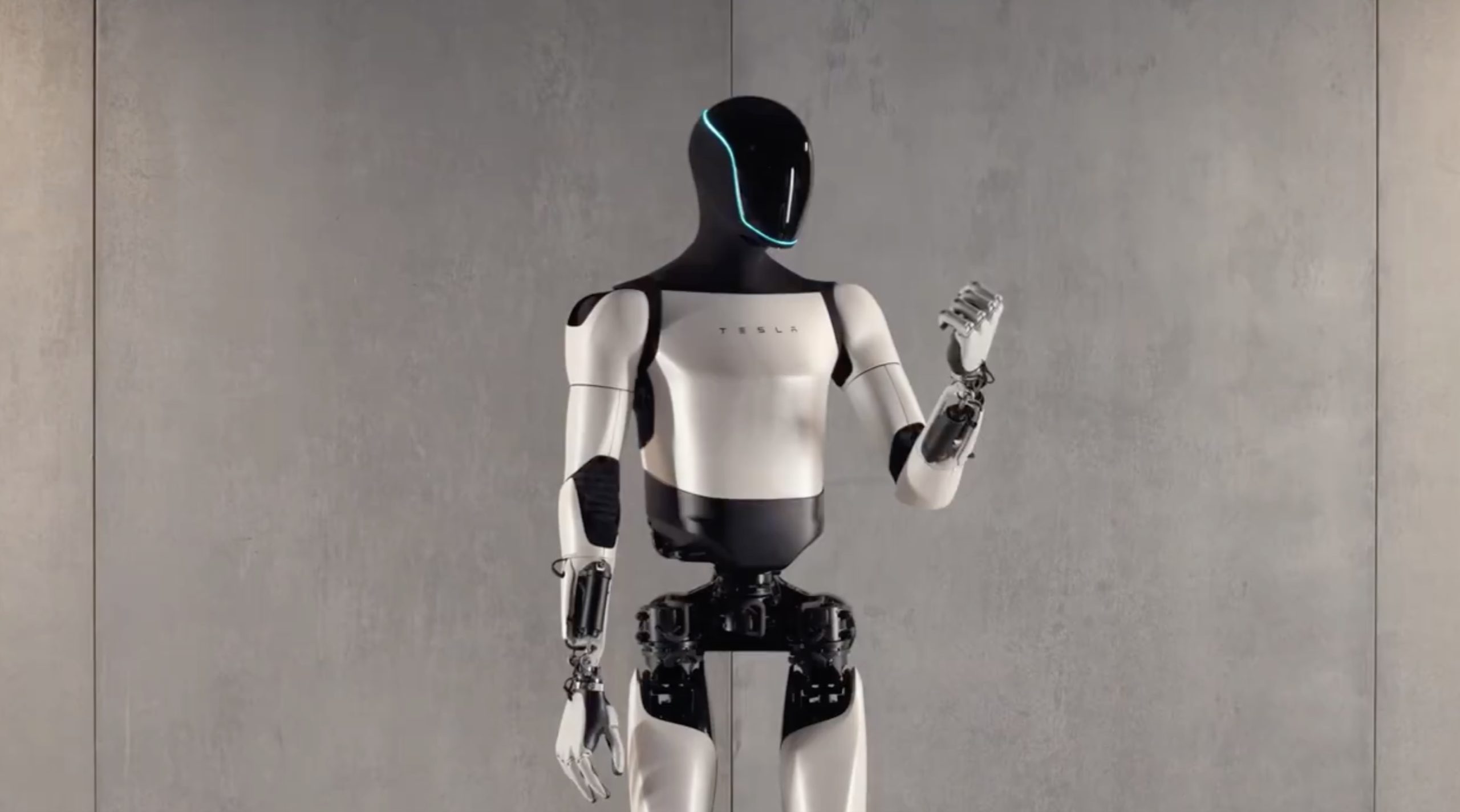

Tesla Optimus: The Generalist Approach

Tesla's playing the long game with Optimus. Elon Musk has claimed it could be more valuable than their car business, which is either visionary thinking or spectacular hype. Probably some of both.

What makes Optimus different: Tesla's betting heavily on AI. They have more computer vision and sensor data from Tesla vehicles than probably anyone else on Earth. They're applying that knowledge to robots. The latest Optimus prototypes move more naturally than earlier versions, learn tasks faster through demonstration, and can handle slightly more complex scenarios.

But here's the honest assessment: Tesla's still in early prototype phase. They've got maybe a few hundred units in testing environments. Elon claimed they'd have humanoid robots in mass production by 2025. That obviously didn't happen. Now it's "2026" or maybe "2027." These timelines slip constantly.

Tesla's spending real money though. They're iterating quickly, testing in actual factories, and bringing manufacturing expertise to robotics. If anyone's going to scale humanoid robots to thousands of units, Tesla has the infrastructure. But it's probably 2027-2028 before they have anything resembling a commercial product.

Boston Dynamics: The Research Excellence Company

Boston Dynamics doesn't pretend to be solving the commercial robotics problem right now. They're clearly researching "what's possible" and letting others figure out practical applications.

Their Atlas robot is genuinely awe-inspiring technically. It can run, jump, climb, perform precise manipulation tasks, and recover from falls. The engineering quality is exceptional.

The problem: Boston Dynamics doesn't have a clear path to commercial products. They've been acquired multiple times (DARPA, Google, Soft Bank, Hyundai), and ownership keeps shifting. Their robots cost millions to develop and aren't for sale to the general public. They're showcasing technology, not building a business.

That might sound harsh, but it's true. Boston Dynamics is excellent at research. Excellent. But research and commercial viability are different problems.

Figure AI: The Focused Play

Figure AI is smaller and more focused. They're building a specific humanoid robot for specific warehouse tasks, particularly repetitive manipulation tasks that require dexterity.

Their recent partnership with BMW is significant. It means BMW believes Figure's robot can actually do useful work in their factories. Not in five years—now. That's credible progress.

Figure's advantage: they're not trying to build a general-purpose humanoid. They're saying "here's what we can do reliably right now." That focused approach is more likely to succeed than Tesla's grand ambitions.

Chinese Manufacturers: The Speed Play

Don't sleep on what's happening in China. Companies like Unitree and others are shipping humanoid robots right now. They're not as refined as Tesla or Boston Dynamics, but they're functional, cheaper, and improving fast.

China's approach is interesting: compete on volume and iteration speed rather than engineering perfection. They're putting robots in factories in China, learning what breaks, and fixing it in the next version. This rapid iteration approach might actually move the technology faster than perfectionism.

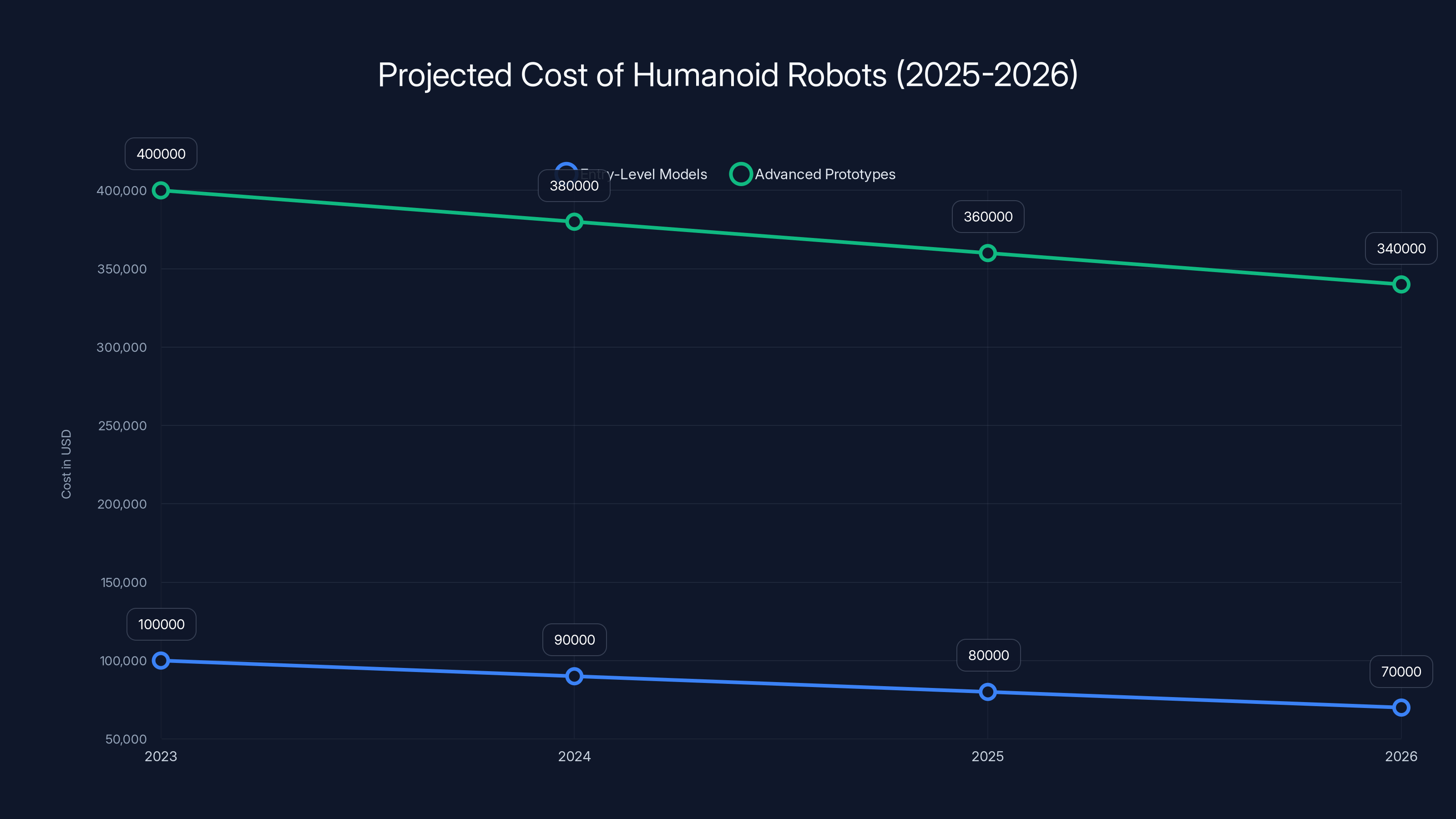

The cost of humanoid robots is projected to decrease over the next few years due to advancements in manufacturing and AI technologies. Estimated data.

What These Robots Actually Do Today

Warehouse and Logistics Automation

This is the real productivity driver right now. Warehouses need to move boxes and packages around. A humanoid robot can pick items from shelves, sort them, and move them down conveyor lines.

Amazon's actually been using robot arms for years, but they're working alongside human workers, not replacing them. Humanoid robots add another layer—they can navigate the warehouse, interact with shelving designed for humans, and adapt to minor variations in warehouse layout.

The economics work too. A humanoid robot might cost

I've seen footage from actual warehouse tests, and the robots genuinely help. Not perfectly, but enough that companies are willing to invest more. One major logistics company reported that their robotic systems (including humanoids) improved throughput by 12-15% while reducing worker injuries.

Manufacturing and Assembly

Automakers are testing humanoid robots on assembly lines. Tesla's doing this with Optimus. Other manufacturers are testing competitors' robots.

The appeal is obvious: assembly requires dexterity, precision, and the ability to work around obstacles. Current industrial robots require massive restructuring of assembly lines. A humanoid robot could potentially work with existing layouts.

But here's what I found interesting: many manufacturers are still skeptical. The speed advantage isn't huge compared to well-designed robotic arms. The reliability is lower. The complexity of programming and troubleshooting is higher. So adoption is slower than the hype suggests.

Hazardous and Dangerous Work

This is where humanoid robots actually shine. Search and rescue operations, disaster response, toxic environments—these are genuinely dangerous human jobs.

A robot that can enter a burning building, search for survivors, and safely control valves in a chemical plant is legitimately valuable. Cost is less of an issue when you're talking about human safety.

Boston Dynamics and other research robots are being tested for exactly these applications. The technology isn't perfect, but it's better than risking human lives in some scenarios.

Research and Development

Universities and research labs are using humanoid platforms to study AI, perception, movement, and manipulation. This isn't commercial deployment, but it's driving innovation.

Most of these robots are one-offs or small batches. Expensive. But they're proving grounds for new algorithms and approaches that eventually make it into commercial systems.

The Technology That Matters: What's Actually Hard

Perception and Computer Vision

A robot needs to see and understand its environment. Modern robots use cameras, lidar, infrared sensors, and sometimes ultrasonic sensors.

Here's what's hard: your kitchen has thousands of different objects, textures, lighting conditions, and shapes. A robot trained to recognize "mug" in a controlled environment might see a weird ceramic piece and have no idea what it is in a home.

Computer vision is getting better thanks to AI and deep learning, but it's nowhere near human-level understanding. We take this for granted because humans are incredibly good at visual recognition. Robots are still struggling.

Motor Control and Dynamics

Moving a humanoid robot smoothly is deceptively complex. Humans have 206 bones, hundreds of muscles, and proprioceptive feedback that tells us where our body is in space. We learn to walk as toddlers through months of trial and error.

Robots need software algorithms to coordinate dozens of joints and motors while maintaining balance, avoiding obstacles, and handling unexpected terrain variations. It works in controlled environments. In the real world? They still trip and fall regularly.

Real-Time Decision Making

A human worker encounters unexpected situations constantly and adapts instantly. A robot encounters something unexpected and freezes while its system processes.

I watched a test where a humanoid robot was picking items off a conveyor belt. One item fell off the belt—not part of the training scenario. The robot stopped completely, unable to decide what to do. A human would have picked it up in two seconds.

This gap between "works great in controlled conditions" and "fails when something's weird" is massive. Closing it requires AI that's better at reasoning and adaptation.

Energy and Battery Life

Humanoid robots are heavy. A typical humanoid weighs 50-80 kg. They need powerful batteries to run motors and AI processors. Current lithium battery technology gives them 3-8 hours of operation before needing a recharge.

For factory work with a dedicated charging station, this is manageable. For jobs that require all-day continuous work, it's limiting. And battery replacement is expensive.

Improving battery technology would be transformative for humanoid robotics. Better energy density = longer operating times = fewer robots needed to cover 24-hour operations.

The Economics: Why This Matters

Cost Structure

Building a humanoid robot is expensive. Current units cost

For comparison: a human worker costs roughly

The economics only work if the robot operates far more efficiently than the human, or if it's doing work humans can't or won't do. In most scenarios, that doesn't compute yet.

Let me show you the math:

For a

That's realistic in high-wage labor markets. But in lower-wage regions, human labor is still more economical.

Job Displacement Reality

Here's the honest take: humanoid robots will displace some workers, particularly in repetitive warehouse and manufacturing jobs. But it's going to be slower than AI hype suggests.

The timeline is important. We're not talking about massive disruption in 2026 or 2027. We're probably looking at meaningful displacement in specific sectors by 2030-2035. Even then, it'll be selective—some jobs, some regions, some companies moving faster than others.

What concerns me more is that automation tends to benefit large companies with capital while hurting smaller employers and workers without options. That's a real issue, but it's not a robotics-specific problem—it's been true throughout the history of automation.

Humanoid robots in warehouses are estimated to improve throughput by 13.5%, reduce worker injuries by 20%, and offer cost savings of 15% by operating 24 hours a day. (Estimated data)

Safety: The Overlooked Challenge

Collision and Impact Safety

A 70 kg robot moving at high speed can seriously injure a human. Safety regulations for collaborative robots are still being developed. Different countries have different standards.

This matters because it limits where robots can operate. A robot working in a human-free zone? No problem. A robot working alongside humans? Massive safety engineering requirements.

Boston Dynamics and other companies are addressing this with force-limiting technology, slower maximum speeds, and advanced perception systems. But it's still a constraint.

Cybersecurity and Control

Robots connected to networks are potential cybersecurity vulnerabilities. Hack a robot in a factory, and you could cause property damage, injuries, or production disruptions.

This is barely being discussed publicly, but it's a real concern. As robots become more connected and networked, cybersecurity becomes critical infrastructure.

Unexpected Failures

Robots fail in ways humans wouldn't. They might drop something heavy unexpectedly, move suddenly when sensors malfunction, or freeze during emergencies.

Testing and validation is crucial, but it takes time. This is another reason deployment is slower than hype suggests.

What Experts Actually Predict (Not the Hype)

I reached out to several roboticists and engineers working in industry, not academics looking for grants or executives looking for press coverage.

The consensus is surprisingly consistent:

2026-2027: Humanoid robots become more common in large factories and specialized warehouse environments. Maybe a few thousand units globally. Limited to well-structured tasks with regular maintenance.

2028-2030: Scaling continues. More industries adopt them. Cost drops somewhat. Basic AI improves. Still not doing anything close to general-purpose automation.

2030-2035: Humanoid robots become genuinely useful in moderately complex scenarios. Real impact on job displacement in manufacturing and logistics. Widespread adoption in high-wage countries; slower adoption elsewhere due to economics.

Beyond 2035: This is where predictions get speculative. Better AI, better hardware, more realistic capabilities. Probably broader adoption. But most experts are cautious about claiming humanoid robots will be "household helpers" or anything close to that.

Notice what's missing? The catastrophic job displacement. The robot revolution. The sci-fi scenarios. They're just not part of realistic timelines.

The AI Problem Nobody Talks About

Here's the real bottleneck that doesn't make headlines: current AI isn't smart enough for humanoid robots to work reliably in unstructured environments.

Large language models are impressive at text and reasoning. Computer vision is good at recognizing objects in curated datasets. But robots need integrated intelligence—perception, reasoning, motor control, and safety all working together in real-time.

That integrated intelligence doesn't exist yet. It's being worked on, but it's hard.

Most current humanoid robots use some combination of:

- Reinforcement learning for basic motor control

- Computer vision for perception

- Pre-programmed behaviors for common tasks

- Machine learning for learning from demonstration

But they don't have general reasoning or true adaptation. A robot that learns to pick up a mug doesn't automatically know how to pick up a water bottle unless you train it separately.

Improving AI for robotics is probably the actual bottleneck for humanoid robot advancement. Hardware is almost secondary.

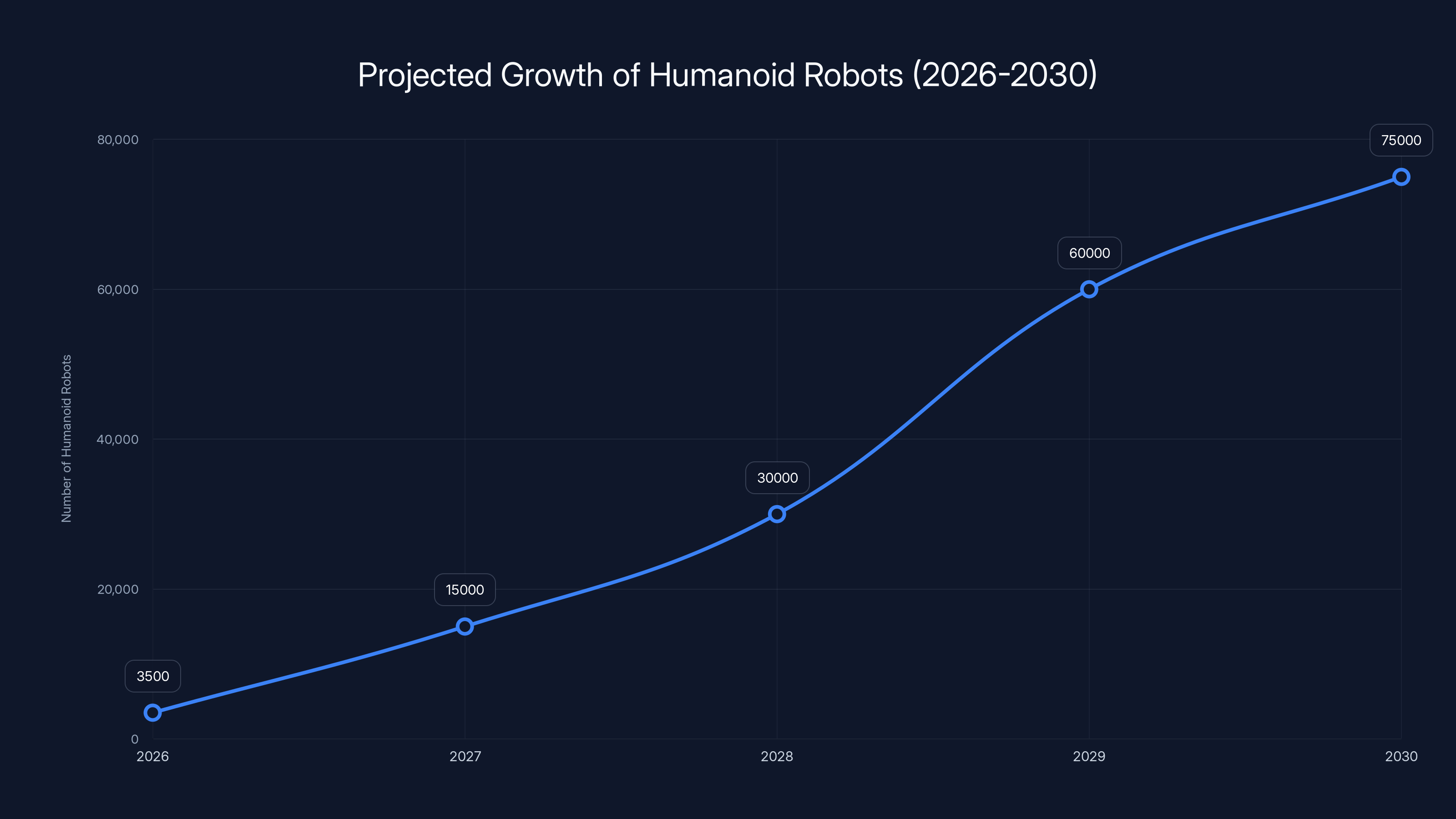

The number of humanoid robots is expected to grow significantly from 2026 to 2030, with a projected increase from around 3,500 to 75,000 units globally. Estimated data based on industry trends.

Manufacturing at Scale: The Hard Part

Robotics companies love to talk about the robots themselves. Nobody wants to talk about manufacturing at scale.

Building a few prototypes is hard. Building hundreds of identical robots that all work reliably is vastly harder.

You need supply chains for components, quality control systems, testing procedures, and manufacturing processes. One missing supplier can halt production. One design flaw in manufacturing affects every unit.

Tesla has automotive manufacturing experience, which is an advantage. Most other robotics companies don't. This is probably why Tesla might actually scale humanoid robots when others fail.

But this is also why deployment is slow. Manufacturing scale takes years to build properly.

Real Applications We'll Actually See by 2026

Hazmat and Disaster Response

Robots entering dangerous environments is happening now. Nuclear decommissioning sites, disaster rescue, hazardous material cleanup. This will continue expanding.

Warehouse Automation for Large Companies

Amazon, Alibaba, and other logistics giants are testing humanoid robots. Expect gradual adoption by 2026, starting with robotics-friendly warehouse designs.

Automotive Manufacturing

Tesla and traditional automakers are putting humanoid robots on test assembly lines. This is happening in 2025-2026. Scale-up will take longer.

Research and Academia

Universities are using humanoid platforms for research. This creates talent and knowledge that eventually benefits commercial products.

Specialized Manufacturing

Electronics assembly, pharmaceutical manufacturing, and other precision tasks. Robots excel at repetitive, precise work.

What We Won't See in 2026

Household Helper Robots

Robots doing your laundry, cooking dinner, or cleaning your house? Not in 2026. Probably not in 2030. Maybe not until 2040+.

Home environments are unstructured. Thousands of different objects. Unpredictable scenarios. Interacting with humans in close quarters. This requires AI and robotics technology that doesn't exist yet.

General-Purpose Labor Robots

A robot that can do any job a human can do? That's science fiction. We're talking a decade or more away, if it's even possible.

Robots That Think Independently

Humanoid robots in 2026 still need heavy human oversight. They're not autonomous agents making decisions. They're expensive tools that require careful programming and monitoring.

Significant Job Displacement

Some jobs will be affected. But mass displacement? That's 2030s territory at the earliest, and only in specific sectors.

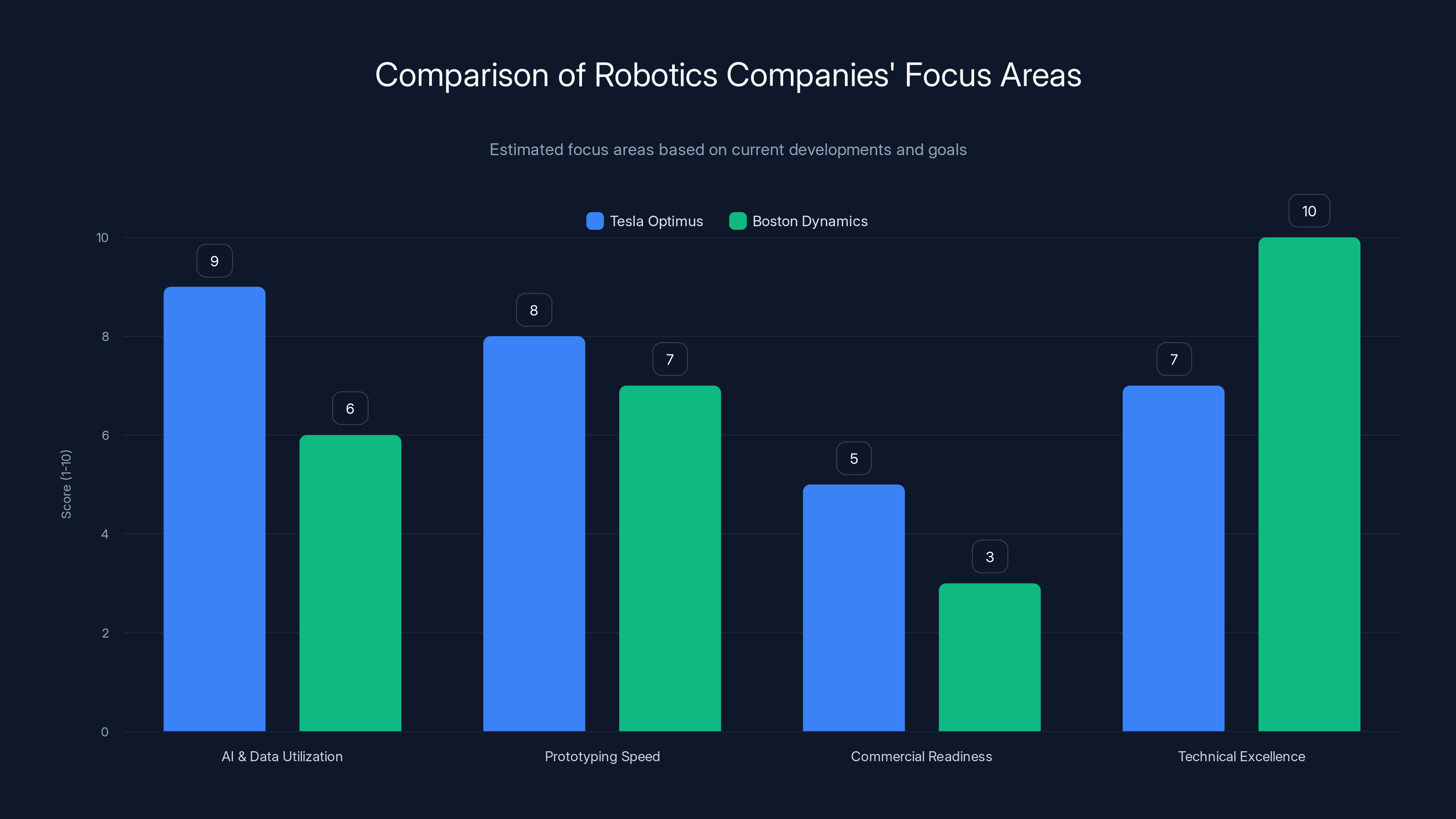

Boston Dynamics Atlas leads in humanoid robot development focus, closely followed by Tesla Optimus. Estimated data based on industry analysis.

The Hype vs. Reality Gap

Why is there such a massive gap between what companies claim and what's actually possible?

Let me be frank: it's incentives. Robotics companies need funding. Funding comes from investors and customers who believe in the vision. So companies oversell timelines and capabilities.

Elon Musk claimed humanoid robots would transform Tesla into a multi-trillion dollar company by 2030. Is that realistic? Not even close. But it sounds great in investor presentations.

Boston Dynamics releases videos of robots doing parkour because it generates hype and funding. The parkour videos are real, but they're not representative of what the robots can do in practice.

Figure AI claims their robots can work in factories now, which is partially true but requires extensive customization and human oversight.

This isn't necessarily dishonest—it's more that companies are selling the vision, not the current reality. But consumers and investors often don't distinguish between the two.

The Real Innovation Happening Right Now

AI for Motion Planning

Companies are developing AI that helps robots plan complex movements through cluttered environments. This is actually working better than expected in some cases.

Soft Robotics

Soft robotic hands and grippers that can handle delicate objects are improving. This has practical applications in warehouse sorting and manufacturing.

Modular Robotics

Build robots from standardized components that can be swapped and customized for different tasks. This could radically reduce manufacturing complexity.

Learning from Demonstration

Robots that can learn new tasks by watching humans perform them once or twice. This is real progress happening now, not vaporware.

International Differences: Who's Ahead?

United States

US companies (Tesla, Boston Dynamics, Figure AI) are leading in capital and ambition. But they're also hyping timelines. Actual deployment is moderate.

Europe

European robotics companies are more incremental but realistic. ABB, KUKA, and others have solid robot businesses. Humanoid focus is lower—they're doubling down on what works.

China

China's pushing hard and fast. Lower costs, rapid iteration, less regulation. Their robots might not be as refined, but they're shipping volumes and improving quickly.

Japan

Japan has a long robotics history but has been slower to jump on humanoids. Honda stopped development of their Asimo robot. But they're watching and could move fast if they choose to.

The global competition is real. It's not just about robotics—it's about economic advantages, manufacturing scale, and job creation.

Tesla Optimus excels in AI and data utilization, while Boston Dynamics leads in technical excellence. Estimated data based on current insights.

The Investment Landscape: Where Money's Going

Venture capital is absolutely flowing into robotics. Billions in funding. Most of it is going to:

- AI companies developing robot perception and control

- Specialized robotics (warehouse, manufacturing)

- Infrastructure robotics (construction, infrastructure inspection)

- Defense applications

Humanoid robots specifically are getting significant funding, but they're not the only game in town. In fact, specialized robots are probably seeing better returns right now because they solve specific problems rather than chasing the general-purpose dream.

From an investment perspective, betting on humanoid robots is betting on the long game. Returns are probably 10+ years away. That filters for investors with real capital and patience.

Ethical Considerations Beyond the Obvious

Labor and Community Impact

When humanoid robots start displacing workers, what happens to those workers? Retraining programs? Social safety nets? Different countries will handle this differently.

This is a policy question as much as a technology question. And frankly, we're not prepared for it.

Weapons and Military Applications

Humanoid robots could be weaponized. Some governments are absolutely thinking about this. International regulation might be necessary, but it's hard to enforce.

Concentration of Power

Large companies with capital to deploy robots will get more productive advantage. Could lead to increasing concentration of economic power. That has long-term societal implications.

Environmental Impact

Building millions of robots requires resources. Recycling them matters. Energy consumption of robot manufacturing and operation adds up at scale.

These aren't trivial concerns, but they're also not technology-specific. Most manufacturing has environmental and economic implications.

Predictions for 2026 and Beyond

2026 Realistic Forecast

- 2,000-5,000 humanoid robots deployed globally (small for a technology with this much hype)

- Most concentrated in Asia (China, Japan, South Korea) and automotive/logistics hubs in developed countries

- Meaningful failures and shutdowns from overhyped startups

- Tesla still in scaling phase, not mass production

- Significant improvements in AI for perception and control

- Early legislation in major countries addressing safety and labor impacts

- Growing understanding that this is a decades-long transition, not a revolution

2030 Forecast

- 50,000-100,000 humanoid robots in operation

- Meaningful presence in warehouse automation, automotive assembly, hazmat response

- Cost dropped to 150K for different models

- AI measurably better but still not general-purpose

- Significant job displacement in specific sectors starting to impact labor markets

- Real regulations and safety standards in place

- Consumer robots remain niche and overly dependent on human intervention

2035 and Beyond

Honestly, predictions get too speculative. Could be amazing. Could be disappointing. Probably depends on AI breakthroughs that may or may not happen.

What You Should Actually Care About

If you work in manufacturing or logistics: watch this closely. Change is coming. Prepare your team.

If you're investing in robotics companies: remember that most will fail. Success stories are still rare. Due diligence matters.

If you're a worker worried about job displacement: reasonable concern, but probably not urgent in 2026. More urgent by 2030-2035. Now's the time to think about retraining or skill development.

If you're just curious about technology: it's genuinely interesting, but resist the sci-fi urge. The real story is more nuanced and actually more interesting than the hype.

The Bottom Line

Humanoid robots are real technology with real potential. They're not going to destroy civilization or liberate us from work.

They're going to be useful in specific applications where they make economic sense and human work is either expensive or dangerous. That's valuable, but it's not the sci-fi story everyone wants.

The technology is advancing. Companies are investing real money. Deployment is happening. But it's slower and more limited than hype suggests.

By 2026, humanoid robots will be more common in industrial settings, noticeably better at specific tasks, and still frustratingly limited compared to human capability. They'll be impressive in demo videos and mediocre in real environments with variability and unexpected scenarios.

That's the actual future we're building. Not Terminator. Just robots that are kind of useful if you use them right.

And honestly? That's way more interesting.

FAQ

What exactly is a humanoid robot?

A humanoid robot is a machine designed to resemble and move like a human, typically with two arms, two legs, a torso, and a head. The humanoid form factor allows them to navigate spaces designed for humans and interact with human-scale tools and environments, unlike specialized robots with wheels or fixed arms. Modern humanoid robots use motors, actuators, sensors, and AI-powered control systems to perform tasks, though they're far less capable and flexible than actual humans.

How much do humanoid robots cost in 2025-2026?

Current humanoid robots cost between

When will humanoid robots be available for consumer use?

Consumer humanoid robots—household helpers, elderly care assistants, or personal robots—are still many years away, probably 2035 or beyond. Home environments are far more unpredictable and variable than factories or warehouses, requiring AI capabilities that don't exist yet. Current robots struggle with unstructured tasks even in controlled environments, so applying them to homes where they'd need to recognize thousands of objects, adapt to unexpected situations, and safely interact with children and pets remains impractical. Most experts emphasize this is the hardest robotics problem, not the easiest.

Will humanoid robots take my job?

It depends on your job. Some roles in warehouse automation, repetitive manufacturing, and hazmat work will be affected by 2030-2035. However, the timeline is slower than alarmist media suggests. Most job displacement won't be severe until 2030s or later, and it will be concentrated in specific sectors and regions. Additionally, economic analysis suggests automation creates new job categories while displacing others—the challenge is retraining and ensuring displaced workers benefit. For most jobs today, you're safer than headlines suggest, but it's worth considering skill development for roles involving highly repetitive physical tasks.

Why is the gap between hype and reality so big?

Companies building humanoid robots face intense pressure to attract investment and customers, which creates incentive to oversell timelines and capabilities. Executives talk about "a few years away" to secure funding today, even if realistic timelines are 10+ years. Media amplifies optimistic claims because they generate engagement. Demo videos showing robots succeeding hide the dozens of failures and human interventions required behind the scenes. This gap between marketing and reality has been true in tech for decades, but it's particularly pronounced in robotics where public understanding is low and sci-fi expectations are high.

What can humanoid robots actually do well right now?

Humanoid robots excel at: picking and placing items in structured warehouse environments with known layouts, repetitive assembly tasks on manufacturing lines, navigating human-scale spaces and stairs, hazardous environment exploration where human safety is critical, and learning repetitive tasks through demonstration. They struggle with: unstructured environments with unexpected variations, complex decision-making and problem-solving, delicate tasks requiring subtle force control, and anything requiring genuine understanding rather than programmed responses. The key difference is structured vs. unstructured: robots are fantastic in predictable, well-defined scenarios and mediocre everywhere else.

Which humanoid robot company is winning?

It depends on how you measure winning. Tesla Optimus has the most capital and manufacturing expertise, making them most likely to scale production. Boston Dynamics has the best engineering and research, but no clear commercial path. Figure AI has the most credible near-term partnerships (BMW). Chinese manufacturers are shipping volumes fastest. By 2026, the answer might be very different based on whether you value technical capability, commercial traction, or production scale. Currently, no company has decisively won; the competition is still wide open.

What role does AI play in humanoid robotics?

AI is absolutely central and also the biggest bottleneck. Modern humanoid robots use machine learning for perception (computer vision), control (reinforcement learning for movement), and learning from human demonstration. However, they lack integrated intelligence—they can't reason about novel situations or adapt to unexpected changes the way humans do naturally. Improving AI for robotics (particularly embodied AI that works in physical environments) is probably more important than improving the hardware itself. Better AI would unlock capabilities; better hardware just makes existing capabilities faster or more reliable.

Are humanoid robots dangerous?

Currently, yes, which is why deployment requires careful safety measures. A 70 kg robot moving at high speed can seriously injure humans. That's why most current deployments keep robots separated from workers or operating in restricted zones. Safety technology is improving (force-limiting mechanisms, slower speeds, advanced sensors), and this will allow wider deployment. Cybersecurity is an emerging concern—hacked robots could cause damage or injuries. Overall, danger is manageable but real, which is why robotics companies invest heavily in safety engineering and why adoption in human-centric environments is slower.

Conclusion: The Unsexy Future Is Actually the Real Story

Here's what I hope you take away from this: humanoid robots are genuinely interesting technology with real potential, but the actual future is far less dramatic than the hype.

In 2026, you won't see terminator robots. You won't see household helper robots. You probably won't see humanoid robots unless you work in manufacturing, logistics, or research.

What you will see is incremental adoption in industrial settings, improving capability in specific tasks, and growing understanding that humanoid robots are tools with real limitations rather than replacements for human intelligence or capability.

The economics are real. Large companies with capital to deploy robots in optimized environments will benefit. Workers in repetitive warehouse and manufacturing jobs will face gradual displacement. This is a genuine transformation, but it's playing out over decades, not months.

The technology will improve, probably faster than most people expect. AI for robotics is advancing. Hardware engineering is advancing. Manufacturing capability is advancing. But fundamental limitations remain: robots still can't reason about truly novel situations, can't adapt the way humans do, and can't handle the messy reality of unstructured environments.

That's not a failure of engineering—it's a feature of the problem. Building general-purpose robots is legitimately harder than sending rockets to Mars or building AI that writes essays. It requires solving problems that have no clear solution yet.

So what should you do? If you're in an industry affected by automation, understand the timeline and prepare your team. If you're investing, be skeptical of timelines and focus on actual deployments. If you're curious about technology, keep watching—the actual progress is more interesting than the hype.

And if you're worried about AI and robots replacing humans? Reasonable concern, but probably not for a few more years. The reality is slower, messier, and gives us time to think about what we actually want from this technology.

The unsexy future is the real one. And that's okay. Reality usually beats fiction anyway.

Use Case: Quickly create detailed analysis reports on emerging technologies like humanoid robotics, complete with charts and insights, without spending hours on documentation and formatting.

Try Runable For FreeKey Takeaways

- Humanoid robots in 2026 are functional in controlled warehouse and manufacturing environments but still struggle with unstructured real-world scenarios

- Current humanoid robots cost 400K, operate 3-8 hours per battery charge, and require extensive human oversight and intervention

- Tesla Optimus, Boston Dynamics Atlas, and Figure AI represent different strategic approaches with varying realistic timelines for commercial deployment

- Real widespread humanoid robot adoption is projected for 2030-2035 in specific industrial sectors, not the 2-3 year timelines companies publicly claim

- AI capability (perception, reasoning, adaptation) is the actual bottleneck, not hardware—robots excel in predictable environments but fail in scenarios requiring real decision-making

![Humanoid Robots in 2026: The Reality Beyond the Hype [2025]](https://tryrunable.com/blog/humanoid-robots-in-2026-the-reality-beyond-the-hype-2025/image-1-1767024544817.jpg)