Introduction: The Tape Storage Revolution Nobody Expected

Here's the thing about data storage—it doesn't evolve the way people think it will. Everyone assumes magnetic tape is obsolete, that cloud dominates everything, that spinning platters belong in a museum. But the reality? Tape is quietly becoming more important, not less.

Tape libraries process petabytes of data every single day in production environments. Banks, governments, media companies, cloud providers—they all depend on it. And it works. But there's been a nagging problem: density. Magnetic tape hasn't grown capacity fast enough to match the exponential data explosion. Enter holographic tape, a storage technology that's been stuck in the research phase for nearly two decades.

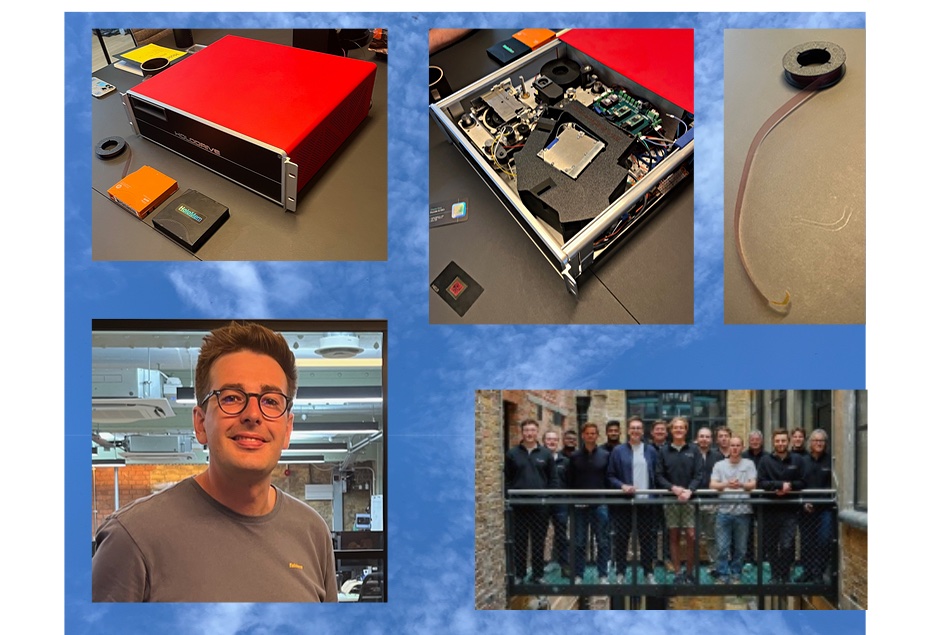

For years, holographic tape existed only in controlled lab environments. It was always "five years away." Then something shifted. A UK startup called Holo Mem ran a critical test that changed the conversation entirely. They placed holographic tape cartridges inside a real, working LTO tape library and did something radical—they actually used it. Not a demo. Not a proof of concept in an isolated test chamber. Real software writing data, real robotic arms moving the cartridges, real workflows running exactly as they would in production.

The cartridges matched standard LTO dimensions perfectly. The library's robotic handler didn't need modifications. The existing software saw the new holographic drives as just another storage option. It all worked. No infrastructure rip-and-replace. No software rewrites. No downtime.

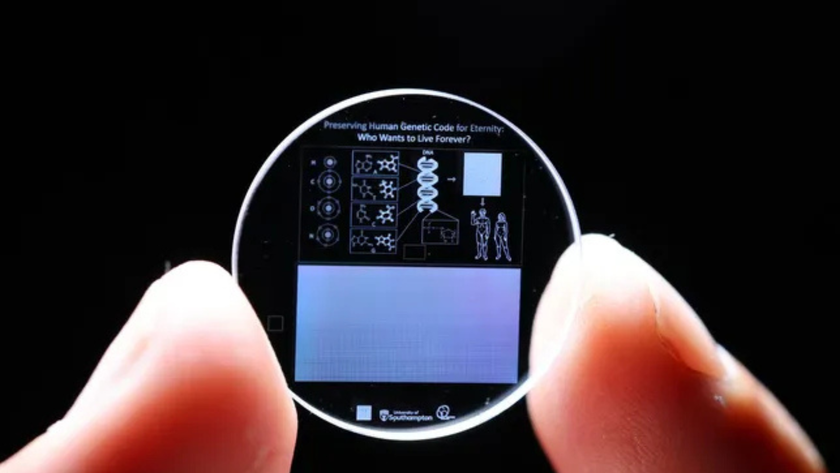

This is a fundamentally different moment than the hype cycles around silicon-based storage alternatives or Project Silica's glass media. Holographic tape isn't asking data centers to rebuild their entire storage architecture. It's asking them to do one simple thing: plug in a new drive, and keep operating like normal.

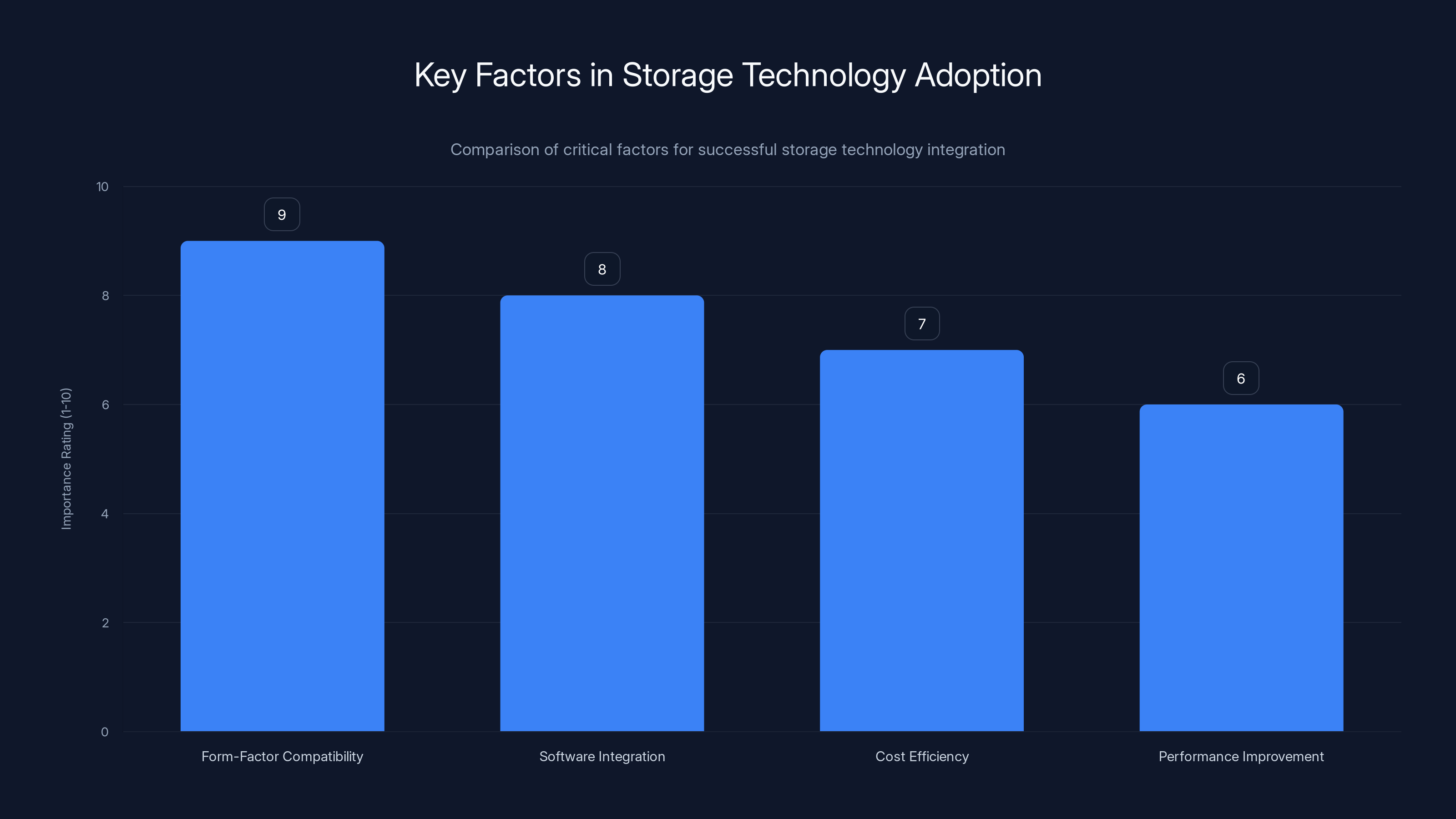

The test proved something critical to the storage industry: deployability matters more than raw technology. You can have the densest, fastest, most durable medium in the world, but if it requires ripping out existing systems, it won't get adopted. Holo Mem understood this. They designed their system to work within existing infrastructure, not around it.

Mass production of the holographic drives is planned for 2027. That's not far away. It's close enough that enterprises are already asking serious questions. Can this actually replace tape? Will it cost less? What happens to my existing LTO investment? These aren't theoretical questions anymore. They're practical ones that affect budgets, procurement timelines, and IT strategy.

This article breaks down what holographic tape actually is, how this test changes the landscape, what companies are racing to deploy it, and what you need to know if your organization handles massive cold storage archives.

TL; DR

- Holographic tape moved beyond the lab: Holo Mem successfully deployed 200TB cartridges inside a working LTO tape library without any infrastructure modifications, proving real-world compatibility.

- No rip-and-replace required: The system plugs into existing tape libraries, works with current software, and lets LTO and holographic drives coexist in the same environment.

- Production hardware launches 2027: Mass manufacturing of holographic drives is scheduled to begin in 2027, with cartridges designed for 50+ year longevity and write-once-read-many (WORM) compliance storage.

- Density beats alternative media: At 200TB per cartridge, holographic tape capacity far exceeds ceramic-based competitors while maintaining backward compatibility with existing data center workflows.

- Game-changing for cold storage: This technology addresses the critical bottleneck in modern data center expansion—how to store petabytes of archival data without replacing everything.

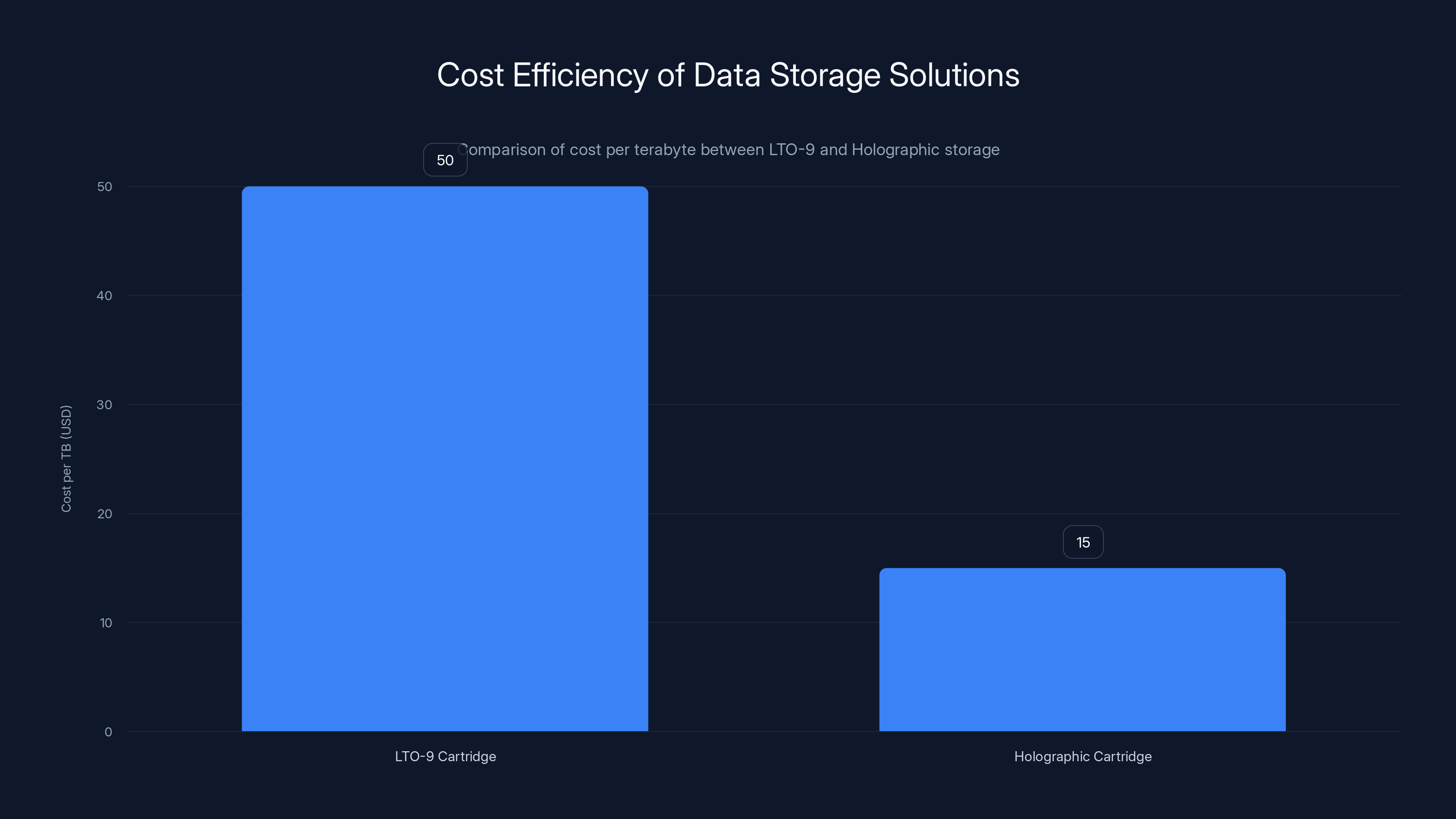

Holographic storage offers a significant cost advantage at

Understanding Holographic Tape: Beyond the Marketing Hype

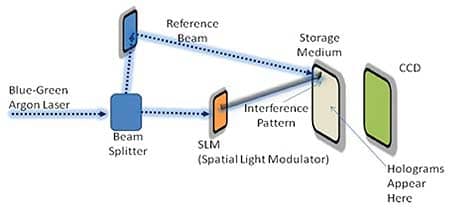

Holographic tape sounds like science fiction, but the core concept is surprisingly elegant. Instead of using magnetic coating on a plastic ribbon (like traditional tape), holographic tape uses polymer cartridges where data is encoded in three dimensions using layered holographic recording.

Think of it this way: magnetic tape is two-dimensional. Information sits on the surface of the coating. Your head reads left to right, forward and backward, but there's no depth. Holographic tape uses laser light to create and read data patterns throughout the entire material thickness. Multiple layers of information stack on top of each other, all in the same physical space.

This is where the density comes from. You're not limited by the surface area of a ribbon. You're leveraging the entire volume of the cartridge. A standard LTO cartridge is roughly the size of a VHS tape. Now imagine storing a hundred layers of data inside that same physical volume. That's closer to the problem holographic tape solves.

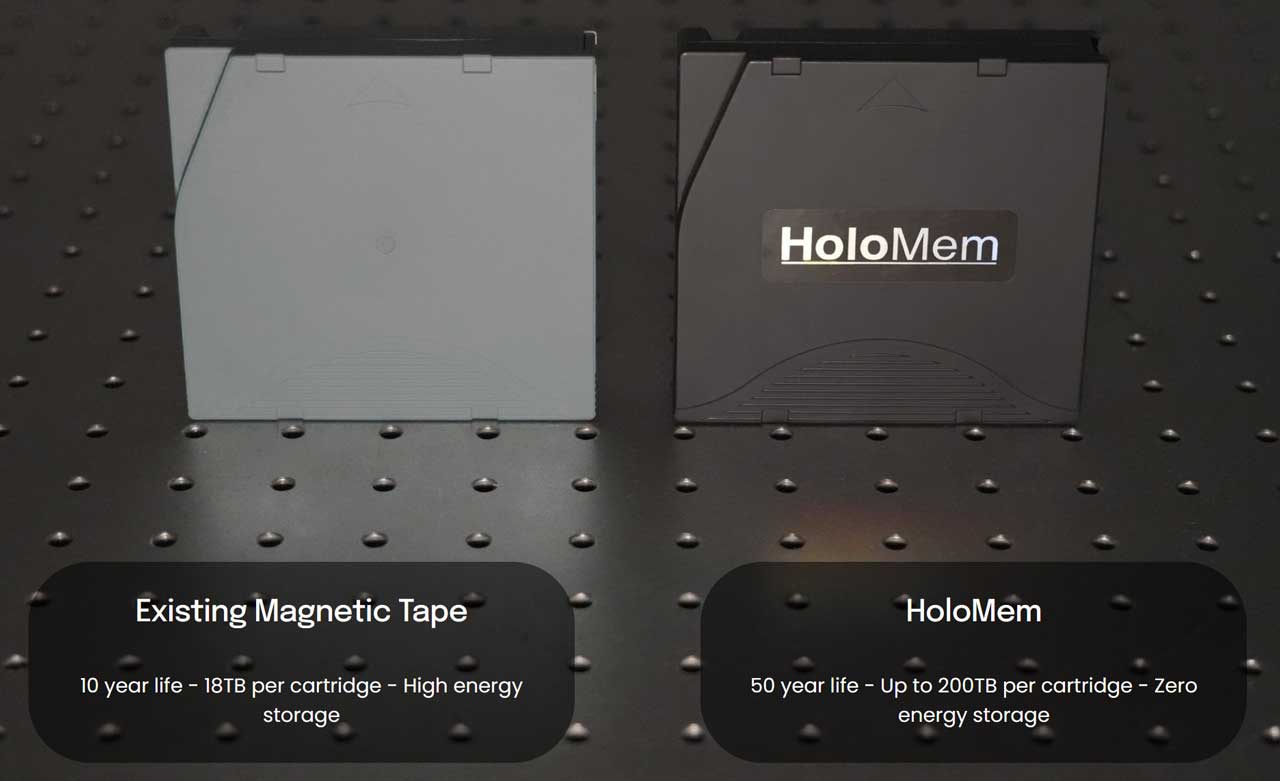

The cartridges tested by Holo Mem are designed to hold up to 200TB per cartridge. To put that in perspective, a modern LTO-9 cartridge holds 18TB native (36TB with compression). You're looking at roughly 10-12x the capacity in the same physical form factor. The cartridges are WORM (write-once-read-many), which is exactly what compliance-driven storage needs—data written once and never modified, but accessed repeatedly.

The technology isn't entirely new. Researchers have experimented with holographic storage since the 1990s. The challenge was never "can we make this work in the lab?" It was always "can we make this work in real data centers with real workflows and real constraints?" That's a completely different problem.

Laboratory conditions are controlled. Temperature stays constant. Vibration is minimal. Lighting is carefully managed. Real data centers are chaos by comparison. Servers running at full capacity, robotic arms moving at high speed, thermal cycles, electromagnetic interference. The Holo Mem test proved the technology could survive that chaos and actually function as intended.

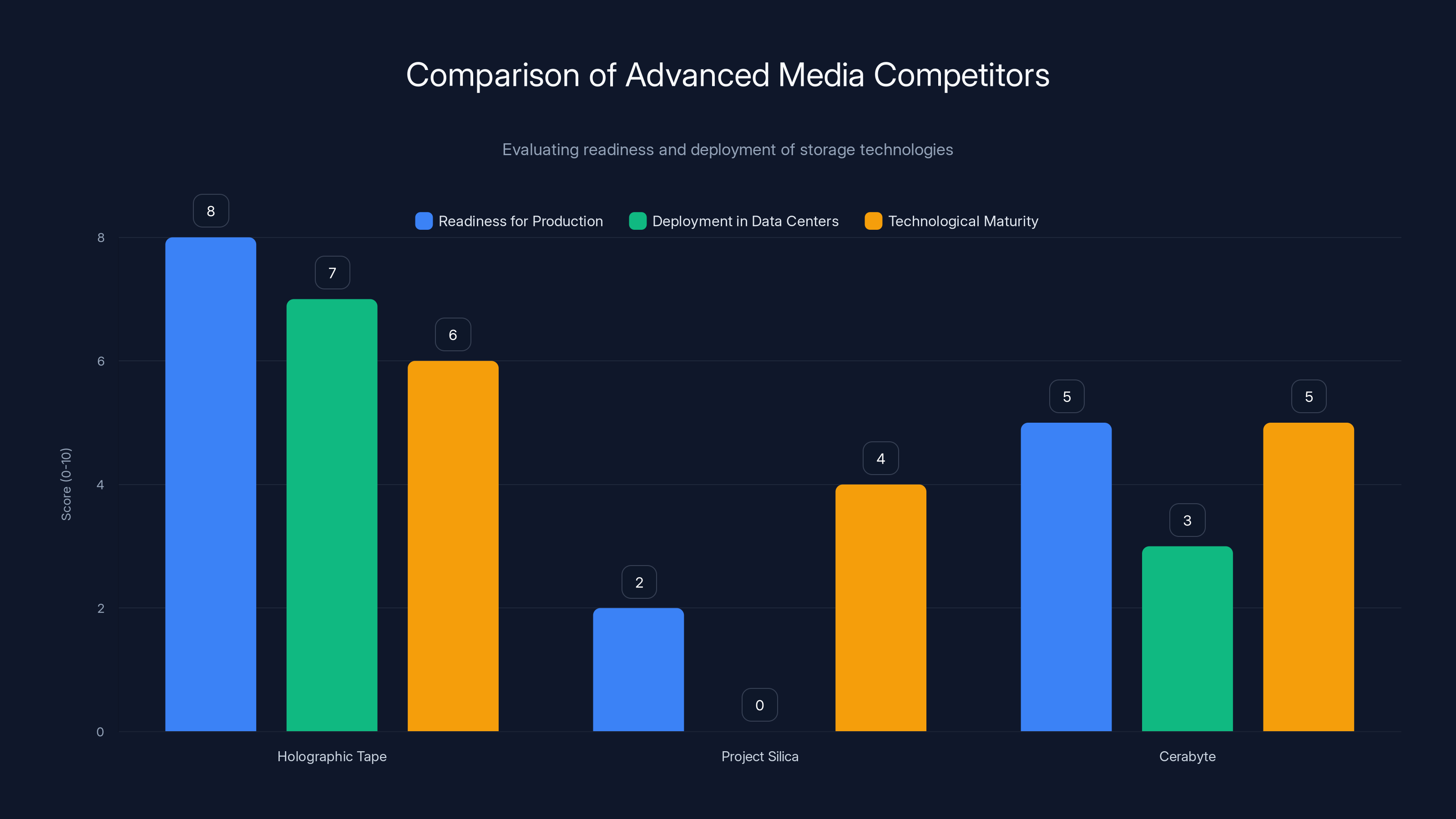

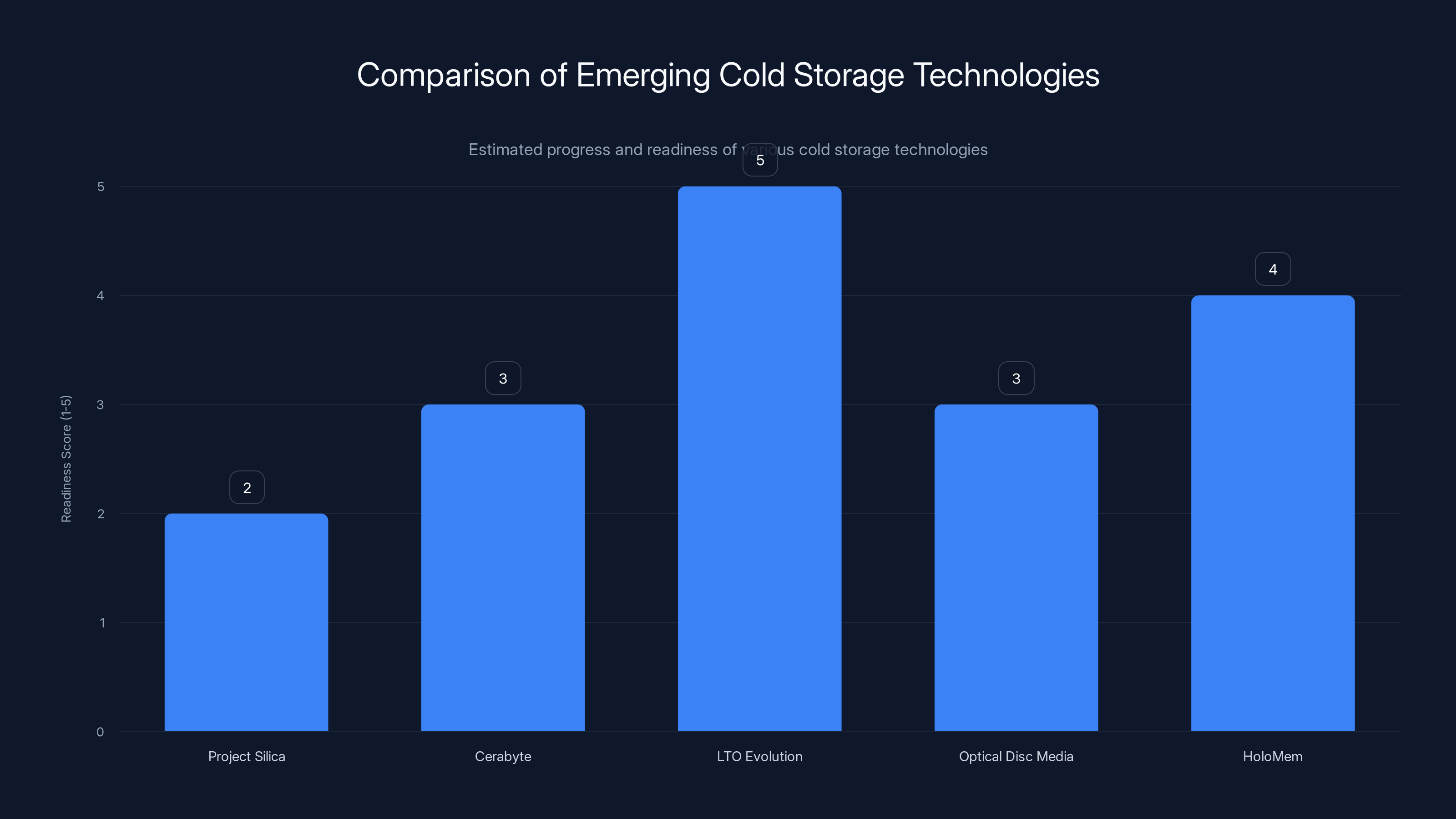

Holographic tape shows higher readiness and deployment potential compared to Project Silica and Cerabyte, which face significant barriers. Estimated data based on current technological status.

The Test That Changed Everything: Integration Meets Reality

Let's dig into what Holo Mem and BDT Media Automation actually did, because this test matters in ways that go beyond the technical achievement. It's a statement about how new storage technology gets adopted in the real world.

The setup was deliberately simple. BDT Media Automation runs production LTO tape libraries for enterprises. They're the vendor that provides the mechanical infrastructure—the robotic arms, the drive slots, the software that orchestrates everything. Holo Mem brought holographic drives and cartridges to a real operating library. Not a test lab. Not a demo environment. An actual facility processing real data for real customers.

The cartridges were engineered to match LTO dimensions exactly. This seems obvious but it's actually crucial. Tape libraries use robotic arms to move cartridges between storage slots and drive positions. The arms are mechanized with specific tolerances. If your new cartridge doesn't fit those tolerances, the entire library needs mechanical rework. Cost, downtime, certification requirements—it all blows up.

Holo Mem solved this by designing their cartridges as form-factor compatible with LTO. The robotic arm picks up a holographic cartridge and treats it exactly like an LTO tape. No special handling. No modified grippers. No custom software for cartridge positioning. The system just works.

On the software side, the holographic drives presented themselves to the library management system as just another storage device type. Existing backup software could write to them. Existing retrieval workflows could read from them. The library didn't see a revolutionary new medium. It saw another drive type, like moving from LTO-8 to LTO-9.

This is remarkably different from competing technologies. Project Silica uses glass plates that require completely different handling and reading mechanisms. Cerabyte's ceramic media needs new drive architectures. Both are genuinely impressive technologies, but both require data centers to essentially rebuild their entire tape infrastructure. With holographic tape, you plug in a drive, and your existing system handles the rest.

The test ran real application software writing data through normal tape library workflows. Not custom testing software. Not academic benchmarking. Real production backup applications, the kind that enterprises depend on every day. The data got written, verified, and read back successfully. The robotic arm moved the cartridges thousands of times. Everything behaved exactly as expected.

This matters because it proves the technology doesn't just work in isolation. It works within a system, integrated with existing hardware, software, and operational workflows. That's the real test for any storage innovation.

Charlie Gale, Holo Mem's founder and CEO, emphasized this in statements about the test: "New technological solutions have to integrate with legacy infrastructure in order to fulfill their potential." This isn't marketing speak. This is a fundamental truth about how data center technology gets adopted. You can have the best innovation in the world, but if it forces enterprises to rip out systems that are working perfectly fine, adoption rates crater.

Why This Test Matters More Than Raw Density Numbers

When storage companies announce new technology, they lead with the impressive specifications. 200TB per cartridge is genuinely impressive. But focus only on that number and you miss why this test was actually significant.

Density is necessary but not sufficient. What matters is deployability. Can you actually get this technology into the thousands of data centers that would benefit from it? Or does the technology remain a curiosity for the few companies willing to completely rebuild their infrastructure?

Historically, advanced storage media have struggled with deployment friction. They arrive with impressive specs but face brutal practical barriers. They require new drivers, new hardware, new certifications. IT teams evaluate the time and cost of upgrading existing systems against the capacity gains and decide the existing system is good enough. The storage innovation languishes in niche deployments.

Holo Mem explicitly designed their system to minimize this friction. The cartridges match LTO dimensions. The drives fit into existing library slots. The software requires no modifications. A data center already running LTO libraries can purchase holographic drives and deploy them without downtime, without staff retraining, without certification delays. They just show up as another drive type in the library.

That's the innovation this test validated. Not the density improvement. The compatibility improvement.

Think about the economics from a data center perspective. You have an existing LTO infrastructure processing your cold storage needs. You're probably not running at absolute capacity. You could upgrade to newer LTO generations (LTO-10 is coming). Or you could add holographic drives to the same library. If holographic cartridges cost roughly the same per terabyte as advanced LTO, but deliver 10x more capacity in the same physical space, the economic case becomes obvious. You get better capacity utilization and don't have to replace working hardware.

This is particularly valuable for organizations with data gravity problems. Large enterprises generate petabytes of data annually. Compliance requirements force them to keep it for 5, 7, sometimes 10+ years. The storage infrastructure becomes massive. Adding capacity means more physical space, more power, more cooling. If you can reduce that footprint by using denser cartridges in existing libraries, the value is enormous.

The test also proved longevity claims have real foundation. Holo Mem claims the holographic cartridges are designed for over 50 years of data preservation. That's longer than LTO guarantees. In compliance-driven storage, longevity is critical. You need media that will be readable decades from now. The successful test doesn't prove 50-year lifespan (that requires actual time), but it demonstrates the engineering is sound enough to base that claim on real science rather than speculation.

Estimated data shows LTO Evolution leading in commercial readiness due to established infrastructure, while HoloMem and Cerabyte are emerging with promising potential.

Comparing Holographic Tape to Other Advanced Media Competitors

Holographic tape isn't the only technology racing to replace magnetic tape. The cold storage market has attracted significant investment, and multiple approaches are competing. Understanding how holographic tape positions against alternatives matters for any enterprise evaluating their storage strategy.

Project Silica: Glass Media That's Not Ready

Microsoft's Project Silica generates headlines because it's Microsoft. They've demonstrated encoding data in glass platelets using femtosecond lasers. The concept is genuinely cool—data doesn't degrade, glass lasts for geological timescales, it's theoretically ultra-durable.

But here's the harsh reality: glass media remains stuck in the research phase. Microsoft hasn't committed to commercial production. The read/write speeds are extremely slow. Glass cartridges require completely new drive architectures that don't exist in production data centers. The cost per cartridge would be astronomical compared to tape. Microsoft talks about Project Silica as a future possibility, not an imminent product.

Comparison metrics: Project Silica has no shipping product, no production timeline, and no deployment in real data centers. Holographic tape has already run in production libraries and has a 2027 production timeline. The technological sophistication matters less than the practical deployment reality.

Cerabyte: Ceramic Competitors Moving Faster

Cerabyte, a Berlin-based startup, is pushing ceramic-based storage media. They claim cartridges will eventually hold multiple terabytes using their approach. The technology is legitimate and they're further along in some respects than holographic tape was a year ago.

But ceramic media faces significant deployment barriers. The drives are completely new. Cartridge handling requires new robotics. Software integration requires custom layers. Data centers would need to parallel-run ceramic systems alongside existing tape infrastructure, essentially doubling their footprint during transition. Cerabyte hasn't demonstrated compatibility with existing tape library infrastructure the way Holo Mem has.

The timeline matters here. Cerabyte is targeting 2026 for proof-of-concept hardware. Holo Mem is planning 2027 for mass production of drives that work today in existing libraries. That's a significant advantage.

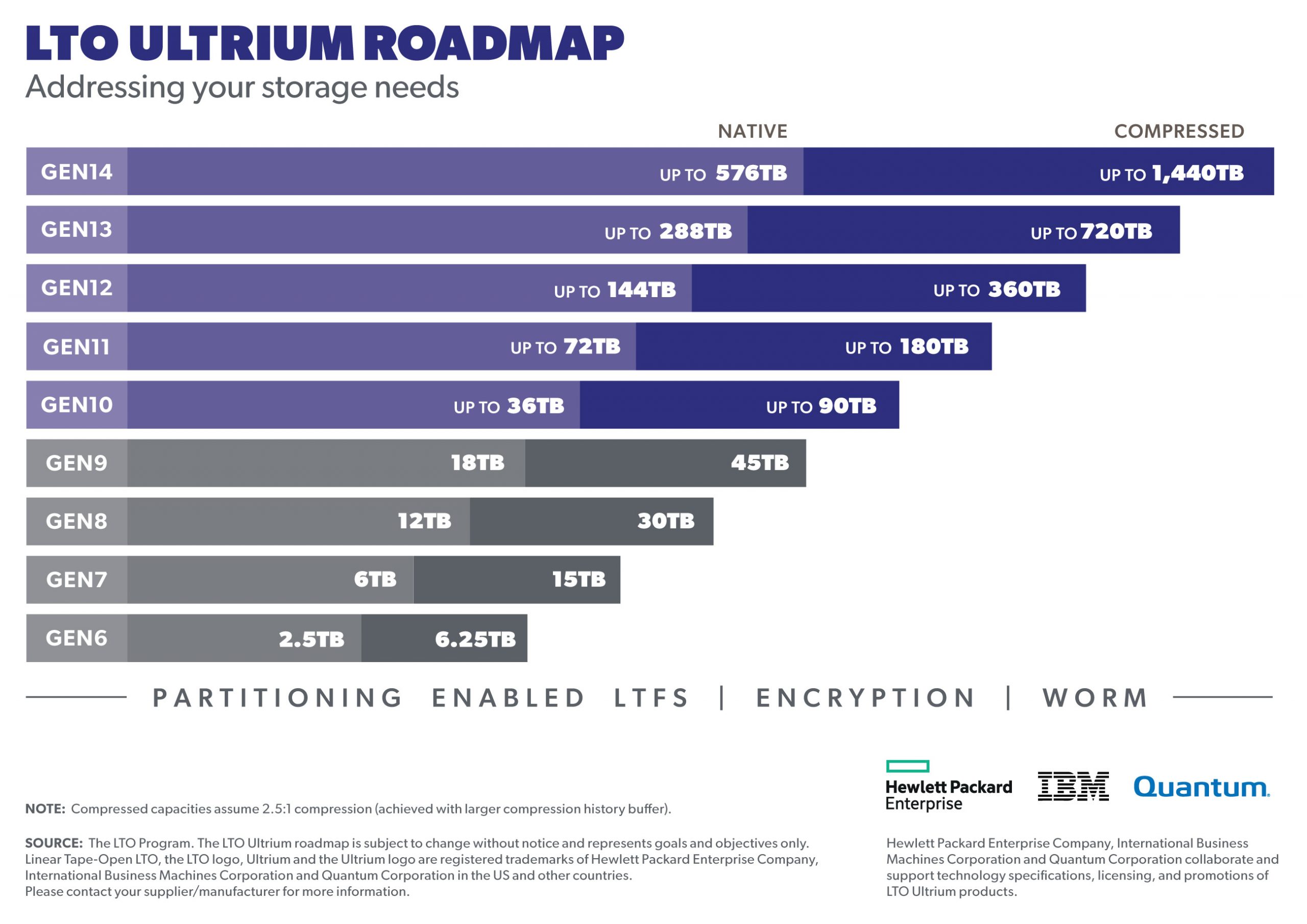

LTO Roadmap: The Evolutionary Path

The LTO Consortium isn't sitting still. They have roadmaps extending to LTO-14, which could eventually reach 960TB with compression (roughly 200TB native per cartridge, closing the gap with holographic tape). But LTO evolution is incremental. Each generation requires manufacturing changes, drive updates, certification cycles. The timeline for reaching 200TB+ per cartridge is a decade away, not a few years.

This is where holographic tape's advantage becomes clear. It offers the capacity density jump within an existing ecosystem. LTO provides evolutionary improvement within a familiar framework. For organizations that need capacity growth now, holographic tape solves the problem faster.

| Technology | Capacity Per Cartridge | Current Status | Production Timeline | Infrastructure Changes Required |

|---|---|---|---|---|

| LTO-9 | 18TB native | Shipping | Incremental upgrades to LTO-14 | Minimal |

| LTO Roadmap (projected) | 200TB+ | Research | ~2034 | Evolutionary |

| Holographic Tape | 200TB native | Production tested | 2027 | None—works in existing libraries |

| Project Silica | TBD | Research phase | Unknown | Complete rebuild required |

| Cerabyte Ceramic | 1-10TB (projected) | Early stage | 2026 Po C | New drive architecture, new robotics |

The Technology Stack: How Holographic Tape Actually Works

Understanding the actual technology helps explain why deployment in real libraries matters so much. The engineering is sophisticated, but fundamentally different from what data centers typically manage.

Holographic tape uses polymer ribbon cartridges as the substrate, similar to magnetic tape. But instead of coating the ribbon with magnetic particles, the cartridge contains photosensitive polymer material. Data is recorded using laser light interference patterns. Two laser beams cross at precise angles within the polymer, creating an interference pattern. That pattern changes the polymer's optical properties, essentially burning data into the material at a specific layer.

The critical insight is that you can create multiple interference patterns at different angles within the same physical space. Layer 1 at angle 1 stores one set of data. Layer 2 at angle 2 stores different data in the same area. The polymer can hold thousands of layers because each is distinguishable by the angle at which it was recorded. Reading requires the exact angle match—when you shine a laser at the correct angle, only that layer diffracts the light back to the sensor.

This is fundamentally different from magnetic tape, which has one-dimensional depth (the coating thickness). With holographic recording, you're using the full three-dimensional volume of the cartridge.

The laser components used in holographic drives are relatively inexpensive—this is critical for cost-effective production. Early holographic storage research used exotic, expensive lasers. Modern implementations use standard semiconductor lasers similar to what's in many consumer devices. This is why Holo Mem's approach is more viable than earlier attempts that required high-end laser systems.

Write speed and read speed aren't equivalent. Writing involves positioning the laser precisely at each angle and recording the data. Reading can retrieve data from any angle without rewriting. For WORM (write-once-read-many) archival use cases, this is perfect. You write once, slowly and carefully, then read millions of times at whatever speed the system requires.

The 200TB target capacity assumes specific recording density—how much data fits per cubic centimeter of polymer. This isn't a lab maximum. It's an engineering target for production hardware. Achieving it requires precise laser control, careful polymer formulation, and robust error correction. But it's not a theoretical number. It's based on actual demonstrated capability in test systems.

Longevity claims of 50+ years rest on the stability of the polymer material itself. Unlike magnetic particles (which can lose their charge over time) or digital media (which require regular power to maintain), polymer holographic storage is passive. Once the data is recorded, the optical properties remain stable indefinitely under normal archival conditions. Laboratory aging studies suggest the polymer maintains its properties for decades, though the full 50-year claim hasn't been proven through real-world time data.

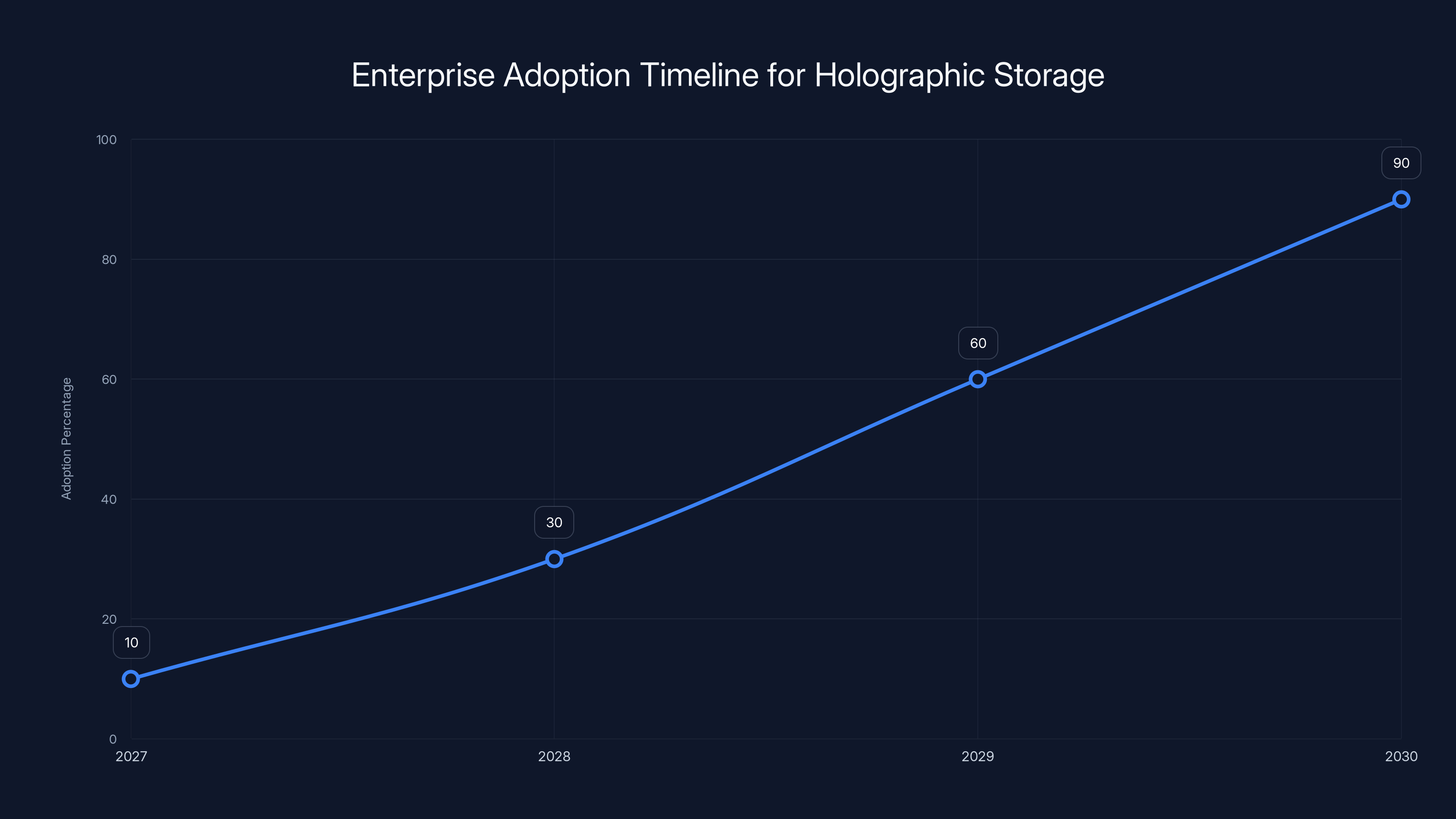

The adoption of holographic storage is projected to grow from 10% in 2027 to 90% by 2030, with significant increases during the certification and cost reduction phases. Estimated data.

Integration Architecture: How Holographic Drives Coexist with LTO

The real innovation in the Holo Mem test wasn't the technology itself. It was the integration architecture—how holographic drives plug into existing tape library ecosystems without creating two separate systems.

A modern tape library is essentially a library management system that orchestrates hardware. You have robotic arms for cartridge movement, drive slots for data operations, and software that decides which cartridges go to which drives based on application requests.

When you add a new drive type, the library management system needs to understand it. Traditional tape libraries maintain a catalog of available storage devices. Each device has properties: capacity, speed, compatibility, format type. When an application requests storage, the library checks the catalog and routes the request to an appropriate device.

Holo Mem designed their holographic drives to present themselves to the library management system exactly like a new tape drive. The drives report their specifications: 200TB capacity, holographic medium, WORM format. Applications can query the library and discover that holographic storage is available. They can specifically request holographic storage or let the library choose based on optimization criteria.

From the robotic system's perspective, holographic cartridges are indistinguishable from LTO cartridges. They're the same physical size. They mount in the same slots. The robotic arm uses the same gripper mechanism. The positioning coordinates are identical. This is critical because it means the mechanical firmware doesn't need updates.

The software abstraction layer is where the magic happens. The library management system presents a unified interface to applications. Instead of separate backup software for LTO and separate software for holographic drives, everything goes through a single API. The application says "store this data" and the library decides the best destination based on policies and availability.

This mixed-mode operation is exactly how data center infrastructure actually evolves in practice. You can't upgrade everything at once. You run legacy systems alongside new systems. You gradually migrate workloads. The holographic tape implementation understands this constraint and designed accordingly.

The test specifically validated this mixed-mode operation. Both LTO drives and holographic drives ran simultaneously within the same library, handling different data streams, without interference. This proves that existing tape libraries can simply add holographic capacity rather than replacing their entire infrastructure.

Cost Economics: When Holographic Tape Makes Financial Sense

Technology adoption decisions at enterprise scale come down to economics. Density matters only insofar as it affects cost per terabyte and footprint efficiency.

Holo Mem hasn't released production pricing, but we can do rough analysis based on manufacturing costs and market patterns. Holographic cartridges are more complex to manufacture than magnetic tape. They require precision laser recording during manufacturing, quality-control testing, and custom polymer chemistry. Production costs will likely be higher per cartridge than LTO.

But the capacity difference changes the calculation entirely. If a holographic cartridge costs

That's before considering secondary costs. Footprint efficiency translates to real savings. Tape libraries require physical space, environmental controls (temperature, humidity), and power delivery infrastructure. A facility storing 500 petabytes of data using LTO-9 cartridges needs roughly 28,000 cartridges. Using holographic cartridges, you need 2,500 cartridges. The reduction in physical footprint, rack space, power consumption, and cooling requirements becomes substantial.

Here's a rough calculation:

For 500 PB with LTO-9:

- Cartridge cost per TB: $50

- 28,000 cartridges requiring facility space costs (amortized)

- Facility costs add significant per-TB charges

For 500 PB with Holographic:

- Cartridge cost per TB: $15

- 2,500 cartridges requiring minimal facility allocation

- Facility costs per TB drop dramatically

The actual break-even depends on facility costs in your region, energy prices, and specific cartridge pricing when holographic tape launches. But for organizations with massive cold storage requirements, the economics strongly favor higher density media.

This economic reality explains why cloud providers and mega-enterprises are interested in holographic tape despite its higher per-unit complexity. They're storing exabytes of data. Every percentage point improvement in footprint efficiency translates to millions of dollars in facility costs.

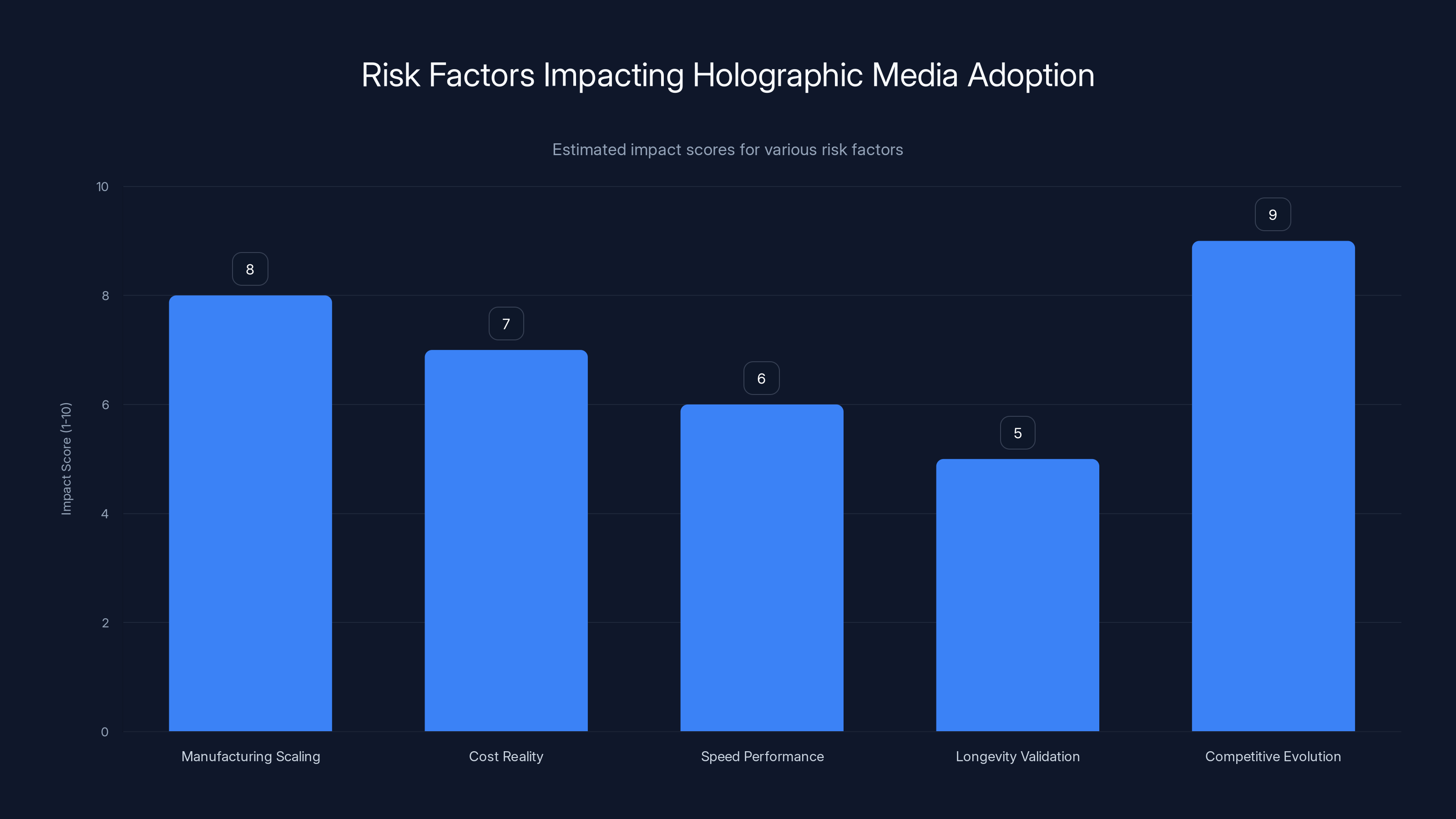

Estimated data suggests that competitive evolution poses the highest risk to holographic media adoption, followed by manufacturing scaling challenges.

Enterprise Adoption Timeline: From 2027 to Mainstream

Production hardware scheduled for 2027 doesn't mean widespread deployment starts immediately. Enterprise adoption cycles for storage technology are measured in years, not months.

First, there's the pilot phase (2027-2028). Selected enterprises will receive early production hardware. They'll run it in their own environments, validate performance, test integration with their specific software stacks. This phase generates the case studies and performance data that justify broader adoption.

Then comes certification (2027-2029). The LTO Consortium will need to evaluate whether holographic media meets their standards. Compatibility testing with various library systems will occur. Industry bodies may establish specifications for optimal performance. Data centers need official certifications before deploying new technology in critical infrastructure.

During certification, competitive positioning crystallizes. Holographic tape will compete directly with LTO evolution and ceramic media development. If Cerabyte achieves significant progress in 2026-2028, the competitive dynamics shift. If Project Silica suddenly announces commercial viability, it disrupts expectations. The storage industry has a history of unexpected breakthroughs.

Pricing will also evolve. First production runs are always expensive. As manufacturing scales, costs drop. By 2029-2030, per-terabyte costs may be 30-40% lower than initial production pricing. Early adopters pay a premium for being first. Late adopters benefit from manufacturing maturity.

The question for enterprises is whether to be early adopters or to wait. Early adopters gain capacity advantages and can rightsize their data centers sooner. But they pay premium prices and take integration risk. Waiting provides better pricing and proven deployments to learn from, but means years of larger-than-necessary storage infrastructure.

For cloud providers storing exabytes, the economics favor early adoption. The per-terabyte savings multiply across massive scale. For enterprises with petabyte-scale archives, the decision is more nuanced. The savings exist, but scaling is smaller, so per-unit pricing premium matters more.

Compliance, Longevity, and the WORM Requirement

Holographic tape's WORM (write-once-read-many) format is genuinely important for a specific but crucial use case: regulatory compliance storage. Understanding this market is essential to understanding why holographic tape exists as a technology.

Regulated industries must preserve data in legally defensible ways. SEC regulations for financial firms, HIPAA for healthcare, GDPR for European data protection—these laws create data retention requirements. The data can't be modified, can't be deleted (during the retention period), must be proven authentic, and must remain readable.

WORM media satisfies these requirements perfectly. Data written to WORM cartridges is physically immutable. No one, regardless of access level, can modify or delete that data. It's legally defensible because the immutability is enforced by hardware, not software. Even if someone breaches your systems, the data remains intact.

Magnetic tape can theoretically support WORM through software controls, but there's always a residual concern about deletion. With WORM-native media, that concern vanishes. The technology itself prevents modification.

Holographic tape's longevity claims are directly relevant to compliance. If you must keep data for 7 years (common for financial records), the media must remain readable for 7 years. If you must keep it for 25 years (some healthcare requirements), the technology must prove 25-year stability. Holographic tape's polymer-based storage promises far better longevity than magnetic particles.

Holo Mem designed their system explicitly around compliance requirements. The cartridges are archival-grade media, not consumer-grade. The drives support secure write operations with verification. The library management system can generate compliance reports showing immutable data with audit trails.

For enterprises managing massive compliance archives—banks with decades of transaction records, healthcare providers with patient histories, governments with administrative files—holographic tape with its 50+ year longevity claim is genuinely valuable.

The test's focus on live deployment proves this compliance value isn't theoretical. The holographic cartridges performed in a real library managing actual customer data, not simulated data. The write-once semantics were enforced. The read operations preserved data integrity. Everything worked as required for production compliance storage.

Form-factor compatibility is crucial for new storage technology adoption, rated highest in importance. Estimated data based on typical industry priorities.

Risk Factors and Realistic Constraints

It's important to acknowledge what the test didn't prove. The successful deployment in one library environment doesn't guarantee universal success. Several risk factors could slow adoption or limit utility.

Manufacturing Scaling Risk: Polymer-based holographic media requires precision manufacturing. Small-scale production works fine. Scaling to millions of cartridges annually involves new challenges. Equipment capabilities, quality control, consistency—these are all harder at scale. There's real risk that production cartridges won't match laboratory performance.

Cost Reality Risk: Holo Mem hasn't released production pricing. The cartridge might be significantly more expensive than rough analysis suggests. If per-terabyte costs aren't competitive with LTO evolution, adoption stalls. The technology needs to be clearly economically superior, not just marginally better.

Speed Performance Uncertainty: The test focused on deployment compatibility, not performance metrics. We don't have published data on write speeds or read speeds for holographic drives. If holographic drives are significantly slower than LTO, they become unsuitable for certain workloads despite capacity advantages. Speed data needs to meet enterprise expectations.

Longevity Validation Gap: The 50+ year longevity claim rests on theoretical modeling and limited laboratory data. Real-world environmental exposure introduces variables that laboratory conditions don't replicate. Dust, humidity fluctuations, temperature cycles—these all affect real media. We won't have proof of 50-year preservation until we've actually stored data for 50 years.

Competitive Evolution Risk: LTO roadmaps are advancing. If LTO-12 or LTO-13 reach 150TB+ capacity with significantly lower cost, the holographic advantage shrinks. Cerabyte might achieve faster development progress than expected. Project Silica might suddenly launch. The storage landscape changes rapidly.

Standards and Certification Delays: The LTO Consortium certification process could introduce unexpected requirements. If holographic tape needs modifications to meet standards, it adds cost and timeline delay. Certification bodies sometimes create barriers for new approaches.

These risks don't invalidate the technology. They're realistic constraints that affect adoption timelines and ultimate market penetration. Any enterprise evaluating holographic tape for 2027-2028 deployment needs to account for these uncertainties.

The Competitive Landscape: Who's Racing Alongside Holo Mem

Holographic tape isn't the only technology racing to revolutionize cold storage. Understanding the competitive landscape helps contextualize where holographic tape fits in the broader evolution.

Project Silica (Microsoft): Glass-based molecular storage using femtosecond laser etching. Microsoft has published papers and demonstrated the concept. The appeal is remarkable longevity—glass lasts for geological timescales. The practical barriers are enormous: no shipping product, no demonstrated performance at scale, no production roadmap. It remains research, albeit well-funded research.

Cerabyte (Berlin startup): Ceramic-based storage media designed for extreme longevity. They're further along in commercialization than Project Silica but still in early stages. Their approach requires completely new drive architectures and library systems. The timeline is comparable to holographic tape, but without demonstrated compatibility with existing infrastructure.

LTO Evolution (IBM, HPE, Quantum): The established tape vendors continue roadmaps toward 960TB+ capacity per cartridge. This is the evolutionary approach, improving within familiar frameworks rather than disrupting with new technology. It's reliable, incremental, and lacks the dramatic density improvements of alternatives, but benefits from proven manufacturing and established market presence.

Optical Disc Media (various): Some vendors continue exploring optical media—Blu-ray style approaches with massive capacity. Optical has advantages in random access but struggles with write speed and durability. It remains niche for very specific use cases.

The real competition for holographic tape isn't against Project Silica or academic approaches. It's against the combined momentum of LTO evolution and the cost inertia of existing systems. Most data centers will stick with incremental LTO upgrades because the friction is low. Holographic tape must be dramatically more economical or offer capabilities LTO can't match.

Holo Mem's strategy is smart: position holographic tape as an enhancement to existing LTO infrastructure, not a replacement. Enterprises don't need to choose between LTO and holographic. They can use both in the same library, coexisting peacefully. That's a far easier sales proposition than "rip out your existing system and move to this entirely new technology."

Use Cases Where Holographic Tape Delivers Maximum Value

Holographic tape isn't universally advantageous. It excels in specific scenarios while being unnecessary or economically unfavorable in others.

Hyperscale Cloud Providers: Netflix, Meta, Google, Amazon all manage exabytes of dark data—vast archives of user content no longer actively accessed but required for regulatory reasons. These organizations pay enormous facility costs for data center real estate. Holographic tape's density reduces footprint dramatically, translating to millions in savings. The ROI calculation favors early adoption and acceptance of price premiums.

Compliance-Heavy Financial Services: Banks store decades of transaction records, communications, and documents. Regulatory requirements demand both immutability and longevity. Holographic tape's WORM format and 50-year preservation claims directly address these needs. The compliance value justifies premium pricing.

Healthcare and Medical Records: HIPAA compliance requires long-term retention of patient records. Hospitals, insurance companies, and medical research organizations all benefit from holographic tape's longevity and immutability. The regulatory requirement creates predictable demand.

Government and Military Archives: Agencies managing classified information, historical records, and government data face strict archival requirements. Holographic tape's immutability and proven performance in compliant deployments align perfectly with government procurement standards.

Media and Entertainment: Content studios managing massive video libraries benefit from holographic density. A content archive containing petabytes of raw footage, edited material, and archived productions could consolidate to 1/10th the footprint using holographic media, enabling more dynamic catalog management.

Scientific Research Archives: Universities, research institutions, and analytical organizations generate massive datasets that require permanent preservation. Genome sequencing data, astronomical observations, climate research datasets—these all benefit from immutable, long-lived storage.

In contrast, holographic tape doesn't add much value for:

Active Workload Storage: Hot storage requiring frequent access benefits from fast drives (SSDs, NVMe) or active tape. Holographic tape's slower performance makes it less suitable.

Short-Term Backup: Organizations backing up for disaster recovery with 3-5 year retention don't benefit from media rated for 50 years. They're paying for longevity they don't need.

Cost-Sensitive Deployments: Smaller enterprises or startups without massive archive requirements may find LTO-9 sufficient. The 10x capacity gain doesn't justify higher per-unit costs if they're only storing petabytes, not exabytes.

Manufacturing and Supply Chain Reality

One aspect often overlooked in technology discussions is manufacturing viability. It's not enough for a technology to work—it must be manufactureable reliably and at scale.

Holographic cartridge manufacturing differs fundamentally from magnetic tape. Magnetic tape is relatively simple: coat a plastic ribbon with magnetic particles, wind it onto a spool, package it. The process is mature, automated, and cost-effective at scale.

Holographic cartridge manufacturing requires:

- Precision polymer formulation with specific optical properties

- Manufacturing facility capable of recording holograms with laser precision

- Quality control testing verifying each cartridge's recording and readback capabilities

- Equipment for precision laser positioning during manufacturing

- Environmental controls ensuring consistent manufacturing conditions

This is significantly more complex than tape manufacturing. It's closer to semiconductor manufacturing in terms of precision requirements. Holo Mem will need to establish manufacturing partnerships with facilities capable of this level of precision or build proprietary manufacturing capability.

The good news: Holo Mem isn't starting from zero. Holographic media manufacturing has been researched and developed for years. Universities and research institutions have created prototype cartridges using similar processes. The path to production isn't inventing an entirely new manufacturing industry—it's scaling existing processes and optimizing for cost.

But there's real risk here. Scaling from laboratory production of tens of cartridges to industrial production of millions is a massive jump. Manufacturing yields might be low initially, driving costs up. Quality consistency might lag. Supply chains for specialized materials might be unpredictable.

Successful technology adoption depends heavily on whether manufacturing scales predictably. If Holo Mem encounters yield problems or inconsistency, the 2027 production date slips. If manufacturing costs remain elevated, the per-terabyte pricing advantage shrinks. The test proved the technology works, but manufacturing at scale is a separate challenge.

The Role of Standardization Bodies and Industry Consortiums

The LTO Consortium—composed of IBM, Hewlett Packard Enterprise, and Quantum—controls tape storage standards. Any technology seeking to integrate with tape libraries needs consortium blessing.

Holo Mem's form-factor compatibility is clever, but it doesn't automatically grant consortium endorsement. The consortium will evaluate holographic tape against performance standards, reliability metrics, and compatibility requirements. They'll likely establish specifications for optimal performance, similar to how they manage LTO standards.

The consortium's role is interesting. On one hand, they represent the established tape industry. On the other hand, they have incentive to maintain tape technology relevance. Holographic tape that runs inside tape libraries and serves tape's market niche actually extends the consortium's domain rather than threatening it.

This creates political dynamics. Some consortium members might view holographic tape as competitive threat to their LTO roadmaps. Others might see it as enhancement enabling continued tape market dominance. The consortium's ultimate positioning could accelerate or slow holographic adoption.

Historically, industry consortiums have been pragmatic. They've absorbed competing technologies and maintained relevant standards. The consortium likely will do the same with holographic tape if it matures as expected. But the process takes time and involves negotiations.

For enterprises considering holographic tape adoption, consortium certification status matters. Uncertified technology creates integration risk. Your library might not work optimally. Your data might not be supported in future equipment upgrades. Most enterprises won't adopt uncertified technology for critical infrastructure.

Holo Mem needs to engage with the consortium early and frequently. The test with BDT Media Automation was strategic partly because it built relationships with consortium stakeholders. By 2026-2027, Holo Mem should have clear pathways to certification if they've managed consortiums politics effectively.

What This Means for Your Organization

If your organization manages massive cold storage archives, you should be paying attention to holographic tape's development even if you're not planning immediate adoption.

For Large Cloud Providers and Hyperscalers: Start planning holographic tape pilots for 2028. The technology's compatibility with existing infrastructure makes it lower-risk than other alternatives. Work with Holo Mem on early access programs. The density and cost advantages are significant enough to justify evaluation.

For Compliance-Heavy Organizations (Finance, Healthcare, Government): Holographic tape's WORM format and longevity claims directly address your requirements. By 2029-2030 when the technology matures, it could become your preferred long-term archival medium. Start conversations with Holo Mem and your library vendors about transition planning.

For Organizations with Stable, Predictable Archives: Maintain your existing LTO infrastructure. Incremental upgrades to newer LTO generations remain cost-effective. Holographic tape becomes interesting only when your archival growth significantly exceeds your facility capacity, or when the per-terabyte cost drops below magnetic tape.

For Smaller Enterprises: LTO-9 or LTO-10 cartridges are likely sufficient. Holographic tape's economics don't justify adoption unless you're storing petabytes. Wait and see how the market develops. Price and performance will improve dramatically after 2029.

For All Organizations: Engage with your storage vendor about roadmaps. Ask them about holographic tape compatibility. Understand how they plan to support emerging technologies. Your vendor's positioning affects your options more than raw technology performance.

Looking Forward: The Path to Mainstream Adoption

Holographic tape's 2027 production target is just the beginning. Mainstream adoption takes years. But the trajectory is becoming clearer.

2025-2026: Early manufacturing pilot runs. Holo Mem proves production processes. Initial cartridges ship to select enterprise partners. Marketing and industry education accelerate.

2027: Mass production begins. Initial pricing is premium. Pilot deployments generate case studies. LTO Consortium certification processes advance. Competing technologies (Cerabyte, potentially Project Silica) make progress or stall.

2028-2029: Widespread pilot programs in major enterprises. Manufacturing yields improve, costs drop. Certification completion and industry standards finalization. Competitive dynamics crystallize.

2029-2030: Mainstream adoption as early evidence proves technology works reliably. Pricing becomes competitive with economic justification clear. Most new archive storage decisions consider holographic option.

2030+: Holographic tape becomes standard component of tape library infrastructure, similar to how LTO-9 is today. Competitive dynamics with LTO evolution and ceramic media settle into market equilibrium.

This timeline assumes no major setbacks. Reality might compress or extend these estimates. Unexpected breakthroughs (Project Silica suddenly ships) or unexpected failures (manufacturing scaling problems) would reshape the picture.

But the foundation is solid. The test proved the concept works in real deployments. The market need is genuine—exabyte-scale archives need denser media. The economic value is clear—footprint reduction delivers massive facility savings. The technology path is credible—holographic recording is well-understood, manufacturing processes exist, integration architecture is sound.

Holographic tape won't be a revolution. It will be an evolution. An important one that addresses real constraints in modern data center design. But it will arrive, not with dramatic fanfare, but with pragmatic enterprises quietly adding holographic drives to their existing libraries and realizing they've just made their archival infrastructure dramatically more efficient.

FAQ

What exactly is holographic tape storage?

Holographic tape is a data storage medium that uses laser-recorded interference patterns within a polymer cartridge to encode data in three-dimensional space. Multiple layers of data can exist in the same physical volume, enabling cartridges to hold 200TB of data while maintaining the same physical size as standard LTO cartridges. This is fundamentally different from magnetic tape, which encodes data on a two-dimensional surface coating.

How does holographic tape differ from magnetic tape?

Magnetic tape stores data in a thin magnetic coating on a plastic ribbon, with data density limited by the surface area. Holographic tape uses the entire three-dimensional volume of the cartridge, storing data in thousands of layers using different laser angles. This allows holographic tape to achieve roughly 10-12x greater capacity in the same physical form factor. Holographic cartridges also promise 50+ year longevity compared to magnetic tape's 20-30 year ratings.

Can holographic tape work with my existing LTO tape library?

Yes, this is a key advantage. Holo Mem's holographic cartridges are sized to match standard LTO dimensions, so library robotic arms can move them without mechanical modifications. Holographic drives fit into library slots like any other drive type. Existing library management software can recognize and work with holographic drives as just another storage device. This coexistence capability eliminates the need to replace existing infrastructure.

When will holographic tape cartridges be available for production use?

Mass production of holographic drives is scheduled for 2027, with cartridge availability following shortly after. However, widespread adoption will likely take several more years as enterprises run pilot programs, validate performance in their specific environments, and work through procurement and certification processes. Mainstream deployment is expected around 2029-2030.

What does WORM format mean and why does it matter?

WORM stands for Write-Once-Read-Many, a format where data can be written once and then never modified or deleted. This is enforced at the hardware level, making it legally defensible for compliance storage. Regulatory requirements in financial services, healthcare, and government sectors mandate immutable data storage. Holographic tape's native WORM capability directly addresses these compliance needs, making it attractive for regulated industries managing long-term archives.

How much will holographic tape cost compared to modern LTO cartridges?

Production pricing hasn't been announced, but analysis suggests holographic cartridges might cost roughly 2-3x more per cartridge than LTO-9. However, because each holographic cartridge holds 10-12x more data, the per-terabyte cost likely remains competitive with or lower than magnetic tape. Additionally, the space savings and reduced infrastructure costs provide significant secondary economic benefits for large-scale deployments.

What's the difference between holographic tape and Project Silica?

Project Silica uses glass plates to store data, promising geological-scale longevity. However, it remains in the research phase with no shipping product, no production timeline, and no demonstrated compatibility with existing data center infrastructure. Holographic tape has already been tested in production libraries and has a credible 2027 production target. Holographic tape integrates with existing infrastructure; Project Silica would require complete system redesigns.

Is holographic tape secure against unauthorized access or data tampering?

Holographic tape's WORM (write-once-read-many) format prevents modification or deletion after writing, which is a security feature. However, the technology itself doesn't include encryption or advanced access controls. Security depends on the library management system, facility access controls, and standard tape security practices. Organizations requiring encrypted storage should implement encryption layers above the holographic tape level, similar to how they handle magnetic tape.

What happens if holographic cartridges fail or become unreadable?

Holo Mem hasn't released extensive reliability data since the technology is still in production preparation. However, holographic storage's mechanical simplicity (no moving parts, no magnetic particles that can degrade) suggests theoretical reliability advantages over magnetic tape. The 50+ year longevity claims are based on polymer stability, though real-world validation is still years away. Early adopters should expect standard warranty and support processes similar to LTO vendors.

Will my existing backup software work with holographic tape?

Yes, this is a major advantage. The Holo Mem test validated that standard backup software can write to and read from holographic drives without modifications. The library management system presents holographic drives as just another available storage type. Your existing backup applications will work unchanged, though you can configure policies to specifically target holographic storage for certain data classes if desired.

Conclusion: A Practical Step Forward in Cold Storage Evolution

Holographic tape's successful test inside a working LTO library marks a significant inflection point in data storage evolution. It's not revolutionary in the way Project Silica's glass media promises to be. It's not disrupting like blockchain-based storage aspirations. It's pragmatic.

The technology addresses a real constraint: modern data centers generate more archival data than existing storage media can efficiently handle. Exabyte-scale deployments require massive physical infrastructure, enormous power consumption, and expensive facility footprints. Doubling storage density while maintaining infrastructure compatibility isn't flashy, but it's valuable. It's the kind of incremental improvement that drives adoption.

The test proved something equally important as the technology itself: new storage media can integrate into existing ecosystems without forcing wholesale replacement. Holo Mem understood that data center upgrades move slowly, driven by capital constraints and operational inertia. By designing holographic tape to coexist with LTO rather than compete with it, they created a path to market that enterprises can actually follow.

Will holographic tape completely replace magnetic tape? Almost certainly not. LTO evolution will continue, and many organizations will stick with magnetic tape because the friction is low and the costs are familiar. But for organizations managing petabytes and exabytes of archival data, holographic tape offers genuine economic advantages. Lower per-terabyte costs. Dramatically reduced facility footprints. Superior longevity for compliance requirements. These aren't minor improvements.

The next few years will reveal whether manufacturing scales as expected, whether production costs hit targets, and whether real-world deployments validate the laboratory performance. These are material questions that will determine whether holographic tape becomes standard infrastructure or remains a niche solution.

But the trajectory is clear. The test happened. It worked. Now it's a matter of execution. By 2030, when holographic drives are available and integrated into standard tape library offerings, today's test will seem obvious in retrospect. Of course you can use more data layers. Of course the same physical size can hold more capacity. Of course you can integrate it into existing libraries.

The interesting innovation wasn't the physics. It was the engineering discipline to ask "how can this integrate with what already exists" rather than "how impressive can this be in isolation." That pragmatism is what makes this technology adoption story worth following.

For your organization managing massive data archives, mark 2027-2028 on your planning calendar. Start conversations with your vendors about holographic tape roadmaps. Begin thinking about whether your facility can accommodate denser media. And pay attention to how the market develops. The boring, practical technology often wins over the flashy alternatives. Holographic tape might be boring. But boring gets deployed.

Key Takeaways

- Holographic tape successfully deployed in production LTO libraries, proving real-world compatibility and eliminating deployment friction that blocks other storage alternatives

- 200TB cartridge capacity delivers 10-12x density improvement over LTO-9 in the same physical size, with meaningful implications for data center footprint and cost efficiency

- WORM format and 50+ year longevity claims position holographic tape as ideal solution for compliance-driven archival storage in financial services, healthcare, and government sectors

- Mass production of holographic drives scheduled for 2027, with mainstream enterprise adoption expected 2029-2030 after certification and pilot validation phases

- Holographic tape's advantage isn't raw performance—it's integration compatibility, allowing enterprises to add capacity to existing infrastructure without replacement or rework

![Holographic Tape Storage Finally Meets Real-World Deployments in 2025 [2025]](https://tryrunable.com/blog/holographic-tape-storage-finally-meets-real-world-deployment/image-1-1771105025993.jpg)