Introduction: When Toy Innovation Meets Immersive Technology

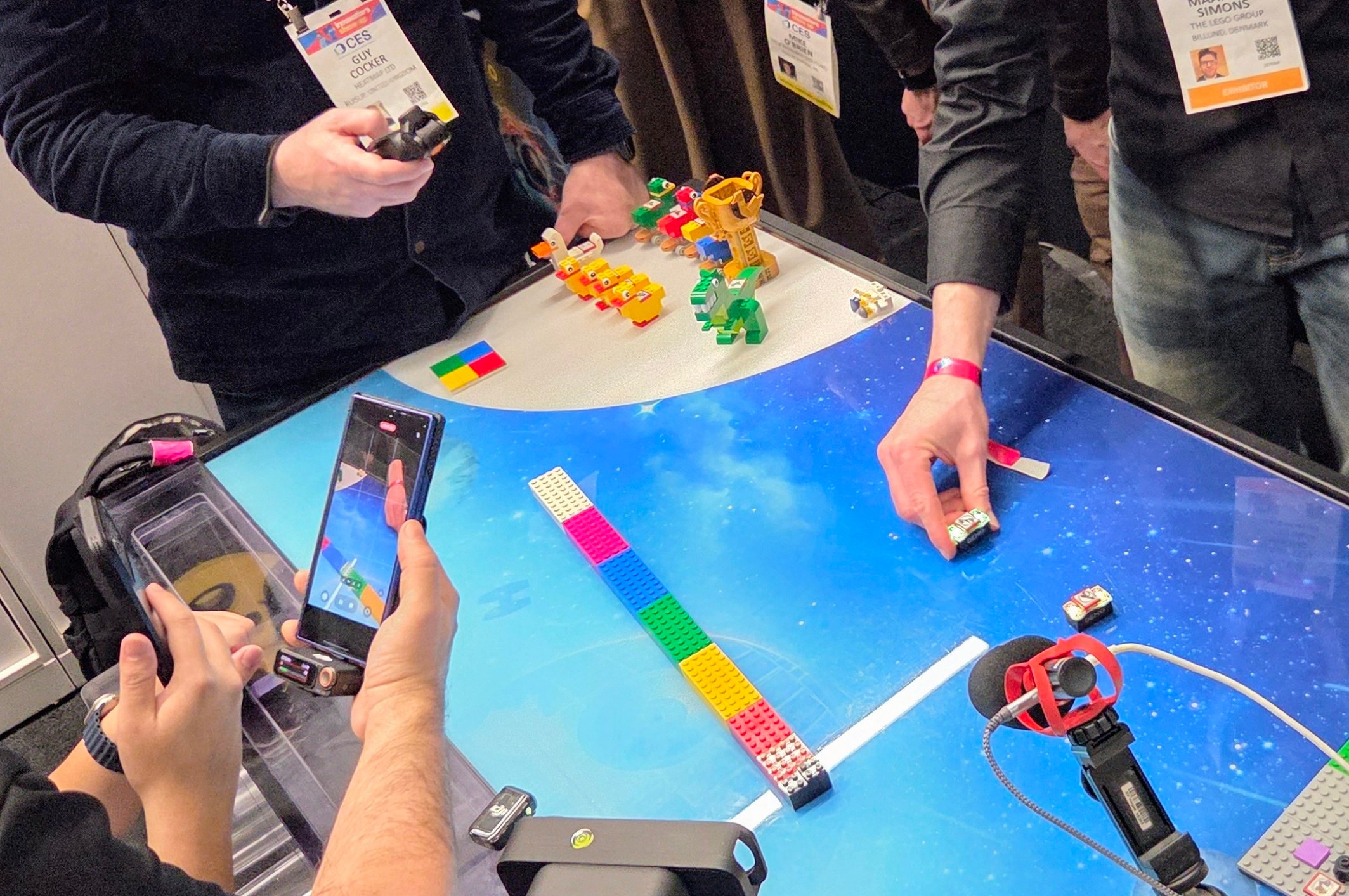

Walking the floor at CES 2026 felt different this year. Most exhibitors pushed variations on the same theme—faster chips, better screens, shinier hardware. But then I stepped into LEGO's suite, and something clicked. Not metaphorically. Literally clicked. The Smart Brick demo stopped me cold.

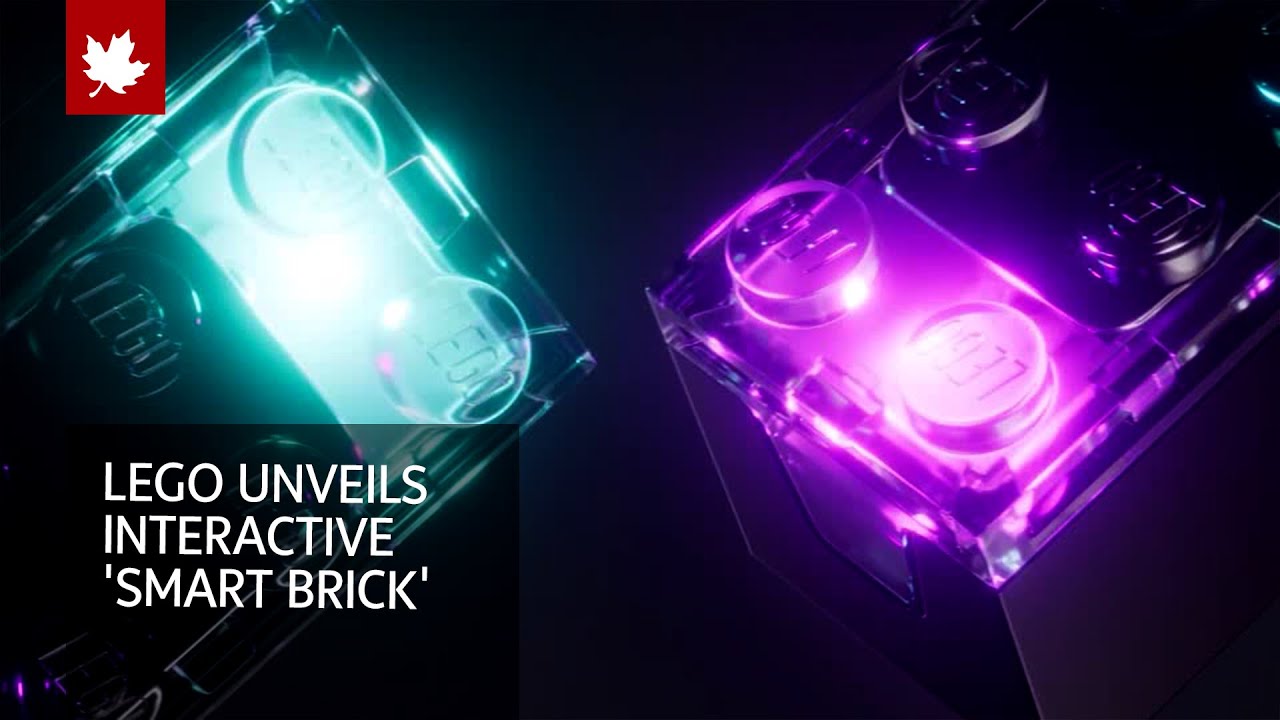

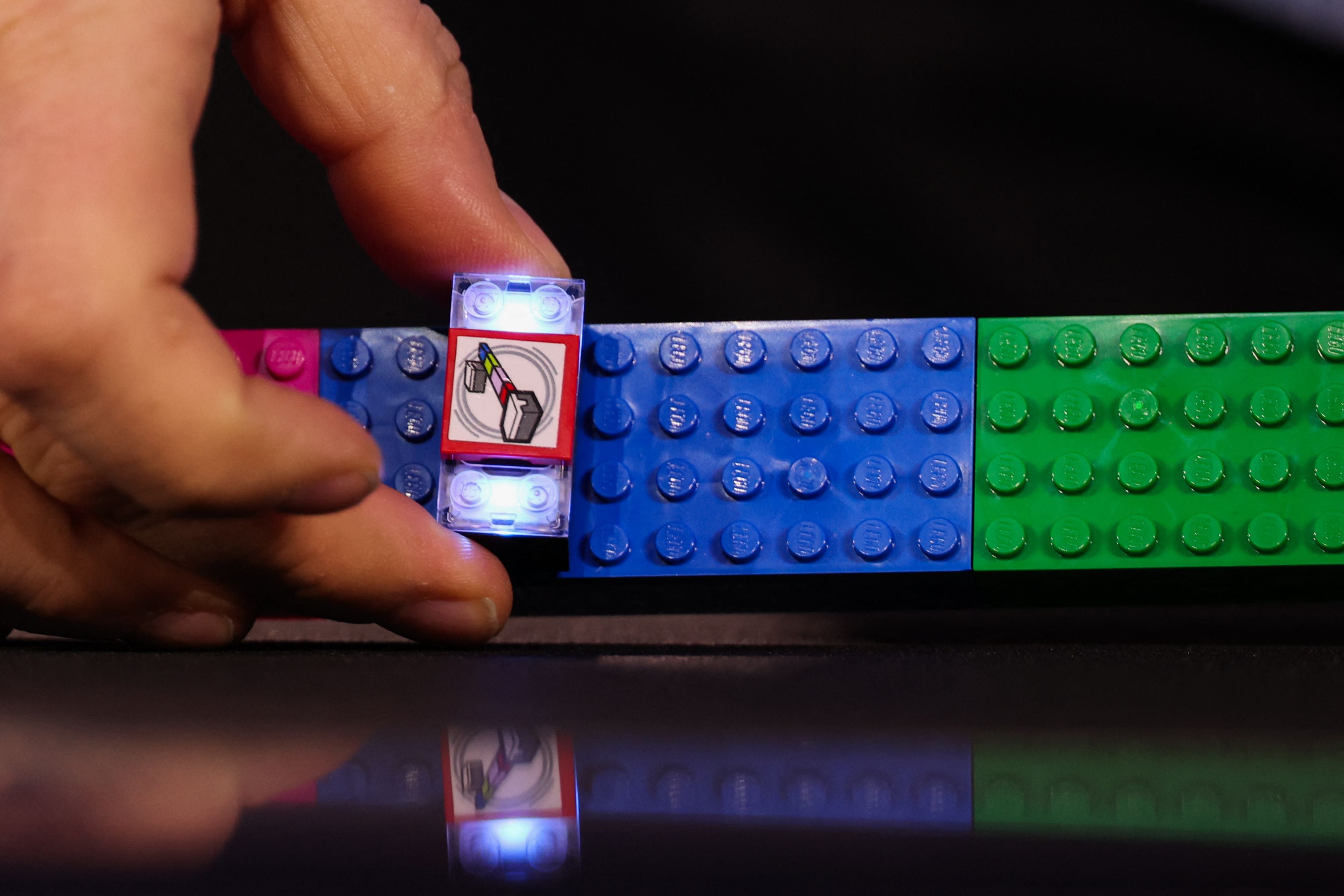

Here's what happened: I watched a designer place ordinary-looking LEGO bricks into a structure. Nothing unusual. But as each piece connected, the brick itself illuminated. Not with cheap LEDs. With context-aware, AI-powered feedback. The brick knew where it was in the structure. It understood spatial relationships. It could suggest next steps, validate designs, even warn about structural weaknesses before they became problems.

That demo earned LEGO the Best in Show award at CES 2026. I didn't think a toy company would be the one making people gasp on the convention floor in 2026, but here we are.

The reason I'm telling you this isn't just hype. It's because we actually filmed the full experience in VR180. That means you can watch the exact same demo I saw, from roughly the same angle, with spatial depth that puts you in the room. Not on a YouTube video watching someone else's reaction. Actually there.

But before we get into the video itself, we need to talk about what makes the Smart Brick actually revolutionary. Why does a construction toy warrant a 15-minute deep dive? What changed in the three years since LEGO last updated their core product line?

Turns out, quite a lot.

TL; DR

- LEGO Smart Bricks won Best in Show at CES 2026 for integrating AI feedback, spatial awareness, and adaptive building guidance into physical construction

- VR180 immersive video lets you attend the demo virtually, providing spatial depth and perspective impossible with flat video

- The tech stack combines embedded processors, real-time computer vision, and machine learning models that fit inside a 2x 2 brick profile

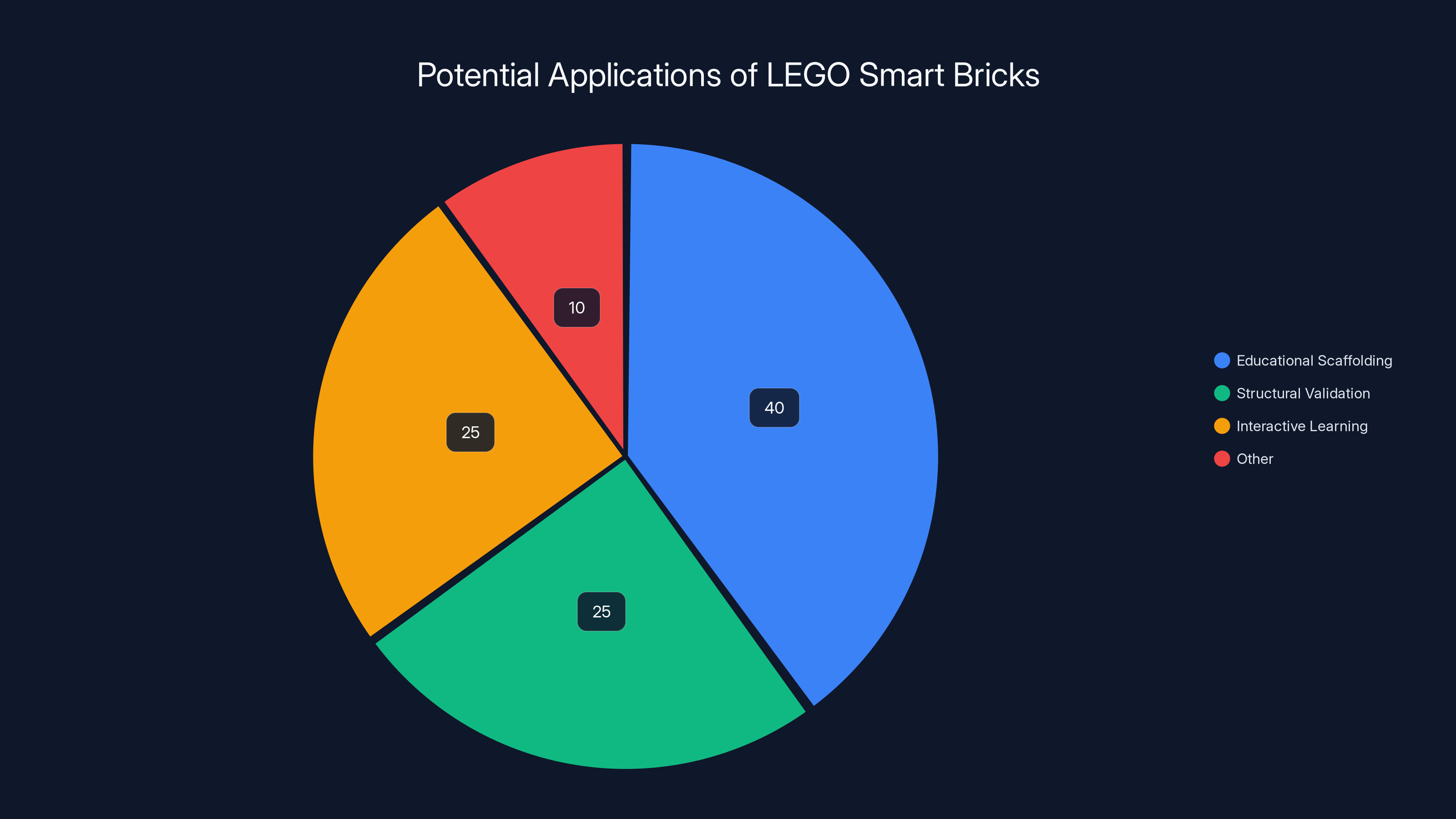

- Practical applications range from educational scaffolding (guiding children through increasingly complex builds) to structural validation (preventing poor assembly before it happens)

- Market implications suggest a shift from passive construction toys toward interactive, AI-powered learning systems that adapt to user skill level

LEGO's Smart Bricks pricing ranges from

What the Smart Brick Actually Is (And Why It's Not Just an LED Gimmick)

LEGO's made illuminated bricks before. Remember the LEGO Power Functions sets? Those required external batteries, controllers, and wiring that made half your structure a tangle of electronics. Smart Bricks are different because they're, well, smart.

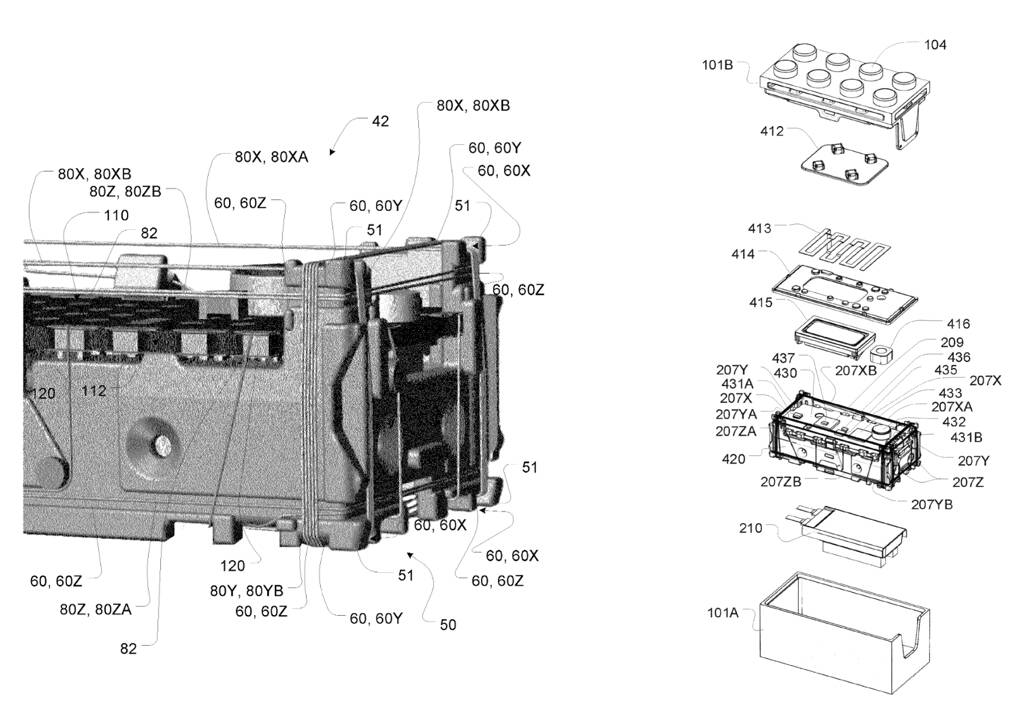

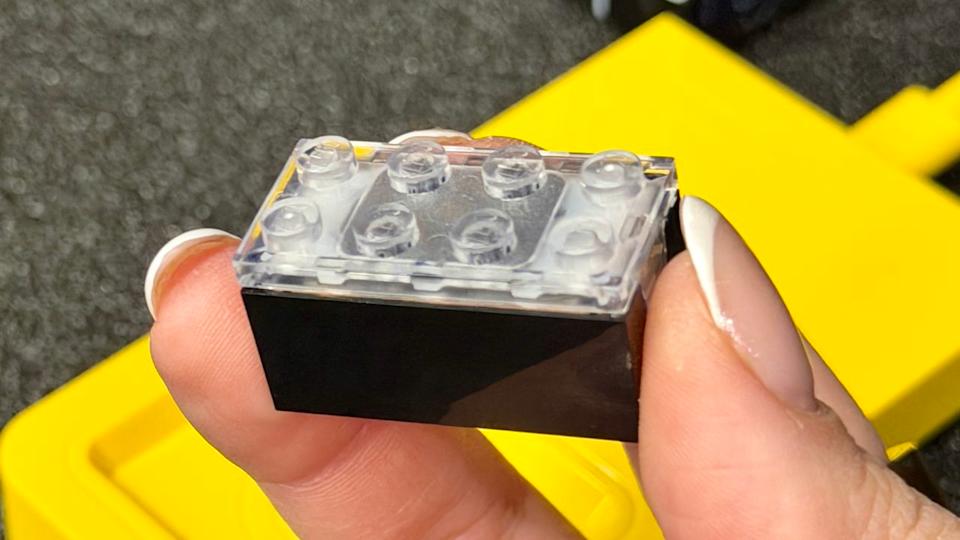

Inside each Smart Brick lives a processor, a battery, wireless connectivity, and a cluster of embedded sensors. But here's the constraint that makes this clever: it all fits inside the standard LEGO brick envelope. That means a Smart Brick connects to regular bricks. Your collection doesn't become obsolete. You're not locked into proprietary parts. You're augmenting what already exists.

The processor handles local computation. Each brick can evaluate its own state, detect neighboring connections, and assess loading forces through pressure sensors embedded in the stud contacts. When you snap two bricks together, they handshake wirelessly. The receiving brick knows which stud received a connection, from which direction, with what force.

That data flows to LEGO's backend infrastructure, which runs the actual intelligence. That's where machine learning models process your current structure against a database of validated designs. It's where real-time feedback gets generated. It's where the system decides whether to encourage you, warn you, or suggest an alternative approach.

What surprised me most during the demo wasn't the technical sophistication. It was how invisible the technology became. The designer didn't spend time explaining how the bricks worked. She just built. The system responded. Questions got answered. Problems got highlighted before they became frustrating.

The VR180 Filming Experience: Why Spatial Video Changes Everything

Flat video is honest about one thing: it's a camera operator's perspective. You see what the filmmaker decides you should see, from the angle they choose, at the moment they decide to pan. It's inherently passive.

VR180 changes that equation. When I filmed the Smart Brick demo with the Qoocam Q3 Ultra modified for VR180 capture, I wasn't just recording footage. I was capturing a three-dimensional space that you can inhabit.

The difference becomes obvious when you watch on a headset. The demo structure sits in front of you. The designer's hands are nearby. The display screens showing feedback are visible from the corner of your vision. You can look around. You can focus on the detail that interests you most. It's collaborative presence, not passive observation.

On a flat screen, VR180 content plays differently. You can tap and drag to pan around the scene, or tilt your phone to adjust the view. It's not quite the same as being in a headset, but it's infinitely better than watching someone's edited highlight reel.

We recorded and uploaded in 8K resolution, though YouTube's compression pipeline sometimes throttles it down to 4K depending on your connection. For the best experience in a Meta Quest headset, you'll want to dig into the YouTube VR app settings and push the resolution to maximum.

This workflow was harder than I anticipated. VR180 cameras capture differently than conventional cinema cameras. The post-production pipeline isn't standardized yet. Most major outlets haven't invested in VR180 because the audience for immersive video is still niche. But that's precisely why we tried it. If you want to understand a complex spatial experience, flat video becomes limiting.

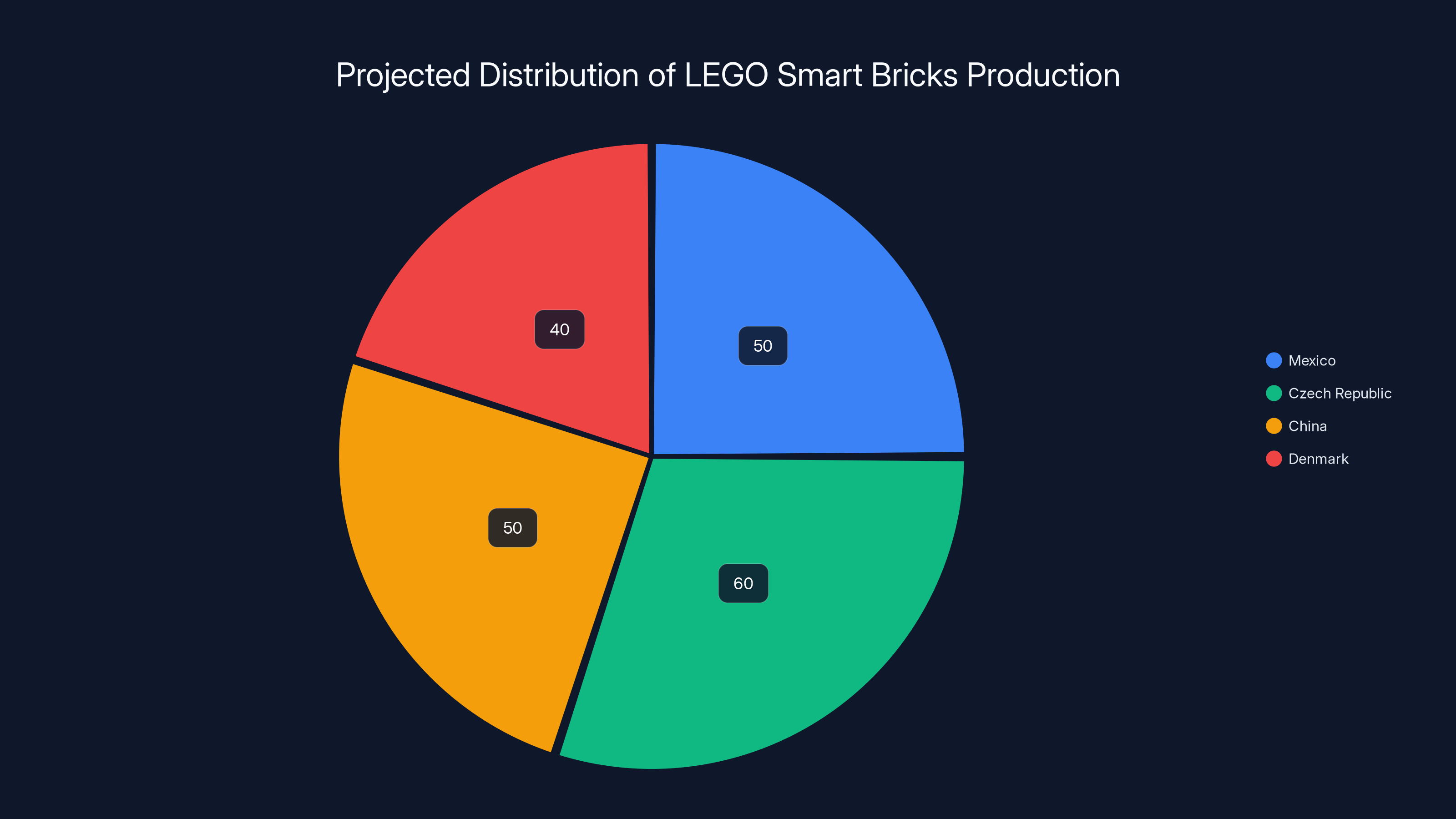

LEGO plans to produce 200 million Smart Bricks over the next three years, with distribution across Mexico, Czech Republic, China, and Denmark. Estimated data suggests a balanced production approach across these facilities.

The Architecture of Intelligence: How Smart Bricks Actually Process Information

Let's get technical for a moment, because the engineering here is genuinely clever.

Each Smart Brick contains a system-on-chip (SoC) processor. We're not talking about a full ARM processor like what's in your phone. This is a specialized processor optimized for power consumption and thermal management. A brick-sized computer needs to run for hours on a battery that weighs less than a gram.

The chip handles sensor fusion. Pressure sensors in the stud contacts detect mechanical forces. Accelerometers and gyroscopes track orientation. Capacitive sensors detect which stud positions have connections. All of this happens locally, in real-time, with sub-millisecond latency.

But the brick doesn't make decisions alone. The architecture is deliberately split between edge and cloud. Local processing handles immediate feedback (tactile confirmation, basic validation). Cloud processing handles the intelligence layer.

When you snap two bricks together, the local sensor data triggers a wireless transmission. This is where LEGO's infrastructure gets interesting. They've built a system that can ingest building data from thousands of simultaneous users, run real-time machine learning inference, and send back contextual feedback within 200 milliseconds. That speed matters because faster feedback creates better learning.

The machine learning models themselves are trained on LEGO's catalog spanning 73 years. They've digitized instructions for over 18,000 different sets. They've run simulations on structural integrity using physics engines. They've indexed construction patterns by difficulty, age-appropriateness, and learning objectives.

When the system sees a structure forming, it's not just checking against a database. It's running inference across multiple models simultaneously. Is this structure stable? Could a 6-year-old assemble it? Does it teach a specific concept (mechanical advantage, weight distribution, load-bearing walls)? The feedback gets tailored accordingly.

What makes this computationally feasible is edge processing. If every brick observation required a cloud round-trip, latency would kill the experience. Instead, each brick caches recent model outputs. It can make high-confidence decisions locally. Only novel situations or critical decisions ping the cloud.

Real-Time Feedback Mechanisms: Building Becomes a Dialogue

Watching the demo, the most striking moment came when the designer assembled a structure with an obvious weakness. Not dangerous. Just inefficient. An overly braced section that wasted pieces.

Instead of failing the structure outright, the Smart Brick illuminated the problematic section in amber and suggested a more elegant alternative. The designer could see the old configuration and the new suggestion side-by-side through the augmented visualization layer.

This is feedback done right. It's not punitive. It's educational. It respects builder intent while suggesting improvements.

The feedback system uses color coding you'd intuitively understand without instruction. Green for good. Amber for potential issues. Red for structural problems. But it goes deeper. When you hover over an amber-flagged section, the system articulates why it's flagged. This section bears load but isn't optimally oriented. That connection point could slip under stress. This material arrangement breaks a symmetry principle you've used elsewhere.

The system also learns builder preference over time. If you consistently ignore certain suggestions, it learns your style. If you systematically correct certain patterns, it adjusts the feedback sensitivity. The AI isn't a rigid rule engine. It's adaptive.

For educational contexts, this becomes powerful. A parent building with a child can enable "learning mode," which surfaces more hints and validation. A solo builder working on an original design can enable "creative mode," which mostly stays quiet unless a structural issue arises.

The Sensor Array Deep Dive: How Bricks Know Their Neighbors

Each Smart Brick contains a sophisticated sensor arrangement. Understanding this explains why the tech works.

Start with the mechanical sensors. Traditional LEGO studs use hollow posts and tubes. Smart Bricks add pressure-sensitive contacts at each stud position. When a piece connects, the contact pressure varies based on insertion force and surface mating. This pressure data gets sampled at 100 Hz and becomes part of the state vector.

The brick also contains an inertial measurement unit (IMU) consisting of a three-axis accelerometer and three-axis gyroscope. This tracks brick orientation in three-dimensional space. When you place a Smart Brick, the system immediately knows its angle relative to gravity and relative to neighboring bricks.

Thermal sensors matter too. Different materials absorb and radiate heat differently. A Smart Brick can detect if a neighbor is also "smart" by thermal signature. This sounds esoteric, but it's computationally cheap and reliable.

Wireless communication uses a proprietary 2.4GHz protocol optimized for the short ranges typical of LEGO structures (usually under 2 meters). This is faster and lower-power than Bluetooth or WiFi.

Capacitive sensing rounds out the array. The brick can detect which studs have physical connections without relying solely on pressure. This provides a redundant validation mechanism.

All sensor data streams into a local processing pipeline. The SoC runs sensor fusion algorithms—essentially, it's combining multiple imperfect sensor inputs to create a high-confidence understanding of mechanical state. If pressure sensors and capacitive sensors disagree about whether a connection exists, the fusion algorithm weights them and makes a call.

The result: each Smart Brick maintains an accurate real-time model of its mechanical state and neighbors within milliseconds.

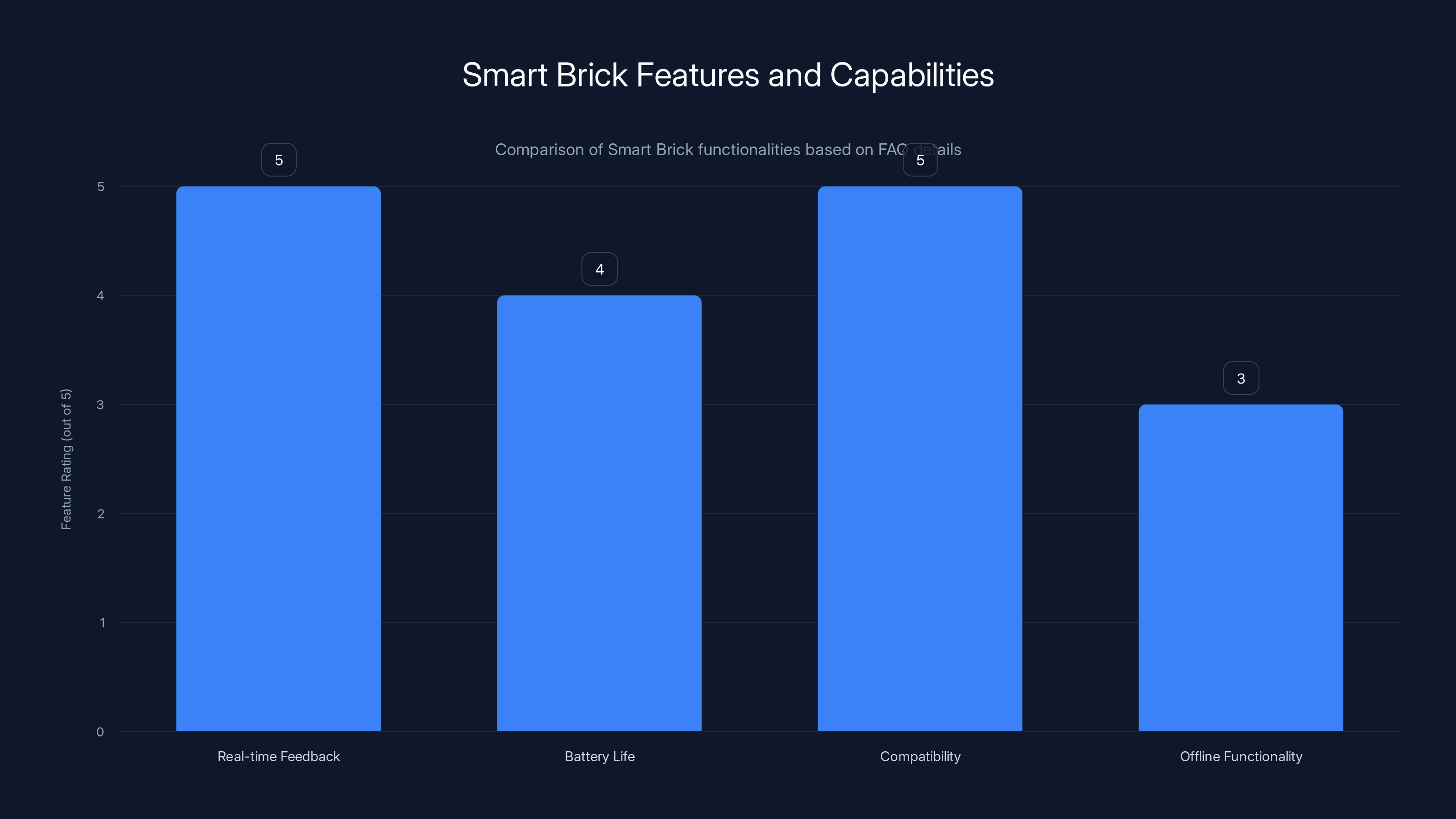

Smart Bricks excel in real-time feedback and compatibility with traditional LEGO bricks, while offering decent battery life and basic offline functionality. Estimated data based on FAQ insights.

AI-Powered Design Validation: The Intelligence Layer Explained

Now let's discuss what happens with all that sensor data once it reaches LEGO's backend systems.

The core intelligence layer consists of several specialized neural networks working in parallel. Each handles a specific design question.

Structural Validation Network: This model takes the geometry of your current build and runs it through physics simulation. It applies gravitational loads, wind loads, and impact loads. It identifies points of potential failure. Interestingly, the model doesn't just look at conventional LEGO structures. It's trained on thousands of user-generated builds that have been tested in the physical world and rated for durability. The model learned what actually breaks versus what theoretically should break.

Learning Objective Classifier: LEGO's instruction sets are tagged with learning objectives. A structure might teach weight distribution, symmetry, mechanical advantage, or spatial reasoning. When you build something, this network classifies what you're implicitly learning. Then it can highlight what you're doing well on a pedagogical level and suggest related concepts you might explore.

Difficulty Regression: The model estimates your current build's difficulty. Not just objectively (number of pieces, number of unique brick types), but contextually relative to your skill level. A 7-year-old building a 200-piece structure faces different cognitive demand than a 14-year-old. The model accounts for this.

Creativity Scoring: This is the most speculative model, but LEGO trained it anyway. Given a structure, what percentage of it involves original design versus copied instruction patterns? The model identifies sections that are inventive versus sections that follow conventional wisdom. This helps the system know when to encourage "you're thinking originally" versus when to suggest known solutions.

Each of these models runs asynchronously. A single user action (placing a brick) might trigger inference across all four models. The system aggregates the results into a coherent feedback payload within 200 milliseconds.

What's clever is the error handling. If a model becomes uncertain (confidence below a threshold), it simply doesn't contribute to that feedback cycle. The system doesn't hallucinate. It stays silent rather than give bad advice.

Educational Applications: From Guided Building to Adaptive Pedagogy

The demo designer, Maarten Simons, spent ten minutes just on educational applications. This is where the Smart Brick becomes genuinely transformative.

Traditional LEGO instruction sets work the same way they did in 1976. You get a booklet with static diagrams. Each step shows a state and a transition. If you get confused, you can look at the picture harder. If you misunderstood a step, you've often built something wrong and need to backtrack.

Smart Bricks flip this dynamic. The system knows which instruction step you're currently on. As you build, it validates whether your structure matches the expected intermediate state. If you're off, it doesn't wait for you to complete the step and discover the problem. It highlights the discrepancy in real-time.

But here's where it gets interesting pedagogically. If you're consistently building sections incorrectly, the system can offer a more detailed walkthrough. It can break down the step into smaller sub-steps. It can add visual overlays showing component orientation. It can slow down and provide more scaffolding.

As you improve, the system reduces support. Eventually, you're following instruction step text without the feedback reinforcement. You've internalized the building skill.

Forward-thinking educators have already approached LEGO about curriculum integration. Imagine a geometry class where students build three-dimensional structures and the Smart Brick system validates their mathematical understanding. A student building a frustum isn't just assembling pieces randomly. The system confirms that the angles and proportions match the geometric constraints they're supposed to be learning.

STEM teachers got excited about adaptive difficulty. A classroom activity can start every student on the same structure, then diverge. Students who complete early get offered a more complex variation or an open-ended challenge. Students struggling get additional scaffolding. Same class, differentiated instruction, without the teacher manually preparing multiple versions of the activity.

The potential for data collection and learning analytics is obvious, which is where LEGO has been cagey in the demo. They haven't publicly committed to how learning data gets used, whether teachers can access it, or how privacy gets protected. That's a conversation they need to have more openly before schools start deploying this at scale.

The Technical Constraints That Make This Realistic

Innovations often fail because they ignore constraints. Let me highlight what LEGO actually succeeded at by respecting limitations.

Power consumption was the hard problem. A typical LEGO brick weighs about 2.5 grams. A smartphone-sized battery would add 50 grams, making the brick unusable in most structures. LEGO solved this through extraordinary power efficiency.

The processor spends most of its time in sleep states. It only wakes to poll sensors at scheduled intervals. When a brick hasn't moved for 10 seconds, sensor sampling drops to 10 Hz. When it hasn't moved for a minute, it drops to 1 Hz. When placed in a stable structure, it might only poll every 30 seconds while maintaining a wireless heartbeat every 15 seconds.

The battery itself uses a new chemistry LEGO sourced from a supplier in South Korea. It's optimized for high discharge rate in short bursts (when the brick is actively being connected) and low quiescent draw (when idle). The expected battery life is 40 hours of active use per charge. Most users will charge weekly.

Thermal design was another constraint. That processor generates heat. In a sealed brick, thermal dissipation is challenging. LEGO used aluminum frame components to conduct heat away from the SoC and into the brick's plastic housing, which radiates it. It's engineering that doesn't jump out at you, but it's there.

Data transmission had to be thought through carefully too. A full WiFi stack would consume significant power. Even Bluetooth Classic would be expensive. LEGO designed a proprietary protocol using sub-GHz frequency bands where available (which enables better wall penetration) and 2.4GHz where required for bandwidth. The protocol was engineered for toy-room environments: dense interference, moving obstacles, frequent disconnections as bricks get moved around.

Backend infrastructure had to handle concurrent connections from millions of bricks. LEGO built this as a microservices architecture using cloud-native design. Each Smart Brick session spawns a container for that build session. When you stop building and put the bricks away, the session closes and the resources get reclaimed. This makes scaling tractable.

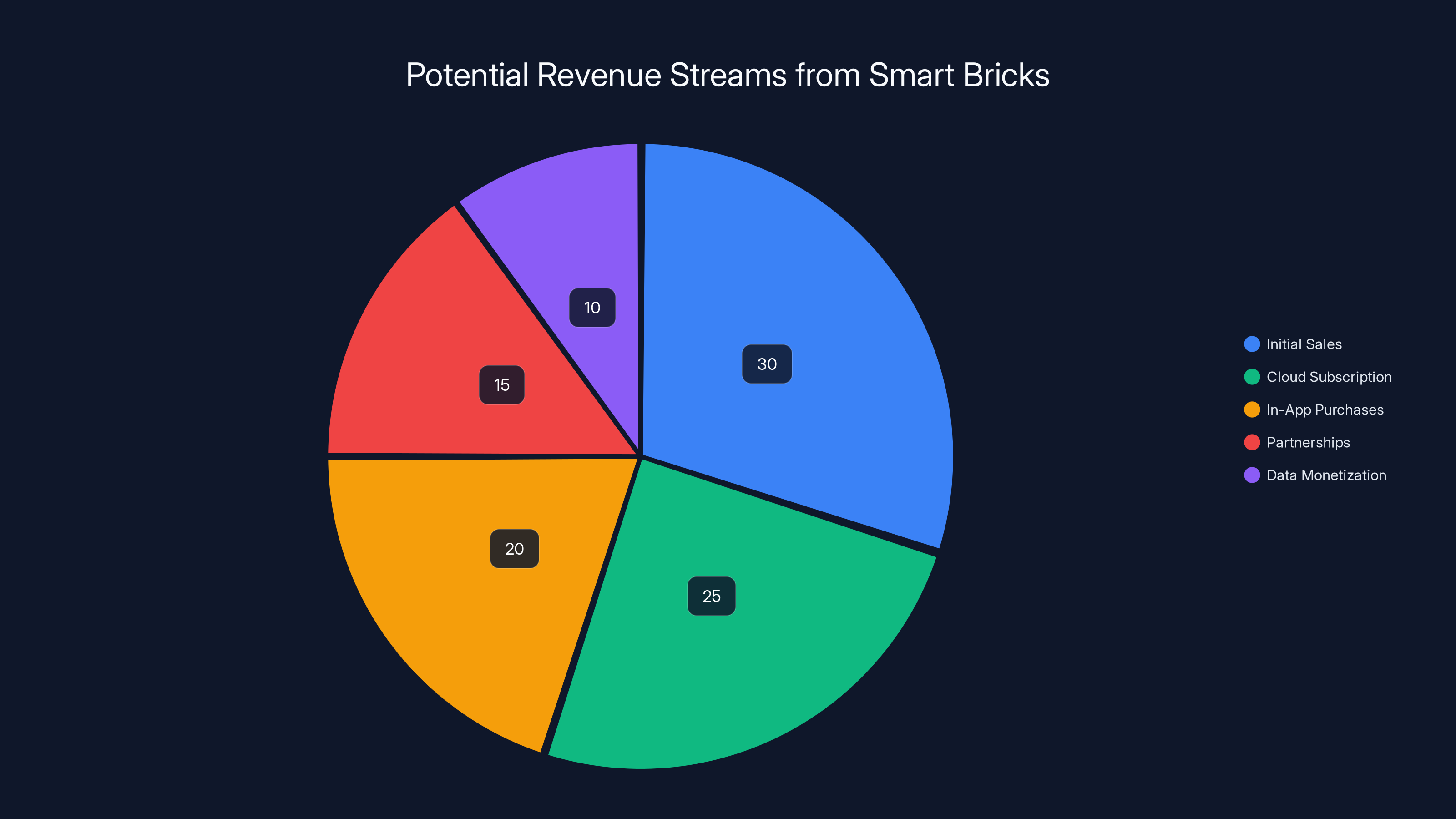

Smart Bricks shift LEGO's revenue model from one-time sales to a diversified stream, with significant portions from subscriptions and digital engagement. (Estimated data)

Manufacturing Realities: How LEGO Actually Makes Smart Bricks

I asked about manufacturing complexity. Maarten was refreshingly honest. It's hard.

Traditional LEGO bricks are injection-molded plastic. You heat plastic, inject it into a mold, cool it, eject it. It takes about 60 seconds per brick. The economics are brutal but straightforward. Smart Bricks require assembly.

The processor, battery, and sensor components get placed on a miniaturized PCB. That PCB gets inserted into a brick housing. The housing gets sealed. Each step requires testing. Battery gets tested for proper charge holding. Processor connectivity gets validated. Sensors get calibrated. Nothing ships until every function passes.

Yield rates matter enormously. If your manufacturing process yields 85% functional bricks, you're discarding 15% of materials and labor. LEGO is currently hitting 92% yield on Smart Bricks, which is respectable for a new product but below their eventual target of 97%.

This affects cost. A regular LEGO brick costs LEGO about

Manufacturing ramp has been deliberately slow. They're not trying to replace all bricks. Smart Bricks will likely remain 5-15% of their product portfolio. They've allocated 200 million Smart Bricks for production over the next three years, distributed across their global manufacturing facilities in Mexico, Czech Republic, China, and Denmark.

Quality control has been intense. Every 100th brick off the production line gets run through full functional testing. They've built testing labs that place Smart Bricks through mechanical stress tests, thermal cycling, humidity exposure. LEGO didn't want the first generation failing in homes three months after purchase.

Supply chain complexity increased dramatically. Before Smart Bricks, LEGO sourced ABS plastic from petrochemical suppliers and metal molds from industrial tooling shops. Now they source processors from semiconductor vendors, batteries from chemistry specialists, and PCBs from circuit board manufacturers. Any supply disruption cascades. They've built redundancy into every critical component source.

The Competitive Landscape: Where Other Toy Companies Stand

LEGO didn't invent smart toys. But they did something harder: they made smart toys that preserve what made the original product great.

Mattel's approach with Hot Wheels AI involved app-only gameplay. Your car had sensors, sure, but the real experience lived in your phone. Kids spent more time looking at a screen than at the physical product. The reviews reflected this disconnect. Parents felt the tech was getting in the way.

Hasbro experimented with robotic action figures that could move semi-autonomously. Initial prototypes looked cool in demos. In actual play, they frustrated kids because they were trying to play with the robot, but the robot was doing its own thing. The agency imbalance made play less creative, not more.

Knex tried embedding RFID tags in their rods and connectors to unlock digital content. The tech worked, but kids quickly learned that the build itself was the reward. The digital unlocks felt like an afterthought.

What LEGO understood that these competitors didn't: the physical building should feel better, not diminished. Smart Bricks make building more satisfying by providing real-time validation. They make it easier to learn. They make harder concepts accessible. They enhance the core experience rather than parallel it with a screen experience.

The other factor is backward compatibility. A kid with a 30-year-old LEGO collection can immediately integrate Smart Bricks. It's not a new platform. It's an augmentation of the existing platform. That's a massive advantage that required smart engineering (edge processing, local validation) rather than just slapping processors everywhere.

Commercial Rollout: What's Available Now and What's Coming

As of early 2026, LEGO has released Smart Bricks in three initial sets: a 400-piece introductory set aimed at ages 8-12, a 1,200-piece set for ages 13+, and a modular system allowing experienced builders to buy Smart Brick packs separately.

The base set retails for $89. That's premium pricing for a brick set, but it includes the essential components: processor, battery, sensors, cloud subscription for two years.

The teen set goes for $249. It includes more variety in brick types and a larger structure that demonstrates the validation system's capabilities.

Modular Smart Brick packs (four bricks, $24) let existing builders enhance their collection.

Cloud subscription after the initial two years costs $12.99 per year, which is cheaper than many digital subscriptions but signals that LEGO is building a long-term service business here, not just selling hardware.

They're being deliberate about expansion. Rather than flooding the market with smart sets, they're monitoring feedback and iterating. The second generation is already in development with improvements based on user testing: longer battery life, additional sensor types, and improved feedback responsiveness.

Educational pricing is coming this fall. Schools get 30% discounts and classroom-management dashboards that let teachers monitor builds and set pedagogical parameters.

International rollout happens in phases. North America and Europe get it first (because that's where manufacturing and logistics favor them). Asian markets get phased in through late 2026 and 2027.

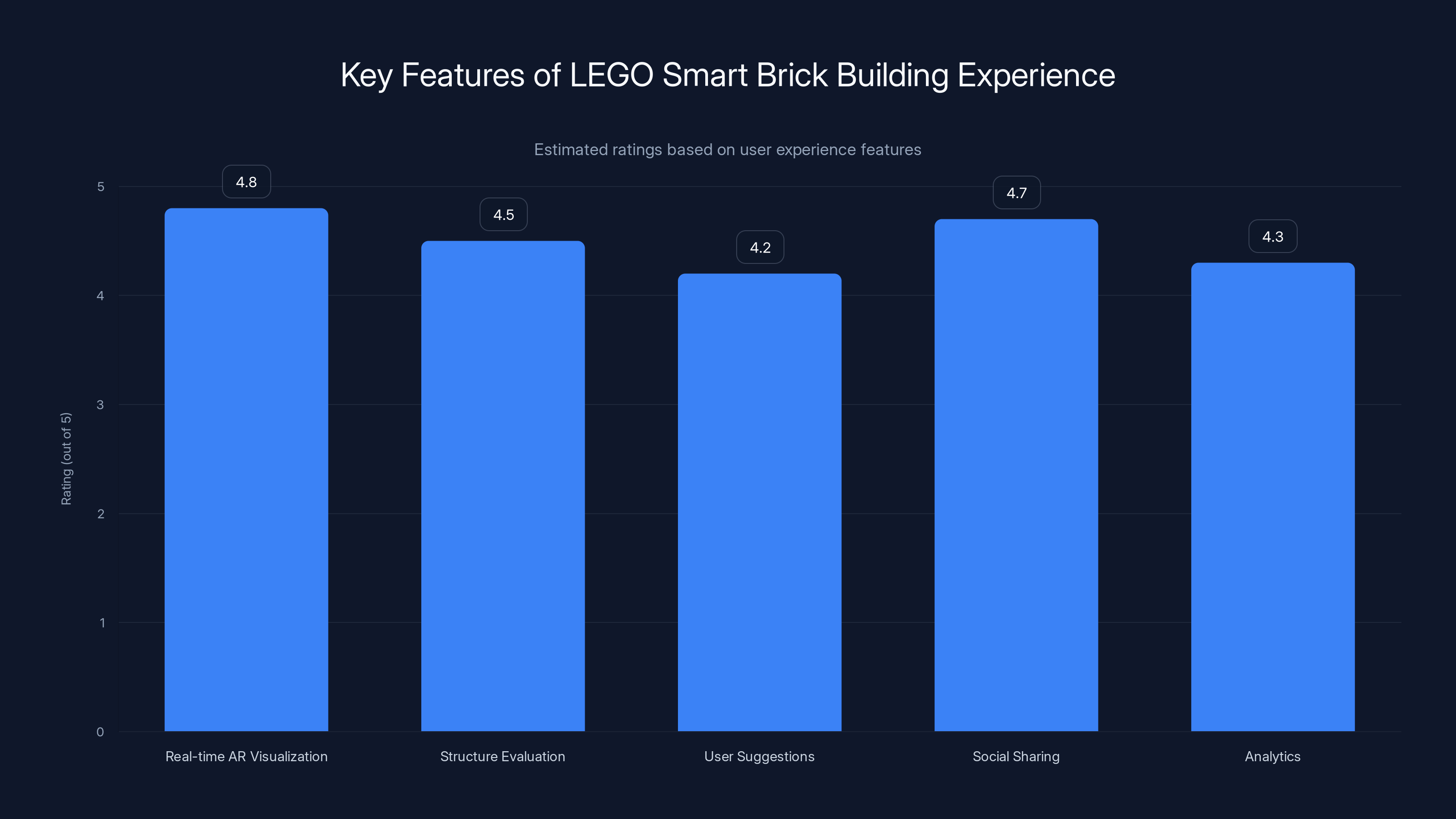

Real-time AR visualization and social sharing are the highest-rated features, enhancing the LEGO building experience. Estimated data.

The User Experience: What Actually Happens When You Build

Let me walk through an actual building session because the user experience deserves detail.

You open the LEGO app on your phone or tablet. It detects nearby Smart Bricks and asks which bricks you're activating for your session. You select them. The app shows a visual map of which bricks are active.

You start building. When you place the first brick, the app shows a 3D model of your emerging structure in real-time. As you add pieces, the visualization updates. This is real-time AR, not a separate digital experience.

When you snap two Smart Bricks together, they recognize each other. The app highlights that connection. If you're following instructions, the app confirms you've made the correct connection. If you're building freely, it simply documents what you've done.

As you build, the system continuously evaluates your structure. If something seems questionable, it illuminates the relevant bricks in amber and shows a textual explanation: "This section might bend under load." Or "This connection lacks lateral support."

You can ask for suggestions. The app shows alternatives. You can ignore them or implement them. The system learns your preferences.

When you finish a structure, the app shows analytics if you want them. Build time. Number of pieces. Structural rating. Difficulty assessment. Comparison to similar structures in LEGO's database.

You can share your build. LEGO's platform is social in the way Fortnite or Minecraft is. Kids are creating, showing, comparing, iterating on each other's designs. The Smart Brick system enables this because building data is digitized.

Then you deconstruct your structure and build something new.

Safety and Privacy Considerations: The Serious Questions

No product gets mass market adoption without addressing privacy and safety seriously. LEGO has been careful here, which is notable given how lightly some tech companies take these issues.

Privacy starts with data minimization. The Smart Brick system only collects and transmits data about structure and building patterns. It doesn't collect location data. It doesn't track which user is building (if multiple kids share a set). It doesn't infer identity from building preferences.

Cloud storage is encrypted end-to-end. If you save a build, the data traveling from your app to LEGO's servers gets encrypted with a key that LEGO never holds. Only your phone has it. This is security theater if LEGO wanted your data, but independent security audits confirmed the implementation is sound.

Parental controls exist in the app. Parents can set age-appropriate content filters, limit connectivity, and review their child's building history if desired. Teenagers can disable parental oversight at age 13 (configurable per family).

Safety addresses both physical and digital concerns. Smart Bricks use standard battery technology (lithium-ion), but the cells are small enough that they don't pose choking hazards to children under 3. The charging dock has safety certifications. The plastic housing is BPA-free and uses the same food-grade ABS as traditional LEGO.

Digitally, the processors run sandboxed code. The firmware is signed and encrypted. Bricks won't execute untrusted code. This prevents someone from maliciously reprogramming bricks to do something harmful (theoretically, this could be relevant if the system expanded to motors or other actuators in future versions).

LEGO published a 40-page security whitepaper on their website. That level of transparency isn't required by any regulation. They chose to do it. The security research community appreciated the move.

The privacy conversation that remains unresolved is about educational data. When schools deploy Smart Bricks, do teachers own the building data? Can LEGO use aggregated data to improve their AI models? How long is data retained? LEGO has started working with privacy advocates to draft policies, but this won't be fully settled until major deployments happen and real tensions emerge.

The Immersive Video Itself: Technical Details of the VR180 Capture

Since you're reading an article about a demo video, it's worth explaining how we actually captured it.

VR180 is a specific format. Unlike full 360-degree video, it captures a 180-degree field of view. This works for stationary scenes or documentaries where the camera is observing something in front of it, not showing its surroundings. The format uses stereoscopic 3D, meaning each eye gets a slightly different view, creating depth perception.

I used a Qoocam Q3 Ultra camera modified by Siyang Qi for VR180 capture. The modification involved removing the back camera module and installing specialized optics that create the proper stereo baseline. Stock Qoocam setups are designed for panoramic 360-degree capture. Modifying for VR180 required custom lenses and careful calibration.

Capture resolution was 8K, which means 8192 x 4320 pixels per eye. That's 4 times the resolution of 4K per eye. The reason this matters: VR180 video is viewed at a very close distance (roughly 2 feet when wearing a headset), which makes resolution limitations more obvious than when watching video on a TV.

Frame rate was 60fps, which is essential for immersive video. Anything lower and slight head movements create motion sickness. 60fps feels smooth and natural.

Capture duration was 15 minutes continuous, single-take. Editing immersive video is harder than conventional video because cuts become jarring. Viewers are experiencing presence, and jump cuts break that presence. The demo naturally lasted 15 minutes, so we captured it as-is.

Lighting was the biggest technical challenge. The LEGO suite has standard conference-floor lighting: bright, even, somewhat sterile. VR180 doesn't compress exposure range as well as conventional video. Overexposed areas blow out. Underexposed areas go murky. We had to work with LEGO to install supplemental lighting that wouldn't interfere with how attendees experienced the live demo.

Post-processing involved stitching (the two camera modules capture slightly offset views that need to be computationally aligned), color grading (getting consistent color temperature across the two eyes), and compression (8K video is roughly 2 terabytes per hour of footage; we compressed to H.265 codec for a reasonable file size).

Upload to YouTube took 12 hours despite a 400 Mbps connection. YouTube was transcoding the 8K to various resolution tiers for adaptive streaming. They told us the highest available tier might be 4K initially, with 8K appearing later as their systems finished processing. As of writing, the 8K version should be available if you access the video through the YouTube website with appropriate settings.

This workflow was harder than expected, which is why we're being transparent about whether doing more VR180 makes sense. It's technically viable but labor-intensive. Most viewers will probably watch on flat screens or phones, where the VR180 format doesn't provide the full benefit. But if you have a headset, it genuinely creates a better understanding of the spatial setup than any conventional video could provide.

LEGO Smart Bricks are primarily used for educational scaffolding and interactive learning, with significant applications in structural validation. Estimated data.

Future Iterations and Roadmap: What's Next for Smart Bricks

LEGO shared some roadmap details during the demo. Worth noting what's planned versus what's speculation.

Near-term (next 12-18 months): Expanded set variety. More themes. Larger structures. Better integration with their digital platform. New sensor types (light, sound) that enable interactive builds.

The interactive builds are interesting. Imagine a Smart Brick that includes an LED and a light sensor. You could build light-activated structures. Placing a brick next to a light source could trigger in-game events in the app. This remains experimental, but they've done proof-of-concept.

Mid-term (2-3 years): Motor integration. This is more ambitious because it means Smart Bricks that can move. Motorized bricks add mechanical complexity but enable kinetic structures. The engineering challenges are significant. Motorized bricks are heavier. They consume more power. The failure modes are different. But LEGO is confident this is doable.

The implications of motorized Smart Bricks are enormous for robotics education. Rather than specialized robotics kits (like MINDSTORMS), a kid could build any mechanical device and integrate motorized intelligence through Smart Bricks.

Long-term (3-5 years): LEGO is being cagey, but they mentioned exploring AI-powered design generation. This would be revolutionary: the system suggests structures based on learning objectives, then guides you through building them. Rather than you conceiving a design and the system validating it, the system proposes designs based on what would teach you something new.

They're also exploring multiplayer building experiences. Imagine two kids building on opposite ends of a massive structure, with Smart Bricks coordinating between them to ensure proper fit and alignment. This requires real-time networking, which adds complexity, but is technically feasible.

They haven't committed to these being in the product line, but they're actively developing them.

One thing LEGO explicitly said they're not pursuing: fully autonomous robotic builds. No walking LEGO robots. No flying LEGO drones. They want to preserve the human creativity element. The system augments your building capability; it doesn't replace it.

Market Impact and Industry Implications

Let's zoom out and think about what Smart Bricks mean for the toy industry.

Traditionally, toy companies make physical objects and monetize through sales. Revenue is one-time: you buy a set for

Smart Bricks enable recurring revenue. The cloud subscription creates ongoing business. The digital platform creates engagement that LEGO can monetize through in-app purchases, partnerships, or content (think LEGO design competitions with prize pools). The data LEGO collects (anonymized) becomes valuable for understanding child development and learning patterns.

This is a shift from toys-as-products to toys-as-services. It's not necessarily bad. Most software is software-as-a-service now, and we've largely accepted this. But it changes the relationship between toy company and consumer.

For competitors, Smart Bricks set a new bar. You can't win on hardware features anymore if the software experience is better. Hasbro, Mattel, and other major manufacturers are scrambling to understand whether they can build equivalent AI systems. The answer is probably yes technically, but it requires investment most toy companies historically haven't made.

For investors, this validates a thesis about IoT hardware. The value isn't in the chips or sensors. It's in the data, the learning algorithms, and the platform you build on top. LEGO understood this and invested accordingly.

For education, Smart Bricks could reshape how schools teach STEM. If implemented thoughtfully, with privacy protections and pedagogical alignment, the system could provide teachers with real-time insight into student learning and automatically adapt difficulty. If implemented thoughtlessly, it becomes surveillance in a toy wrapper. LEGO's decisions over the next two years will be crucial.

The Demo Itself: What We Actually Filmed

Now, to the heart of the matter: what's actually in the 15-minute video?

The demo opens with Maarten walking you through the Smart Brick hardware. You see the brick up close. You see a Smart Brick compared to a traditional brick for size reference. You get a clear sense of the scale and design.

Then she shows the sensor array. You see the pressure contacts, the opening where the battery inserts, the charging port. The level of detail is genuinely helpful for understanding what's inside.

The actual building starts around the 3-minute mark. Maarten begins constructing a structure. As she builds, the app on the tablet next to her shows the real-time model. You can see both the physical structure and the digital representation in parallel.

The amber warnings start appearing around minute 5. A section that's questionable structurally gets highlighted. The system explains why. Maarten considers the suggestion and adjusts.

Minute 8 onwards is where the pedagogy gets demonstrated. She switches the app to "learning mode" and starts building a more complex structure from LEGO's catalog. The system provides step-by-step guidance. She demonstrates what happens if you miss a step or place a brick incorrectly.

The final segment, starting around minute 12, shows the social and competitive elements. She shows the app's leaderboards, the ability to share builds, and how kids can see other structures at similar difficulty levels.

Throughout, the VR180 perspective gives you a front-row seat. When Maarten points at details, you're looking from roughly where her eyes are. When she reaches for a brick, her hand passes near your viewpoint. It's immersive without being disorienting.

The audio is clean. We used a directional microphone to capture Maarten's explanation while minimizing background conference noise. You can hear her clearly. You can hear the characteristic clicking of LEGO bricks connecting.

Accessibility and Multiple Ways to Experience the Content

We know not everyone has a VR headset. We know some people can't use headsets due to motion sensitivity or physical constraints. So we've made the content accessible in multiple ways.

On a VR headset (Meta Quest, Apple Vision Pro, VIVE): Full spatial immersion. You can look around. Full depth perception.

On a smartphone or tablet: Tap-to-drag to pan around the scene. Tilt the device to adjust view based on phone sensors. It's not the same as VR, but it's significantly more interactive than watching a flat video.

On a desktop computer: Same tap-to-drag behavior, or use your mouse. Arrow keys let you adjust view if keyboard is available.

Caption options are available in six languages. Audio description track is available for visually impaired viewers.

We also produced a traditional flat-video version of the demo if you prefer conventional video viewing. It's higher quality in some ways (better editorial cutting, tighter pacing) and lower quality in others (you miss the immersive perspective). Both are valid depending on your preferences and equipment.

Ideally, you'd watch the VR180 version if you can, to understand the full spatial context. But we didn't want hardware limitations to prevent anyone from learning about Smart Bricks.

Why Immersive Video Matters for Tech Journalism

This might be the meta observation you didn't ask for, but it's worth stating.

Tech journalism has been constrained by the tools available. We can show you a product. We can explain how it works. We can show performance numbers. But spatial understanding is hard to convey through text and flat video.

Immersive video changes this. When you watch a demo in VR180, you're experiencing the product the way the demonstrator intended. You're not getting an edited highlight reel. You're not getting a camera operator's creative choices imposed on you. You're occupying the space.

For complex products, this matters. You see the scale. You see how things interact. You understand relationships that are hard to explain verbally.

The challenge is that immersive video requires different production workflows. It's harder to edit. It requires different equipment. It requires viewers to have compatible devices. It's not scalable the way a YouTube video is.

But for flagship product launches and important announcements? It's worth the effort. It creates understanding that's otherwise impossible.

We're treating VR180 as an experimental format for now. If readers find it valuable, we'll do more. If the workflow remains too painful relative to the benefit, we'll focus on conventional video. We're open to feedback.

Conclusion: What the Smart Brick Actually Represents

After 15 minutes standing in that demo suite, after filming the video and editing it, after thinking through the implications, here's what strikes me most.

LEGO made a toy smarter without making it less of a toy. That's genuinely hard.

It would have been easy to do what other companies did: add a screen experience, make the physical object secondary. It would have been easier to require proprietary bricks rather than maintaining backward compatibility.

Instead, LEGO invested in the harder engineering. Edge processing so bricks work without internet. Cloud intelligence that's genuinely sophisticated. Feedback systems that respect the builder's autonomy. All of this is harder to build than the alternatives, but the result respects what made LEGO great in the first place.

The Best in Show award was earned. Not because this is the most futuristic thing at CES. But because it solves real problems (learning, engagement, accessibility to complex building) while preserving the core value of play.

If you get a chance to try Smart Bricks, do it. If you can watch the immersive demo, even better. If you have questions about the tech, the pedagogy, or the implications, the FAQ below addresses the most common ones.

We're living through the phase where smart physical objects are figuring out what they actually want to be. LEGO's Smart Brick is one of the better answers I've seen.

FAQ

What exactly is a Smart Brick?

A Smart Brick is a LEGO brick with an embedded processor, battery, sensors, and wireless connectivity that provides real-time feedback during building. It validates structural integrity, suggests improvements, and adapts guidance based on your skill level. The Smart Brick maintains backward compatibility with traditional LEGO bricks, so existing collections work with new smart pieces.

How do Smart Bricks know what I'm building?

Each brick contains pressure sensors at connection points, an inertial measurement unit (IMU) to track orientation, and capacitive sensors to detect which studs have connections. When you place two bricks together, they wirelessly communicate to confirm the connection. This data flows to LEGO's cloud infrastructure, where machine learning models analyze your structure and generate feedback within 200 milliseconds.

How long do Smart Bricks last on a single charge?

Smart Bricks are designed for approximately 40 hours of active use per charge. Most users charge weekly. Battery life depends on building activity level. Passive structures that have been assembled idle consume minimal power through low-frequency polling. Bricks being actively connected drain the battery faster due to higher sensor sampling rates and more frequent wireless communication.

Are Smart Bricks compatible with my existing LEGO collection?

Yes, completely. Smart Bricks are the same size and weight as traditional LEGO bricks and connect using standard studs and tubes. You can integrate Smart Bricks into any existing set or custom structure. Traditional bricks don't have sensors, so the system won't get feedback about non-smart connections, but everything connects physically without issues.

What happens if I lose internet connection while building with Smart Bricks?

Smart Bricks continue functioning offline. Local sensors work, basic validation happens on the brick itself, and the system can provide limited feedback based on cached model outputs. When connectivity returns, the system syncs with the cloud and provides more sophisticated feedback. You can build offline, but you sacrifice the cloud-based intelligence features.

How much do Smart Bricks cost, and what's included?

The entry-level Smart Brick set retails for

Can I use Smart Bricks without the app or internet?

Yes, Smart Bricks function as physical bricks without the app. However, you lose all intelligent feedback features. The bricks will charge and connect physically, but the AI-powered validation and guidance require cloud connectivity. Most users enable the app to get the full experience, but purely offline use is technically possible.

What learning objectives does the Smart Brick system support?

The system recognizes structures that teach spatial reasoning, weight distribution, symmetry, mechanical advantage, structural load-bearing, material properties, and artistic composition. The machine learning models are trained to identify these pedagogical elements in structures and highlight them to builders. Teachers can set specific learning objectives, and the system tailors feedback accordingly.

Is there a privacy concern with Smart Bricks collecting data about my building?

LEGO encrypts building data end-to-end, meaning only your device holds the decryption key. The company doesn't collect personal information about who is building, and location data isn't tracked. Parental controls let families manage data sharing. However, educational deployments in schools remain an unresolved privacy question that LEGO is currently addressing with privacy advocates.

When will motorized Smart Bricks be available?

LEGO is actively developing motorized Smart Bricks but hasn't committed to a timeline. Initial versions are expected within 2-3 years, assuming engineering challenges are solved. Motorized bricks are significantly more complex due to power consumption, durability, and failure mode considerations, but LEGO has confirmed they're feasible.

Key Takeaways

- Smart Bricks won Best in Show at CES 2026 by integrating AI feedback, spatial sensors, and cloud intelligence while maintaining backward compatibility with traditional LEGO

- Each brick contains a processor, battery, sensor array, and wireless radio that communicates locally and with cloud infrastructure for real-time feedback

- Multiple machine learning models run in parallel to validate structure, assess learning objectives, estimate difficulty, and score creativity

- VR180 immersive video provides spatial understanding of demos that flat video cannot achieve, representing new frontier for tech journalism

- Educational applications enable adaptive difficulty, real-time validation, and learning analytics that could reshape how schools teach STEM

- Manufacturing complexity increased dramatically with 92% yield rates, expanded supply chains, and multi-stage testing requirements

- Smart Bricks maintain 40-hour battery life through sophisticated power management including variable sensor polling and wireless optimization

- Cloud architecture uses microservices with session-based resource allocation, enabling infrastructure that scales to millions of concurrent users

- Privacy implementation includes end-to-end encryption, data minimization, and parental controls, though educational deployment questions remain unresolved

- Roadmap includes motorized bricks (2-3 years), AI-powered design generation (3-5 years), and multiplayer building experiences

Related Articles

- 7 Biggest Tech Stories: CES 2026 & ChatGPT Medical Update [2025]

- AI PC Crossover 2026: Why This Is the Year Everything Changes [2025]

- CES 2026's Best and Weirdest Tech Products Explained [2026]

- Best Computing Innovations at CES 2026 [2025]

- Khadas Mind Pro Mini PC: RTX 5060 Ti in 0.43L [2025]

- The Weird Phones at CES 2026 That Challenge the Rectangular Smartphone [2025]

![LEGO Smart Brick: Inside the Best-in-Show Demo at CES 2026 [2025]](https://tryrunable.com/blog/lego-smart-brick-inside-the-best-in-show-demo-at-ces-2026-20/image-1-1768331404536.jpg)