The Next TV Revolution Nobody's Watching (Yet)

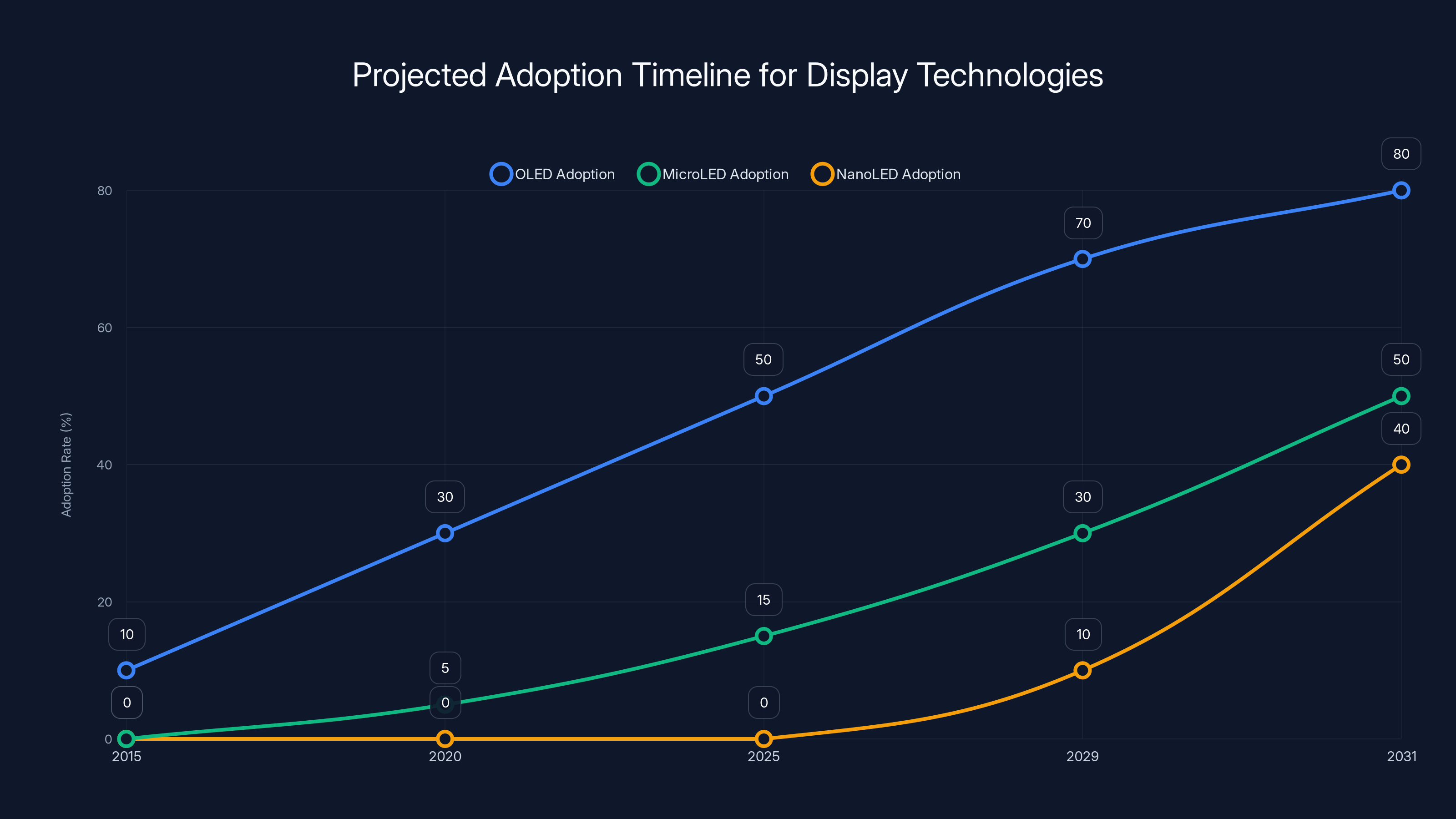

We're living in a strange time for TV technology. OLED has dominated the conversation for nearly a decade, micro LED keeps getting delayed, and now a company that made its name with quantum dots is promising something that sounds straight out of a sci-fi pitch: Nano LED televisions arriving around 2029.

If you're thinking this sounds too good to be true, you're not alone. The TV industry has made bold predictions before. Remember when everyone thought 8K would be mainstream by now? Or when companies promised OLED panels wouldn't suffer from burn-in? Yet here we are, and those problems still exist.

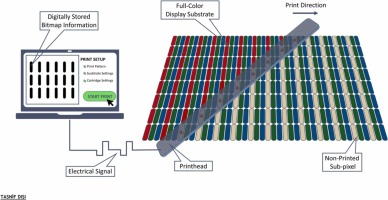

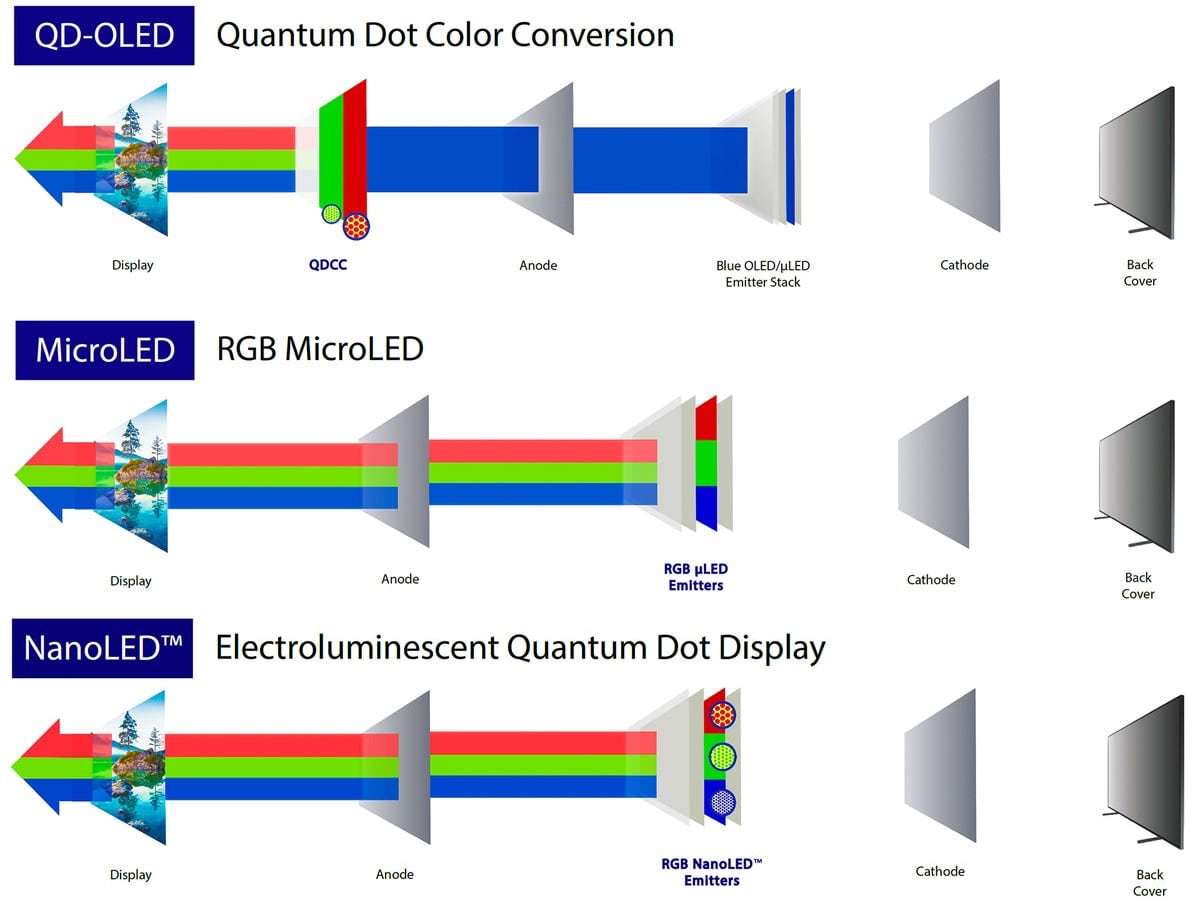

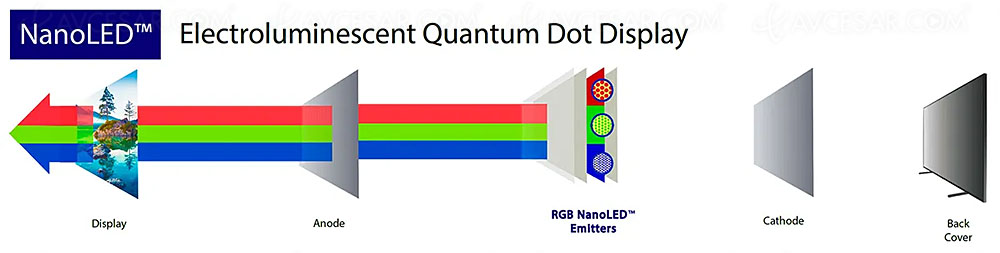

But Nano LED isn't just another vague promise from a marketing department. The technology represents a genuinely different approach to display manufacturing. Instead of the complicated, expensive processes required for OLED or the scaled production challenges of micro LED, Nano LED uses inkjet printing technology to deposit nanometer-scale particles directly onto a substrate. Think of it like printing with invisible ink, except the ink contains billions of quantum dots engineered to emit light at specific wavelengths.

This matters because the display industry is stuck. OLED is incredible for image quality but costs manufacturers a fortune to produce, suffers from degradation over time, and historically struggled with white uniformity. Micro LED promised to fix all these problems but has spent over a decade trying to scale production without cracking the cost problem. Consumers are left buying expensive OLED TVs that work beautifully for five years, then gradually lose brightness and develop color shifts.

Nano LED isn't trying to be better at everything. It's trying to be good enough at most things while fixing the fundamental manufacturing problem that's kept the industry from progressing. That's actually a more interesting story than another incremental improvement.

Let's unpack what this technology actually is, why it matters, and whether the 2029 timeline is realistic or just another industry fantasy.

TL; DR

- Nano LED uses inkjet printing to deposit quantum dots onto displays, potentially reducing manufacturing complexity compared to OLED and micro LED

- 2029 arrival date is aggressive but possible, though previous display tech timelines have consistently slipped by 2-4 years

- Cost advantage could be substantial if production scales, potentially bringing high-quality displays to mainstream price points

- OLED still dominates the current market with unmatched contrast and response times, but aging and cost remain limitations

- Micro LED remains stalled in niche applications, suggesting even ambitious display tech rollouts face real manufacturing barriers

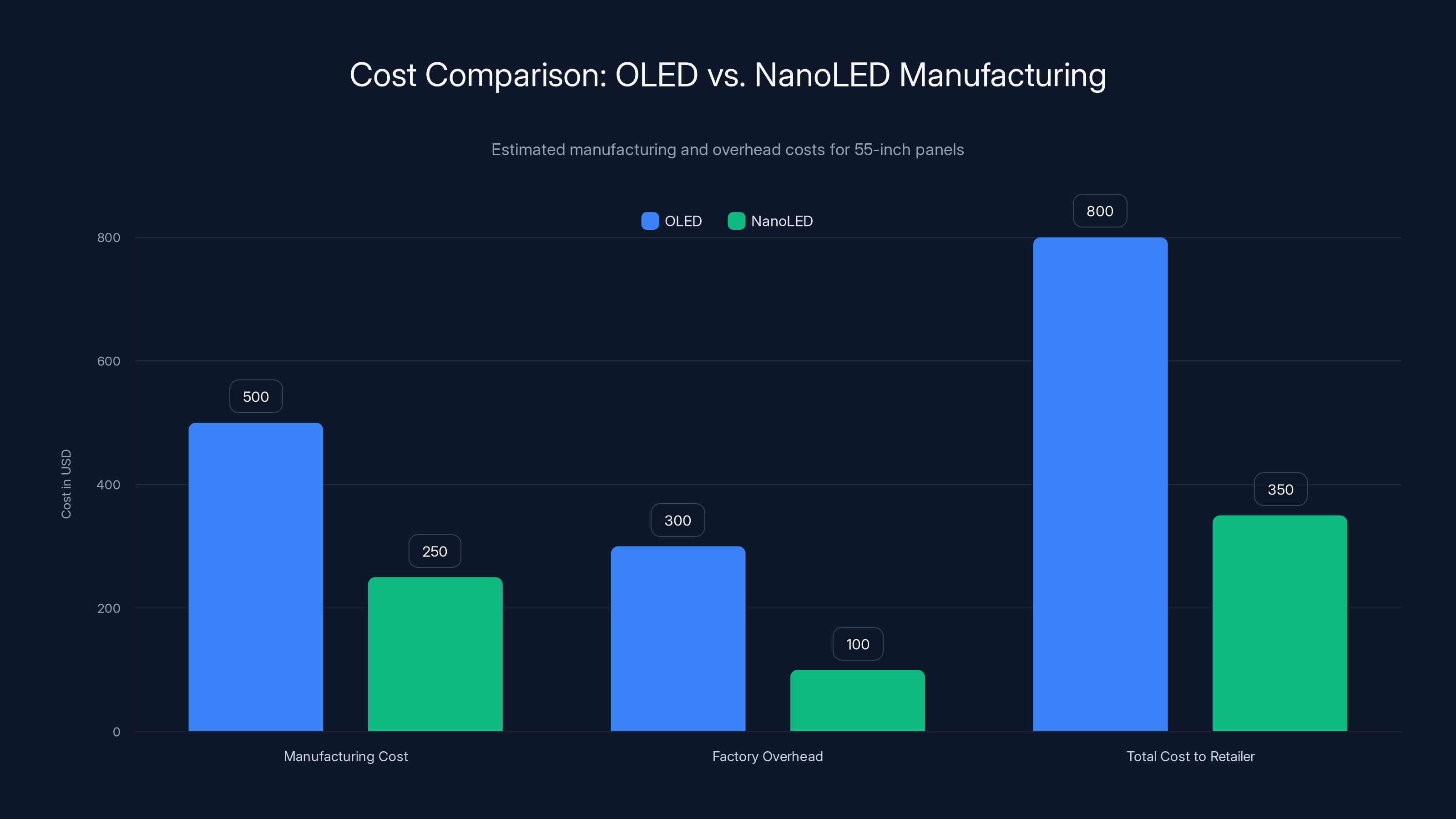

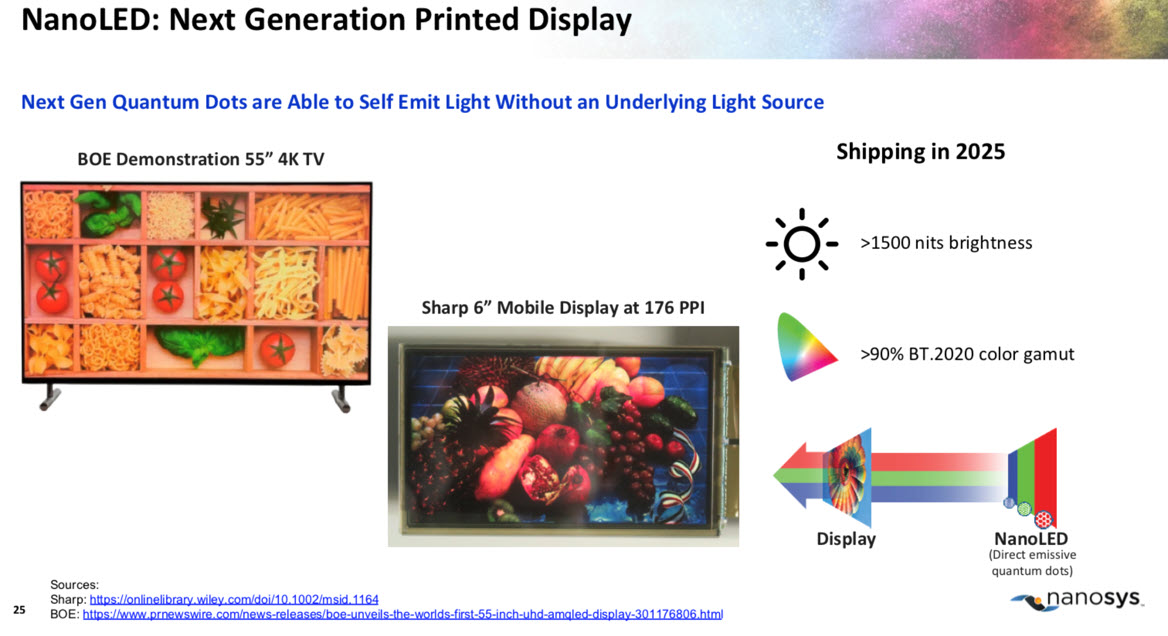

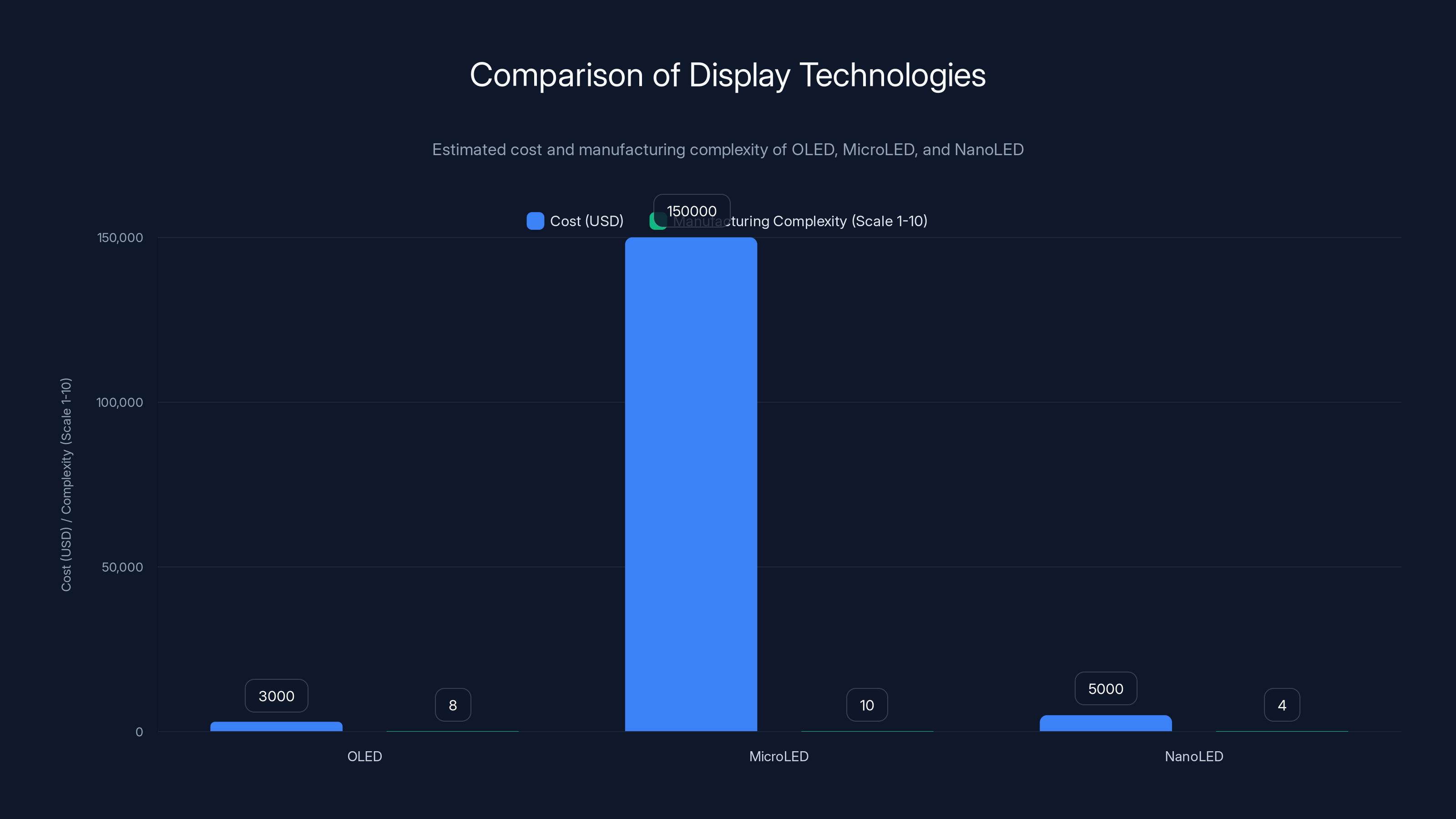

Estimated data shows NanoLED panels could be significantly cheaper to manufacture and sell than OLED panels, with a total cost to retailer of

What Nano LED Actually Is (And Why It's Different)

Before diving into Nano LED, you need to understand what makes current TV technology either brilliant or broken.

OLED works by having each pixel emit its own light. This gives you perfect blacks (because the pixel just turns off), infinite contrast ratios, and incredible color accuracy. Every smartphone flagship, every premium gaming monitor, and most high-end TVs now use OLED. The problem: manufacturing is nightmarish. You're essentially printing millions of tiny lights that need to work independently, and they degrade over time. Making a 55-inch OLED TV panel takes weeks and an enormous amount of raw materials, which is why a premium OLED TV costs

Micro LED took a different approach: tiny LEDs in a grid, each one smaller than a grain of salt. In theory, this solves OLED's degradation problem and offers brighter displays. In practice, manufacturing micro LEDs at scale and assembling billions of them into a grid has proven nearly impossible. Samsung's micro LED TVs exist, but they're specialty products starting at $150,000. That's not a consumer technology yet.

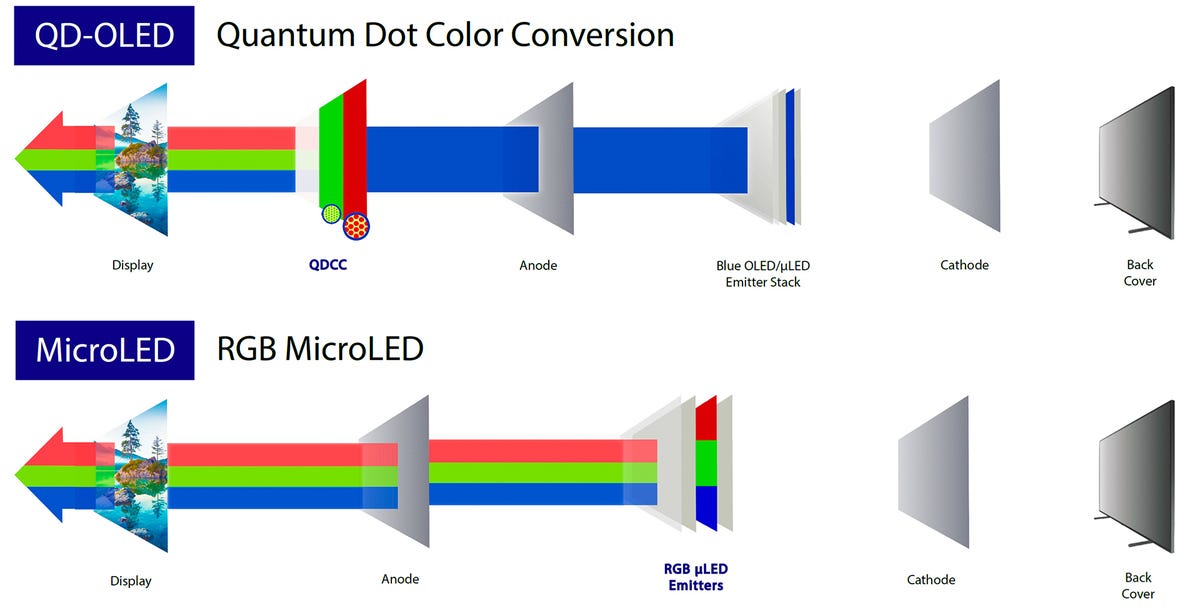

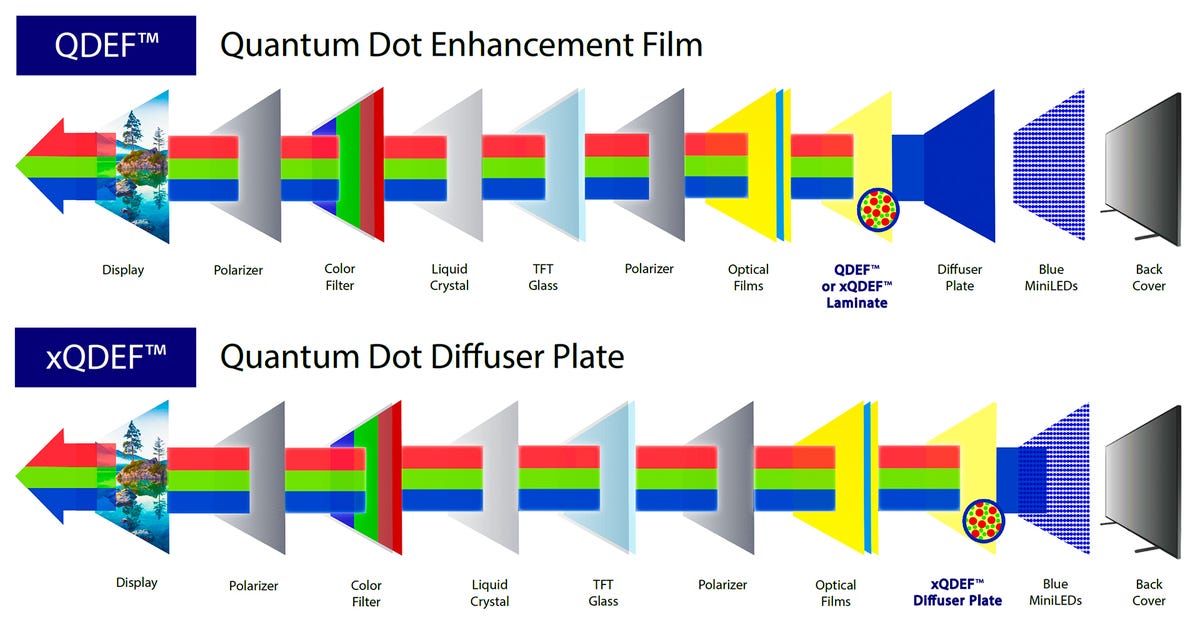

Nano LED sits between these extremes. Here's the core innovation: instead of trying to print or assemble individual light-emitting structures, you use inkjet printing (the same basic technology as your home printer, but with dramatically more precision) to deposit quantum dots onto a substrate. The dots themselves don't emit light. Instead, they're stimulated by a backlight (like an LED array) and emit specific wavelengths. This is similar to how some QLED TVs already work, except Nano LED promises to make the process manufacturable at massive scale and lower cost.

The efficiency gain comes from precision. Current quantum dot displays use a film deposited across the entire panel. Nano LED would deposit dots only where they're needed, in exact concentrations to hit specific color targets. This means less material waste, fewer manufacturing steps, and theoretically, faster production.

Why does this matter? Because the TV industry's biggest bottleneck isn't innovation in image quality. It's manufacturing efficiency. Companies know how to make incredible displays. They can't make them profitably at scale. Nano LED theoretically solves that by replacing complex multi-step fabrication with a process borrowed from consumer printer technology.

The Company Behind the Promise: Quantum Dot Reputation on the Line

When a quantum dot manufacturer announces they're going to revolutionize displays by 2029, your first reaction should be skepticism. But context matters here.

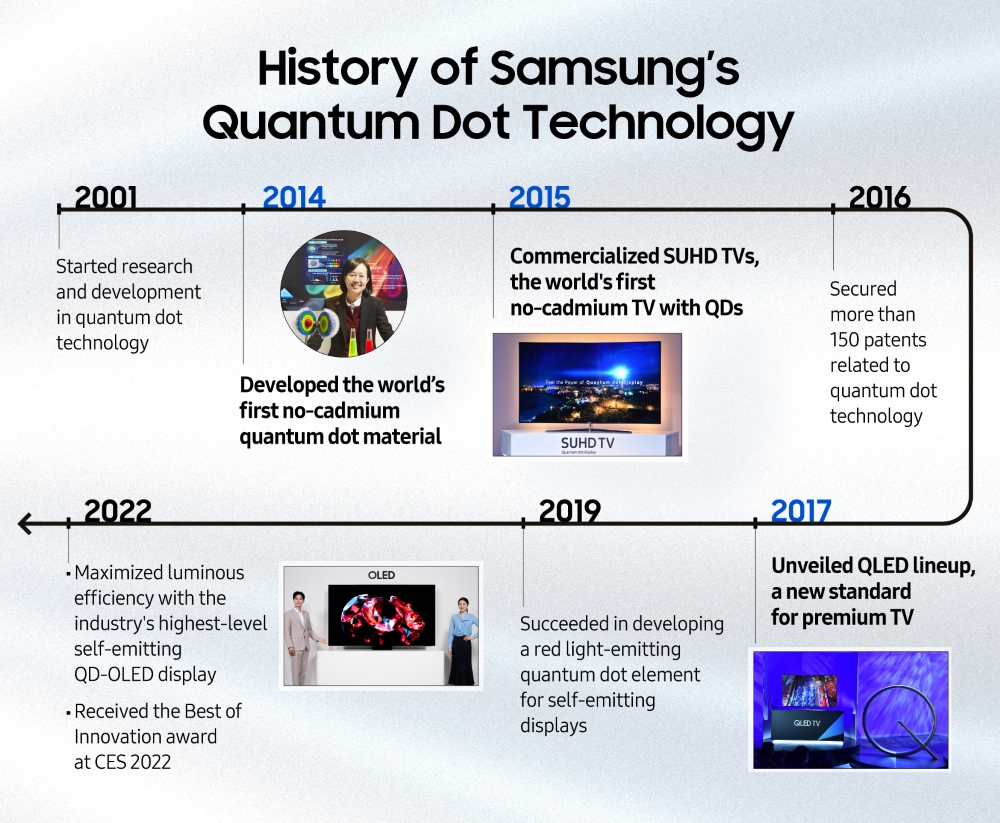

The company making these claims has a track record in quantum dot technology that's actually solid. Quantum dots aren't new. Nanosys pioneered them in the early 2000s. Samsung acquired them and has been steadily improving quantum dot panels for over a decade. Sony, LG, and other manufacturers have all integrated quantum dot technology into QLED and similar product lines.

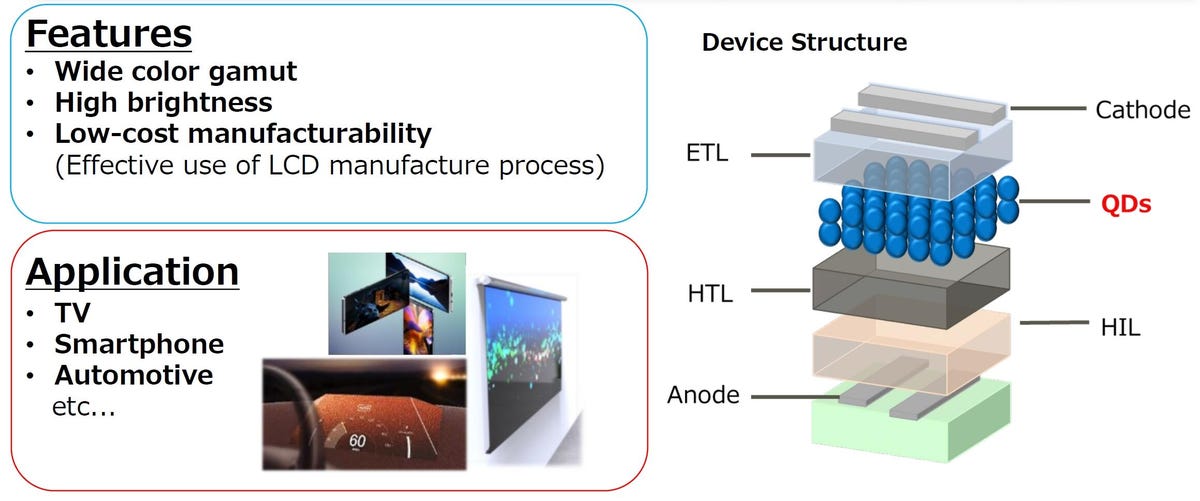

The reason quantum dots work is straightforward chemistry. When you hit a quantum dot with light (typically blue light from an LED), it re-emits light at a specific wavelength determined by its size. Larger dots emit red, smaller dots emit green or blue. By mixing dots of different sizes, you can create any color. The color purity is superior to traditional LCD panels because the re-emission is efficient and pure.

What's being claimed now is that the next evolution uses inkjet deposition to create displays with quantum dots arranged precisely, as opposed to the film-based approach of today. This sounds incremental until you think about manufacturing: inkjet is a well-understood, scalable process. Printers have been getting better at precision for decades. The hardware exists. What's needed is engineering optimization to make it work with quantum dot inks and display layer substrates.

The company behind this has already demonstrated proof-of-concept prototypes. Photos and videos show TVs with the expected improvements in color accuracy and brightness. But there's a massive gap between a prototype that works in a lab and a production line that can make millions of units annually.

Here's the critical question: is this company being optimistic about timelines, or are they being realistic? The 2029 date is roughly four to five years away. That's technically enough time for a major manufacturer to move from prototype to production if everything goes right. But in the display industry, everything rarely goes right.

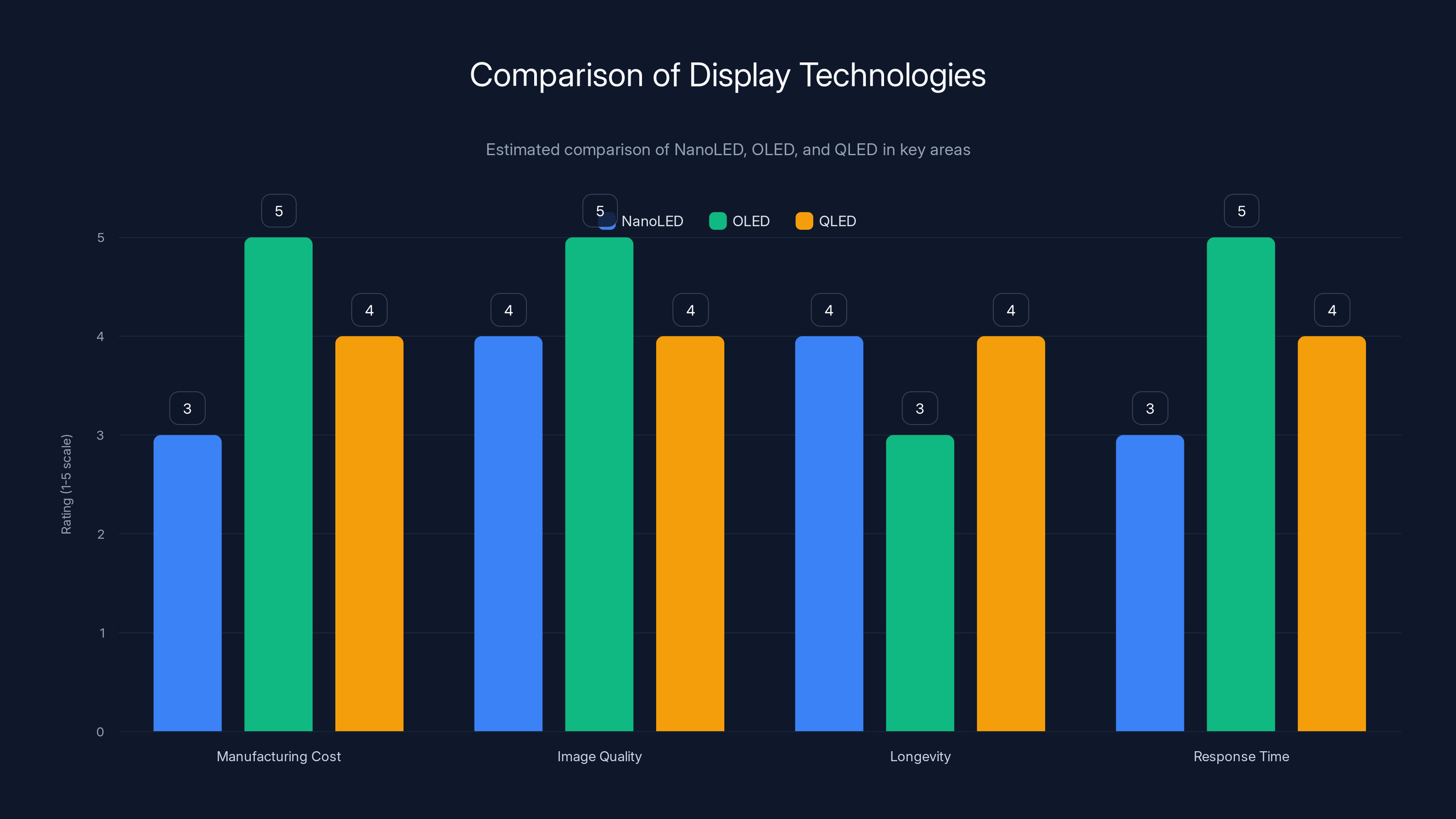

Estimated data suggests NanoLED could offer competitive image quality and longevity at a lower manufacturing cost compared to OLED and QLED.

The Problem With "Coming in 2029"

Let's be blunt: display manufacturers have a terrible track record with timelines.

In 2015, major TV makers predicted OLED would be the mass-market standard by 2020. It hasn't. OLED remains a premium product, with LCD still dominating overall sales. Micro LED was supposed to be here by 2020, then 2023, then 2025. We're now in 2025, and Samsung's micro LED offerings are still specialty products costing six figures.

Why do these timelines slip? Manufacturing scale is brutally difficult. A technology can work perfectly in a laboratory and still fail to scale because:

- Material costs increase when you move from lab quantities to industrial volumes. Suppliers have limited capacity.

- Yield rates are catastrophic initially. You might get 10% of panels working perfectly at first, which makes production economically impossible.

- Equipment doesn't exist yet, and building new manufacturing lines costs billions. No company is willing to invest that much until demand is proven.

- Supply chain dependencies create bottlenecks. One component supplier failing can delay an entire product launch.

- Engineering problems emerge at scale that weren't visible in prototypes. Inkjet deposition sounds simple, but printing trillions of quantum dots precisely, consistently, across panels the size of a TV screen? That's genuinely hard.

Nano LED faces all of these challenges. The company is probably being somewhat optimistic about timing. A more realistic expectation might be 2030 or 2031 before mass-market availability, with early adopter products in 2029 at premium prices.

But the bigger question isn't whether 2029 is achievable. It's whether Nano LED will have a market once it arrives.

Why OLED Still Dominates (And Why That Might Not Last)

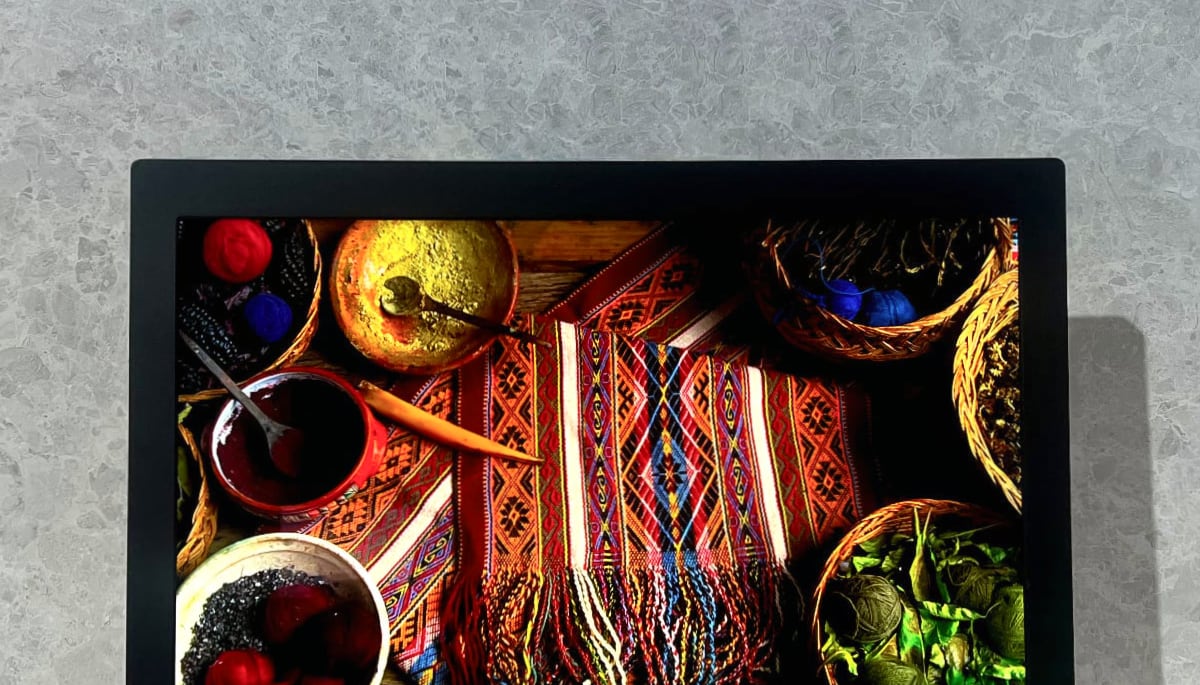

OLED's dominance isn't an accident. It's legitimately the best display technology available today for most consumers.

OLED delivers perfect blacks. When you turn off a pixel, it emits zero light. There's no backlight creating glow. This creates contrast ratios that are technically infinite—the ratio between the brightest and darkest pixels on screen. For watching movies, playing games, or any content with dark scenes, OLED is unbeatable.

Response time is also incredible. OLED pixels change instantly. This is why every gaming monitor worth buying uses OLED now. LCD panels, even with quantum dots, have ghosting—the tail of motion blur—because the backlight is always on and the liquid crystal layer takes time to respond.

Color accuracy is excellent because each pixel can be controlled independently. There's no color shift, no uniformity issues (except where OLED's own manufacturing challenges create them).

So why would anyone want Nano LED instead?

The honest answer: they probably won't, unless Nano LED offers something OLED can't. That something is cost and longevity. An OLED TV costs

Longevity is another factor. OLED panels degrade. Brightness drops over time. Blue subpixels fade faster than red or green. After five years, an OLED TV is noticeably dimmer and less color-accurate than when it was new. Some manufacturers have improved this with OLED panels specifically designed for TVs (LG's OLED. EX line, for example), but degradation is still present.

Quantum dots, by contrast, don't degrade significantly over time. They're passive structures. As long as the backlight remains functional, the color accuracy and brightness should stay stable for the entire lifespan of the TV.

This is the real value proposition: an OLED-like experience at LCD prices and with better longevity. If Nano LED can deliver that, it becomes genuinely disruptive.

The catch: current Nano LED prototypes still use a backlight. That means no true blacks (the backlight creates some glow). Contrast won't match OLED. Response time might not either. Nano LED isn't trying to beat OLED at everything. It's trying to reach 95% of OLED's image quality at 60% of the cost.

For most people, that trade-off is worth it.

Micro LED: A Cautionary Tale of Ambitious Timelines

If you want to understand why skepticism about 2029 is justified, look at micro LED.

Micro LED was supposed to be revolutionary. Tiny LEDs, each one an independent light source, eliminating the need for a backlight entirely. In theory, you get OLED's infinite contrast with LED reliability. Color saturation and brightness would exceed both OLED and quantum dots. Manufacturers have been talking about micro LED for over a decade.

Samsung announced micro LED TVs in 2017. The company said mass-market production would follow within a few years. In 2024, Samsung's micro LED display is called "The Wall" and costs

Why has micro LED been so hard to scale? The fundamental problem is assembly. A 55-inch micro LED panel needs roughly 23.5 million individual LEDs (at about 78 pixels per inch). Assembling 23.5 million components precisely, soldering each one's electrical connections, and testing everything is enormously complex. The industry has tried various automation approaches, but yield rates remain low.

Micro LED also faces brightness degradation, despite the theoretical advantage over OLED. LEDs don't last forever. They dim over time. This means every micro LED display is on a slow countdown to reduced brightness.

The micro LED experience teaches us: ambitious display technologies take longer than expected, cost more than projected, and often face unexpected technical hurdles. Nano LED likely faces similar challenges. The inkjet manufacturing process might solve the assembly problem that killed micro LED scaling, but it will create new problems we don't anticipate yet.

A realistic timeline for Nano LED is probably: 2028-2029 for early prototypes in specialty markets, 2030-2032 for meaningful consumer availability, and 2035+ before it's a standard, mainstream technology.

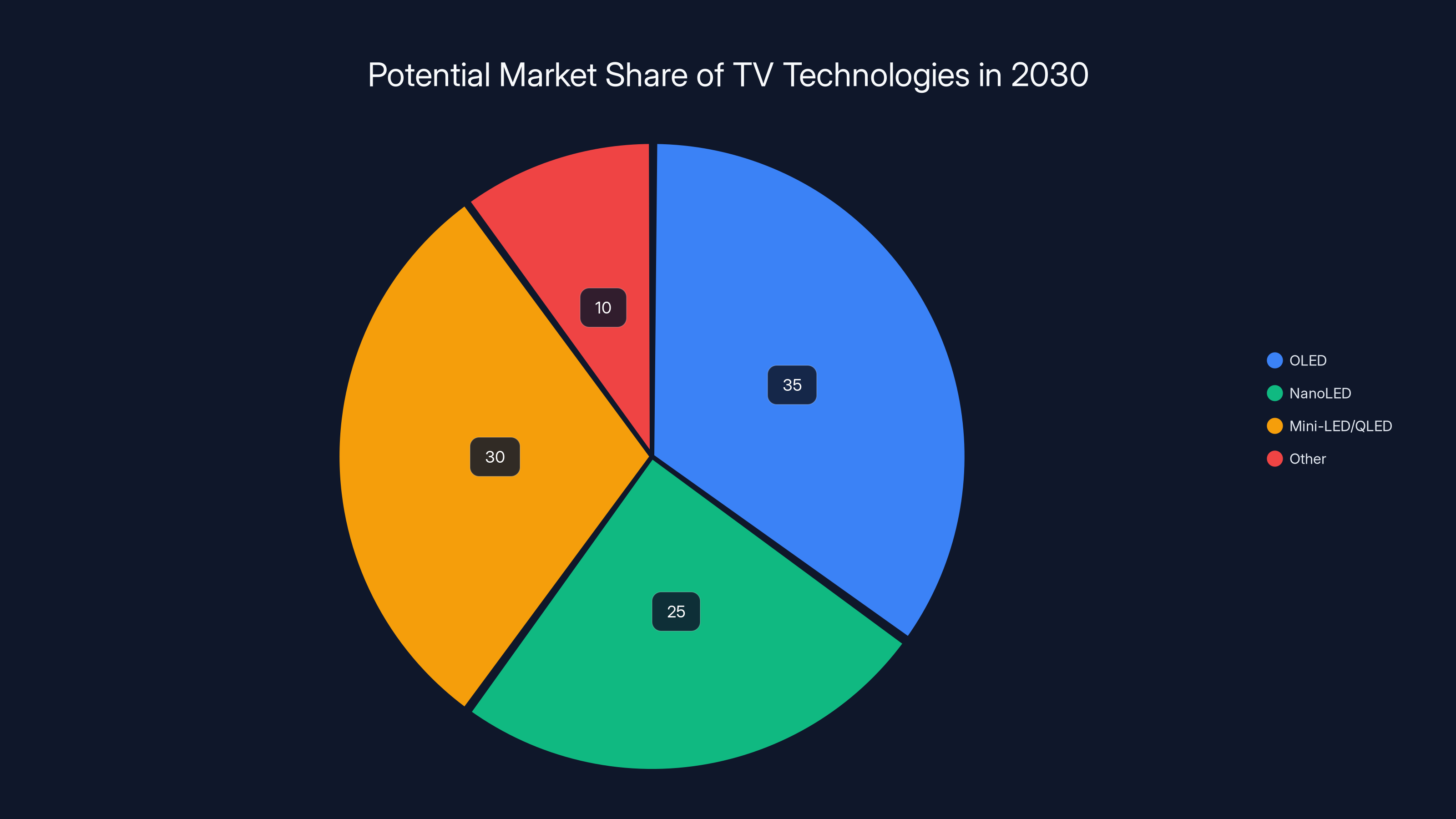

Estimated data suggests NanoLED could capture 25% of the market by 2030 if it offers a significant price advantage and competitive quality. OLED is expected to maintain dominance in the premium segment.

Inkjet Printing: Why It's the Key to Everything

The most interesting part of Nano LED isn't the quantum dots. It's the manufacturing process.

Inkjet printing has been improving for decades. Commercial inkjet printers can now deposit material with micron-level precision. This technology has already found applications in printed electronics, flexible displays, and functional materials. Companies like Kateeva have been developing inkjet-printed OLED panels for years.

Why is inkjet appealing for displays? Speed, primarily. An inkjet system can deposit material across a large area quickly, without the need for masks, exposure, or complex mechanical alignment. Current quantum dot display manufacturing involves depositing a film, then using photolithography or other techniques to pattern it. That's multiple steps, each adding time and cost.

Inkjet simplifies this to essentially one step: spray the quantum dots where you want them, let them dry, done. If the system can be optimized for TVs, production speed could be dramatically higher than OLED or micro LED manufacturing.

The engineering challenges are real, though. Quantum dot inks need to be formulated correctly so they deposit evenly and don't clog the inkjet heads. The substrate needs to be compatible with the process. The heating and drying steps need to be controlled precisely to avoid defects. Environmental factors like humidity matter significantly.

But none of these problems are unsolved. They're engineering challenges, not physics-breaking issues. Companies have inkjet-printed quantum dots before in lab settings. The question is whether they can do it reliably at production scale.

This is why the 2029 timeline isn't completely crazy. Inkjet technology already exists and works. The barriers are engineering and scale, not invention. A well-funded company with existing expertise in both quantum dots and manufacturing could plausibly reach consumer products within four to five years.

Is it likely? Probably not. But it's possible in a way that micro LED was never really possible with assembly-line approaches.

The Cost Advantage: Where Nano LED Actually Wins

Let's talk numbers, even though they're estimates.

Manufacturing a 55-inch OLED panel currently costs somewhere between

Quantum dot displays (like QLED) cost significantly less to manufacture. A 55-inch QLED panel runs roughly

Nano LED, theoretically, could split the difference. Inkjet-printed quantum dots might cost

Factory overhead includes rent, equipment depreciation, salaries, and utilities. If you can push twice as many panels through the same facility, those costs per unit are cut in half. That alone could be the game-changer.

Let's model this roughly. Assume:

- OLED manufacturing cost: $500

- OLED factory overhead per unit: $300

- Total OLED cost to retailer: $800

Nano LED, with lower material cost and higher throughput:

- Nano LED manufacturing cost: $250

- Nano LED factory overhead per unit: $100 (due to higher production speed)

- Total Nano LED cost to retailer: $350

Retailers typically mark up displays 150-200%. So an OLED TV might retail for

Now, these are rough estimates. Real costs depend on many factors: materials pricing, energy costs, labor, yield rates, and competition. But the directional advantage is clear. Nano LED could be significantly cheaper to make than OLED, which is why manufacturers are interested.

For consumers, this means: if Nano LED delivers 90% of OLED's image quality at 50% of the price, it becomes a very attractive option. Especially if it offers better longevity and no burn-in risk.

Inkjet OLED: The Technology That Never Happened

Before we get too excited about inkjet quantum dots, remember inkjet OLED.

Several companies, including Samsung Display and LG, invested heavily in inkjet-printed OLED technology. The promise was similar: use inkjet printing to manufacture OLED displays faster and cheaper than evaporation-based methods. Companies like Kateeva built entire businesses around this idea.

What happened? Inkjet OLED progressed slower than expected, faced technical barriers that proved harder to overcome than anticipated, and never reached commercial production for consumer products. Samsung Display eventually shifted focus. Kateeva pivoted to other applications.

Why did inkjet OLED fail to scale while inkjet quantum dots might succeed? Several reasons:

- OLED organic materials are more sensitive. They degrade more easily, are more susceptible to defects, and require more precise processing. Quantum dots are inorganic and more robust.

- Yield requirements are stricter for OLED. You need near-perfect pixels because any defect creates a visible flaw. Quantum dots have more tolerance for minor imperfections.

- The economics of inkjet OLED were unclear. Companies couldn't prove the cost savings would justify the R&D investment.

These factors could apply to inkjet quantum dots too. The technology might hit similar scaling walls. But quantum dots' inherent robustness gives them a better chance.

This is a crucial lesson: the fact that inkjet OLED didn't work doesn't mean inkjet quantum dots won't. But it does suggest that ambitious manufacturing approaches face real barriers.

Estimated data shows OLED adoption increasing steadily, while MicroLED and NanoLED lag behind due to manufacturing challenges. NanoLED is projected to start gaining traction around 2029.

OLED Burn-In and Longevity: Still Unsolved

If you own an OLED TV or phone, you probably worry about burn-in. The concern is legitimate.

OLED pixels degrade over time as the organic materials in the emissive layer break down. If you display the same image for extended periods (like a TV news logo), those pixels degrade faster than surrounding pixels, creating a permanent ghost image. This is especially problematic if you use your OLED TV as a computer monitor or watch a lot of content with static UI elements.

Manufacturers have added mitigations: pixel shifting (moving the image slightly), screen savers, reduced brightness limits, and improved materials. But burn-in hasn't been eliminated. It's been reduced and managed, not solved.

Longer-term, OLED panels simply get dimmer. After 2-3 years of moderate use, brightness drops noticeably. After 5-10 years, an OLED TV is significantly dimmer than when new. Some sources suggest OLED TVs lose 30% of their brightness by 10,000 hours of use.

Quantum dot displays don't suffer these problems because the dots aren't organic. They're inorganic semiconductor particles. They don't degrade from electroluminescence. They're passive structures that simply re-emit light from a backlight. As long as the backlight lasts, the quantum dots continue to work identically.

This is an enormous advantage for longevity. A quantum dot display in your house could work perfectly for 15-20 years. An OLED display of the same age would be noticeably degraded.

For people who keep TVs for a decade or longer, Nano LED's longevity advantage could be the deciding factor. It's not flashier than OLED, but it's more practical.

The Quantum Dot Pipeline: What Else Is Coming

Nano LED isn't the only quantum dot advancement in development.

Companies are working on display-emissive quantum dots (where the dots themselves emit light, like OLED) and higher brightness quantum dot displays. There's also research into perovskite quantum dots, which offer different properties than cadmium-based dots.

The quantum dot industry is expanding beyond displays into LED lighting, sensors, and biomedical applications. Companies are investing because quantum dots are genuinely useful materials with many potential applications.

This broader investment ecosystem means quantum dot manufacturing expertise is improving industry-wide. Techniques developed for one application benefit others. Manufacturing costs are declining. Material quality is improving. All of this creates a tailwind for Nano LED specifically.

If Nano LED faces adoption challenges, quantum dots won't disappear from displays. They'll continue improving in current QLED and similar product lines. Manufacturers have already proven they can make money selling quantum dot displays at current price points. Nano LED is just the next step, not the only path forward.

This reduces risk somewhat. Even if Nano LED timelines slip to 2030 or 2031, the quantum dot technology platform continues advancing. There's no downside for the industry if Nano LED takes longer than expected.

Competing Display Technologies: The Landscape in 2025

Let's contextualize where we are right now.

OLED dominates the premium market. Every flagship smartphone uses OLED. Most gaming monitors are OLED now. High-end TVs are increasingly OLED. The technology is proven, manufacturers have optimized production, and consumers value the image quality. Cost is the main limitation.

QLED and quantum dot displays are everywhere in the midrange. These offer better brightness than traditional LCD while maintaining color accuracy. They're more affordable than OLED and more durable. They lack OLED's contrast and response speed, but they're genuinely good for most use cases.

Micro LED remains a niche product in specialty applications. Samsung is the only company bringing micro LED displays to market at scale (for commercial use). Consumer micro LED TVs don't exist yet.

Mini-LED is the current compromise. It's essentially an LCD with thousands of individually controlled LED backlights instead of a monolithic backlight. This offers much better contrast than standard LCD while remaining cheaper and more manufacturable than OLED or micro LED. LG and others have mini-LED TVs, and the segment is growing.

LCD with quantum dots (QLED, ULED, etc.) remains the most cost-effective option for good image quality.

Where does Nano LED fit? Theoretically, above mini-LED but below OLED in price, while offering image quality closer to OLED than to mini-LED. It would be the new sweet spot in the market.

Will that sweet spot exist in 2029? Probably. But the market evolves fast. By 2029, we might have seen dramatic OLED cost reductions. Mini-LED might be mature and cheaper. Micro LED could finally scale (unlikely but possible). The competitive landscape could shift significantly.

OLED excels in contrast ratio and response time, but NanoLED could offer a balance of quality and cost if it scales successfully. Estimated data based on current technology trends.

The Materials Challenge: Are Quantum Dot Inks Ready?

One underappreciated challenge for Nano LED is the ink itself.

Quantum dots are manufactured as powder, nanocrystals, or colloidal solutions. For inkjet printing, you need to formulate them as an ink that:

- Flows through an inkjet nozzle without clogging

- Deposits uniformly on the substrate

- Dries or cures at controlled rates

- Doesn't aggregate or settle

- Maintains quantum efficiency after deposition

This is non-trivial chemistry. The ink needs to be carefully formulated with solvents, binders, and additives that don't interfere with the quantum dots' optical properties. Too much binder, and you lose efficiency. Too little, and the dots don't adhere to the substrate.

Companies have made progress. Several research groups have published papers on inkjet-compatible quantum dot inks. But moving from research publications to production-grade inks that can be manufactured consistently at scale is another challenge entirely.

There's also the question of which quantum dots work best for inkjet printing. Most quantum dot displays today use cadmium selenide (Cd Se) dots, which are efficient but involve cadmium (a heavy metal, though in trace quantities). For mass production, companies might prefer cadmium-free alternatives like indium phosphide (In P), but In P dots are less mature and less efficient.

All of these material challenges are solvable, but they require real R&D effort and time. It's the kind of thing that easily adds 12-24 months to a product timeline when unexpected issues emerge.

Color Science: Why Precision Matters

Here's something most people don't think about: quantum dot displays need precise color control to compete with OLED.

In a quantum dot display, the color you see depends on:

- The size and composition of the quantum dots

- The concentration of dots in each pixel region

- The brightness of the backlight

- The color filters, if any

With inkjet printing, you can control concentration precisely. You can deposit exactly the right number of quantum dots in each pixel region to hit specific color targets. This is actually an advantage over film-based quantum dot deposition, where the concentration is uniform across the entire display.

But it's also a precision challenge. If your inkjet system deposits slightly different amounts in adjacent pixels, you get color banding or uniformity issues. The dots need to land in precise positions, in the right quantities, consistently.

This is where manufacturing maturity matters. A company with expertise in inkjet printing and color science can make this work. A company trying to do it for the first time will struggle.

The company behind Nano LED likely has that expertise (given their quantum dot background), but executing at scale is different from understanding the theory.

The Market Readiness Question: Will Anyone Buy?

Let's assume Nano LED arrives in 2029 as promised. Will anyone buy it?

The answer depends on several factors:

- Price advantage. Does it cost meaningfully less than OLED? If the price gap is under 20%, people will just buy OLED for superior image quality. The gap needs to be substantial (30-40% or more) to matter.

- Image quality. Does it look good enough? Most consumers don't notice the difference between very good and perfect. If Nano LED looks almost as good as OLED, the price advantage wins.

- OLED cost reduction. By 2029, OLED manufacturing might be cheaper than we expect. If OLED TVs are under $1,000, Nano LED's advantage disappears.

- Tech fatigue. Consumers are tired of new display technologies. They want something that works and lasts. If Nano LED is proven reliable, that story is compelling.

- Environmental considerations. Quantum dots are less problematic than OLED for some environmental metrics. If this becomes a marketing angle, it could matter.

My bet: Nano LED succeeds in the midrange market (50-60 inch TVs, $1,000-1,500 price range) if it can undercut OLED by 30% or more and deliver competitive image quality. In the premium segment, OLED keeps dominance. In the budget segment, mini-LED or QLED remains competitive.

Nano LED becomes "that technology that's really good and popular in the 2030s" but doesn't revolutionize the industry. It's incremental progress, not revolutionary change.

Which is fine. Revolutionary changes are rare. Incremental progress is how industries evolve.

NanoLED offers a balance between cost and manufacturing complexity, making it a promising technology for future consumer displays. Estimated data.

Investment and Manufacturer Support: Who Needs to Believe?

For Nano LED to reach market, it needs support from major TV manufacturers.

The company developing Nano LED can build the technology, but they can't manufacture it at scale alone. They need Samsung, LG, Sony, or TCL to license the technology and build production lines. These companies won't do that unless they believe the business case is solid.

What needs to happen:

- Successful prototype demonstration. The company needs to show working displays that meet retail standards.

- Cost modeling. Manufacturers need to understand the economics and believe the cost advantage is real.

- Supply chain validation. Ink suppliers, substrate manufacturers, and component suppliers need to confirm they can support production at scale.

- Regulatory pathway. Any new display technology needs to clear environmental and safety regulations, especially around materials.

- Market demand signals. Retailers and consumers need to show interest in the price/performance proposition.

All of this is achievable, but it requires the company to execute beyond just inventing the technology. Many display innovations fail not because the technology doesn't work, but because manufacturers don't see sufficient market demand to justify tooling up new production lines.

The positive signal here is that the company is publicly discussing Nano LED with a specific timeline. This suggests they've already had conversations with potential manufacturing partners. You don't announce 2029 timelines without some confidence that major manufacturers are interested.

But interest and commitment are different. A manufacturer might express interest in 2025 and decide in 2027 that they'd rather stick with OLED because it's proven and costs have come down. These decisions are made strategically, not just technologically.

Looking Beyond 2029: The Long-Term Display Roadmap

Whether Nano LED arrives on schedule or not, the display industry is clearly heading toward higher efficiency and lower costs.

Emerging technologies to watch:

Microplasmonics - Using nanoscale metal structures to control light emission. This could improve quantum dot efficiency significantly.

Perovskite displays - Perovskites are a class of materials that might enable more efficient light emission than quantum dots or OLEDs. Several companies are investing. Timelines are probably 2030+.

Holographic displays - This is longer-term (2035+), but research is advancing. True holographic displays would eliminate the need for traditional screen technology entirely.

Quantum well displays - These use engineered semiconductor heterostructures to emit light. Similar concept to quantum dots but using engineered layers instead of particles.

The display industry isn't sitting still. There's a genuine innovation pipeline. Nano LED is one arrow in that quiver, but not the only one.

What this means: the display technology landscape in 2029 will be more diverse than 2025. OLED will still be around, but probably cheaper. Micro LED might finally be in consumer products. Nano LED could be launching. Mini-LED will still be popular in the midrange. New technologies might be emerging. It's a competitive landscape with multiple viable options.

The Realism Check: Are We Falling for Marketing?

Let's be honest: this entire Nano LED announcement could be smart marketing disguised as technology news.

A quantum dot company announces a revolutionary new technology with a specific timeline and bold claims. This generates press coverage, attracts investment interest, and gets potential manufacturing partners to pay attention. Whether the technology actually works at scale is almost secondary to the narrative.

This isn't cynical. It's how the technology industry works. Marketing and R&D are intertwined. A smart company uses announcements strategically to influence market perception and business development.

Should you be skeptical? Absolutely. A 2029 timeline should be read as "optimistically, 2029; realistically, 2031-2032; possibly later." Bold performance claims should be tested independently before believing them. Manufacturing timelines from any company should be discounted by 20-30%.

But should you dismiss it entirely? No. The underlying technology (quantum dots, inkjet printing) is real. The engineering challenges are real but solvable. The market opportunity is real. A 2029-2031 launch is plausible, even if not certain.

Take it as a signal about where the industry is heading, not a guarantee about what's coming. Quantum dot displays are improving. Manufacturing is getting better. Within a few years, you'll probably have better display options at better prices. Nano LED might be part of that story, or it might be a footnote. Either way, the trajectory is positive.

What This Means for Your Next TV Purchase

If you're thinking about buying a TV in the next couple of years, Nano LED shouldn't factor into your decision.

Buy what's available now: OLED if you want the best image quality and can afford $2,000+, mini-LED if you want good quality at a reasonable price, or QLED if you want a dependable workhorse display. All of these technologies are mature, proven, and will work excellently for 5-7 years or longer.

Waiting for Nano LED is a mistake. You lose years of enjoyment from a good display for a technology that might not arrive on schedule and might not be better for your specific use case anyway.

If you're planning a TV purchase for 2028-2029, then start paying attention to Nano LED developments. By then, you'll have real information about whether the technology is scaling as promised. You can make an informed decision between Nano LED, mature OLED, whatever micro LED has become, and other options that will exist then.

The key takeaway: the display market is evolving, and you'll have better options in the future. But waiting indefinitely for perfect is the enemy of good. Buy the best technology that exists today, and upgrade when something meaningfully better arrives.

FAQ

What exactly is Nano LED technology?

Nano LED is a display technology that uses inkjet printing to deposit quantum dots (nanometer-scale semiconductor particles) onto a substrate. When stimulated by a backlight, these dots emit specific colors of light. Unlike OLED, Nano LED retains a backlight but potentially offers lower manufacturing costs and better longevity than OLED displays.

How does Nano LED differ from QLED and current quantum dot displays?

Qualitatively, both use quantum dots for color generation. The key difference is manufacturing: current QLED TVs use a blanket quantum dot film across the entire panel, while Nano LED uses inkjet printing to deposit dots precisely where needed. This precision could reduce waste, speed manufacturing, and lower costs. Quantitatively, the image quality and functionality should be similar until manufacturers optimize Nano LED-specific designs.

Why is 2029 considered an aggressive timeline?

Display technology has a poor track record with timelines. OLED was supposed to be mainstream by 2020 (it's still premium). Micro LED has missed targets repeatedly and hasn't reached consumers yet. Scaling new manufacturing processes from prototype to mass production typically takes 3-5 years longer than companies estimate. 2029 is possible but 2031-2032 is more realistic.

How does Nano LED compare to OLED in image quality?

OLED has advantages in contrast (perfect blacks, infinite contrast ratio) and response time (instant pixel switching) because each pixel emits its own light. Nano LED uses a backlight, so blacks aren't pure black and response time is slightly slower. However, optimized Nano LED could deliver 90-95% of OLED's visual quality at significantly lower cost, which might be the better trade-off for most consumers.

Could Nano LED actually be cheaper than OLED and QLED?

Yes, potentially. OLED manufacturing requires vacuum chambers and complex vapor deposition equipment. Nano LED uses inkjet printing, which is faster and simpler. Cost estimates suggest Nano LED manufacturing could be

What's preventing Nano LED from launching sooner?

Several barriers exist: quantum dot ink formulation (needs to flow through inkjet nozzles without clogging), manufacturing precision (dots must land in exact positions consistently), yield rate optimization (starting production typically has 70-80% yield, which is economically unviable), supply chain development (inks and specialized substrates need suppliers), and regulatory approval (new materials and processes need testing and certification).

Why didn't inkjet OLED succeed if inkjet quantum dots have the same promise?

Organic materials in OLED are sensitive to defects and degradation. Quantum dots are inorganic and more robust, giving them better tolerance for imperfections. OLED also has stricter yield requirements because any defect is visible. The economics of inkjet OLED never justified the R&D cost, while quantum dots might because they're less sensitive.

Will OLED still be dominant when Nano LED arrives?

Likely yes, but in a smaller market segment. By 2029, OLED manufacturing will probably be more efficient and cheaper. OLED will remain the premium choice for people who value perfect contrast and response time. Nano LED would target the midrange market with a price-to-quality sweet spot that OLED can't match at lower prices. Both technologies can coexist and be profitable.

Should I wait for Nano LED before buying a TV?

No. The technology is 4+ years away, timelines often slip, and waiting for future tech costs you years of enjoyment with current displays. OLED, mini-LED, and QLED TVs available now are excellent and will serve you well for 5-7 years. If you're shopping in 2028-2029, then evaluate Nano LED options alongside what's available then. Don't let hypothetical future products dictate today's purchasing decisions.

What are the environmental advantages of quantum dot displays?

Quantum dots are inorganic semiconductors, so they don't suffer from organic degradation like OLED. This means longer display lifespan before noticeable brightness loss. Longer-lasting displays mean fewer replacements, less e-waste, and lower environmental impact over time. However, quantum dot manufacturing and sourcing have their own environmental considerations, so the net benefit depends on full lifecycle analysis.

Final Thoughts

Nano LED represents the display industry's ongoing evolution. It's not revolutionary in the way OLED was (OLED fundamentally changed what's possible in image quality). It's evolutionary, offering an incremental step forward in cost-efficiency and manufacturability while maintaining display quality that's very close to OLED.

Will it arrive in 2029? Probably not on the first attempt, but 2030-2032 is realistic. Will it become a mainstream technology? Likely, if manufacturing scales and costs play out as theorized. Will it replace OLED? No, but it might capture the midrange market that's currently split between OLED, mini-LED, and QLED.

What matters most isn't whether Nano LED succeeds exactly as promised. It's that the display industry has multiple promising technologies in development, competition is driving down costs, and consumers will have better options at better prices within a few years. That's good news regardless of which specific technology wins.

For now, buy the best display available today. Pay attention to Nano LED developments when we get closer to 2029. And enjoy knowing that display technology is genuinely improving, even if the timelines are always optimistic.

Key Takeaways

- NanoLED uses inkjet printing to deposit quantum dots, potentially reducing manufacturing costs and complexity compared to OLED and microLED

- The 2029 timeline is aggressive; realistically expect 2031-2032 based on historical display technology rollout delays

- Cost advantage could be substantial if manufacturing scales, bringing near-OLED image quality to mainstream prices

- OLED remains superior in contrast and response time, but quantum dot displays offer better longevity without degradation

- Don't wait for NanoLED—buy current technology (OLED, mini-LED, QLED) and upgrade when proven options exist at better value

Related Articles

- Micron Kills Crucial Brand: What It Means for RAM Consumers [2025]

- Best Amazon Tech Deals on TVs, Headphones & Smartwatches [2025]

- CES 2026's Best and Weirdest Tech Products Explained [2026]

- Apple AirTags 4-Pack $65 Deal: Complete Buying Guide [2025]

- Pebble's Comeback: Why Eric Migicovsky Says His New Company Isn't a Startup [2025]

- Best Buy Winter Sale 2025: The Complete Deal Guide [Up to 50% Off]

![NanoLED TVs Could Revolutionize Your Screen by 2029 [2025]](https://tryrunable.com/blog/nanoled-tvs-could-revolutionize-your-screen-by-2029-2025/image-1-1768498625409.jpg)