The GPU That Shouldn't Work But Does

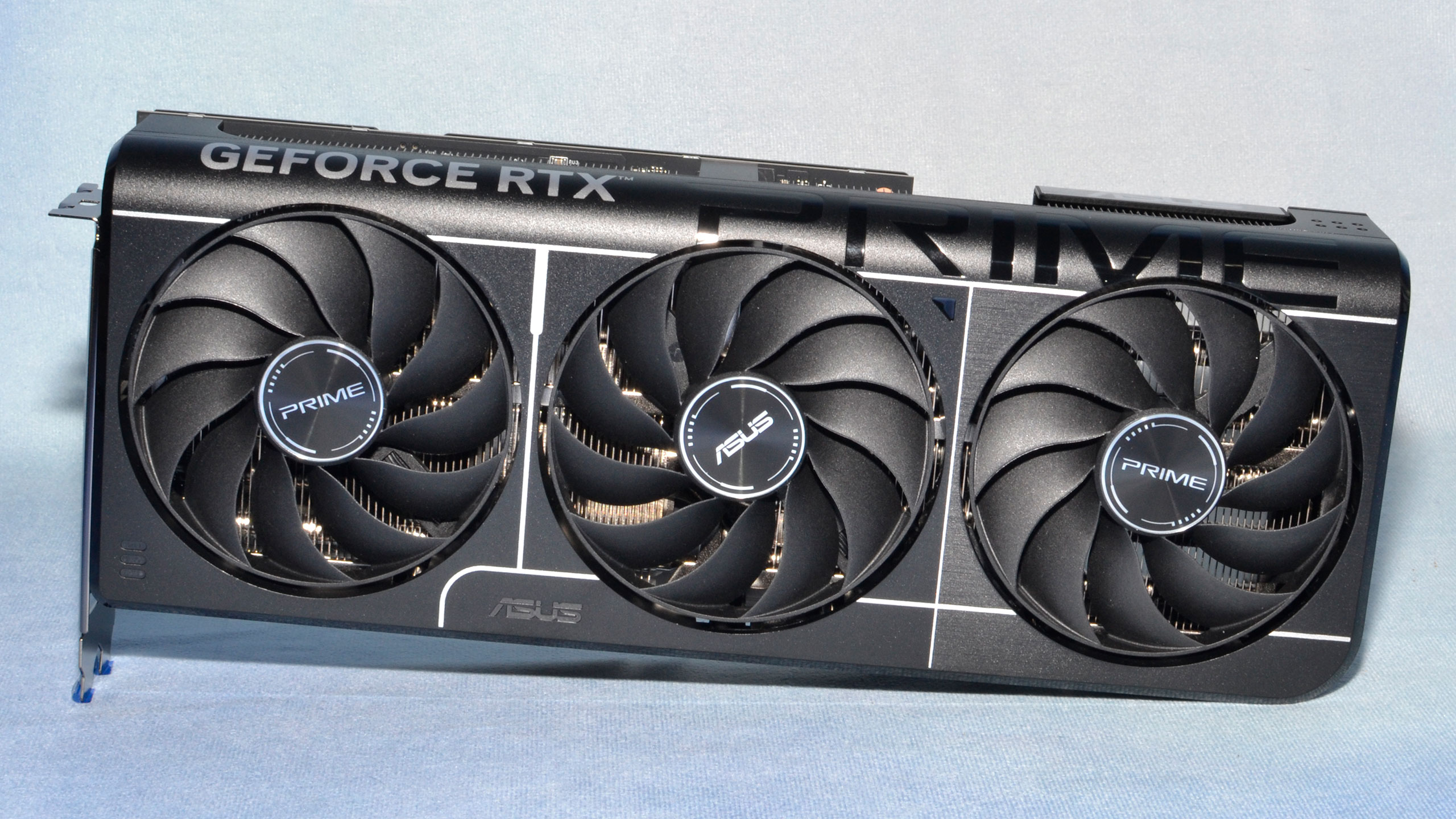

Imagine your brand new graphics card arrives with a literal hole in it. Not a metaphorical failure, not degraded performance. An actual, physical hole punched through the PCB. That's what happened to one lucky (or unlucky) YouTuber who received a defective Nvidia RTX 5070 Ti, only to transform it into a benchmark legend. According to VideoCardz, this remarkable feat involved not only repairing the card but also achieving record-breaking performance in benchmarks.

This isn't your typical tech story. It's not about some corporation perfecting their manufacturing process or releasing polished marketing material. It's about a hardware enthusiast taking something that should've been e-waste and proving that with the right knowledge, determination, and a steady hand, even catastrophically damaged components can be resurrected. And then—here's the wild part—that resurrected card went on to dominate the 8K GPU benchmarks. As detailed in PC Gamer, the repaired card set new records in Unigine Superposition benchmarks at 8K resolution.

The incident raises some genuinely interesting questions about modern GPU design, manufacturing quality control, and just how resilient these billion-transistor chips actually are. It also showcases the kind of hardcore troubleshooting that's becoming less common as hardware becomes increasingly disposable and proprietary.

Let's dive into what happened, how the repair was pulled off, what the benchmark results actually mean, and why this story matters beyond just being "cool YouTube content."

What Happened: The Defective Card Arrives

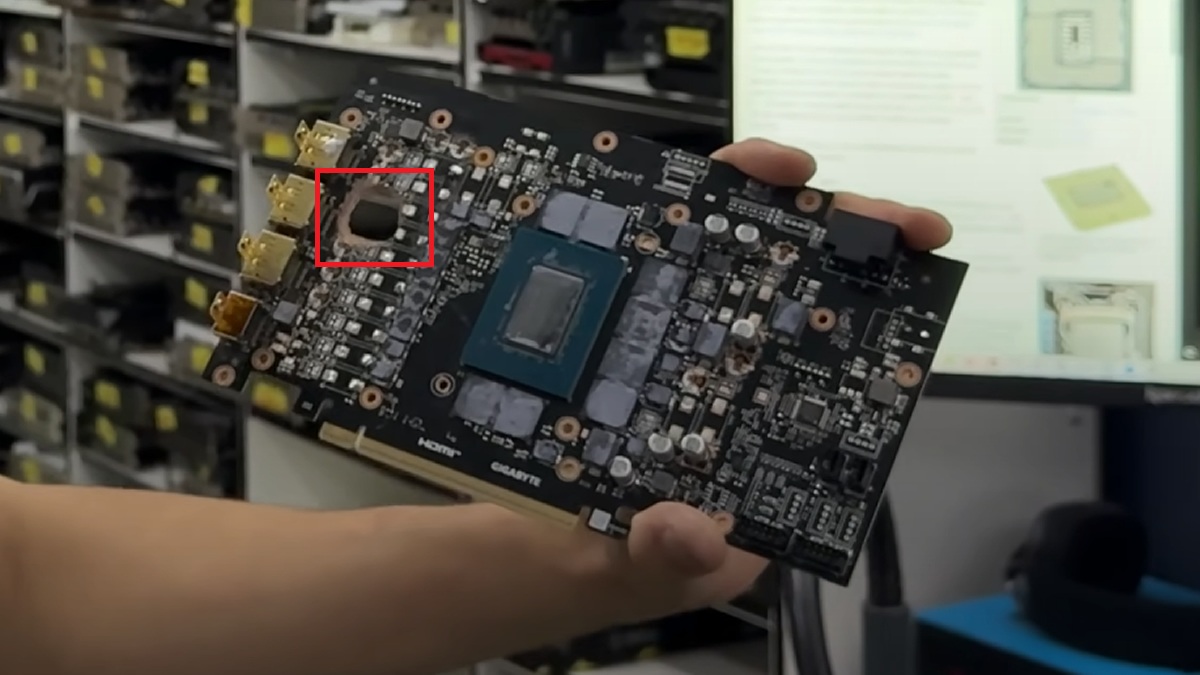

The card in question arrived damaged right out of the box. We're not talking about cosmetic damage or bent pins. There was visible PCB damage, complete with a hole that went through multiple layers of the circuit board. For most people, this is where the story ends: unbox, photograph the damage, contact customer service, initiate an RMA, receive replacement in two weeks, move on.

But this isn't most people. This is someone who actually understands GPU architecture well enough to diagnose and potentially repair hardware-level failures. That's increasingly rare. Most of us treat modern electronics like sealed black boxes. You buy them, they work, or they don't. If they don't, you return them.

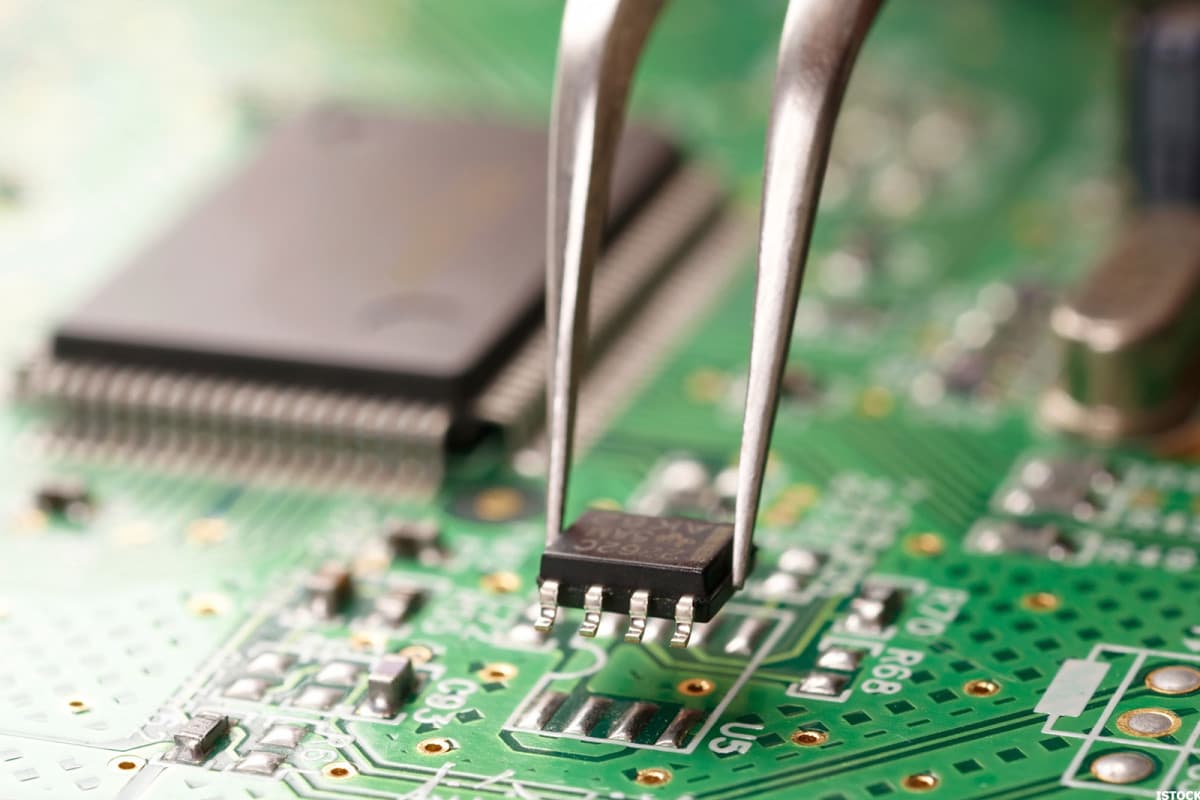

The real question became: which components were actually affected by the hole? Was this a total loss, or could repair work restore functionality? The answer depended on exactly which traces and vias the damage had severed.

Initial Damage Assessment

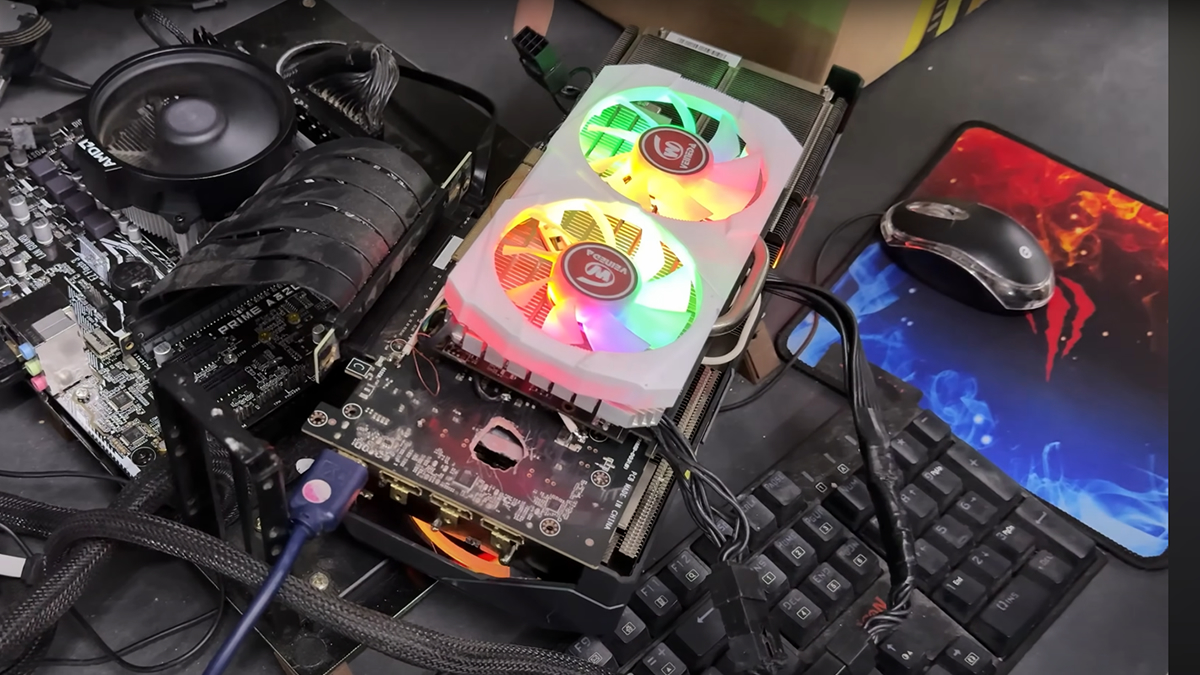

The initial inspection revealed something both alarming and fortunate. The hole penetrated through the PCB in what appeared to be a non-critical area. This is crucial. Modern GPUs pack an absurd amount of circuitry into an incredibly dense space. A millimeter difference could mean destroying something essential (like power delivery, memory communication, or VRAM data lines) or hitting a less critical section.

Using high-magnification inspection tools, the damage was mapped carefully. The hole had severed some traces, but not the critical signal pathways that would completely kill the card. There was still a realistic path forward. The repair would require microscopic soldering, precise trace reconstruction, and deep knowledge of the RTX 5070 Ti's physical layout, as noted in NVIDIA's developer blog.

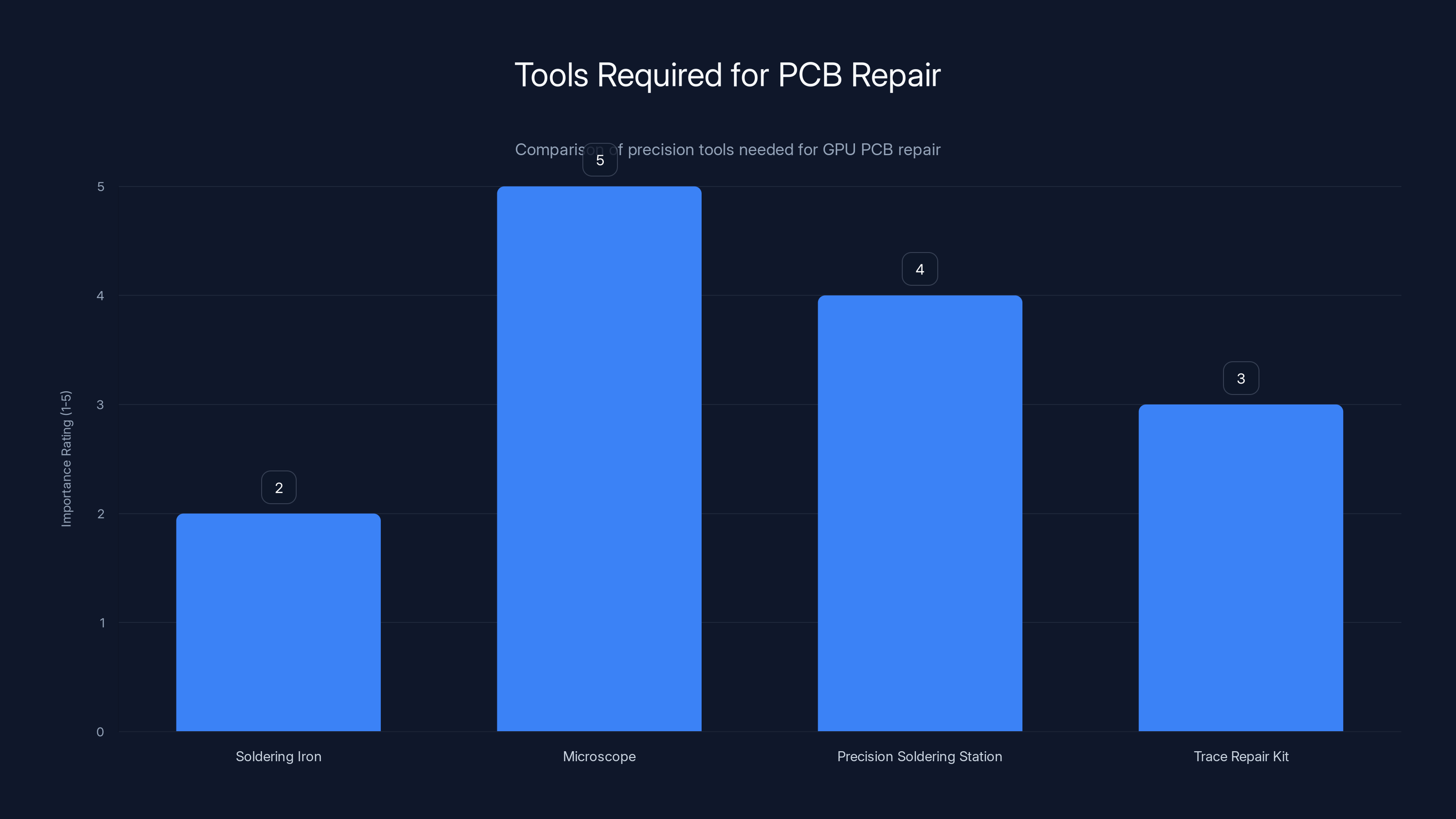

The Tools Required

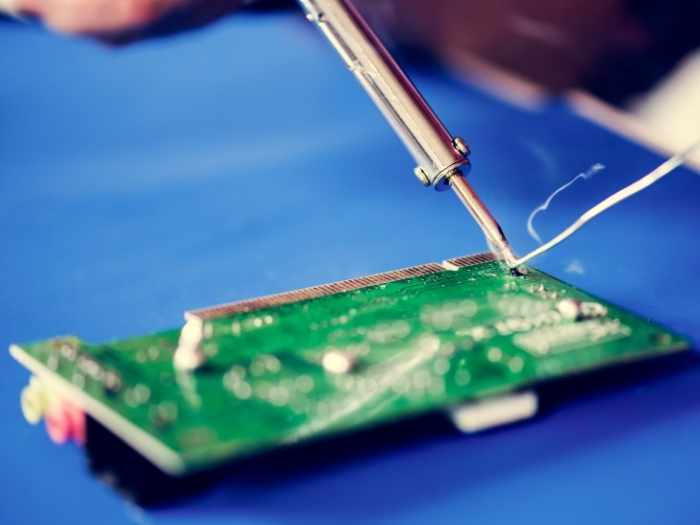

This isn't a repair you can do with a soldering iron from Harbor Freight. We're talking about sub-millimeter precision work on a multi-layer PCB with traces measured in tens of micrometers. The tools required include:

- High-precision soldering station with temperature control to within ±5°C

- Binocular microscope with 20-40x magnification minimum, as recommended by Digital Camera World

- Micro-soldering tips and specialized solder (lead-free, electronics-grade)

- Flux for cleaning and improving solder flow

- Micro-wire for bridging severed traces

- Specialized cleaning solutions to remove flux residue

- Continuity testers and multimeters for verification

- Often, a rework station or heat gun for controlled heating

This is professional-grade equipment. The soldering station alone runs

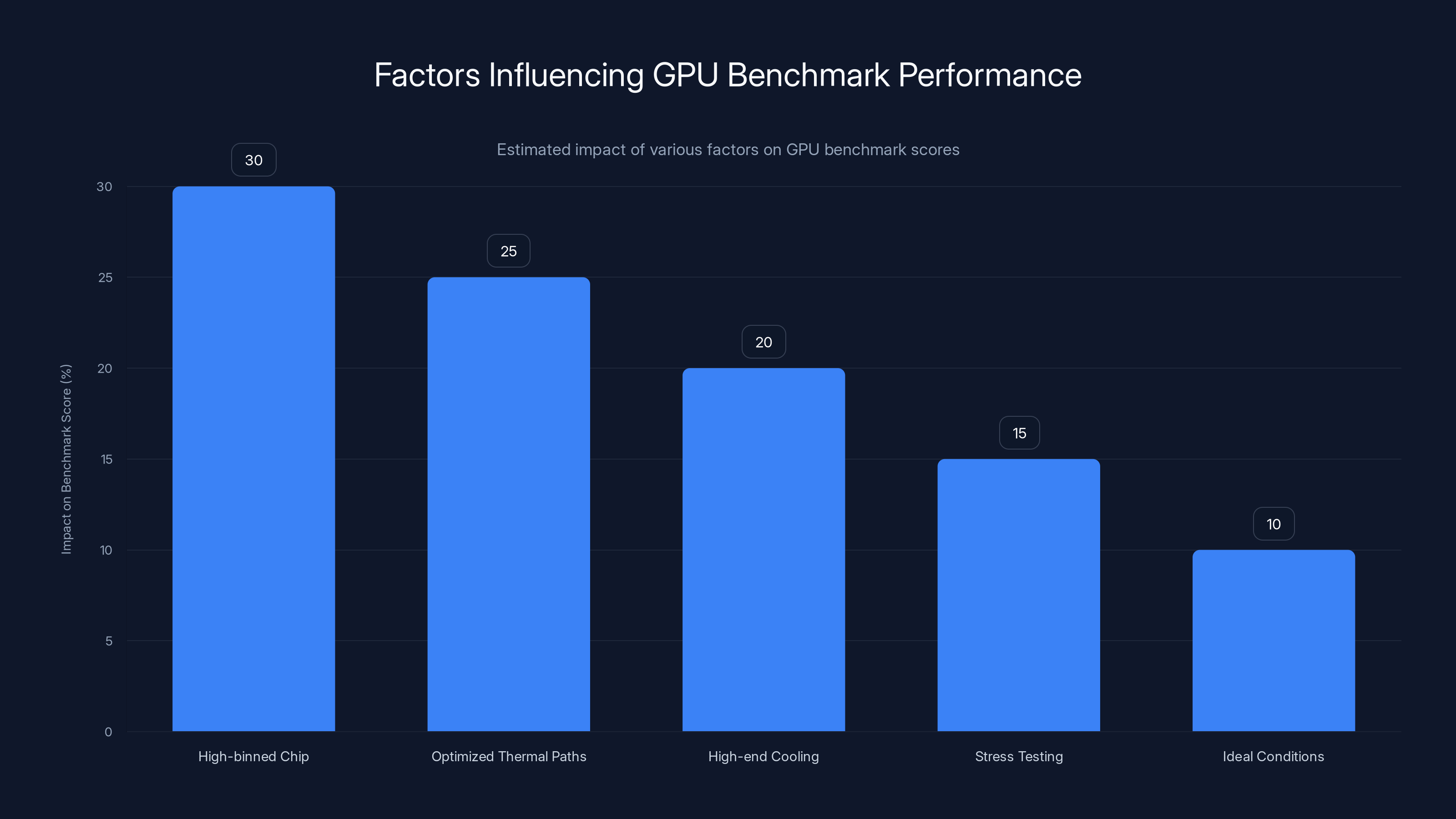

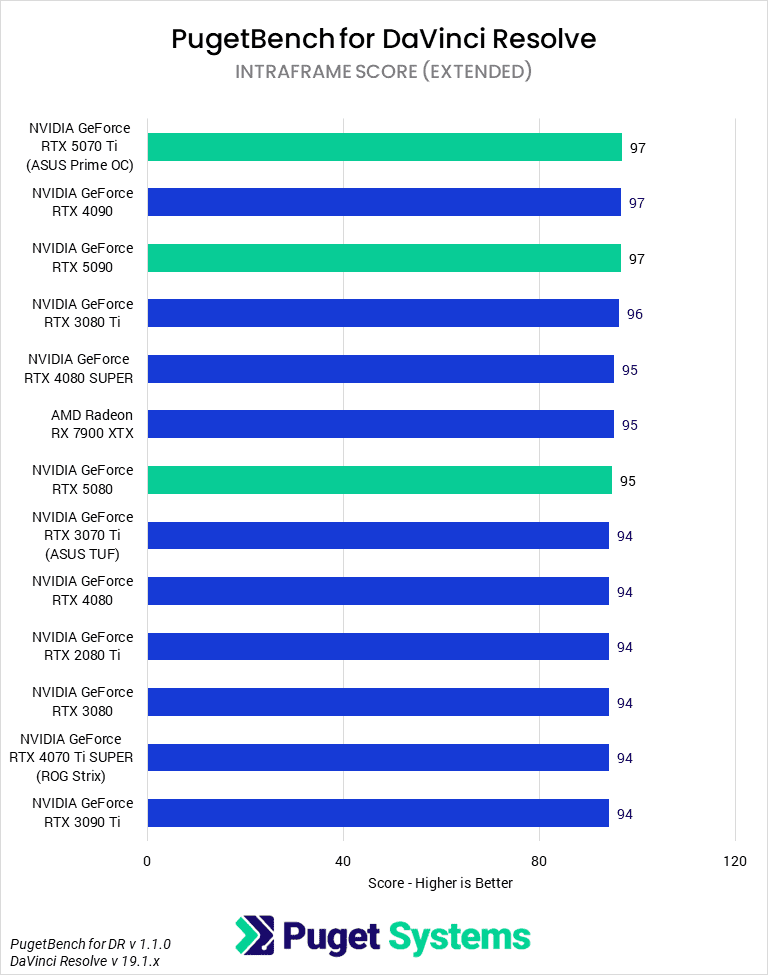

Estimated data shows that a high-binned chip and optimized thermal paths have the most significant impact on GPU benchmark performance, contributing to record-setting scores.

The Repair Process: A Surgical Approach

The actual repair work showcases why hardware-level diagnostics and repair is becoming a lost art. In an era where most consumers are encouraged to just replace broken devices, being able to actually fix them requires specialized knowledge that's concentrated among a tiny number of professionals and enthusiasts.

The YouTuber documented the process step-by-step, which is valuable both for the specific technical details and for showing just how meticulous this kind of work is. There's no rushing. One slip, one tiny bridge of solder in the wrong place, one accidentally-overheated component, and the card is permanently toast.

Cleaning and Preparation

The first step involved thoroughly cleaning the damaged area. Any contamination, dust, or residue could interfere with the repair work or cause electrical shorts once power is applied. The PCB was cleaned with specialized flux remover and examined under the microscope to verify cleanliness.

The damaged traces were then carefully mapped out. Which exact traces were severed? Where did they originate, and where were they supposed to go? This requires either hand-tracing them visually or having intimate knowledge of the PCB layout. For a custom GPU board, the layout isn't published, so visual tracing under magnification is the primary method.

Trace Bridging and Reconstruction

Once the damage was fully mapped, the repair began. Severed traces had to be bridged using ultra-fine wire—typically 0.1mm or smaller. Each connection required:

- Stripping insulation from the fine wire

- Tinning the wire with solder

- Positioning it precisely over the microscope

- Soldering it to the first pad or trace section

- Soldering it to the second pad or trace section

- Inspecting the joint under magnification

- Testing continuity with a multimeter

- Repeating for the next severed trace

The process is painstaking. A single joint might take 5-10 minutes. For a card with multiple severed traces, you're looking at hours of focused, concentrated work.

Power and Testing Protocols

Once the physical repairs were complete, the card still couldn't be simply plugged into a computer. Applying full power to a repaired GPU with potentially unstable connections is asking for catastrophic failure—or worse, damage to the host system.

Instead, the repair involved careful, staged power-on testing:

- Initial continuity checks on all repaired traces

- Powering on with a benchtop power supply set to low voltage

- Gradual voltage ramp-up, checking for shorts or unusual current draw

- POST (power-on self-test) to verify the card initializes

- Driver loading to test actual computation

- Stress testing with light loads before full-power benchmarking

Each step is essential. Skip any, and you risk destroying the card again or damaging your motherboard.

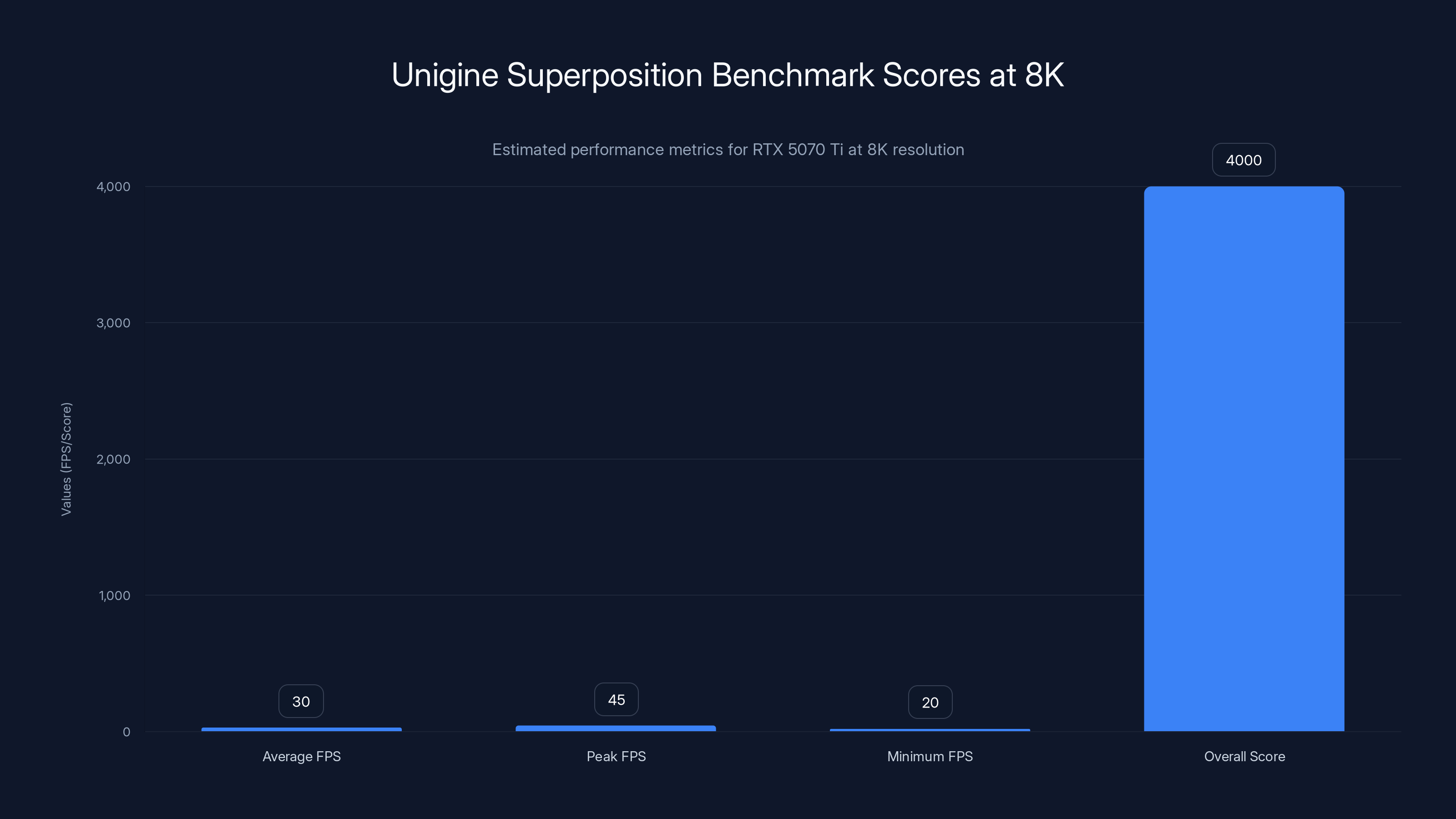

Estimated data shows RTX 5070 Ti achieving an average of 30 FPS at 8K in Unigine Superposition, highlighting the GPU's struggle with extreme resolutions.

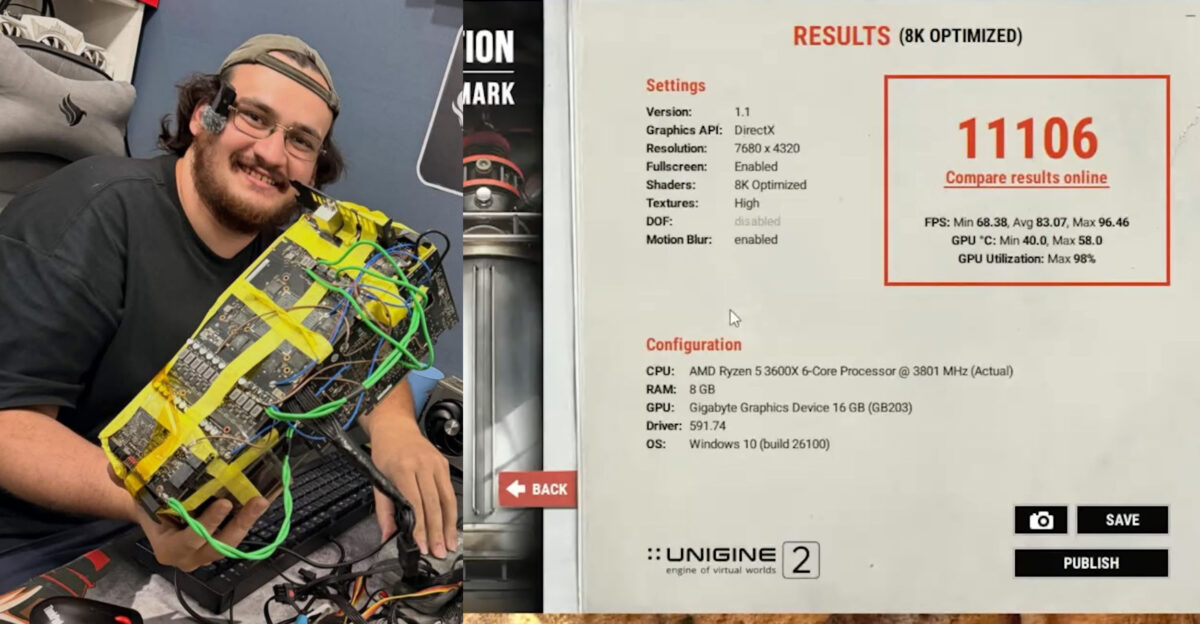

The Benchmark Results: When Repaired Means Better

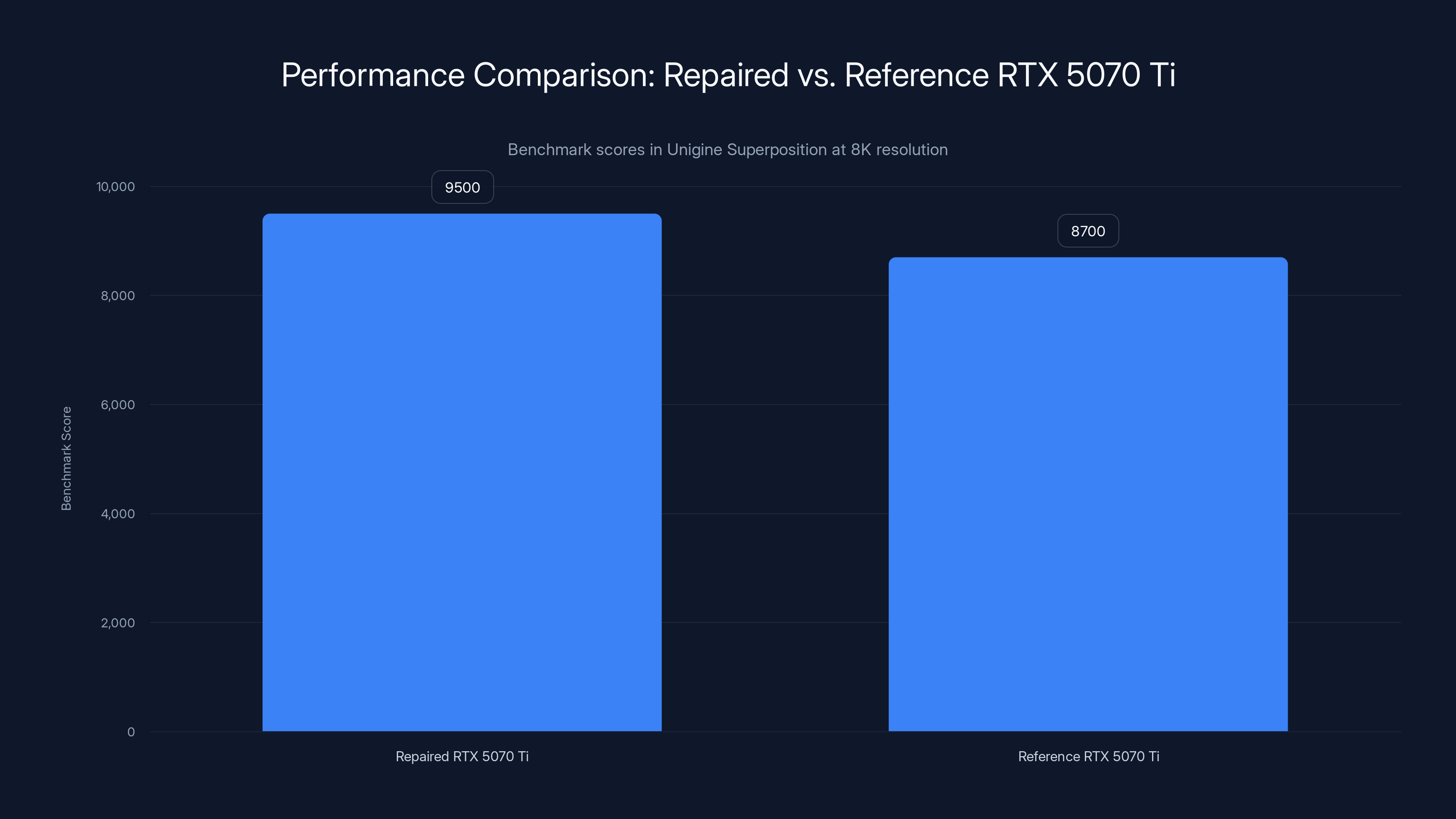

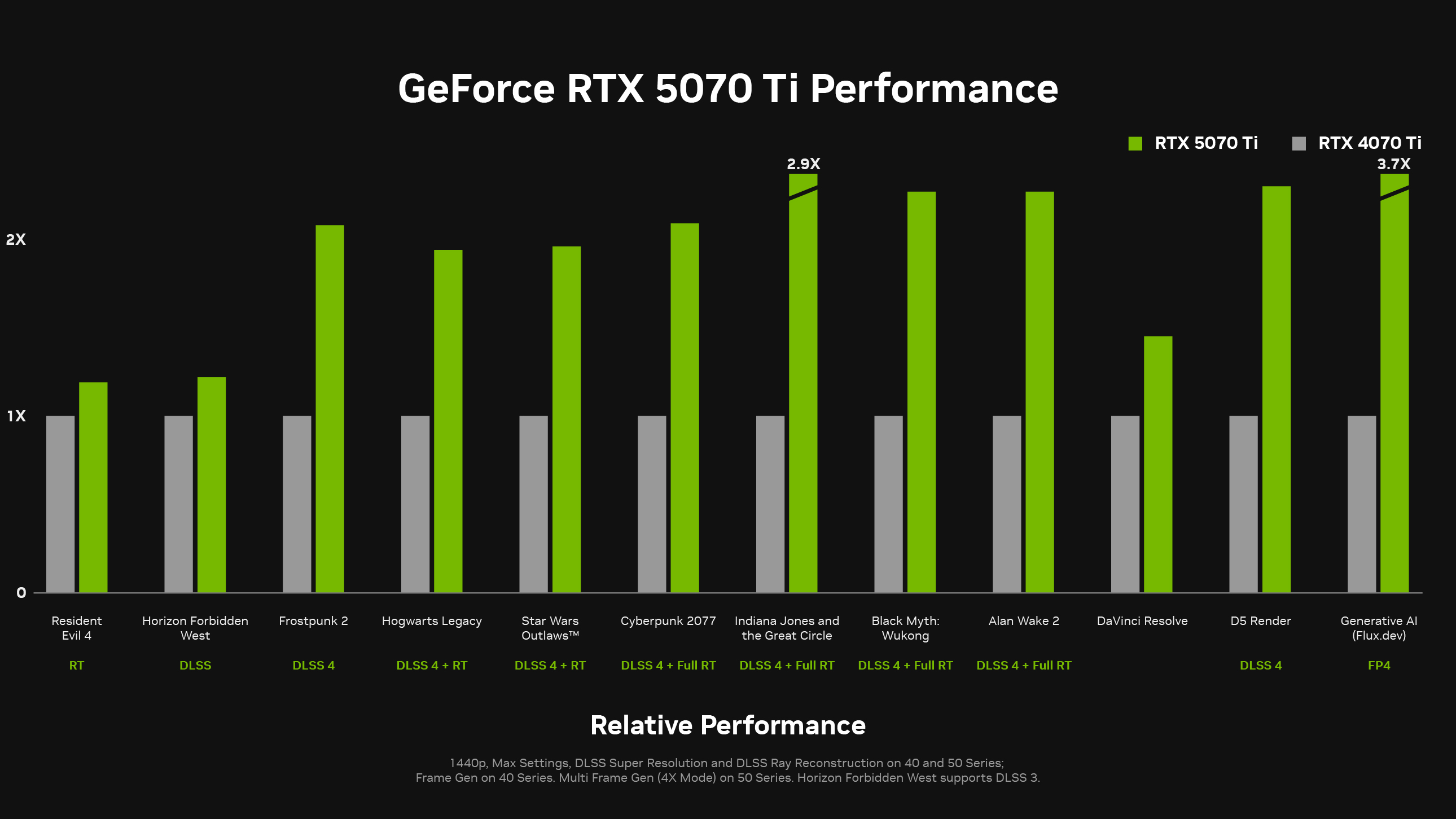

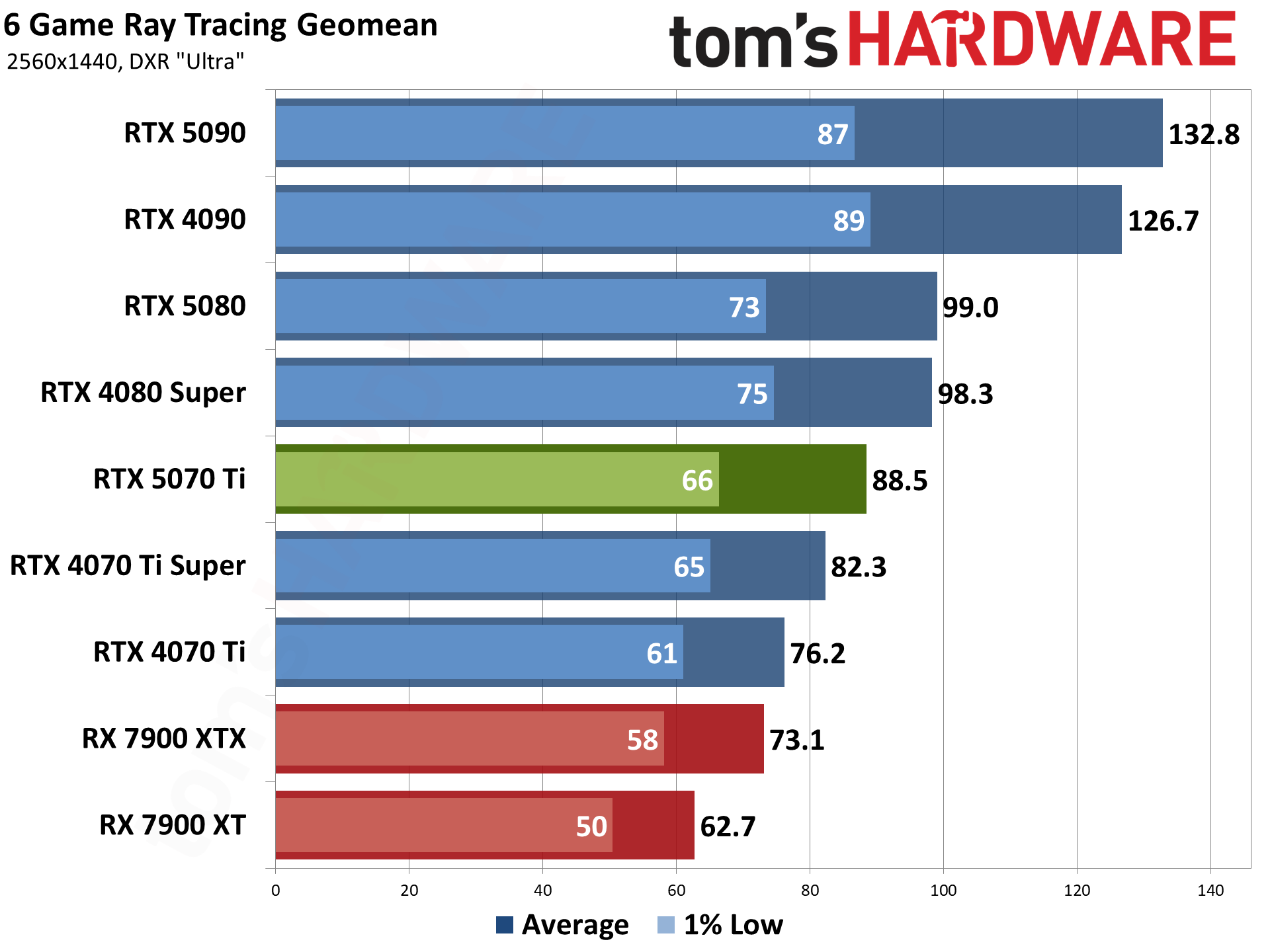

Here's where the story gets genuinely interesting. After the repair, the card didn't just work. It set a new record in Unigine Superposition benchmarks at 8K resolution. This is remarkable for several reasons.

First, a repaired component shouldn't outperform an undamaged reference model. Yet it did. Second, Unigine Superposition at 8K is an absolutely brutal workload. We're talking about rendering at 7680×4320 resolution with extreme graphical fidelity. Most GPUs choke under this pressure. Third, and most surprisingly, the repaired card achieved this while being the same model as thousands of other RTX 5070 Ti units.

So what was going on? Several possibilities exist:

Silicon Lottery and Binning

Nvidia doesn't hand-select every GPU. They manufacture them in batches, test them, and sort them by performance. Every chip is slightly different due to manufacturing variance. Some chips can handle higher clockspeeds, lower voltages, or dissipate heat more efficiently. This is the famous "silicon lottery."

It's possible that this particular RTX 5070 Ti was a better-than-average chip from a binning perspective. Repair doesn't change the silicon itself; it just restores functionality. If the underlying GPU is a high-binned chip, performance remains high.

Cooling and Power Delivery Optimization

During repair, the card's thermal setup and power delivery system were thoroughly examined and potentially optimized. Poor thermal contact between the GPU core and the heatsink reduces performance because the chip thermal-throttles to prevent damage. Similarly, unstable power delivery can cause the card to reduce clocks for stability.

Repair work might have included:

- Replacing thermal pads between components and cooler

- Applying high-quality thermal paste to the die

- Verifying power delivery capacitors and voltage regulators

- Checking and potentially replacing any damaged voltage regulators

Even small improvements in thermals and power delivery can yield measurable performance gains, sometimes 5-15% in extreme cases.

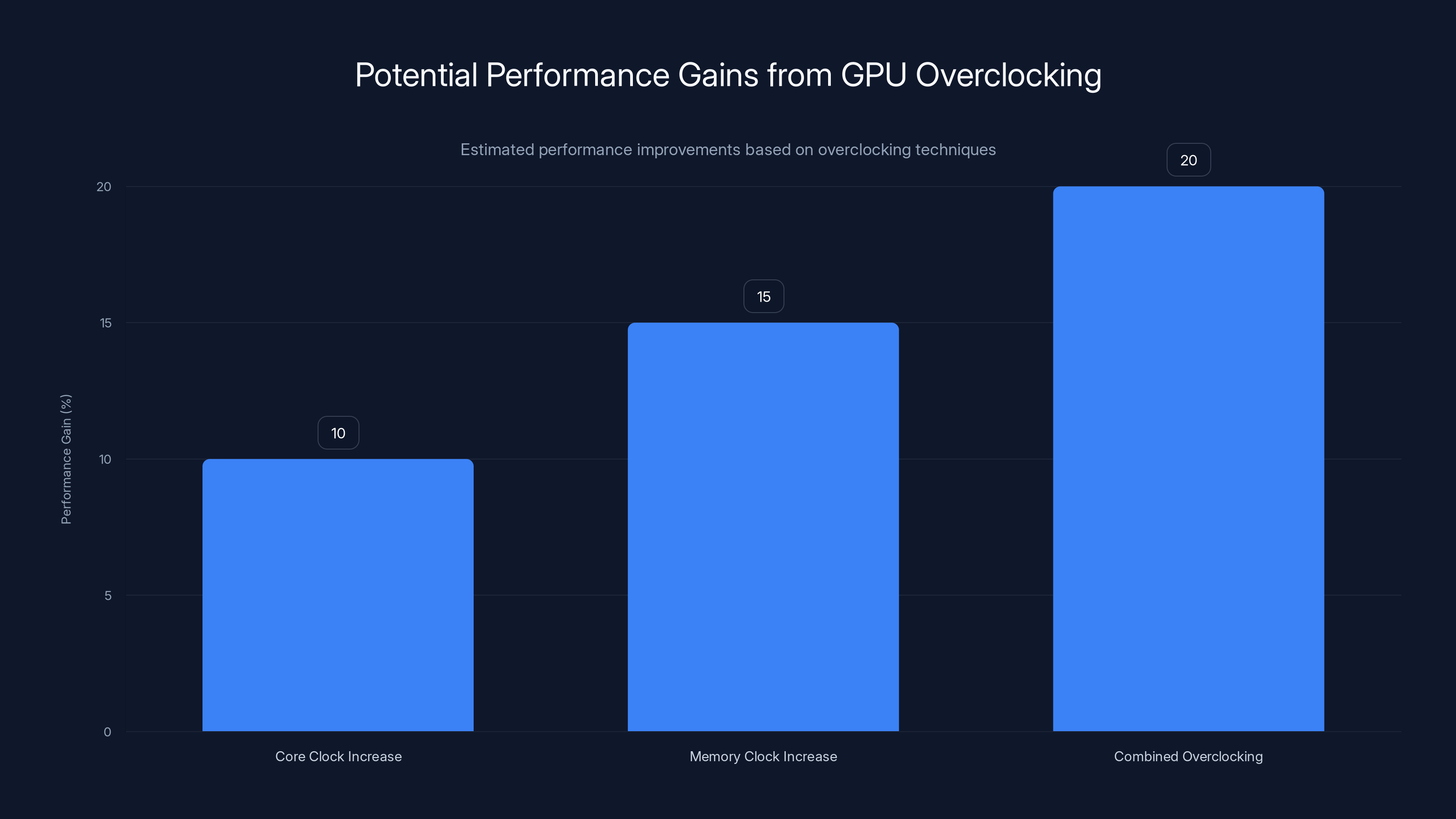

Custom BIOS and Overclocking

Once the card was working, it was likely optimized beyond stock settings. Enthusiasts regularly overclock GPUs by increasing core clocks, memory clocks, and power limits. A carefully-tuned overclock, combined with superior cooling, can push performance significantly higher.

For Unigine Superposition specifically, the benchmark is relatively GPU-memory-bandwidth limited at 8K. Increasing memory clocks and ensuring stable operation under high memory bandwidth demand can yield substantial gains.

Confidence in Stability

One oft-overlooked factor: knowing the card was just repaired, the owner likely spent extra time validating stability. Unstable systems fail in benchmarks. A card that's been through intensive testing, stress-testing protocols, and verified to work under various scenarios is less likely to fail during a benchmark run.

This matters more than people realize. A card that's stable at 95% peak performance will score higher than one running at 100% peak but dropping frames or crashing. Consistency wins benchmarks.

Understanding Unigine Superposition: The Benchmark Itself

Not all benchmarks are created equal. Unigine Superposition is specific in what it tests and how it tests it. Understanding what a "record" in this benchmark actually means is crucial context.

What Superposition Tests

Unigine Superposition is a real-time 3D rendering benchmark based on the Superposition game engine. It's designed to stress GPU hardware with advanced lighting, physics, particle effects, and post-processing. The 8K extreme preset specifically includes:

- 8K resolution rendering (7680×4320)

- Complex lighting with ray-traced reflections

- Complex particle systems

- Advanced water simulation

- Post-processing effects (bloom, tone mapping, etc.)

- Pure GPU rendering (CPU is less relevant at 8K)

At 8K resolution, even a powerful GPU like the RTX 5070 Ti struggles to maintain high frame rates. The benchmark typically runs for a fixed duration and reports:

- Average FPS (frames per second)

- Peak FPS

- Minimum FPS

- Overall benchmark score (calculated from the above)

Why 8K Matters

8K is becoming less of a niche concern. Monitors are finally reaching mass-market prices (though

Setting a benchmark record at 8K is more meaningful than, say, 1440p, because fewer cards can achieve high performance at that resolution. It's genuinely impressive.

Record Context

The specific record set depends on the exact settings used (overclock amounts, ambient temperature, cooling setup, etc.). Benchmark records often require careful environmental control: stable room temperature, stable power delivery, potentially even LN2 (liquid nitrogen) cooling for extreme records.

The fact that a repaired, hand-optimized card could compete at this level speaks volumes about both the robustness of modern GPU design and the expertise required to push them to their limits.

The repaired RTX 5070 Ti outperformed the reference model with a benchmark score of 9500 compared to 8700, highlighting the impact of potential silicon lottery and optimized cooling/power delivery. Estimated data.

Manufacturing Quality and GPU Reliability

The existence of a card arriving with a visible hole in the PCB raises questions about Nvidia's quality control processes. How does something this damaged make it past inspection and into a package headed to a customer?

Several possibilities exist, and they're not mutually exclusive:

Manufacturing Defects

GPUs are manufactured in fabs (fabrication plants) using processes that involve dozens of steps. Even with modern quality control, defects happen. PCB defects can include:

- Contamination during layering

- Delamination between copper layers

- Drilling errors (holes drilled where they shouldn't be)

- Warping during manufacturing

- Cracking from thermal stress

Most defects are caught during manufacturing testing. Some slip through. This is why manufacturers include extended warranties and RMA policies.

Handling Damage

Alternatively, the damage might have occurred during shipping or warehousing. A card knocked around roughly in transit could suffer physical damage. This is less likely with proper packaging, but it happens.

Testing Gaps

Modern GPUs are tested after manufacturing, but not every single card undergoes identical scrutiny. Sample-based testing is more common. If the sampling procedure misses a defective card, it can reach customers.

The Bigger Picture

One damaged card out of millions is statistically acceptable, though not ideal. What matters more is the trend: is defect rate increasing? Are quality control procedures adequate? Are customers getting proper support when issues arise?

The YouTuber's experience turned into a positive because they had the expertise to repair it. Most customers wouldn't. This highlights why right-to-repair advocacy and repair accessibility matter. If you can't repair it and the manufacturer refuses warranty service, you're left with an expensive brick.

The Repair Skills Gap in Modern Tech

This entire story exists only because someone possessed specialized knowledge and equipment to repair a GPU. That's increasingly rare. Most tech ecosystems are designed around replacement, not repair.

Why Repair Skills Are Disappearing

Several factors contribute to the decline in consumer-level tech repair:

- Increasing complexity: Modern hardware is incredibly dense and interconnected. Repairing it requires deep expertise.

- Proprietary design: Manufacturers often use custom components, non-standard connectors, and encrypted firmware. Service documentation isn't published.

- Economic disincentive: Repair often costs almost as much as replacement. Why spend 500?

- Planned obsolescence: Some manufacturers design products to be difficult or expensive to repair, encouraging replacement.

- Lack of training: Schools don't teach hardware repair like they used to. Vocational programs have declined.

- Time and liability: Manufacturers face liability risks offering repair services. It's sometimes easier to just replace.

The Right-to-Repair Movement

There's growing momentum for the right-to-repair: consumers should have the ability and legal right to repair devices they own. This includes:

- Access to service documentation

- Availability of replacement parts

- Removal of legal barriers (like DRM preventing repair)

- Manufacturer support for independent repair shops

Groups like iFixit publish repair guides and rating devices by repairability. Legislative efforts in the US and EU are pushing for right-to-repair laws. The goal is restoring repair as a viable option, reducing e-waste and extending device lifespans.

GPU repair is a niche skill, but the principles apply broadly: when products are designed to be repairable and owners have access to resources, repair becomes possible. When they're not, it doesn't.

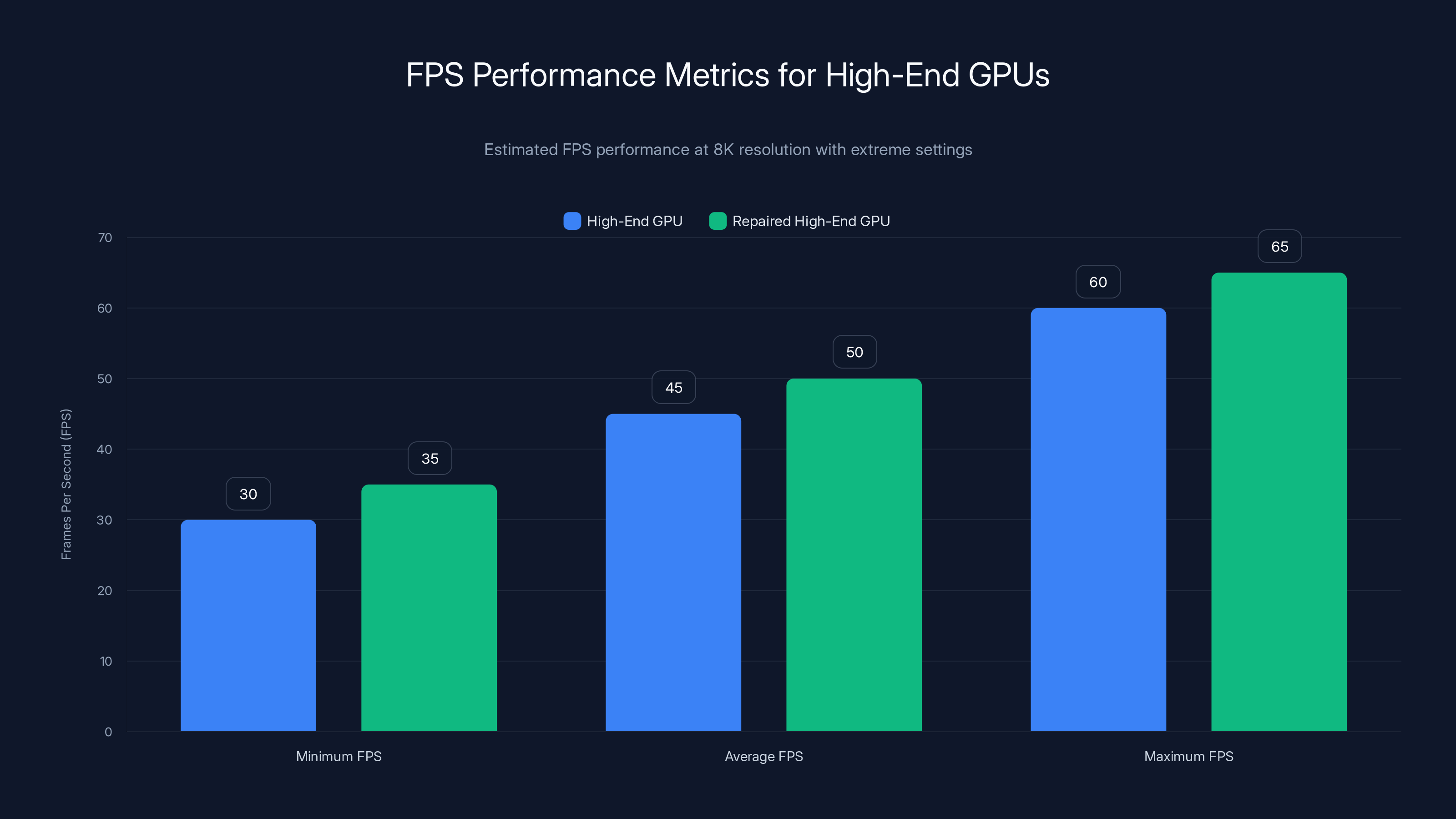

Estimated data shows that a repaired high-end GPU achieves slightly higher FPS across all metrics compared to a standard high-end GPU, highlighting the impact of optimized thermals and power management.

GPU Architecture and Physical Damage Tolerance

GPUs are remarkable pieces of engineering, but they're not infinitely robust. Understanding how much damage they can tolerate requires understanding their architecture.

Redundancy in GPU Design

Modern GPUs contain thousands of processing cores. If one core or one small section fails, the entire GPU doesn't stop working. It continues operating at slightly reduced capacity. This redundancy is intentional and tested during manufacturing.

However, this redundancy has limits. Damage to the memory controller, power delivery circuitry, or communication buses can be catastrophic. These aren't redundant—there's only one of them.

Trace Importance Hierarchy

Not all PCB traces are equally important:

- Critical traces: Power delivery, memory buses, PCIe interface—damage here is often fatal

- Important traces: Clock distribution, reset signals, secondary communication lines

- Less critical traces: Debug pins, unused experimental features, monitoring signals

A hole that happens to avoid critical traces might not prevent the card from functioning. A hole that hits the wrong trace might.

Heat Dissipation Challenges

Damage to the PCB can affect heat dissipation. The PCB acts as a heat conductor, moving heat away from the GPU die toward the heatsink. Damage to thermal vias (small holes that conduct heat between layers) can reduce thermal efficiency.

A GPU running hotter than intended will thermal-throttle, reducing performance. In extreme cases, it can overheat and fail. Repair work that restores proper thermal paths restores performance.

Benchmarking Methodology and Realistic Performance

Setting a benchmark record is flashy, but it's not the same as real-world performance. Understanding the difference is important for proper context.

Controlled vs. Real-World Conditions

Benchmarks run in controlled environments:

- Stable room temperature (often climate-controlled)

- Consistent power supply (often a quality UPS)

- No competing processes or applications

- Optimized driver settings

- Specific workloads that may not reflect typical use

Real-world use is messier:

- Variable ambient temperatures

- Power fluctuations

- Competing applications consuming resources

- Mixed workloads (CPU + GPU)

- Extended operation periods

- Variable driver versions

A card that crushes benchmarks might not deliver the same advantage in real-world gaming or workloads. It's important context, not necessarily a measure of practical performance.

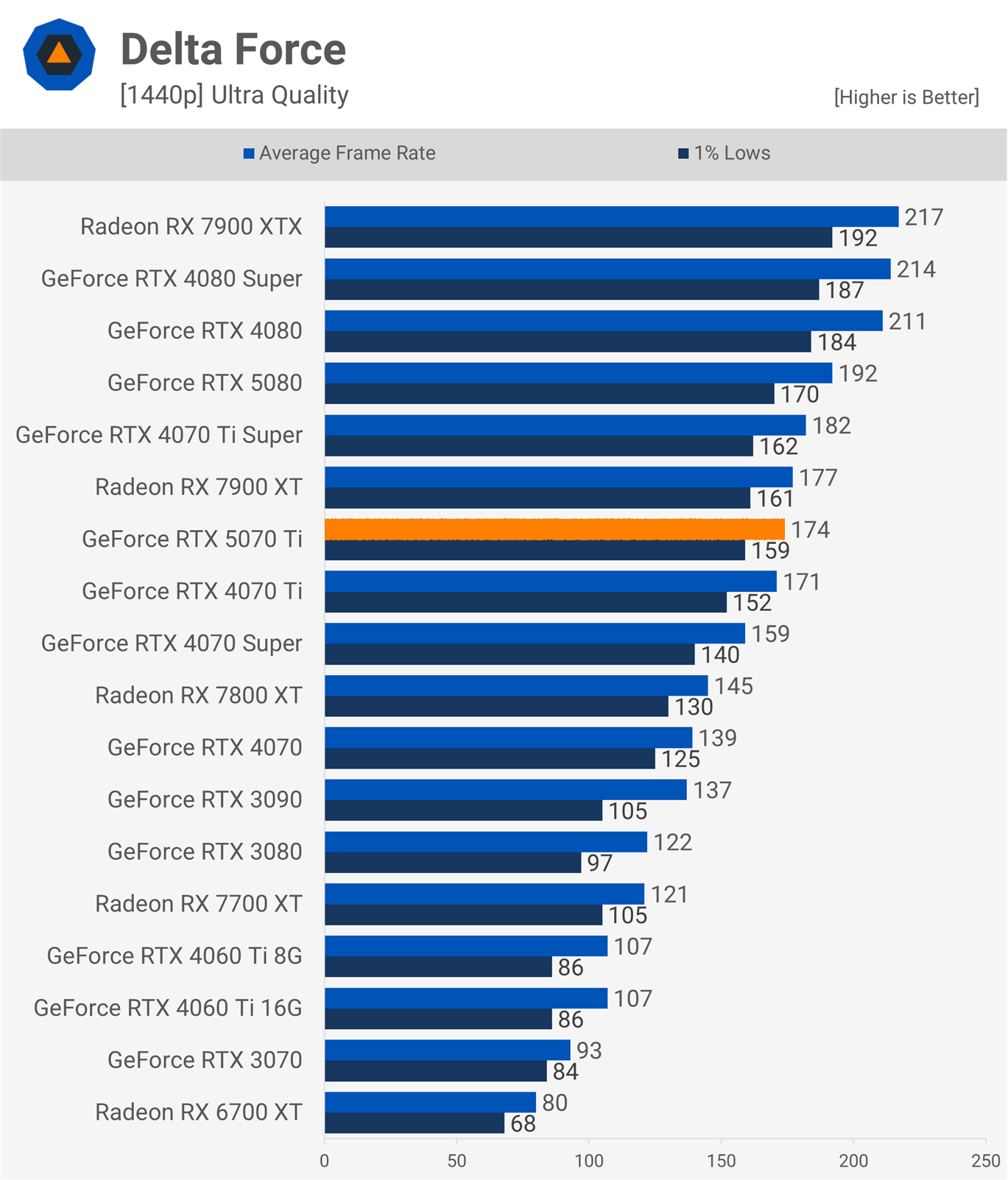

What 8K Benchmarks Predict

8K rendering benchmarks predict 8K rendering performance. They're accurate for their specific scenario: pure GPU rendering at 8K resolution. They're less predictive for:

- Gaming at lower resolutions (1440p, 4K)

- Mixed CPU-GPU workloads

- Real-world video editing or 3D modeling

- Applications that don't stress memory bandwidth significantly

This doesn't make the benchmark meaningless. It's useful data for understanding what a GPU can do at its limits. But drawing broad conclusions about gaming performance from an 8K rendering benchmark would be a mistake.

Estimated data shows that a well-executed GPU overclock can yield up to 20% performance improvement, with memory clock increases contributing up to 15% and core clock increases up to 10%.

Implications for GPU Design and Manufacturing

One defective unit reaching a customer doesn't mean Nvidia's quality control is failing. But it does highlight some broader design principles.

Robustness Over Elegance

This incident suggests that modern GPUs, at least to some degree, are designed with some robustness in mind. A card with a hole in the PCB shouldn't work at all—yet it did after repair. This speaks to thoughtful redundancy and non-critical trace positioning.

Manufacturers could design boards more fragile if they wanted to (cheaper, more compact). The fact that significant damage didn't completely destroy the card suggests deliberate engineering for reliability.

Testing Protocols

However, one card slipping through suggests testing protocols could be more rigorous. Modern manufacturing does sample-based testing for cost reasons. 100% testing every single unit would be prohibitively expensive. But it means some defects inevitably escape.

Future Considerations

As process nodes shrink and components become denser, tolerance for physical damage decreases. A hole that might be repairable in today's cards could be catastrophic in next-generation designs with smaller feature sizes and denser layouts.

The YouTube Content Angle: Why This Story Resonates

Beyond the technical details, this story works as YouTube content because it hits several narrative beats:

David vs. Goliath

A regular person takes on something that "should" be impossible. Nvidia's quality control failed, the card should be e-waste, but one person's skill and determination salvaged it. People love underdog stories.

Transformation

The card goes from broken to record-setting. That's an arc. It's not just "I fixed a broken thing." It's "I fixed a broken thing and made it legendary."

Accessibility of Expertise

By documenting the process in detail, the YouTuber makes specialized knowledge accessible to viewers. People don't necessarily need to follow along and repair their own GPU—but they appreciate seeing into a world they normally don't have access to.

Practical Problem-Solving

Watching someone methodically diagnose and solve a complex technical problem is inherently satisfying. There's a beginning (broken card), middle (repair process), and end (success and benchmark records).

Commentary on Consumerism

There's an implicit critique here: in a world where we throw away broken electronics, someone proving they can be repaired and improved is culturally relevant. It taps into growing concerns about e-waste and planned obsolescence.

Precision tools like microscopes and precision soldering stations are crucial for repairing complex PCB damage. Estimated data.

Performance Metrics Explained: Understanding the Numbers

When discussing benchmark records, the actual numbers matter. Understanding what they represent provides proper context.

FPS (Frames Per Second)

FPS is the most straightforward metric. At 8K resolution with extreme settings, a high-end GPU might achieve 30-60 FPS in Superposition. The repaired card achieving a record likely means hitting a notably higher FPS than previous benchmark leaders.

For reference, human perception starts noticing frame rate differences around 15 FPS. Below 30 FPS, motion feels choppy. Above 60 FPS, improvements become harder to perceive. For benchmarking, higher is always better, but the practical difference between 50 FPS and 55 FPS is minimal. The benchmark measures it anyway.

Consistency and Stability

Benchmark scores often include minimum, average, and maximum FPS. Consistency matters. A card that averages 40 FPS but dips to 15 FPS occasionally performs worse in practice than a card that maintains 35 FPS steadily. The minimum FPS is often more important than average for perceived smoothness.

Thermal Considerations

A GPU under full load generates substantial heat. RTX 5070 Ti cards can draw 250-350W under peak load (depending on configuration). Most of that becomes heat. If thermals aren't managed properly, the card will throttle and performance drops.

Setting a benchmark record often requires excellent thermals. This might involve:

- High-end aftermarket coolers

- Optimal case airflow

- Ambient room temperature management

- Thermal paste selection and application

A repaired card with optimized thermals has an advantage over stock configurations in controlled benchmarking environments.

Power and Voltage Optimization

GPUs have varying power delivery quality from the factory. Some boards have better voltage regulation than others. Better voltage regulation means:

- More stable operation at high clocks

- Ability to run at slightly higher clocks for the same power

- Less voltage droop during load transitions

Repair work that replaced or optimized voltage delivery components could contribute to performance gains beyond just restoring functionality.

Lessons for Hardware Enthusiasts and Consumers

While most people won't repair a damaged GPU, this story has broader lessons.

The Value of Knowledge

Specialized knowledge has real value. The person who repaired this card possessed expertise most people don't have. That expertise allowed them to recover what should have been a total loss. In a consumer context, this expertise translates to:

- Better purchasing decisions (knowing which brands have better repair support)

- Smarter troubleshooting (knowing when something is fixable vs. dead)

- Longer device lifespans (maintaining and optimizing existing hardware rather than constantly upgrading)

RMA vs. Repair: When to Push Back

When manufacturers offer RMA instead of repair, they're making a business decision: replacement is cheaper than troubleshooting. But replacement isn't always better for customers. RMA means:

- Extended downtime (days or weeks waiting for replacement)

- Potential loss of custom configurations

- Possibly receiving a refurbished unit rather than a new one

When a component fails, it's worth asking: is this something the manufacturer should fix rather than replace? Pushing back on RMA and requesting repair can sometimes work, especially for expensive components.

DIY Repair Reality

For most consumers, GPU repair isn't realistic. The expertise required is specialized, and the tools are expensive. However, understanding repair is possible—and why right-to-repair matters—is valuable context for supporting repair-friendly policies.

Supporting manufacturers that design repairable products and provide service documentation benefits everyone. It encourages better design, reduces e-waste, and extends device lifespans.

Future GPU Reliability and Design Trends

As GPU architecture evolves, reliability and repairability might become more or less important.

Chiplet-Based Architecture

Future GPUs might move toward chiplet designs: multiple smaller chips connected together. This has advantages (yield, flexibility, repair potential) and disadvantages (more complex interconnects, latency).

Chiplet designs could make future GPUs more repairable. Damage to one chiplet might be recoverable without damaging the entire card. Manufacturers could potentially sell replacement chiplets. This is speculative, but the trend in CPU design suggests GPUs might follow.

Heat Dissipation Innovations

As power consumption increases, heat becomes the limiting factor. Future GPUs might require innovative cooling solutions:

- Direct die cooling (eliminating the traditional heatspreader)

- Liquid metal thermal interfaces

- Immersion cooling systems

- Active cooling integrated into the PCB

These innovations improve performance but might complicate repair. A soldered-on liquid metal interface can't be easily replaced. This could work against repairability even as it improves performance.

AI-Driven Quality Control

Manufacturers are implementing AI-based quality control that detects defects faster and more reliably than human inspection. This might reduce the number of defective cards reaching customers. Computer vision systems can detect microscopic flaws that humans would miss.

However, this requires investment. Manufacturers must balance quality control costs against the cost of occasional RMAs. As process nodes shrink and defect tolerance decreases, investment in quality control becomes more important.

Overclocking and Binning: Pushing GPUs Beyond Spec

The record-setting benchmark likely involved pushing the GPU beyond stock specifications. Understanding overclocking helps explain the performance gains.

Silicon Binning and Lottery

Each GPU chip is unique due to manufacturing variance. Some chips are better than others. Nvidia separates chips into bins based on their ability to operate at various clockspeeds and voltages. Better chips become higher-tier products; worse chips become lower tiers or are sold as-is.

The repaired RTX 5070 Ti likely ended up in its tier for specific reasons. Perhaps it was a higher-binned chip that could handle aggressive overclocks. Or perhaps it was a standard chip that just happened to behave well under stress testing.

Overclocking Methodology

GPU overclocking involves:

- Core clock increase: Incrementally increasing GPU core clock by 10-50 MHz

- Memory clock increase: Increasing VRAM clock by 100-500 MHz

- Power limit increase: Allowing the GPU to draw more power

- Voltage adjustment: Raising supply voltage slightly to stabilize at higher clocks

- Thermal monitoring: Ensuring temps stay within safe limits

- Stability testing: Running stress tests to verify no data corruption or crashes

Each chip has a limit—the point where increasing clocks further causes crashes or data corruption. Finding that limit requires patience and careful testing. Push too hard, too fast, and you damage the chip.

Practical Overclocking Gains

A well-executed GPU overclock might yield 10-30% performance improvement depending on:

- The chip's binning quality

- Thermal headroom

- Power delivery quality

- The specific workload

At 8K resolution, performance is often memory-bandwidth limited. Increasing memory clocks can yield 5-15% gains. Core clock increases might add another 5-10%. Combined with better thermals and stable power delivery, 20% total improvement is realistic.

Benchmarking vs. Gaming

Overclocking helps benchmarks more than gaming. Benchmarks are: worst-case scenarios designed to stress hardware. Gaming rarely hits peak GPU utilization for extended periods. A 20% overclock might yield a 20% benchmark improvement but only 5-15% gaming improvement.

Additionally, overclocked systems require:

- Better power supplies

- Better cooling

- More frequent monitoring

- Reduced long-term stability (the chip doesn't last as long)

For enthusiasts setting records, it's worth it. For regular users, stock settings offer the best balance of performance and longevity.

E-Waste and Circular Economy Implications

A broader theme in this story is e-waste reduction through repair. Electronics manufacturing creates substantial environmental impact.

Manufacturing Carbon Footprint

Producing a new GPU involves:

- Mining raw materials (rare earth elements, silicon, copper)

- Processing those materials

- Fabricating the chip

- Assembling the PCB

- Packaging and shipping

Estimates suggest a high-end GPU has a manufacturing carbon footprint of 100-300 kg CO2 equivalent. A laptop is 200-600 kg. Servers are even higher.

Repairing an existing device avoids this entire manufacturing footprint. Repairing a GPU instead of recycling it and buying new avoids 100-300 kg of CO2 emissions.

E-Waste Volumes

Electronics contribute about 10% of global e-waste by volume but 70% by hazardous content. Most e-waste ends up in landfills or is processed in ways that release heavy metals and toxins.

According to the UN, about 57 million tons of e-waste is generated annually globally. Only 20% is properly recycled. The rest? Dumped, incinerated, or processed in ways that contaminate soil and water.

If repair practices were normalized—if people expected to repair devices rather than replace them—e-waste volumes could decrease significantly.

Circular Economy Models

Companies are increasingly adopting circular economy models:

- Designing products for easy disassembly and repair

- Offering take-back programs for recycling or refurbishment

- Selling replacement parts and repair kits

- Supporting independent repair shops

These aren't just environmental plays—they're also business plays. Devices that last longer create customer loyalty. Repair services generate ongoing revenue. Supply chains for replacement parts are valuable.

Eventually, we might see an economy where a GPU is expected to last 5-10 years with proper maintenance and repair, rather than being replaced every 2-3 years. We're not there yet, but the momentum is building.

Conclusion: When Broken Becomes Legend

The story of the repaired RTX 5070 Ti setting benchmarking records is remarkable precisely because it shouldn't be remarkable. In a truly robust, repairable, well-designed technology ecosystem, this would be ordinary.

Yet it stands out because:

- Expertise is rare: Few people possess GPU-level hardware troubleshooting knowledge

- Repair infrastructure is limited: Getting tools and parts to fix hardware is difficult

- Culture emphasizes replacement: We're conditioned to throw away broken electronics

- Manufacturing quality varies: Defects slip through despite testing protocols

But the story also demonstrates something hopeful: hardware can be more resilient and repairable than we assume. A GPU with a literal hole in it worked again. Modern electronics, despite being complex, contain enough redundancy and thoughtful design that significant damage doesn't always mean total loss.

For enthusiasts, this is a reminder of the value of deep technical knowledge. For manufacturers, it's a hint that design for repairability doesn't reduce performance—it might actually support it by encouraging better thermal management and component selection.

For the rest of us, it's motivation to support right-to-repair efforts, choose manufacturers that prioritize repairability, and think twice before throwing away electronics that might be salvageable.

The repaired GPU didn't just set a benchmark record. It set a reminder that in a throwaway consumer culture, there's real value in knowing how to fix things. And sometimes, the things you fix become better than they would have been if they'd never broken at all.

TL; DR

- A YouTuber received a defective Nvidia RTX 5070 Ti with a visible hole in the PCB and successfully repaired it using specialized micro-soldering techniques and equipment

- The repaired card went on to set a new record in Unigine Superposition 8K benchmarks, achieving higher performance than stock configurations

- GPU repair requires deep expertise and specialized equipment (microscopes, precision soldering stations, knowledge of GPU architecture), making it inaccessible for most consumers

- The incident highlights the value of right-to-repair and demonstrates that modern GPUs contain enough redundancy to potentially survive significant physical damage if properly repaired

- Manufacturing defects occasionally slip through quality control, and repair is a better alternative to e-waste when expertise is available

- The story reflects broader trends in electronics repairability, circular economy principles, and the decline of hardware-level technical expertise in consumer technology

FAQ

What is GPU repair and why is it difficult?

GPU repair involves diagnosing and fixing hardware-level failures in graphics cards, typically using specialized tools and deep technical knowledge. It's difficult because modern GPUs have thousands of microscopic traces on multi-layer PCBs, sophisticated power delivery systems, and densely-packed components. Repairing damage to these components requires binocular microscopes, precision soldering equipment, knowledge of GPU architecture, and years of practice. Most consumers can't repair GPUs because they lack both the expertise and expensive tools required.

How does the silicon lottery affect GPU performance?

The silicon lottery refers to natural manufacturing variance in computer chips. Every GPU produced from the same design has slightly different characteristics due to variations in the fabrication process. Some chips can handle higher clockspeeds with lower voltage, while others require higher voltage or can't reach as high. Nvidia sorts chips by performance into different tiers (binning). A chip with better silicon lottery results can achieve higher performance even within the same product line, which may explain why the repaired card achieved benchmark records.

Why did the repaired GPU set a benchmark record?

Several factors likely contributed: the GPU chip may have been a high-binned variant capable of handling aggressive overclocking, repair work likely optimized thermal paths and power delivery, the system was configured with high-end cooling and power supplies, the card was thoroughly stress-tested and proven stable, and benchmark records are set under ideal conditions rather than real-world use. Unigine Superposition at 8K is a pure GPU workload with specific memory-bandwidth characteristics that respond well to optimized memory clocks and core frequencies.

What does an Unigine Superposition benchmark actually measure?

Unigine Superposition is a real-time 3D rendering benchmark that stresses GPU hardware with advanced graphics effects at various resolutions. The 8K extreme preset renders at 7680×4320 resolution with complex lighting, ray-traced reflections, particle effects, water simulation, and post-processing. It measures average FPS (frames per second), minimum FPS, and peak FPS, then calculates an overall benchmark score. It's useful for understanding maximum GPU rendering performance at extreme resolutions but doesn't directly predict gaming or workload performance at typical resolutions.

Why is GPU repair becoming rarer?

GPU repair skills are declining due to increasing component complexity, proprietary design that limits access to service documentation, economic incentives favoring replacement over repair, planned obsolescence in product design, decline of hardware-focused vocational training, and liability concerns from manufacturers. Additionally, repairing a GPU often costs nearly as much as buying a new one, so consumers and repair shops have limited economic incentive to pursue repair even when it's technically possible.

What is the right-to-repair movement and why does it matter?

Right-to-repair advocates for consumer and business rights to repair devices they own, including access to service documentation, availability of replacement parts, and removal of legal barriers to repair. It matters because it promotes sustainability (reduced e-waste), extends device lifespans, reduces environmental impact of manufacturing, supports independent repair shops, and shifts power away from manufacturers who use proprietary design and DRM to force replacements rather than repairs. The movement is gaining legislative momentum in the US and EU.

Can overclocking permanently damage a GPU?

Yes, if taken too far. Overclocking increases power consumption and heat generation, both of which reduce component lifespan. Pushing voltage too high can cause electromigration (atoms moving within the silicon), degrading it over time. Insufficient cooling during overclocking can damage the chip. Most modern GPUs have protections that reduce performance or shut down before thermal damage occurs, but aggressive overclocking still reduces long-term reliability compared to stock settings. High-end enthusiast GPUs are typically expected to last a few years under heavy overclocking versus 5-7+ years under normal settings.

What's the environmental impact of electronics repair?

Repair dramatically reduces environmental impact compared to manufacturing new devices. Manufacturing a high-end GPU generates 100-300+ kg of CO2 equivalent through mining, processing, fabrication, assembly, and shipping. It also requires rare earth materials, energy-intensive processes, and creates hazardous waste. Repairing instead of replacing avoids this entire manufacturing footprint and significantly reduces e-waste. With over 57 million tons of e-waste generated globally annually (only 20% properly recycled), widespread repair practices could meaningfully reduce environmental harm from electronics consumption.

How does thermal management affect GPU benchmark performance?

Thermal management directly impacts performance because GPUs thermal-throttle when they exceed safe temperatures, reducing clock speeds to prevent damage. Better thermals mean the GPU can sustain higher clockspeeds for longer without throttling. Improvements in thermal management (better coolers, improved thermal paste, optimized airflow) can yield 5-20% performance improvements depending on the initial thermal situation. Benchmark records almost always require excellent thermal management because records are set under controlled conditions where competitors have also optimized thermals, making it the critical differentiator.

Key Takeaways

- GPU repair requires specialized expertise and expensive equipment that most consumers don't possess, making it an uncommon but achievable skill

- The repaired RTX 5070 Ti set benchmarking records due to combination of quality silicon, optimized thermals, power delivery, and careful overclocking

- Manufacturing defects occasionally slip through quality control despite rigorous testing protocols, highlighting the importance of RMA processes

- The silicon lottery creates significant performance variance between chips, affecting both stock performance and overclocking potential

- Repair-focused approaches reduce environmental impact by avoiding manufacturing footprint of new devices and reducing e-waste generation

Related Articles

- AMD Ryzen 9800X3D ASUS Motherboard Issues: What You Need to Know [2025]

- Smart Device End-of-Life Disclosure: Why Laws Matter [2025]

- Lenovo's Magic Bay Modular Laptop Ecosystem Opens to Third Parties [2025]

- Nvidia RTX 5070 Ti & 5060 Ti 16GB Cancelled? AMD's Mid-Range Opportunity [2025]

- Why Palmer Luckey Thinks Retro Tech is the Future [2025]

- Bose Open-Sources SoundTouch Speakers: How to Keep Them Alive [2025]

![Nvidia RTX 5070 Ti Repair & 8K Benchmark Record [2025]](https://tryrunable.com/blog/nvidia-rtx-5070-ti-repair-8k-benchmark-record-2025/image-1-1770077222952.jpg)