How Rivian Redesigned the R2's Manual Door Release for Emergency Access

There's something unsettling about being trapped inside a car. It shouldn't happen. The doors should open. But over the past few years, as automakers have rushed to embrace electronic systems, they've created a problem that nobody really anticipated: what happens when the power dies and you can't get out?

Tesla has faced multiple lawsuits and safety investigations over this exact issue. Bloomberg reported at least 15 deaths in crashes where occupants couldn't open the doors because the electronic systems failed. Ford had to recall the Mustang Mach-E because of power-delivery failures in the electronic door latches. The issue isn't hypothetical anymore. It's real, it's serious, and regulators are starting to notice.

Rivian, the electric vehicle startup that launched the R1T and R1S to generally positive reviews, decided to tackle this problem head-on with its upcoming R2 SUV. Instead of hiding behind marketing speak about redundancy, the company actually changed how the manual door release works. And for once, a design change that sounds boring on paper might actually save lives.

Let's break down what Rivian changed, why it matters, and what it tells us about the future of electric vehicle safety design.

The Problem with Modern Electronic Door Handles

When you buy a modern electric vehicle, you're signing up for a certain level of technological complexity. That complexity extends to things you'd never think about before. Door handles, for instance. In traditional cars, you pull a handle, a mechanical linkage opens the latch, and the door swings open. Simple. Reliable. Tested across a century of automotive history.

Modern EVs? They often use electronic actuators instead. You press a button, the system receives the input, verifies that you're authorized to open the door, checks that the vehicle is parked, confirms that the latch mechanism is ready, and then mechanically opens the door. It's elegant from a design perspective. It's also a single point of failure when things go wrong.

Here's what happened at Tesla: the company designed electronic door handles that required the manual release to be accessed through a specific sequence. On some models, you had to pull a plastic panel, find a hidden cord or lever, and activate it. In a panic situation, in the dark, possibly injured, with seconds counting down, that process becomes impossibly difficult. Rescue personnel reported struggling to get doors open. Parents couldn't extract children from back seats.

The underlying issue is that automakers treated manual releases as afterthoughts rather than critical safety systems. They hid them because they wanted clean interior designs. They made them hard to find because they assumed you'd never need them. They buried them behind panels and under trim pieces. And then, when someone did need them, they couldn't find them in time.

Regulators began asking uncomfortable questions. The National Highway Traffic Safety Administration (NHTSA) started investigating. Other manufacturers watched and took notes.

Rivian's Approach: Learning from Competitors' Mistakes

Rivian didn't invent a new way to solve this problem. Instead, it looked at what worked and what didn't, and it borrowed the best solution. The company had a distinct advantage: it could watch Tesla's stumbles, Ford's recalls, and other manufacturers' missteps before launching its own vehicle. That's not innovation in the sense of doing something nobody has ever done before. It's better than that. It's learning from real-world data.

The R1T and R1S, Rivian's first vehicles, already had manual door releases. But they weren't ideal. On those vehicles, passengers in the rear seats had to pull off an interior door panel to access a release cord. That's not a hidden handle or a push button. That's a full panel removal. It's significantly more difficult than accessing a front door manual release, and it creates a two-tier safety system where rear passengers are less protected than front passengers.

For the R2, Rivian made a conscious decision: rear manual releases would be repositioned to match the logic of the front door releases. No more panel removal. No more hidden cords. Just find the latch in a consistent location.

This is a small change from an engineering perspective. But from a safety perspective, it's significant because it treats all occupants equally and reduces the time needed to access the manual release in an emergency.

Understanding the R2's New Manual Release Design

Let's get specific about what changed. On the R2, both front and rear doors have electronic buttons for opening. That part hasn't changed. What changed is the mechanical backup system that activates when the electronics fail.

On the front doors, there's a manual release latch tucked into the front part of the interior handle. If the power goes out, if the button stops responding, if the door's electronic actuator fails, you can find this latch. It's visible. It's accessible. You don't need tools. You don't need to remove anything. You reach in, you find it, you pull it, the door opens.

On the R1 vehicles, rear doors worked differently. There was a release cord, but you had to remove a panel first. That added complexity and added time.

On the R2, Rivian moved the rear manual release to that same front-of-the-handle position. It's still partially hidden behind a piece of plastic that you need to pop out, so it's not quite as accessible as the front door release. But it's in a logical, consistent location. It's where passengers would expect it to be. They don't need to remove a panel. They don't need to search the entire door. They find it in the handle area, they figure out how to activate it, and the door opens.

This might sound like a trivial change. But consider the scenario: a vehicle has been in a collision. The power systems are damaged. A passenger in the back seat is conscious but needs to get out immediately. They're not thinking about where an obscure release cord might be hidden behind a panel. They're reaching for the door handle because that's what you do when you need to open a door. The new design puts the backup system exactly where instinct says it should be.

The Engineering Challenge: Balancing Form and Function

Designing a modern car interior is a series of compromises. Every cubic inch is precious. Every component needs to fit within weight budgets, cost targets, and safety standards. And aesthetics matter. People spend hours in their cars. They want them to look good, not like engineering exercises.

Hiding mechanical systems isn't purely about vanity. It's also about protecting them. A fully exposed mechanical backup system can be damaged by moisture, dust, or accidental contact. It can wear out faster. It can snag clothing or catch skin. So automakers encapsulate these systems, hide them, and make them accessible only when needed.

But there's a line. Rivian apparently decided that the R1's approach crossed that line. Making rear passengers remove an entire panel to access a safety-critical system seemed excessive. The benefit of a cleaner interior design didn't justify the safety trade-off.

So the company redesigned the system. The release mechanism is still behind plastic that needs to be popped out, so it's not fully exposed. But it's in a location that makes sense. It's documented. It's consistent with the front door design philosophy. And crucially, it's where someone in a panic would likely look for it.

This required changes to the door architecture, the interior trim pieces, the handle design, and the latch mechanism itself. It wasn't a simple tweak. But Rivian apparently determined that the safety improvement justified the engineering complexity.

Lessons from Tesla's Door Handle Controversies

Tesla's journey with electronic door handles is instructive because it shows what happens when companies prioritize design aesthetics without maintaining adequate mechanical backups. Tesla's approach has evolved over time, but the company's earlier models created situations where occupants genuinely couldn't get out of vehicles.

The Cybertruck's door handles, for instance, became something of an internet meme because they were so difficult to operate in normal circumstances, let alone emergencies. Over time, Tesla has adjusted, but the damage to public perception has been done. Lawsuits have been filed. Investigations have been opened. The company has had to make public statements about addressing the issue.

Rivian's approach is notably different. Rather than defending a design choice or claiming it's not really a problem, the company simply changed it. The message is clear: safety comes first, even if it means the interior door handle isn't as minimalist as it could be.

This isn't revolutionary. It's actually just sensible engineering. But in an industry where companies often double down on controversial design choices, it stands out.

How Occupants Would Actually Use the New Release System

Let's imagine a real scenario. A Rivian R2 has been in an accident. The battery has been damaged. All power systems are offline. A rear-seat passenger needs to get out, but the electronic door button is dead. What happens next?

The passenger reaches for the door handle. Behind a piece of plastic trim, they find a release mechanism. They pop out the plastic. They locate the manual release cord or lever (exact design details haven't been fully disclosed, but it's similar to the front door approach). They pull it. The mechanical linkage activates, the latch releases, the door opens.

Compare this to the R1: same scenario, but now the passenger has to find and remove an interior door panel. They have to locate the hidden release cord. If they're injured, if visibility is poor, if they're panicking, this becomes exponentially harder. Every second matters in a real emergency.

The R2's approach reduces friction at every step. The mechanism is in an obvious location. It doesn't require tool access or knowledge of the vehicle's interior architecture. It's intuitive.

Now, realistically, how often does this scenario occur? Rarely. Modern vehicles have multiple power management systems, multiple batteries, and multiple redundancies. A total power loss that disables all door operation is uncommon. But in a severe crash, where the vehicle's main battery and backup systems have both been compromised, this is exactly when you need the mechanical backup to work reliably.

Rivian's design acknowledges this reality and prioritizes it accordingly.

Industry-Wide Pressure: The Push for Better Manual Releases

Rivian didn't start this conversation. Tesla's lawsuits and investigations put manual door releases on the radar. NHTSA's scrutiny added pressure. But once one major automaker starts addressing it, others feel compelled to follow.

Ford's Mustang Mach-E had its own issues with electronic door latches, leading to a recall. That recall forced engineers at every other company to review their own systems. Are our doors safe? Are our backups adequate? What could go wrong?

The irony is that this conversation never needed to happen. Mechanical door releases have been solved for over a hundred years. Cars open from the inside. It's a basic expectation. But somewhere along the way, as automakers pursued minimalist interior designs and fully electronic systems, the basics were de-prioritized.

Now, the industry is course-correcting. Some manufacturers are making manual releases more accessible. Some are adding mechanical overrides to doors that were previously electronic-only. Some are redesigning interiors to make backup systems more prominent.

Rivian's choice to redesign the R2's rear door release is part of this broader trend. It's not leadership in the sense of setting the direction. It's more like recognition that a previous design choice was suboptimal and fixing it before the vehicle ships.

The Technical Details: What We Know and Don't Know

Exact specifications for the R2's new release system haven't been fully detailed by Rivian. The company hasn't published engineering documentation explaining the mechanism. What we know comes from early preview videos and hands-on reviews.

From those sources, we know that the rear manual release is positioned at the front of the interior handle, similar to the front door design. We know it's still behind plastic trim that must be popped out. We know it's more accessible than the R1's design.

What we don't know are specifics like the exact location and depth of the mechanism, the force required to activate it, whether it's a cord or a lever, and how it's documented in the owner's manual.

These details matter because accessibility in an emergency depends on precision. A mechanism that's intuitive for a tall, uninjured adult might be impossible for a small child or someone with limited mobility. Visibility and lighting matter. The distance the mechanism needs to move matters. The force required matters.

Rivian will need to test this extensively. NHTSA will likely review it. And real-world feedback from owners will reveal whether the design achieves its goals.

Safety Standards and Regulatory Implications

There's no federal requirement for manual door releases in electric vehicles. This is a gap in regulation that's only now being addressed. NHTSA has been investigating, but no new rules have been formally adopted.

This puts automakers in an awkward position. They have to comply with existing regulations, which often predate electronic door systems. But they also have to deal with public expectations and safety concerns that regulations haven't caught up with.

Rivian's approach is to exceed the existing standard. Rather than meeting minimum requirements, the company is building in a system that acknowledges the real-world scenario of total power loss. This is good engineering practice. It's also good business practice, because it demonstrates that the company takes safety seriously.

However, this also highlights a problem: if there are no regulatory requirements, then automakers can choose how much safety they want to prioritize. Some will go above and beyond, like Rivian. Others will do the minimum. This creates a patchwork of different approaches across the industry.

Eventually, someone will likely push for federal standards that specify how manual releases must be accessible, how they must be labeled, and how vehicles must be tested to ensure they work reliably. When that happens, all automakers will need to comply. Those who've already invested in good designs, like Rivian, will be ahead of the curve.

Comparing R2 to R1: The Evolution of Rivian's Safety Philosophy

Rivian's first vehicles, the R1T truck and R1S SUV, established the company's basic approach to vehicle design. They're well-reviewed vehicles overall, but the rear door manual release design was acknowledged as suboptimal from the start.

Some reviewers noted the complexity of accessing the release. Some safety advocates flagged it as a potential issue. But the vehicles shipped as designed, and the company didn't issue a recall or major update.

With the R2, which launches later in 2025 and into 2026, Rivian had a second opportunity to get it right. The company apparently took that opportunity seriously. Rather than incrementally tweaking the R1's design, Rivian fundamentally reconsidered how the rear manual release should work.

This suggests that the company was listening to feedback and taking safety seriously. It also suggests that the R2 is genuinely a fresh design, not just a smaller version of the R1. Major architectural decisions were revisited and reconsidered.

Will this translate to owner satisfaction? Probably. People appreciate when companies acknowledge past issues and fix them. But it also depends on how well the new design is executed and how clearly it's communicated to owners and rescue personnel.

The Role of Crowdsourced Testing and Early Reviews

Before the R2 ships in volume, early adopters and reviewers will test it. Some YouTube channels, like Jerry Rig Everything, have already published detailed looks at the new vehicle's design. These early videos show the manual release location and how to access it.

This kind of crowdsourced testing and documentation is valuable because it provides real-world feedback before millions of vehicles are on the road. If the manual release design has issues, reviewers will discover them. If it's genuinely accessible, reviewers will confirm that.

The fact that Rivian apparently allowed early reviewers to document the manual release mechanism suggests confidence in the design. Companies that are worried about safety issues typically try to minimize documentation of potential problems. Rivian's apparent openness is a good sign.

Of course, early reviews are limited. They might miss edge cases or rare failure modes. But they provide valuable data points that inform both consumers and the automotive industry.

Common Questions About Manual Door Releases

When videos of the R2's manual release started circulating, people had questions. How exactly do you pop out the plastic? How much force is required? Is it immediately obvious what to do? What if you're panicking or injured?

These questions don't have complete answers yet because the R2 hasn't shipped in volume. But Rivian will presumably provide clear instructions, both in the owner's manual and possibly with labels on the door itself.

Good design often includes clear labeling. If the R2's manual release has a label that says "Emergency Release" or "Manual Open," that's helpful. If it requires knowledge of the vehicle's design to figure out, that's less helpful.

Safety features that depend on user knowledge are less reliable than safety features that are self-evident. This is a principle in safety engineering called "intuitive design." Can someone figure out how to use the system without instruction? If yes, it's better designed.

Rivian's choice to put the manual release in a consistent location across front and rear doors is a step toward intuitive design. But the fact that it's still hidden behind plastic suggests there's room for further improvement.

Future Evolution: Where Door Safety Design is Headed

In the long term, automakers might move beyond mechanical backup systems entirely. Imagine a vehicle with multiple independent battery systems, multiple independent door control systems, and redundant mechanical lockups that ensure doors can always be opened mechanically, even if all electronics fail.

This level of redundancy would be expensive and complex. But it would eliminate the question of whether a manual release is accessible enough. The doors would simply work, always, under any condition.

In the near term, though, mechanical backups are the standard solution. And improving how those backups work is a sensible engineering goal.

Rivian's R2 represents a middle ground. It's not revolutionary, but it's thoughtfully executed. The company looked at what worked in other vehicles, what didn't work, and what NHTSA was likely to prioritize. Then it designed accordingly.

Other automakers will probably follow similar logic. Over the next few years, you'll likely see manual door releases become more accessible across the industry. Some companies will emphasize labeling. Some will make the mechanisms more prominent. Some will add multiple redundant systems.

The goal, ultimately, is to return to a basic truth: cars should always be able to be opened from the inside. That expectation has been tested by modern electronics, but it's not negotiable.

What This Means for R2 Owners and Prospective Buyers

If you're considering buying an R2, the improved manual door release is a minor but genuine safety improvement. It's not going to be the deciding factor for most buyers. But it's worth knowing about.

More importantly, it suggests that Rivian is thinking seriously about safety. The company didn't have to redesign the rear door release. It could have left it as is. Instead, it chose to improve it based on industry feedback and safety considerations.

This design choice is a signal. It tells you that Rivian is listening to safety concerns, that the company is willing to make changes to address them, and that the R2 has been thoughtfully designed rather than rushed to market.

For current R1 owners, there's probably no retrofit available. The R1's design is baked into the vehicle. But knowing that the R2 addresses this issue might influence future purchase decisions or upgrade timing.

The Bigger Picture: Why Door Design Matters

Electric vehicles are new. Many of them are pushing the boundaries of what's possible with automotive design. But some of the most basic expectations—like being able to open the door in an emergency—are older than cars themselves.

There's a temptation in the industry to assume that multiple electronic redundancies make mechanical backups obsolete. But real-world incidents have proven that assumption wrong. When batteries fail, when electronics malfunction, when unexpected scenarios occur, the mechanical backup system is all that stands between occupants and a truly dangerous situation.

Rivian's decision to improve the R2's manual door release acknowledges this reality. It's not complicated or revolutionary. It's just good engineering: identify a potential failure mode, design a backup system, make sure the backup system works reliably, and make sure people can use it in an emergency.

This is exactly what automakers should be doing across all their safety systems. It's refreshing to see a company execute on it, even if it's for something as basic as a door handle.

Industry Standards and Best Practices Going Forward

As the industry evolves, there will likely be more formal standards for manual door releases. These standards might specify:

- Accessibility: How visible and accessible the mechanism must be

- Activation force: How much force is required to activate the release

- Documentation: How the release must be labeled and described in owner's manuals

- Testing: How vehicles must be tested to ensure the system works reliably

- Rescue access: How rescue personnel can access the release

Rivian's R2 design seems to anticipate some of these standards. By positioning the release in a consistent, accessible location, the company is implementing good practice.

Other automakers will likely follow similar approaches. Over time, this will lead to greater consistency across the industry, which is good for consumers and rescue personnel alike.

The alternative is a patchwork of different designs where every vehicle requires different knowledge to open in an emergency. That's not acceptable from a safety perspective.

Testing and Validation: How Rivian Ensures Reliability

Before shipping the R2, Rivian must test the manual door release system extensively. This testing should include:

- Functional testing: Does the mechanism work reliably across thousands of cycles?

- Environmental testing: Does it work in cold, heat, humidity, and salt spray conditions?

- Accessibility testing: Can people of different ages, sizes, and abilities activate it?

- Emergency scenario testing: Does it work when people are panicked or injured?

- Integration testing: Does it work properly when integrated with the rest of the door system?

Rivian doesn't publish detailed test results, but the company presumably conducts this testing. If early reviews report that the manual release works smoothly and is easy to find, that's a good sign that the testing was successful.

As the R2 ships and thousands of vehicles go into real-world use, additional validation occurs. If the system has issues, owners will report them. If there are problems, Rivian can address them through recalls or design changes for future vehicles.

Conclusion: Small Design Changes That Make a Difference

The redesign of the R2's rear manual door release might sound like a minor engineering detail. It's not going to make headlines. It's not going to drive sales decisions. But it's genuinely important.

It represents a commitment to safety that goes beyond regulatory requirements. It shows that a company is willing to revisit design decisions and improve them based on feedback and real-world data. It demonstrates that even in the rush to build new electric vehicles, the basics—like making sure people can get out of cars in an emergency—remain important.

Ford, Tesla, and other automakers have had to deal with door-related safety issues. Rivian looked at those issues and decided to do better with the R2. That's not revolutionary. But it's exactly what we should expect from automakers: continuous improvement driven by learning from the industry and commitment to safety.

As more electric vehicles reach market, this kind of thoughtful design work becomes increasingly important. Customers need to trust that their vehicles are safe under normal conditions and in emergencies. Rivian's approach to the R2's manual door release contributes to that trust.

The result is a vehicle that's not only innovative in its power systems and technology, but also fundamentally sound in its approach to basic safety. That's worth noting, even if it is just a door handle.

FAQ

What is a manual door release in electric vehicles?

A manual door release is a mechanical backup system that allows occupants to open a vehicle door from the inside without relying on electronic systems. In modern electric vehicles with electronic door handles and buttons, the manual release serves as a critical safety backup if the power systems fail, the battery is damaged, or the electronic door actuators malfunction.

How does the Rivian R2's new manual door release work?

On the Rivian R2, the rear manual door release has been repositioned to the front part of the interior handle, matching the design of the front doors. While still partially hidden behind plastic trim that must be popped out, this new location is more accessible than the previous R1 design, which required removing an interior door panel. The mechanism allows passengers to mechanically open the door by pulling the release, even if all electronic systems have failed.

Why did Rivian change the manual door release design?

Rivian redesigned the R2's manual door release to improve accessibility and safety, addressing industry-wide concerns about electronic door systems. Following high-profile incidents with other electric vehicles and regulatory scrutiny from the National Highway Traffic Safety Administration (NHTSA), Rivian decided that the R1's design was overly complex. By moving the release to a more logical location, the company reduced the time and difficulty required to access the mechanism in an emergency.

What was wrong with the R1's manual door release system?

The Rivian R1 required rear-seat passengers to remove an interior door panel to access the manual release cord. This added significant complexity and time to accessing the emergency mechanism. In a crisis situation, where every second counts, this design created unnecessary friction and made the safety backup system less accessible than it should be.

How does the R2's design compare to Tesla's door handle problems?

Tesla faced multiple lawsuits and investigations when occupants couldn't open their doors during emergencies due to complex or inaccessible manual releases. Rivian's approach with the R2 is notably different: rather than defending a design choice, the company proactively improved it. By positioning the manual release in an intuitive location and eliminating the need for panel removal, Rivian demonstrated commitment to making the backup system genuinely accessible.

Are there regulatory requirements for manual door releases in electric vehicles?

Currently, there are no specific federal regulations mandating how accessible manual door releases must be in electric vehicles. However, the National Highway Traffic Safety Administration (NHTSA) has been investigating door-related safety issues and is likely to establish formal standards in the future. Rivian's R2 design appears to anticipate these potential standards by implementing best practices for accessibility and consistency.

Will other automakers follow Rivian's approach to manual door releases?

Likely yes. As safety concerns about electronic door systems have become more prominent and regulatory scrutiny has increased, other automakers are reassessing their own designs. Ford's recall of the Mustang Mach-E due to electronic door latch issues and ongoing scrutiny of Tesla's designs are pushing the industry toward more accessible manual release systems. Rivian's R2 represents a practical solution that other manufacturers can learn from.

How important is the manual door release in modern vehicles?

Very important, though rarely needed in normal circumstances. The manual release serves as a critical last resort in severe crashes where the vehicle's main battery, backup power systems, and electronic door actuators have all been compromised. While such total power loss is uncommon, when it does occur, the mechanical backup system can be the difference between occupants being able to exit the vehicle safely and being trapped inside.

Can the R2's manual door release be easily retrofitted to R1 vehicles?

Unlike a software update, the R2's improved manual door release design would require significant structural modifications to the R1's doors, handles, and trim components. A complete retrofit would likely be impractical and expensive. However, Rivian could potentially offer retrofit kits for the most critical components, though the company hasn't announced any plans to do so.

What happens if you try to use the R2's manual release with the power on?

The manual release mechanism is independent of the electronic system, so it should work whether the power is on or off. However, the exact interaction between the mechanical release and the electronic latch system hasn't been fully detailed by Rivian. In normal use, owners would rely on the electronic button to open doors. The manual release is strictly for emergency scenarios when the electronic system isn't functioning.

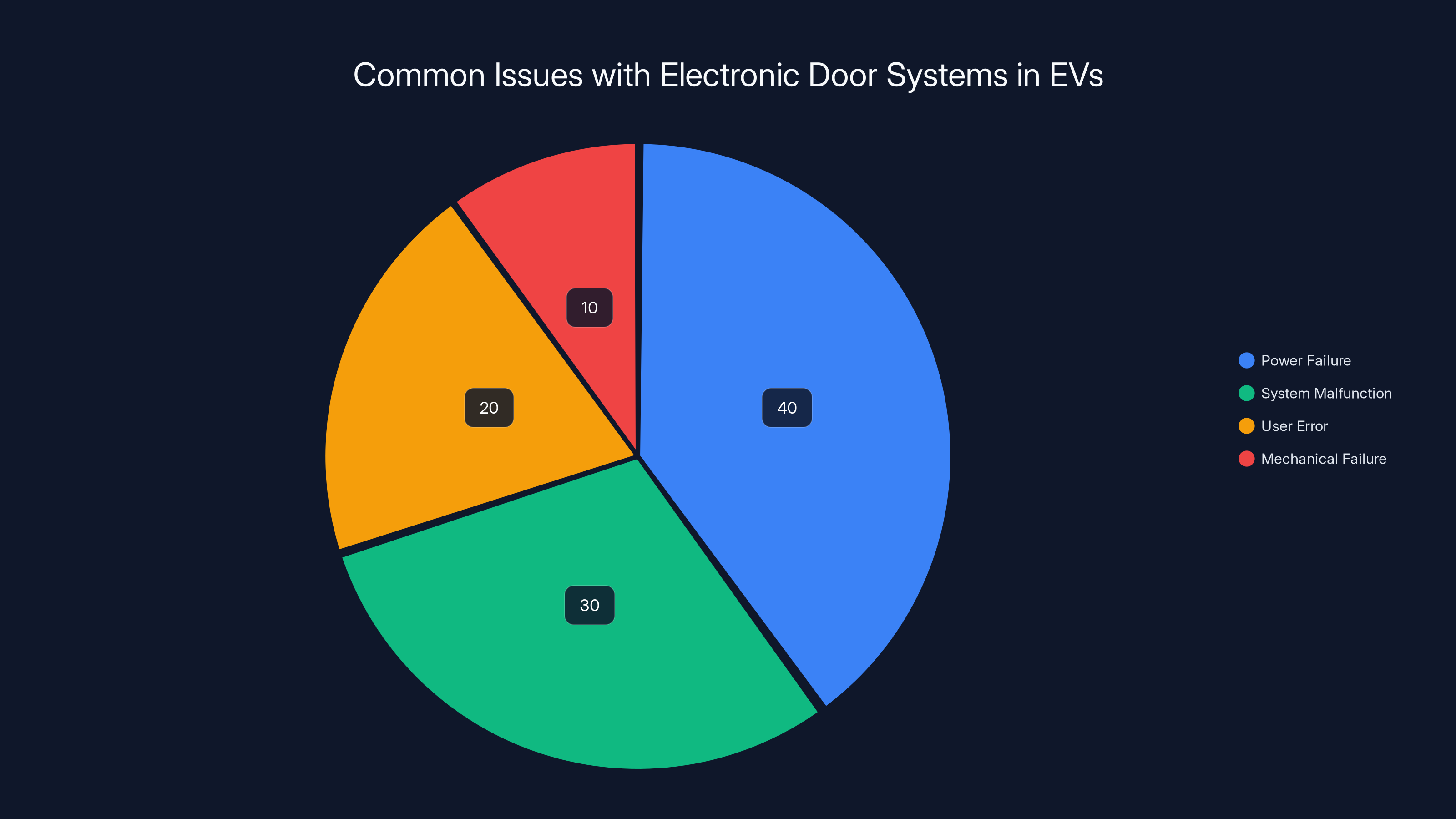

Power failures account for the largest share of issues with electronic door systems in EVs, highlighting the need for reliable manual overrides. Estimated data.

Understanding Modern Vehicle Safety: A Deeper Look

The conversation about manual door releases reveals something broader about how modern vehicles are engineered. Every system is designed with redundancy in mind, but not all redundancies are created equal.

Electronic systems fail. Batteries get damaged in accidents. Components malfunction. Good engineering acknowledges these realities and designs accordingly. The question isn't whether backups are needed. The question is whether the backups are actually usable when needed most.

Rivian's approach with the R2 suggests the company understands this principle. By making the manual release accessible and intuitive, Rivian is saying that safety isn't just about having a backup. It's about having a backup that actually works when you need it.

This kind of thinking extends to other vehicle systems as well. Emergency brakes, power steering backups, fuel shutoff mechanisms, and dozens of other safety features all follow the same logic: primary system, redundant backup, and assurance that the backup works reliably.

For consumers, this should be reassuring. Modern electric vehicles aren't less safe than traditional cars. But they are different, and understanding those differences helps you appreciate both the capabilities and the limitations of the vehicles you drive.

Rivian's willingness to publicly discuss and improve its door release design is a positive signal about how the company approaches safety overall. The R2 will be tested thoroughly before it ships, and early adopters will provide additional real-world feedback. Over time, we'll know whether the redesign actually achieved its safety goals.

Until then, the fact that the company took the concern seriously enough to redesign the system is worth noting. In an industry where some companies defend controversial safety decisions, Rivian chose to improve instead. That's exactly what we should expect from automakers.

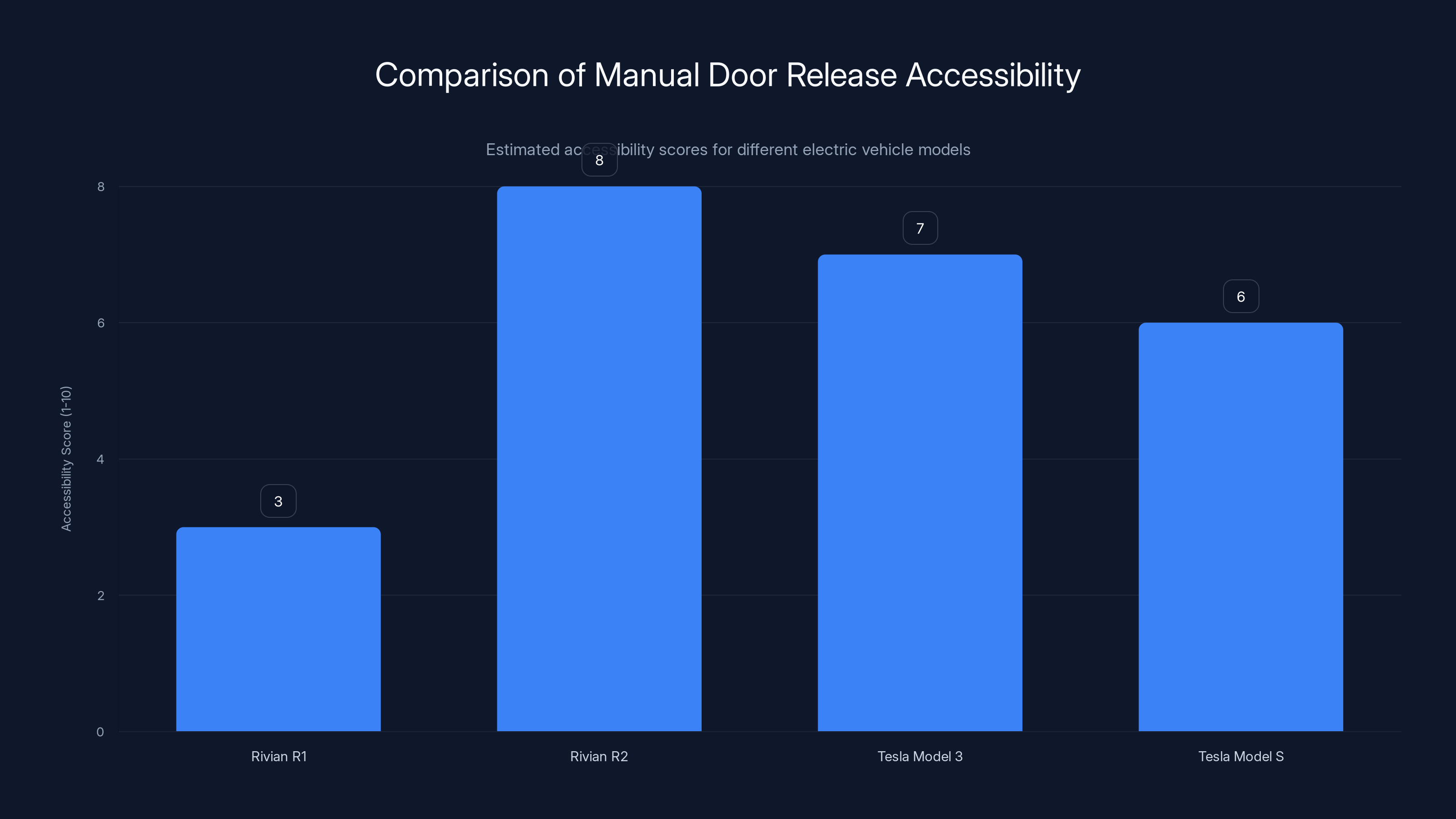

The Rivian R2's manual door release design significantly improves accessibility compared to the R1, aligning more closely with Tesla's models. (Estimated data)

Key Takeaways

- Rivian repositioned the R2's rear manual door release to be consistent with front door design, eliminating the need for panel removal

- The redesign was motivated by safety concerns raised by Tesla lawsuits and NHTSA investigations into electronic door system failures

- Manual door releases serve as critical backup systems when vehicle electronics fail, a scenario that while rare, can occur in severe accidents

- The R2's improved design reduces emergency access time and makes the system more intuitive for occupants in crisis situations

- Industry-wide pressure is pushing automakers toward more accessible manual release mechanisms and formal safety standards

Related Articles

- Tesla Electronic Door Handles: Deaths, Lawsuits, and Safety Concerns [2025]

- Toyota's Fluorite Game Engine: Redefining In-Car Graphics [2025]

- 2026 Lamborghini Temerario: The Hybrid Supercar Revolution [2025]

- Waymo Robotaxi Hits Child Near School: What Happened & Safety Implications [2025]

- TikTok Data Center Outage: Inside the Power Failure Crisis [2025]

- TikTok's US Data Center Outage: What Really Happened [2025]

![Rivian R2 Manual Door Release: Design Changes Explained [2025]](https://tryrunable.com/blog/rivian-r2-manual-door-release-design-changes-explained-2025/image-1-1770753962435.jpg)