Samsung's Plankton E-Paper Display: The Future of Sustainable Screens

Here's something you probably didn't expect to read today: Samsung is literally building screens from ocean plankton. Not metaphorically. Actually. And it might be one of the most significant breakthroughs in display technology we've seen in years. According to TechBuzz, this innovation is set to revolutionize the industry.

When you first hear this, your brain probably goes to the same place mine did. Screens made from plankton sounds like science fiction. Like something out of a far-future tech magazine where they're also serving lab-grown caviar and traveling via submarine. But Samsung's research team is dead serious about this, and the implications are honestly wild.

The reason this matters goes way beyond the novelty factor. E-ink displays have been around since the early 2000s, and they haven't fundamentally changed all that much. Your Kindle uses the same core technology your Kindle from 2009 used, just refined and faster. Those displays rely on electrophoretic particles suspended in a liquid solution. Samsung's plankton-based approach replaces traditional materials with bio-derived components that are more sustainable, potentially cheaper to produce at scale, and could open entirely new possibilities for display performance, as noted by Android Police.

But here's the thing nobody's talking about yet: this isn't just about making environmentally friendly e-readers. This is about rethinking how we manufacture displays from the ground up. Traditional e-ink involves rare earth materials, complex chemical processing, and significant environmental footprint. Plankton is renewable. It grows in the ocean. You can harvest it sustainably. Scale up production, and suddenly you're not mining materials from the earth—you're farming them from the water.

What makes Samsung's announcement particularly interesting is the timing. The display industry is under increasing pressure to reduce its environmental impact. Consumer electronics manufacturers are facing regulatory scrutiny around supply chains, waste, and carbon footprints. Meanwhile, demand for e-readers, digital signage, smart labels, and other e-ink applications keeps growing. Samsung found a way to solve both problems simultaneously, as highlighted in Vocal Media.

What Exactly is Plankton-Based E-Paper?

Let's get into the actual technology, because it's more sophisticated than just "putting plankton on a screen."

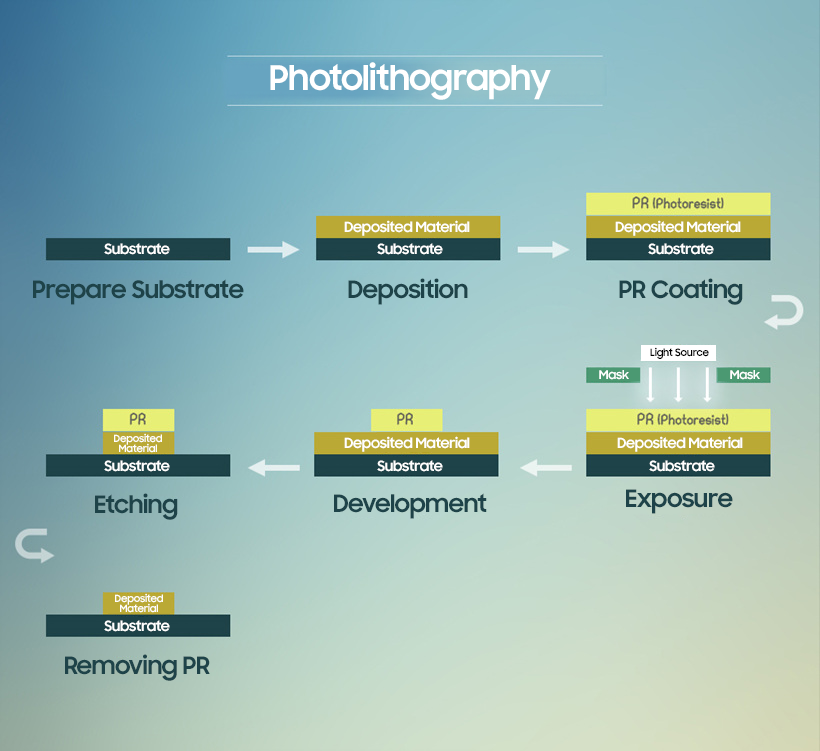

Traditional e-ink displays work through a principle called electrophoresis. Inside a layer of microencapsulated liquid, tiny colored particles (usually titanium dioxide for white and carbon black for dark) are suspended. When you apply an electrical charge, these particles move toward different electrodes, creating visible text or images. The image stays on screen with zero power consumption until you change it. That's why e-readers are famous for their incredible battery life.

The problem with traditional e-ink is what goes into that liquid suspension and what creates those particles. The manufacturing process involves chemical synthesis, requires precise control over particle size and shape, and depends on materials that don't grow naturally. You're essentially creating everything from scratch, which is energy-intensive and generates waste.

Samsung's plankton-based approach replaces the synthetic particles with naturally-occurring organic structures derived from marine phytoplankton. Plankton cells have an interesting property: they're already structured at the microscopic level in ways that can respond to electrical fields. Instead of synthesizing particles, Samsung's team is essentially using biology to create the functional components, as reported by TechRadar.

This is the crucial difference. You're not reinventing the wheel—you're using nature's engineering. Plankton has evolved over millions of years to have characteristics that make it surprisingly useful for this application. The organisms have cell structures that can hold pigments, reflect light efficiently, and respond predictably to electrical stimulation.

What Samsung figured out is how to stabilize these biological structures, remove the living components, and leave behind the structural framework. The resulting material has several advantages. First, it's completely renewable—you can grow more plankton. Second, the manufacturing process generates significantly less waste because you're not synthesizing chemicals from scratch. Third, the material cost should theoretically be lower because you're harvesting rather than manufacturing.

But there's a practical engineering challenge here that's worth understanding. Biological materials are inherently variable. One batch of plankton isn't identical to another. You can't get the same quality control with naturally-derived materials that you can with synthetic ones. Samsung's breakthrough isn't just discovering plankton works—it's developing the processing techniques to make plankton-derived materials consistent enough for mass manufacturing.

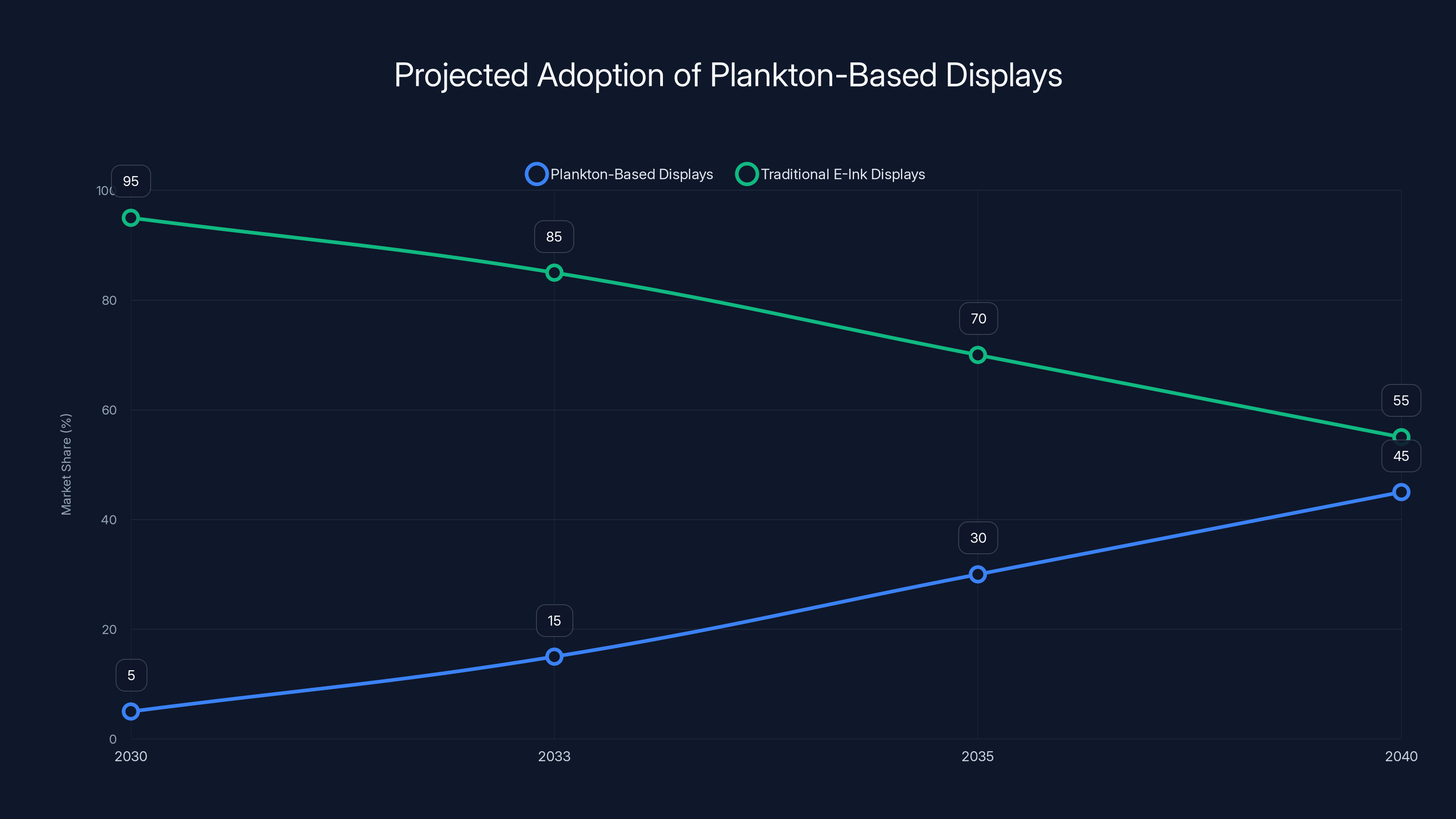

Plankton-based displays are projected to capture up to 45% of the e-paper market by 2040, driven by sustainability and technological advancements. (Estimated data)

How Does Samsung's Discovery Actually Work?

The actual mechanics of Samsung's plankton-based display involve several steps that represent genuine innovation.

First, Samsung had to identify which plankton species would work best. Not all plankton is created equal. Different phytoplankton species have different pigmentation, different structural properties, and different responses to electrical fields. Samsung's research team tested hundreds of species, looking for ones that naturally exhibit the right characteristics. They probably focused on species that are already commercially harvested or easy to cultivate, which matters because you can't build a manufacturing process around something that only exists in three specific locations on Earth.

Once they identified promising species, the next step was developing a harvesting and processing methodology. You can't just take raw ocean water and put it in your display. The plankton needs to be concentrated, processed, and converted into a form that's stable and consistent. This likely involves removing water, stabilizing the cellular structures, and potentially modifying them chemically to improve performance characteristics.

The third major challenge was integration into existing display manufacturing. Samsung couldn't just replace the e-ink material in current production facilities and call it a day. The entire manufacturing pipeline probably needed adjustment. The viscosity of the plankton-based suspension might be different from traditional e-ink. The electrical properties might differ slightly. The way the material encapsulates might need modification. Every step of the process probably required optimization, as detailed by Hackster.io.

What's particularly clever about Samsung's approach is that it's theoretically compatible with existing e-ink display architecture. You don't need to completely reinvent the display structure. The plankton-based material can work in microencapsulated form, just like traditional e-ink. That means Samsung can scale production more quickly because they're not building entirely new manufacturing lines from scratch.

Another key consideration is the electrical properties. Traditional e-ink particles respond predictably to electric fields because their properties are engineered precisely. Plankton-derived particles might respond slightly differently. Samsung would need to adjust the voltage characteristics, the refresh speed, and the refresh pattern to optimize performance. This could actually be an advantage—if plankton-based materials respond better to certain electrical properties, it might enable faster refresh rates or lower power consumption.

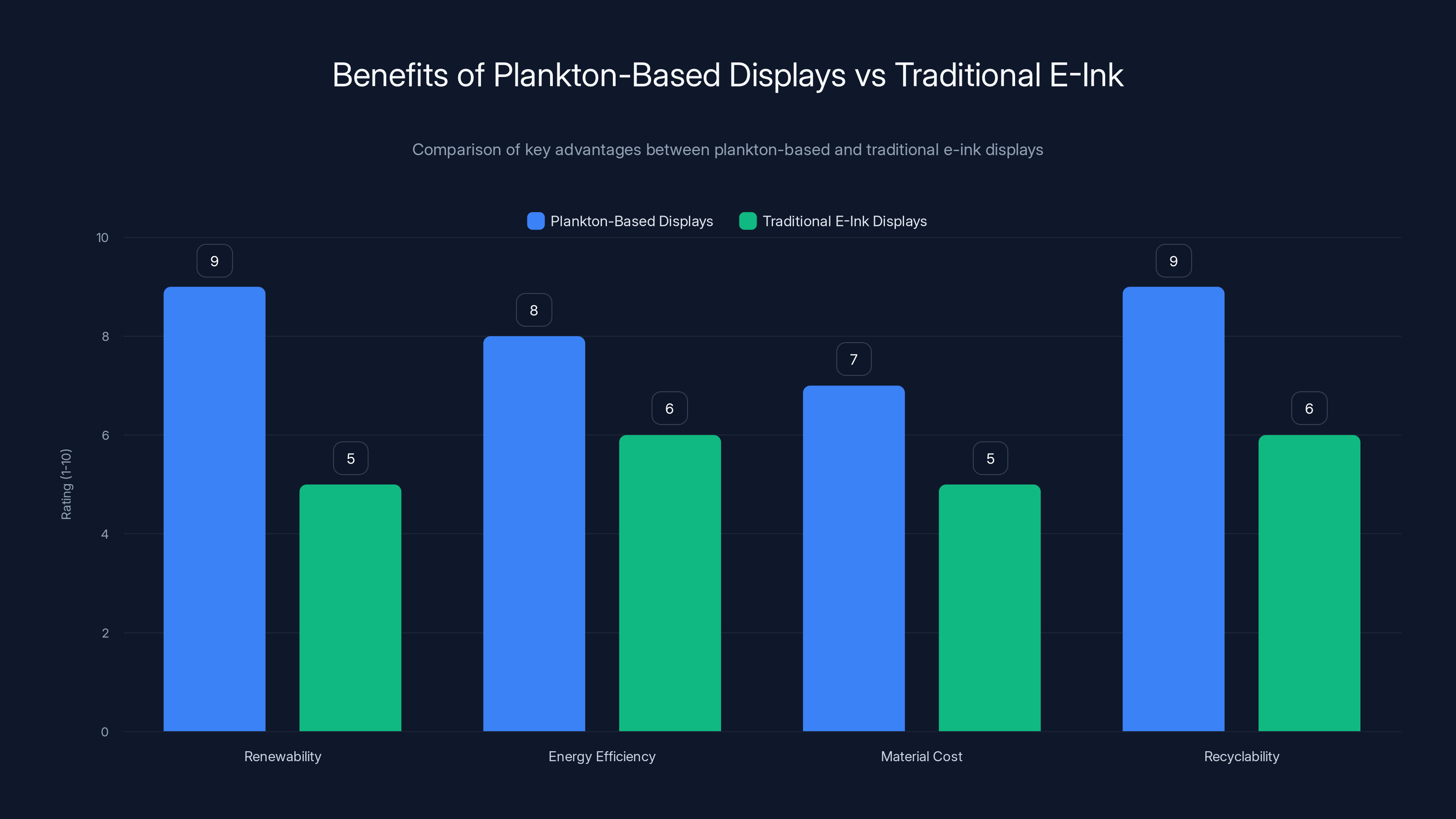

Plankton-based displays are estimated to offer superior renewability, energy efficiency, lower material costs, and better recyclability compared to traditional e-ink displays. Estimated data based on theoretical advantages.

The Sustainability Argument: Why This Matters

Now let's talk about why this is actually important beyond the headline novelty.

The electronics industry generates roughly 57 million metric tons of e-waste annually. That number keeps growing. Most of that waste ends up in landfills or gets shipped to countries where recycling infrastructure is weak. E-reader devices themselves aren't huge contributors to that problem—they're small, they last years, and they have relatively simple construction. But their supply chains are complicated, and every component has an environmental footprint.

Traditional e-ink manufacturing requires mining and refining materials, chemical processing, and energy-intensive manufacturing. The carbon footprint of producing a single e-reader is substantial. A study comparing e-readers to printed books found that it takes about reading 40 to 50 books on an e-reader for the device's environmental impact to be offset by the trees saved from not printing those books. That's not terrible, but it's not great either.

Plankton-based e-paper potentially changes that equation. Here's why.

First, plankton is renewable at a much faster rate than trees or traditional resource extraction. Phytoplankton reproduce rapidly, doubling their populations in days under ideal conditions. You can sustainably harvest plankton without depleting natural ecosystems if done properly. Some research suggests plankton farming could actually be beneficial, removing excess nutrients from water and reducing algal blooms.

Second, the manufacturing process is less energy-intensive. You're not smelting metals or running complex chemical synthesis. You're cultivating organisms, harvesting them, and processing them into usable material. That's significantly less energy than traditional manufacturing. Samsung could theoretically power plankton farms with renewable energy, and suddenly you've got a carbon-negative manufacturing process, as discussed in Market Data Forecast.

Third, plankton-based displays should be easier to recycle. Because the material is biological in origin, it can decompose naturally rather than sitting in a landfill for decades. You might be able to compost end-of-life displays or break them down into constituent materials more easily than traditional e-ink.

Fourth, the supply chain becomes more distributed. You don't need to mine materials in specific locations on Earth. Any region with appropriate coastline and water chemistry could theoretically farm plankton for display manufacturing. That means companies can source materials locally, reducing transportation emissions and creating local economic opportunities.

But here's where we need to be honest about the reality. The sustainability benefits only materialize if Samsung does this right. Plankton farming at industrial scale requires careful management to avoid environmental damage. You need to prevent plankton farms from affecting wild ecosystems. You need to ensure the farming operations themselves aren't energy-intensive or problematic. You need to make sure the entire supply chain from plankton cultivation to display manufacturing to end-of-life recycling is actually more sustainable than the traditional approach.

Samsung isn't making any grand claims yet. The company is in the research phase. But if they can solve the scaling and manufacturing challenges, this could genuinely shift the entire display industry toward more sustainable practices, as highlighted by BusinessWire.

Comparing Traditional E-Ink vs. Plankton-Based Display Technology

Let's break down how these two approaches actually differ in practical terms.

Material Sourcing

Traditional e-ink relies on synthesized particles, primarily titanium dioxide for white and carbon black for dark areas. These materials require mining and industrial processing. Titanium dioxide comes from ilmenite deposits that need to be mined, processed, and refined. Carbon black is produced by incomplete combustion of heavy petroleum products. Both materials have established supply chains but also established environmental footprints.

Plankton-based materials are harvested from cultured organisms. The plankton grows in water, you harvest it, you process it. In theory, this is renewable and repeatable indefinitely. In practice, the sustainability depends entirely on farming methodology.

Manufacturing Complexity

Traditional e-ink manufacturing is highly standardized. Companies have been refining the process for over 20 years. The particle synthesis is well-understood, quality control is predictable, and the process integrates seamlessly into existing display manufacturing infrastructure.

Plankton-based manufacturing is novel. Samsung is essentially pioneering a new approach. The processes will be less established, more variable initially, and will require investment in new equipment and expertise. But once the processes are optimized, plankton farming could actually be simpler than chemical synthesis—growing organisms might be more efficient than synthesizing chemicals.

Performance Characteristics

Here's where it gets interesting. Traditional e-ink has been optimized to death. Refresh rates are fast (though still slower than LCD displays). Contrast is excellent. Color capabilities have improved dramatically in recent years with advances in color e-ink technology. The performance characteristics are well-understood and highly reliable.

Plankton-based e-paper is unproven at scale. We don't know yet if it matches or exceeds traditional e-ink performance. It might have advantages—potentially faster refresh rates, better contrast, or new color capabilities if different plankton species have different pigmentation properties. Or it might have disadvantages—potentially slower refresh rates, lower contrast, or more limited color range. Samsung hasn't published performance specifications yet.

Cost Structure

Traditional e-ink has enormous manufacturing infrastructure investment already in place. Companies like E Ink Holdings have been building factories and optimizing production for two decades. That's created economies of scale that are hard to beat. A new e-ink display from a major manufacturer is inexpensive largely because the process is so established.

Plankton-based displays would require new infrastructure initially, driving up costs. But the raw material cost should be lower because you're farming rather than mining and synthesizing. At scale, plankton farming could become incredibly cheap—you're just growing organisms. As manufacturing processes improve and become standardized, costs could drop below traditional e-ink.

Let me be honest though: it'll probably take five to ten years before plankton-based displays are cheaper than traditional e-ink at scale. The initial deployment will likely be premium products where Samsung can charge more because of the sustainability angle.

Environmental Impact

This is where plankton-based displays have their strongest argument. Traditional e-ink's environmental impact is well-documented: mining emissions, chemical processing emissions, waste generation, and transportation. The full lifecycle carbon footprint is significant.

Plankton-based displays could have a dramatically lower environmental impact if farmed sustainably. The farmed organism growth actually sequesters carbon. The processing should be less energy-intensive. The materials decompose naturally rather than persisting in the environment. And the entire supply chain can be localized.

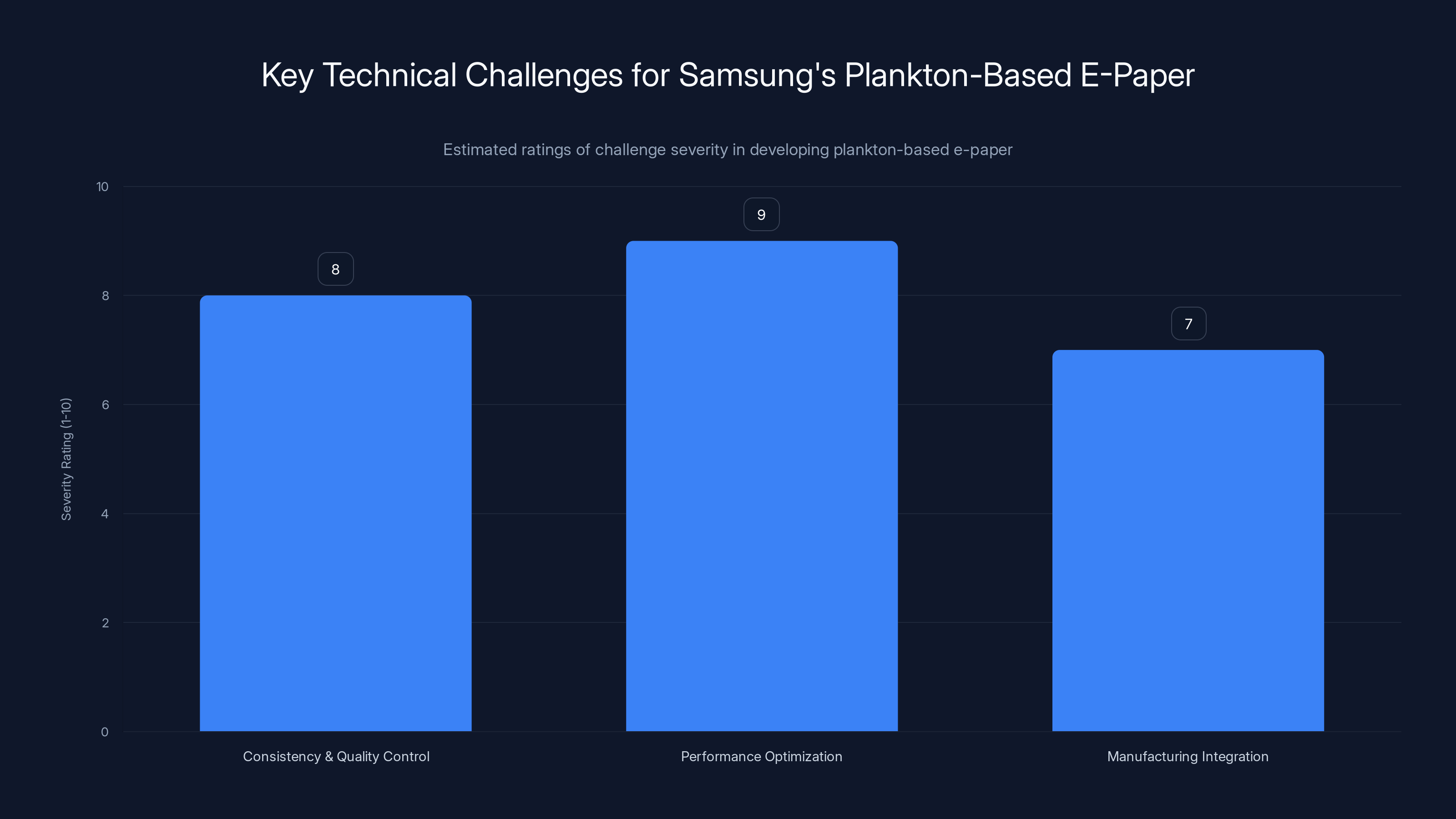

Samsung faces significant challenges in developing plankton-based e-paper, with performance optimization being the most severe. Estimated data.

Potential Applications Beyond E-Readers

Here's what most people miss when they hear about plankton-based e-paper: the implications extend far beyond e-readers.

Digital signage is a massive market. Retailers use electronic shelf labels to display prices and product information. Right now, these are printed in bulk or use traditional e-ink. Plankton-based e-ink could revolutionize this space. Imagine sustainable electronic price labels throughout every retail store, updated remotely, with essentially zero power consumption when displaying static content.

Public information displays are everywhere. Bus stops, transit stations, airport signage, hospital wayfinding. Most of these still use paper or printed materials that need constant replacement. Some use LCD displays that consume significant power. Plankton-based e-paper could provide a sustainable alternative that's readable in sunlight, uses minimal power, and can display different information dynamically.

Smart clothing and wearables represent an emerging market. What if you could manufacture flexible e-paper displays from plankton-based materials and integrate them into clothing? Imagine a jacket with an e-paper display showing weather information, or a shirt with dynamically changing patterns. The sustainability argument becomes even stronger because clothing already has significant environmental impact—adding sustainable displays could improve the overall sustainability profile.

Think of ambient displays and Internet of Things devices. Thousands of small Io T sensors could benefit from e-paper displays that require minimal power. Right now, many Io T devices have no display at all because traditional displays consume too much power. Plankton-based e-paper could enable ubiquitous displays throughout smart homes and industrial environments.

Biomedical applications are worth considering. What if you could create implantable or wearable medical displays from biocompatible plankton-derived materials? It sounds far-fetched, but the biocompatibility of naturally-derived materials makes this theoretically possible.

Book-like devices and portable reading devices represent the original and still-largest market. But the expansion to these other applications multiplies the market opportunity. If Samsung can successfully demonstrate plankton-based e-paper, we could see it spread across an enormous range of applications over the next decade.

Technical Challenges Samsung Still Needs to Solve

Before plankton-based e-paper hits the market, Samsung needs to overcome some significant engineering challenges.

Consistency and Quality Control

Biological materials are inherently variable. One batch of cultured plankton isn't identical to another. Water chemistry changes. Growing conditions fluctuate. Harvest timing affects cell properties. All of these factors introduce variability that would be problematic in display manufacturing.

Samsung needs to develop processes that normalize this variability. This might involve selective breeding of plankton strains, optimized growing conditions, or post-processing treatments that standardize the material properties. The company probably needs to achieve consistency levels comparable to synthetic e-ink—meaning batch-to-batch variations need to be minimal enough that display performance remains consistent.

Performance Optimization

There's a long list of display characteristics that need optimization: refresh speed, contrast ratio, color accuracy, pixel response time, viewing angle, temperature stability, and long-term stability. Traditional e-ink has been refined across two decades to optimize all of these factors.

Plankton-based e-ink starts from scratch on many of these dimensions. Samsung needs to figure out the electrical properties of plankton-derived particles, determine optimal suspension liquid chemistry, establish refresh protocols, and validate long-term performance across thousands of refresh cycles.

Manufacturing Integration

Even if the material itself works perfectly, integrating it into existing display manufacturing requires solving practical engineering problems. Microencapsulation processes might need adjustment. Coating processes might need modification. Electrical connection methods might need optimization. Quality assurance testing needs to be developed.

Samsung can leverage its existing e-ink display expertise here, but each of these integration challenges requires solving before mass manufacturing is viable.

Scaling and Cost Reduction

Lab demonstrations are one thing. Scaling to the millions of displays produced annually is something else entirely. Samsung needs to develop plankton farming infrastructure, establish supply chains, train manufacturing personnel, and optimize every step of the process for cost and efficiency.

The initial cost structure will probably be higher than traditional e-ink. Samsung needs a clear roadmap for cost reduction as manufacturing scales up. Otherwise, plankton-based displays will remain expensive novelties rather than becoming mainstream products.

Regulatory and Environmental Compliance

Manufacturing plankton-derived materials requires different regulatory considerations than traditional e-ink. Environmental agencies will want assurance that plankton farming doesn't damage ecosystems. Health agencies will want verification that the final displays are safe for consumer use. Chemical agencies will want confirmation that processing chemicals are handled appropriately.

Samsung needs to navigate these regulatory frameworks, potentially across multiple jurisdictions if the company sources plankton from different regions. This isn't a technological challenge per se, but it's a real hurdle that could delay market entry.

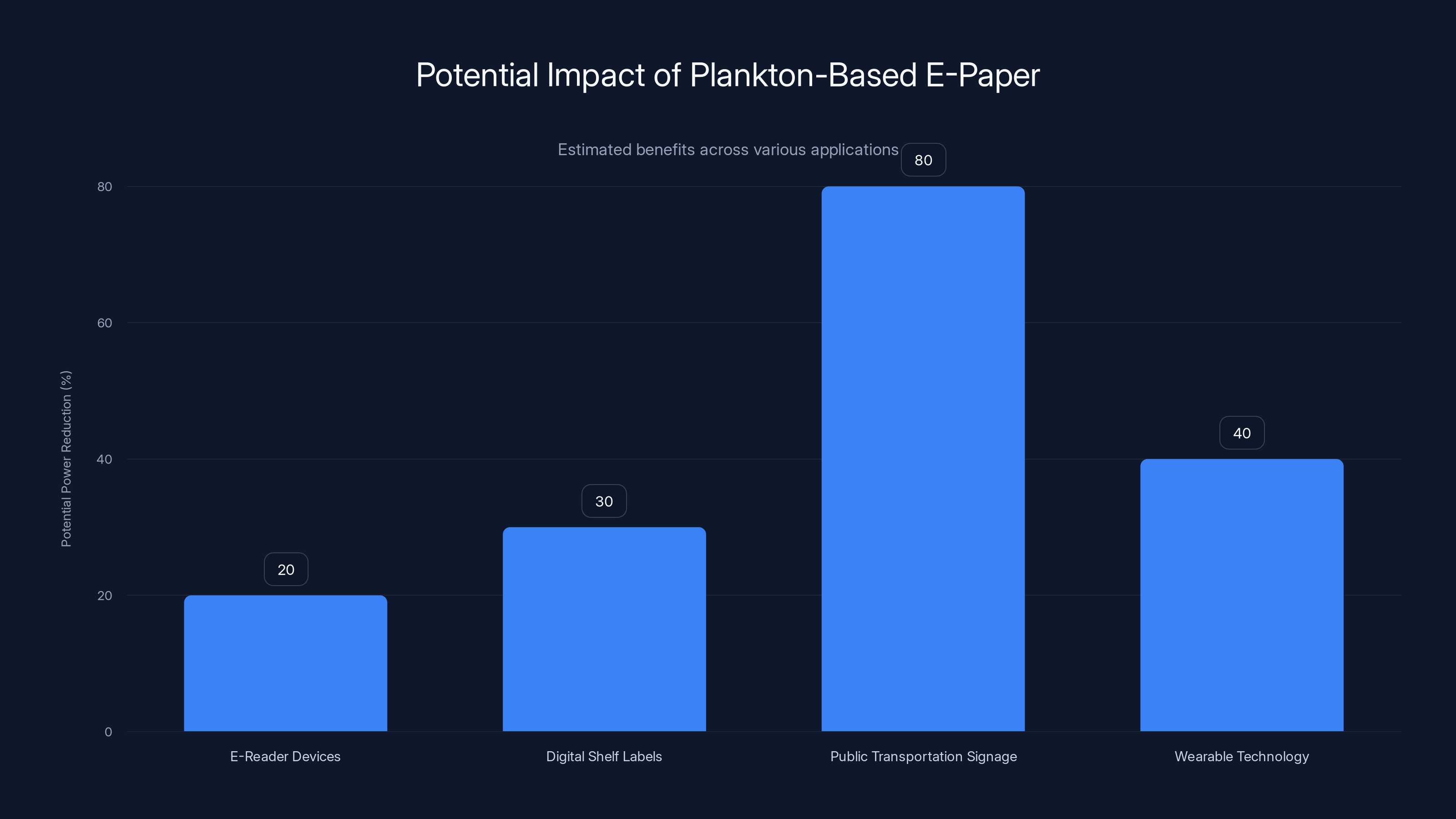

Plankton-based e-paper could significantly reduce power consumption, with public transportation signage seeing up to 80% reduction. Estimated data.

When Could We Actually See Plankton-Based Displays?

Let's be realistic about the timeline. Samsung announced this research, but that doesn't mean plankton-based displays are arriving next year.

The research phase typically lasts three to five years for a material science breakthrough like this. Samsung is working on optimizing the material, developing manufacturing processes, and validating performance. The company probably has working prototypes, but scaling from lab prototype to manufacturing-ready process takes substantial additional work.

Assuming Samsung successfully completes R&D, the next phase is pilot manufacturing. The company needs to build or retrofit factories to produce plankton-based e-ink at meaningful volumes. This might start with small production runs, perhaps a limited edition e-reader made with the new material. This phase typically takes one to two years.

Full-scale commercial production would come next. If Samsung decides plankton-based displays are viable commercially, the company would invest in larger manufacturing facilities and potentially license the technology to competitors. This phase could take another two to three years.

Realistic timeline: we're probably looking at 2027 to 2029 before plankton-based e-readers could reach consumers in meaningful volumes. That's five to seven years from now. It could happen faster if Samsung prioritizes the program and the technical challenges prove less difficult than anticipated. It could happen slower if engineering complexity exceeds current expectations.

But here's the important point: Samsung is investing real resources into this. The company wouldn't announce plankton-based research unless the internal evaluation showed promise. Samsung doesn't have the luxury of betting company resources on moonshot technology that has no practical viability. The fact that this research is being pursued suggests Samsung's engineers believe plankton-based e-paper can actually work and can eventually be competitive with traditional e-ink.

The Broader Impact on Display Technology

Regardless of whether plankton-based e-paper becomes mainstream, Samsung's research signals an important shift in the display industry.

For two decades, the industry has optimized for performance: faster refresh rates, better color, higher contrast, lower power consumption for active displays. Samsung is saying: we also need to optimize for sustainability. That's a meaningful change in industry priorities.

Competitors will take notice. If Samsung successfully demonstrates plankton-based e-paper, other display manufacturers will investigate similar approaches. We might see alternative bio-derived materials explored. Other companies might develop competing plankton-based technologies. Within five years, sustainable display materials could become an active area of competition, the way energy efficiency and color accuracy are today.

The broader display industry is facing pressure from multiple directions. Environmental regulations are tightening. Consumer demand for sustainable products is growing. Supply chain risks for traditional materials are increasing. Any material innovation that addresses these concerns will attract industry-wide attention.

Samsung's announcement also signals to suppliers and manufacturing partners that bio-derived materials are worth investing in. We might see innovation in plankton farming, in material processing, in display manufacturing techniques, all driven by companies preparing for a potential shift toward sustainable display materials.

This could ripple across consumer electronics more broadly. If plankton-based e-paper proves viable, why not explore similar approaches for other display types? Could LCD displays incorporate bio-derived materials? Could OLED displays use organic compounds derived from sustainable sources? The path Samsung is exploring could inspire innovations across the entire display industry.

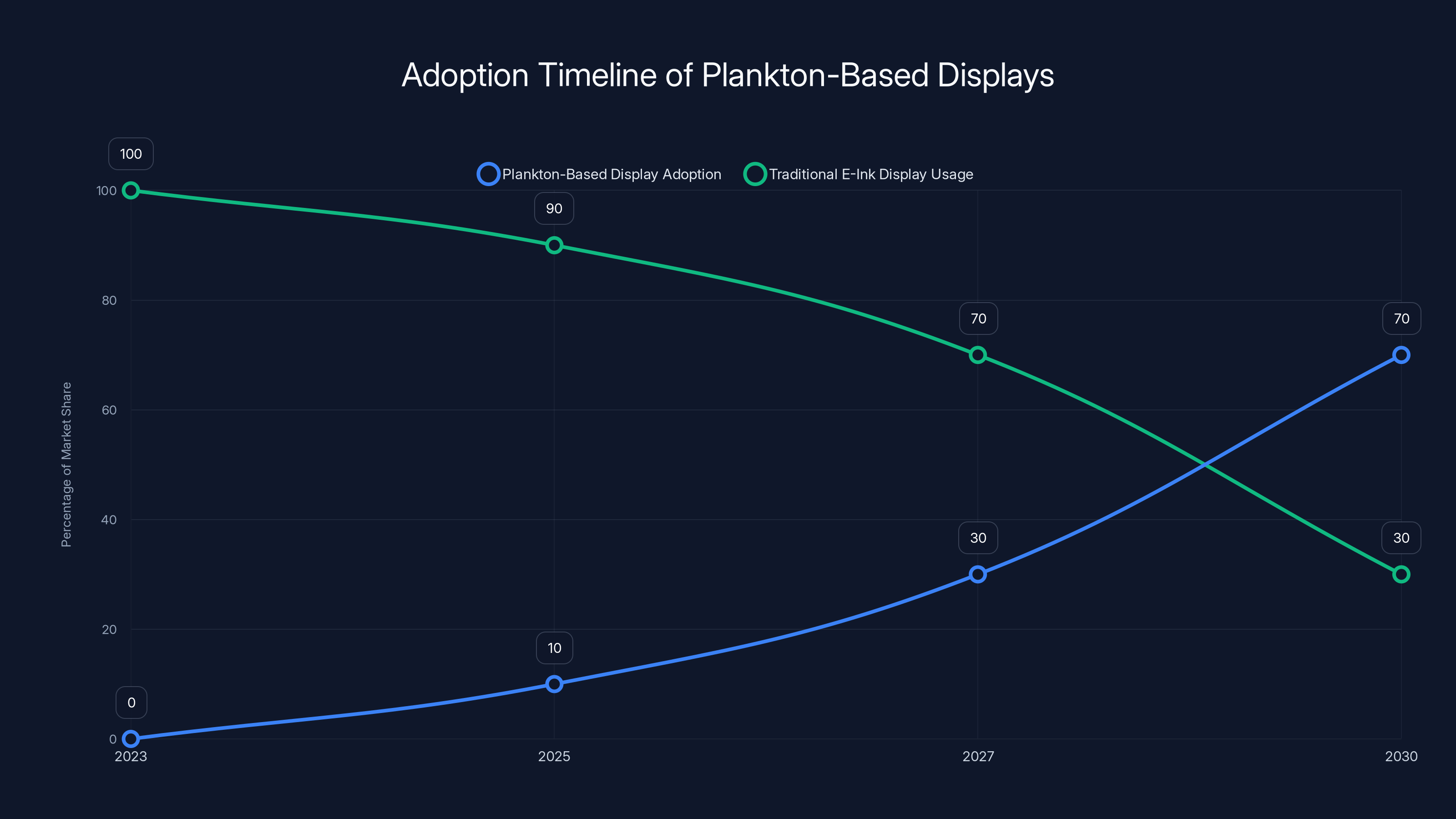

Plankton-based displays are expected to gradually gain market share, becoming mainstream by 2030. Estimated data.

Environmental Considerations and Potential Concerns

While plankton-based e-paper sounds great from a sustainability perspective, it's worth considering potential challenges and concerns.

Plankton farming at scale requires significant water resources. You need suitable water chemistry, appropriate temperature ranges, and minimal contamination. This might be challenging in some regions. If plankton farming becomes a major manufacturing input, water availability could become a constraint in certain areas.

There's also the question of ecosystem impact. If plankton farming becomes economically important, there could be incentive to modify natural ecosystems to optimize plankton growth. Coastal waters could be altered to favor certain plankton species. This could have unforeseen ecological consequences. The industry would need strong environmental regulations to ensure plankton farming doesn't damage ecosystems.

Transportation of farmed plankton from farms to manufacturing facilities creates carbon emissions. The entire supply chain needs to be analyzed to ensure plankton-based displays are genuinely more sustainable than traditional e-ink, not just locally sustainable while generating emissions elsewhere.

There's also the question of competitive advantage and market dynamics. If plankton-based displays become viable, will Samsung keep the technology proprietary or license it widely? If Samsung maintains exclusive manufacturing, competitors might invest in alternative approaches rather than adopting plankton-based technology. This could fragment the industry and reduce the overall environmental benefit.

These aren't reasons to abandon plankton-based e-paper research. They're reasons to pursue it thoughtfully, with environmental considerations built into the development process from the start. Samsung likely understands these challenges and is probably designing the supply chain with sustainability in mind.

Real-World Applications and Use Cases

Let's get specific about where plankton-based e-paper would actually benefit consumers and businesses.

E-Reader Devices

This is the obvious application. Amazon's Kindle line, Kobo readers, and other e-reader manufacturers could eventually transition to plankton-based displays. The benefit for consumers? Largely symbolic initially—the device functions identically, but you get the satisfaction of using a product with lower environmental impact. Over time, as manufacturing scales and costs decrease, this could contribute to lower prices. A premium e-reader might eventually use plankton-based displays as a differentiator for environmentally conscious consumers.

Digital Shelf Labels in Retail

Retailers currently use thousands of electronic shelf labels in stores. Most use traditional e-ink. These displays consume power, require maintenance, and need periodic replacement. Plankton-based displays could reduce power consumption further, extend device lifespan, and enable retailers to market their sustainability initiatives. A large retailer could significantly reduce carbon footprint by deploying millions of plankton-based price labels throughout their stores.

Public Transportation Signage

Bus stops, transit stations, and airport signage could benefit significantly. These displays run constantly and consume substantial electricity. Plankton-based e-paper could reduce power consumption by 80-90% compared to LCD displays. For a major metropolitan transit system, this could translate to measurable environmental impact and cost savings.

Wearable Display Technology

A smartwatch or fitness tracker with a plankton-based e-paper display could offer better battery life than current LCD or OLED displays. The static information display capability makes this particularly suitable for health metrics, weather, and notifications that don't change frequently. The sustainability angle becomes stronger when you consider that wearables are often replaced annually.

Educational Technology

Schools and universities could equip students with plankton-based e-readers instead of traditional textbooks or tablets. The sustainability story becomes part of the educational mission. For institutions focused on environmental education, this has symbolic importance beyond the practical benefits.

Smart Home and Io T Applications

Smart displays for home energy monitoring, security system displays, or environmental sensors could use plankton-based e-paper. These devices typically sit unused most of the day, just displaying static information. E-paper is vastly more efficient than LCD for this use case. Plankton-based e-paper would improve that value proposition further.

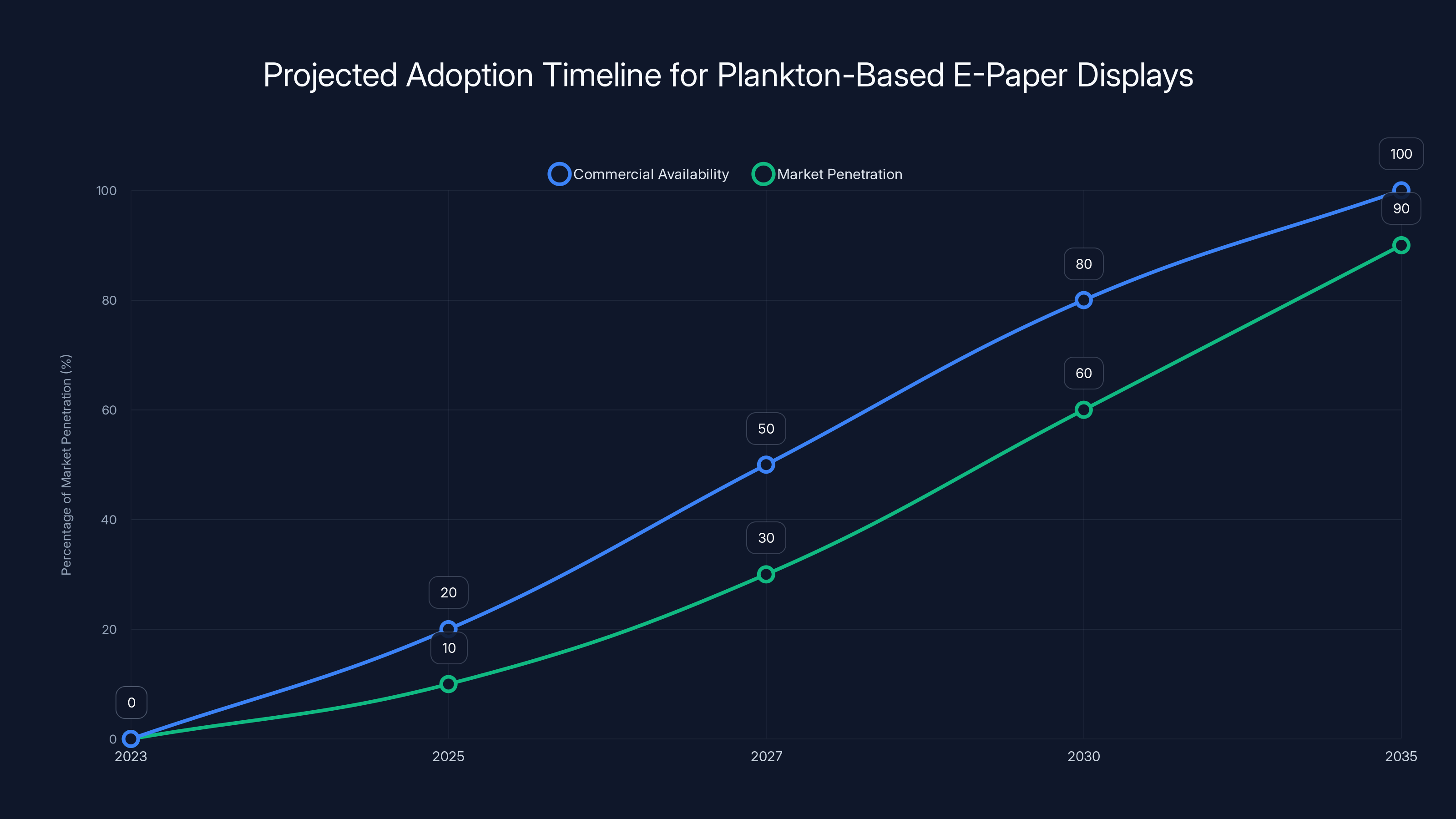

Estimated data suggests that plankton-based e-paper displays could achieve full market penetration by 2035, with initial commercial products available by 2027.

The Competitive Landscape and Industry Response

Samsung isn't the only player in the e-paper display space. How might competitors respond to this innovation?

E Ink Holdings is the dominant e-paper technology provider, supplying most e-ink displays used globally. The company has invested decades into refining traditional e-ink technology. Samsung's research might prompt E Ink to investigate alternative materials or partner with suppliers on bio-derived display research.

Other display manufacturers including BOE, LG Display, and AU Optronics might explore similar approaches. If plankton-based displays prove viable, these companies can't afford to ignore the technology. They might conduct their own research, partner with startups, or license Samsung's technology if it becomes available.

Smaller display companies and startups might see opportunity here. A startup with expertise in plankton farming or material science could potentially develop competing technologies or partner with larger manufacturers. The plankton-based display space could attract new entrants and investment.

Regional display manufacturers in Asia, particularly in countries with strong environmental policies, might prioritize plankton-based display research. China and South Korea both have significant display manufacturing capacity and policy incentives for sustainable technology.

The competitive response will largely depend on how successful Samsung's research proves to be and how well the company controls the intellectual property. If plankton-based displays work, competitive pressure will accelerate industry-wide adoption. If Samsung keeps the technology proprietary and dominates the market, competitors might focus on other sustainability approaches.

Future Predictions and Long-Term Outlook

Let me extrapolate what the next 10-15 years might look like based on Samsung's research direction.

By 2030, we'll probably have seen first-generation commercial plankton-based e-readers from Samsung, perhaps marketed as a premium sustainability-focused product. These devices will likely cost 20-30% more than traditional e-readers, justified by sustainability credentials. Performance will probably match traditional e-ink on most metrics, with potential advantages in specific areas like refresh speed or color range.

By 2033, if first-generation products succeed, we'll see expanded application to digital signage, wearables, and Io T displays. Multiple manufacturers will have their own plankton-based display technologies or will be licensing Samsung's approach. The cost premium will begin shrinking as manufacturing scales and processes optimize.

By 2035, plankton-based displays could achieve price parity with traditional e-ink for some applications. Environmental benefits will be well-documented, and regulatory pressure might accelerate adoption. We might see legislation in some regions prioritizing sustainable display materials for government and educational use.

By 2040, plankton-based displays could represent 40-50% of e-paper display market share, with traditional e-ink occupying the remainder. The industry will have normalized bio-derived materials, and companies will be researching the next-generation sustainable display technologies.

Of course, this assumes Samsung's research succeeds and market adoption follows. There are legitimate scenarios where plankton-based displays never achieve commercial viability, either because technical challenges prove insurmountable or because competing sustainable display technologies prove superior.

But based on Samsung's reputation for display innovation and the logical viability of the approach, I'd assess the probability of successful commercialization at around 70-75%. The technology is sound in theory, and Samsung has the resources and expertise to make it work in practice.

What This Means for Consumers

If you're someone who uses e-readers, digital devices, or cares about environmental impact, here's what Samsung's research means for you.

Short term (next 2-3 years): not much changes. Your current e-readers continue working fine. If you're planning to buy a new device, traditional e-ink remains your best option with the widest selection and best pricing.

Medium term (3-7 years): you'll start seeing plankton-based display options from Samsung and potentially other manufacturers. These will likely be marketed as premium, sustainable products. If environmental impact is important to you, these might be worth the price premium. For most consumers, traditional e-ink options will still be available and cheaper.

Long term (7+ years): plankton-based displays could become mainstream. As manufacturing scales and costs decrease, they could eventually replace traditional e-ink in most applications. The environmental benefit compounds across hundreds of millions of devices. Your consumer choice becomes not "traditional or plankton-based" but rather "which plankton-based display technology do I prefer."

The realistic takeaway: Samsung's research is exciting from an environmental and technological perspective. But it's not a revolution that changes consumer behavior overnight. It's an evolution that gradually shifts manufacturing processes toward more sustainable approaches. You won't suddenly throw away your Kindle in favor of a plankton-based alternative. But when you buy your next e-reader in 2027 or 2028, plankton-based options might exist and could be worth considering.

FAQ

What is plankton-based e-paper display technology?

Plankton-based e-paper display technology is an innovation where Samsung replaces the synthetic particles traditionally used in e-ink displays with organic structures derived from cultivated marine phytoplankton. Instead of chemically synthesizing the colored particles that create text and images on the screen, Samsung harvests naturally occurring plankton cells, processes them, and uses them as the functional components in e-ink. This approach theoretically offers environmental benefits through renewable sourcing and reduced manufacturing complexity.

How does plankton-based e-paper actually work in a display?

Plankton-based e-paper works using the same fundamental principle as traditional e-ink: electrophoresis. The plankton-derived particles are suspended in liquid within microencapsulated cells. When electrical current is applied to the display, these particles move toward different electrodes based on their charge, creating visible text and images. When you stop applying electricity, the image remains stable on screen without consuming any power, which is why e-paper displays have exceptional battery life compared to LCD or OLED screens.

What are the main benefits of plankton-based displays over traditional e-ink?

Plankton-based displays offer several potential advantages: the materials are renewable and sustainable since plankton grows continuously in water rather than requiring mining or chemical synthesis; the manufacturing process should be less energy-intensive because you're cultivating organisms rather than synthesizing materials; the material cost should be lower at scale since farming is generally cheaper than industrial synthesis; and the displays should be more easily recyclable since the material is biologically derived and can decompose naturally. However, these benefits depend on responsible plankton farming practices and sustainable supply chain management.

When will plankton-based e-readers actually become available to consumers?

Based on Samsung's typical development timeline for display innovations, the earliest we might expect commercial plankton-based e-readers would be around 2027-2029. The company is currently in the research and development phase, optimizing the material properties and manufacturing processes. After successful lab demonstrations and pilot manufacturing tests, Samsung would need to build or retrofit manufacturing facilities and scale production to commercial volumes. Initial products will likely be premium models marketed to sustainability-conscious consumers at prices 20-30% higher than traditional e-readers.

Could plankton-based displays eventually replace traditional e-ink completely?

Yes, plankton-based displays could eventually become the industry standard if Samsung successfully commercializes the technology and competitors adopt or develop similar approaches. As manufacturing processes optimize and scale, production costs could eventually drop below traditional e-ink, making the plankton-based approach economically preferable regardless of environmental considerations. However, this transition would likely take 10-15 years, and traditional e-ink might persist in specific niche applications. The transition speed depends on how quickly manufacturing costs decline and how aggressively companies invest in the new technology.

What environmental challenges could plankton farming create?

While plankton farming offers environmental benefits, it could create challenges if not managed carefully. Large-scale plankton cultivation requires significant water resources and could impact coastal ecosystems if farming operations modify natural water conditions. The farming and processing operations must be carefully regulated to prevent damage to marine environments. Additionally, transporting farmed plankton from cultivation sites to manufacturing facilities generates carbon emissions that need to be minimized. The true environmental benefit of plankton-based displays depends on whether the entire supply chain operates sustainably, not just the core material sourcing.

How does Samsung's plankton-based e-paper compare to color e-ink technologies?

Color e-ink has advanced significantly in recent years, with manufacturers like E Ink offering Kaleido and Gallery displays that show millions of colors. Samsung's plankton-based approach is likely compatible with color display technology—the company could potentially use different plankton species or treated variants to achieve different color properties. However, Samsung hasn't yet published performance specifications for plankton-based color displays. The initial commercial applications will probably focus on black-and-white displays where performance is most straightforward to validate, with color variants potentially coming later.

What about the taste comparison to the Krabby Patty secret formula?

That was a playful reference from the source article, mixing the legitimate technology discussion with Sponge Bob Square Pants humor. There's no actual connection to Krabby Patty recipes—it's just a joke about putting ocean materials into products. The plankton is being processed into display materials, not anything consumable, so no one's eating plankton-based e-readers.

Could plankton-based materials be used in other display types like LCD or OLED?

That's theoretically possible but would require different approaches than e-paper displays. LCD displays use liquid crystals to modulate light, which is a fundamentally different mechanism than e-ink electrophoresis. OLED displays use organic compounds that emit light, which is also different from e-ink operation. However, the core insight of Samsung's research—that naturally derived organic materials can function as display components—could inspire research into bio-derived materials for other display technologies. We might eventually see sustainable alternatives for LCD backlighting or OLED emissive materials, but that's speculative territory.

What's the realistic market impact of plankton-based displays over the next 5-10 years?

Over the next 5 years, plankton-based displays will likely remain a niche premium product if they launch at all, with Samsung and potentially one or two other manufacturers offering early products to sustainability-focused consumers. Market penetration probably won't exceed 5-10% of the e-paper display market during this period. Over 10 years, if commercialization succeeds and manufacturing costs improve, market share could grow to 30-50% of the e-paper display market as the technology becomes more economically competitive. The broader impact on environmental sustainability would depend on adoption rates and the scale of plankton farming operations.

Key Takeaways

Samsung's plankton-based e-paper display research represents genuine innovation in display technology with real environmental implications. The core technology is sound: using naturally-derived organic materials instead of synthesized compounds in e-ink displays is theoretically viable and could offer substantial sustainability benefits. The challenge now is scaling from laboratory success to manufacturing viability. If Samsung succeeds, this could trigger industry-wide shift toward bio-derived display materials. Even if plankton-based displays never become mainstream, the research signals that the display industry is taking sustainability seriously. And that's good news for consumers and the planet.

The timeline is probably 5-7 years until commercial products reach consumers, with early adopters and sustainability-focused buyers seeing premium options from Samsung. Full market penetration and cost competitiveness with traditional e-ink might take 10-15 years. But for an industry that's been refining the same fundamental display technology for 20 years, plankton-based e-paper represents meaningful innovation that could reshape how we think about manufacturing electronic displays.

Use Case: Create detailed product comparison documents and technical specifications for new display technologies automatically with AI.

Try Runable For Free

Related Articles

- How E-Bike Battery Swapping Powers Food Carts: The PopWheels Model [2025]

- General Fusion's $1B SPAC Merger: Fusion Power's Survival Strategy [2025]

- reMarkable E Ink Tablet Bundles: Complete Buying Guide [2025]

- InkPoster's 41-Inch E-Paper Display: The Premium Art Wall Revolution [2025]

- Pebble Round 2: The Smartwatch Comeback That Fixes Everything [2025]

- Pebble Round 2 Review: Thinnest Smartwatch Returns [2025]

![Samsung's Plankton E-Paper Display: The Future of Sustainable Screens [2025]](https://tryrunable.com/blog/samsung-s-plankton-e-paper-display-the-future-of-sustainable/image-1-1769611094470.jpg)