AI & Sustainability: Why This Isn't a Contradiction

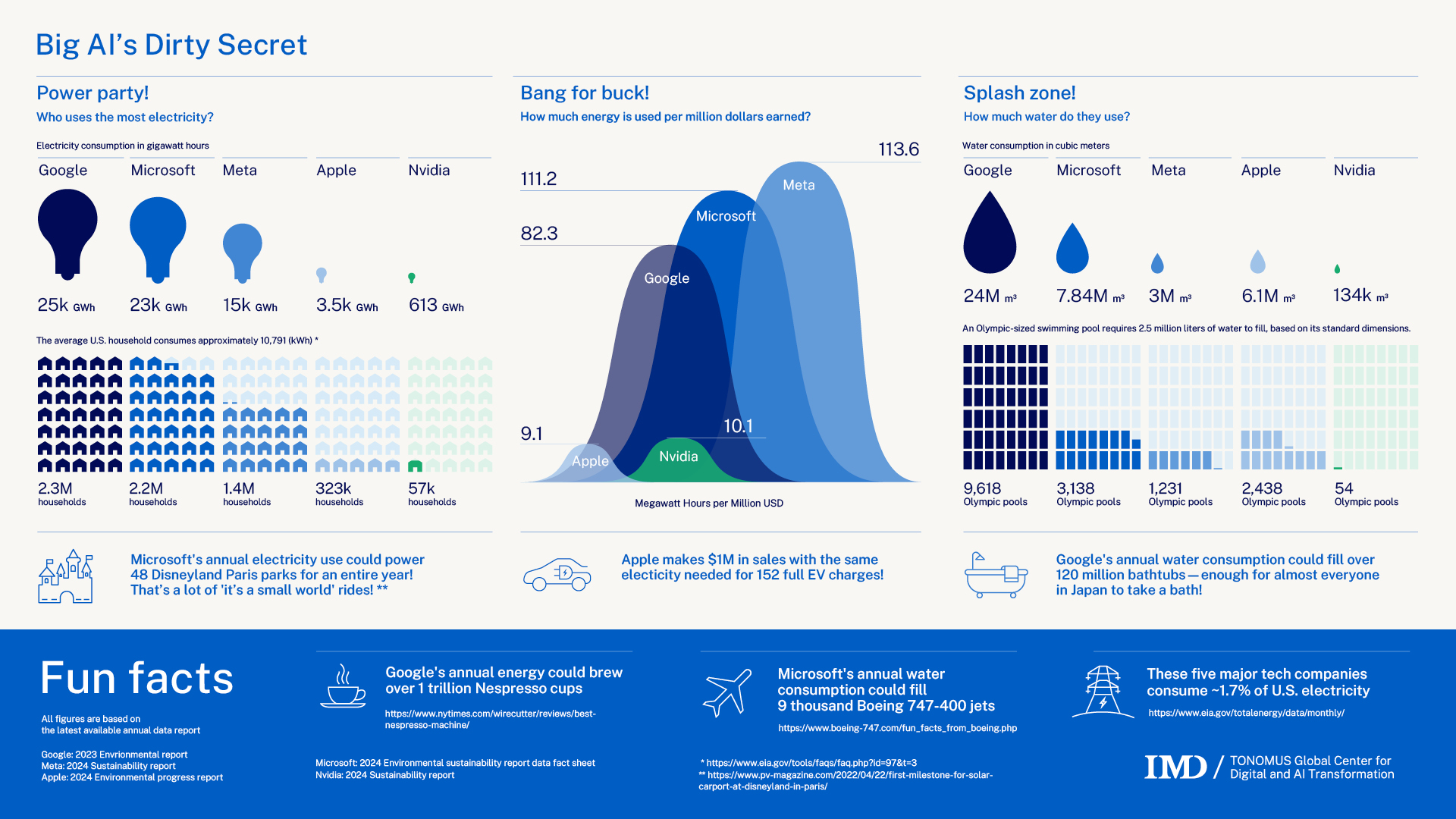

Listen, I get it. You've heard that data centers are power-hungry monsters. You've seen the headlines about AI's electricity consumption. And you're thinking: "This doesn't sound sustainable at all."

Here's the thing though: that's only half the story.

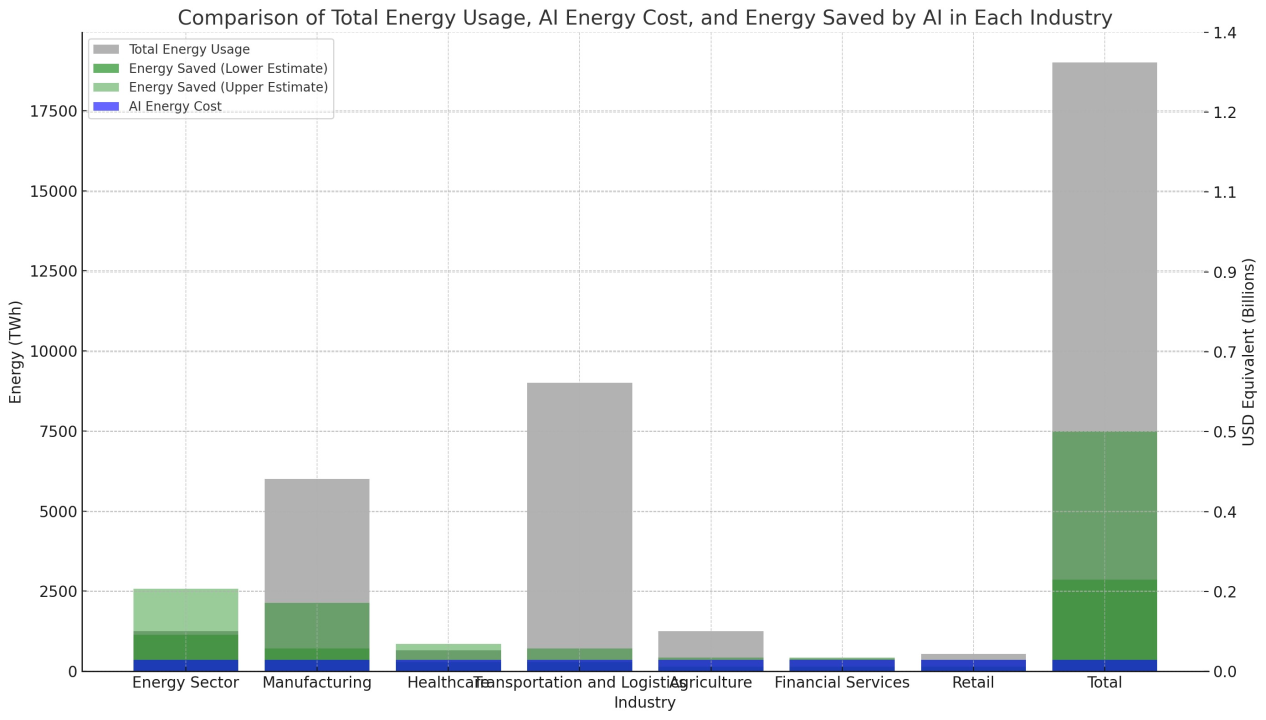

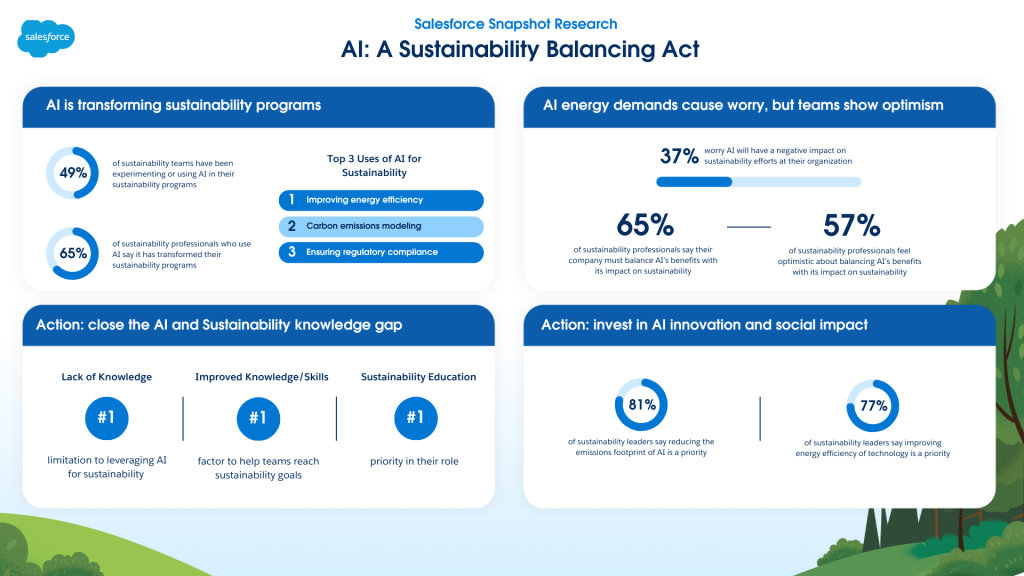

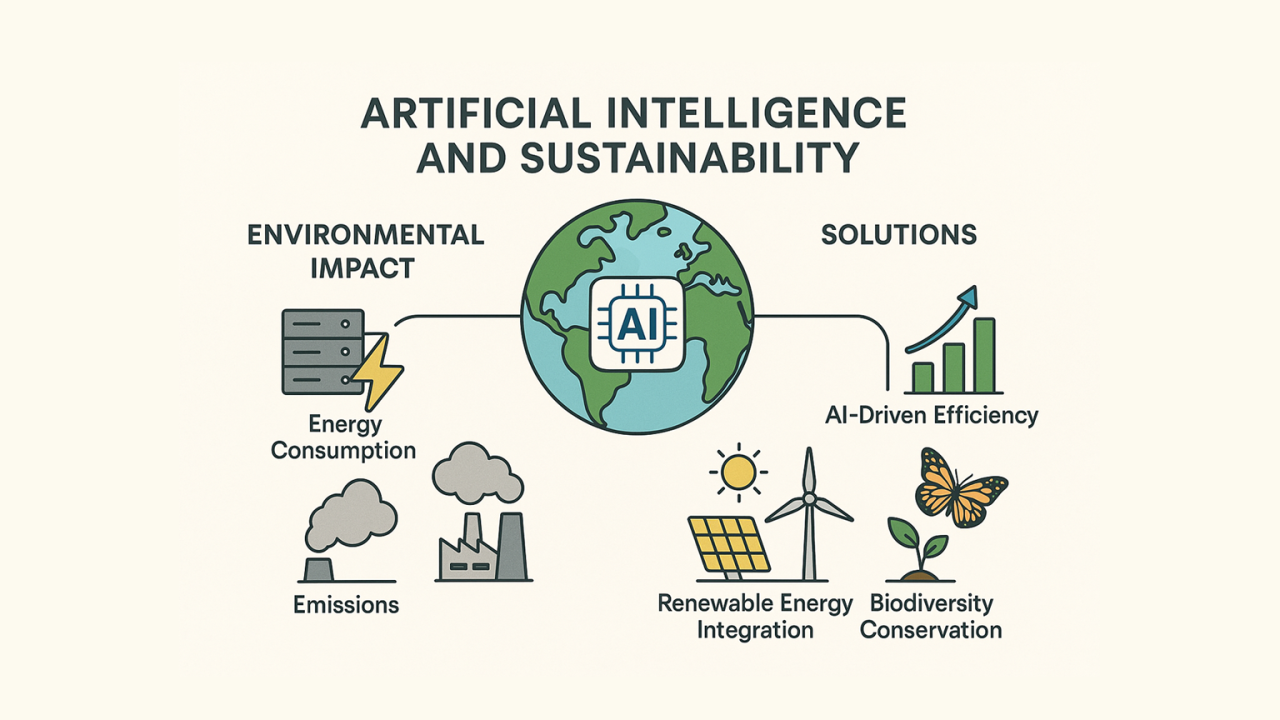

Yes, AI demands serious energy. Data center electricity consumption is expected to double by 2030, and that's a real concern. But what gets lost in the conversation is this simple fact: AI is also one of the most powerful tools we've ever built for actually solving sustainability problems.

The paradox isn't really a paradox at all. It's an optimization problem. And when you look at what companies are doing right now—across manufacturing, supply chains, product design, and customer engagement—the math actually works in AI's favor.

I've spent the last few months talking to sustainability leaders, engineers, and executives building AI systems specifically designed to cut emissions. What emerged was clear: AI isn't the enemy of sustainability. When built responsibly and deployed strategically, it's becoming one of our most powerful weapons against climate change.

This isn't corporate greenwashing. This is real, measurable impact. And it's worth understanding how.

TL; DR

- AI enables real-time emissions tracking: Manufacturing facilities using AI-powered sensors detect inefficiencies in seconds rather than weeks, cutting waste and energy costs simultaneously

- Supply chain optimization is AI's biggest win: AI-driven scheduling can reduce excess inventory by 20-30%, eliminating unnecessary air freight and overproduction

- Scope 3 emissions become manageable: For most companies, supplier emissions dwarf their own operations; AI tools now make these visible and actionable for the first time

- Design decisions improve dramatically: AI compares materials, components, and manufacturing processes to identify lower-carbon alternatives before products enter production

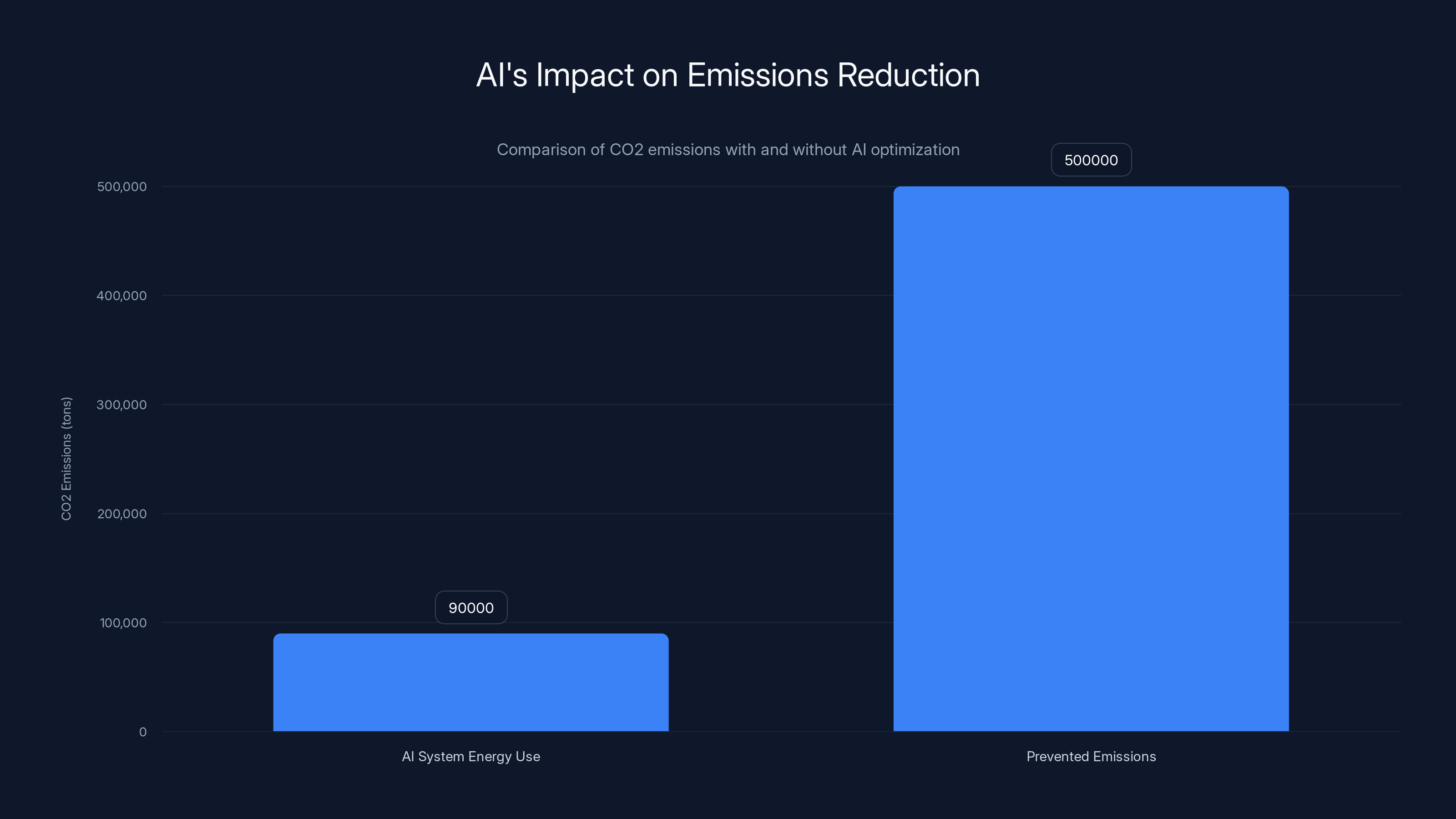

- The energy investment pays back: The emissions prevented by AI applications typically exceed the energy consumed by the AI systems themselves within 1-3 years

- Bottom line: AI consumes energy upfront. But it prevents far more emissions long-term. That's the deal worth understanding.

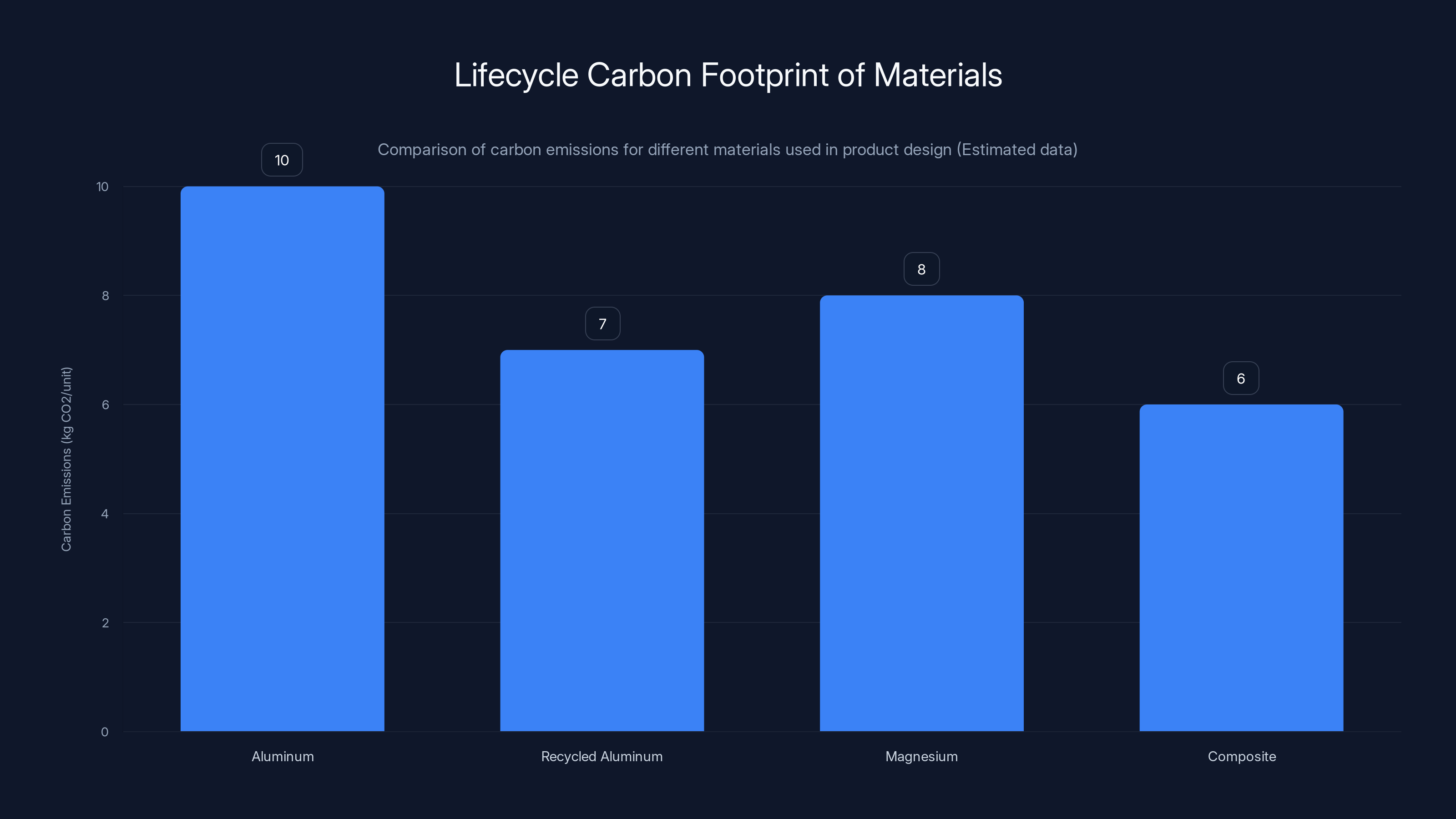

AI tools help design teams compare lifecycle carbon footprints of materials, enabling more sustainable choices. Estimated data shows recycled aluminum has the lowest emissions.

The AI Energy Problem (And Why It's More Nuanced Than Headlines Suggest)

Let's start with the uncomfortable truth: training a large language model does use a lot of electricity.

We're talking about infrastructure that requires massive cooling systems, distributed computing across multiple data centers, and constant power demands. A single training run for a large model can consume the annual electricity usage of several hundred American homes. That's not nothing.

But here's what gets missed in most conversations: that's the cost of building the model once. Once it exists, the marginal cost of using it is dramatically lower. A user querying an AI model consumes far less energy than, say, running complex climate simulations on traditional supercomputers—which is what researchers would've had to do ten years ago for the same kind of analysis.

The real issue isn't that AI uses energy. The real issue is whether that energy investment prevents more emissions than it consumes. And increasingly, across multiple industries, the answer is yes.

Consider the baseline: companies were already running complex analysis, forecasting, and optimization before AI existed. They used statistical models, hired armies of analysts, and often made decisions based on incomplete information. All of that consumed energy and time and still produced inferior results.

AI doesn't replace no solution. It replaces less efficient solutions. And that changes the math entirely.

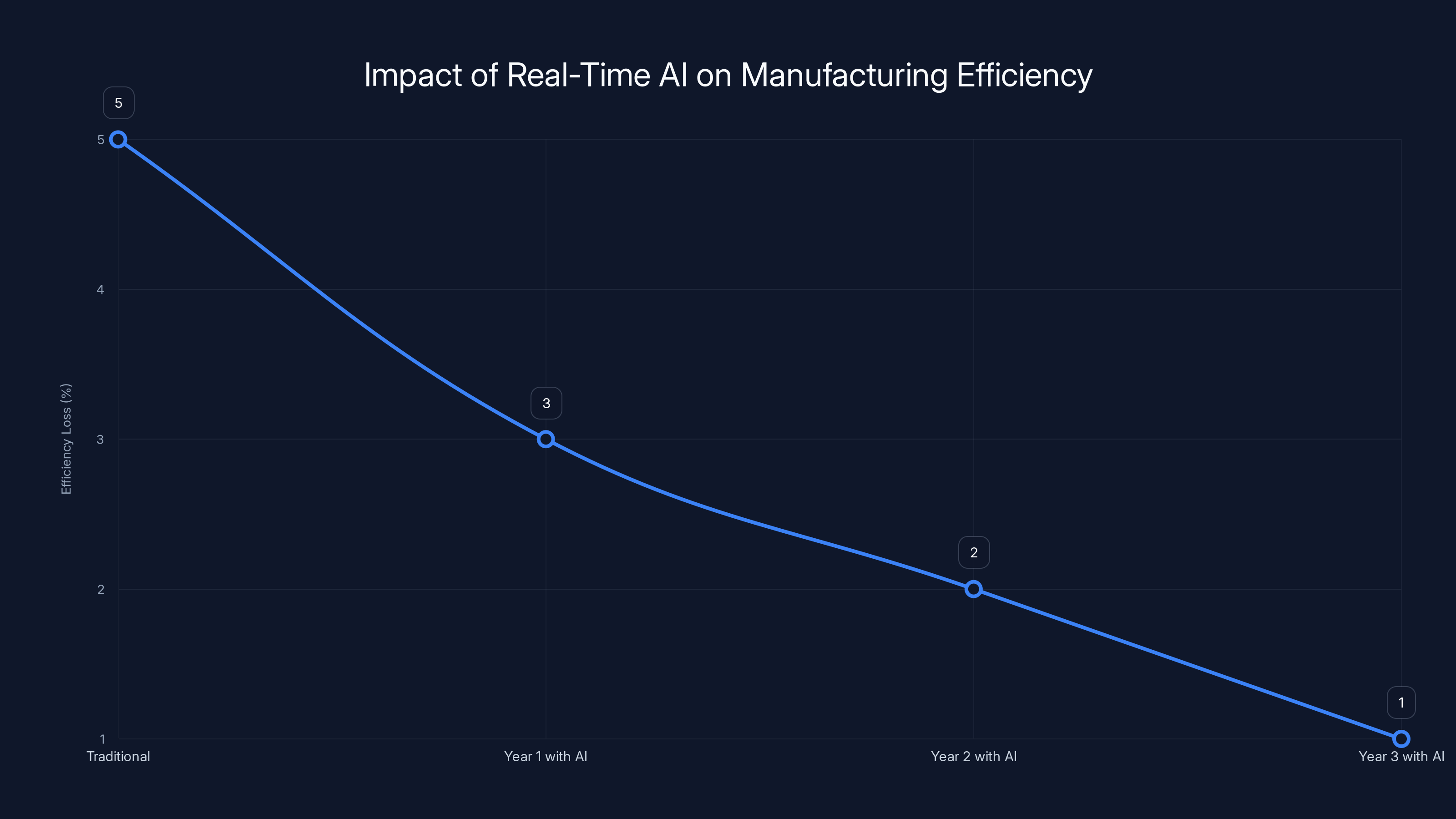

AI implementation in manufacturing can significantly reduce efficiency loss over time, from an initial 5% to just 1% by the third year. Estimated data.

Real-Time Manufacturing Intelligence: From Blind Spots to Second-by-Second Optimization

Manufacturing is where AI's sustainability impact becomes immediately visible.

Traditional manufacturing relies on periodic audits and reports. You install monitoring systems. You collect data. You wait for analysis. By the time you identify an inefficiency—excessive energy use, water waste, temperature variations—weeks or months have passed, and you've been bleeding efficiency the entire time.

Now introduce AI with real-time sensor networks.

Factories can install hundreds of IoT sensors across production lines, capturing data on temperature, pressure, water consumption, emissions, energy draw, and dozens of other variables. Instantly. Continuously. In real time.

AI systems process this stream and detect anomalies in seconds. A heating system running inefficiently? Flagged. A valve leaking? Detected. An assembly line operating outside optimal parameters? Identified. Not at the end of the month when you review logs. Right now. This second.

This matters because manufacturing inefficiency compounds. A 5% efficiency loss on a production line running 24/7 isn't a small issue—it's thousands of dollars per day in wasted energy and materials. Catching that in real-time rather than at the next monthly audit means five days of unnecessary waste prevented.

Multiply that across dozens of production lines, hundreds of facilities, thousands of days per year, and you're talking about substantial emissions reductions.

The second layer is even more interesting: AI doesn't just detect problems, it learns patterns. Over time, systems begin to predict when inefficiencies will occur and can trigger preventive maintenance or process adjustments automatically. You're not just responding to problems—you're preventing them before they happen.

One of the biggest breakthroughs here is breaking down data silos. Sustainability teams at large organizations often struggle because critical environmental data lives in different systems. Production data in one platform. Energy consumption in another. Water usage in a third system. Different teams manage different pieces, and nobody has a unified view of the facility's actual environmental impact.

AI platforms now integrate these data streams, giving sustainability teams (and operators) a complete, real-time picture of environmental performance across an entire operation. No more waiting for monthly reports. No more incompatible data formats. Just unified intelligence on what's happening, where the problems are, and what to optimize next.

The third impact: AI helps with something manufacturing teams rarely have time to do manually—optimization across multiple competing variables. Energy efficiency sometimes trades off against production speed. Water conservation might affect product quality. Emissions reduction could require different materials that affect costs.

Manually optimizing across all these constraints? Nearly impossible. You pick the most critical constraint and optimize for that, accepting compromises on everything else.

AI can optimize across multiple variables simultaneously, finding solutions that improve several metrics at once. Use this material instead of that one—same cost, lower carbon footprint, no quality impact. Run this process at this speed—slightly slower, dramatically better energy efficiency, total time to completion actually shorter due to fewer rework cycles.

This kind of multi-variable optimization is where AI really shines in sustainability. And it's where the payback is almost certain.

Supply Chain Optimization: Where AI's Sustainability Impact Gets Massive

If manufacturing is where AI proves its worth in operations, supply chain optimization is where it becomes genuinely transformative.

Supply chains are complicated. Companies need to forecast demand, schedule production, coordinate shipping, and manage inventory across multiple facilities, suppliers, and distribution networks. Get it right and everything flows smoothly. Get it wrong and you have massive inefficiencies: excess inventory that never sells, air freight to meet unexpected demand, overproduction that ends up as waste, suppliers waiting for orders that don't come while other suppliers scramble to fill gaps.

All of these inefficiencies are also carbon inefficiencies. Excess inventory means storage, handling, and eventual disposal. Air freight is dramatically more carbon-intensive than ocean shipping. Overproduction means wasted materials and energy. Demand forecasting errors cascade through the entire system.

This is where AI becomes almost unfairly powerful.

Advanced AI scheduling and forecasting systems can predict demand with accuracy that's been improving dramatically. These systems don't just look at historical sales data—they incorporate dozens of variables: seasonal patterns, market trends, economic indicators, weather forecasts, even social media signals. They learn which variables matter most for different products and regions.

The result: more accurate demand forecasts. And that unlocks everything else.

When you know what you actually need, when you need it, and where, you can optimize shipping routes, consolidate shipments, reduce safety stock, and eliminate overproduction. You're also, critically, shifting from fast air freight to slower but vastly less carbon-intensive ocean and rail transport.

Here's the financial angle that makes this stick: reducing excess inventory, minimizing overproduction, and shifting to more efficient shipping methods all save money. The sustainability wins aren't separate from the business wins—they're the same wins looked at from different angles.

Companies that implement AI-driven supply chain optimization typically see 15-30% reductions in excess inventory, 20-25% reductions in overproduction, and meaningful shifts from air freight to sea and rail. That's not a guess. That's consistent outcome from implementations across multiple industries.

Which brings us to the biggest opportunity: Scope 3 emissions.

Scope 3: The Emissions That Matter Most

If you work in sustainability, you already know this tension: most companies' direct emissions (Scope 1 and 2—operations and purchased electricity) are only a fraction of their total impact.

Scope 3—indirect emissions from the broader value chain—is where the real impact lives. For most companies, Scope 3 is 5-10x larger than direct emissions. It includes everything your suppliers emit to make what they sell you, what customers emit using your products, how products are transported, and what happens when they're disposed of.

The problem? It's incredibly hard to measure, let alone optimize.

You can't just install sensors at your supplier's facility. You don't control their processes. You're working with incomplete data, inconsistent reporting standards, and information that changes frequently. Most companies have a rough estimate of Scope 3 but almost no ability to drive changes.

AI changes this fundamentally.

AI systems can now predict Scope 3 emissions based on supplier data, product characteristics, transportation modes, and usage patterns. They can identify which parts of the value chain create the highest emissions impact. They can simulate the emissions impact of switching suppliers, changing materials, or shifting to different transportation modes.

This is transformative because Scope 3 is where companies actually have meaningful leverage. You can work with suppliers to reduce their emissions. You can design products that generate fewer lifetime emissions. You can optimize how products are shipped and used.

AI makes this suddenly actionable instead of theoretical.

The mechanics work like this: AI systems ingest data from your suppliers (or use industry averages and process data to infer likely emissions). They track where materials come from, how they're transported, and how products are used. They calculate the total lifecycle carbon footprint for different supply chain scenarios.

Then they simulate: what if we used this supplier instead of that one? What if we switched to this material? What if we changed the transportation route? The system calculates the emissions impact of each scenario, revealing the highest-leverage changes.

With that intelligence, procurement teams can negotiate with suppliers who are willing to improve efficiency, product design teams can select lower-carbon materials without sacrificing quality or cost, and operations teams can optimize logistics for emissions, not just for speed or cost.

This level of visibility and optimization was literally impossible five years ago. The calculations were too complex, the data too fragmented, the coordination too difficult. AI made it tractable.

AI systems consume energy but prevent significantly larger emissions, with a typical payback period of 12-24 months. Estimated data based on typical AI optimization scenarios.

Product Design: How AI Identifies Lower-Carbon Alternatives Before Production Starts

Here's a tough reality about sustainability: preventing emissions upfront is orders of magnitude easier than trying to fix them later.

Once a product design is locked and manufacturing is ramped up, changing materials, redesigning components, or altering processes becomes prohibitively expensive. So the critical window for impact is the design phase, before anything goes into production.

Historically, design teams made material and component choices based on limited information. Cost was usually the primary driver. Performance requirements were the secondary driver. Environmental impact was almost never quantified in the design process because the analysis was too complex and time-consuming.

You'd design a product around one hinge because it was cheapest. Nobody did the lifecycle carbon analysis to see if a slightly more expensive hinge made from recycled aluminum would reduce total emissions more than the cost increase.

Now, AI tools are changing that calculation.

AI systems can rapidly compare the lifecycle carbon footprint of different materials, different component suppliers, different design approaches, and different manufacturing processes. What's the carbon cost of aluminum vs. recycled aluminum vs. magnesium vs. composite materials? How does that change if sourced from different regions? What about the manufacturing emissions difference—does one material process more efficiently?

Design teams can now see these comparisons in real-time as they're designing. "That hinge from supplier A has 15% lower lifecycle emissions than supplier B for an extra $0.23 per unit. Here's why: different primary material sourcing, more efficient manufacturing process, and longer expected lifespan that reduces replacement frequency."

With that information, design teams can make genuinely informed decisions. Some designers will accept the higher cost for lower emissions. Some won't. But at least everyone's working from actual data instead of guesses.

The second impact is on manufacturing process selection. Different ways of manufacturing the same part have dramatically different environmental footprints. One supplier might use renewable energy, another coal. One might have optimized for water conservation, another wastes significantly. One might have excellent recycling practices, another disposes of waste to landfill.

Quantifying these differences accurately requires analyzing data from multiple suppliers, understanding their actual operational practices (not just their claims), and calculating true environmental impact. That's expensive and time-consuming when done manually.

AI systems can aggregate supplier data—both disclosed in sustainability reports and inferred from operational metrics—to create accurate comparative footprints. Now when design teams are selecting between manufacturing partners for a critical component, they can see the environmental trade-offs with actual numbers.

The third angle is optimization for longevity and repairability. Products that last longer generate fewer lifetime emissions (because fewer replacements are needed). Products that are easy to repair consume fewer raw materials.

But designing for longevity and repairability requires understanding actual usage patterns, failure modes, and repair economics. Traditional design teams have limited data on this. AI systems trained on product performance data, warranty claims, customer feedback, and repair costs can identify design changes that extend product life or improve repairability without increasing manufacturing emissions or costs.

One particularly interesting application: material substitution at the very end of a product's life. What materials are easy to recycle? Which ones create value in secondary markets? AI systems can help design products with end-of-life in mind, selecting materials and construction methods that enable recycling rather than landfill disposal.

The financial payback here is interesting too. Designing with lifecycle emissions in mind often costs nothing—it's just making better-informed decisions. Sometimes it costs slightly more upfront but saves money in warranty costs (fewer failures to repair), reputation cost (sustainable products can command premium pricing), and regulatory risk (as emissions regulations tighten, products designed with emissions in mind navigate future regulations more easily).

Customer Empowerment: AI Enabling Individual Sustainability Decisions

One of the most underrated sustainability impacts of AI is helping customers understand and reduce their own environmental footprint.

This works on two levels. First, at the point of purchase. Second, throughout the product's use.

At purchase, customers increasingly want to understand the environmental impact of what they're buying. But that information is almost never available in a useful way. A product's environmental footprint depends on where it was made, where you live, how you'll use it, and how long you'll keep it. The same product has completely different environmental impact for a customer in Norway (grid is almost 100% renewable) versus Australia (coal-heavy grid).

AI tools can now calculate this in real-time. A customer in Germany considering a laptop can see: "This model has a carbon footprint of 157 kg CO2 over its expected lifespan in our region, accounting for manufacturing, electricity consumption based on Germany's current grid mix, shipping, and end-of-life processing."

That's actually meaningful information. The customer can compare different models and see not just the price difference but the emissions difference. Some customers will switch to a model with 15% lower emissions. Some won't. But everyone's making an informed decision.

The scale of this impact is subtle but real. If 20% of customers shift purchasing decisions based on transparent environmental information, that's potentially millions of tons of emissions prevented annually, just from smarter individual choices. And that's working from conservative estimates.

The second level is during product use. The environmental impact of most products is dominated by the energy they consume while you're using them, not the energy to manufacture them. For a smartphone, manufacturing accounts for 50-60% of lifetime emissions. For a refrigerator or air conditioning unit, operation is 85-90% of lifetime emissions.

AI systems can now provide real-time guidance on using products more efficiently. What's the most efficient temperature setting for your AC system based on your home's specific characteristics and your local climate? When should you charge your EV to minimize your carbon footprint (if it's connected to a grid with variable renewable energy availability)? What appliance settings minimize energy use while meeting your needs?

Again, individual impact is modest. But across millions of users, this drives measurable emissions reductions.

The third angle is lifecycle communication. A customer who buys a product today needs to know its environmental impact. But they also need to know: if I keep this for 5 years instead of 3 years, what's the impact? If I recycle it properly instead of throwing it away, how much difference does that make? If I return it for refurbishment instead of buying new, what's the carbon savings?

AI systems can quantify all of this, giving customers the information they need to make decisions that extend product life (the single biggest lever for reducing product-related emissions) and maximize recycling rates.

Air freight is significantly more carbon-intensive than ocean shipping and rail transport, highlighting the sustainability benefits of optimizing supply chain logistics.

The Energy Cost of Sustainability AI: Yes, It's Real. But the Math Works

Let's get honest about the elephant in the room: running all these AI systems requires electricity.

We need to account for that. We need to be precise about it. And we need to ask the hard question: does the emissions prevented exceed the emissions consumed by the AI systems themselves?

For most applications we've discussed, the answer is yes. Sometimes overwhelmingly so. Sometimes barely. But typically yes.

Here's how the math typically works.

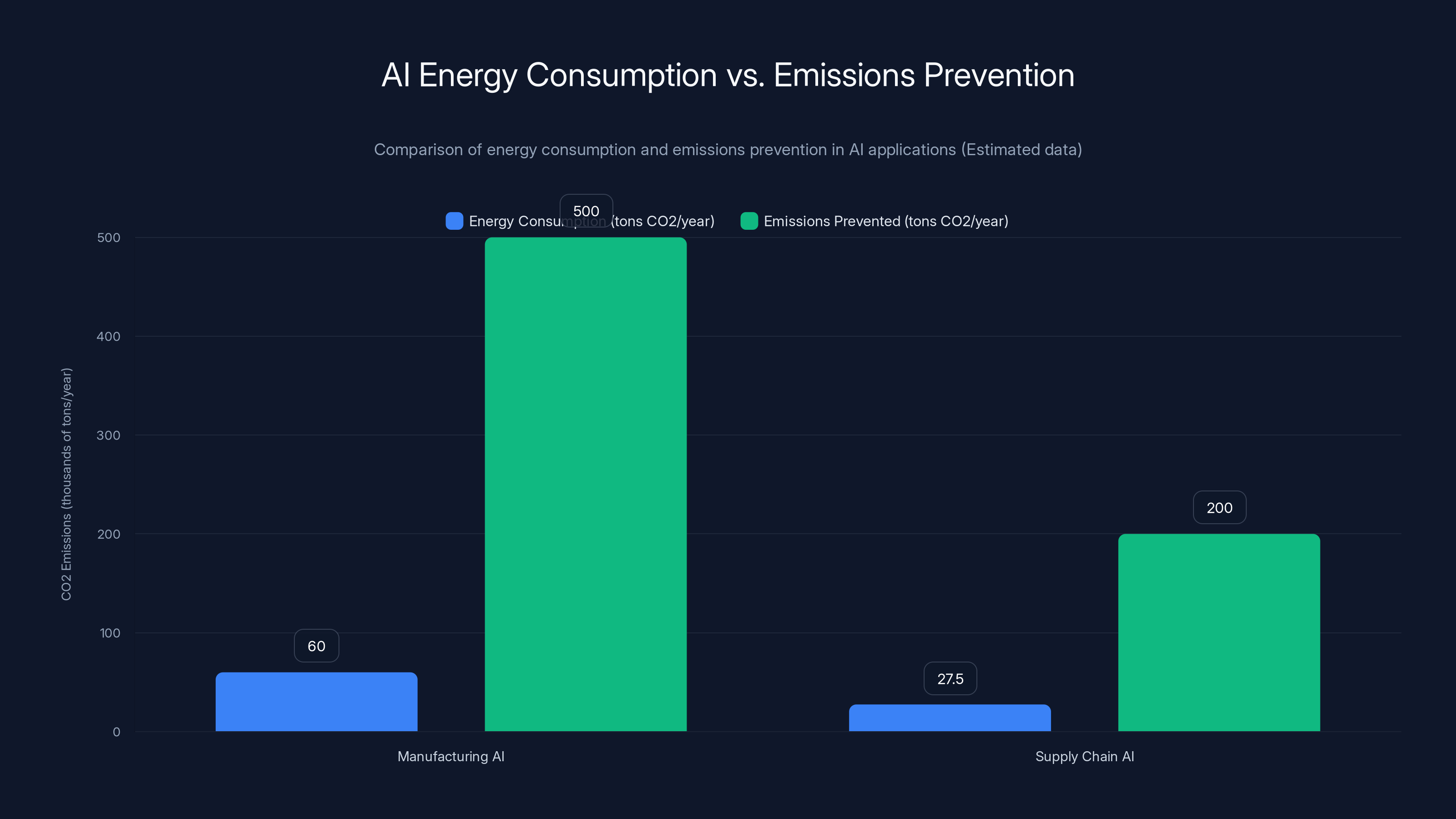

A manufacturing facility implementing AI-powered real-time monitoring and predictive maintenance might consume 10-15 MW of additional computing infrastructure. Over a year, that's roughly 90-130 GWh of electricity. Depending on the grid's carbon intensity, that's maybe 30,000-90,000 tons of CO2 per year from the AI system itself.

What does it prevent? That same facility might reduce energy consumption by 8-12% across operations. For a major manufacturing facility, that's typically 500,000+ tons of CO2 per year. The payback period is less than a year. After that, every year of operation is net emissions prevented.

For supply chain optimization, the math is even more favorable. An AI system for demand forecasting and supply chain optimization might consume 2-5 MW of computing. That's maybe 15,000-40,000 tons of CO2 per year. But it prevents overproduction that ends in waste, unnecessary air freight, and excess inventory. For a large company, that's often 200,000+ tons prevented annually. Again, payback in less than a year.

This is why the headline "AI is bad for the environment" misses the actual story. AI systems designed to optimize and prevent emissions typically exceed the energy cost through prevented emissions within 12-24 months, and then continue providing benefits with positive ROI for years.

The key caveat: this assumes the AI systems are well-designed, well-implemented, and actually solving real problems. A badly designed system that doesn't significantly improve efficiency will indeed be a pure cost. But that's not an AI problem—that's an implementation problem.

There's also the trajectory angle. Data center efficiency has been improving significantly. Cloud infrastructure from major providers is now 3-5x more efficient per computation than on-premises data centers. And efficiency improvements are accelerating. AI hardware optimization and innovative cooling techniques continue to reduce the energy cost of computation.

Meanwhile, the climate crisis is becoming more urgent. We need to decarbonize every industrial process, redesign supply chains for sustainability, and make clean choices the easy choice for billions of consumers. The tools that make this possible at scale, quickly, and cost-effectively—whatever their energy cost—are increasingly necessary.

Building Responsible AI: The Sustainability Foundation

Here's something that doesn't get nearly enough attention: you can't actually build sustainable AI without thinking deeply about responsibility and governance.

What do I mean by that? Well, a system that optimizes for emissions reduction while creating other environmental harms isn't actually sustainable. A supply chain optimization that reduces carbon but creates labor exploitation isn't sustainable. An AI implementation that's technically sound but opaque and unaccountable isn't truly sustainable.

Responsible AI—systems built with transparency, governance, ethical consideration, and accountability—is actually a prerequisite for sustainable AI.

First, the transparency angle. Sustainability teams need to understand how AI systems are making recommendations. Why is the system suggesting switching to supplier A instead of supplier B? What data influenced that decision? Are there any hidden biases or errors?

Without this transparency, you end up with black-box optimization that might actually make things worse while appearing to improve things. The classic example: supply chain optimization that reduces carbon emissions but accomplishes it through labor cost reduction that pressures supplier wages. Technically optimized. Ethically questionable. Not actually sustainable.

Second, governance and oversight. AI systems making sustainability decisions need human oversight. Not because humans are smarter (they're usually not), but because we need accountability. If an AI system makes a decision that has business implications or environmental implications, someone needs to be responsible for that decision and able to explain it.

This gets particularly important at scale. One wrong decision by an AI system in one facility is a learning opportunity. One wrong decision propagating across hundreds of facilities because the AI is autonomous and unsupervised is a crisis.

Third, diversity and inclusive design. AI systems trained on limited data, built by homogeneous teams, and deployed without considering different contexts will inevitably encode biases and create unintended consequences.

A supply chain optimization system trained on historical data from companies in Western Europe might make recommendations that work fine for those contexts but fail catastrophically in developing markets with different infrastructure, supply chains, and constraints. A manufacturing optimization system built without input from frontline workers might optimize for metrics that matter on spreadsheets but create impossible working conditions.

Responsible AI development means bringing diverse perspectives to the design process and then testing systems across different contexts before full deployment.

Fourth, environmental impact accounting for the AI systems themselves. This should be standard but often isn't. You should know: how much energy does this system consume? Where does that electricity come from? What's the carbon footprint of the hardware? What happens to the hardware at end-of-life?

This isn't just ethical accounting. It's practical. If you're running an AI system for emissions reduction and you don't know its actual energy consumption, you can't verify that you're actually preventing more emissions than you're consuming.

AI systems in manufacturing and supply chain optimization consume energy but prevent significantly more emissions, achieving net positive environmental impact within a year. Estimated data.

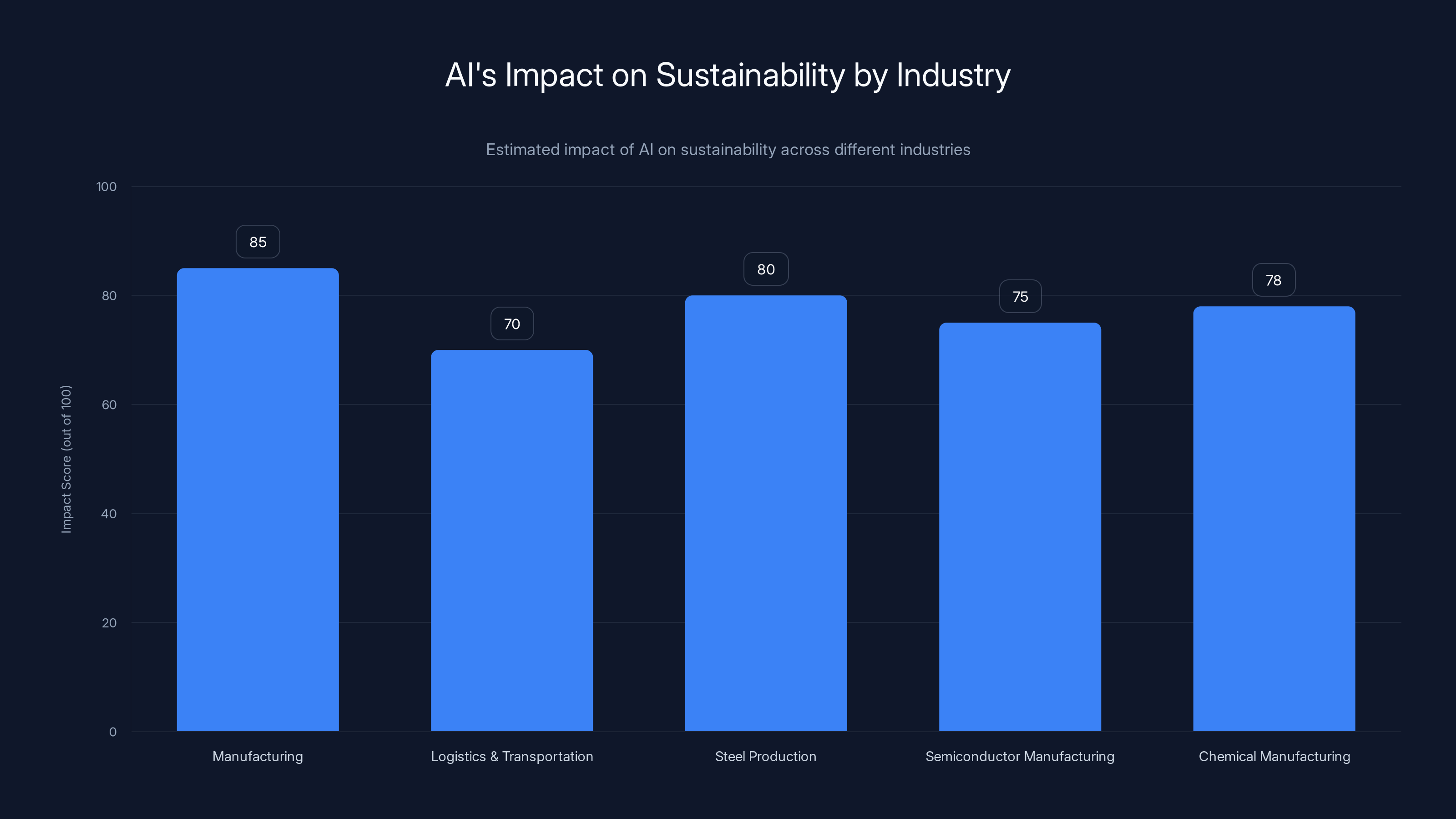

Industry-Specific Applications: Where AI's Sustainability Impact Is Clearest

AI's impact on sustainability varies wildly depending on the industry. Let's look at where it's already making the biggest difference and where it's just beginning.

Manufacturing: Early Leader in AI Sustainability

Manufacturing is where we see the clearest results because the data exists, the impact is measurable, and the incentives align. Reduced waste = reduced costs. Lower energy consumption = lower bills. Better efficiency = higher output from the same facility.

Steel production, semiconductor manufacturing, chemical manufacturing, pharmaceutical production—these are all complex processes with tight tolerances, significant energy consumption, and tremendous waste reduction opportunities. AI tools that optimize these processes simultaneously improve efficiency (profit) and reduce emissions (sustainability).

The implementations are getting increasingly sophisticated. Real-time sensor networks that would've cost millions ten years ago are now affordable. AI systems that can process this data in real-time are becoming commodity infrastructure. The remaining work is domain expertise—understanding the specific process well enough to configure the AI for the right optimizations.

Logistics & Transportation: Massive Untapped Potential

Logistics is where AI could be doing even more than it currently is.

Route optimization for delivery is the obvious application—figuring out the most efficient route saves fuel, time, and emissions. But the bigger opportunity is consolidation and mode shift. How do you get items to customers using the lowest-carbon method? Often that's ocean shipping (low emissions), sometimes rail (moderate emissions), occasionally air (high emissions).

Optimizing this at scale—across millions of shipments, hundreds of destinations, complex supply constraints—is an AI problem. The companies doing this well are seeing 10-15% reductions in transportation emissions.

Electric vehicle routing is even more interesting. EV batteries have limited range. Cold weather reduces range. Going uphill uses more battery than going downhill. The optimal route for an EV is different than for a gas vehicle. It also varies based on where charging stations are located and how long you're willing to stop.

AI systems that optimize routes considering all of these constraints—while still meeting delivery windows and balancing driver preferences—are becoming critical infrastructure for fleets transitioning to electric.

Energy Systems: Grid-Level Optimization

At a grid level, AI is enabling renewable energy integration at scales that weren't previously possible.

Variable renewable energy (solar and wind) creates a central problem: supply is unpredictable. The sun goes behind clouds. The wind stops blowing. Grid operators need to have enough power generation capacity available to meet demand even when renewables underperform. That's expensive and wasteful.

AI systems that predict renewable output hours or days in advance, that automatically shift flexible loads (like EV charging or industrial processes) to times of high renewable availability, and that optimize storage (batteries, thermal, pumped hydro) for maximum efficiency—these systems are transforming grid operations.

The result: higher renewable energy penetration is possible because the grid can handle the variability. Countries with 50-60% renewable energy now are managing that using AI-optimized grid balancing that would've been impossible manually.

Agriculture: Precision Farming at Scale

Agriculture accounts for 10-15% of global emissions. It's also incredibly complex—millions of farmers, diverse crops, highly variable local conditions, and tremendous data gaps.

AI tools that analyze satellite imagery, weather data, soil sensors, and crop health to optimize fertilizer application, pesticide use, irrigation, and planting decisions can reduce emissions, cut costs, and increase yields simultaneously. It's one of those rare situations where all three outcomes improve together.

The challenge is deployment. These tools are most valuable for large-scale industrial agriculture, but they could also benefit small farmers in developing economies who don't have access to information and expertise. The tractability of AI tools for agriculture in these contexts is still developing.

The Future of AI-Enabled Sustainability: What's Coming

Looking forward, we're going to see several major developments that amplify AI's sustainability impact.

Better Emissions Accounting

One of the biggest blockers right now is that emissions measurement is inconsistent and incomplete. Companies use different methodologies. Data quality varies. Scope 3 emissions are estimated, not measured.

AI systems that ingest inconsistent data from multiple sources and create standardized, comparable emissions accounting are going to unlock massive improvement. Once you can measure consistently, you can optimize systematically.

Expect to see AI systems that are explicitly designed for sustainability accounting become standard infrastructure over the next 3-5 years.

Autonomous Optimization

Right now, most AI systems make recommendations that humans then implement. The next frontier is autonomous optimization within defined parameters—the AI can make certain decisions and take certain actions without human review.

This could look like: an energy management system that automatically shifts loads to times of grid carbon intensity. A supply chain system that automatically reroutes shipments based on changing supplier emissions profiles. A manufacturing system that autonomously adjusts processes within pre-approved parameter ranges.

This requires sophisticated governance, risk management, and oversight. But when implemented correctly, it lets optimization respond in real-time to changing conditions in a way that humans can't match.

Integration Across Value Chains

Right now, most AI systems optimize within individual companies or facilities. The next frontier is optimization across entire value chains.

Imagine: suppliers, manufacturers, logistics companies, and customers all sharing standardized emissions data through secure APIs. AI systems optimize not just within each company but across the entire value chain.

This could reduce supply chain emissions by 30-40%. It would require unprecedented coordination and trust. But it's technically tractable. Early pilots are starting to emerge.

AI for Circular Economy

One of the most interesting frontiers is AI for circular economy—designing and operating systems where products are used, recovered, refurbished, and remanufactured into new products.

Circular systems are more complex than linear systems. But they're vastly more sustainable. AI systems that optimize circular flows—determining which returned products should be refurbished, which should be disassembled for parts, which materials should be recycled—can make circular economics profitable at scale.

Expect to see AI-optimized circular economy systems become increasingly common as companies look for ways to reduce raw material costs and capture value from end-of-life products.

Manufacturing leads in AI-driven sustainability with a high impact score, while logistics shows significant untapped potential. Estimated data.

Challenges, Limitations, and Honest Assessment

Let me be clear about what AI can't do, where it falls short, and what remains genuinely hard.

AI Can't Solve Everything

AI is powerful for optimization within existing systems. But some sustainability challenges require systemic change that AI can't force.

The energy system needs to be decarbonized at the source. No amount of optimization helps if your electricity comes from coal. You need actual renewable energy generation capacity. That's infrastructure and policy, not AI.

Some products are inherently unsustainable. You can optimize a coal-powered electricity system to be more efficient, but it's still coal. Sometimes the solution isn't optimization—it's replacement.

AI is a tool for how to transition to sustainable systems. It's not a substitute for whether to make that transition.

The Data Problem Remains Real

Many of the AI applications we've discussed require good data. But data infrastructure for sustainability is fragmented and incomplete.

Supply chain data is often proprietary and fragmented. Facility-level operational data requires sensor infrastructure that doesn't exist everywhere. Supplier emissions data is inconsistent.

Before you can deploy AI, you often need to build data infrastructure. That's expensive, time-consuming, and genuinely difficult in some industries.

Rebound Effects Are Real

When you make something more efficient, sometimes people use more of it. More efficient transportation might lead to more frequent trips. More efficient manufacturing might enable lower prices that increase consumption.

This is a real effect that reduces the sustainability impact of optimization. It's not unique to AI—it's true for any efficiency improvement. But it's important to account for.

The Governance Problem Scales

As AI systems become more autonomous and more consequential, governance becomes harder. A well-governed AI system in one facility is tractable. Coordinating governance across hundreds of autonomous AI systems across multiple companies is genuinely difficult.

We don't yet have standard frameworks for this. We're making it up as we go.

Building Your AI Sustainability Strategy

If you're thinking about deploying AI for sustainability impact, here's a practical framework.

1. Identify Your Biggest Emissions Sources

Not all emissions are created equal. Focus on the 20% of sources that create 80% of your impact.

For most companies, this is: energy consumption (manufacturing or operations), supply chain emissions (Scope 3), and product use (for some industries). Identify which is largest for your business.

2. Quantify What You're Trying to Optimize

You can't optimize what you don't measure. Before deploying AI, establish baseline measurements.

How much energy does your manufacturing facility currently consume? How much waste does it generate? What's your supply chain emissions baseline? The AI's job is to reduce these numbers. You need to know where you're starting.

3. Assess Your Data Infrastructure

AI is only as good as the data it processes. Before investing in AI, assess: do we have the sensor networks needed? Is data being collected consistently? Is data integrated or fragmented across systems?

If you're starting from zero, building data infrastructure comes before building AI infrastructure.

4. Start Small, Prove Value, Scale

Don't try to optimize your entire operation at once. Pick one facility, one process, or one supply chain—something constrained enough to be tractable, but large enough to matter.

Implement the AI system. Measure the results. Once you have evidence of impact, apply it elsewhere.

5. Build Governance From Day One

Governance seems like overhead. Until it's not. Then it seems like the most important decision you made.

Define: who reviews recommendations, what gets auto-implemented, what requires approval, who's responsible, how are disputes resolved, how do you handle errors.

This doesn't have to be elaborate. But it has to exist.

6. Plan for Integration With Other Systems

AI systems don't operate in isolation. They need to integrate with existing business systems, data platforms, and decision-making processes.

How does the AI system feed data into your sustainability reporting? How do procurement teams access supply chain emissions data? How do design teams get lifecycle assessment information?

Integration is often where the value gets locked or lost.

The Sustainability Paradox Resolved

Let's come back to where we started: the apparent contradiction between AI's energy consumption and its sustainability benefits.

It's not really a contradiction. It's an investment.

Yes, running AI systems consumes energy. That energy has an environmental cost. But that investment typically prevents emissions several times larger than the cost within 12-24 months. After that, it's net positive.

This is how progress works. You invest resources now to prevent larger problems later.

The real contradiction would be not using these tools while facing a climate crisis that demands massive, rapid emissions reductions. The tools exist. They work. They provide positive ROI on emissions (and usually on finances too).

The next decade of sustainability isn't going to be solved by anyone doing less. It's going to be solved by everyone doing what they do but doing it better. And AI is one of the most powerful tools we have for "doing it better" at scale and speed.

Are there challenges? Yes. Do we need good governance and responsible deployment? Absolutely. Should we be skeptical and demanding about proving actual emissions impact? Of course.

But dismissing AI as inherently unsustainable because it consumes energy is looking at the cost side of the balance sheet while ignoring the benefit side. The math, when done honestly and completely, shows that this isn't a contradiction at all. It's one of our best options.

FAQ

What is AI sustainability, and how does it differ from general sustainability?

AI sustainability refers to using artificial intelligence tools specifically to measure, optimize, and reduce environmental impact across operations, supply chains, and products. It differs from general sustainability in that it leverages computational intelligence to identify efficiency opportunities, predict outcomes, and optimize across complex systems at speed and scale that would be impossible manually. Rather than relying on periodic audits and historical data, AI sustainability systems enable real-time monitoring and continuous optimization.

How does AI actually reduce emissions if it requires significant energy to operate?

AI systems consume energy upfront, but they prevent significantly larger emissions through optimized operations, supply chains, and product design. For example, a manufacturing facility implementing AI-powered optimization might consume 90,000 tons of CO2 annually for the AI system itself, but prevent 500,000+ tons of CO2 through improved efficiency. The payback period is typically 12-24 months, after which every additional year is net emissions prevention. The key is measuring both sides of the equation, not just the AI system's energy cost.

What are Scope 3 emissions, and why does AI matter for reducing them?

Scope 3 emissions are indirect emissions from an organization's entire value chain, including supplier operations, product transportation, customer use, and end-of-life disposal. For most companies, Scope 3 is 5-10x larger than direct (Scope 1 and 2) emissions, but it's traditionally been impossible to measure and optimize. AI systems can now predict and analyze Scope 3 emissions across the value chain, identify high-impact suppliers and processes, and simulate the emissions impact of different decisions. This transforms Scope 3 from unmeasurable to actionable.

Can AI help individual consumers make more sustainable choices?

Yes. AI systems can calculate the lifecycle carbon footprint of products in real-time based on manufacturing location, transportation method, local electricity grid composition, and expected product usage. At the point of purchase, consumers can see accurate environmental impact and compare alternatives. During product use, AI can recommend efficiency optimizations (temperature settings, charging times, maintenance practices) that reduce operational emissions. Studies show that 60-70% of consumers care about environmental impact, but only 30-40% have access to accurate information. AI closes this gap.

What's the difference between AI optimization and genuine sustainability?

AI optimization within existing unsustainable systems can improve efficiency without creating fundamental sustainability. For example, optimizing coal-fired electricity generation makes it more efficient but still coal-powered. True AI sustainability requires that AI tools help transition to fundamentally sustainable systems (renewable energy, circular economy, sustainable materials). The best approach is AI as a tool for accelerating transitions that are necessary anyway, not as a substitute for systemic change.

How do companies ensure their AI sustainability systems don't create unintended negative consequences?

Responsible AI governance is essential. This includes transparency about how recommendations are made, human oversight of critical decisions, involvement of diverse teams in system design, and monitoring for unintended effects. A supply chain optimization system that reduces carbon emissions while exploiting supplier labor isn't truly sustainable. Companies should establish clear governance frameworks that define which decisions can be autonomous, which require human review, and who is responsible for the system's performance. Regular audits for unintended consequences should be standard practice.

What industries benefit most from AI sustainability tools, and where is progress lagging?

Manufacturing, logistics, energy systems, and agriculture are seeing significant AI sustainability benefits because they have clear metrics, existing data infrastructure, and strong financial incentives aligned with environmental goals. Progress is lagging in less centralized industries (like consumer goods with distributed retailers) and in developing economies where data infrastructure and AI expertise are limited. The sustainability gap often correlates with the AI adoption gap, which suggests that broader AI infrastructure development will have spillover sustainability benefits.

How do you calculate the carbon payback period for an AI sustainability system?

Carbon payback period is calculated by dividing the total carbon cost of building, deploying, and operating the AI system by the annual carbon emissions prevented by the system. For example, if an AI system costs 30,000 tons of CO2 to implement and operate, and it prevents 150,000 tons of emissions annually, the payback period is 30,000 ÷ 150,000 = 0.2 years (about 2.4 months). Most well-designed sustainability AI systems achieve payback within 12-24 months. Systems taking longer should be evaluated for redesign or redeployment.

What's the role of data quality in AI sustainability systems?

Data quality is absolutely critical. AI systems are only as good as the data they process. Garbage in, garbage out. Sustainability AI requires consistent, accurate data on energy consumption, material flows, supplier operations, and environmental metrics. If data is fragmented across systems, incomplete, or inconsistent in methodology, the AI system will produce unreliable recommendations. Companies often need to invest in sensor networks, data integration platforms, and data governance before they can effectively deploy AI sustainability systems.

How will AI sustainability tools evolve over the next 5-10 years?

Expect convergence on standardized emissions accounting frameworks, enabling AI systems to work across company and industry boundaries. Autonomous optimization within defined parameters will increase as governance matures. Integration of AI across entire value chains (suppliers, manufacturers, logistics, customers) will unlock optimization impossible at individual company level. AI for circular economy optimization will become increasingly important as companies look to reduce raw material costs. Finally, AI will play a larger role in helping design fundamentally new sustainable systems rather than just optimizing existing ones.

The Bottom Line

AI consuming energy doesn't make it unsustainable any more than a water treatment plant consuming electricity makes water treatment unsustainable. What matters is whether the investment prevents more problems than it creates.

For most AI sustainability applications, the answer is clearly yes. The emissions prevented typically exceed the energy consumed within one to two years, and the benefits compound from there.

Is every AI implementation positive? No. Some will be poorly designed, badly governed, or solving non-problems. That's why governance, measurement, and honest accounting matter.

But blanketly dismissing AI as an environmental threat while facing a climate crisis that demands massive, rapid transformation misses the actual opportunity. These tools work. They're already deployed. They're delivering measurable results.

The real question isn't whether AI is sustainable. It's whether we have the wisdom to use it responsibly, the discipline to measure actual impact, and the courage to deploy it at the scale that climate change requires.

Key Takeaways

- AI systems typically prevent emissions 5-10x larger than their energy consumption within 12-24 months—the math works in favor of deployment

- Real-time manufacturing monitoring and predictive maintenance detect inefficiencies in seconds rather than weeks, preventing waste and unnecessary costs

- Supply chain optimization shifts shipments from high-carbon air freight to low-carbon ocean transport, reducing excess inventory and overproduction simultaneously

- Scope 3 emissions (supplier and customer-related) account for 75-85% of most companies' impact—AI makes these previously invisible emissions visible and actionable

- Product design AI identifies lower-carbon material and manufacturing alternatives before production starts, when changes are feasible and cost-effective

- Responsible AI governance is not optional overhead—it's essential for preventing unintended consequences and maintaining accountability as systems scale

- Consumer-facing AI transparency about product environmental impact drives purchasing decisions toward sustainable options, amplifying impact across markets

Related Articles

- Terradot Acquires Eion: Carbon Removal Market Consolidation [2025]

- Why States Are Pausing Data Centers: The AI Infrastructure Crisis [2025]

- Microsoft CEO: AI Must Deliver Real Utility or Lose Social Permission [2025]

- Ocean Robots in Category 5 Hurricanes: Oshen's Breakthrough [2025]

- Wikimedia's AI Partnerships: How Wikipedia Powers the Next Generation of AI [2025]

- Microsoft's $0 Power Cost Pledge: What It Means for AI Infrastructure [2025]

![AI & Sustainability: Why This Isn't a Contradiction [2025]](https://tryrunable.com/blog/ai-sustainability-why-this-isn-t-a-contradiction-2025/image-1-1771061799426.jpg)