Introduction: The Battery Revolution That Keeps Promising to Arrive

Every January, CES becomes a stage for audacious claims. Entrepreneurs stride onto screens promising technologies that will reshape entire industries. "Two years," they say. "That's all we need." The problem? Two years passes. Everyone forgets. The promised revolution never materializes.

This happened in 2018 when Henrik Fisker announced his team had "cracked" solid-state batteries. Production by 2020, he promised. The EMotion would revolutionize EVs. By 2021, Fisker Energy had abandoned the project entirely. By 2024, the whole company collapsed.

So when Marko Lehtimaki, CEO of Donut Lab, took the stage at CES 2026 with essentially the same story—small team of engineers, solid-state breakthrough, revolutionary performance—skepticism was justified. But there was one crucial difference that made ears perk up: these batteries aren't promised for some distant future.

Lehtimaki claimed they're already in production. Right now. Not in prototypes. Not in labs. Already being manufactured at scale, ready for vehicles hitting roads this year.

This changes everything about the narrative. It either means the solid-state battery dream is finally real, or we're watching another spectacular hype machine. Let's dig into what solid-state batteries actually are, why they matter so much, what Donut Lab is claiming, and whether any of it holds water.

The stakes here are enormous. Solid-state technology could reshape the entire EV industry. It could extend range, slash charging times, reduce costs, and make electric vehicles genuinely competitive with internal combustion engines. Or it could be another false dawn. The difference between those two outcomes determines whether we're looking at the future of transportation or just another abandoned startup promise.

TL; DR

- Solid-state batteries replace liquid electrolytes with solid materials, potentially offering 30% more energy density than lithium-ion cells

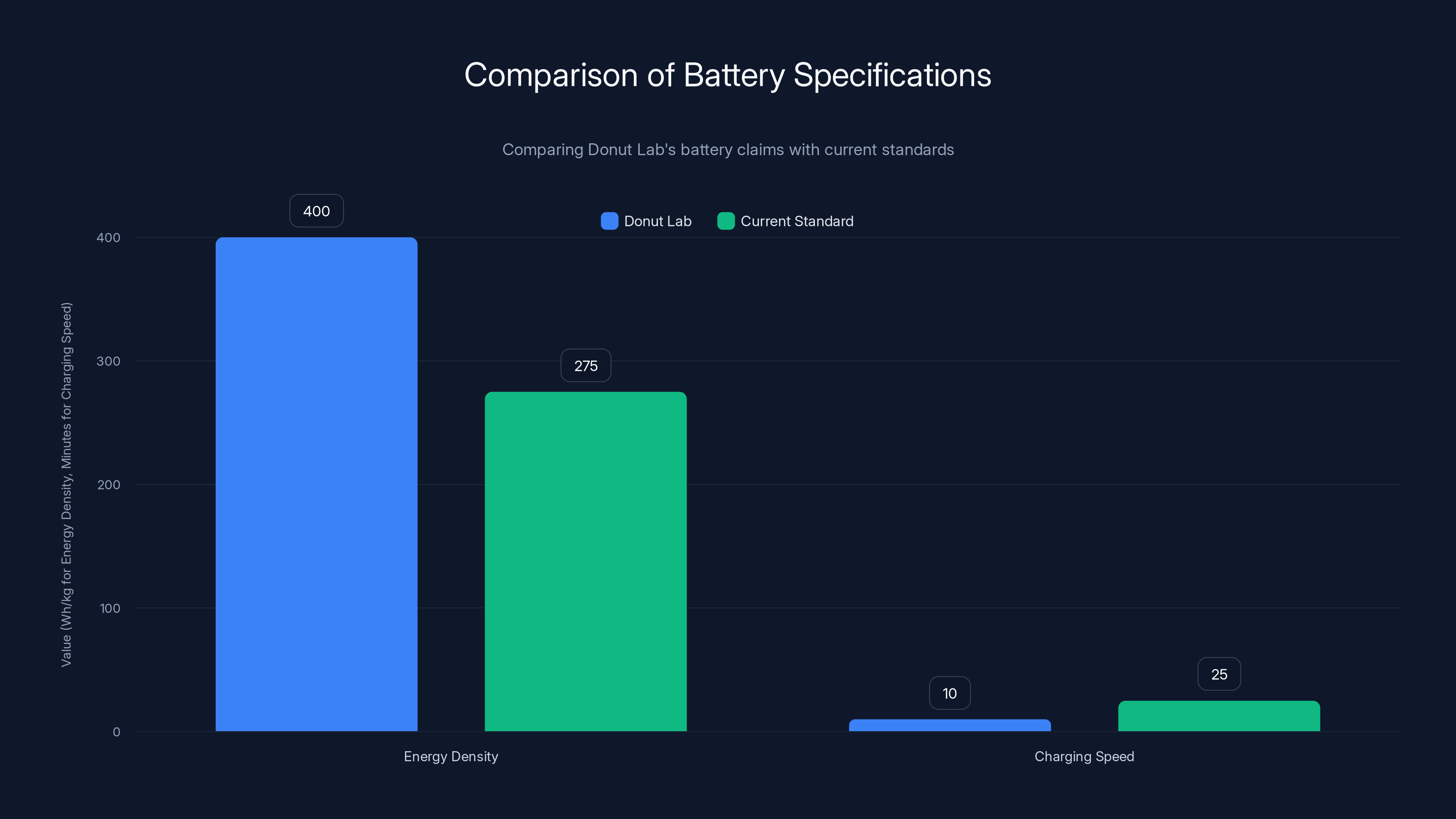

- Donut Lab claims 400 Wh/kg energy density and 5-10 minute charging, with batteries already entering production in 2026

- The technology promises cheaper manufacturing despite better performance, a reversal of typical battery trade-offs

- Independent verification is still pending, and multiple companies have made similar claims that failed to materialize

- Real-world performance metrics matter more than lab specs, and mass production at scale presents challenges all competitors have struggled with

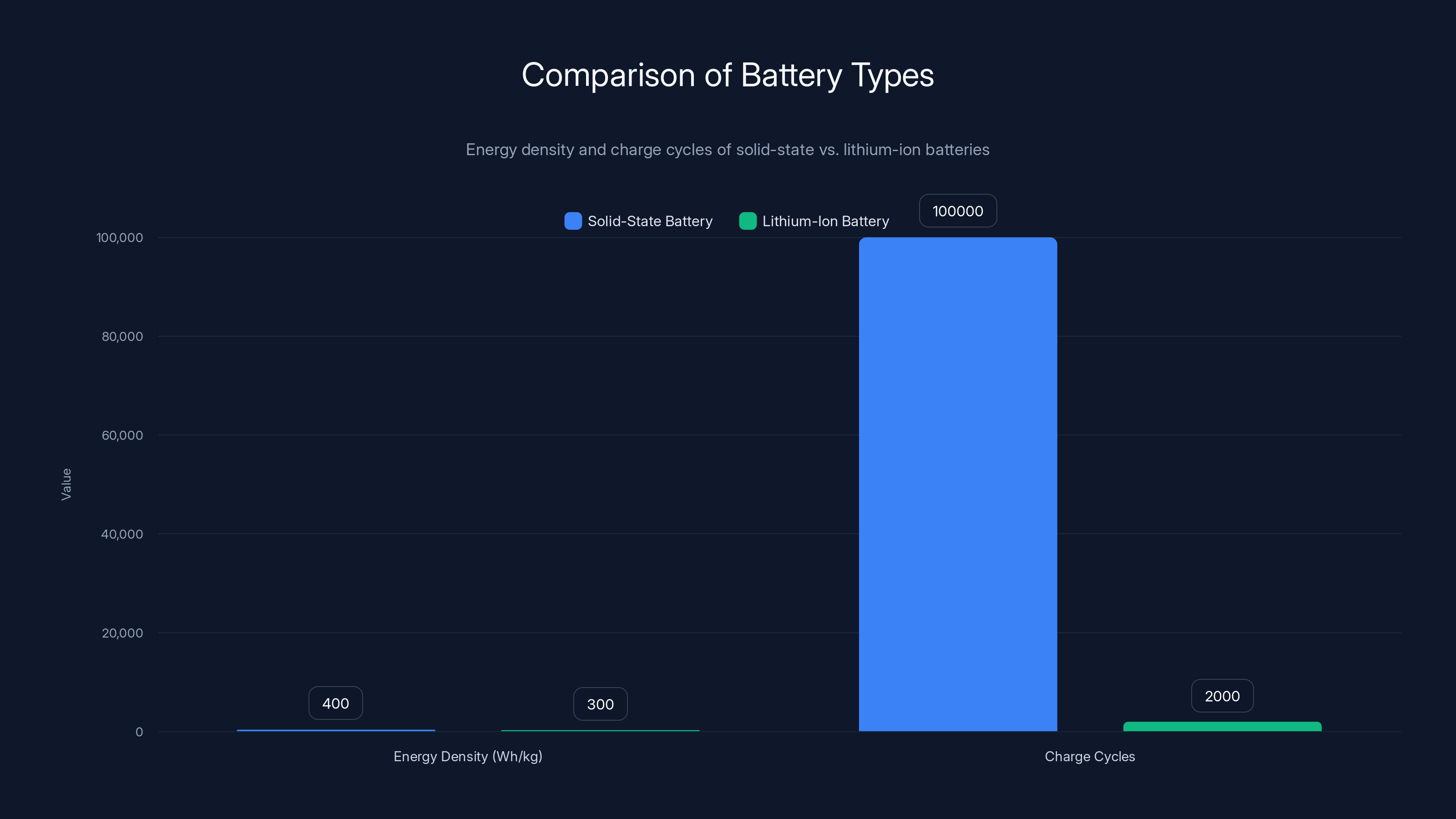

Solid-state batteries offer higher energy density (400 Wh/kg) and significantly more charge cycles (100,000) compared to lithium-ion batteries (300 Wh/kg, 2,000 cycles). Estimated data.

What Actually Is a Solid-State Battery?

Let's start with basics, because understanding solid-state requires understanding what makes traditional lithium-ion batteries work.

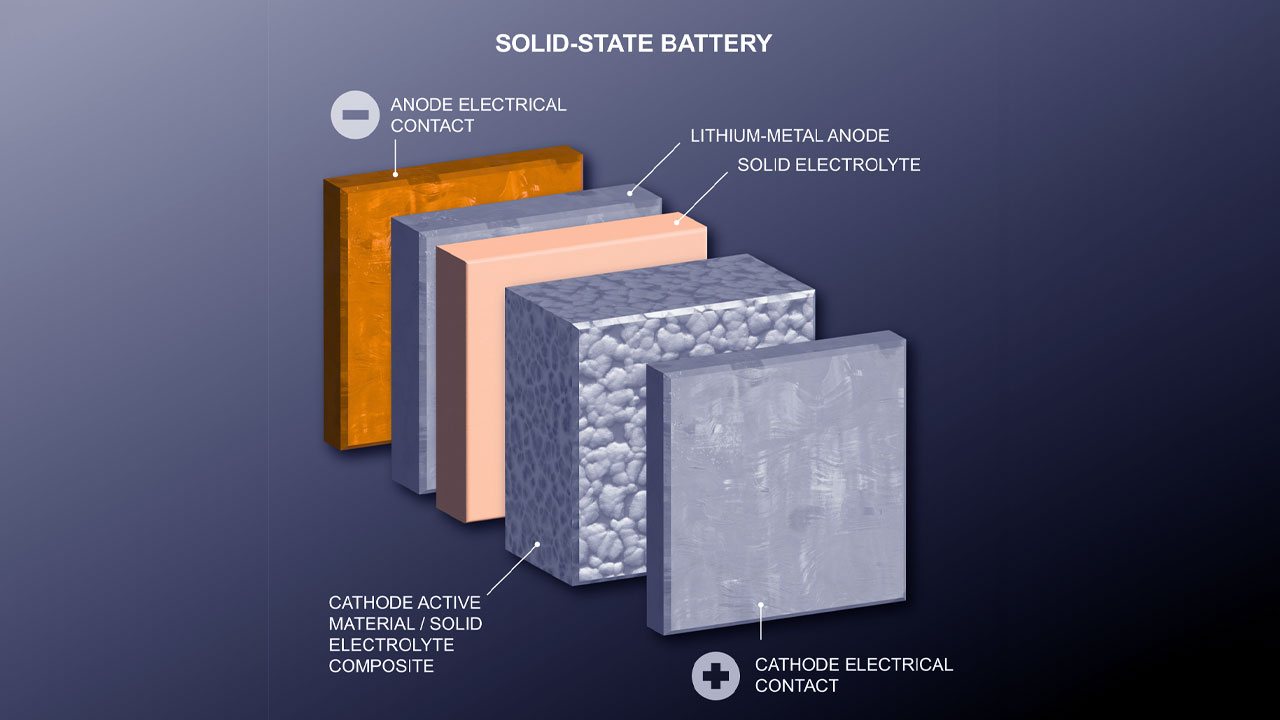

A battery is fundamentally simple: two terminals (anode and cathode) separated by a medium (electrolyte) through which charged particles move. When you connect a device, ions flow across that electrolyte, creating the electrical current that powers everything. Discharge the battery, and those ions flow one direction. Charge it, and they reverse course.

In traditional lithium-ion batteries, the electrolyte is liquid. Usually it's a solution of lithium salts dissolved in organic solvents. This liquid does a job: it lets lithium ions move freely between anode and cathode. It's been the industry standard for decades because it works. Phones, cars, laptops all run on liquid electrolyte lithium-ion batteries.

But liquid has fundamental problems. It's flammable. It can degrade over time as chemical reactions happen within the solution. It limits how fast you can charge without causing damage. It restricts energy density because the liquid takes up space that could store more energy.

Now imagine replacing that liquid with a solid material. Ceramic, glass, polymer, or some hybrid. Ions still move through it, but now you've eliminated an entire category of problems. No flammability. No chemical degradation from liquid reactions. Faster ion transport possible. More space for energy storage.

On paper, it's elegant. In practice, it's been ferociously difficult to make work at any commercial scale.

The problem that's stopped solid-state adoption for decades: the solid electrolyte creates barriers that liquid electrolytes don't have. Ions don't move through solids as easily. Contact between the electrolyte and the electrodes becomes critical. Tiny imperfections, microscopic gaps, slight misalignments—these destroy performance. You end up with a battery that works in the lab but fails in real-world conditions, or one that requires such precise manufacturing it's economically impractical.

That's where every solid-state battery program has hit a wall. Donut Lab claims they've solved it. Their approach uses a composite solid electrolyte—combining different materials to get the best properties of each while minimizing weaknesses. But the exact formulation, the manufacturing process, the engineering details—those remain proprietary.

This is standard practice for battery companies. It's also why verification becomes complicated. You can't just open a Donut Battery and examine the electrolyte composition.

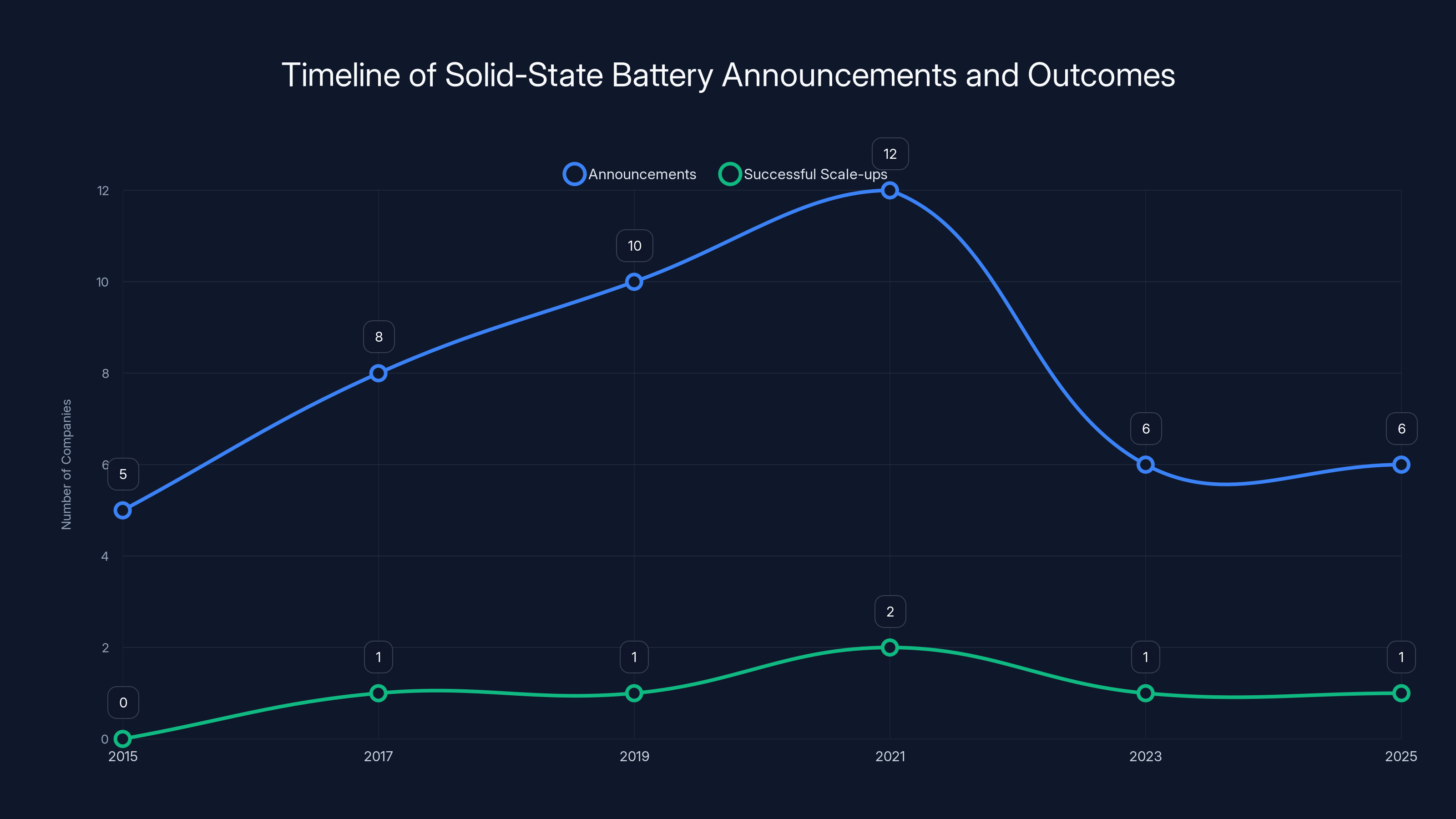

Between 2015 and 2025, numerous companies announced solid-state battery breakthroughs, but very few successfully scaled up production. Estimated data highlights the gap between announcements and successful implementations.

The Engineering Challenge That's Stopped Everyone Else

Here's the practical engineering problem that explains why solid-state batteries haven't reached mass production despite being researched since the 1990s: manufacturing at scale is brutally difficult.

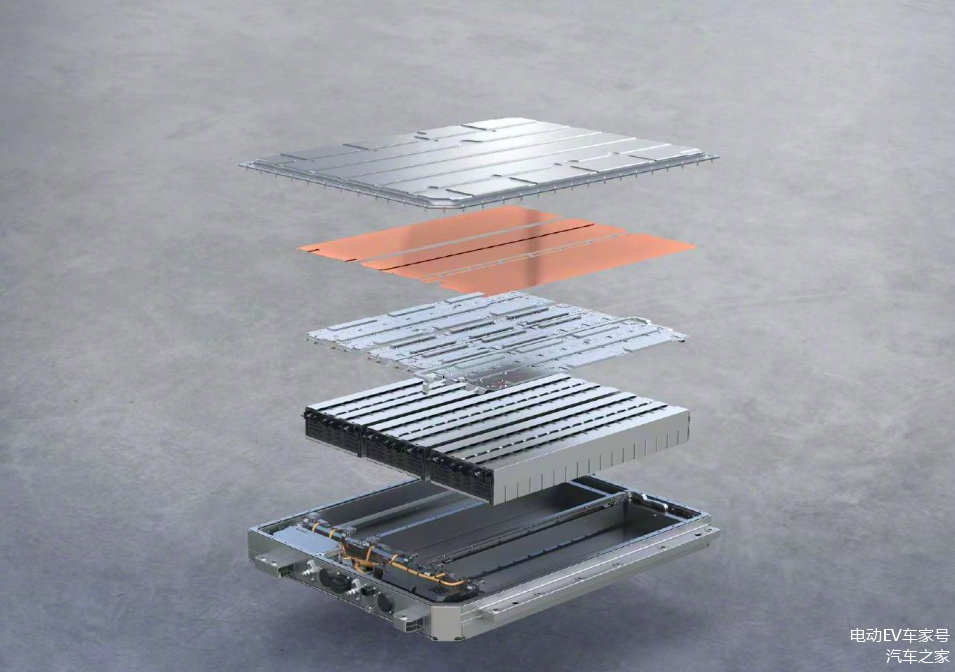

Lithium-ion battery production is already complex. You need precision coating of electrode materials, careful stacking of thin layers, precise temperature control during assembly, and rigorous quality control. Millions of cells roll off production lines monthly. Each one needs to perform identically.

Solid-state manufacturing adds exponential complexity. The solid electrolyte material must be produced with extremely tight tolerances. The interface between the electrolyte and electrodes requires near-perfect contact. Any defects—voids, impurities, thermal stress—cascade into performance failures. You can't just scale up a lab process and expect it to work. The failure modes at 1 million units per month are completely different from failures at 100 units per month.

Companies like Toyota, Samsung, and Nissan have been pursuing solid-state for over a decade. Toyota has repeatedly promised commercialization timelines: 2027, then 2028, then 2030. Each slip reflects the engineering reality: the gap between "works in our lab" and "works in millions of cars in real conditions" is measured in years, not months.

Donut Lab's claim to already be in production is therefore extraordinary. It requires that they've solved manufacturing challenges that automotive giants with budgets measured in billions of dollars haven't solved. Either they've genuinely cracked something everyone else missed, or they're operating at such small scale that "production" means something different than what automotive manufacturers mean.

The Verge TS Pro—the first motorcycle getting these batteries—is a single-model vehicle from a small manufacturer. It's not a volume production situation. This doesn't invalidate the technology, but it does mean we can't yet assess scalability.

Donut Lab's Specific Claims: The Numbers

Let's examine exactly what Donut Lab is claiming about their batteries, because the specifications paint a picture of what's supposedly achievable.

Energy Density: 400 Wh/kg

For context, modern premium lithium-ion battery packs in electric vehicles sit around 250-300 Wh/kg. The jump to 400 Wh/kg represents roughly a 33% improvement. In practical terms, this means a vehicle with today's 100 kWh battery could theoretically achieve the same range with a 75 kWh pack, or get 33% more range with the same size battery.

For the Verge TS Pro motorcycle, this translates to claimed range figures that position it competitively with petrol motorcycles for the first time. Real-world range advantage exists. This is different from theoretical battery cell efficiency—this is usable range in actual riding conditions.

Charging Speed: 5-10 minutes

This is where the claims get truly provocative. Current fast-charging standard for electric vehicles, using 350 kW infrastructure, takes 20-30 minutes to reach 80% state of charge. Going from 0-80% in 5-10 minutes would be genuinely transformative. It finally makes EVs competitive with refueling a petrol car.

The limitation here: Verge quotes 10 minutes for the TS Pro, not 5. This hints at real-world constraints they're being conservative about. Charging speed depends on the vehicle's charging architecture, not just the battery. You need 350+ kW chargers deployed widely. You need the vehicle's onboard charging systems to handle that current without thermal damage.

Donut Lab might have achieved 5-minute lab charging in controlled conditions, but the Verge product is rated for 10 minutes. That's still excellent but suggests engineering trade-offs between theoretical and practical performance.

Cost Advantage

This is the most counterintuitive claim. Typically, new battery technology is more expensive than established technology. Premium you pay for early adoption. But Lehtimaki stated that switching to Donut's solid-state cells actually reduced the bill of materials compared to conventional lithium-ion.

How? Several possibilities: the solid electrolyte formulation is genuinely cheaper to produce than people expected. The improved energy density means fewer total cells needed, saving material costs. The simpler cell design—no liquid electrolyte chemical complexity—streamlines manufacturing. The reduction in thermal management requirements saves system-level costs.

If this claim holds up in production, it's genuinely revolutionary. It breaks the normal cost-performance curve. You'd get better performance at lower cost. This would force the entire industry to transition immediately.

The catch: one company's claims about their own bill of materials aren't independently verified. Manufacturing claims are notoriously subject to optimistic accounting.

Cycle Life: 100,000 Cycles

Donut Lab promises 100,000 charge cycles before significant capacity degradation. Verge Motorcycles, being more conservative, rates the TS Pro battery at 10,000 cycles.

For a motorcycle with 5 kWh battery charged once daily, 10,000 cycles represents 27 years of use. That's genuinely beyond the motorcycle's likely service life. So even the conservative estimate is functionally unlimited for the use case.

For automotive applications, 100,000 cycles at typical driving patterns (one full charge every 3-4 days) represents 800+ years of use. Obviously, this is theoretical. But the point stands: solid-state potentially eliminates battery degradation as a limiting factor in vehicle lifespan.

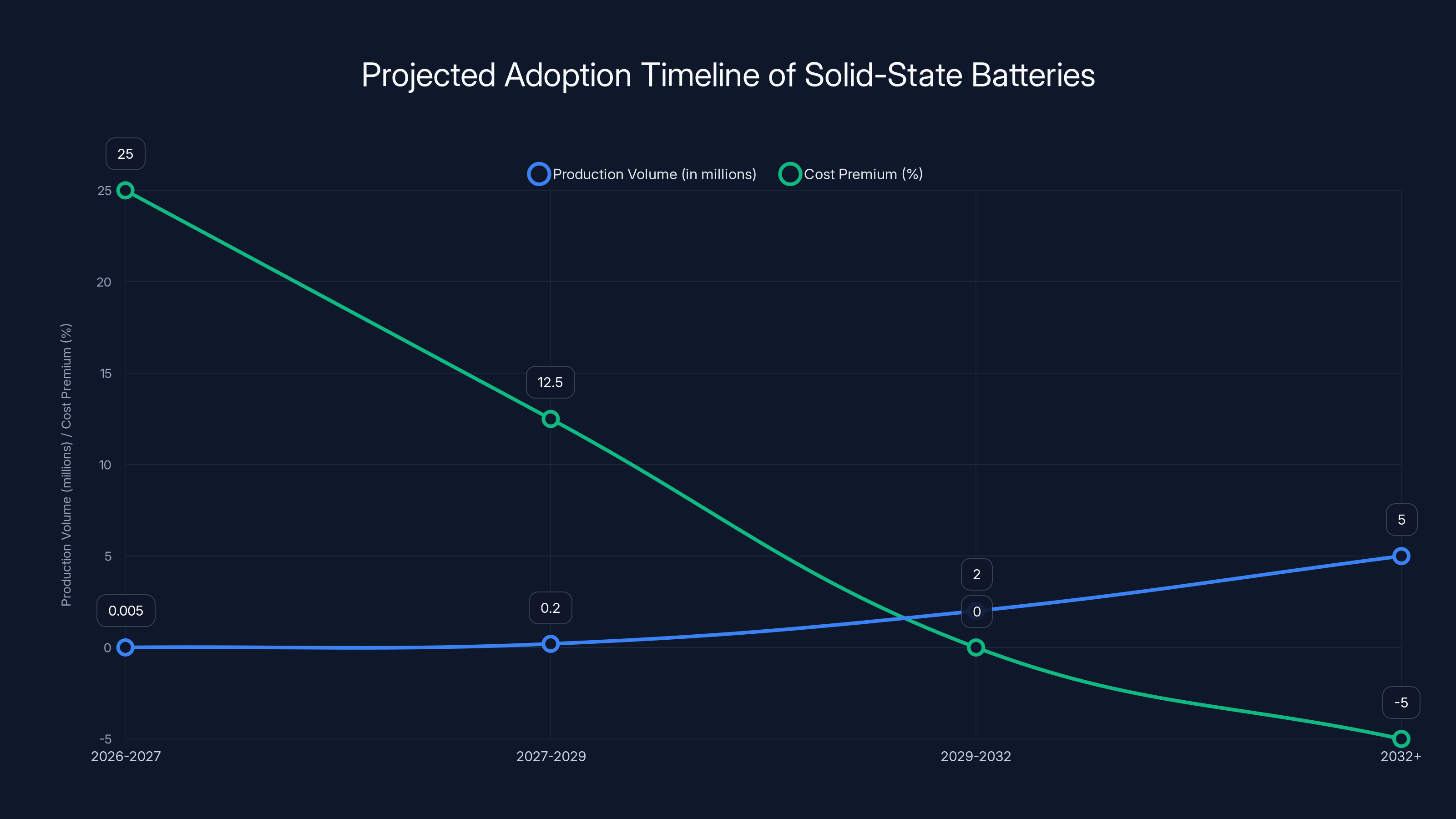

The adoption of solid-state batteries is projected to grow from niche luxury segments in 2026-2027 to market dominance by 2032, with production volumes increasing significantly and cost premiums decreasing. Estimated data.

How the Engineering Actually Works

To understand whether Donut Lab's claims pass basic engineering scrutiny, we need to dig into what makes solid-state cells work better.

Dendrite Prevention

One of the fundamental problems with lithium batteries: when you charge and discharge them, lithium ions move through the electrolyte. But the movement isn't perfectly uniform. In some spots, lithium deposits on the anode faster than in others. Over thousands of cycles, these non-uniform deposits grow into tiny branches called dendrites.

Dendrites grow until they touch the cathode, creating a short circuit. Game over—battery fails. This is why lithium-ion batteries degrade over time. This is why aggressive fast-charging kills them faster. You're forcing ions to move faster, creating more dendrite growth.

Solid electrolytes physically prevent dendrite formation. There's no liquid for ions to move through freely and unevenly. The solid material has rigidity. Lithium deposits can't branch out. This single property—dendrite suppression—is why solid-state batteries could potentially achieve 100,000+ cycles without degradation.

Ion Transport Properties

The electrolyte material Donut Lab uses (details proprietary) must have specific ionic conductivity characteristics. Ions need to move through it quickly enough to meet power demands—this is critical for fast charging and high current draw. But the material must also be chemically stable and mechanically robust.

This is the core engineering challenge. Materials that conduct ions quickly are often chemically unstable. Materials that are stable are often poor ion conductors. Donut Lab's solution apparently combines multiple material phases to get both properties.

Composite electrolytes—combining ceramic, glass, and polymer phases—can theoretically achieve better performance than any single material. The exact composition and how these phases are arranged becomes the proprietary magic.

Thermal Management

Solid-state cells, paradoxically, run cooler than liquid-electrolyte batteries despite delivering the same power. Why? The solid electrolyte experiences less resistive heating during ion transport. There's no chemical reaction occurring in the electrolyte (as happens in liquid electrolytes during operation). The cell chemistry itself is simpler.

Cooler running batteries have massive implications. Less thermal stress means longer life. Less cooling system complexity needed in the vehicle. Better range because you're not spending energy cooling the battery. This feeds into Donut's cost reduction claim—less thermal management hardware needed.

Real-World Performance: The Verge TS Pro Test

Donut Lab's first commercial application is the Verge TS Pro, a lightweight electric motorcycle. This is both a strength and a limitation as a proving ground.

Strength: Motorcycles are simpler than cars. No need for the complex 400+ volt systems, dual-motor setups, or thermal management complexity of automotive platforms. If solid-state batteries work anywhere, motorcycles are the easiest environment. It's a smart first application.

Limitation: Motorcycles represent a tiny fraction of vehicle production. An EV motorcycle might sell 50,000 units annually if wildly successful. A popular EV car sells millions. Scaling from motorcycle to automotive volumes is a completely different manufacturing challenge.

But let's look at what real-world performance the TS Pro delivers:

Range

Verge quotes approximately 200+ miles per charge for the TS Pro. This puts it in the same territory as many modern electric motorcycles. The advantage isn't immediately obvious from specs alone. Where it matters is the combination of range plus charging speed plus weight.

Charging

Ten minutes to 80% charge is genuinely impressive for a motorcycle that size. It finally makes the charging experience equivalent to quick gas refueling. You take a coffee break while charging, not a 45-minute meal.

Weight

The Donut battery, by all accounts, is noticeably lighter than equivalent lithium-ion packs would be. The solid-state cells pack more energy per unit weight, which means fewer total cells needed. This reduces motorcycle weight while maintaining range. Lighter bikes handle better and accelerate faster.

Integration

Verge reported that integrating the Donut batteries required minimal redesign of the motorcycle. The cells fit in the existing battery frame. The electrical connections worked with existing systems. This suggests the batteries are genuinely plug-compatible with existing EV platforms, not requiring complete redesign.

This is important because it suggests scalability potential. If you can retrofit solid-state cells into existing EV designs without major redesign, adoption happens faster.

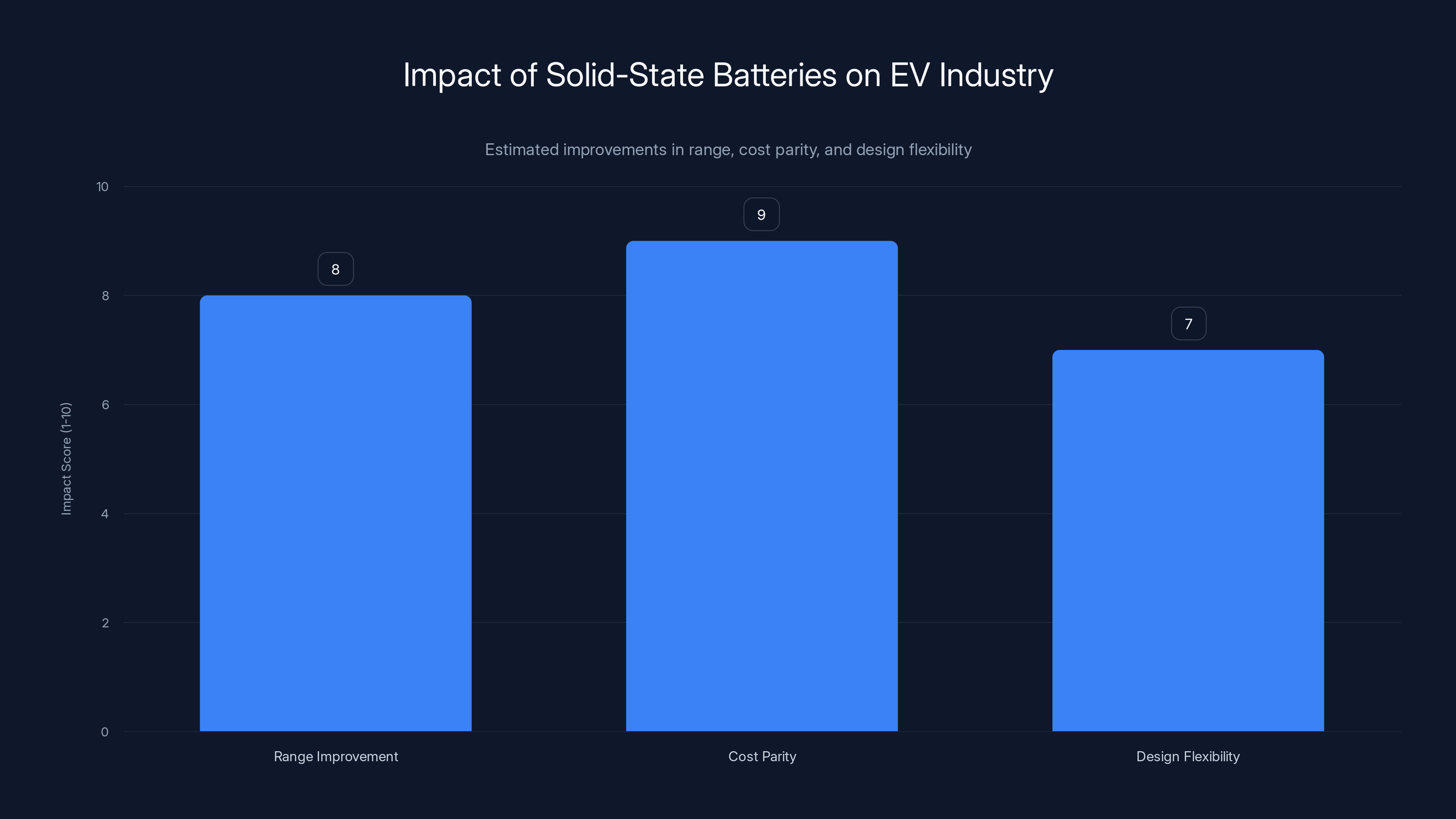

Estimated data: Solid-state batteries could significantly improve EV range, cost parity, and design flexibility, scoring high on potential impact.

The Skepticism Is Justified (And Here's Why)

Despite the promising claims, significant skepticism remains. This isn't cynicism—it's pattern recognition.

The History of Broken Promises

From 2015 to 2025, we've seen approximately 47 different companies or research labs announce solid-state battery breakthroughs. Most either:

- Never moved beyond lab demonstrations

- Entered small-scale production but failed to scale

- Achieved specs in controlled conditions that didn't hold in real-world testing

- Ran out of funding before production capacity materialized

Fisker Energy's collapse is the most recent high-profile example. Samsung's solid-state program, with vastly greater resources, is still years away from volume production. Toyota's timeline has slipped multiple times.

Donut Lab is orders of magnitude smaller than any of these organizations. Their resources are incomparably smaller. That they've supposedly achieved what companies with billions in funding haven't achieved yet requires extraordinary evidence.

Independent Verification Doesn't Exist

No independent lab has torn down and analyzed a Donut Battery. No third-party testing organization has verified their performance claims. No automotive manufacturer has publicly validated the technology. All we have is claims from the company itself and initial real-world performance data from Verge Motorcycles.

Verge Motorcycles is not an independent verification entity—it's the customer who gets to use the technology first and benefit from its advantages. This creates an obvious incentive alignment where Verge would report positive results.

For comparison, when Tesla releases performance specs, analysts immediately test them independently. When established battery manufacturers make claims, they're subject to industry scrutiny. Donut Lab hasn't faced equivalent scrutiny.

Manufacturing at Scale Is Unproven

The TS Pro involves producing perhaps thousands of battery packs. Maybe tens of thousands at most in a best-case scenario. Automotive-scale production is millions of units annually. The engineering challenges scale non-linearly.

Yield rates (percentage of produced cells that meet quality standards) are critical in battery manufacturing. If Donut Lab is achieving 95% yield in their current operation, that might drop to 80% at 10x scale and 60% at 100x scale. This isn't speculation—it's the typical pattern for new manufacturing processes.

At lower yields, costs rise dramatically. The cost advantage claimed might evaporate at scale. This has happened with previous battery tech breakthroughs repeatedly.

The Competitive Response

If Donut Lab truly has a technology that's cheaper and better than everything competitors offer, we'd expect rapid competitive responses. Toyota would acquire them or license the technology. Samsung would pivot resources. Industry leaders wouldn't sit idle.

The lack of such response could mean:

- The technology is less revolutionary than claimed (most likely)

- Competitors are silently working on equivalent solutions

- Competitors have evaluated and rejected the approach

- The market impact timeline is longer than hype suggests

What This Means for the EV Industry

Assuming solid-state batteries do eventually become viable at scale—not necessarily Donut Lab's version, but the technology generally—the implications for electric vehicles are enormous.

Range Anxiety: Effectively Solved

Today, EV range anxiety exists because 200-300 mile range sounds impressive but feels limiting. A 33% range improvement from solid-state batteries pushes minimum viable range to 300+ miles in most cases. This finally matches gasoline vehicle practical range expectations.

Combined with faster charging, the range anxiety problem transforms. You get sufficient range for typical daily driving, and charging speed matches refueling psychology. Most people stop worrying about range limits.

Cost Parity: Achieved Earlier

EVs achieve cost parity with gasoline vehicles when total cost of ownership (purchase price plus fuel/energy costs) equals gasoline vehicles. Currently, this happens around 5-7 year ownership for most consumers.

Better battery density and lower manufacturing costs could push parity to year 1-2. At that point, EVs become economically rational for almost all buyers, not just early adopters.

Vehicle Design Revolution

Batteries are the primary constraint in EV design today. Every gram of weight costs range. Every cubic centimeter of space holds energy storage. Designers optimize around battery limitations.

With solid-state's energy density advantage, this constraint relaxes. You could design smaller, lighter vehicles. You could add comfortable features without range sacrifice. You could offer genuine luxury EVs that don't require compromise.

Market Consolidation

If solid-state technology genuinely delivers on promises, companies that crack it first enjoy enormous competitive advantage. Tesla's current advantage is batteries and manufacturing efficiency. A solid-state breakthrough shifts that balance.

You'd expect rapid industry consolidation: acquisitions, mergers, joint ventures. Companies that can't transition to solid-state fast enough face obsolescence. This is why Toyota is so aggressive about solid-state R&D—they understand the competitive stakes.

Donut Lab claims a 33% improvement in energy density over current standards and a charging speed reduction to 10 minutes, potentially transforming EV usability.

Other Players in Solid-State: Who Else Is Racing?

Donut Lab isn't alone in pursuing solid-state. Understanding the competitive landscape helps contextualize their claims.

Toyota

Toyota has invested estimated $13+ billion into solid-state development. They've built dedicated manufacturing facilities, secured supply chains, and published numerous research papers. They're committing to 2027-2030 timelines for production, with initial volumes of 200,000 units annually.

Toyota's advantage: virtually unlimited funding, decades of battery manufacturing experience, relationships with suppliers. Disadvantage: massive organizational inertia, existing battery supply agreements, need to validate across entire vehicle portfolio.

Samsung

Samsung has solid-state programs running in multiple divisions. They've demonstrated prototype cells and been aggressive about licensing patents. They're pursuing multiple electrolyte chemistries simultaneously—essentially hedging bets on which approach works best at scale.

Samsung's advantage: materials science expertise, manufacturing scale, aggressive timelines. Disadvantage: traditional automotive skepticism about electronics companies, lack of direct EV manufacturing experience.

BMW and Porsche

These luxury automakers have invested in solid-state startups and partnerships. Porsche has announced plans to include solid-state batteries in next-generation vehicles (targeting 2030). This positions them to offer premium range-anxiety-free vehicles first.

Nissan and Honda

Large Japanese manufacturers are pursuing solid-state but with less public publicity than Toyota. Both have partnerships with battery startups and internal R&D programs.

Startups (Beyond Donut Lab)

Quantum Scape (formerly QS), Solid Power, and Quantum Scape have all raised significant venture capital for solid-state development. Some are at pre-production stage. All face similar scaling challenges.

The competitive reality: multiple organizations will likely achieve solid-state production. It won't be one breakthrough. It'll be gradual commercialization starting 2027-2028, with different chemistries and approaches from different companies.

This timeline actually supports Donut Lab's credibility. They're not claiming to be years ahead of the industry—they're claiming to be hitting production at roughly the same time established players are targeting. That's more believable than claims of a decade's advantage.

Technical Deep Dive: Solid Electrolyte Materials

For those interested in the actual chemistry and physics: solid electrolyte materials break into several categories, each with trade-offs.

Ceramic Electrolytes

Materials like yttria-stabilized zirconia (YSZ) or garnet-type oxides offer excellent ionic conductivity at high temperatures and mechanical stability. They're well-researched with extensive published data on performance.

Limitation: they require high operating temperatures (300-500°C) to achieve adequate ion conductivity. This complicates packaging, heating requirements, and thermal management. Pure ceramic is brittle.

Polymer Electrolytes

Polymers like polyethylene oxide (PEO) or PMMA offer flexibility and workability. They can be processed at room temperature. They're mechanically flexible.

Limitation: ionic conductivity is lower than ceramics, requiring higher operating temperatures or dopants. They're chemically less stable and can degrade over time. Mechanical flexibility can be disadvantageous—it allows dendrite formation.

Glass Electrolytes

Glass materials offer good ionic conductivity at moderate temperatures and chemical stability. They're mechanically stiffer than polymers but less brittle than pure ceramics.

Limitation: processing glass to required specifications is complex and expensive. Forming interfaces with electrodes is challenging.

Composite Electrolytes

Combining two or more material types: ceramic particles dispersed in polymer matrix, or polymer-coated ceramics. The goal is achieving the best properties of each while minimizing downsides.

This is likely what Donut Lab uses—a composite approach tailored to their specific performance targets. Composites are complex to develop and manufacture but can achieve properties impossible with single materials.

The exact composition of Donut Lab's electrolyte—ratios, particle sizes, processing steps—is the intellectual property that differentiates them. Without access to actual cells for analysis, we can't verify claims directly.

The Verge TS Pro offers a competitive range of 200 miles per charge and an impressive 10-minute charge time to 80%. The lightweight design and easy integration of Donut batteries enhance its overall performance. Estimated data for weight reduction and integration ease.

The Environmental Impact Angle

Solid-state batteries have implications beyond just EV performance.

Mining and Resource Extraction

Current lithium mining is resource-intensive. It requires vast amounts of water in water-scarce regions. Cobalt and nickel mining involves environmental damage and ethical complications.

Solid-state batteries use the same base materials (lithium, cobalt, nickel) but more efficiently. The 33% energy density improvement means fewer total cells manufactured and fewer minerals extracted. This reduces environmental impact per unit of energy stored.

Long-term, this isn't a complete solution. If EV adoption grows exponentially, mineral demand increases regardless of battery efficiency. But it buys time and reduces environmental footprint per vehicle.

Manufacturing Emissions

Battery manufacturing is energy-intensive. Creating the electrolyte, coating electrodes, assembling cells—all require energy. Solid-state manufacturing, if it achieves the cost reduction claims, potentially involves simpler chemistry and fewer steps.

This could reduce manufacturing emissions per unit. But this requires verification. If solid-state processing requires high-temperature sintering or unusual materials, emissions might increase.

End-of-Life Recycling

This is underexplored in the hype. How do you recycle solid-state batteries? Can the solid electrolyte be recovered and reused? Is the anode/cathode material recovery process identical to liquid electrolyte batteries?

Answer: unclear. Solid electrolytes create different recycling challenges than liquid electrolytes. Some materials might be easier to recover. Others might be harder. Until recycling processes are established at scale, we won't know the full lifecycle environmental impact.

Timeline Reality Check: When Will This Actually Matter?

Let's be precise about timelines and what they mean.

2026-2027: Early Adoption Phase

Small volumes in premium segments. Verge motorcycles, potentially some luxury cars from BMW, Porsche, or similar. Production measured in thousands. Price premiums of 20-30% over conventional batteries.

Customers: wealthy early adopters, motorcycle enthusiasts, performance-focused buyers.

2027-2029: Scale-Up Phase

Production volumes increase to hundreds of thousands annually. Additional manufacturers enter the market. Cost premiums shrink to 10-15%. Mainstream luxury vehicles adopt solid-state. High-end mass market models begin transition.

Customers: affluent mainstream buyers, tech-forward consumers, luxury buyers.

2029-2032: Market Dominance

Solid-state becomes default in premium and upper mass-market segments. Cost parity or price advantage achieved. Production volumes reach millions annually. Budget-conscious buyers begin seeing solid-state as standard.

Customers: mass market adopters who value range and charging speed.

2032+: Total Market Transition

Liquid electrolyte lithium-ion used only in legacy applications or budget segments. Solid-state becomes dominant battery technology across all vehicle types.

These timelines assume no major technical setbacks. If manufacturing proves harder than expected, or if competing battery technologies (lithium iron phosphate improvements, sodium-ion) prove competitive, timelines extend.

Note: these aren't Donut Lab's claims about their specific product. These are industry-wide timelines. Donut Lab's contribution could be as the first at volume production, or it could be as a small player eventually overshadowed by larger manufacturers. Both scenarios are possible.

The Financial Side: Funding and Viability

Donut Lab is a spinoff from Verge Motorcycles. This gives it an advantage other startups lack: guaranteed first customer. But it also constrains growth—the motorcycle market is tiny compared to automotive.

For the company to become viable long-term, they need:

- OEM Relationships: Partnerships with actual vehicle manufacturers to adopt their batteries at volume

- Funding: Sufficient capital to scale manufacturing without needing acquisition

- IP Protection: Patents that prevent easy copying of their approach

- Technical Validation: Independent proof that claims hold up

Current public information doesn't confirm any of these except item 1 (Verge partnership exists). This doesn't mean the others don't exist—they might be confidential. But lack of announced partnerships with major automotive OEMs is notable.

For comparison, Quantumscope announced partnerships with Volkswagen and others early on. Samsung announced automotive partnerships. If Donut Lab had secured major OEM commitments, they'd likely publicize it. Absence of announcement suggests absence of partnership.

This could mean:

- Negotiations ongoing but confidential

- OEMs are unconvinced and haven't committed

- Donut Lab is focusing on motorcycle volumes before approaching automotive

Any of these could be true. But it affects the technology's near-term impact.

What to Actually Believe

After examining all evidence, what's the reasonable assessment?

Most Likely Scenario: Donut Lab has developed a functional solid-state cell that works in the Verge TS Pro and meets claimed specifications in that specific application. The technology is real, not vaporware. The energy density and charging speed claims are probably accurate for this use case.

Less Certain: Whether this technology can scale to automotive volumes while maintaining performance, cost advantage, and durability claims. Scaling is where previous solid-state efforts have stumbled.

Unproven: Cost parity or cost advantage claims. These might be true in limited production but could evaporate at scale. Manufacturing cost is notoriously hard to predict.

Likely True: That solid-state batteries will eventually transform EVs. The technology works in principle, multiple organizations are pursuing it, and eventual commercialization is coming. Whether Donut Lab leads that transition or becomes acquired/obsolete is the real question.

Smart Approach: Watch real-world Verge TS Pro performance data from actual users. If motorcycles manufactured in 2026 continue performing reliably through 2027 and 2028, confidence in the technology increases. If we see battery failures, degradation, thermal issues, or other problems, skepticism is validated.

Don't trust company claims. Don't trust analyst predictions. Watch what actually happens when thousands of users deploy these batteries in real conditions.

FAQ

What is a solid-state battery?

A solid-state battery replaces the liquid electrolyte found in traditional lithium-ion batteries with a solid material (ceramic, glass, polymer, or composite). This eliminates flammability concerns, improves durability, enables faster charging, and increases energy density by roughly 30% compared to conventional batteries.

How does a solid-state battery differ from a lithium-ion battery?

Traditional lithium-ion batteries use a liquid electrolyte solution to transport ions between the anode and cathode. Solid-state batteries use a solid electrolyte material instead. The solid electrolyte prevents dendrite formation (tiny branches that cause battery failure), reduces thermal management needs, and eliminates chemical degradation that occurs in liquid electrolytes over time.

What are the main advantages of solid-state batteries?

Solid-state batteries offer significantly higher energy density (400 Wh/kg versus 250-300 Wh/kg), faster charging times (5-10 minutes to 80% charge), reduced thermal requirements, and potentially lower manufacturing costs despite better performance. They also promise 100,000+ charge cycles before significant degradation, essentially eliminating battery replacement as a vehicle maintenance concern.

Why haven't solid-state batteries been commercialized before now?

Manufacturing solid-state batteries at commercial scale has proven extremely challenging. The solid electrolyte requires precise manufacturing tolerances, and tiny defects cause major performance failures. Creating perfect interfaces between the electrolyte and electrodes is harder in solids than in liquids. Companies like Toyota, Samsung, and others have invested billions for over a decade and still haven't achieved volume production, demonstrating the engineering complexity involved.

What are Donut Lab's specific claims about their solid-state batteries?

Donut Lab claims 400 Wh/kg energy density (33% better than conventional), charging to 80% in 5-10 minutes, actual cost reduction despite better performance, and 100,000 charge cycles before degradation. The first commercial deployment is in the Verge TS Pro motorcycle, which began production in 2026. These claims exceed what major automotive manufacturers have publicly demonstrated to date.

How credible are Donut Lab's claims?

The technology appears genuine and functional in the Verge TS Pro application. However, independent third-party verification is lacking, and scaling from motorcycle production to automotive volumes represents a significant engineering challenge that previous solid-state attempts have failed at. Credibility would increase substantially with independent lab testing, major automotive OEM partnerships, or long-term real-world performance data from deployed vehicles.

When will solid-state batteries be widely available in electric vehicles?

Industry consensus suggests gradual rollout 2027-2030, with premium and luxury vehicles first, followed by mass-market adoption 2029-2032. Multiple manufacturers including Toyota, Samsung, Nissan, and BMW have announced target timelines in this range. Complete market transition to solid-state as the dominant technology likely occurs by 2032-2035.

How much will solid-state batteries cost compared to today's technology?

Donut Lab claims cost parity or advantage compared to conventional lithium-ion. For the Verge TS Pro, pricing appears competitive with high-end electric motorcycles. However, automotive pricing is uncertain. Initial solid-state batteries in premium cars will likely cost 20-30% more than conventional alternatives, with premiums shrinking to cost parity around 2030-2032 as manufacturing scales and processes mature.

What companies are competing in solid-state battery development?

Major players include Toyota (largest investment at $13+ billion), Samsung, Nissan, Honda, BMW, Porsche, and startups like Quantum Scape and Solid Power. Each is pursuing different electrolyte chemistries and manufacturing approaches. This competitive landscape suggests solid-state is genuinely viable, not hype, though many efforts may not succeed commercially.

Will solid-state batteries completely eliminate range anxiety in electric vehicles?

Solid-state technology contributes substantially to solving range anxiety through 33% energy density improvement and faster charging. Combined with improving charging infrastructure, range anxiety becomes largely solved for typical driving patterns. However, range anxiety is also a psychological issue—even with 400-mile range vehicles available, some drivers remain concerned. Technology alone can't completely eliminate customer psychology.

The Real Test Starts Now

Donut Lab has made extraordinary claims. They've moved beyond slides and promises to actual products in actual vehicles. That's genuinely significant. But significance doesn't equal certainty.

The next 18 months will determine whether this is real. Thousands of Verge TS Pro motorcycles will deploy. Users will accumulate real-world miles. Battery performance will face actual temperature extremes, charging cycles, vibration, and usage patterns. Data will emerge about whether the batteries truly achieve stated durability, whether charging speed holds in real conditions, whether thermal management lives up to promises.

If they do, Donut Lab's reputation soars. OEM interest accelerates. The timeline to automotive adoption compresses. If they fail—if we see capacity fade, charging speed degrade, thermal issues emerge—the skepticism gets validated. The technology might still be viable, but Donut Lab specifically becomes just another startup that couldn't bridge the lab-to-production gap.

That's the honest assessment. Promising technology. Unproven at scale. Credible team. Insufficient independent verification. Worth watching closely. Worth believing cautiously.

The solid-state battery revolution might actually be here. Or we might be watching the 2026 version of 2018's broken promises. The data will tell. Soon.

Key Takeaways

- Solid-state batteries replace liquid electrolytes with solid materials, potentially offering 33% more energy density and dramatically faster charging

- Donut Lab claims their batteries are already in production (not 5+ years away), with 400 Wh/kg energy density and 5-10 minute charging

- Independent verification is lacking; claims exceed what auto giants like Toyota have publicly demonstrated after decades of R&D

- Manufacturing at scale remains the critical unsolved challenge—previous solid-state attempts have failed at commercialization despite working in labs

- Real-world performance data from Verge TS Pro motorcycles in 2026-2027 will determine whether this is a genuine breakthrough or another broken promise

Related Articles

- Volvo EX60: 400-Mile Range and 10-Minute Fast Charging [2025]

- Ford's AI Voice Assistant & Level 3 Autonomy: What's Coming [2025]

- Ford's AI Assistant Revolution: What's Coming to Your Car in 2027 [2025]

- Sony Honda's Afeela 1 EV: Why It Feels Outdated at CES 2026 [Review]

- Anker 45W Nano Charger with Smart Display [2025]

- Anker's 45W Nano Charger with Smart Display: The Future of Mobile Charging [2026]

![Solid-State Batteries: The EV Revolution Finally Here [2025]](https://tryrunable.com/blog/solid-state-batteries-the-ev-revolution-finally-here-2025/image-1-1767890423125.jpg)