The Volvo EX60 Explained: What Drivers Actually Need to Know

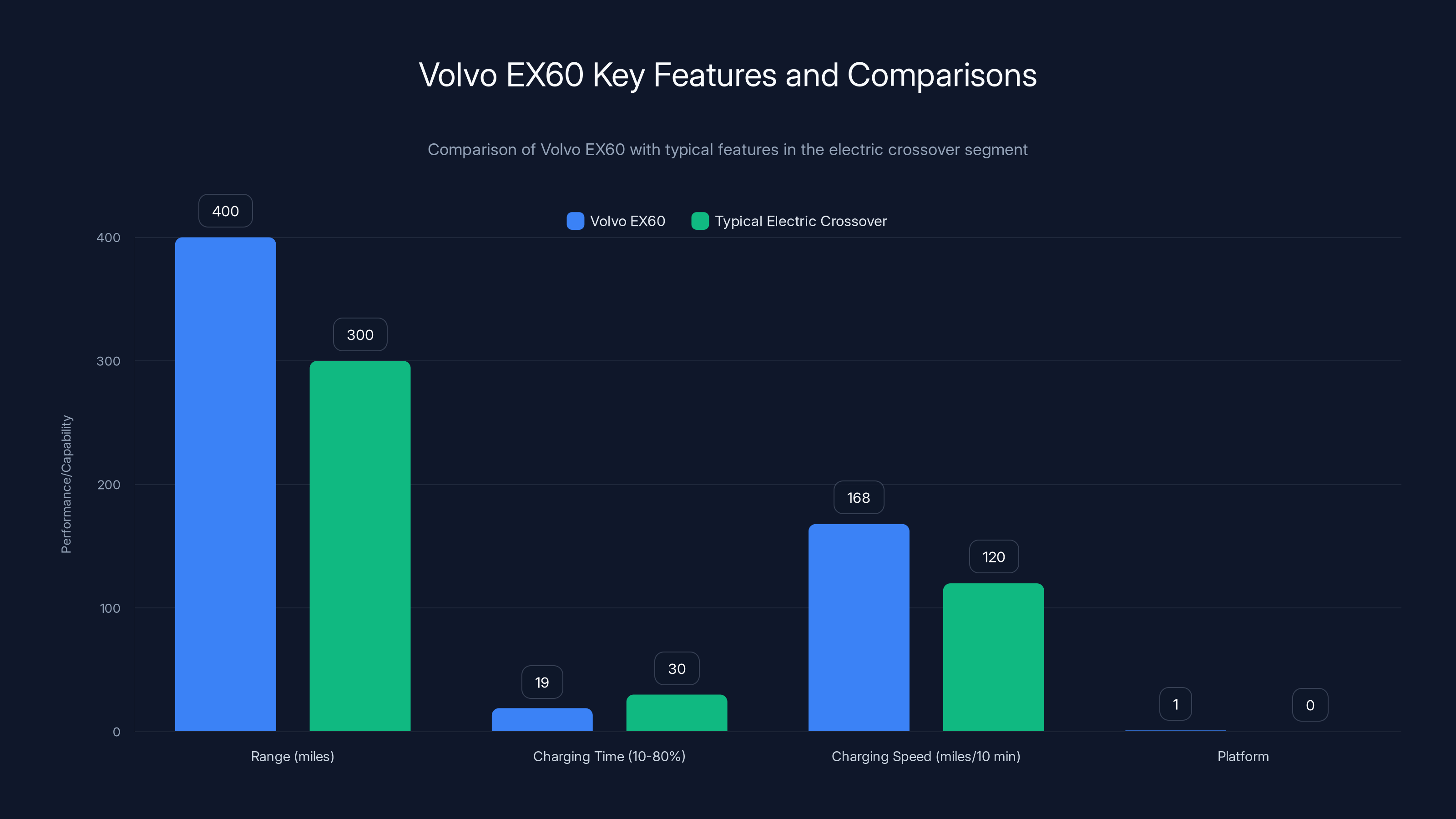

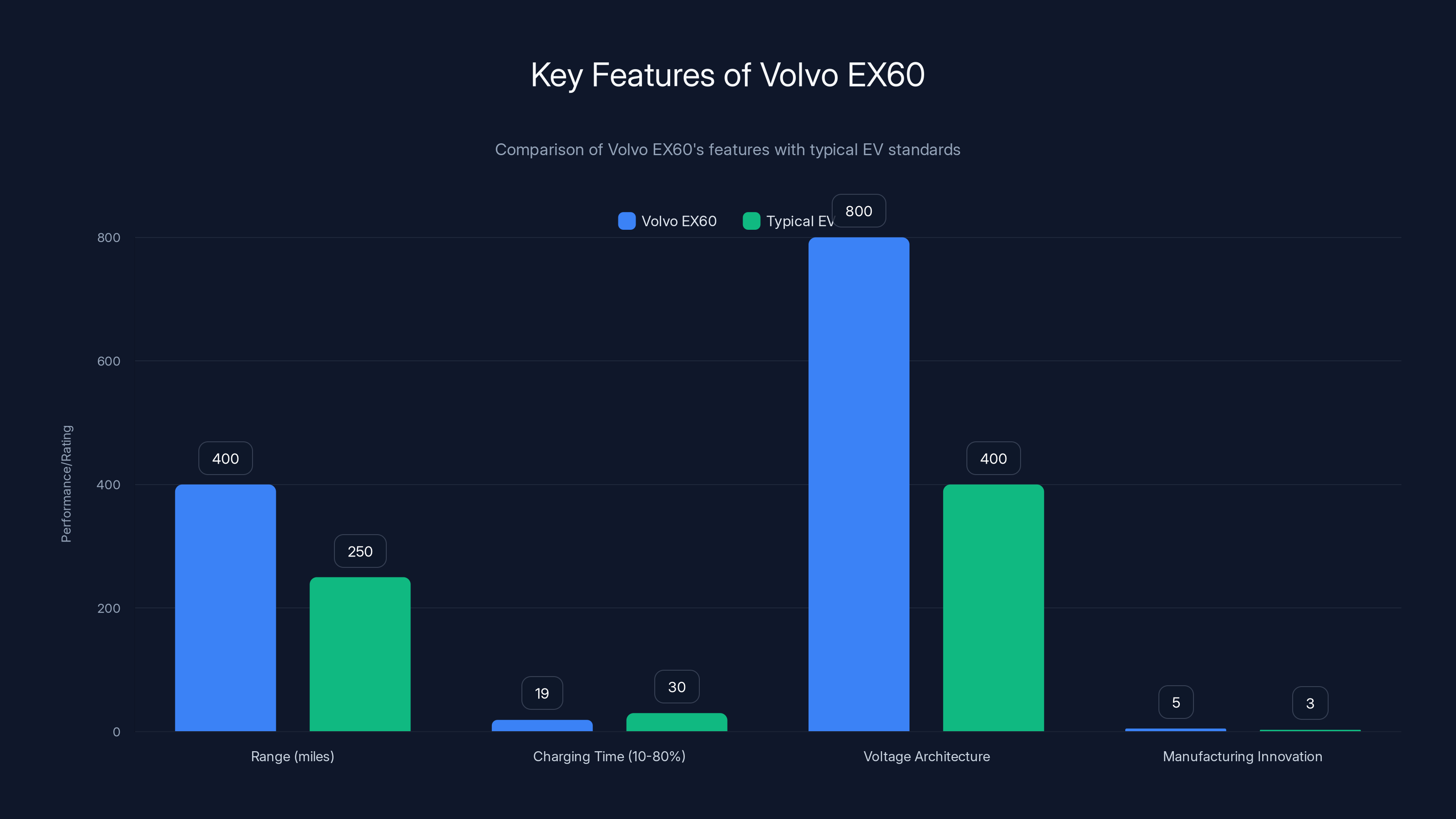

Volvo is making a bold move into the competitive electric vehicle market with its upcoming EX60 crossover, and frankly, the specs are turning heads. We're talking 400 miles of estimated range, charging from 10 to 80 percent in just 19 minutes using the right infrastructure, and a completely new manufacturing approach that's supposed to cut costs while improving quality. But here's the thing: specifications don't tell the whole story. What matters is whether this Swedish automaker can actually deliver on the promise of "no compromises" when choosing electric.

The EX60 arrives at a critical moment for Volvo. The global EV market is cooling after years of explosive growth. Consumers are asking harder questions about value, charging convenience, and whether electric really makes sense for their lifestyle. Volvo's been making electric vehicles since the early 2020s with the EX30 and EX90, but the EX60 represents something different: a midsize crossover built from the ground up on a new platform, using manufacturing techniques that the industry is still figuring out, and priced competitively with gasoline alternatives.

Understanding the EX60 means understanding several interconnected technologies and design philosophies. The 400-mile range doesn't come from a battery breakthrough or exotic chemistry. It comes from weight reduction through megacasting, structural battery packs, and careful engineering across every system. The fast charging capability depends on an 800-volt electrical architecture that's becoming standard in high-end EVs but still relatively rare. The pricing strategy reflects Volvo's confidence that manufacturing innovation can offset battery costs. Each of these elements deserves attention, because together they paint a picture of where the EV industry is heading.

This guide breaks down the EX60 from every angle: what the specifications really mean, how the technology compares to competitors, what you're actually paying for, and what questions remain unanswered before the vehicle reaches dealers. Whether you're considering an EV purchase, curious about automotive technology, or tracking the industry's evolution, you'll find practical insights here.

TL; DR

- 400-mile range achievable without battery breakthroughs, using weight reduction and structural engineering instead

- 19-minute charging (10-80%) requires 400k W fast chargers, but Volvo optimized the car for more common 250k W units too

- Megacasting manufacturing reduces components by 20-35% and cuts weight, lowering production costs significantly

- 800-volt architecture is Volvo's first, enabling faster charging and competitive performance with Hyundai and Kia platforms

- $63,000 starting price targets the XC60 plug-in hybrid market, positioning EX60 as cost-competitive with traditional alternatives

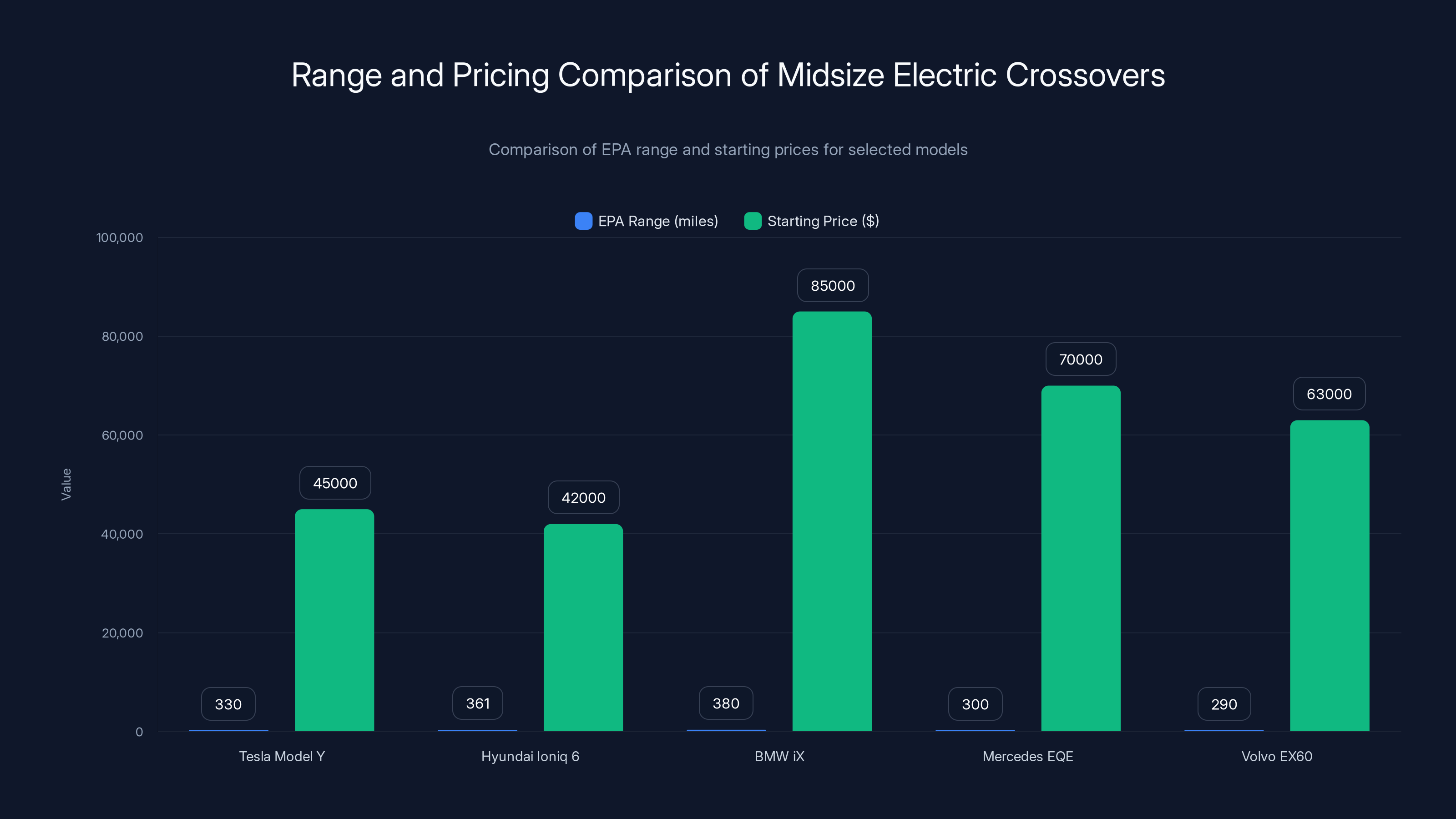

The Volvo EX60 offers competitive range and pricing, positioning itself as a cost-effective alternative in the midsize electric crossover segment. Estimated data used for Volvo's range.

Understanding Range: The 400-Mile Promise

Four hundred miles. That number gets thrown around a lot in the EV space, but it means something specific when Volvo claims it. This isn't an EPA rating yet—the EX60 won't be officially certified until it hits the market later in 2025. Instead, Volvo's using the European WLTP standard (Worldwide Harmonized Light Vehicle Test Procedure), which actually tends to be more generous than EPA testing. Converting that 810-kilometer figure to miles gives the 400-mile estimate, though real-world range will vary based on driving conditions, weather, and driving behavior.

Here's what makes this achievement interesting: Volvo didn't chase this range through battery chemistry wizardry. The cell chemistry is nickel-cobalt-manganese, identical to what Volvo already uses in the EX30 and EX90. There's no secret silicon anode, no cutting-edge solid-state technology, no exotic materials. Instead, the range comes from making the car lighter and more efficient across the board.

Weight reduction through manufacturing innovation is the real story. Megacasting—forming large sections of the vehicle frame as single pieces instead of welding multiple components together—eliminates weight. Fewer welds mean fewer fasteners. Fewer fasteners mean less material. A structural battery pack that integrates the battery into the vehicle's frame adds rigidity without extra weight. These aren't flashy technologies, but they're effective. The entire vehicle benefits from this approach: better structural integrity, improved handling, reduced manufacturing complexity, and lower energy consumption per mile.

The structural battery pack deserves its own explanation. Traditional EV designs treat the battery as cargo—a heavy object bolted to the floor. Volvo's approach makes the battery a stressed member of the frame, like a bridge beam that carries loads. This is more efficient because you're not duplicating the structural purpose of components. One engineering challenge with this approach is crash safety and repairability, but Volvo claims to have solved these through careful design and testing.

Real-world range expectations are crucial here. EPA testing in the United States typically shows 20-30% lower range than WLTP figures. A 400-mile WLTP estimate might translate to 280-300 miles of EPA range. That's still excellent for a midsize crossover. Highway driving at 70+ mph will reduce this further—maybe 250-270 miles in steady-state highway conditions. City driving, short trips, and moderate speeds will consistently exceed the baseline estimate. Cold weather reduces range by 15-20%, a critical consideration for northern climates.

Comparing to competitors tells you where the EX60 stands. The Tesla Model Y Long Range offers around 330 miles of EPA range. The Hyundai Ioniq 6 delivers 361 miles EPA range. Mercedes' EQE offers around 300 miles EPA range. Volvo's claiming to compete at the high end of this range. Whether the WLTP-to-EPA conversion plays out favorably remains to be seen, but the starting position is competitive.

Volvo's philosophy here is worth noting. Akhil Krishnan, the head of program management, called it transforming "range anxiety" into "range comfort." The idea is that drivers shouldn't worry about tank size when choosing a gasoline car, and shouldn't worry about range when choosing an EV either. Four hundred miles is designed to be "enough" for nearly all daily use cases and most road trips. You charge at home overnight, wake up with a full battery, and drive through an entire week without planning around charging. For that substantial percentage of drivers, this removes a major barrier to EV adoption.

The 10-year battery warranty covering up to 240,000 kilometers (150,000 miles) reflects Volvo's confidence in its battery technology and manufacturing. This extends beyond previous coverage and signals that Volvo believes in long-term battery durability. Warranty policies often indicate manufacturer confidence—a company won't extend coverage on parts it doubts will last.

Fast Charging: The 19-Minute Game Changer

Nineteen minutes. That's the claim for 10-80 percent charging using a 400k W ultra-fast charger. To put this in perspective, most current production EVs require 25-35 minutes for the same charge level, even with high-power charging capabilities. The EX60's speed advantage comes from its 800-volt electrical architecture, a first for Volvo, making it competitive with premium options from Hyundai, Kia, and Porsche.

Understanding fast charging requires understanding electrical physics. Higher voltage allows higher current flow with the same wire gauge and losses. Moving from typical EV voltage (400 volts) to 800 volts cuts resistive losses in half, meaning more power actually reaches the battery pack instead of dissipating as heat. This enables faster charging without overheating the battery management system.

The practical charging scenario that Volvo's optimized for is worth considering. Krishnan mentioned that customer research showed EV owners felt forced to plan their lives around 40-minute charging stops. Volvo's solution: design a vehicle that charges meaningfully in 10 minutes—the time needed for a coffee break or restroom stop. Adding 168 miles of range in 10 minutes means you can spend a quarter-hour on yourself and add a significant chunk of driving range. This is fundamentally different from current charging culture, where you sit at a charger for half an hour.

Battery preconditioning makes this speed possible. The EX60 heats or cools the battery to optimal temperature before connecting to a fast charger, ensuring maximum charging current throughout the session. Without preconditioning, battery temperature rises during fast charging, and the battery management system automatically reduces charging speed to protect cell health. Volvo's approach prevents this throttling by starting at the ideal temperature.

The infrastructure reality check is important. A 400k W charger is extraordinarily powerful and still relatively rare in most of North America. As of early 2025, you'll find these mostly on major highway corridors and in premium EV charging networks. The good news: Volvo specifically optimized the EX60 for more common 250k W chargers as well, which are becoming standard at major charging stations. On 250k W infrastructure—currently the high end of what most networks offer—charging will be slower but still competitive with current-generation EVs.

The 800-volt architecture also brings secondary benefits. Higher voltage enables lighter-weight wiring and power conversion systems throughout the vehicle. This contributes to overall weight reduction. The electrical system can support rapid power delivery for performance driving, something important for a vehicle targeting the luxury-to-premium market segment. Regenerative braking—the system that captures energy during deceleration—can be more efficient with higher voltage, recovering more energy per brake event.

Competing vehicles offer similar fast charging capabilities. The Genesis GV60 and Ioniq 5 both use 800-volt systems and charge similarly quickly. The Porsche Taycan pioneered 800-volt architecture in a mass-market-adjacent vehicle. Volvo's adoption brings this technology to a midsize crossover, democratizing what was recently a premium feature. As the technology becomes standard, charging speeds across the industry converge, making it less of a differentiator and more of a table-stakes requirement.

Charge curve analysis matters for real-world experience. Most EV batteries charge fastest in the middle percentage range—say 20-60 percent. Below 20 percent, the battery's colder and the system limits current. Above 80 percent, the battery approaches full voltage and can't accept current as quickly. Volvo's claiming 10-80 percent in 19 minutes, which is the practical sweet spot. Charging from 80-100 percent is rarely worth the time; you'd sit around for another 20 minutes for the last 20 percent of battery. This explains why efficiency-focused drivers often target 80 percent as the practical full charge.

Estimated data: V2H can save around

Megacasting: The Manufacturing Revolution

Megacasting might be the least sexy term in automotive manufacturing, but it's genuinely transformative. The technique involves casting large structural components—traditionally multiple smaller parts welded or bolted together—as single monolithic pieces. Volvo's using this approach for the rear floor and other major sections of the EX60's platform.

The advantages compound across the manufacturing process. Fewer components means fewer part numbers to track, fewer suppliers to manage, fewer assembly steps, and fewer potential quality issues. When you weld or bolt multiple pieces together, you're creating joints that might fail, fasteners that might loosen, and points where manufacturing variation accumulates. A single cast piece eliminates these concerns. Structural integrity improves because there's no joint weakness. Manufacturing tolerance stacks are reduced because you have fewer cumulative tolerances.

Cost reduction at component level is substantial. Volvo claims 20-35 percent component-level savings, which might seem like inflated marketing speak until you think through the details. You're eliminating multiple part numbers, reducing assembly labor by eliminating welding and fastening steps, reducing inspection requirements (fewer failure points to check), and reducing scrap and rework. These savings don't come from cheaper materials; they come from smarter production. A single megacast component might cost more than one of the simpler parts it replaces, but less than the totality of five components plus the assembly process.

The capital investment required for megacasting is substantial. You need multi-million-dollar casting equipment, tooling, and facility modifications. The metal dies used for high-pressure casting are expensive and require long production runs to amortize. This is why megacasting makes sense for vehicles with long production runs—the per-unit savings only justify the upfront investment at scale. Volvo's betting that the EX60 will be produced in numbers sufficient to justify this investment.

Design constraints and possibilities shift with megacasting. You can't just weld anything together; casting requires different thinking about wall thickness, draft angles, and structural layout. Designers must account for the unique properties of cast aluminum or other casting materials. But these constraints also enable shapes and structures that would be difficult to weld or assemble. You can create complex internal geometries, integrate functions into single pieces, and optimize for specific loads in ways that traditional manufacturing prevents.

Quality control becomes both easier and more critical. Once a casting die is correct, every part from it will be consistent—if the casting process is controlled. But if there's a flaw in the die or the process, you potentially get thousands of identical defects. Volvo will need robust quality systems to validate castings and ensure that defects are caught early. This isn't a new problem—manufacturers have been managing casting quality for a century—but it's particularly important in structural components where failure could be dangerous.

The automotive industry is racing toward megacasting as standard practice. Tesla's been using megacasting extensively in the Model Y, famously describing it as central to their manufacturing strategy. Traditional manufacturers like Ford and Volkswagen are investing in megacasting facilities. BMW's using it in new models. The technology represents a fundamental shift toward fewer, larger, more integrated components—the opposite of traditional automotive design philosophy, which favored many small, simple, interchangeable parts.

Real-world implications include improved crash safety. More robust structural integration means better load distribution in impacts. Fewer joints mean fewer places where impacts can cause catastrophic failure. The tradeoff is that repairing megacast components requires replacement rather than traditional welding or bolting repairs. This will impact service costs and collision shop practices, which is a real consideration for owners but an abstract issue for the purchasing decision.

Weight savings from megacasting contribute directly to efficiency. Every pound you remove from the vehicle reduces energy consumption proportionally. The 20-35 percent component savings translate into genuine weight reductions—maybe 500-1000 pounds less than an equivalent non-megacast design. That directly translates to longer range per kilowatt-hour, faster charging as a percentage of the total (lighter vehicles charge slightly faster), and better handling and performance.

The SPA3 Platform: Electric-First Design Philosophy

The EX60 is built on Volvo's new SPA3 platform, which differs fundamentally from older Volvo platforms that were originally designed for gasoline engines and adapted for electric powertrains. SPA3 was designed exclusively for electric vehicles, which means every system assumes batteries and electric motors from the start.

This might seem like an obvious point—of course electric vehicles should be designed as electric vehicles—but the automotive industry took years to do this. Early electric vehicles like the Nissan Leaf used platforms originally designed for gasoline cars. Tesla proved that building platforms exclusively for EVs yields better efficiency, better packaging, and better performance. Every major manufacturer is now developing electric-first platforms.

Packaging implications are immediate. Without an engine, transmission, or fuel tank, designers have complete freedom over interior layout. The EX60 can have a low floor, optimized cargo space, and a more efficient overall shape. Front and rear crumple zones can be optimized for electric powertrains, which concentrate weight at the center (battery pack) rather than at the front (engine). This affects safety design, weight distribution, and handling characteristics.

Thermal management becomes a designed system rather than an afterthought. Electric motors generate less waste heat than engines, and batteries need careful temperature control. Volvo's SPA3 platform likely includes integrated thermal pathways for cooling (or heating) the battery pack efficiently. The motor and power electronics can be located strategically rather than where tradition dictates an engine should be.

Electrical architecture is fundamentally different. SPA3 was designed around 800-volt systems from the start, rather than grafting 800-volt capabilities onto a 400-volt platform. Power distribution, safety systems, charging infrastructure, and integration all start from the 800-volt assumption. This cascades through every system, yielding better efficiency than retrofitted solutions.

Production flexibility is an underappreciated benefit of dedicated EV platforms. Because the platform isn't trying to accommodate gasoline and electric variants, manufacturing can optimize for one powertrain configuration. Volvo can design the production process around battery and motor installation without accommodating legacy combustion engine tooling. This simplifies manufacturing, improves throughput, and reduces costs.

Future updates to the platform don't require protecting gasoline compatibility. If battery technology improves, if charging standards evolve, if power electronics become more efficient, Volvo can integrate those advances into SPA3 without compromising compatibility with gasoline variants (because there won't be any). This gives electric-first platforms an inherent upgrade path that platforms designed for dual powertrains lack.

Competitive Positioning: Where the EX60 Stands

The midsize electric crossover segment is crowded and getting more so. The EX60 faces competition from established players and new entrants, each claiming superior technology, design, or value. Understanding how the EX60 actually stacks up requires looking beyond the specifications to real-world context.

Range comparisons show the EX60 in the competitive mainstream. Tesla's Model Y Long Range, the segment leader in sales, offers around 330 miles of EPA range. The Hyundai Ioniq 6 delivers 361 miles. The BMW i X x Drive 50 offers around 380 miles EPA. Mercedes EQE SUV delivers similar numbers. Volvo's 400-mile WLTP claim translates to roughly 280-300 miles of real-world EPA range if the conversion holds, which would place it slightly below the segment leaders but well within acceptable range. The caveat: Volvo hasn't yet released EPA estimates, and WLTP-to-EPA conversion is historically optimistic.

Charging speed is where the EX60's real advantage lives. The Ioniq 5 and Genesis GV60, which use 800-volt systems, charge comparably quickly. Most other competitors, including Tesla and BMW, use 400-volt systems and charge more slowly. Volvo's matching the fastest-charging competitors in the segment, which matters for long-distance road trips. In practice, for owners who charge at home overnight (the typical use case), charging speed matters less than range. For frequent road-trippers, it matters greatly.

Pricing strategy is bold. Volvo plans to price the EX60 around the same as the XC60 plug-in hybrid, which starts near

Design and comfort differentiate the EX60 in harder-to-quantify ways. Volvo's design language is known for understated elegance. The interior is expected to be as distinctive as the EX30 and EX90, with premium materials and thoughtful details. The EX60's size—between the EX30 compact and the EX90 flagship—targets the sweet spot for daily driving and family needs. This is where Volvo could genuinely stand out against competitors who emphasize performance or technology specs.

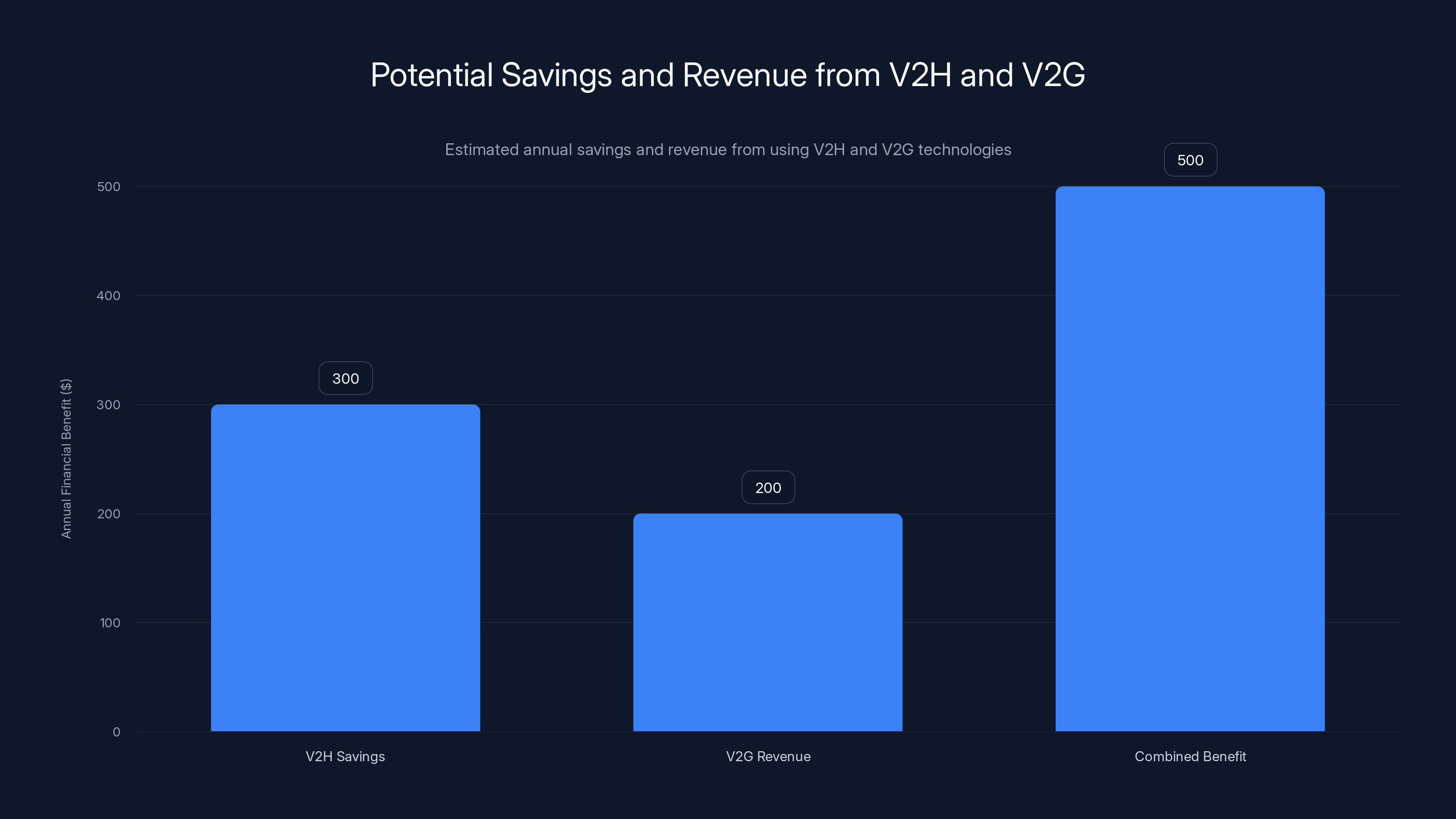

Software and connectivity will matter increasingly. The EX60 will include vehicle-to-home (V2H) and vehicle-to-grid (V2G) functionality as standard, meaning owners can discharge the battery to power their homes or send power back to the grid. This is becoming table-stakes for premium EVs but isn't universal yet. Hyundai and Genesis offer similar capabilities. Tesla notably has been slower on V2H/V2G integration. Software updates and over-the-air capability improvements will likely be important throughout the EX60's lifecycle.

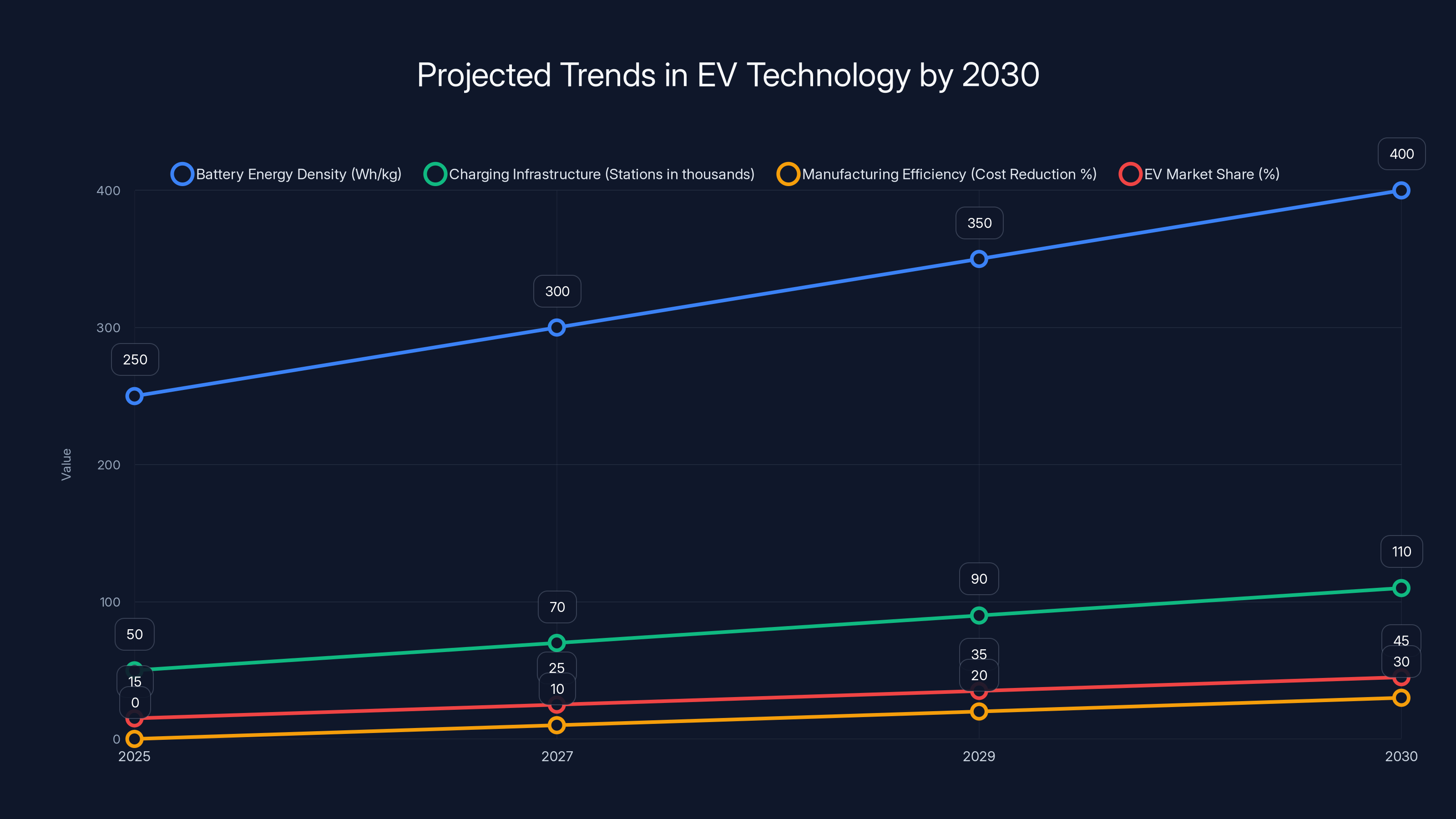

By 2030, battery energy density is expected to reach 400 Wh/kg, while charging infrastructure will expand significantly. Manufacturing efficiency will improve by 30%, and EV market share could reach 45%. Estimated data.

Battery Chemistry and In-House Manufacturing

Volvo's using nickel-cobalt-manganese (NCM) battery chemistry for the EX60, the same chemistry in current Volvo EVs. This isn't a cutting-edge formulation. It's a mature, proven chemistry with known trade-offs: good energy density, good cycle life, reasonable cost, and established supply chains. Volvo's not chasing the latest battery chemistry breakthroughs.

Instead, Volvo is investing in in-house battery cell manufacturing. The company built a battery cell factory and now manufactures cells for its vehicles. This vertical integration has several implications. Manufacturing control improves quality consistency. Supply chain risk decreases when you control a critical component. Cost structure improves when you eliminate middleman markups. But the capital investment is enormous, and cell manufacturing is capital-intensive with low margins—it's a bet that scale and efficiency will justify the investment.

The battery technology roadmap includes evolutionary improvements rather than revolutionary changes. Volvo has mentioned increasing energy density, improving cycle life, and optimizing manufacturing efficiency. These come from incremental chemistry tweaks, manufacturing process improvements, and engineering optimization. They won't deliver 10x improvements, but they'll move the needle by 10-20% every couple of years, which compounds significantly.

Solid-state batteries, which many manufacturers tout as future game-changers, remain in research and development. Volvo hasn't announced when or if it will adopt solid-state technology. The company seems focused on extracting maximum efficiency from conventional chemistries first. This is a pragmatic approach: mature technology with known characteristics, deployed at scale, often beats emerging technology with promise but unproven reliability.

The 10-year warranty extending to 240,000 kilometers signals confidence in battery durability. Most batteries degrade at predictable rates: roughly 2-3 percent per year under normal use. A battery that holds 85 percent capacity after 10 years isn't degraded—it's normal. Volvo's warranty presumably covers unexpected failures rather than normal degradation. The extended duration reflects that Volvo expects these batteries to last longer than previous generations.

Vehicle-to-Grid Technology: The Bi-Directional Future

The EX60 includes V2H and V2G capability as standard. This is significant and represents where the industry is heading. These technologies turn an EV from a one-way consumer of electricity into a two-way participant in the power grid.

Vehicle-to-home (V2H) means charging infrastructure in your garage can work bidirectionally. During peak electricity rates, you draw power from the grid. During off-peak rates, you charge your vehicle. When your home experiences a power outage or you want to reduce peak draw, the vehicle's battery powers your home. This provides backup power, reduces electricity costs by arbitraging rate differences, and improves grid stability by shifting loads.

Vehicle-to-grid (V2G) extends this to the broader electrical grid. Your vehicle can export power to the grid during peak demand periods, helping balance supply and demand. Utilities can pay you for this service, creating a potential revenue stream from vehicle ownership. At scale, millions of EVs with V2G capability could provide significant grid stability, reducing the need for power plants to ramp up or down quickly.

The practical implications are emerging. Owners with V2H infrastructure can optimize charging around electricity rates and peak demand times. An owner might charge at night when rates are lowest, use the battery during the day when rates are highest, and still have a full battery for driving. Over a year, this reduces electricity costs. V2G capable vehicles also provide backup power during outages, a feature that gasoline cars can't match (unless you have a generator, which adds cost and maintenance).

The infrastructure challenge remains substantial. Not every home has the electrical capacity for bidirectional charging. Installing V2H-capable chargers costs more than standard charging equipment—roughly $1000-2000 additional for the charger hardware plus potential electrical panel upgrades. V2G participation requires utility cooperation, smart grid infrastructure, and standardized protocols. These are evolving but not yet universal.

Standardization matters. Different regions use different protocols for communicating between vehicles and chargers. The CHAde MO standard dominated early EV adoption in Japan. The Combined Charging System (CCS) became standard in North America and Europe. Newer protocols like ISO 15118 promise better communication and faster charging. Volvo needs to ensure the EX60 can use whatever standards become dominant in key markets.

Interior Design and Practicality

Volvo's known for distinctive interior design. The EX90 features a minimalist aesthetic with few physical buttons, dominated by a central touchscreen. The EX30 has a similar philosophy at a smaller scale. The EX60 is expected to continue this tradition—clean lines, premium materials, thoughtful organization, and heavy reliance on touchscreen interfaces.

The challenge with minimalist touchscreen-dominated design is user experience during driving. Fewer physical buttons mean more fumbling on the touchscreen to control climate, seat heaters, and other frequently-adjusted features. Some owners appreciate the clean aesthetic; others find it less practical than traditional button layouts. This is personal preference territory where design philosophy matters as much as objective functionality.

Smart storage has been highlighted as an EX60 feature. Without an engine, designers can integrate storage cleverly throughout the vehicle. Frunk (front trunk) space is available where the engine would be. Under-floor storage might be possible. Door pockets and center console can be optimized. These small touches improve the ownership experience, particularly for road trips and daily practicality.

The cabin size reflects the midsize crossover positioning. The EX60 targets customers who need more space than a compact car but don't need three-row SUV capacity. This is the sweet spot for many families: enough room for passengers and cargo without the bulk and expense of a large SUV. Cargo volume hasn't been officially released yet, but expect something comparable to the BMW X4 or Mercedes GLC, which offer around 60-70 cubic feet of cargo space.

The Volvo EX60 offers a competitive 400-mile range and rapid charging capabilities, outperforming typical electric crossovers in charging speed and platform innovation. Estimated data for typical crossovers.

Safety Features and Autonomous Capabilities

Volvo's brand identity includes a strong safety focus. The company invests heavily in crash safety, collision avoidance systems, and autonomous driving technology. The EX60 will likely include a comprehensive suite of safety features as standard equipment.

Electric vehicles have advantages in safety engineering. Low center of gravity (batteries mounted in the floor) improves stability and handling. Weight distribution is better balanced than gasoline cars (no heavy engine over the front wheels). The rigid structure of megacast components provides better crash protection. No high-pressure fuel system eliminates fire risks associated with gasoline.

Disadvantages include tire wear (EVs are heavier than equivalent gasoline cars) and regenerative braking peculiarities (the braking feel can take adjustment). The low center of gravity also means longer emergency stopping distance compared to lighter vehicles—physics is physics, and more weight requires more stopping energy.

Autonomous driving capabilities remain evolving. Volvo has been testing autonomous technology for years but, like most manufacturers, has been cautious about launching autonomous features to market. The EX60 will likely include advanced driver assistance systems: adaptive cruise control, lane-keeping assist, automatic parking, collision avoidance. Full autonomous driving isn't expected in the initial launch.

Environmental Impact and Lifecycle Analysis

Electric vehicles reduce tailpipe emissions completely, obviously. But lifecycle analysis—accounting for manufacturing, energy generation, and battery disposal—reveals a more complex picture. Manufacturing an EV produces more emissions than manufacturing an equivalent gasoline car, primarily due to battery production. An EV needs to be driven roughly 20,000-30,000 miles to offset this manufacturing impact through reduced operational emissions (this varies based on grid electricity sources—it's faster if you're on a grid with renewable power, slower if coal dominates).

Over a typical 150,000-mile vehicle lifespan, an EV produces roughly half the lifetime emissions of a gasoline car, even accounting for manufacturing and assuming average US grid electricity. If you're on a grid with significant renewable energy, the advantage is greater. The advantage shrinks, but remains, if your grid is heavy on fossil fuels.

Battery recycling remains an evolving field. Current recycling processes can recover 95%+ of battery materials, including valuable lithium and cobalt. This reduces dependence on mining and improves the circular economy. Volvo's in-house battery manufacturing positions the company well for implementing advanced recycling processes. Second-life applications, where degraded EV batteries power stationary energy storage systems, extend useful life before recycling.

The broader question: Is manufacturing millions of EV batteries a net environmental benefit? The answer is yes—replacing fossil-fuel-powered vehicles with electric alternatives reduces total carbon emissions by 50%+. But it's not a silver bullet. Manufacturing still requires energy. Mining lithium, cobalt, and nickel has environmental costs. The transition away from gasoline makes more progress when paired with decarbonization of the electrical grid through renewable energy expansion.

Pricing Strategy and Market Positioning

Volvo plans to price the EX60 around $63,000, matching the starting price of the XC60 plug-in hybrid. This is a strategic statement: we're not charging you more for electricity. This differs from many EV launch strategies where manufacturers positioned EVs as premium alternatives commanding price premiums.

The calculation behind this pricing: manufacturing cost parity. Batteries remain expensive, but as production scales and technology matures, the cost differential between electric and traditional powertrains narrows. Megacasting and other manufacturing innovations reduce costs. Component consolidation (fewer parts) simplifies assembly. At sufficient scale and with mature technology, electric can cost the same as hybrid despite the battery expense.

This strategy works if: first, Volvo achieves expected manufacturing efficiency; second, battery costs continue declining; third, they achieve sales volume to justify the upfront investment in new platforms and manufacturing facilities. It's a bet on all three, which is why execution matters as much as vision.

Market segment context: The

Option pricing will likely push real-world prices higher. A typical EX60 purchase probably runs $75,000-80,000 when you factor in all-wheel drive, premium audio, enhanced technology, and practical upgrades. This is market standard for the segment. Volvo will likely offer multiple trim levels and options packages to let buyers customize based on needs and budget.

Financing availability will matter for adoption. Lease programs, particularly those with low down payments and reasonable monthly costs, help drive EV adoption. Loan programs with favorable terms encourage purchase. Federal tax credits (if available) and state incentives reduce effective purchase price. Volvo's pricing strategy only works if financing is accessible to the target buyer.

Volvo's EX60 is priced at

Manufacturing Capacity and Production Timeline

Volvo stated the EX60 will enter production later in 2025. This is relatively soon, which means production preparations are underway. Manufacturing capacity is the next constraint: how many EX60 units can Volvo actually produce? Demand almost certainly exceeds initial production capacity, which is typical for new EV launches.

Volvo's manufacturing footprint includes plants in Sweden, China, and elsewhere. The EX60 will likely be produced in multiple facilities to serve regional markets efficiently. Chinese production serves Asian and European markets. Swedish or other European plants might serve European and North American markets. This geography matters for cost, supply chain efficiency, and geopolitical considerations.

Supply chain for batteries is critical. Volvo's in-house cell manufacturing provides some capacity, but probably not the total volume needed for all EX60 vehicles. The company likely supplements with cells from battery suppliers. Sourcing cells from multiple suppliers diversifies risk and ensures adequate supply.

The ramp-up curve will likely follow typical EV launch patterns: limited initial production as manufacturing processes are validated, increasing volume as efficiency improves, reaching peak capacity within 2-3 years. Early adopters will get priority access; wait times might stretch to several months as demand exceeds supply.

Feature Comparison: EX60 vs. Competitors

Comparing the EX60 meaningfully to competitors requires understanding that these are personal preference assessments as much as objective measurements.

Versus Tesla Model Y: The Model Y has longer real-world range, established Supercharger network, and renowned acceleration. The EX60 will likely offer better charge speed on optimal hardware, superior interior design refinement, and similar performance. Model Y has established market presence and ownership community; EX60 will be new territory.

Versus Hyundai Ioniq 5: Both use 800-volt charging architecture. The Ioniq 5 is already on the market with proven reliability. The EX60 promises better range and comparable charging speed. Design preference will drive many purchase decisions here—one isn't objectively better, just different.

Versus Mercedes EQE SUV: Both aim at the premium segment. The EQE SUV offers higher luxury positioning and established brand prestige. The EX60 promises better value and comparable performance. Mercedes has years of market presence; Volvo's still building its EV lineup.

The Bigger Picture: What the EX60 Signals

The EX60 represents a maturation of EV technology and manufacturing. This isn't an experiment or a niche product category—this is mass-market vehicle strategy. Volvo is committing manufacturing capacity, design resources, and capital to an electric midsize crossover because they believe this is the future of transportation.

Manufacturing innovation like megacasting will become industry standard within a few years. Every major manufacturer is investing in similar techniques. The EX60's advantage in this area is temporary; it's a leadership position that competitors will match.

Range and charging speed were constraints five years ago. The EX60 shows these constraints are largely solved. Four hundred miles is common-sense range for most users. Fast charging meets practical needs when the infrastructure catches up. The next frontier is reducing battery manufacturing cost, improving battery energy density, and scaling production to meet global demand.

Pricing parity with traditional vehicles is significant. This removes the "premium for going electric" argument. An EV is no longer a wealthy person's indulgence; it's a practical alternative at roughly the same cost. This should accelerate adoption because buyers can make the choice based on preference and practicality rather than price penalty.

The Volvo EX60 offers a superior range and faster charging time compared to typical EVs, thanks to its advanced 800-volt architecture and innovative manufacturing techniques. Estimated data for typical EVs.

Design Philosophy and Brand Positioning

The EX60 embodies Volvo's approach to electric vehicles: responsible, thoughtful, Swedish. Not flashy, not performance-focused, not trying to be Tesla. Instead, distinctive design, premium materials, safety focus, and practical engineering.

This positioning differentiates Volvo from competitors who emphasize performance (Tesla, Porsche), affordability (Hyundai, Volkswagen), or luxury (Mercedes, BMW). Volvo's saying: "Build something good, make it last, design it well, don't overcomplicate it."

The interior design will likely emphasize simplicity and quality over technological flashiness. The exterior will be recognizably Volvo—contemporary without being trendy, attractive without demanding attention. This design philosophy appeals to buyers who see vehicles as functional tools that should be well-made rather than status symbols.

Brand heritage matters here. Volvo's reputation for safety and reliability built over decades gives credibility to EV claims. The company isn't unproven in vehicle manufacturing or engineering; it's an established player extending its expertise to new technology.

What Questions Remain Unanswered

Until the EX60 reaches the market and owners accumulate real-world experience, some questions remain:

Real-world range: WLTP figures are generous. EPA testing will show realistic US range. Highway range, cold weather range, and range in typical driving patterns will matter more than specification sheets.

Charging infrastructure maturity: 400k W chargers need to be available when owners buy EX60s. If fast charging requires traveling to rare mega-chargers, the advantage disappears. The timeline for widespread 400k W and 350k W infrastructure remains uncertain.

Reliability and durability: New platform and manufacturing processes mean Volvo's still learning how they perform in service. The first years of production will reveal issues manufacturers couldn't anticipate. Modern EVs are generally reliable, but any first-generation product carries risk.

Software and OTA updates: Will Volvo push meaningful over-the-air updates that improve capability over time, or will the software stagnate? This affects long-term ownership experience significantly.

Resale value: EV depreciation patterns are still establishing. Early adopters might face steep depreciation as new models improve and battery costs drop. Later buyers might achieve better long-term value.

Integration with broader Volvo ecosystem: How does the EX60 fit alongside the EX30 and EX90? What's the upgrade path for owners? What's the service and support experience?

These questions will answer themselves once cars are in customers' hands. The specifications and engineering are sound; execution will determine actual customer satisfaction.

Future Outlook: Where EV Technology Heads

The EX60 represents where the industry is in early 2025. Where does it go from here?

Battery technology evolution will likely focus on energy density (fitting more power in smaller packages), cycle life (lasting longer), and cost reduction (cheaper per kilowatt-hour). Solid-state batteries might arrive in the next decade but probably not before 2030. Current chemistry has years of optimization ahead.

Charging infrastructure will continue expanding. DC fast charging along highways will become ubiquitous. Home charging will become standard equipment, not a premium feature. Charging speed will improve, but at a slower pace than battery capacity growth. Standardization will eventually eliminate the connector confusion of today.

Manufacturing processes will mature. Megacasting will become standard. Factories will achieve higher efficiency and lower cost. Vertical integration (like Volvo's battery manufacturing) will become more common as manufacturers seek cost control. Supply chains will stabilize as commodity prices and sourcing patterns normalize.

Vehicle segment evolution will follow consumer demand. Midsize crossovers like the EX60 will likely dominate EV sales because they match what consumers actually buy. Luxury sedans and performance vehicles will stabilize in smaller niches. Affordable mass-market EVs will grow but at slower pace due to battery cost constraints.

Regulatory environment will keep pushing electrification. Most developed nations have policies targeting internal combustion engine phase-outs. This creates certainty that EV adoption is happening regardless of technology preference. Manufacturers have no choice but to electrify.

Why the EX60 Matters Beyond Volvo

The EX60 isn't important because Volvo invented something revolutionary. Megacasting, 800-volt architecture, 400-mile range, and fast charging all exist in competing vehicles. The EX60 matters because it represents an established vehicle manufacturer committing to electrification at scale, using proven technologies, and pricing competitively. This signals that EVs are no longer experimental; they're just vehicles that happen to be electric.

Volvo's approach—responsible engineering, thoughtful design, proven reliability—might not excite performance enthusiasts or tech evangelists. But it appeals to practical buyers making the transition to electric. That's where the market's actually moving.

The industry will watch whether Volvo executes successfully. If the EX60 achieves sales targets, delivers on range and charging promises, and achieves customer satisfaction, it validates the manufacturing strategy for other competitors considering similar investments. If it stumbles—if range falls short in real-world use, if charging infrastructure proves inadequate, if quality issues emerge—it signals caution to manufacturers considering similar bets.

More broadly, the EX60 tests whether you can build competitive electric vehicles without cutting-edge battery chemistry, without premium pricing, and without performance excess. The answer likely matters as much as any individual vehicle specification.

The Road Ahead: Transition vs. Transformation

Electrification of transportation is a transition, not a transformation, and that distinction matters. A transformation would mean completely reimagining how transportation works: fully autonomous vehicles, shared mobility networks, urban design changes, energy systems evolution. What's actually happening is more gradual: traditional vehicles powered by batteries instead of engines, mostly unchanged in purpose and use.

The EX60 embodies this transition. It's a crossover—practical, familiar, unexciting. It seats five, hauls cargo, and serves as daily transportation. You charge it at home or at public chargers, then drive it. This isn't glamorous, but it's real and it's working.

This transition creates opportunity for manufacturers like Volvo to succeed not by inventing futuristic technology but by engineering practical solutions that make electric ownership achievable for mainstream buyers. Four hundred miles of range, fast charging, competitive pricing, and quality engineering solve real problems. These solutions are valuable not because they're revolutionary but because they're sufficient.

FAQ

What is the Volvo EX60 and when will it be available?

The Volvo EX60 is a midsize electric crossover built on Volvo's new SPA3 platform, designed exclusively for electric vehicles. The company plans to enter production later in 2025, with official market availability expected shortly after. The EX60 targets buyers seeking practical electric transportation with competitive range and charging speed comparable to premium vehicles in the segment.

How does the EX60 achieve 400 miles of range without new battery technology?

Volvo achieves 400-mile WLTP range through engineering and manufacturing innovation rather than battery breakthroughs. The vehicle uses megacasting to reduce weight by forming large structural components as single pieces instead of welding multiple parts together. A structural battery pack integrates the battery into the frame, improving efficiency and reducing weight. The EX60 also uses the same proven nickel-cobalt-manganese battery chemistry as current Volvo EVs, optimized for maximum efficiency through careful design across every system. Together, these engineering choices reduce vehicle weight and energy consumption per mile, extending range without exotic battery materials.

What makes the EX60's charging capability significant?

The EX60's 800-volt electrical architecture is a first for Volvo and enables significantly faster charging than previous Volvo EVs. The vehicle can charge from 10-80 percent in just 19 minutes using a 400k W ultra-fast charger, or add 168 miles of range in 10 minutes. More importantly, Volvo optimized the charging system to work well on more common 250k W chargers, not just rare 400k W units. This balances performance on cutting-edge infrastructure with practicality on what's actually available today. Battery preconditioning (warming or cooling the battery to optimal temperature before charging) enables this speed while protecting long-term battery health.

How does megacasting reduce manufacturing costs?

Megacasting reduces manufacturing costs through component consolidation and process simplification. Traditional manufacturing welds or bolts together multiple smaller parts; megacasting forms large sections as single pieces. This eliminates part numbers, fasteners, assembly steps, and potential failure points. Volvo claims component-level cost savings of 20-35 percent, achieved not through cheaper materials but through smarter production. Fewer parts mean lower inventory costs, reduced supplier management, less assembly labor, and fewer quality control checkpoints. The upfront investment in casting equipment and tooling is substantial, but at production scale, the per-unit savings justify the investment.

What is vehicle-to-grid (V2G) capability and why does it matter?

Vehicle-to-grid capability allows the EX60 to discharge its battery back to your home (V2H) or the electrical grid (V2G), not just charge from them. During periods of high electricity prices, you can use stored battery power instead of drawing from the grid. During peak demand periods when you're not driving, your vehicle can export power to the grid, potentially earning money while helping balance electrical demand. The EX60 includes V2H and V2G as standard, making it practical to reduce electricity costs through time-of-use rate arbitrage and provide backup power during outages.

How does the EX60's real-world range compare to its 400-mile specification?

The 400-mile figure is based on WLTP testing, the European standard, which tends to be more generous than EPA testing used in the United States. Historical conversion between WLTP and EPA suggests the EX60 might achieve 280-300 miles of EPA range, likely lower than the WLTP figure but still competitive within the segment. Real-world range varies based on driving conditions: highway driving at 70+ mph reduces range by roughly 20-30 percent compared to the specification, while city driving typically exceeds it. Cold weather reduces range by 15-20 percent. For most owners charging at home and driving 200-250 miles most days, the 400-mile range should prove sufficient for multi-day road trips with single charging stops.

What is the SPA3 platform and why is it designed exclusively for electric vehicles?

The SPA3 platform is Volvo's new architecture designed from the ground up for electric powertrains, unlike older platforms retrofitted from gasoline designs. Electric-first design means every system assumes batteries and motors from the start, optimizing layout, weight distribution, and efficiency. Without engines, transmissions, or fuel tanks, designers gain freedom for interior packaging and cabin layout. Thermal management, electrical architecture, and crash safety design can optimize for EV-specific requirements. The result is better efficiency, better packaging, and lower manufacturing complexity than platforms adapted from combustion engines.

How is the EX60 priced and what is the value proposition?

Volvo plans to price the EX60 starting near $63,000, roughly matching the XC60 plug-in hybrid starting price. This positions the EX60 as cost-competitive with hybrid alternatives rather than commanding an electric vehicle premium. The value proposition emphasizes no-compromise electrification: sufficient range for daily driving and road trips, fast enough charging for practical use, and engineering quality reflecting Volvo's reputation. This strategy signals that manufacturing cost parity between electric and traditional powertrains is achievable, eliminating the price penalty typically associated with going electric.

What battery warranty does Volvo offer with the EX60?

Volvo provides a 10-year battery warranty covering up to 240,000 kilometers (150,000 miles), extending the company's previous 8-year coverage. This extended warranty reflects Volvo's confidence in battery durability and its in-house battery manufacturing capabilities. The warranty typically covers unexpected failures rather than normal degradation; modern EV batteries retain 85-90 percent capacity after 10 years of typical use, which is normal aging not covered by warranty.

How does the EX60's manufacturing approach compare to competitors?

Most competitors use traditional assembly combining multiple welded components. Volvo's megacasting approach forms large structural sections as single pieces, reducing weight and complexity. Tesla has pioneered this approach; Volvo is bringing it to a midsize mainstream vehicle. Other manufacturers are investing in similar capabilities, but as of 2025, the EX60 arrives with a first-mover advantage in this manufacturing technology for the midsize crossover segment. However, this advantage is temporary; competitors will match this capability within a few years as the technology becomes industry standard.

What are the real-world ownership costs of the EX60 compared to gasoline vehicles?

Electricity costs roughly one-third the cost of gasoline for equivalent driving, though this varies by regional electricity prices. Maintenance costs are lower for EVs due to simpler drivetrains (no oil changes, transmission fluid, spark plugs, or timing belts). Tire wear is slightly higher due to vehicle weight. Insurance costs are comparable to similar gasoline vehicles. Depreciation patterns for EVs are still establishing, but early evidence suggests EVs depreciate faster than traditional vehicles, particularly in early years as new models improve. The most significant variable is electricity costs in your region and whether you have access to time-of-use rates that let you charge during off-peak periods.

Conclusion: A Glimpse of Where We're Headed

The Volvo EX60 arrives at an inflection point. Electric vehicles are no longer novel; they're mainstream. Manufacturing processes are maturing. Performance and range meet practical needs. The question is no longer "Should I go electric?" but rather "Which electric vehicle meets my requirements and budget?"

Volvo's entry with the EX60 positions the company as a serious electrification player. The engineering is sound: 400-mile range through smart design, fast charging through 800-volt architecture, cost-competitive manufacturing through megacasting. These aren't revolutionary breakthroughs, but they're the breakthroughs that matter—practical solutions to actual problems.

The EX60 won't excite performance enthusiasts or early-adopter tech evangelists. That's intentional. Volvo's targeting practical buyers making the transition to electric, offering quality engineering and distinctive design rather than chasing performance records or technological flash. This positioning might prove smarter than competitors' strategies as the market matures and mainstream buyers—not enthusiasts—drive adoption.

Execution matters now. Will Volvo deliver on range and charging promises? Will manufacturing efficiency achieve expected cost savings? Will the market accept the design philosophy and brand positioning? These questions will answer themselves once vehicles hit the road and accumulate real-world experience. The specifications are sound; the strategy makes sense. What happens next depends on whether Volvo can execute at scale and whether infrastructure catches up with vehicle capability.

The bigger picture: the EX60 represents transportation's transition to electric powertrains, not a transformation of how mobility works. It's a crossover that happens to use batteries. It's practical, sufficient, and accessible. That might not sound exciting, but it's exactly what actually changes the world.

Key Takeaways

- Volvo EX60 achieves 400-mile range through engineering innovation (megacasting, structural battery pack) rather than battery breakthroughs

- 800-volt electrical architecture enables 19-minute 10-80% charging and competitive performance with premium EV competitors

- Megacasting manufacturing reduces component costs by 20-35% while improving structural integrity and reducing weight

- SPA3 platform designed exclusively for electric vehicles, optimizing layout, efficiency, and manufacturing compared to adapted platforms

- Pricing strategy targets $63,000 starting price, competitive with XC60 hybrid, signaling manufacturing cost parity with traditional powertrains

Related Articles

- Sony Honda's Afeela 1 EV: Why It Feels Outdated at CES 2026 [Review]

- CES 2026: Why EVs Lost to Robotaxis & AI – Industry Shift Explained

- Samsung Galaxy S26 Rumors and Expected Features [2025]

- Ford's AI Assistant and BlueCruise 2.0: The Future of In-Car Intelligence [2025]

- Ford's AI Voice Assistant & Level 3 Autonomy: What's Coming [2025]

- Ford's AI Assistant Revolution: What's Coming to Your Car in 2027 [2025]

![Volvo EX60: 400-Mile Range and 10-Minute Fast Charging [2025]](https://tryrunable.com/blog/volvo-ex60-400-mile-range-and-10-minute-fast-charging-2025/image-1-1767861498412.jpg)