Agentic AI & Supply Chain Foresight: Turning Volatility Into Strategy [2025]

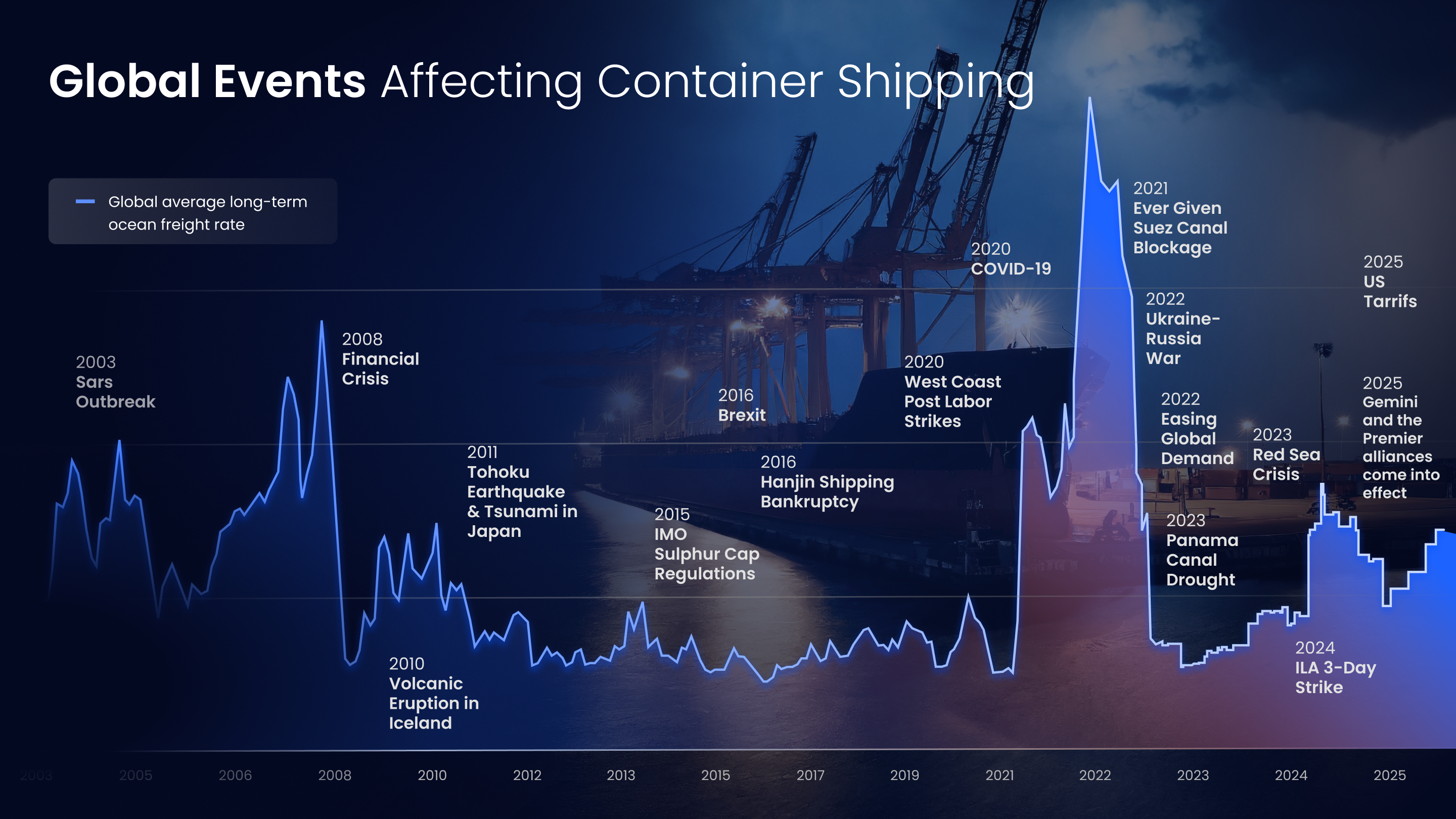

Introduction: The Supply Chain Crisis That Never Ends

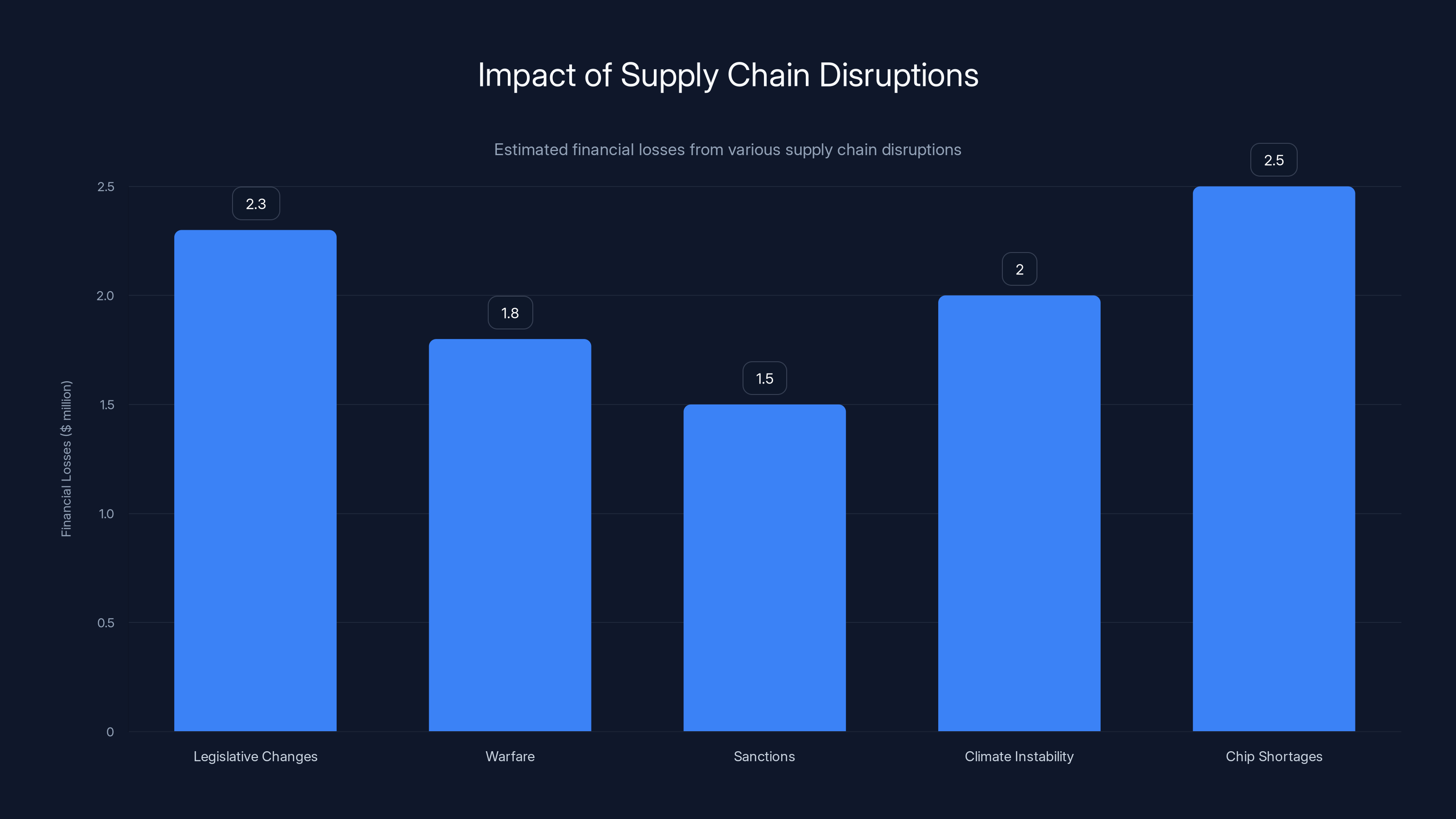

Last Tuesday, a major automotive supplier's single-source component went down. Not because of a factory fire or equipment failure, but because a legislative change halfway across the world suddenly made that material illegal to import. By Wednesday morning, three plants were scrambling. By Friday, they'd lost $2.3 million in production capacity.

This isn't hypothetical. It's what happens when supply chains operate without real foresight.

We're living through the most volatile decade in modern logistics. Warfare can fracture European supply lines overnight. Sanctions reshuffle where you can source materials. Climate instability makes crop yields unpredictable. Chip shortages feel like they're permanent features now, not temporary blips. And every time something breaks, executives get blindsided because their data systems are still operating like it's 2015.

Here's what makes this worse: everyone's rushing to adopt AI to solve the problem. But most organizations are doing it completely wrong.

They're bolting Chat GPT-style tools onto existing workflows. They're creating dashboards that nobody updates. They're building AI systems that operate in silos, disconnected from real-time data, constraints, and business context. And when these disconnected AI systems make decisions? The cascading failures are spectacular. Wrong inventory gets shipped to the wrong market. Overproduction decimates margins. Regulatory violations pile up.

The real solution isn't just adopting AI. It's adopting the right kind of AI, integrated the right way.

Agentic AI represents the inflection point. Not because it's some miraculous new technology, but because it's fundamentally different from the copilots and analysis tools most companies deployed in 2023 and 2024. Agentic systems can actually act on insights, coordinate across the enterprise, and operate with full context and guardrails. When done right, they transform volatility into foresight.

The catch? There's a narrow path between transformation and disaster.

This guide walks you through that path. You'll learn what agentic AI actually is, why most pilots fail, how human oversight becomes your competitive advantage, and exactly how to integrate these systems into supply chain workflows without creating new risks.

Estimated data shows that chip shortages and legislative changes are among the most costly supply chain disruptions, with losses reaching up to $2.5 million.

TL; DR

- Agentic AI is fundamentally different from copilots and generative AI tools because it can both analyze and act on recommendations with full business context and guardrails

- Most AI pilots fail because they're disconnected from real-time data, lack clear governance, and operate in silos rather than integrated workflows

- Human oversight isn't a limitation, it's the design that makes agentic systems actually work at enterprise scale with compliance and trust

- The real ROI comes from integration, not from the AI itself, meaning success depends on how deeply you embed agentic systems into your decision-making workflows

- Supply chain leaders who get this right will transform volatility into competitive advantage while leaders who don't will face cascading failures and regulatory exposure

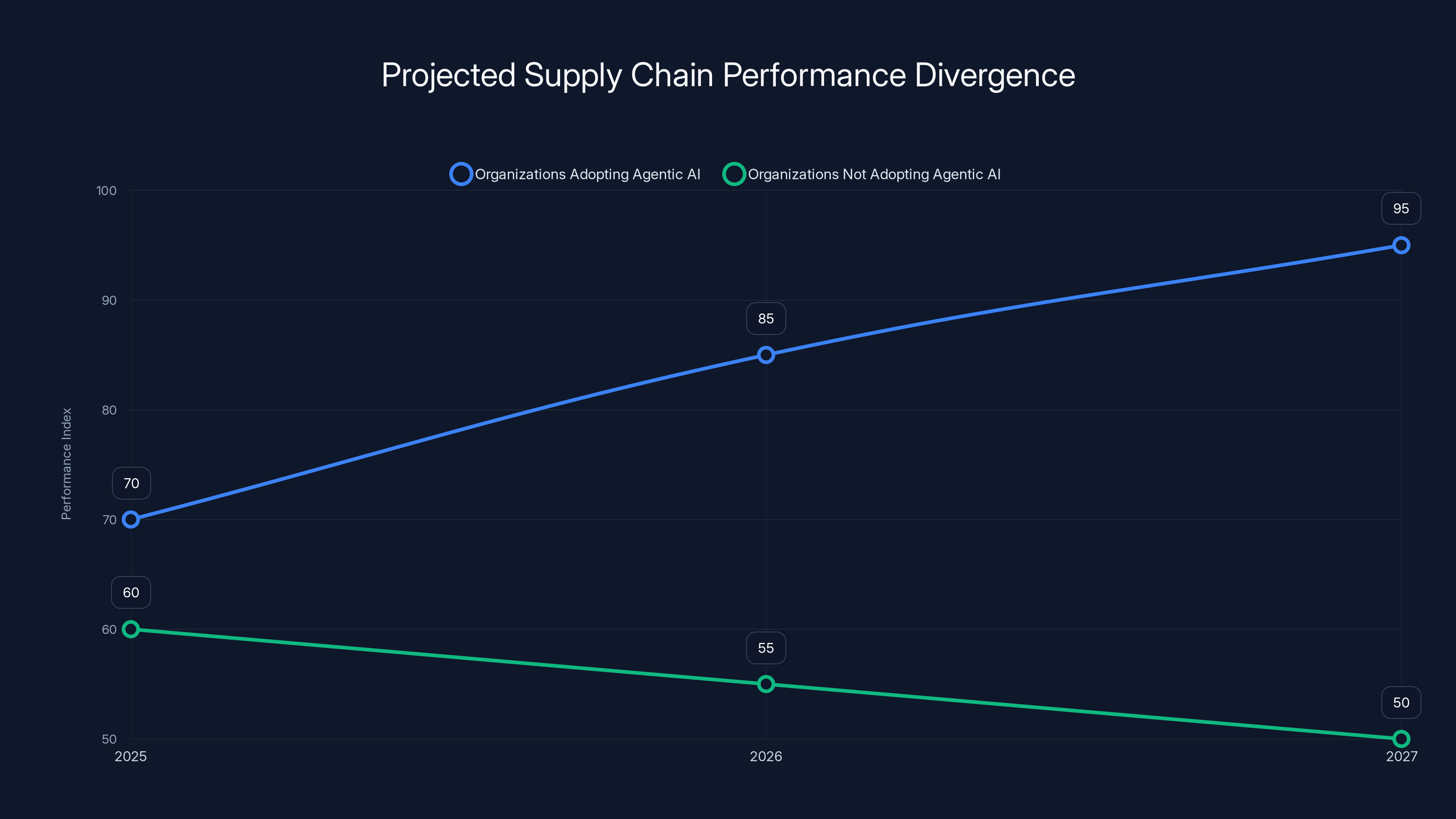

Estimated data suggests a significant performance gap will emerge by 2027 between organizations adopting Agentic AI and those that do not.

The Current State: Why Your AI Isn't Working

The Copilot Trap: Intelligence Without Action

Most organizations deployed their first "AI" systems between 2023 and 2024. These were typically generative AI tools, copilots, or advanced analytics platforms that sat alongside existing workflows rather than being integrated into them.

The appeal was obvious. Relatively easy to deploy. Quick wins that looked impressive in presentations. You could feed the AI some data, get a recommendation, and show executives a better forecast in 30 minutes.

But here's what happened in practice: The AI analyzed data in isolation. It didn't have access to your actual constraints. It didn't know about pending supplier negotiations or regulatory changes. It couldn't coordinate with finance to understand cost impacts or with logistics to check feasibility. Most importantly, when it gave you a recommendation, someone still had to manually translate that into action—and by then, the window of opportunity had often closed.

So you got better analysis, sure. But not better decisions. The AI operated on fragmented information and produced recommendations that, while statistically sound, lacked the contextual understanding needed for complex supply chain situations.

The Data Silos Problem

Supply chains are notoriously fragmented. You've got your ERP system (probably 8-12 years old and hosted on-premises). Separate systems for procurement, inventory, logistics, finance, and compliance. Data lakes that don't talk to operational systems. Spreadsheets that are source-of-truth for critical decisions because the official systems can't provide the answer fast enough.

When your AI is bolted onto this mess, it's working with incomplete information. It sees inventory data from 4 hours ago. It has no idea about a supplier quality issue flagged last night. It can't see the variance between what your systems say you ordered and what actually showed up.

In complex supply chain scenarios, these information gaps create cascading failures. An AI recommends shifting production to a secondary supplier without knowing that supplier is already at 94% capacity. It suggests forward-buying a material that's currently volatile without seeing the hedge contract your finance team just put in place. It creates an operational recommendation that violates a compliance requirement.

These aren't failures of the AI. They're failures of integration.

The Accountability Vacuum

Here's the uncomfortable reality: when a bolted-on AI system makes a bad recommendation that costs you money or creates liability, who's accountable?

The organization deployed it, sure. But the board wants to know why the risk controls didn't catch it. Finance wants to know whose P&L is taking the hit. Legal wants to know if there's regulatory exposure. And nobody has a clear answer because the decision chain is murky. The AI recommended X. Someone approved it (or didn't, and the system auto-executed it). Now there's a problem and nobody has clear ownership.

Complex supply chains require explainable decisions with clear accountability. You need to be able to trace exactly why a decision was made, what data went into it, who approved it, and what guardrails were applied. Without that transparency, you're actually increasing risk rather than reducing it.

Why Early Pilots Failed

Flip through any enterprise Slack channel and you'll find pilots that stalled or failed. The pattern is consistent:

Month 1: "We're going to use AI to optimize our safety stock levels." Team gets excited, allocates resources, deploys a proof-of-concept.

Month 2: "The model is actually pretty good. It's picking up patterns our analysts missed." Early results look promising. Stakeholders approve moving to pilot.

Month 3-4: "It recommended something that violated our supplier agreements. Also, the data it's using is inconsistent with how procurement actually tracks things. And we realized we don't have governance in place for how to handle edge cases."

Month 5: Project gets shelved. Budget reallocated. Team moves on to the next initiative.

This isn't because AI doesn't work. It's because of these specific failure points:

- No decision framework. The organization didn't define what "success" looks like or what constraints the AI must respect

- Disconnected from workflows. Humans still have to manually translate AI recommendations into actions, which is slow and lossy

- No governance structure. Nobody explicitly approved the guardrails or was accountable for outcomes

- Wrong stakeholders involved. The team that deployed the AI wasn't the same team that owned the supply chain decisions it was influencing

- Measurement confusion. They measured model accuracy, not business impact

The lesson: deployment difficulty isn't the problem. Integration difficulty is.

Understanding Agentic AI: What's Different

Agentic vs. Generative vs. Copilots: The Real Difference

Let's clear up the terminology because it matters for how you think about implementation.

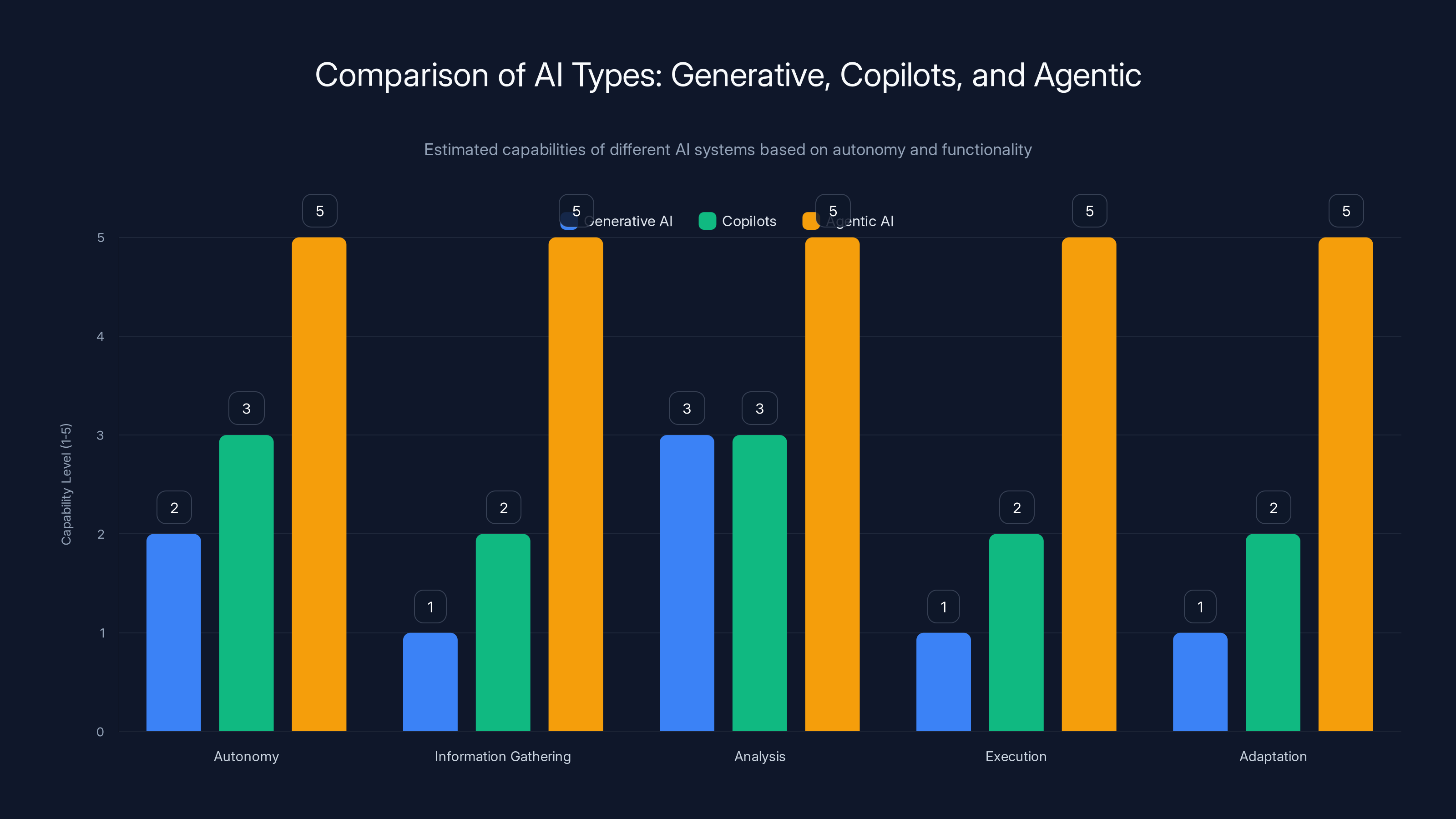

Generative AI (2023-2024 wave): Systems trained to predict and generate text, code, or images based on prompts. Chat GPT, Claude, Gemini. They're powerful for analysis and creativity, but they're fundamentally reactive. You ask them a question, they generate an answer. They don't do anything.

Copilots: These are generative AI systems integrated into applications to assist with specific tasks. Think Copilot in Excel suggesting formulas or Microsoft's GitHub Copilot writing code suggestions. They amplify human capability but still require humans to execute the actual decision. They're also typically limited to a single domain.

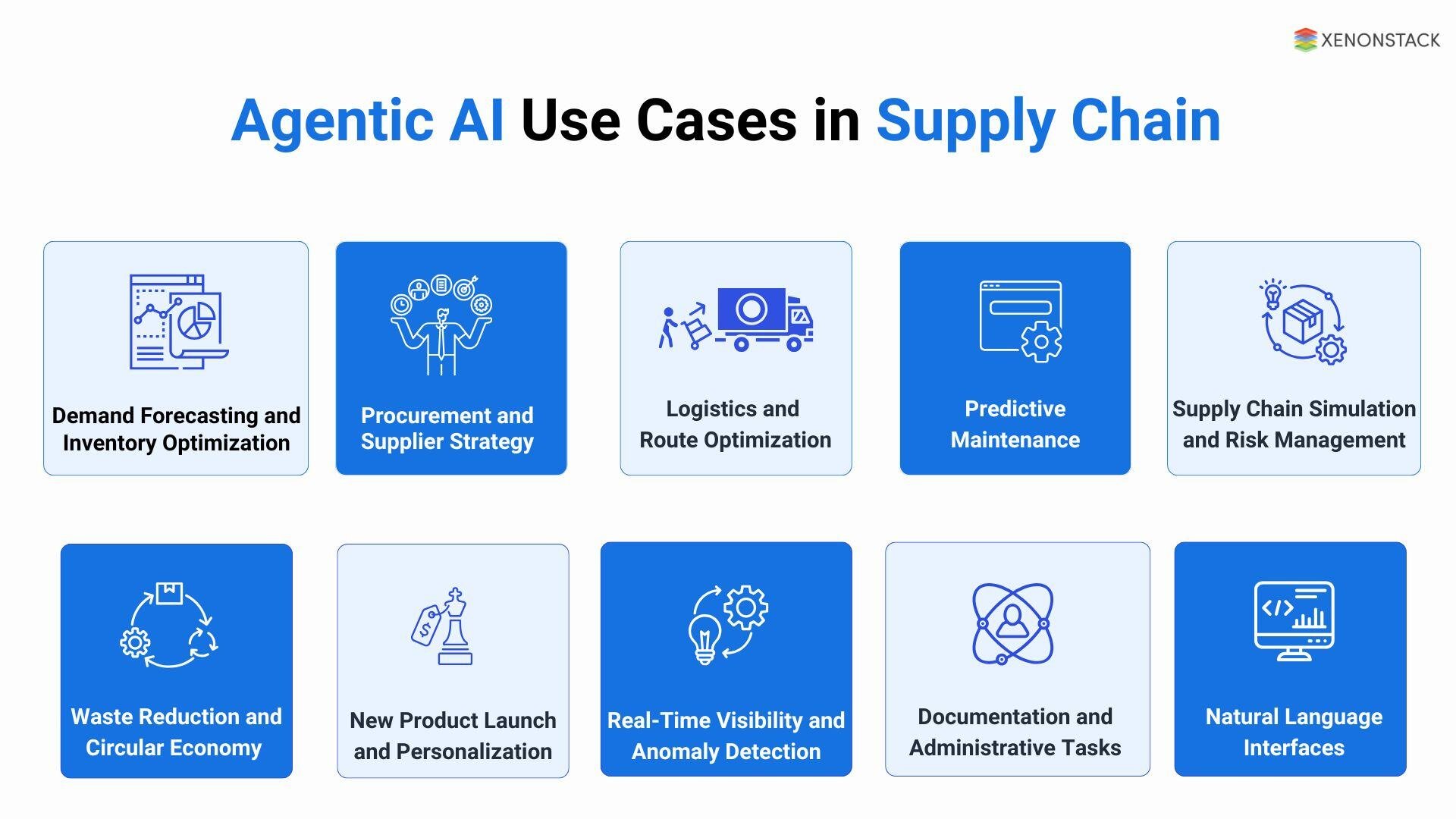

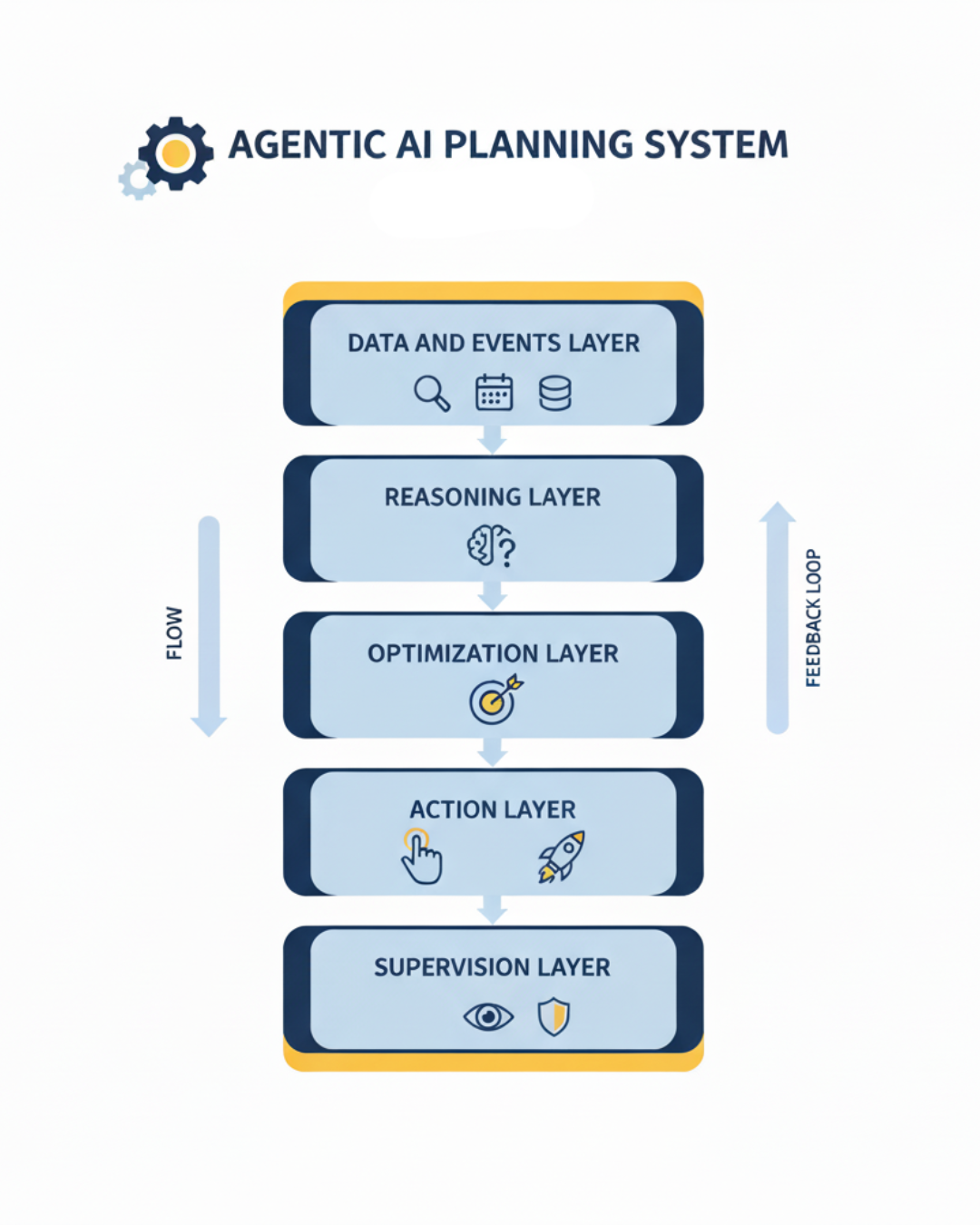

Agentic AI: This is where it gets fundamentally different. Agentic systems can:

- Autonomously gather information from multiple systems

- Analyze that information with actual business context and constraints

- Generate response options

- Execute actions (or recommend actions with full transparency)

- Monitor outcomes and adapt

- Do all of this without requiring human intervention on routine decisions

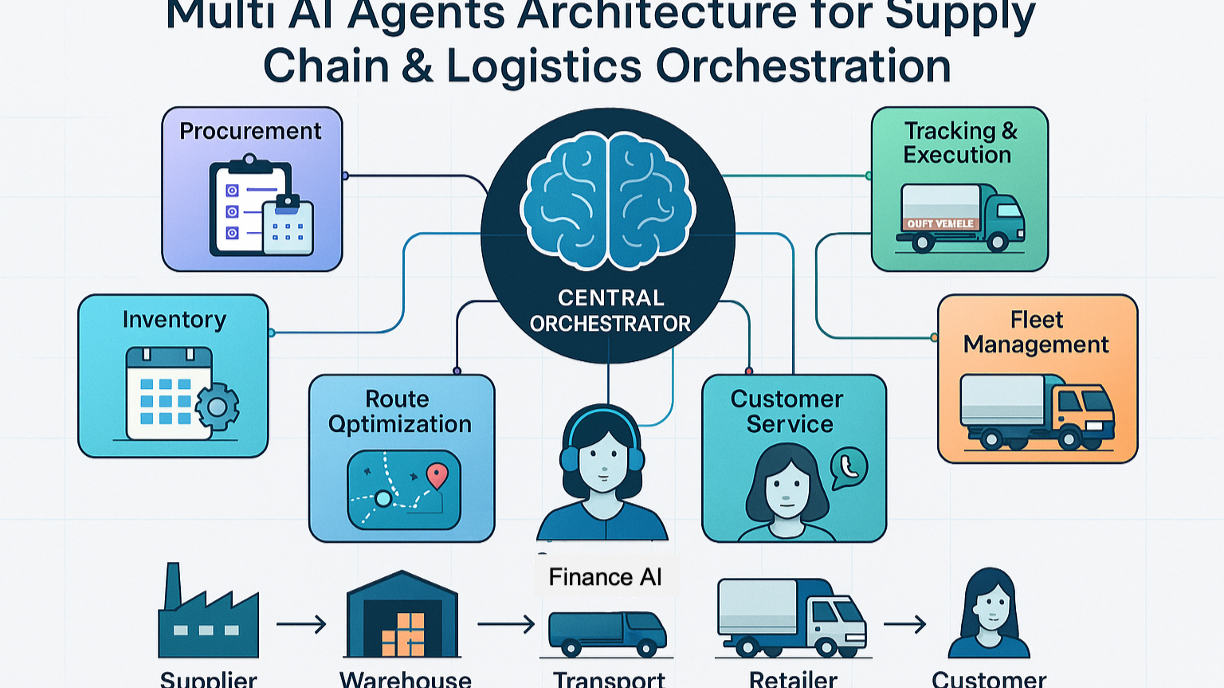

The key difference is autonomy within defined boundaries. An agentic AI doesn't just tell you what to do. It coordinates across systems, respects your guardrails, and can actually implement decisions.

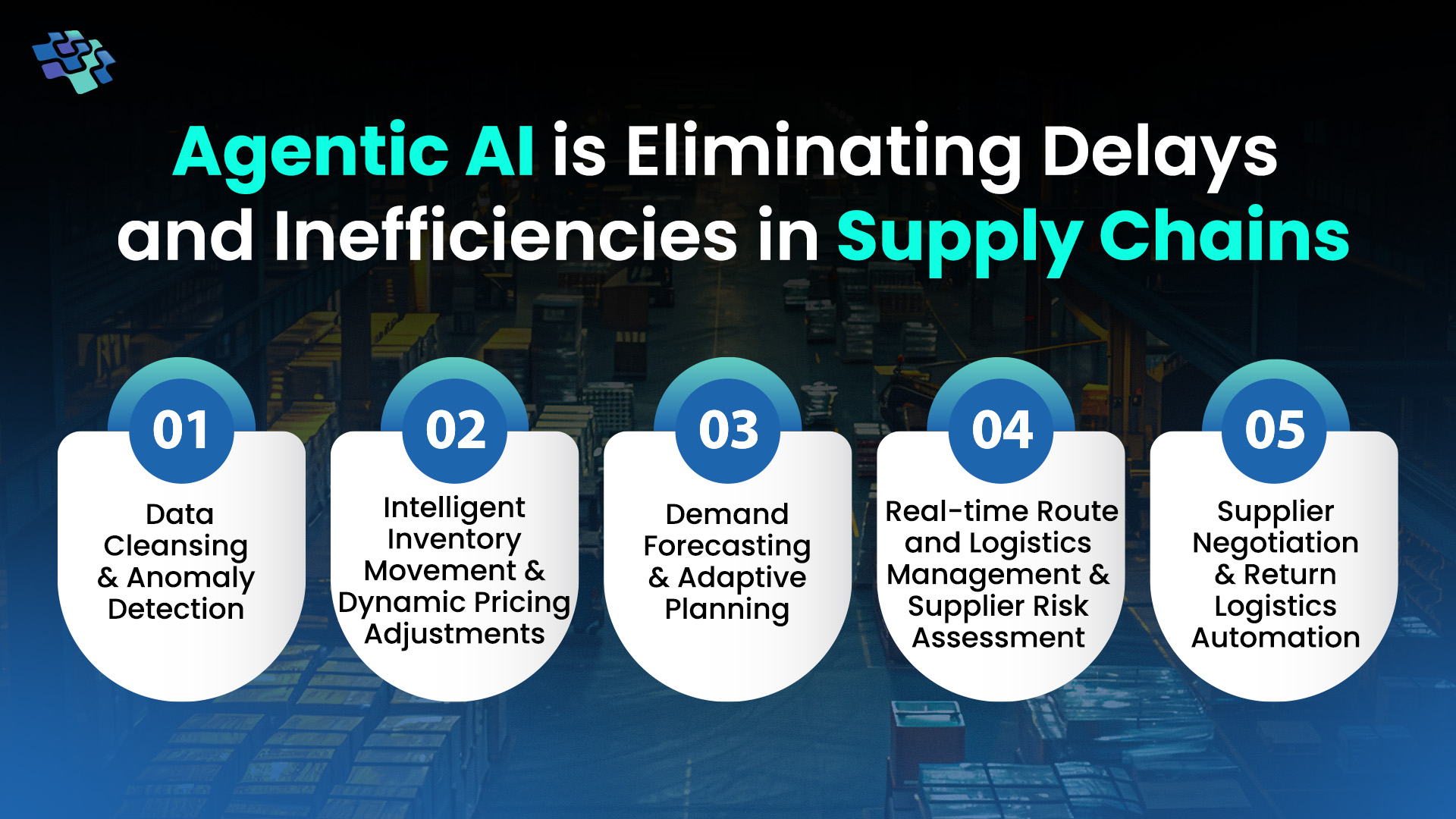

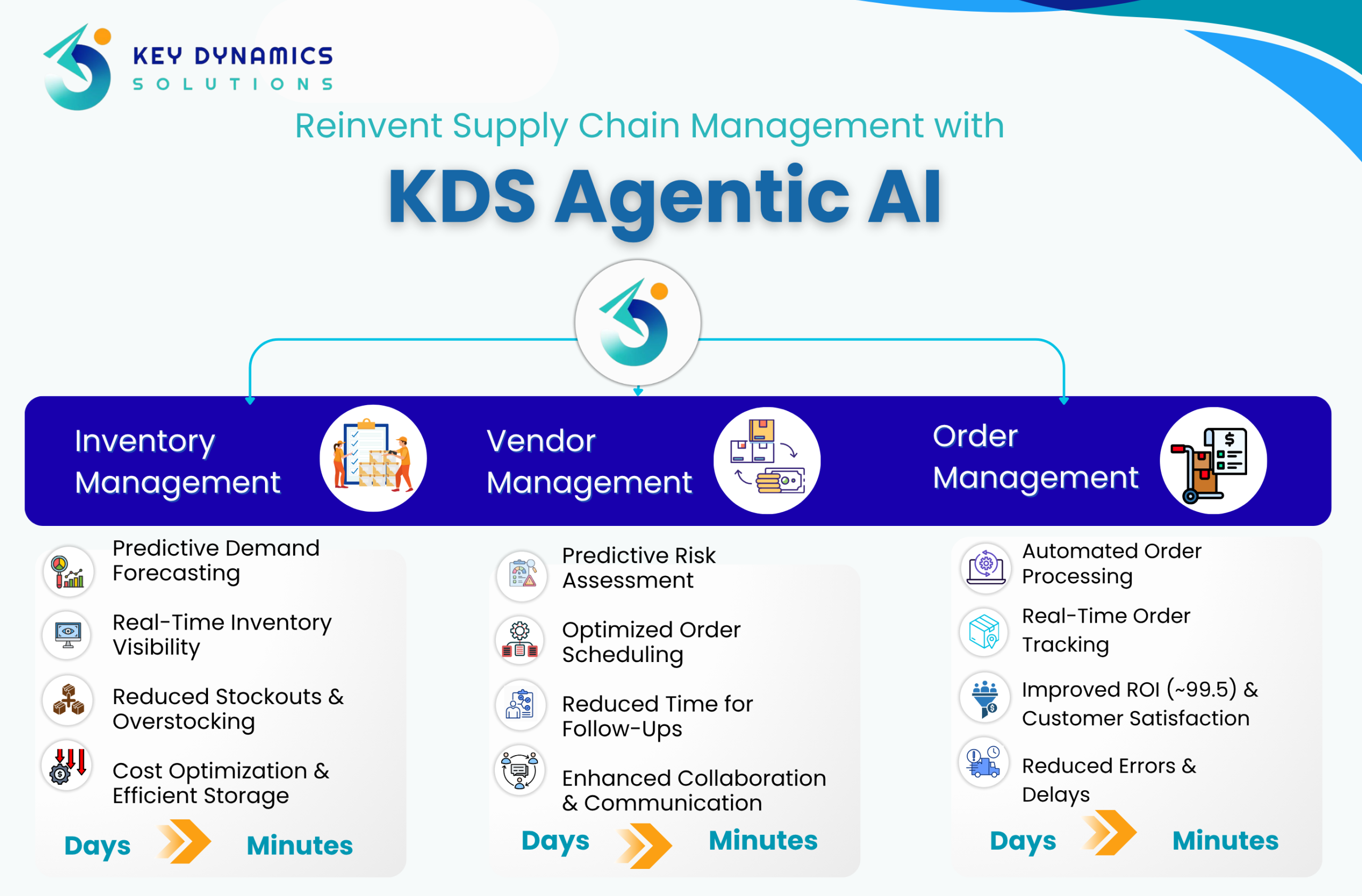

For supply chains, this is game-changing because supply chain decisions require coordination. You can't optimize inventory without talking to procurement. You can't rebalance logistics without checking finance impact. You can't approve a supplier change without confirming compliance. Agentic systems can do all of that internally before surfacing a recommendation for human approval.

How Agentic AI Actually Works in Supply Chains

Let me walk you through what this looks like in practice.

Imagine a pharmaceutical company manufacturing critical medicines. A supplier suddenly notifies them of a production delay. With traditional AI, here's what happens:

- Human analyst gets the notification

- Human manually checks inventory systems

- Human runs an analysis in a tool (which took 20 minutes to set up)

- Human gets recommendations and tries to coordinate responses

- Human checks with different teams (procurement, finance, logistics) to see if recommendations are feasible

- By the time all parties align, 6-8 hours have passed and the problem has compounded

With properly integrated agentic AI, here's what actually happens:

- System automatically detects the supplier notification and ingests it

- Agent simultaneously checks:

- Real-time inventory levels

- Current supplier capacity across all sources

- Transportation costs and lead times from alternatives

- Financial impact of different response options

- Compliance and quality constraints for each alternative

- Customer demand forecasts

- Agent generates 3-5 coordinated response options, each showing:

- What will happen if we implement this

- Cost impact to each business unit

- Compliance implications

- Risk level

- Alternatives this depends on (e.g., "this requires approval from supplier X")

- Agent flags it for human decision-maker with all context

- Human approves, and agent coordinates execution across procurement, finance, and logistics

- Agent monitors actual execution and alerts if something deviates

The whole thing takes 90 minutes instead of 8 hours. The decision is made with full context. Accountability is crystal clear. And the human made the final call.

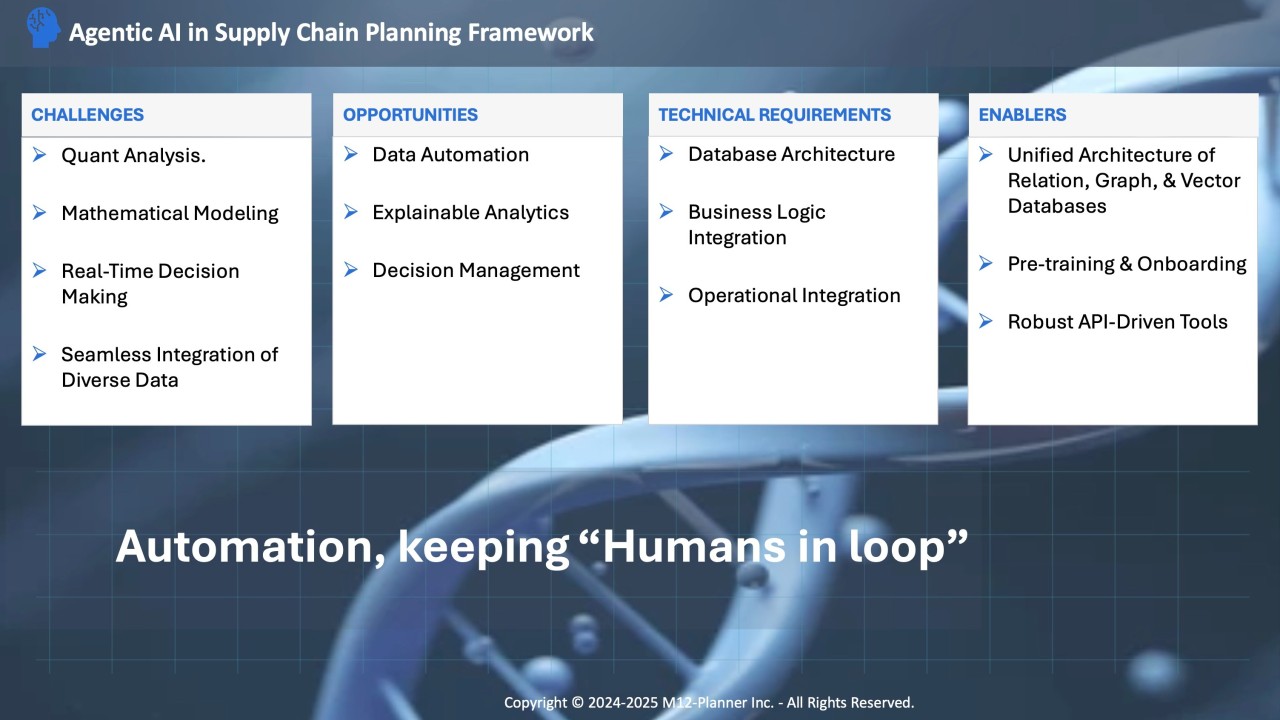

The Three Structural Requirements

For agentic AI to actually work at enterprise scale in supply chains, three things have to be true:

1. Single Source of Truth for Data

Your agent can't operate effectively if it's pulling inventory data from ERP, supplier data from procurement system, and financial data from spreadsheets. It needs one authoritative source for each data domain. This doesn't mean you eliminate all other systems, but rather that you establish which system is authoritative for which data, and agents always pull from there.

This is harder than it sounds because legacy systems were designed to work independently. But it's non-negotiable for agentic AI. The agent needs to know it's working with current information.

2. Clear Decision Rules and Guardrails

Your agentic system needs explicit programming for what it can and can't do. This includes:

- Financial thresholds (e.g., "don't approve orders over $100K without escalation")

- Supplier constraints (e.g., "don't use this supplier for aerospace components")

- Compliance rules (e.g., "cannot source materials from sanctioned countries")

- Quality standards (e.g., "if defect rate > 2%, don't order from this source")

- Risk parameters (e.g., "maintain 60 days of safety stock for critical materials")

These aren't optional. They're how you ensure the agent operates within your risk tolerance and business strategy.

3. Integration Into Actual Workflows

The agent can't be a separate system. It has to be embedded in the actual workflows where supply chain decisions get made. That might mean:

- Integration into your ERP system so procurement sees agent recommendations directly in their order management interface

- Connections to your forecasting system so the agent can trigger replanning when disruptions occur

- Integration with your compliance system so guardrails are automatically enforced

- Real-time connections to your supplier management platform

Without this integration, you still have a bolted-on tool that humans have to manually use.

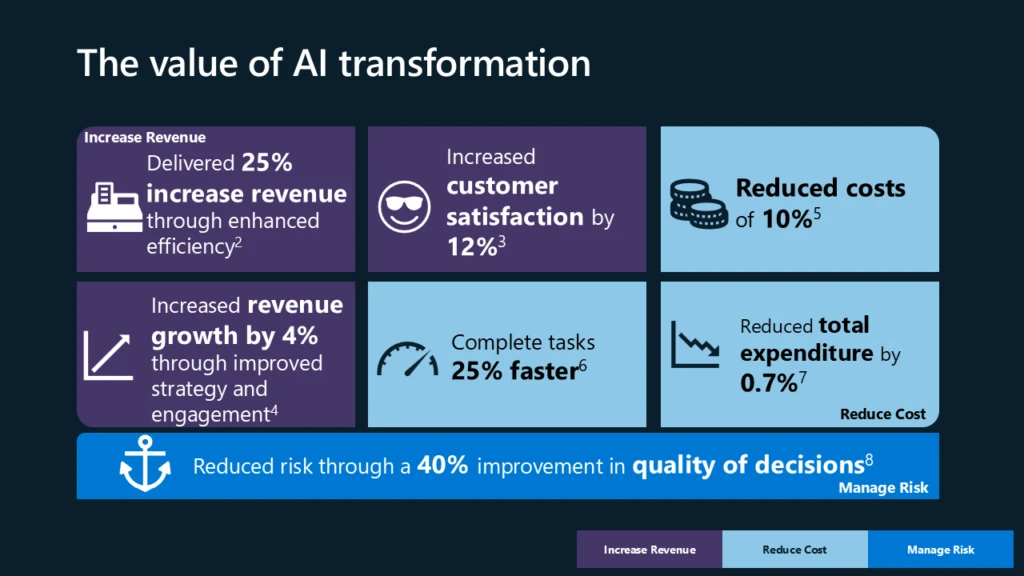

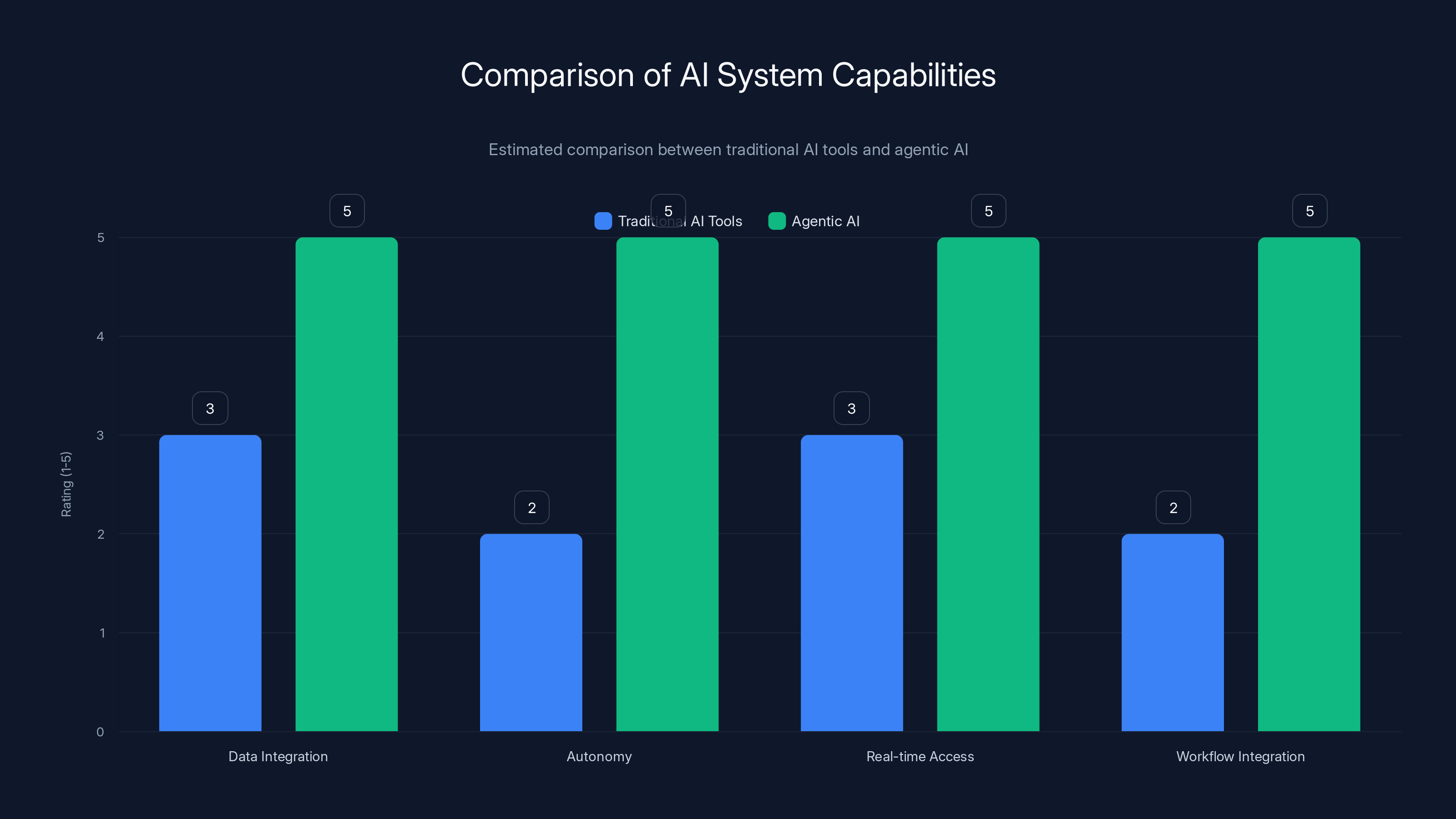

Agentic AI systems exhibit the highest level of autonomy and functionality, capable of executing and adapting decisions independently, unlike Generative AI and Copilots. Estimated data.

The Volatility-to-Foresight Transformation

What Foresight Actually Means in Supply Chains

When people talk about supply chain "foresight," they usually mean prediction. "Can we forecast demand better?" "Can we predict disruptions?"

That's part of it, but not the whole story.

Real foresight in supply chains means three things:

1. Early signal detection. You identify problems before they cascade. A supplier's financial health deteriorates. A geopolitical risk emerges. A customer's buying pattern shifts. Traditional systems detect these things days or weeks later. Agentic systems, operating on real-time data, catch them immediately.

2. Trade-off visibility. Every supply chain decision involves trade-offs. If you shift to a secondary supplier, you save money but lose some quality. If you increase safety stock, you improve resilience but reduce cash flow. Foresight means you see all the trade-offs before making a decision, not discovering them after.

3. Coordinated response. Most supply chain decisions ripple across the organization. You can't optimize inventory without considering finance. You can't manage supplier relationships without considering quality. Foresight means you've already worked through these coordinations before the decision lands on a human's desk.

How Volatility Becomes Advantage

Here's the counter-intuitive truth: organizations with the best agentic AI systems will actually thrive when volatility increases.

Why? Because volatility creates opportunities for organizations that can move faster than competitors.

When a supplier goes down, competitors scramble. They don't have visibility into alternative sources. They take days to coordinate across procurement, quality, and finance. You (with agentic AI) have already generated three response options with full impact analysis and are moving within hours.

When tariff regimes change, competitors have to manually recalculate their sourcing models. You've already got an agent that's recalculated costs across 47 different supplier-nation combinations and is presenting you with a new optimal sourcing plan.

When a geopolitical situation changes, competitors issue new risk assessments. You've already identified your exposed supply lines and are de-risking in real time.

This isn't theoretical. Companies with advanced supply chain systems have consistently outperformed during disruption cycles. During the 2021-2022 shortage periods, companies with integrated visibility and automated response mechanisms recovered 2-3 months faster than competitors.

Volatility doesn't stop being volatility. But for organizations with agentic AI properly integrated, it stops being a liability and becomes a tactical advantage.

The Human-AI Partnership Model

Why Human Oversight Isn't a Constraint

There's a widespread fear that agentic AI means removing humans from decisions. That's a fundamental misunderstanding of how these systems actually work at enterprise scale.

The best agentic AI systems don't minimize human involvement. They redirect it.

Instead of humans spending 80% of their time on routine operational tasks (monitoring inventory levels, checking supplier capacity, running scenario analysis), they spend 100% of their time on decisions that actually require human judgment:

- Should we challenge this supplier on quality issues?

- What's our strategic direction for this material category?

- How do we balance long-term supplier relationships against short-term cost optimization?

- Are there regulatory or ethical considerations the agent can't see?

- What's our appetite for risk in this particular situation?

These decisions require context that AI can't fully access. Strategic intent. Relationship dynamics. Ethics. Regulatory nuance. These are human decisions, and they always will be.

What changes is that humans make these decisions with complete information and multiple pre-analyzed options, instead of having to gather information and run analysis themselves.

Guardrails as Competitive Advantage

You know what separates well-integrated agentic AI from poorly integrated stuff? The guardrails.

Badly designed systems treat guardrails as restrictions that slow down the AI. "Oh, we can't do that because of compliance requirements." Treated as an afterthought.

Well-designed systems treat guardrails as the core specification. Before you even build the agent, you define:

- What decisions can it make autonomously?

- What decisions require human approval?

- What constraints are non-negotiable?

- How do we prevent the agent from creating unintended consequences?

This is harder upfront, but it's what makes the difference between an AI system that creates new risks and one that reduces them.

The Approval Workflow Framework

Here's how the best organizations structure human-AI workflows:

Autonomous Decisions (AI handles entirely):

- Routine reorders within established parameters

- Inventory rebalancing between warehouses

- Routine supplier capacity checks

- Compliance verification for standard transactions

Flagged Decisions (AI prepares, human approves):

- New suppliers outside established list

- Orders exceeding financial thresholds

- Changes to safety stock levels

- One-time procurement exceptions

- Any decision where guardrails might be triggered

Escalated Decisions (AI alerts, human drives):

- Supply chain disruptions

- Major geopolitical or regulatory changes

- Supplier relationship issues

- Strategic shifts in sourcing

- Situations outside the agent's known decision space

The key insight: the agent doesn't decide whether to escalate to humans. The organization decides, upfront, what the boundaries are. The agent operates within those boundaries and flags everything that crosses them.

Transparency and Traceability

This is the part that often gets skipped but shouldn't. When an agentic system makes a recommendation (or executes a decision), you need to be able to trace exactly:

- What data did the agent consider?

- What was the decision logic?

- What guardrails applied?

- What trade-offs did the agent analyze?

- Who approved it (if human approval was required)?

- What was the outcome and did it match predictions?

This traceability serves multiple purposes:

- Audit trail for compliance. Especially important if regulators ask about decisions

- Continuous improvement. You can see where the agent's recommendations were good and where they missed nuance

- Trust building. When stakeholders can see exactly how a decision was made, they're more likely to trust and embrace the system

- Accountability. Clear traceability means clear accountability

Organizations that skip this typically regret it when they hit their first incident where they need to explain to auditors or leadership why a particular decision was made.

Agentic AI systems excel in integration, autonomy, and real-time access compared to traditional AI tools. Estimated data.

Implementation: Getting From Vision to Reality

The Readiness Assessment

Before you deploy agentic AI, you need to honestly assess whether your organization is ready. This isn't about technology readiness. It's about organizational readiness.

Data Readiness:

- Do you have a clear picture of which systems are authoritative for which data domains?

- Can you access real-time or near-real-time data across procurement, inventory, logistics, and finance?

- Do you have data quality standards for the key inputs the agent will use?

- Can you audit data lineage if needed?

If you're not at least 70% ready on data, you'll struggle.

Process Readiness:

- Have you explicitly defined your current supply chain decision processes?

- Can you articulate the guardrails and constraints for each decision type?

- Do you have stakeholder alignment on what "success" looks like?

- Is there executive sponsorship that understands this will take 9-12 months, not 3 months?

Organizational Readiness:

- Do your supply chain teams see this as an opportunity to focus on strategy rather than a threat to their jobs?

- Is there a clear owner who has the authority to make changes across multiple functions?

- Do you have the internal expertise to manage this, or will you need external help?

- Are you willing to evolve processes if the agent surfaces better ways to do things?

If you're not ready on these dimensions, you'll likely hit the same stalled pilot pattern as everyone else.

Phase 1: Foundation (Months 1-3)

You're not building agentic AI in phase one. You're building the foundation it sits on.

Step 1: Data Inventory and Assessment

- Map all your data sources (ERP, procurement systems, inventory management, logistics, finance)

- Identify data quality issues and gaps

- Establish which systems are authoritative for each data domain

- Build connections to make data accessible in real time or near-real time

This usually takes 4-6 weeks and reveals surprises. "Wait, our warehouse management system doesn't actually talk to our inventory system?" Yeah, that's common.

Step 2: Process Definition

- Document your current supply chain decision processes in detail

- For each process, identify where disruption typically occurs

- Identify the data needed to make better decisions

- Map out the stakeholders involved

Don't try to "optimize" at this stage. Just document what's actually happening now.

Step 3: Guardrail Definition

- For each major decision type, define what the agent can do autonomously

- Define what requires human approval

- Define constraints and constraints (financial limits, compliance requirements, risk parameters)

- Get buy-in from stakeholders

This is where a lot of organizations stumble because it requires making explicit decisions you might have been implicit about before. "Should the agent be able to approve new suppliers?" "What's the financial threshold?" These are strategic questions, not technical ones.

Phase 2: Pilot (Months 4-8)

Now you build and test the actual agent, but in a limited scope.

Step 1: Narrow Problem Selection

- Pick one specific supply chain scenario, not the entire supply chain

- Example: managing safety stock levels for a specific material category, not all materials

- Or: managing reorders for a specific supplier, not supplier relationship management

- Start with a scenario that's important but not mission-critical

Narrowing scope reduces risk and accelerates learning.

Step 2: Agent Development

- Build the agent with access to the real-time data you identified in phase one

- Implement the guardrails you defined

- Test extensively with historical data

- Run shadow scenarios where the agent makes recommendations but humans make the actual decisions

The shadow period is critical. You're watching the agent operate in your real environment without the agent actually making decisions. This surfaces edge cases and cultural issues.

Step 3: Go-Live and Monitoring

- Move from shadow to live, with the agent making autonomous decisions

- Maintain heavy monitoring to catch problems early

- Measure both technical metrics (accuracy, decision speed) and business metrics (cost impact, disruption response time)

- Keep humans in the loop even for autonomously triggered decisions initially

Phase 3: Expansion (Months 9-12)

Once pilot proves out, you expand, but methodically.

Step 1: Scope Expansion

- Apply the successful agent to similar scenarios

- Example: if safety stock agent worked for Material A category, expand to Material B category

- Add complexity gradually

- Keep monitoring at high levels

Step 2: Additional Agent Development

- Develop agents for other supply chain decisions

- Use the guardrails and integration approach you validated in the pilot

- Cross-train teams so multiple people understand how agents work

Step 3: Integration Deepening

- Start connecting agents to automated execution systems

- Move from recommendations to coordinated action

- Implement monitoring and adaptation loops

Real-World Scenarios: Where Agentic AI Changes Everything

Scenario 1: Sudden Supplier Disruption

Let's walk through what actually happens when a major supplier goes down and you have integrated agentic AI.

The Trigger: Your semiconductor supplier in Taiwan notifies you that a typhoon has shut down their fab for an estimated 5 days. This affects 40% of your microcontroller supply.

Without Agentic AI:

- Someone notices the notification

- That person escalates to the supply chain director

- Supply chain director manually pulls current inventory data from three systems (takes 30 minutes because the systems don't talk easily)

- Director tries to estimate how long current inventory lasts (complicated because usage varies by product mix)

- Director reaches out to secondary suppliers (many of whom don't answer immediately)

- Meanwhile, production is potentially at risk and nobody knows if it's a real problem or manageable

- By the time everyone understands the situation, it's been 4-6 hours

With Agentic AI:

- The notification triggers the agent immediately

- Agent simultaneously checks:

- Current inventory levels (real-time)

- Daily usage rates for affected products

- Lead times from secondary suppliers

- Current capacity of each secondary supplier

- Cost differential if we move volume

- Long-term contract implications

- Compliance status of secondary suppliers

- Agent runs three scenarios:

- Scenario A: Move all volume to Secondary Supplier X (cost +8%, delivery -2 days)

- Scenario B: Split across Suppliers X and Y (cost neutral, delivery -1 day)

- Scenario C: Reduce production volume temporarily (margin impact, delivery on time)

- Agent flags the decision for supply chain director with full analysis and recommendation

- Director approves Scenario B within 90 minutes

- Agent coordinates execution:

- Updates orders with Secondary Suppliers X and Y

- Notifies production about the temporary volume shift

- Updates financial forecasting with the cost impact

- Alerts quality assurance to accelerate incoming inspection

- Agent monitors: Did the suppliers confirm acceptance? Are they hitting their promised delivery dates? Is production adjusting as expected?

Business Impact:

- Decision made 4x faster

- Production disruption prevented or minimized

- Trade-offs visible upfront so no unexpected surprises

- Lessons captured for future disruptions

Scenario 2: Regulatory Change

A new EU regulation takes effect that affects 30% of your raw material sourcing. Materials from certain origins are now restricted.

Without Agentic AI:

- Legal or compliance team notices the regulation

- That team escalates to supply chain

- Supply chain has to manually identify all affected materials and suppliers

- Supply chain has to assess alternatives for each

- Takes 2-3 weeks before you have a sourcing plan

- By then, you might have unknowingly ordered restricted materials

With Agentic AI:

- Compliance team feeds the regulation into the agent

- Agent immediately scans all supplier contracts and material sourcing

- Agent identifies 47 materials from 12 suppliers that are affected

- Agent automatically checks alternative sources, cost impact, lead time impact, and compliance status

- Agent generates a transition plan showing:

- Phase 1 (this week): Stop new orders from affected suppliers

- Phase 2 (this month): Transition to pre-identified alternatives

- Phase 3 (over next quarter): Optimize final sourcing

- Cost impact: +2.3% for affected materials, fully absorbed

- Compliance is maintained, supply chain continuity is preserved, stakeholders are aligned

Business Impact:

- Compliance achieved without disruption

- Process took days, not weeks

- Risk of accidental non-compliance eliminated

- Finance has accurate cost impact upfront

Scenario 3: Demand Volatility

Your largest customer suddenly shifts their demand from a forecast of 10,000 units to 15,000 units with a 2-week lead time.

Without Agentic AI:

- Customer notifies you

- You scramble to check if you have capacity

- You reach out to suppliers manually to see if they can increase delivery

- Some suppliers can, some can't

- You have to make trade-offs between hitting customer deadlines and managing inventory

- Takes 3-4 days to have a plan

With Agentic AI:

- Customer notification triggers the agent

- Agent immediately models the impact:

- What's our current production capacity? (95% allocated)

- Can we pull from safety stock? (Yes, 3,000 units without violating minimums)

- What additional capacity do we need? (2,000 units)

- Can existing suppliers expedite? (Yes, 1,500 units at 12% premium, 1,000 units at 25% premium)

- Can we use secondary suppliers? (Yes, 500 units from pre-qualified alternative)

- What's the cost impact? (8.3% premium on 2,000 units)

- Agent generates a response plan:

- Use 3,000 from safety stock

- Expedite 1,500 from Supplier A (12% premium)

- Use 500 from alternative supplier (pre-qualified)

- Short 500 units, deliver in week 3 instead of week 2 (negotiated with customer)

- You approve the plan

- Agent coordinates execution across procurement, production, and customer management

Business Impact:

- Customer gets 9,500 of 10,000 units on their timeline (vs. potentially none if planning took too long)

- Cost premium is quantified and approved upfront

- Supplier relationships are managed professionally

- Financial impact is visible to the business

Estimated data shows that organizations need at least 70% readiness in data, process, and organizational dimensions to successfully implement agentic AI.

The Organizational Shift: From Operations to Strategy

What Changes for Supply Chain Leaders

When agentic AI actually works, the job changes for supply chain leaders in a fundamental way.

What You Stop Doing:

- Firefighting tactical disruptions (the agent handles those)

- Manually monitoring KPIs (the agent alerts you when thresholds are exceeded)

- Running analysis on what-if scenarios (the agent generates those)

- Following up with suppliers on routine deliveries (the agent tracks and alerts)

- Reconciling inventory between systems (the agent ensures single source of truth)

What You Start Doing:

- Defining strategy for supplier relationships

- Making trade-off decisions the agent can't make autonomously

- Identifying emerging risks before they become crises

- Optimizing the supply chain for new business priorities

- Driving continuous improvement based on agent insights

- Building resilience into the supply chain architecture

Some leaders love this shift. They came into supply chain because they wanted to solve hard problems, and suddenly they have time to actually solve them.

Other leaders struggle because their expertise was built on the tactical firefighting, and they're not sure how to add value in the new model.

This is a real organizational change management issue. The best organizations address it directly: redefine roles, invest in training leaders to think strategically, and celebrate the leaders who successfully make the transition.

Building an AI-Native Supply Chain Culture

Successfully deploying agentic AI requires cultural shifts:

From Skepticism to Partnership

- Initially, teams view AI as a threat ("This will replace me")

- Through transparent implementation, they see it differently ("This lets me focus on what I actually want to do")

- You accelerate this by involving teams early, showing them the benefits, and proving that the system respects their expertise

From Process Rigidity to Managed Evolution

- Supply chains are often process-heavy for good reason (you need control)

- But agentic AI works better when processes are explicit and can evolve

- You need to create space for experimentation while maintaining guardrails

From Data Hoarding to Data Transparency

- Many organizations have departments that treat "their data" as proprietary

- Agentic AI requires shared, transparent data

- This requires trust that data will be used responsibly

- You build that trust through governance, not by trying to work around the problem

From Human Authority to Human Accountability

- Previously, supply chain decisions were made by people with authority

- With agentic AI, the question becomes: does the agent have the authority or does the human?

- The answer in the best organizations is: the agent has authority within guardrails, but humans are accountable for defining those guardrails

- This is a subtle shift, but it changes how people relate to AI systems

Risk Management and Failure Modes

What Can Go Wrong (And How to Prevent It)

Agentic AI systems can fail in specific ways that non-agentic systems typically don't. It's worth understanding these failure modes upfront.

Failure Mode 1: Context Collapse

The agent has access to real-time data but lacks the broader context needed for the decision. For example, you've told the agent "minimize cost" so it switches all purchasing to the cheapest supplier. But you didn't tell the agent about a strategic relationship you're building with a different supplier, or quality issues with the cheap option, or supply concentration risk.

The agent's recommendation is locally optimal but globally suboptimal.

Prevention:

- Make strategic context explicit in guardrails

- Build decision hierarchies (some factors override cost optimization)

- Include regular audits of agent decisions to surface context gaps

- When you find context the agent was missing, update its guardrails

Failure Mode 2: Data Quality Cascades

The agent is operating on real-time data, which is great. But if that data has quality issues, the agent will act on bad information, and the wrong action cascades across the system. For example, an inventory system miscounts stock by 500 units, the agent thinks you have more safety stock than you actually do, the agent commits inventory to a customer you don't actually have.

Prevention:

- Invest in data quality upfront, not after agent deployment

- Build quality verification into the agent's decision logic

- Create alerts for unlikely data values (if the agent detects data that violates business logic, it should flag it)

- Maintain data audit trails so you can trace decisions back to source data

Failure Mode 3: Unintended Emergent Behavior

The agent is making locally correct decisions, but the aggregate of those decisions creates problems. For example, the agent is optimizing inventory levels for individual products, but the aggregate effect is that you're carrying excess inventory overall because it's optimizing each one independently.

Prevention:

- Test agent behavior against multiple scenarios, not just the base case

- Implement monitoring that looks for emergent problems (inventory, cash flow, asset utilization)

- Create feedback loops where monitoring data influences agent behavior

- Review agent decision patterns regularly to spot systemic issues

Failure Mode 4: Supplier Relationship Degradation

The agent is making optimal sourcing decisions but in a way that damages supplier relationships. For example, the agent constantly tests secondary suppliers and shifts volume to whoever's cheapest, which breaks trust with your primary suppliers.

Prevention:

- Include relationship factors in guardrails, not just transaction factors

- Define minimum commitment levels to suppliers

- Create decision rules that account for long-term relationship value, not just immediate cost

- Maintain human ownership of strategic supplier relationships

Failure Mode 5: Regulatory Non-Compliance

The agent has guardrails designed to ensure compliance, but a regulatory environment changes faster than you update the guardrails. The agent continues operating under the old rules.

Prevention:

- Create automated regulatory monitoring that alerts you to relevant changes

- Build a process for quickly updating agent guardrails when regulations change

- Maintain a "compliance first" principle where any ambiguity defaults to the conservative option

- Have compliance review all major agent decision patterns regularly

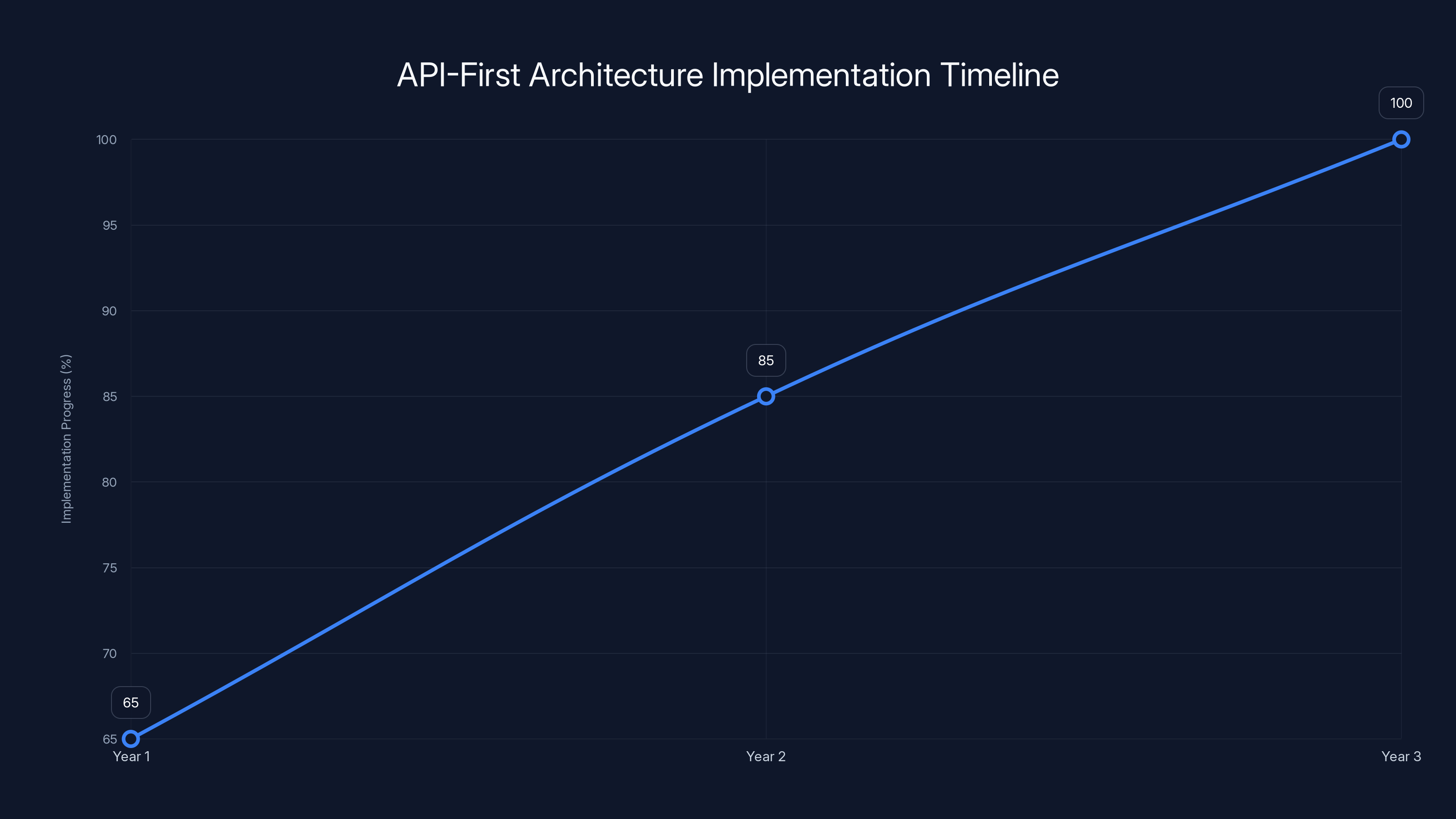

Estimated data shows a progressive increase in API implementation, reaching full functionality by Year 3, enabling agents to operate with minimal oversight.

Integration Patterns: How to Actually Connect Things

API-First Architecture

The most robust agentic AI implementations are built on API-first architecture. That means every system talks to every other system through well-defined APIs, not through custom integrations or manual exports.

Why this matters:

- Agents can access real-time data from any system

- You can change or replace underlying systems without breaking the agent

- You get clear visibility into what data flows where

- You can audit and control data access

What this looks like:

- ERP exposes APIs for inventory, orders, supplier data

- Procurement system exposes APIs for supplier performance, contracts

- Logistics system exposes APIs for transportation, delivery data

- Finance system exposes APIs for costs, budgets, commitments

- Compliance system exposes APIs for regulatory rules and audit trails

The agent orchestrates across these APIs. When there's a disruption, the agent pulls data from all of them, analyzes, and potentially writes data back to them (creating orders, updating forecasts, etc.).

Real world implementation:

- Year 1: Build out 60-70% of needed APIs

- Year 2: Fill in gaps, build monitoring on top of API layer

- Year 3: Agents can operate with minimal manual oversight

Workflow Integration

APIs are necessary but not sufficient. You also need the agent integrated into actual workflows.

This means:

- Procurement workflow: Agents generate POs that flow directly into the approval workflow

- Forecasting workflow: Agents update demand forecasts that automatically trigger planning runs

- Customer management workflow: Agents flag customer commitments that need attention

- Finance workflow: Agents create accruals and commitments that flow directly into financial systems

Without this workflow integration, the agent recommendations still require manual translation into action, which reintroduces delay and error.

Monitoring and Observability

This is the part that separates mature agentic systems from immature ones.

You need:

Real-time Dashboards Showing:

- What decisions the agent made today

- What decisions were approved/rejected by humans

- What alerts are currently active

- Agent performance metrics (decision accuracy, response time)

Audit Trails Showing:

- For each decision: what data did the agent use, what guardrails applied, who approved it (if anyone), what was the outcome

- Where decisions diverged from guardrails

- Where human overrides occurred and why

Alert Systems:

- When agent behavior deviates from expected patterns

- When decisions violate guardrails (shouldn't happen, but needs to surface if something broke)

- When data quality issues are detected

- When regulatory changes occur

Organizations that invest in this observability layer are 3-4x more effective at refining their agentic systems over time.

The Competitive Advantage: Why This Matters Now

Why 2025 Is the Inflection Point

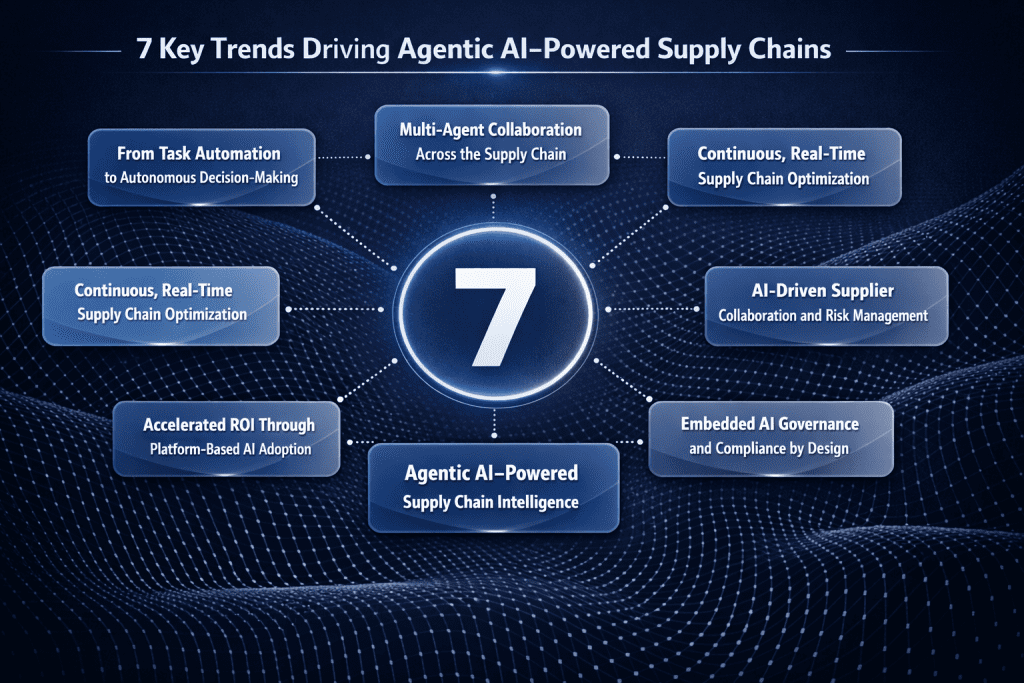

Agentic AI isn't brand new technology. The foundational techniques have existed for years. So why is this the inflection point moment?

1. Volatility Has Reached a Level Where Organizational Agility Became Table Stakes

Ten years ago, supply chain changes were measured in months. Now they're measured in weeks or days. Organizations that can't respond fast enough simply can't compete.

Traditional approaches to supply chain management (good forecasting, supplier relationships, inventory positioning) are necessary but insufficient when disruptions hit. You need to be able to respond in hours, not days.

Agentic AI is the only approach that enables this.

2. Data Infrastructure Has Matured

Five years ago, getting real-time data across multiple systems was technically hard. Now it's still hard, but it's possible and increasingly standard. Cloud infrastructure, modern databases, and API ecosystems have made it feasible to build the single source of truth that agentic systems need.

3. AI Techniques Have Reached a Point Where They Can Handle Real Complexity

Large language models and multimodal AI systems are capable of understanding complex business logic, constraint satisfaction problems, and trade-off analysis at a level that makes them genuinely useful for supply chain optimization.

They're not perfect, but they're good enough that, with human oversight, they can drive real value.

4. Talent Has Shifted

Two years ago, the people who understood how to build agentic systems were rare. Now there's enough momentum in the AI community that talented engineers are learning these patterns, and more implementations are happening.

This lowers the barrier to entry for organizations willing to invest.

The 2025-2027 Window

Here's my prediction: in the next 18-24 months, we'll see a divergence in supply chain performance that correlates almost directly with agentic AI adoption.

Organizations that:

- Invest in real-time data infrastructure

- Implement agentic AI with proper governance

- Shift culture toward human-AI partnership

- Build monitoring and observability

...will outperform competitors on speed, cost, and resilience by 20-40%.

Organizations that:

- Continue using traditional forecasting and planning

- Bolt on AI tools without integration

- Struggle with data silos

...will gradually lose market share to faster, more resilient competitors.

This isn't guaranteed. It depends on execution. But the technological capability is clearly there, and organizations with leadership that understands the opportunity will move fast.

The Threshold Effect

There's an interesting phenomenon that happens around 2026-2027. Once some competitors have operationalized agentic AI effectively, it stops being a competitive advantage and becomes table stakes.

At that point:

- Investors start asking whether supply chain management is "AI-native" or not

- Customers start expecting faster response to disruptions

- Talent gravitates to companies with modern supply chain systems

- Regulatory expectations shift toward AI-enabled transparency

If you wait until that threshold to start, you'll be playing catch-up for years.

Building Your Implementation Roadmap

Year 1: Foundation and Pilot

Q1:

- Assess readiness (data, processes, organization)

- Build executive alignment on vision and investment

- Establish governance model

- Start data inventory and quality assessment

Q2-Q3:

- Complete data integration for priority systems

- Document supply chain decision processes

- Define guardrails for initial use case

- Build agent for narrow problem (e.g., safety stock optimization for one material category)

Q4:

- Deploy agent in shadow mode (recommendations only, humans execute)

- Monitor and refine

- Build internal expertise

Year 2: Expansion and Hardening

Q1-Q2:

- Move agent to autonomous execution (within guardrails)

- Expand to similar use cases

- Build second agent for different supply chain problem

- Invest heavily in monitoring and observability

Q3-Q4:

- Expand to enterprise scope

- Integrate with procurement and planning workflows

- Shift culture and organizational structure

- Measure business impact and ROI

Year 3: Optimization and Continuous Evolution

Ongoing:

- Continuous improvement of agent decision logic

- Expansion to adjacent supply chain problems

- Integration with customer-facing systems (demand sensing, order management)

- Use agent insights to drive supply chain strategy

Conclusion: The Path Forward

We're at a genuine inflection point in supply chain management. The convergence of volatility, data infrastructure, AI capability, and organizational readiness has created a narrow window where agentic AI deployment can transform how companies manage disruption.

But transformation isn't guaranteed. It requires:

Clear Vision: You need to understand that agentic AI isn't about replacing humans. It's about redirecting human effort from tactical firefighting to strategic decision-making. Leaders who get this build different systems than leaders who see AI as a replacement technology.

Discipline: The temptation is to move too fast. Deploy AI across the supply chain. Minimize human oversight. Automate everything. The organizations that resist this temptation, that stay disciplined about narrow pilots and careful expansion, are the ones that win.

Integration: Technology is the easy part. Integration is the hard part. You need real-time data infrastructure. API-first architecture. Workflow integration. Monitoring and observability. It's unglamorous work, but it's what separates the companies that talk about AI from the companies that actually use it.

Culture: Your team needs to believe that AI is a partner, not a threat. That transparency and accountability matter more than raw autonomy. That human judgment on hard decisions is more valuable than ever. If you don't build this culture, the technology won't deliver.

The organizations that do this work well will have supply chains that are fundamentally more resilient, responsive, and efficient than their competitors. They'll respond to disruption in hours instead of days. They'll comply with regulatory changes without operational pain. They'll balance trade-offs with visibility instead of after-the-fact surprise.

They'll have transformed volatility into foresight. And in an increasingly volatile world, that's a competitive advantage that's hard to match.

The time to start is now. Not in 2026, not in 2027. Now. Because the organizations that understand this opportunity and move with discipline will build a 2-3 year lead on competitors who haven't yet made the decision.

FAQ

What exactly is agentic AI?

Agentic AI refers to artificial intelligence systems that can autonomously gather information from multiple sources, analyze it with business context and constraints, generate response options, and execute actions—all within defined guardrails and with clear human oversight. Unlike traditional AI copilots that provide recommendations for humans to manually implement, agentic systems can coordinate across an organization and take action, making them fundamentally different from earlier generations of AI tools for supply chain management.

How is agentic AI different from the AI tools we already deployed?

Traditional AI tools (copilots, analytics platforms, predictive models) typically operate in isolation, analyzing data but requiring humans to manually translate recommendations into action. Agentic AI is integrated directly into workflows, has access to real-time data across multiple systems, respects defined guardrails, and can coordinate responses across procurement, finance, logistics, and other functions—all without requiring constant human intervention for routine decisions. The key difference is integration, not just capability.

Why do most AI pilots fail in supply chains?

Most pilots fail because they treat AI as a bolt-on tool rather than an integrated system. They operate on siloed data, lack governance and guardrails, aren't connected to real workflows, and measure accuracy rather than business impact. Additionally, many organizations try to go enterprise-wide too quickly instead of learning from narrow pilots first, and they don't invest enough in change management and culture shift that's necessary for teams to embrace the systems.

How do we maintain human control with autonomous agents?

Human control is built into agentic systems through several mechanisms: explicit guardrails that define what agents can do autonomously (routine reorders) versus what requires human approval (new suppliers, decisions exceeding thresholds); escalation rules for decisions outside the agent's known decision space; transparent audit trails showing exactly how each decision was made; and continuous monitoring for agent behavior that violates expected patterns. The key is designing this governance upfront, not trying to add it after deployment.

What's the realistic timeline for implementing agentic AI?

Realistic implementation takes 18-24 months from initial assessment to enterprise deployment. The first 3-6 months focuses on readiness assessment and foundation-building (data infrastructure, process definition, guardrail development). Months 6-12 covers pilot development and shadow testing. Months 12-18 involves moving to autonomous execution and expanding scope. Months 18-24 focuses on enterprise scaling and culture transformation. Organizations that try to compress this timeline typically hit the same failure modes that caused earlier AI pilots to stall.

How much does agentic AI cost compared to traditional systems?

Cost depends on your starting point and scope. If you already have integrated data infrastructure and modern systems, implementation costs are primarily in agent development and integration work, typically

What regulatory concerns should we consider?

The main regulatory concerns are transparency (being able to explain why decisions were made, especially important in EU regulatory environments), compliance (ensuring agents respect relevant regulations and constraints), data protection (managing data access and privacy), and accountability (having clear ownership for outcomes). These are addressed through proper governance design, audit trails, compliance guardrails, and human oversight. Organizations that build governance upfront typically have fewer regulatory complications than those trying to retrofit compliance.

How do we measure success of an agentic AI implementation?

Success should be measured on multiple dimensions: business impact (cost reduction, improved margins, faster disruption response), operational metrics (decision speed, accuracy, coverage), team engagement (whether supply chain professionals see it as partner or threat), and compliance/risk (whether the system reduces rather than increases organizational risk). Early pilots should measure on operational metrics; enterprise implementations should focus on business impact and risk reduction alongside operational metrics.

What's Next?

If you're ready to explore agentic AI for your supply chain, start with a readiness assessment focused on three areas: data readiness (can you access real-time information across systems?), process readiness (can you articulate your decision-making processes and constraints?), and organizational readiness (do your teams see AI as opportunity or threat?).

Use a tool like Runable to start building automated workflows and decision documentation that will inform your agentic AI roadmap. Runable's AI-powered automation capabilities let you model how agents could coordinate across your organization, create decision documentation, and generate the guardrails and response options you'll need.

Then build a narrow pilot with one supply chain problem where you're confident you can achieve 60%+ improvement in decision speed or accuracy. Learn from that pilot. Apply those learnings to the next problem.

The organizations that move thoughtfully and with discipline will build a competitive advantage that's hard to replicate. Those that wait will find themselves playing catch-up in a supply chain world where speed and resilience are everything.

Key Takeaways

- Agentic AI is fundamentally different from copilots because it integrates across systems, respects guardrails, and can coordinate action autonomously within defined boundaries

- Most AI pilots fail because they treat AI as bolt-on tools rather than integrated systems connected to real workflows and decision-making

- Human oversight isn't a limitation—it's the core design principle that makes agentic systems trustworthy and operationalizable at enterprise scale

- Successful implementation requires 18-24 months focusing on narrow pilots first, then disciplined expansion, not rushing to enterprise scale

- Organizations implementing agentic AI effectively will achieve 2-3x faster disruption response and 20-40% better supply chain performance than competitors

Related Articles

- OpenAI Hires OpenClaw Developer Peter Steinberger: The Future of Personal AI Agents [2025]

- OpenClaw AI Ban: Why Tech Giants Fear This Agentic Tool [2025]

- The AI Agent 90/10 Rule: When to Build vs Buy SaaS [2025]

- Japanese Hotel Chain Hit by Ransomware: What You Need to Know [2025]

- Infosys and Anthropic Partner to Build Enterprise AI Agents [2025]

- X Platform Outage: What Happened, Why It Matters, and How to Stay Connected [2025]

![Agentic AI & Supply Chain Foresight: Turning Volatility Into Strategy [2025]](https://tryrunable.com/blog/agentic-ai-supply-chain-foresight-turning-volatility-into-st/image-1-1771429031963.jpg)