Introduction: The Future of Manufacturing Procurement Automation

Manufacturing procurement has traditionally been a labor-intensive process plagued by fragmented communication, manual data entry, and inefficient supplier coordination. Until recently, companies operating in global supply chains had no choice but to employ large procurement teams who spent their days chasing down suppliers via email, phone calls, and WeChat messages—only to manually input the information into enterprise resource planning (ERP) systems. This workflow hasn't fundamentally changed for decades, despite revolutionary advancements in technology.

Enter Didero, a startup that has just raised $30 million in Series A funding to automate this exact problem. Co-led by Chemistry and Headline with participation from Microsoft's venture fund M12, this funding round validates a critical insight: the manufacturing and distribution sectors are ready for AI-powered procurement automation at scale.

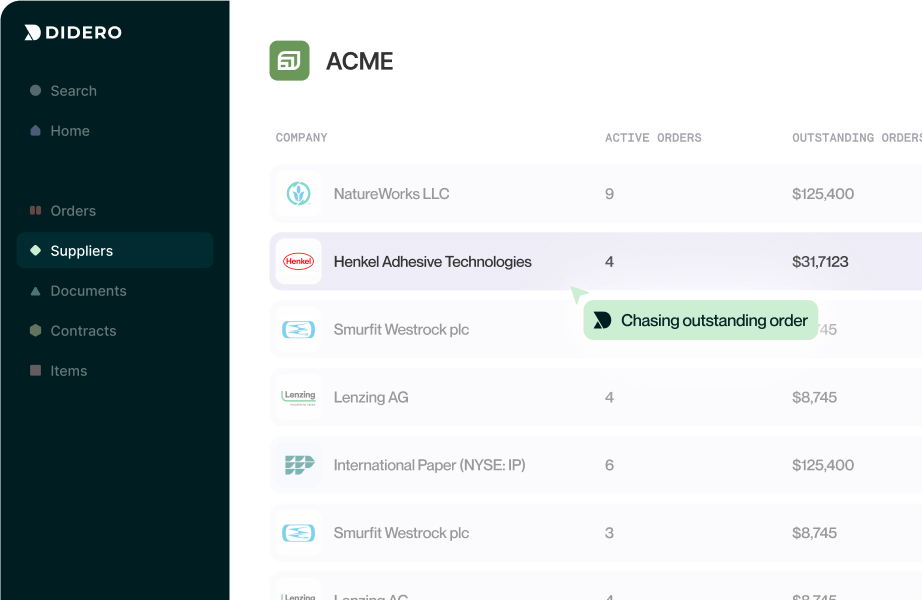

Didero represents a new category of enterprise software—the agentic AI layer. Unlike traditional procurement tools that require users to input data, Didero functions as an autonomous agent that sits atop existing ERP systems. It reads incoming communications from suppliers in their native formats (emails, messaging apps, purchase orders, packing lists) and automatically executes procurement tasks without human intervention. The company's founding team combines deep operational experience with technical expertise: Tim Spencer ran Markai, an e-commerce startup managing thousands of suppliers across dozens of countries; Lorenz Pallhuber spent years at McKinsey advising on procurement transformation; and Tom Petit was the technical co-founder of Landis, a logistics technology company.

This convergence of founders with real-world manufacturing pain points and modern AI capabilities creates a unique opportunity. Global trade, according to Didero's founders, runs fundamentally on natural language communication. Emails, WeChat messages, phone call transcriptions, purchase orders, and packing lists contain all the information needed to manage procurement—yet that information currently requires human interpretation and manual systems updates. By applying generative AI to this problem, Didero claims to eliminate vast portions of this workflow entirely.

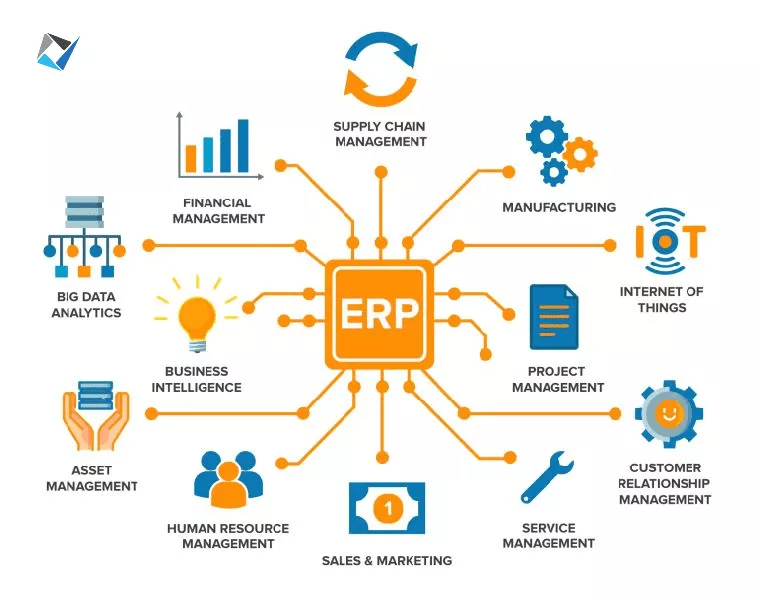

The manufacturing and distribution markets represent a $1.2 trillion addressable market opportunity for procurement automation. Currently, most companies in these sectors use legacy ERP systems (SAP, Oracle, NetSuite) that haven't evolved significantly since the 1990s. The rise of generative AI creates a unique window for new entrants to build better experiences on top of these incumbent systems without requiring companies to rip-and-replace their technology infrastructure.

This comprehensive guide explores Didero's platform, its capabilities, its market positioning, and the broader landscape of procurement automation solutions available to manufacturing companies today.

What Is Didero? Understanding Agentic Procurement Automation

The Concept of Agentic AI in Enterprise Workflows

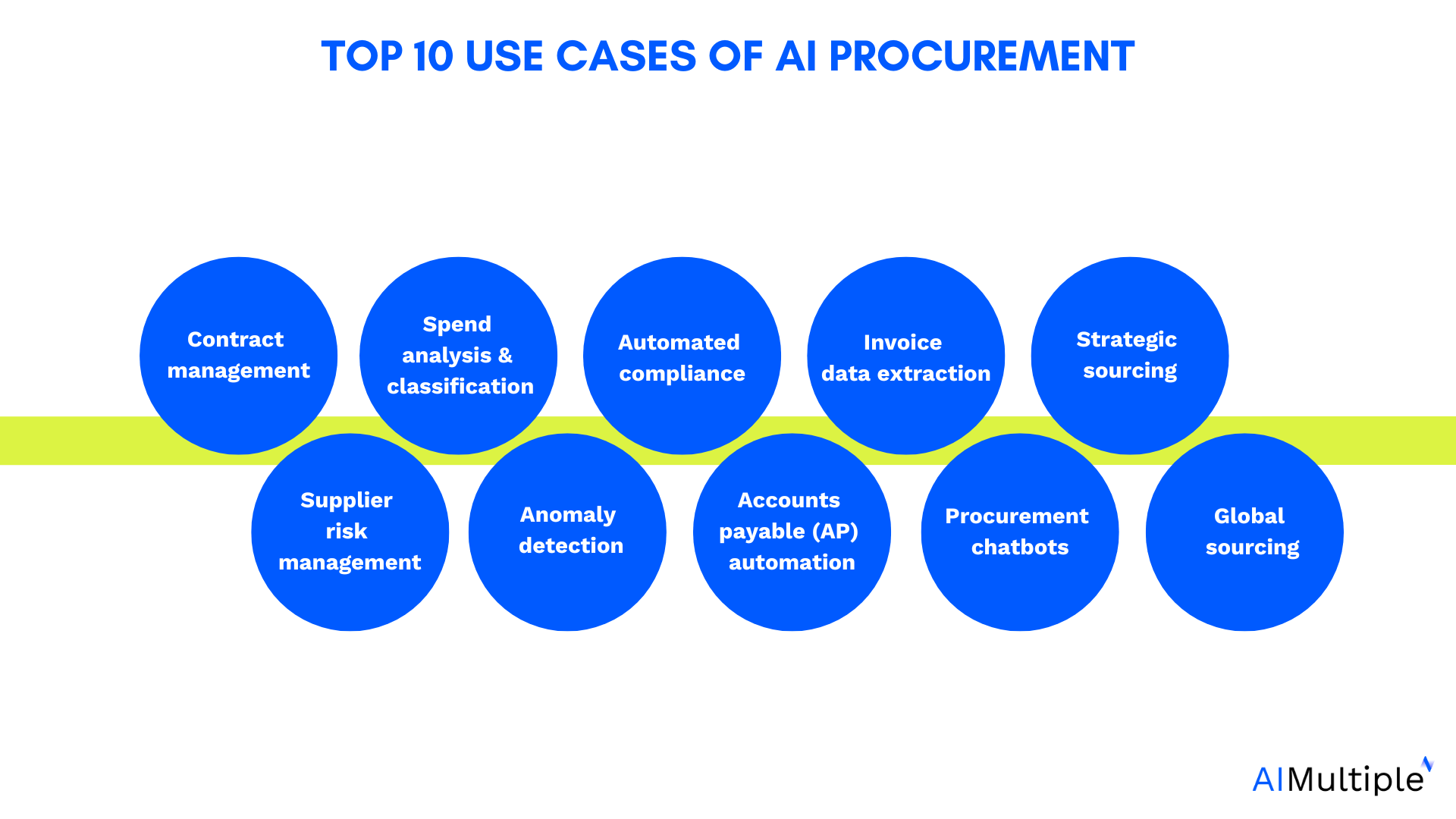

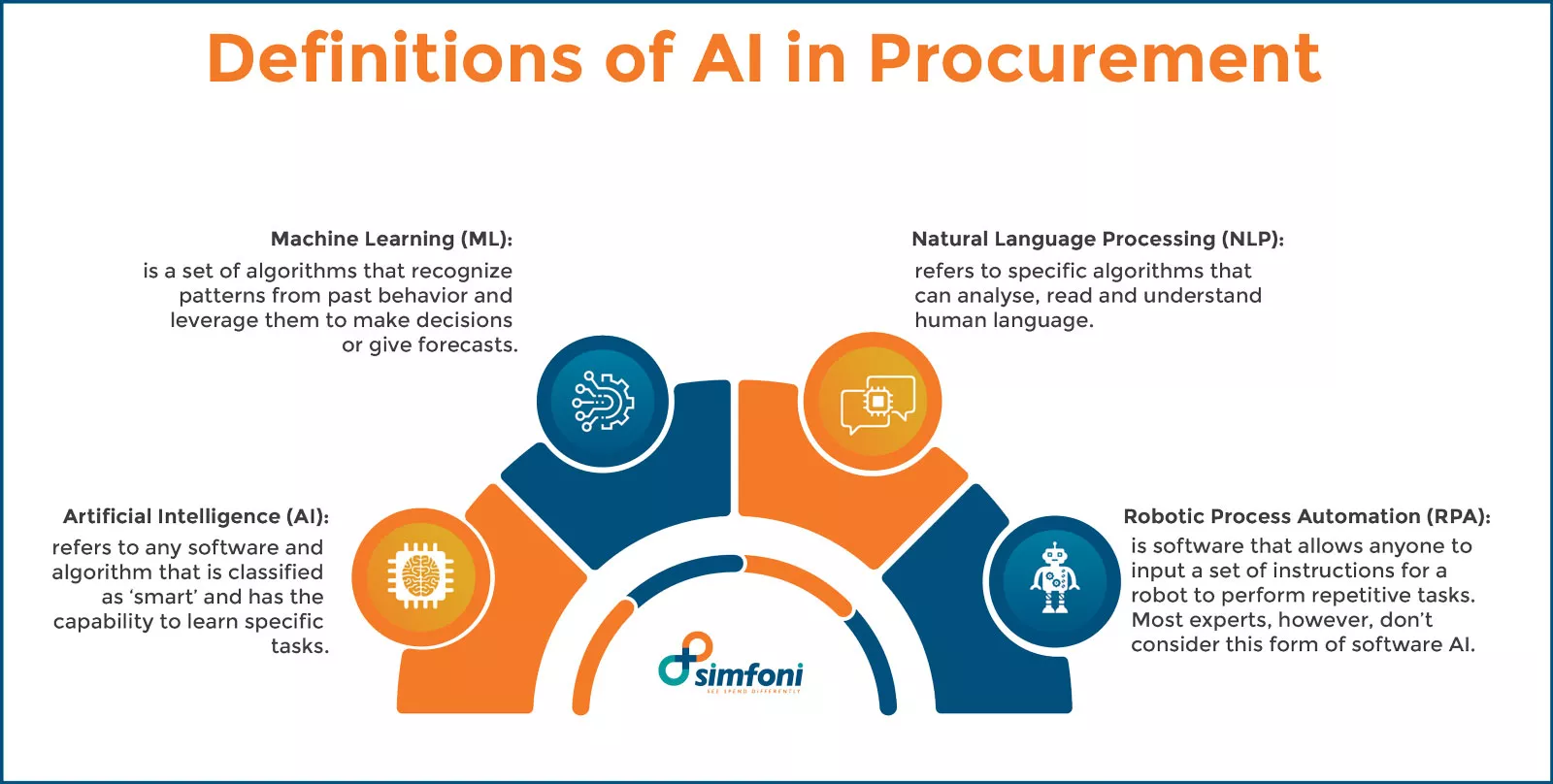

Agentic AI represents a fundamental shift in how enterprise software operates. Rather than serving as a tool that requires human direction for each task, agentic systems autonomously complete workflows by understanding objectives and taking necessary actions. In the context of procurement, Didero's approach differs markedly from traditional procurement software dashboards and systems.

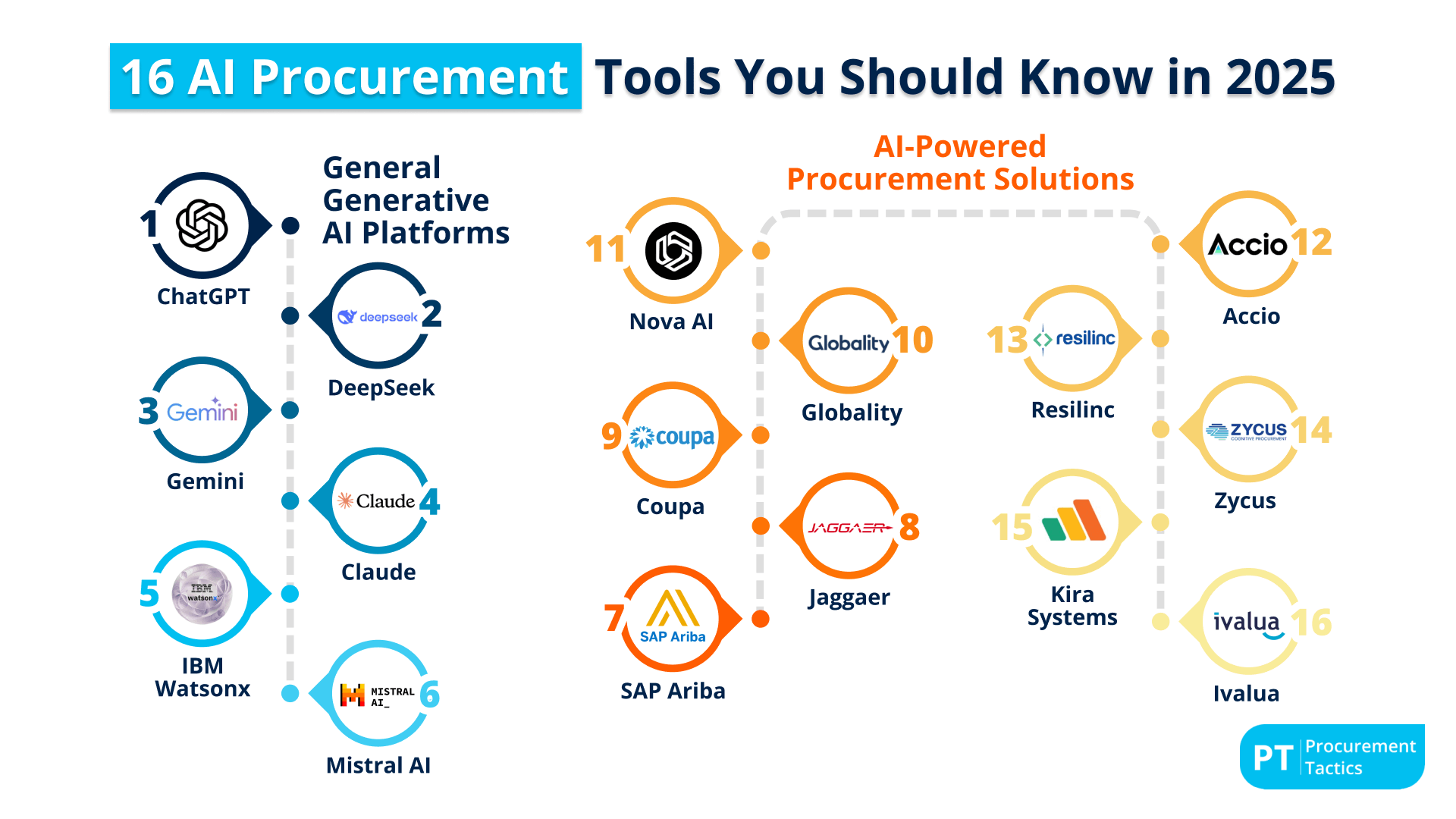

Traditional procurement platforms (like Coupa or Jaggr) function as centralized repositories where users manually input purchase requests, track orders, and manage supplier relationships. These systems require continuous human oversight. A buyer must check their email for supplier quotes, compare options, input the winning bid into the system, generate a purchase order, and then track fulfillment. Each step requires human decision-making and data entry.

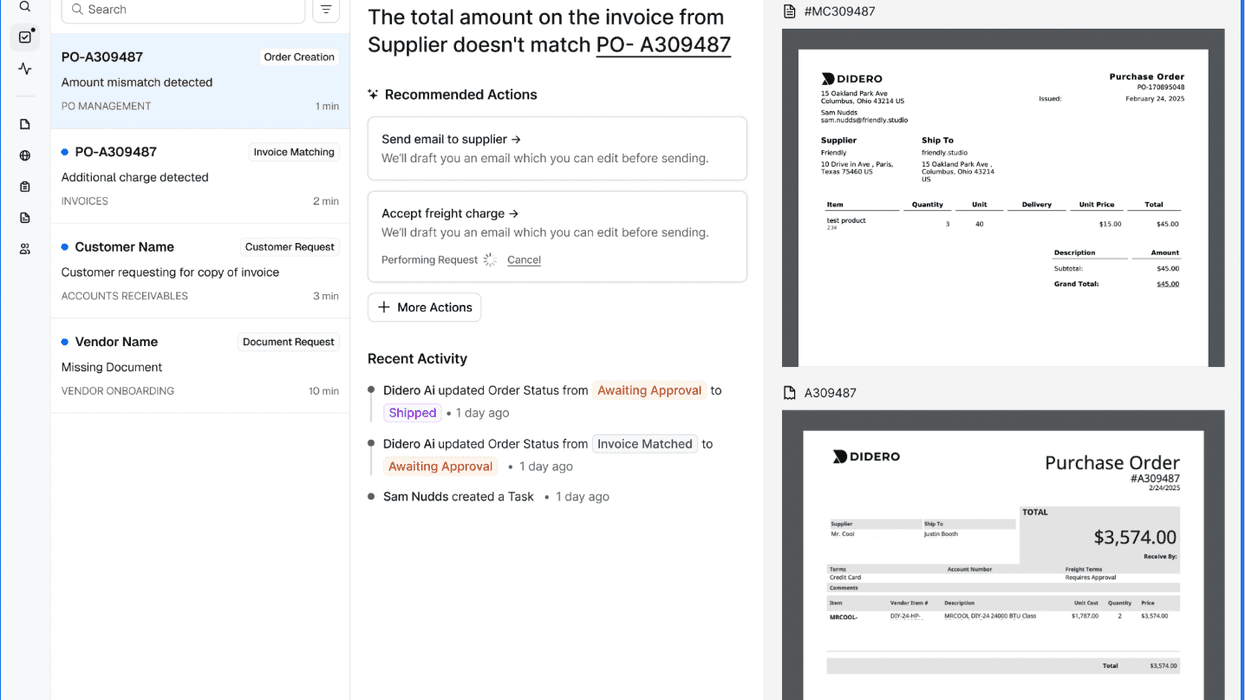

Didero inverts this paradigm. Rather than forcing suppliers and procurement teams to conform to a single platform interface, Didero meets stakeholders where they already communicate. When a supplier sends pricing information via email, Didero's AI reads that email, parses the relevant data, and automatically executes the corresponding action in the company's ERP system. This automation extends from initial quote requests through final payment processing.

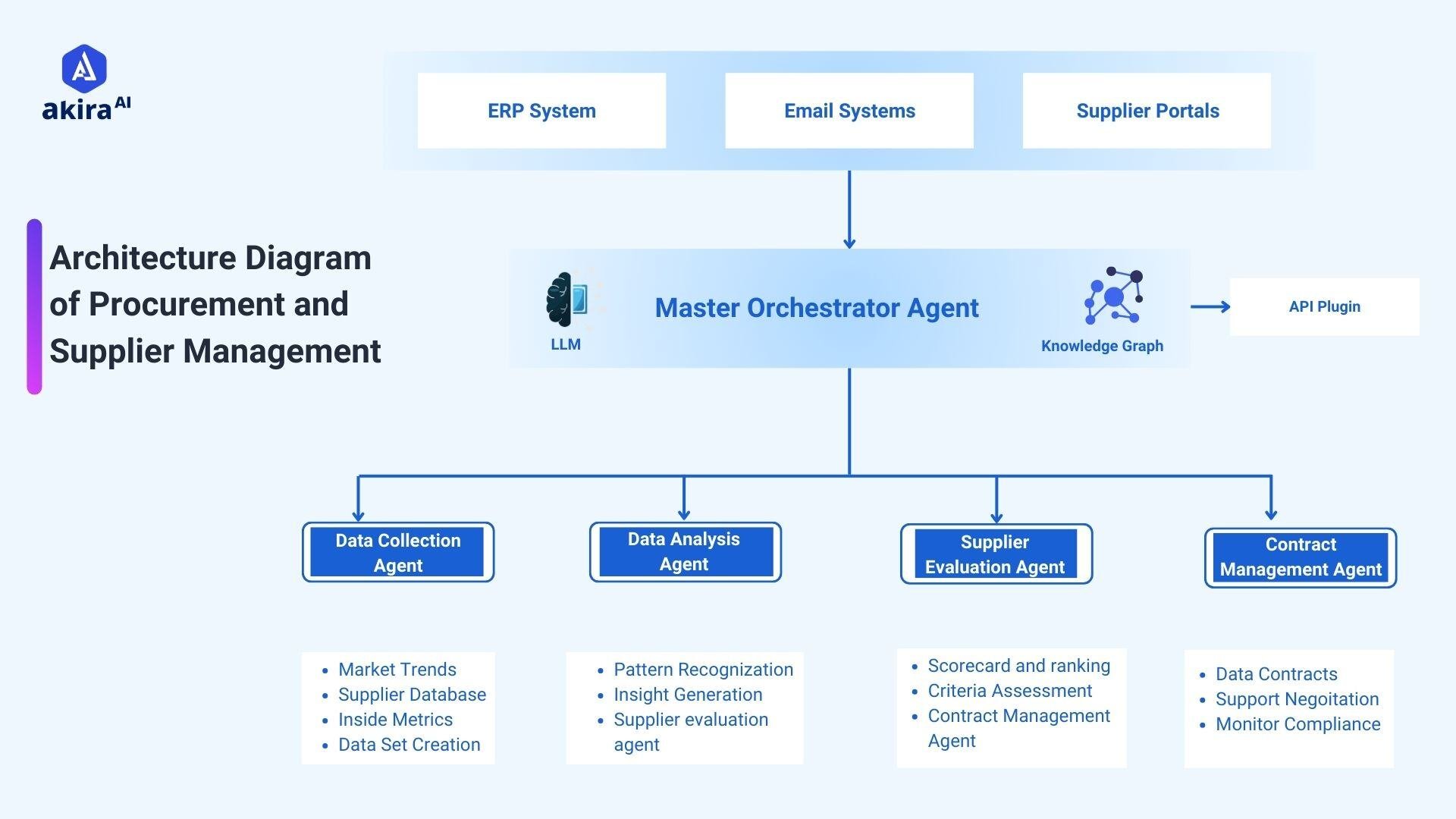

The technical architecture enabling this innovation rests on recent breakthroughs in large language models (LLMs) and vision transformers. These AI systems can now process unstructured communication (emails with PDF attachments, images of handwritten notes, transcribed phone calls) and extract structured business information with sufficient accuracy to trigger automated actions. The key innovation isn't the AI itself—it's the engineering required to reliably connect LLM output to ERP system inputs while maintaining data integrity and audit trails.

How Didero Integrates with Existing ERP Systems

Didero's true advantage lies in its integration approach. Rather than asking customers to migrate to a new system, Didero acts as a middleware layer between communication channels and existing ERP systems. When a manufacturing company already uses SAP, Oracle NetSuite, or another ERP platform, Didero doesn't require abandoning that investment.

The platform ingests data from multiple sources: email inboxes, messaging platforms (WeChat, DingTalk), uploaded documents, and trade portals. Through its AI capabilities, Didero:

- Reads and interprets purchase order confirmations, price quotes, shipping notices, and payment terms

- Extracts structured data from unstructured documents, converting emails and PDFs into actionable information

- Updates ERP systems automatically by creating purchase orders, updating delivery schedules, and recording supplier communications

- Manages exceptions by flagging discrepancies (price variations, delivery delays, quality issues) that require human intervention

- Maintains compliance by creating complete audit trails of all procurement decisions and approvals

This integration strategy explains Didero's appeal to enterprise customers. Large manufacturers already have substantial investments in their ERP systems and have trained their teams around existing workflows. Asking them to migrate to a new, unfamiliar system would face internal resistance and require years of implementation. By working within existing infrastructure while adding AI-powered automation on top, Didero dramatically reduces adoption friction.

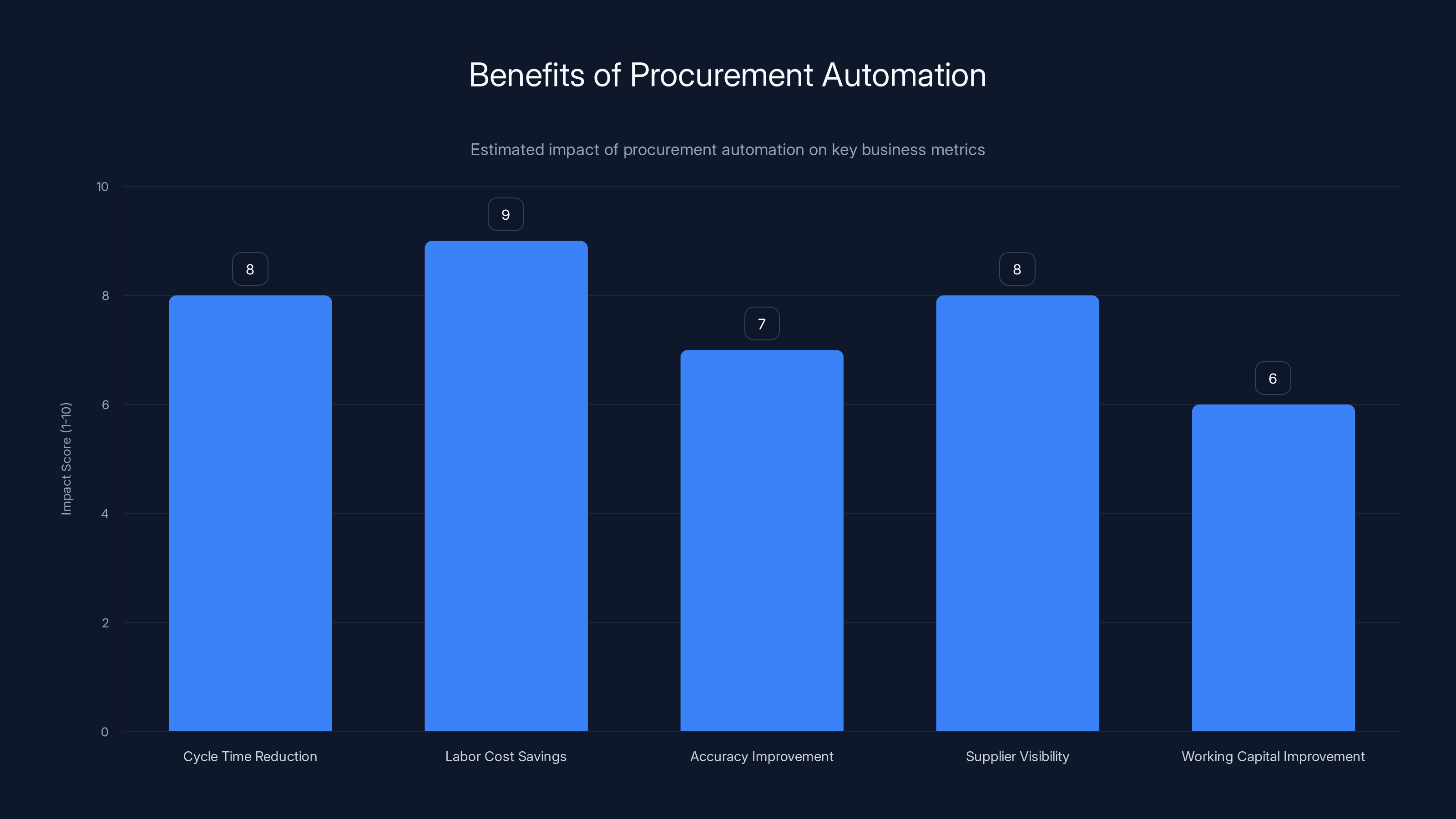

Procurement automation significantly improves labor cost savings and reduces cycle times, with high impact scores across various business metrics. Estimated data.

The Manufacturing Procurement Problem: Why Didero Matters

The Hidden Costs of Manual Procurement Processes

To understand Didero's value proposition, we must first understand the manufacturing procurement challenge it addresses. Manufacturing companies operate within complex supply chains with hundreds or thousands of supplier relationships. A mid-sized manufacturer might source raw materials, components, and packaging from suppliers across Asia, Europe, and North America.

The procurement process for each supplier involves multiple touchpoints: initial quote requests, price negotiations, purchase order issuance, delivery tracking, invoice reconciliation, and payment processing. When Tim Spencer ran Markai during the pandemic, his procurement team managed thousands of suppliers with constant communication flowing through multiple channels. A supplier might send pricing information via email, request revised payment terms through WeChat, confirm delivery dates by phone, and send packing lists via PDF. Each communication required someone to read the message, extract the relevant information, and manually input it into the company's ERP system.

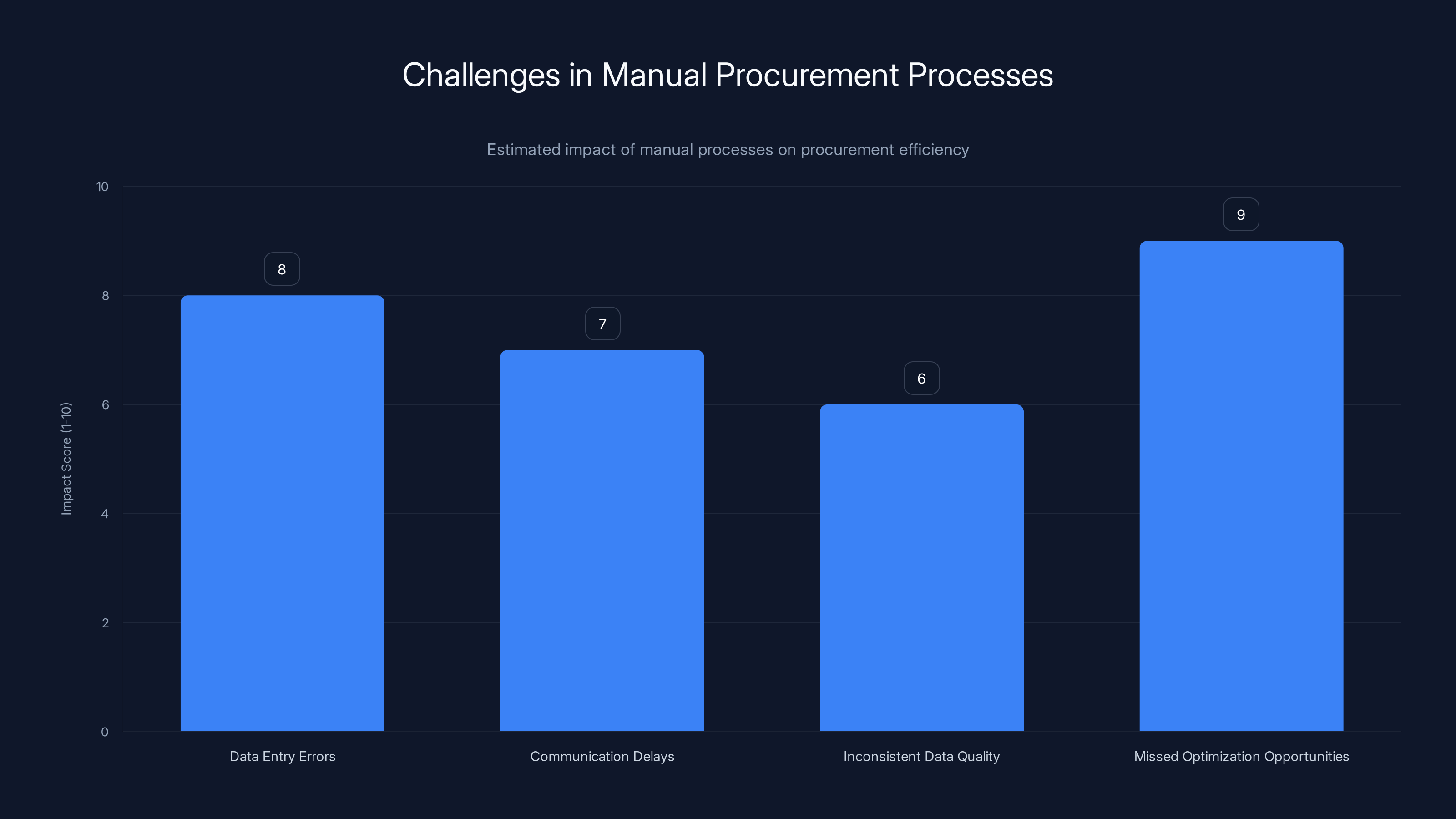

This manual process creates several costly problems:

- Data entry errors: When humans manually input information from emails into ERP systems, errors inevitably occur. A misplaced decimal point in unit pricing can cascade through an entire purchase order.

- Communication delays: Suppliers don't always check the centralized ERP system. They expect responses through the channels they used to initiate contact. This forces procurement teams to constantly monitor multiple communication platforms.

- Inconsistent data quality: Different suppliers use different formats, languages, and documentation standards. Normalizing this information requires significant manual effort.

- Missed opportunities for optimization: When procurement data is fragmented across emails, spreadsheets, and ERP systems, identifying cost savings opportunities becomes nearly impossible. A procurement team might unknowingly pay different prices to different suppliers for identical materials.

- Supplier relationship friction: Suppliers may perceive slow responses or requests to change communication channels as difficult. This damages relationships and can lead to higher pricing or lower priority during supply shortages.

Industry estimates suggest that procurement professionals spend 40-60% of their time on administrative tasks rather than strategic supplier management. In a manufacturer with 50 procurement staff members, this translates to 25-30 full-time employees dedicated purely to data entry and communication coordination—not supplier selection, negotiation, or relationship management.

Why Existing Solutions Fall Short

The manufacturing procurement market already has competing solutions, yet Didero's $30 million funding round suggests the market believes Didero addresses gaps that existing competitors haven't solved effectively.

Traditional procurement platforms like Coupa, Jaggr, and Eprocurement systems focus on streamlining procurement workflows within their own platforms. However, they require extensive training for suppliers, many of whom are small manufacturers unlikely to maintain accounts on multiple systems. These platforms also generate significant change management overhead within customer organizations.

Logistics and supply chain software (companies like project 44, Blue Yonder, and Four Kites) track shipments and provide visibility into supply chain operations. However, they focus on the physical movement of goods rather than the business processes that precede and follow movement.

Specialized procurement services like Cavela and Pietra help brands source manufacturers and negotiate pricing. However, according to Didero's positioning, these services primarily serve small and medium-sized companies and don't handle the complete procurement lifecycle from initial quote through final payment.

General business automation platforms like Zapier or Make (formerly Integromat) can automate some tasks between disconnected systems. However, they lack the AI capability to understand natural language communication or the enterprise integration expertise to reliably handle the complex logic required in procurement workflows.

Didero's innovation combines the AI capability to understand natural language with deep procurement domain expertise and enterprise integration architecture. This convergence creates a solution qualitatively different from existing approaches.

Volume-based and value-based pricing models are estimated to be the most expensive, reflecting the scalability and value capture potential of agentic procurement solutions. Estimated data.

How Didero's Platform Works: Technical Deep Dive

The AI Agent Architecture

Understanding how Didero actually processes procurement information requires examining the underlying AI architecture. The platform operates as a multi-stage pipeline that transforms unstructured communication into structured business actions.

The first stage involves data ingestion. Didero integrates with multiple communication channels, email systems, and file storage platforms. When a procurement professional or supplier sends information through any connected channel, Didero captures it. This might include an email attachment containing a price quotation, a WeChat message with delivery dates, or a PDF uploaded to a supplier portal.

The second stage performs natural language understanding. Didero's AI models read the ingested communication and extract key business information. This requires understanding not just explicit statements ("the price is

Machine learning models trained on historical procurement documents help Didero's AI recognize common patterns in supplier communications. Over time, as the platform processes more documents, these models improve in accuracy. This creates a virtuous cycle where each new customer's procurement data makes the platform smarter for all customers.

The third stage involves business logic application. Extracted information must be evaluated against company-specific rules and policies. For example, a company might have policies requiring competitive bidding when a purchase exceeds $10,000, or automatically rejecting supplier quotes that exceed a certain price threshold. Didero applies these rules to determine what actions should be taken automatically versus flagged for human review.

The fourth stage executes ERP system updates. Once the system has determined the appropriate action, it interfaces with the customer's ERP system through APIs or direct database connections. This might involve creating a new purchase order record, updating a supplier contract, recording a price agreement, or triggering payment processing.

Throughout this process, Didero maintains explainability and audit trails. For regulated industries (pharmaceuticals, automotive, aerospace), proving that procurement decisions followed required procedures is critical. The platform logs every step of the decision-making process, allowing customers to demonstrate compliance and review exactly why the system took specific actions.

Machine Learning Model Training and Continuous Improvement

Didero's competitive advantage deepens as the platform processes more data. Each new customer brings unique supplier communication patterns, document formats, and business rules. Rather than treating each customer as an isolated implementation, Didero can leverage insights from collective customer data to improve core AI models.

Suppose Customer A receives supplier price quotes in a unique format that Didero's model doesn't initially handle well. The implementation team manually processes some examples to create training data. Once Didero's model learns this pattern, every other customer benefits. The company essentially builds a shared procurement knowledge base across its entire customer base.

However, this approach requires careful data handling to maintain customer confidentiality and comply with data protection regulations. Didero likely uses federated learning or differential privacy techniques to improve models without exposing individual customer data to other users.

The continuous improvement process extends beyond AI models to domain knowledge. Procurement practices vary significantly by industry. Automotive suppliers negotiate contracts differently than electronics manufacturers. Food and beverage companies have different compliance requirements than pharmaceutical manufacturers. As Didero accumulates customers across industries, the platform can develop specialized models for each vertical, further improving accuracy and reliability.

Didero's Market Positioning and Competitive Differentiation

Target Customers and Ideal Use Cases

Didero specifically targets manufacturers and distributors who source raw materials and components for production or resale. The ideal Didero customer:

- Operates a global supply chain with suppliers in multiple countries and time zones

- Uses an incumbent ERP system (SAP, Oracle NetSuite, IFS) with significant customization and training investment

- Manages substantial supplier relationships (hundreds to thousands of active suppliers)

- Experiences high procurement volume where automation creates meaningful time savings

- Values supplier relationship management and wants to reduce friction from requesting suppliers to change systems

- Requires audit trails and compliance documentation for regulated industries

Footprint, the company Didero highlighted as a customer in Series A announcements, fits this profile well. As a sustainable packaging manufacturer, Footprint sources raw materials (plant-based fibers, natural additives) from multiple suppliers, manages manufacturing operations across multiple facilities, and must maintain detailed supplier quality and compliance records. Automating their procurement workflow directly impacts manufacturing efficiency and cost management.

Conversely, companies that might not be ideal Didero customers include startups with minimal procurement activity, companies using modern cloud-based procurement platforms (which have better native APIs and user adoption), or manufacturers with deep supplier relationships requiring constant human negotiation and customization.

Competitive Differentiation from Existing Procurement Solutions

Didero positions itself as distinct from several categories of existing procurement software:

Versus traditional procurement platforms (Coupa, Jaggr, Eprocurement): Didero's advantage centers on reducing supplier and user training requirements. Traditional platforms require extensive change management—training thousands of people to use a new system, convincing suppliers to adopt the platform, reengineering workflows around the platform's capabilities. Didero adds value on top of existing systems without requiring fundamental change to established workflows. This dramatically reduces implementation friction and time-to-value.

Versus niche supply chain solutions (project 44, Blue Yonder): These companies excel at visibility and planning across physical supply chains. Didero focuses earlier in the process—automating the business transactions that determine what gets ordered, from which supplier, at what price. The two types of solutions complement each other; a manufacturer might use both Blue Yonder for supply chain planning and Didero for procurement automation.

Versus general business automation tools (Zapier, Make): General-purpose automation platforms lack the domain expertise and deep understanding of manufacturing procurement to handle complex decision logic. When a supplier sends an email with pricing contingent on minimum order quantities that conflict with the company's available storage space, a general automation tool can't recognize this implicit conflict. Didero's AI and procurement-specific logic can flag this issue for human review or recommend optimal ordering quantities based on storage constraints and discount thresholds.

Didero's core differentiation rests on the insight that procurement is fundamentally a communication problem, not a software usability problem. By meeting stakeholders in their preferred communication channels and using AI to transform natural language communication into structured business actions, Didero solves the real problem manufacturers face rather than forcing them to adopt new communication platforms.

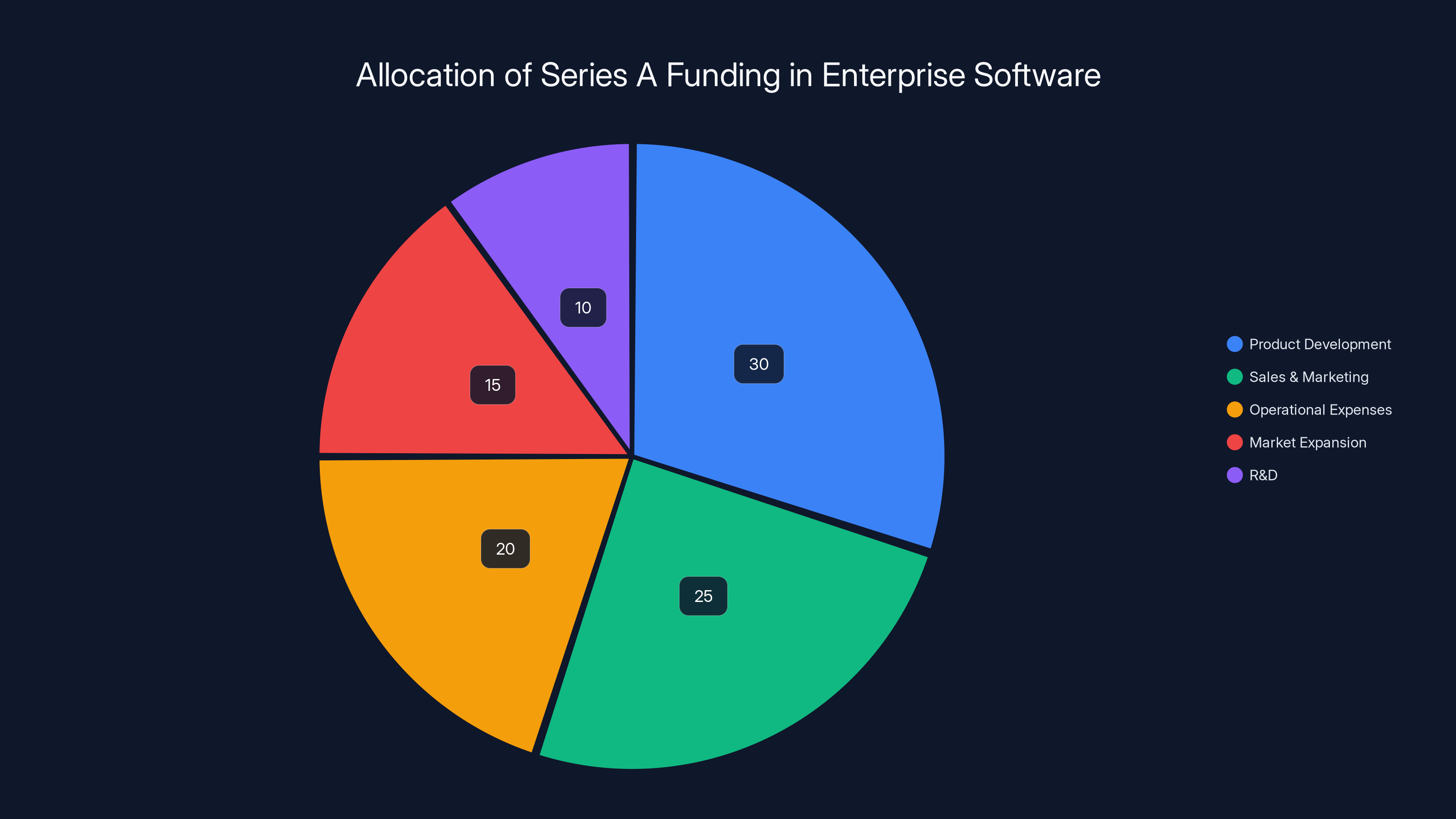

Estimated data shows typical Series A funding allocation in enterprise software, with the largest portion dedicated to product development and sales & marketing.

Didero's Series A Funding: Market Validation and Growth Implications

The $30 Million Funding Round and Strategic Investors

Didero's ability to raise $30 million in Series A funding from Chemistry, Headline, and Microsoft's M12 venture fund signals strong market validation. This funding round occurs during a period when venture capital investment in enterprise software has become more selective, with investors focusing on companies solving clear problems with scalable solutions.

The participation of Chemistry (led by founders who previously built successful manufacturing-focused companies) and Headline (investors in deep tech and infrastructure companies) indicates investor confidence in both the market size and Didero's ability to execute. Microsoft's M12 participation carries additional significance—it suggests potential integration opportunities with Microsoft's enterprise ecosystem, including Dynamics 365 (Microsoft's ERP system) and broader AI integration.

For context, $30 million Series A rounds in enterprise software typically target companies with:

- $1-5 million ARR (annual recurring revenue) at funding time

- Strong unit economics showing clear ROI for customers

- Expanding customer base with positive retention metrics

- Technical defensibility through patents, data advantages, or specialized expertise

The timing of Didero's raise (early 2026) coincides with broader market recognition that agentic AI represents a significant opportunity for enterprise automation. Companies like OpenAI, Anthropic, and Mistral have released increasingly capable AI models that can reliably understand complex business logic and execute autonomous actions. The manufacturing sector, with its fragmented communication patterns and significant automation needs, represents an ideal proving ground for agentic AI applications.

Use of Proceeds and Expansion Plans

Series A funding in enterprise software typically allocates capital across several priorities:

- Sales and marketing (40-50% of funding): Building sales teams to land enterprise customers and marketing to establish brand awareness

- Product development (25-35% of funding): Engineering resources to expand platform capabilities and improve core functionality

- Operations and infrastructure (15-25% of funding): Finance, legal, human resources, and cloud infrastructure costs

For Didero specifically, we can infer likely allocation priorities based on the company's stage:

Horizontal expansion: While Didero initially focuses on manufacturing and distribution, the same agentic procurement automation logic could extend to other procurement-heavy industries (healthcare systems sourcing medical supplies, hospitality groups managing multi-location supplier relationships, construction companies coordinating sub-contractors). Series A funding likely supports building solutions for adjacent verticals.

Deeper ERP integrations: Didero currently integrates with major ERP systems, but deeper integrations create higher switching costs and stickiness. Funding likely supports building native integrations and pre-built connectors for popular ERP platforms, reducing implementation time for new customers.

International expansion: Global manufacturing procurement often involves suppliers and buyers in different regions. Building localized AI models for different languages and procurement traditions, plus establishing local sales presence in key manufacturing regions (Southeast Asia, Europe, Latin America), represents significant growth opportunity.

AI model improvements: Continuous improvement to core AI models directly impacts customer experience and competitive advantage. Funding supports hiring machine learning researchers and building internal benchmark datasets to improve model accuracy.

Key Features and Capabilities of Didero's Platform

Automated Supplier Communication Processing

At its core, Didero handles supplier communications automatically. Rather than procurement professionals reading emails and manually checking quote details, Didero monitors incoming communications and extracts relevant information.

When a supplier sends a price quotation via email, Didero's AI recognizes this is a quote (distinguishing it from other supplier communications), extracts the unit price, minimum order quantities, volume discounts, validity dates, and other relevant terms. The system then evaluates this quote against company policies and historical pricing data.

If the quote is within acceptable parameters, Didero can automatically create a supplier quote record in the ERP system and notify relevant stakeholders. If the quote is unusual (significantly higher than historical prices, or lower in ways that suggest potential quality issues), the system flags it for human review.

The platform extends this logic to other supplier communications: delivery confirmations automatically update order fulfillment tracking; invoices are matched against purchase orders and automatically approved if they match; payment notifications trigger cash management processes.

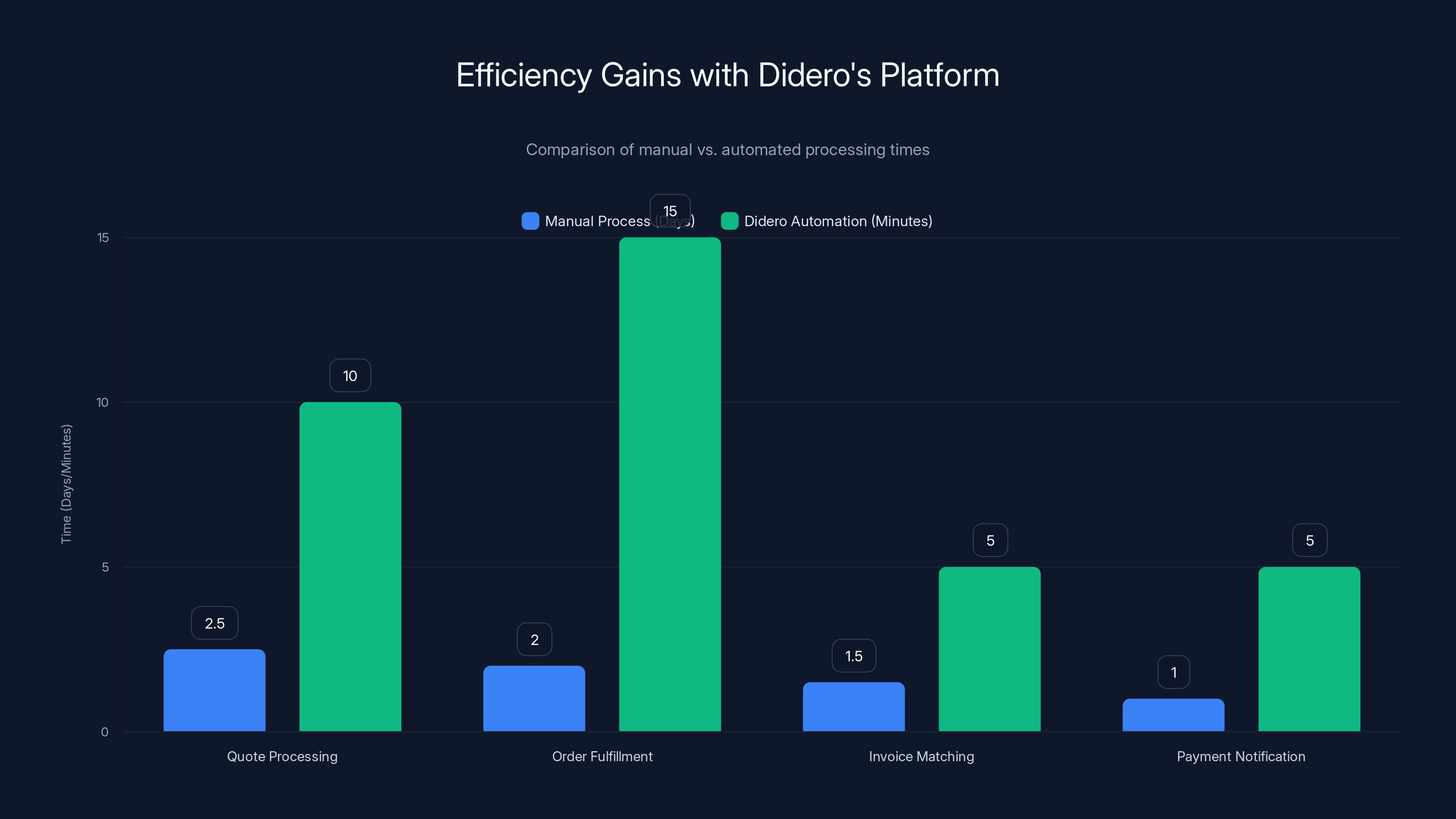

This automation eliminates rekeying data, reduces errors, and dramatically speeds cycle times. Where a manual process might take 2-3 days from quote receipt to PO issuance, Didero can complete it in minutes.

Intelligent Document Processing and Data Extraction

Supplier communications often include attachments: price lists as Excel spreadsheets, quality certifications as PDFs, product specifications as images, contracts as scanned documents. Didero uses advanced computer vision and document understanding models to extract information from these varied formats.

When a supplier sends a price list as a PDF, Didero's vision models recognize tables, read cell contents, and convert the information into structured data. When a supplier sends product specifications as a scanned image, the system performs optical character recognition and semantic understanding to extract specifications.

This capability handles real-world messy documents: price lists with watermarks, images taken at angles on mobile phones, documents in multiple languages. The system must be robust enough to handle consistent accuracy across diverse scenarios.

Importantly, Didero maintains linkages between extracted data and source documents. If a procurement professional questions whether the system interpreted a price list correctly, they can review the original document alongside the extracted data. This transparency is essential for gaining customer trust and maintaining audit trails.

Exception Handling and Escalation Logic

While Didero aims to automate procurement workflows, not all scenarios warrant automatic execution. The platform includes sophisticated exception handling logic that escalates decision-making to appropriate humans when necessary.

Scenarios requiring human review might include:

- Policy violations: A supplier quote comes from an unapproved vendor

- Data inconsistencies: Multiple suppliers provide conflicting information about the same product

- Approval thresholds: The purchase quantity exceeds limits requiring senior management approval

- Contract terms: A new supplier proposes terms inconsistent with company standards

- Quality concerns: A supplier's delivery includes quality metrics below acceptable thresholds

When exceptions occur, Didero routes them to appropriate stakeholders based on the exception type and organizational structure. A price variance from a regular supplier might go to the procurement manager, while a new supplier introduction goes to quality assurance. The system provides context to help reviewers make quick decisions: historical pricing data, supplier performance metrics, contract terms.

This two-tier approach (automatic processing for standard scenarios, human review for exceptions) balances efficiency gains with risk management. As the system learns from human decisions on exceptions, it gradually expands its autonomous decision-making scope.

Supplier Relationship Management and Performance Tracking

Beyond individual transaction automation, Didero aggregates supplier data to provide insights into supplier relationships and performance. The platform tracks:

- Pricing trends: How supplier pricing has evolved over time; whether specific suppliers consistently offer better terms

- Quality metrics: Defect rates, on-time delivery percentages, return rates

- Responsiveness: How quickly suppliers respond to communications; whether they meet requested lead times

- Compliance: Whether suppliers maintain required certifications and meet regulatory requirements

These insights enable procurement managers to make strategic supplier decisions. If one supplier consistently delivers quality products on-time while a competing supplier misses deadlines, the system makes this relationship dynamic visible and can recommend prioritizing orders to the more reliable supplier.

Supplier performance data also feeds back into automatic decision-making. If a supplier's quality metrics decline, the system might increase scrutiny on their shipments or automatically route new purchase orders to alternative suppliers until quality improves.

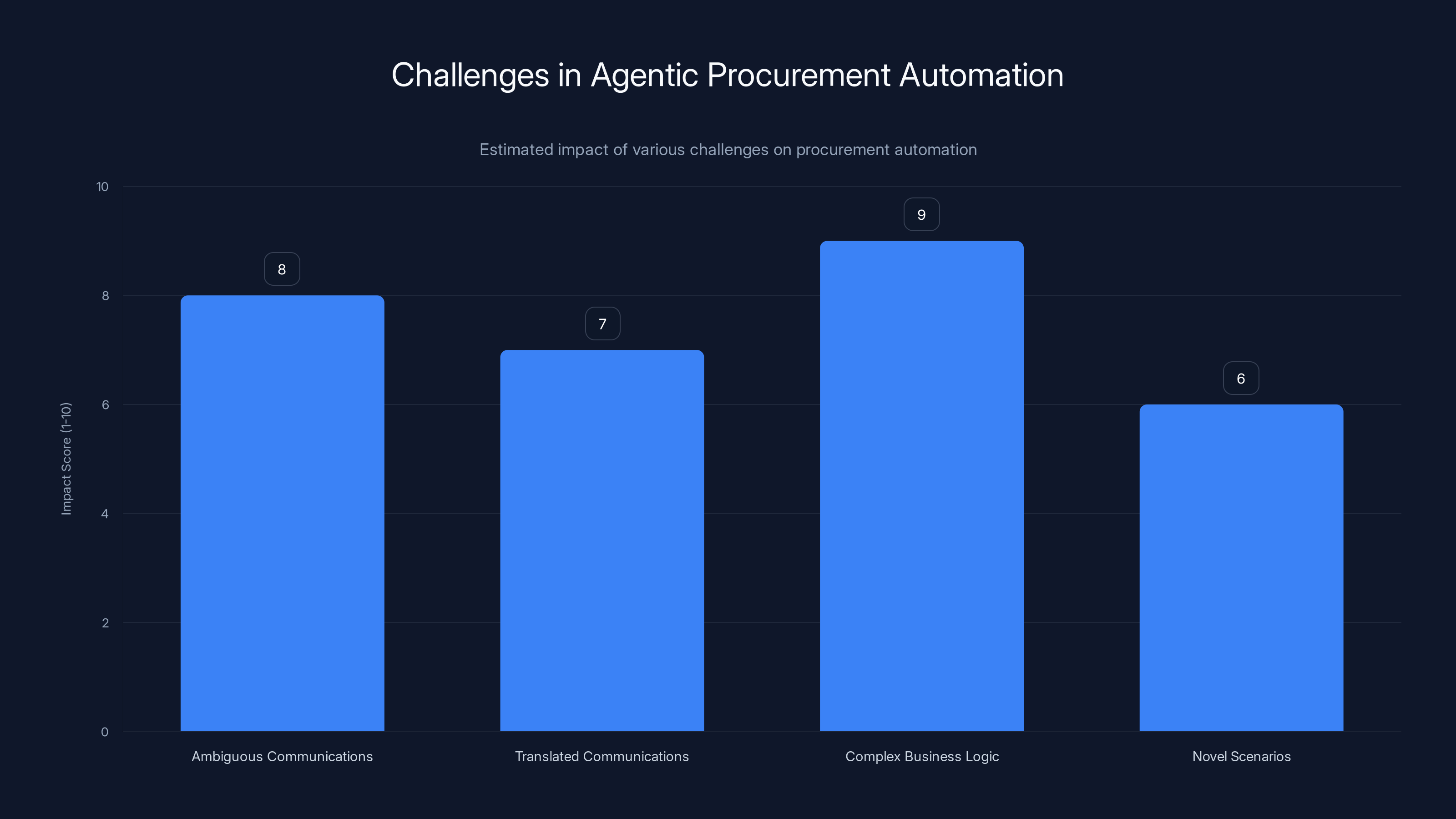

The chart estimates the impact of different challenges on procurement automation, highlighting complex business logic as the most significant hurdle. Estimated data.

Use Cases: How Manufacturers Benefit from Didero

Global Manufacturing with Multi-Supplier Networks

Consider a midsize electronics manufacturer producing consumer IoT devices. The company sources components from 500+ suppliers across China, Taiwan, Vietnam, South Korea, Germany, and the United States. Components include semiconductor chips, plastic housings, batteries, circuit boards, and assembly labor.

Without automation, the procurement process involves constant back-and-forth communication. When design requirements change, procurement must reach out to multiple suppliers to get revised pricing on new component specifications. Suppliers respond via email, WeChat (common in Asia), and occasionally phone calls. Once pricing is gathered, the procurement team must consolidate information, compare options, and recommend sourcing approaches.

With Didero, when new component specifications are loaded into the system, the platform automatically sends requests to relevant suppliers through their preferred communication channels. As suppliers respond with updated pricing, Didero automatically processes their responses, extracts pricing and terms, and populates the ERP system. Procurement professionals see a consolidated view showing all supplier quotes automatically organized by cost, delivery time, and quality metrics.

Where the manual process might require weeks, Didero enables completion in days. The procurement team focuses on strategy (which suppliers offer the best value proposition? should we diversify sourcing for critical components?) rather than administrative coordination.

Just-In-Time Manufacturing with Tight Delivery Coordination

Just-in-time (JIT) manufacturing systems depend on precise coordination between suppliers and manufacturers. Parts must arrive exactly when needed—not early (which creates storage costs) or late (which stops production lines). Coordinating JIT procurement across multiple suppliers, especially internationally, requires constant communication and rapid adjustments.

A manufacturer using JIT might need to adjust order quantities based on real-time production schedules or supplier availability. Without automation, making these adjustments requires reaching out to suppliers, confirming new delivery dates, updating internal systems, and communicating changes back to production teams.

Didero automates this coordination. When production schedules change, the system automatically calculates adjusted procurement needs, identifies which suppliers should fulfill revised orders, and sends updated requests. As suppliers confirm revised delivery dates, Didero updates the manufacturer's production scheduling system, ensuring production teams have current information.

This automation dramatically reduces the manual overhead of JIT coordination and improves reliability. Production teams can confidently base plans on real-time supplier confirmation rather than estimates. Suppliers can see real-time demand signals, improving their own planning.

Seasonal and Peak-Period Procurement

Many manufacturers experience seasonal demand variations. A toy manufacturer, for example, experiences massive demand surges before holiday seasons. A beverage manufacturer experiences peak demand in summer months. These demand cycles require rapidly scaling procurement and supplier coordination.

During peak periods, procurement teams become overwhelmed managing increased volume. Orders must be placed faster, suppliers require more frequent coordination, and the risk of manual errors increases. Some companies hire temporary procurement staff to handle peak seasons.

Didero's automation becomes especially valuable during these periods. The platform can handle increased order volume without proportional increases in manual effort. As orders scale up, the system automatically processes supplier communications, updates inventory systems, and coordinates fulfillment without requiring additional personnel.

Complex Multi-Item Orders and Bill of Materials

Some manufacturing products require coordinating purchases across dozens or hundreds of components and subassemblies. An automotive manufacturer, for example, might source 5,000+ unique parts from 200+ suppliers for a single vehicle model. Managing bill-of-materials across this complexity is incredibly difficult manually.

When a design change affects multiple components, procurement must identify all affected parts, reach out to relevant suppliers, obtain new pricing, update cost models, and ensure all components remain synchronized. This cross-component coordination is a prime source of errors.

Didero handles this complexity by maintaining relationships between bill-of-materials items and supplier quotes. When a design change cascades through multiple components, the system automatically identifies all suppliers that need to be contacted, sends requests to all relevant suppliers simultaneously, and tracks responses ensuring consistency across all components.

Industry Context: The State of Manufacturing Procurement in 2025

Digital Transformation in Manufacturing

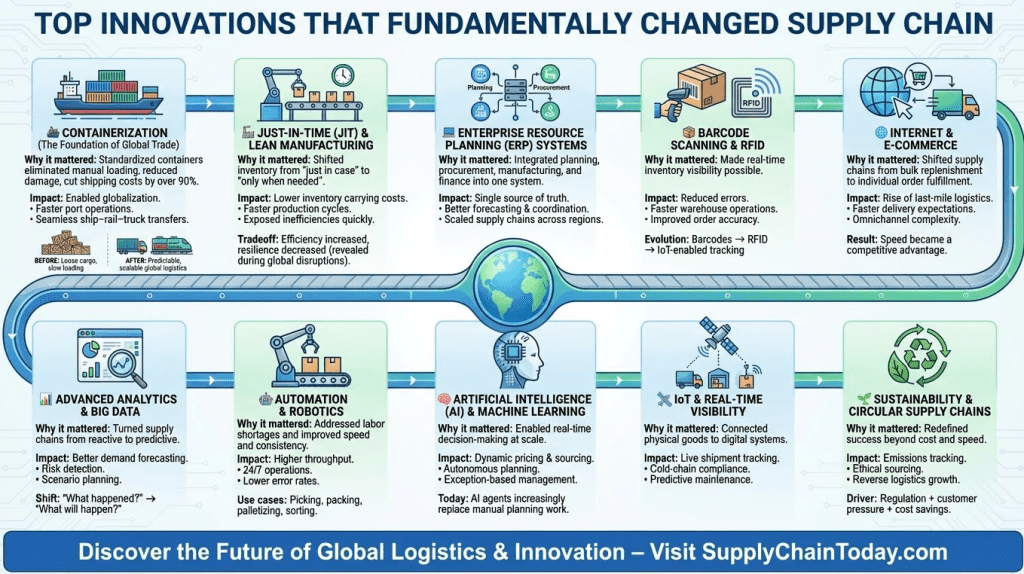

The manufacturing sector is in the midst of significant digital transformation, often referred to as Industry 4.0 or the Industrial Internet of Things (IIoT). This transformation includes:

- Production automation through robotics and CNC machines

- Real-time monitoring of equipment and production lines through sensors

- Supply chain visibility through IoT tracking of shipments and inventory

- Predictive maintenance using machine learning to prevent equipment failures

- AI-assisted quality control through computer vision inspection systems

Procurement automation represents a natural extension of this broader digital transformation. Companies already investing in digital infrastructure find procurement automation aligns with existing modernization initiatives.

The AI Readiness of Manufacturing Organizations

Manufacturing companies vary significantly in their AI readiness. Large manufacturers (companies with

Didero's strength in this landscape is that it doesn't require customers to be AI-sophisticated. The platform handles all AI complexity internally; customers simply benefit from the results. A procurement professional using Didero doesn't need to understand how generative AI works—they just see purchase orders being automatically processed with greater speed and accuracy.

This abstraction of AI complexity is essential for adoption. Companies won't adopt AI procurement automation if implementation requires hiring data scientists or completely retraining procurement teams. Didero's approach of adding automation on top of existing workflows makes AI adoption feel natural and low-risk.

ERP System Modernization Trends

Most manufacturing companies use ERP systems that are 10-20+ years old. SAP, Oracle, and IFS command significant market share in the manufacturing vertical. These systems contain decades of customizations and process logic reflecting each company's unique operations.

Replacing legacy ERP systems is extremely difficult and expensive. A typical ERP replacement project costs millions of dollars, requires 12-24+ months of implementation, and carries significant risk of disruption. Most manufacturing companies have decided to keep their existing ERP systems for the foreseeable future.

This creates the perfect opportunity for middleware solutions like Didero. Rather than forcing companies to migrate ERP systems, Didero works within existing infrastructure, adding modern AI capabilities without disruption. This approach aligns with observed trends in enterprise technology where middleware and integration layers increasingly add value rather than core applications.

Manual procurement processes significantly impact efficiency, with missed optimization opportunities scoring highest. (Estimated data)

Competitive Landscape: Who Else Is Playing in Manufacturing Procurement?

Direct Competitors and How Didero Differs

Didero operates in an increasingly crowded space as the potential for procurement automation attracts new entrants and existing companies expand into this area.

Cavela helps brands source manufacturers and negotiate pricing, primarily serving small and medium-sized companies. However, Cavela focuses on the supplier selection and initial negotiation phase rather than the full procurement lifecycle. Didero covers broader scope—from initial quote through final payment—and emphasizes integration with existing systems rather than requiring brands to work primarily through Cavela's platform.

Pietra similarly specializes in connecting brands with manufacturers, primarily for apparel and accessories. The platform's value centers on providing access to pre-vetted manufacturers and streamlined communication channels. However, like Cavela, Pietra focuses on supplier selection rather than ongoing procurement automation.

Korob (now part of Wizer) provided procurement solutions focused on supplier discovery and price comparison. However, Korob's acquisition and integration into Wizer's platform suggests this approach alone isn't sufficient for sustainable growth.

Oro Labs (mentioned in TechCrunch coverage) uses AI to streamline corporate purchasing but focuses more on expense management and procurement analytics rather than the full automation pipeline Didero offers.

None of these competitors fully replicate Didero's specific approach: an agentic AI layer that integrates with existing ERP systems while automating communication processing across multiple channels.

Adjacency Competitors from Different Markets

Beyond direct procurement competitors, several adjacent categories of software could potentially expand into procurement automation:

Traditional procurement platforms (Coupa, Jaggr, Ariba): These established players have strong customer relationships and significant resources. Coupa, for example, serves major multinational corporations. These platforms could develop agentic AI capabilities to compete with Didero. However, their approach of requiring centralized platforms puts them at a disadvantage for global supply chains where suppliers resist adopting new systems.

Supply chain visibility platforms (Blue Yonder, project 44): These companies focus on monitoring physical movement of goods but could expand into the business process automation preceding shipments. Their existing customer relationships and supply chain expertise provide a foundation for competing in procurement automation.

ERP vendors (SAP, Oracle, Microsoft): These companies have the deepest integration with manufacturing customers' core systems. They could develop competing agentic AI capabilities. However, the pace of innovation at large enterprise software companies is generally slow, giving startups like Didero a 2-3 year window to establish market position before incumbents respond seriously.

Business process automation platforms (UiPath, Blue Prism, Automation Anywhere): These companies specialize in automating business processes but typically through rules-based approaches rather than AI understanding of natural language. They could incorporate generative AI into their platforms but would need significant R&D investments to develop manufacturing procurement expertise.

Market Consolidation Possibilities

The procurement automation space may eventually see consolidation, with larger players acquiring smaller competitors. Possible acquisition targets for Didero include:

- By ERP vendors: SAP, Oracle, or Microsoft might acquire Didero to add AI procurement automation to their platforms

- By supply chain software leaders: Blue Yonder or other supply chain specialists might acquire Didero to expand their capabilities

- By consulting firms: Major consulting firms (McKinsey, Boston Consulting Group) might acquire Didero to build software-enabled procurement services offerings

- By private equity: Growth equity firms might acquire Didero, help the company grow to scale, and then exit through a strategic sale

These acquisition possibilities represent important context for customers evaluating Didero. While the company has strong investor backing and clear product-market fit signals, procurement is strategic enough that customers should consider long-term vendor viability and roadmap alignment.

Pricing, Economics, and Implementation

Likely Pricing Models for Agentic Procurement Solutions

While Didero hasn't publicly released detailed pricing information, industry context suggests likely models for agentic procurement platforms:

Volume-based pricing: Many enterprise procurement solutions charge based on transaction volume (purchase orders processed, invoices handled, or suppliers managed). For Didero, pricing might scale based on monthly purchase order volume or annual procurement spend. A manufacturer processing 1,000 POs monthly might pay

Seat/user-based pricing: Some solutions charge per procurement user who accesses the platform, typically $500-2,000 per seat annually. However, this model creates wrong incentives for agentic platforms—companies should be incentivized to use less human time, not more.

Hybrid models: Combining transaction volume with base platform fees creates alignment. A

Value-based pricing: Procurement automation directly impacts company bottom lines through lower supplier costs, reduced labor costs, and improved working capital. Sophisticated vendors might charge 5-10% of identified cost savings, allowing customers to achieve positive ROI while vendors capture portion of their value creation.

For customers, Didero's economics become compelling when considering total cost of procurement. A manufacturer with 50 procurement staff members might reduce headcount to 30-35 through automation, saving

Implementation Timeline and Complexity

Implementing procurement automation requires more planning than typical SaaS deployments. Critical considerations include:

ERP system integration (2-8 weeks): Integrating Didero with existing ERP systems requires technical implementation. If the ERP system has modern APIs, integration can proceed relatively quickly. If it's a legacy system with limited API capability, integration may require custom development or workarounds.

Procurement process documentation (2-4 weeks): The implementation team must document current procurement workflows, identify which steps can be automated, and configure Didero rules for exception handling and policy enforcement. This step often reveals process inconsistencies that must be resolved.

Communication channel setup (1-2 weeks): Integrating with email systems, messaging platforms, and supplier portals must occur. This includes configuring authentication, ensuring data privacy compliance, and testing information flow.

Pilot phase (2-8 weeks): Rather than immediately automating all procurement, successful implementations usually start with a pilot category (e.g., one type of supplier or one product line). This allows teams to verify the system works correctly and build organizational confidence before broader rollout.

Full-scale rollout (2-4 weeks): Once the pilot succeeds, the implementation team gradually expands automation to additional suppliers and procurement categories. This phased approach reduces risk and allows for adjustments based on pilot learnings.

Total implementation timeline typically ranges from 8-16 weeks for midsize manufacturers, with larger organizations potentially requiring 4-6 months due to more complex ERP systems and supplier networks.

Return on Investment Calculation

Procurement automation generates ROI across multiple dimensions:

Labor cost savings: If procurement automation reduces required procurement staff by 30-40%, a company with 50 procurement professionals might reduce headcount to 30-35. At average procurement salaries of

Working capital improvement: Automated procurement accelerates order-to-payment cycles. Reducing cycle time by 20% releases working capital currently tied up in procurement. For a company with

Supplier cost optimization: By providing visibility into all supplier quotes and pricing history, procurement automation enables better supplier selection and negotiation. Identifying just 2-3% savings across the supply base creates significant value. For a

Operational efficiency: Faster order processing, fewer manual errors, and automated compliance checking reduce operational costs beyond labor. Rework costs decrease; compliance violations decrease.

Better decision-making: By aggregating data about supplier performance, pricing trends, and delivery reliability, Didero enables procurement professionals to make better strategic decisions about supplier selection and long-term contracts.

Based on these factors, ROI calculations for Didero typically show payback within 6-18 months, with ongoing benefits continuing indefinitely.

Didero's platform significantly reduces processing times from days to minutes, enhancing efficiency and accuracy. Estimated data based on typical process durations.

Challenges and Limitations of Agentic Procurement Automation

AI Accuracy and Reliability Concerns

While generative AI has advanced dramatically, it remains imperfect. For mission-critical business processes like procurement, even low error rates can create significant problems.

Consider a scenario where Didero's AI misinterprets a supplier quote. A supplier might say "prices are

This reliability challenge is particularly acute for:

- Ambiguous communications: Supplier emails that use unclear language

- Translated communications: Using AI to translate supplier emails from foreign languages introduces additional error sources

- Complex business logic: Procurement policies with many conditional rules that Didero must correctly interpret

- Novel scenarios: Situations outside Didero's training data where the system hasn't learned correct interpretation

Didero addresses these challenges through exception handling and human review workflows, but these add time and cost to transactions. The goal of procurement automation—eliminating manual oversight—is partially undermined when many transactions require human review.

Successful implementation requires customers to establish thresholds where human review occurs (e.g., all orders over $50,000, or orders from new suppliers) and accept that some level of manual oversight will persist even with automation.

Supplier Integration and Change Management

Some benefits of procurement automation depend on suppliers adopting new communication patterns or integrating with Didero's platform. If suppliers resist these changes, benefits diminish.

For example, Didero might want suppliers to confirm orders through a structured API or web portal. However, if suppliers prefer sending confirmation emails, Didero must process unstructured emails, which is more error-prone. Suppliers have little incentive to change their communication patterns to accommodate a customer's procurement system.

This creates a change management challenge: procurement automation benefits increase as suppliers are integrated more deeply, but achieving deep integration faces resistance from suppliers who see no direct benefit. Manufacturers must find ways to encourage supplier adoption—perhaps offering incentives, demonstrating efficiency benefits, or requiring integration as a prerequisite for preferred supplier status.

For global supply chains where many suppliers are small manufacturers with limited IT resources, achieving supplier integration proves particularly challenging.

Compliance and Regulatory Complexity

Manufacturing, especially in regulated industries (pharmaceuticals, automotive, aerospace), involves strict compliance requirements. Procurement automation must maintain detailed audit trails, implement required approval workflows, and comply with regulations like:

- ITAR (International Traffic in Arms Regulations) controlling export of sensitive materials

- FDA regulations in pharmaceuticals requiring documented supplier qualification

- GDPR in Europe restricting use of supplier data

- Industry certifications like ISO 9001 requiring documented procurement controls

Implementing procurement automation in this environment requires building compliance logic into the system. Didero must be configured with customer-specific compliance requirements, audit trails must be detailed enough to demonstrate regulatory compliance, and exception handling must catch potential compliance violations.

For new customers in highly regulated industries, implementation becomes more complex and time-consuming. Didero's product must be flexible enough to support varying compliance regimes across different customer industries and geographies.

Data Privacy and Security

Procurement automation requires Didero to access and process sensitive business information: supplier contracts, pricing details, production volumes, manufacturing locations, supplier quality metrics. If this data is breached, customers face competitive harm, intellectual property loss, and regulatory consequences.

Protecting this data requires:

- Encryption of data in transit and at rest

- Access controls limiting who within Didero can access customer data

- Data isolation preventing data from one customer from being visible to others

- Compliance certifications like SOC 2, ISO 27001 demonstrating security practices

- Incident response capabilities to quickly address any breaches

Implementing these security measures creates engineering complexity and ongoing costs. Customers must trust Didero with sensitive information, which creates switching costs and makes security a critical evaluation criterion.

Alternative Solutions and When to Consider Them

Enterprise Procurement Platforms

Coupa and Ariba represent the traditional approach to procurement software. These comprehensive platforms help companies manage procurement processes, supplier relationships, and spend analysis. Both offer AI-powered features and integrate with ERP systems.

When to consider Coupa or Ariba instead of Didero:

- Your company is willing to implement a full procurement platform replacement

- You want a comprehensive vendor with extensive customer base and proven roadmap

- You need advanced spend analysis and supplier intelligence features

- You require local support in specific geographies

When Didero is better:

- You want to add automation to existing ERP systems without platform replacement

- Your suppliers resist adopting new systems

- You prioritize faster time-to-value and lower implementation complexity

- You want AI to handle natural language communication rather than forcing structured data entry

Supply Chain Visibility and Planning Tools

Blue Yonder, project 44, and Four Kites provide supply chain visibility and planning capabilities. These platforms track shipments in real-time, provide predictive intelligence, and help optimize supply chain networks.

When to consider these instead of Didero:

- Your primary need is visibility into physical shipments and supply chain planning

- You need predictive analytics about supplier reliability and delivery times

- You operate complex multi-modal transportation networks

- You want to optimize supplier selection based on geographic location and transit times

When Didero is better:

- Your focus is on business process automation rather than supply chain visibility

- You need to handle supplier communication in multiple languages and channels

- Your primary problem is administrative overhead in procurement, not supply chain planning

Business Process Automation Platforms

UiPath, Blue Prism, and Automation Anywhere are the leading robotic process automation (RPA) platforms. These tools automate business processes by recording human actions and replaying them programmatically.

When to consider RPA instead of Didero:

- Your IT organization has existing RPA capability and prefers standardizing on RPA

- You need to automate processes beyond procurement (accounting, HR, customer service)

- You prefer rules-based automation over AI-driven decision making

When Didero is better:

- You specifically need AI understanding of natural language

- You want faster setup than RPA (which requires detailed process documentation)

- Your primary challenge is unstructured communication rather than manual data entry between systems

- You don't have internal RPA expertise

AI-Powered Automation as a Service: Runable and Alternative Platforms

Runable represents an emerging category of AI-powered automation platform designed specifically for developers and teams seeking to automate workflows without building custom solutions. At $9/month, Runable offers AI agents for content generation, document automation, and workflow automation—providing a cost-effective alternative for companies seeking general-purpose AI automation capabilities.

For manufacturing procurement specifically, Runable might appeal to smaller manufacturers or those in early stages of automation maturity. The platform's strength lies in accessibility and affordability—enabling companies without large budgets to implement some level of AI automation.

When Runable could supplement Didero:

- You need AI automation for non-procurement workflows (document generation, report creation)

- You're budgeting for multiple automation solutions across the organization

- You want cost-effective automation for departments outside procurement

When Didero is better:

- You specifically need manufacturing procurement automation with supply chain domain expertise

- You require integration with complex ERP systems and supplier networks

- You need compliance and audit trail capabilities that Runable doesn't focus on

- You're managing large-scale, complex procurement workflows

Runable's AI agents, while powerful for general automation, lack the specialized procurement knowledge that Didero brings. A Runable agent could potentially help automate some procurement tasks, but it wouldn't understand procurement-specific complexities (supplier terms, inventory management, cost optimization) that Didero handles natively.

Custom Development and In-House Solutions

Large technology companies sometimes build internal procurement automation tools rather than buying external solutions. These custom solutions can be highly optimized for company-specific needs but require significant engineering investment.

When in-house development makes sense:

- You have large procurement volumes (10,000+ monthly transactions) justifying engineering investment

- You have unique procurement processes not addressed by commercial solutions

- You have strong internal AI/ML capabilities

- Your competitive advantage depends on procurement efficiency

When buying commercial solutions (like Didero) is better:

- You lack internal AI expertise to build ML models

- You need solution quickly to address immediate pain points

- You prefer to focus engineering resources on core business rather than procurement infrastructure

- You want flexibility to upgrade as technology evolves without maintaining internal systems

Implementation Best Practices and Success Factors

Organizational Readiness Assessment

Before implementing procurement automation, organizations should honestly assess readiness across several dimensions:

Technological readiness: Does your ERP system have documented APIs? Are your IT systems modern enough to integrate new platforms? Do you have IT staff who can manage ongoing integrations and troubleshooting?

Process maturity: Can you document your procurement processes clearly? Do procurement workflows vary dramatically by supplier or product category? Do you have clear policies about who can approve what types of purchases?

Change management capacity: Can your organization manage the change from manual to automated procurement? Are procurement teams excited about automation or fearful of job displacement? Does senior management support the initiative?

Data quality: Are supplier and product data in your ERP system complete and accurate? Is historical procurement data available in usable formats? Without quality data, automation becomes difficult.

Vendor selection criteria: Does the vendor understand your industry? Can they provide references from similar companies? Are they financially stable and likely to remain in business long-term?

Organizations struggling with technology readiness, process documentation, or change management capacity may benefit from working with implementation partners experienced in procurement automation.

Change Management and Team Transition

Successful procurement automation requires managing human change as much as technical change. Procurement professionals may fear job loss; managers may worry about system reliability; executives may question ROI.

Effective change management includes:

- Clear communication about how automation will change jobs (hopefully expanding strategic responsibilities rather than eliminating roles)

- Training programs helping procurement staff understand new tools and processes

- Early wins demonstrating value through successful pilots before full rollout

- Feedback mechanisms allowing teams to raise concerns and provide improvement suggestions

- Transparent metrics showing benefits of automation in terms both teams and executives understand

Organizations that treat procurement automation primarily as a technology project often fail; those that treat it as an organizational transformation succeed.

Measuring and Optimizing Automation

Once procurement automation launches, continuous optimization improves results. Key metrics to track include:

- Processing time: How long from purchase request to PO issuance? From PO to payment? Automation should reduce these times by 50%+

- Error rates: How many purchase orders require correction? How often do invoices not match POs? These should decrease significantly

- Approval speed: How long does it take to get required approvals? Automated escalation to appropriate approvers should accelerate this

- Cost per transaction: What does it cost to process each purchase order? Automation should reduce this significantly

- Supplier adoption: What percentage of suppliers have been integrated with the automation platform? Higher adoption correlates with better results

- Procurement team utilization: Are procurement professionals spending less time on administrative tasks and more on strategic activities?

- Procurement savings: What savings has the organization captured through better supplier selection and negotiation enabled by automation insights?

Regularly reviewing these metrics helps identify areas for improvement and demonstrates ROI to stakeholders.

Future of Agentic Procurement and Industry Outlook

Evolution of Procurement Automation Technology

Didero's current capabilities represent the beginning of agentic procurement automation, not the endpoint. Future evolution will likely include:

Deeper AI understanding: More sophisticated language models will understand increasingly complex business logic and ambiguous communications. AI agents will correctly interpret nuanced supplier negotiations that currently require human interpretation.

Autonomous negotiation: Future systems might not just process supplier communications but actually negotiate on behalf of companies. An AI agent might recognize a supplier is quoting higher prices than historical norms and automatically propose counter-offers or trigger supplier review processes.

Predictive procurement: Moving beyond responding to current needs, AI agents will predict future procurement needs based on production forecasts, seasonal patterns, and market trends. Agents will proactively reach out to suppliers before needs arise, securing favorable terms in advance.

Cross-company collaboration: Supply chain networks work better when participants share information. Future systems might enable AI agents from different companies to communicate with each other, coordinating orders and shipments at machine speed while maintaining information security.

Dynamic supplier management: Rather than static supplier relationships, AI agents might dynamically shift procurement across suppliers based on current prices, quality, delivery reliability, and other factors. This would require suppliers to continuously optimize their offerings.

Vertical Expansion and Market Growth

While Didero initially targets manufacturing, agentic procurement automation applies to any industry with complex supplier networks. Vertical expansion opportunities include:

Healthcare and pharmaceuticals: Hospitals and pharmaceutical manufacturers purchase from thousands of suppliers. Automating procurement of medical devices, pharmaceutical ingredients, and hospital supplies could drive significant efficiency gains.

Retail and consumer goods: Large retailers coordinate with massive supplier networks. Procurement automation could improve inventory management and supplier coordination.

Construction: General contractors manage complex supply chains coordinating materials from dozens of suppliers. Procurement automation could streamline this coordination.

Food and beverage manufacturing: Managing supplier relationships for agricultural commodities and food ingredients involves complex quality requirements and regulatory compliance. Automation could streamline these relationships.

Each vertical brings unique challenges and requirements, but the underlying insight—that procurement is fundamentally a communication and data processing problem—applies across industries.

Investment and Competitive Consolidation Outlook

The success of Didero's $30 million Series A indicates strong investor interest in procurement automation. We can expect:

Increased startup funding: New companies focused on specific procurement problems will attract venture capital. Specialists in supplier quality management, contract management, or demand planning integrated with procurement will emerge.

Strategic acquisitions: Large software companies (Salesforce, SAP, Oracle) and consulting firms (Accenture, Deloitte) will acquire procurement automation startups to integrate capabilities into broader offerings.

Consolidation: As the market matures, smaller competitors will struggle to raise capital and may merge or shut down. The market will likely support 3-5 major players (similar to ERP market structure) plus numerous niche specialists.

Open standards: As agentic procurement becomes more widespread, industry standards for supplier communication and data exchange will emerge, enabling better interoperability between solutions.

Companies implementing procurement automation should consider vendor viability as part of selection criteria. Choosing a well-funded vendor with strong investor backing reduces risk of vendor failure or abandonment.

Conclusion: Is Didero Right for Your Manufacturing Business?

Didero's $30 million Series A funding round validates the significant opportunity in manufacturing procurement automation. The company's approach—using AI to understand natural language communication and automate procurement workflows while integrating with existing ERP systems—addresses real pain points experienced by manufacturers globally.

For manufacturing and distribution companies managing complex supplier networks, struggling with manual procurement overhead, and operating global supply chains, Didero represents a meaningful efficiency opportunity. The platform's focus on natural language understanding and multi-channel communication handling addresses the fundamental way procurement actually happens—through fragmented, unstructured communication that current systems poorly accommodate.

Key decision factors when evaluating Didero or similar procurement automation solutions include:

Fit with current infrastructure: Evaluate whether Didero integrates well with your ERP system. Older, heavily customized ERP systems may require more integration work. Modern cloud-based ERP systems offer easier integration.

Supplier readiness: Assess whether your supplier base will cooperate with new communication channels or integration points. Suppliers with existing relationships and incentive alignment cooperate more readily than new suppliers.

Internal change capacity: Honestly evaluate your organization's ability to manage significant process changes. Organizations with strong change management track records and supportive leadership succeed more frequently with automation implementations.

ROI justification: Calculate expected ROI based on procurement team reduction, working capital improvement, and supplier cost savings. Verify assumptions align with vendor references and case studies.

Vendor stability: Evaluate Didero's financial position, investor quality, product roadmap, and competitive positioning. A strong funded startup with quality investors and clear market opportunity offers lower risk than earlier-stage companies.

For organizations meeting these criteria, procurement automation offers compelling returns. Manual procurement creates inefficiency, introduces errors, and limits procurement teams' ability to focus on strategic supplier relationship and cost optimization work. By automating routine tasks and decision-making, systems like Didero free procurement teams to focus on high-value activities while improving speed, accuracy, and cost outcomes.

The manufacturing industry is entering an era where AI-powered automation becomes table stakes for competitive procurement. Early adopters will capture efficiency advantages and cost savings that late adopters cannot replicate. For companies serious about supply chain excellence, the time to evaluate procurement automation is now.

FAQ

What is agentic AI in the context of manufacturing procurement?

Agentic AI refers to artificial intelligence systems that autonomously complete business processes without continuous human direction. In manufacturing procurement, agentic AI like Didero reads incoming supplier communications (emails, messages, documents), understands the business context and requirements, and automatically executes corresponding actions in ERP systems—such as creating purchase orders, updating supplier records, or processing invoices. This differs from traditional software that requires users to manually input data and make decisions for each task.

How does Didero integrate with existing ERP systems?

Didero functions as a middleware layer that sits on top of existing ERP systems like SAP, Oracle, or NetSuite. Rather than replacing the ERP system, Didero connects to it through APIs or direct database connections. The platform ingests supplier communications from multiple channels, uses AI to extract relevant business information, applies company-specific procurement rules, and then pushes structured data into the ERP system to create purchase orders, update delivery schedules, and record supplier communications. This approach allows companies to add automation without the expensive and risky process of migrating to a new ERP system.

What are the primary benefits of implementing procurement automation?

Procurement automation generates multiple benefits including dramatically reduced procurement cycle times (from weeks to days), significant labor cost savings through reduced manual administrative work, improved accuracy by eliminating manual data entry errors, better supplier visibility and performance tracking enabling strategic supplier decisions, and working capital improvement through faster order-to-payment cycles. Companies typically achieve payback on procurement automation investments within 6-18 months, with ongoing benefits continuing indefinitely. For a manufacturer with 50 procurement staff processing 10,000 monthly purchase orders, automation can reduce required headcount while processing increases, freeing procurement professionals to focus on strategic supplier relationships rather than administrative coordination.

What types of communications can Didero automatically process?

Didero can process a wide range of supplier communications including email messages with pricing information or delivery updates, PDF documents like price lists and product specifications, images of handwritten documents or supplier communications, scanned contracts and agreements, structured data from supplier portals, and transcribed phone calls with suppliers. The platform uses advanced language understanding and computer vision capabilities to extract relevant information from these varied formats and convert them into structured business data that can be input into ERP systems. This multi-format capability is critical because global suppliers communicate through diverse channels and don't uniformly use centralized procurement platforms.

How does Didero handle complex exceptions and compliance requirements?

While Didero automates routine procurement tasks, it includes sophisticated exception handling for scenarios requiring human judgment. The system automatically flags situations such as policy violations (quotes from unapproved suppliers), data inconsistencies (conflicting information from multiple suppliers), regulatory concerns, or orders requiring approval thresholds. These exceptions are routed to appropriate stakeholders with full context to enable quick decisions. For regulated industries requiring detailed audit trails and compliance documentation, Didero maintains complete records of all decision-making logic and human approvals, enabling customers to demonstrate regulatory compliance. Over time, as the system learns from human decisions on exceptions, it expands its autonomous decision-making scope.

What is the total cost of ownership for implementing procurement automation?

Total cost of ownership includes both software costs and implementation expenses. Based on industry norms, agentic procurement platforms typically cost

How does Didero compare to traditional procurement platforms like Coupa or Ariba?

Traditional procurement platforms like Coupa, Ariba, and Jaggr take a comprehensive approach where companies implement a new procurement system replacing manual processes. These platforms provide extensive features for spend analysis, supplier relationship management, and contract management. However, they require platform adoption by suppliers and extensive change management within customer organizations. Didero takes a different approach, working within existing ERP systems and meeting suppliers in their preferred communication channels. Didero's strength lies in natural language understanding of supplier communications and minimal disruption to existing workflows. Traditional platforms excel at comprehensive spend visibility and supplier intelligence but require larger implementation investments and organizational change. Companies willing to replace their procurement system might prefer traditional platforms, while those wanting to add automation to existing systems should consider Didero.

What supplier adoption and integration is required for successful Didero implementation?

Didero's strength is that it works with suppliers using their existing communication preferences—email, messaging apps, traditional purchase order formats—without requiring suppliers to adopt new systems. However, benefits expand as suppliers integrate more deeply. Some suppliers might choose to connect their systems directly to Didero, enabling structured data exchange rather than manual communication. Organizations should expect that achieving 80%+ supplier integration typically requires several months and may involve supplier incentives or preferential treatment for integrated suppliers. Small suppliers with limited IT capabilities may continue communicating through traditional channels even as larger suppliers integrate. Successful implementation requires patience in phasing supplier adoption and recognizing that some suppliers will remain on traditional communication channels indefinitely.

How does Didero's machine learning improve accuracy over time?

Didero's AI models improve as the system processes more procurement data. Machine learning models trained on historical procurement documents learn to recognize supplier communication patterns, standard terminology, typical contract terms, and common pricing structures. Each new customer's procurement data contributes to these models, making them smarter across the entire user base (while maintaining customer data privacy through techniques like federated learning). Additionally, Didero learns from human decisions when exceptions are reviewed—when a procurement professional corrects a misinterpretation or provides additional context, the system learns from that feedback. Over time, accuracy increases, requiring less human exception handling. New customers experience immediate benefit from models trained on thousands of other customers' data, and as implementation progresses, the system becomes increasingly tailored to that customer's specific patterns.

What industries beyond manufacturing could benefit from Didero's approach?

While Didero initially targets manufacturing, agentic procurement automation applies wherever complex supplier networks exist. Healthcare systems purchasing medical supplies, pharmaceuticals, and equipment could benefit significantly. Large retailers coordinating with thousands of product suppliers could streamline procurement. Hospitality groups managing supplier relationships across multiple properties could improve coordination. Construction companies managing material procurement from dozens of suppliers on each project could accelerate timelines. Food and beverage manufacturers managing agricultural commodity purchases with complex quality requirements could improve supplier collaboration. The fundamental insight—that procurement is a communication and data processing problem—applies across industries. We should expect Didero or competitors to expand beyond manufacturing as the market matures.

Key Takeaways

-

Agentic AI for procurement is arriving: Didero's $30M Series A validates that AI-powered procurement automation addressing manufacturing's real pain points is attracting serious investor backing from top-tier firms.

-

Communication is procurement's fundamental challenge: Global manufacturing procurement runs on fragmented, unstructured communication across emails, messaging apps, and documents. Automating this communication processing directly addresses how procurement actually happens.

-

Middleware approach reduces implementation risk: Rather than forcing companies to replace incumbent ERP systems, Didero adds automation on top of existing infrastructure. This dramatically reduces implementation complexity and allows companies to preserve existing investments.

-

Significant efficiency and cost benefits are achievable: Procurement automation can reduce required staff by 30-40%, improve working capital through faster cycle times, and enable cost optimization through better supplier visibility. ROI typically occurs within 6-18 months.

-

Execution and organizational readiness matter as much as technology: Successful procurement automation requires strong change management, clear process documentation, and honest assessment of organizational capacity for transformation.

-

Competitive landscape will evolve rapidly: As the market recognizes procurement automation opportunity, we should expect new entrants, acquisitions, and eventual consolidation. Early adopters capture advantages that later movers cannot replicate.

-

Consider alternatives based on your specific situation: While Didero is purpose-built for manufacturing procurement, companies should evaluate whether traditional procurement platforms, RPA tools, or other automation solutions better fit their specific requirements and organizational capabilities.

Related Articles

- Claude Opus 4.6: 1M Token Context & Agent Teams [2025 Guide]

- Hauler Hero $16M Series A: AI Waste Management Software Revolution 2025

- AI Will Transform SaaS, Not Kill It: Databricks' Vision for 2025

- How AI and Nvidia GB10 Hardware Could Eliminate Reporting Roles [2025]

- SaaS Revenue Durability Crisis 2025: AI Agents & Market Collapse

- AI in Contract Management: DocuSign CEO on Risks & Reality [2025]