Industrial AI Applied: Where the Real Revolution Is Happening

You've probably heard the hype. Big Tech is spending trillions on AI infrastructure. Chat GPT reached 100 million users in two months. Every startup is pivoting to AI. Investors are pouring money into anything with "artificial intelligence" in the pitch deck.

But here's the thing: most of that noise? It's about office automation.

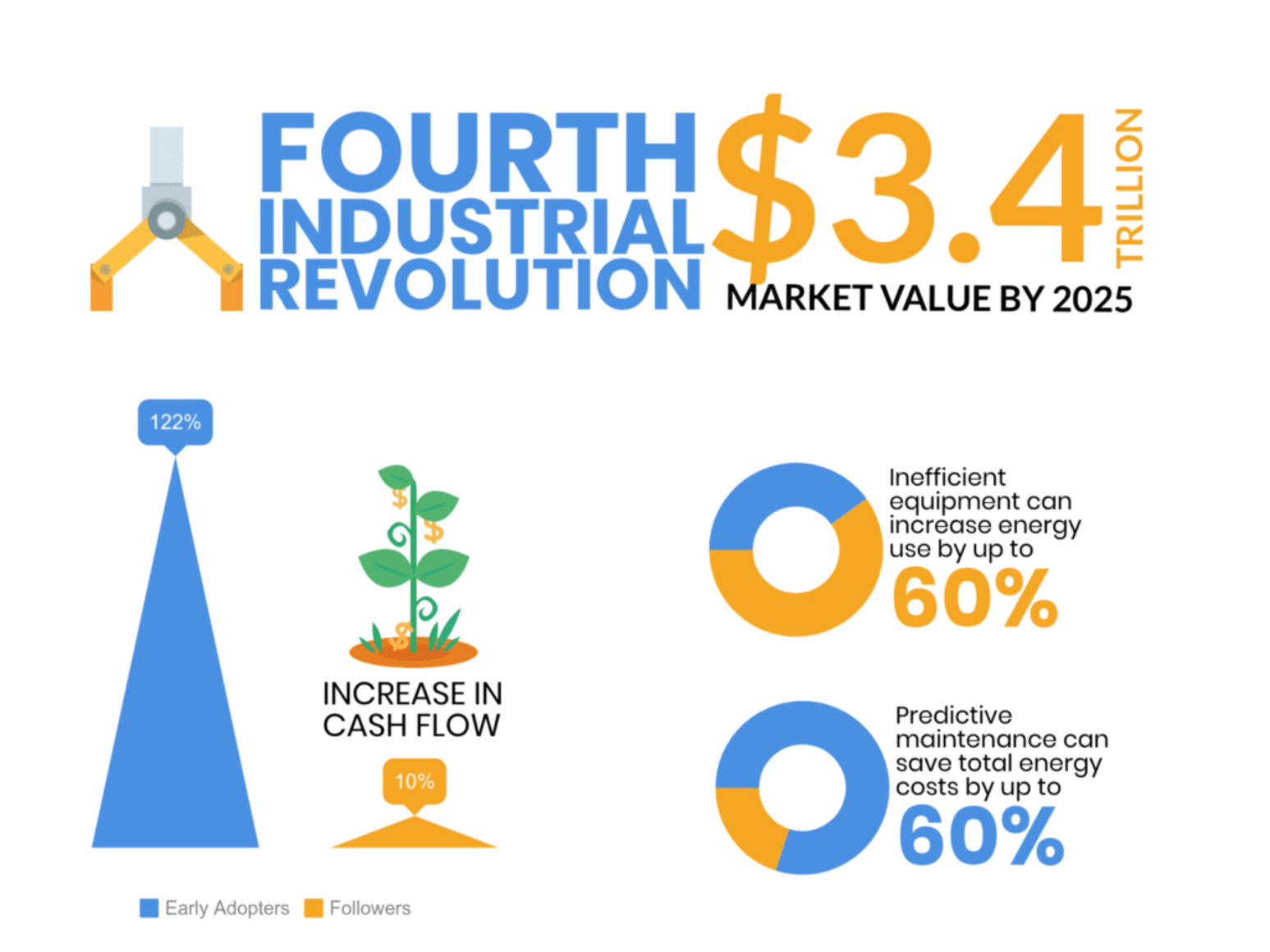

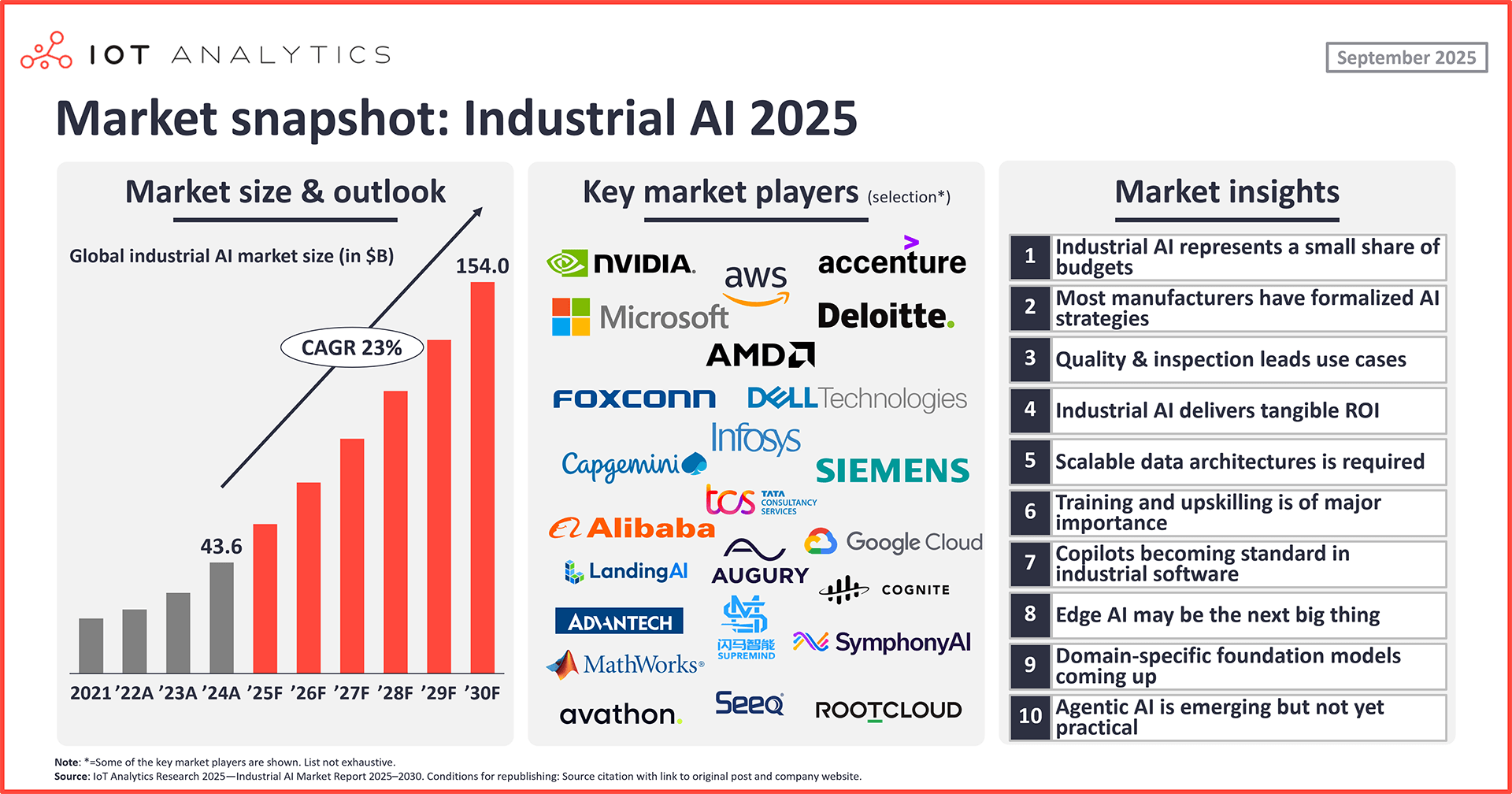

While the industry obsesses over chatbots and content generators, something way more significant is quietly happening on factory floors, in power plants, and at distribution centers. Industrial AI—the application of machine learning, predictive analytics, and intelligent automation to manufacturing, energy, utilities, and logistics—is actually delivering measurable returns. Real productivity gains. Real cost savings. Real safety improvements.

The difference between the AI hype and Industrial AI is simple: one chases novelty, the other solves problems that have plagued industries for decades.

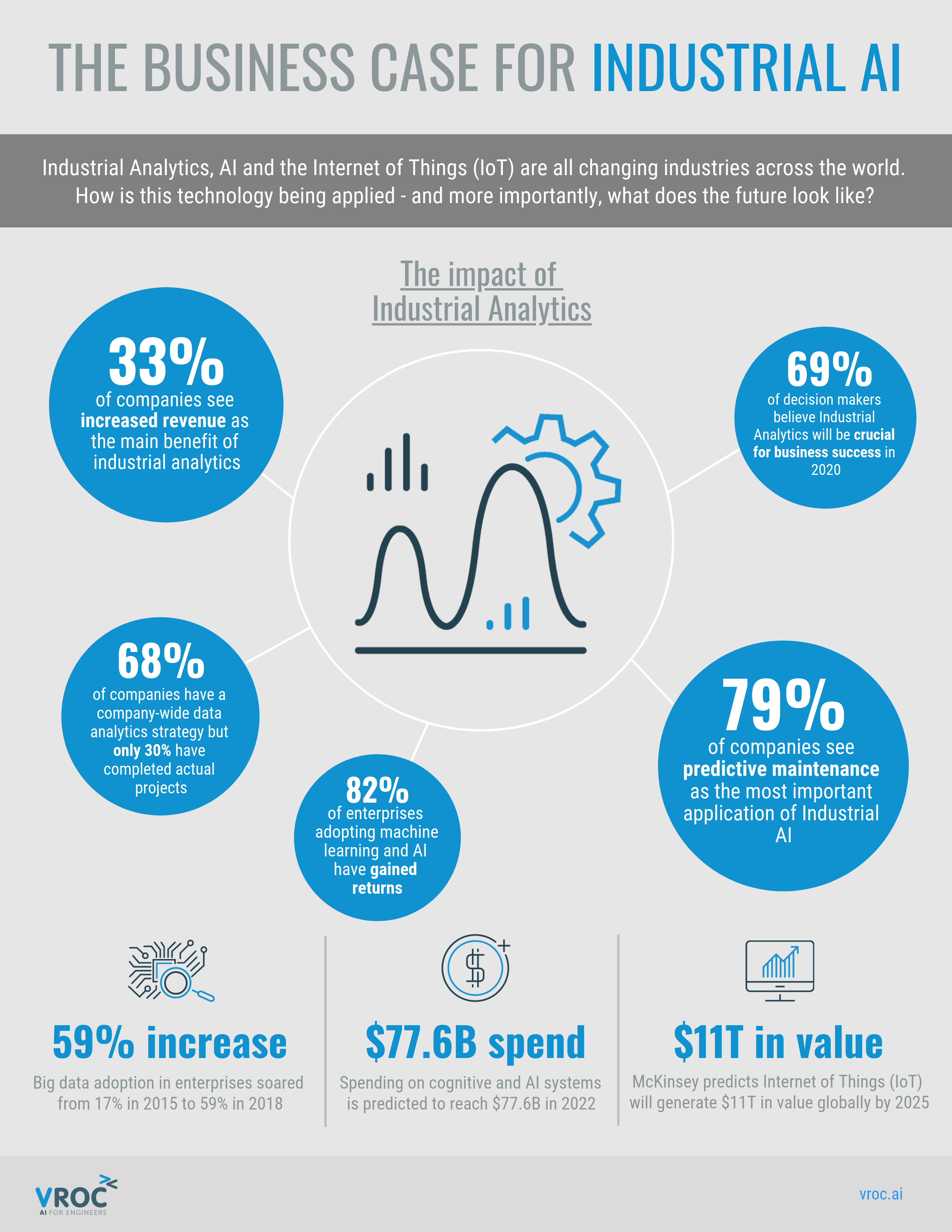

This isn't the first time we've heard AI promises. But Industrial AI is different because the problems it solves are tangible. When a manufacturer prevents equipment failure before it happens, that's not abstract value. That's uptime. That's revenue. When a utility optimizes power distribution in real time, that's not a nice-to-have. That's operational necessity.

I've watched enterprises struggle for years to extract value from AI projects. They launch pilots that never scale. They deploy models that don't generalize. They hire expensive data scientists who spend 80% of their time cleaning data instead of building intelligence. Industrial AI sidesteps most of these pitfalls because the use cases are concrete, the metrics are measurable, and the ROI is obvious.

In this article, I'm walking through what's actually working in Industrial AI. Not the theoretical stuff. Not the vendor white papers. The real applications, the real challenges, and the real transformations happening right now in the industries that keep the world running.

TL; DR

- Industrial AI is solving real problems: Predictive maintenance, anomaly detection, and workflow optimization are delivering measurable ROI in manufacturing, energy, and logistics

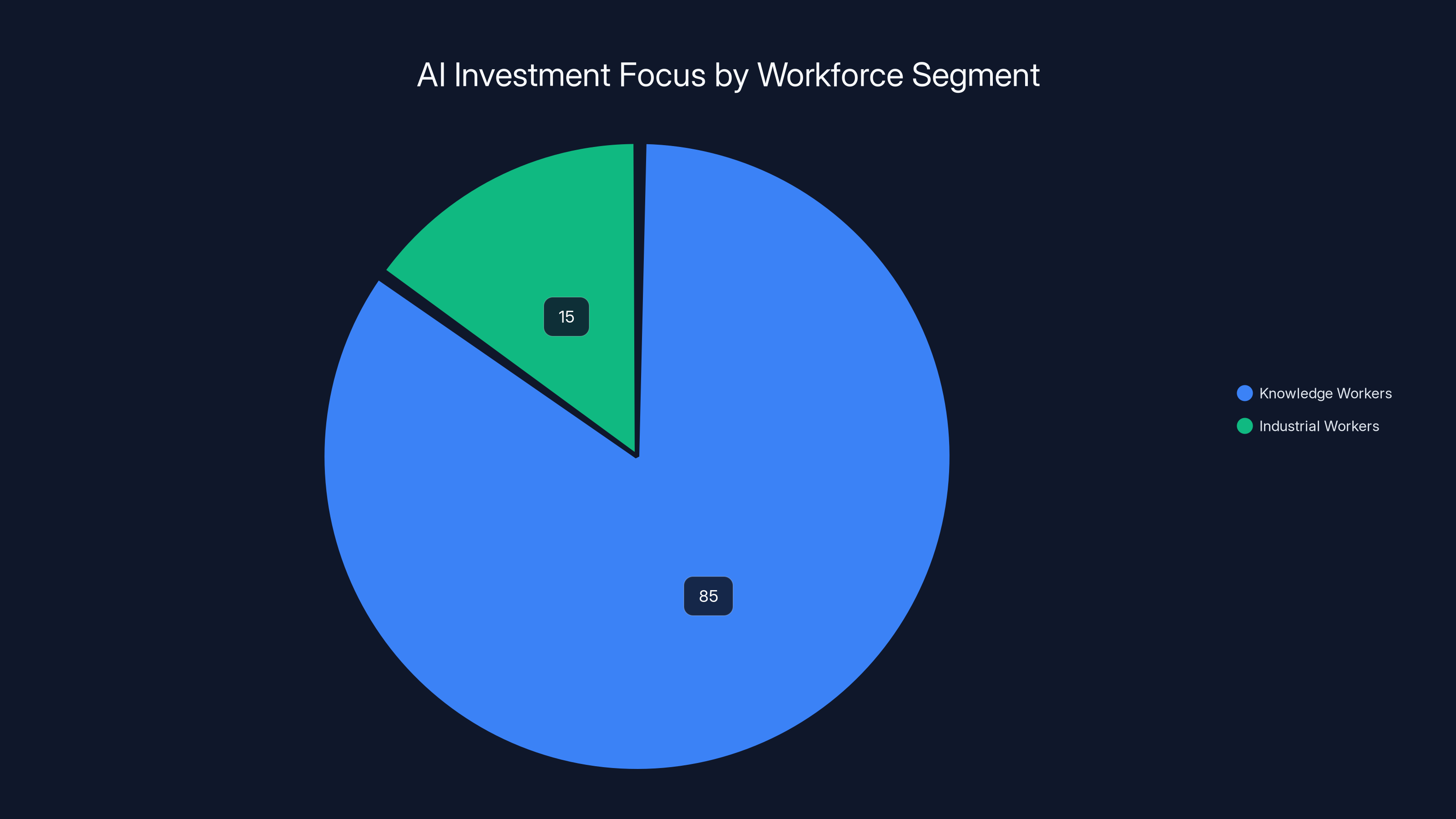

- 70% of the workforce is overlooked: Most AI innovation focuses on office workers, but the industrial workforce needs practical tools for safer, faster operations

- The execution gap is wider than the technology gap: Organizations struggle with change management, workforce retraining, and trust in AI systems more than with model performance

- Agentic AI is reshaping work structure: The future combines human experts in judgment roles, AI agents handling diagnostics, and robotic workers doing hazardous tasks

- Servitization is the business model shift: Companies are moving from selling products to selling outcomes (uptime, efficiency, availability), making AI indispensable

Despite industrial workers comprising 70% of the global workforce, only 15% of AI investment is directed towards their needs, highlighting a significant gap in AI development focus.

The 70% of Workers the AI Industry Forgot

Let's start with the uncomfortable truth: most AI innovation is built for desks.

Content creation. Email assistants. Document summarization. Presentation generation. Code completion. Design tools. Knowledge management systems. The vast majority of visible AI development targets the 30% of the global workforce that sits in front of a computer screen in a climate-controlled office.

That's roughly 500 million knowledge workers out of about 1.6 billion globally employed people. The other 1.1 billion? They work in hospitality, manufacturing, construction, agriculture, utilities, logistics, healthcare delivery, and trades. They're engineers maintaining critical infrastructure. Technicians diagnosing equipment failures in real time. Field workers in environments where a laptop isn't practical.

For them, AI isn't about automating email or generating marketing copy. It's about working safer, faster, and smarter with tools that live in their actual environment.

The practical problems facing these workers are different. A field technician doesn't need a chatbot to draft an email. They need a system that can tell them exactly what's wrong with a pump before they walk onto a factory floor. A plant operator doesn't need a copilot for documentation. They need a system that predicts equipment failure before it happens, preventing catastrophic downtime.

These problems aren't sexy. They don't make for good product demos or venture capital pitches. But they're worth billions in prevented losses.

Consider maintenance. In traditional manufacturing, maintenance is reactive. Equipment breaks, production stops, you fix it. That downtime is expensive. A single unplanned outage in a chemical plant can cost

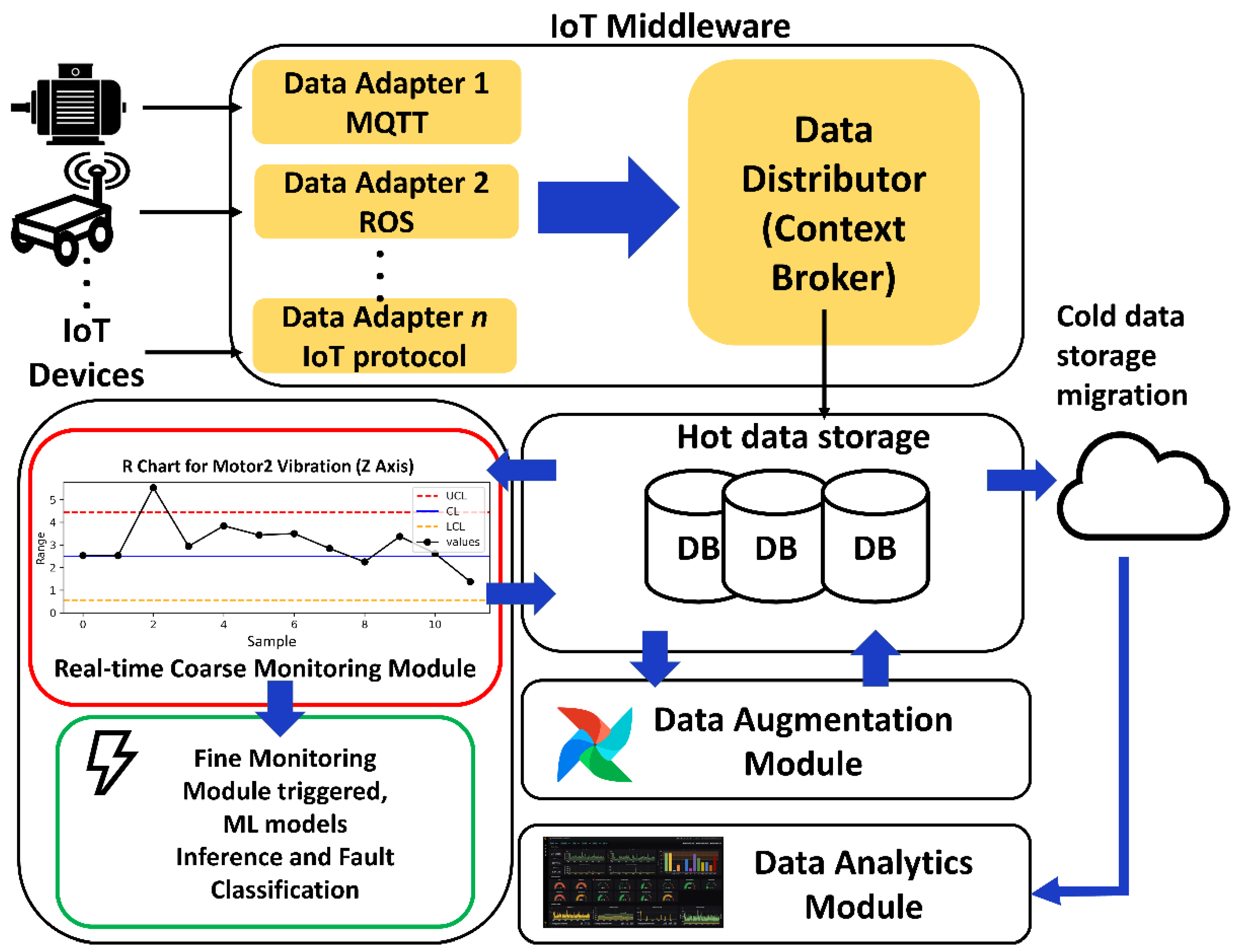

Predictive maintenance using AI flips that model. Sensors continuously monitor equipment. AI analyzes vibration patterns, temperature trends, pressure changes, and acoustic signatures. It learns what normal looks like, then flags anomalies that precede failure. A technician gets an alert before the bearing fails, not after.

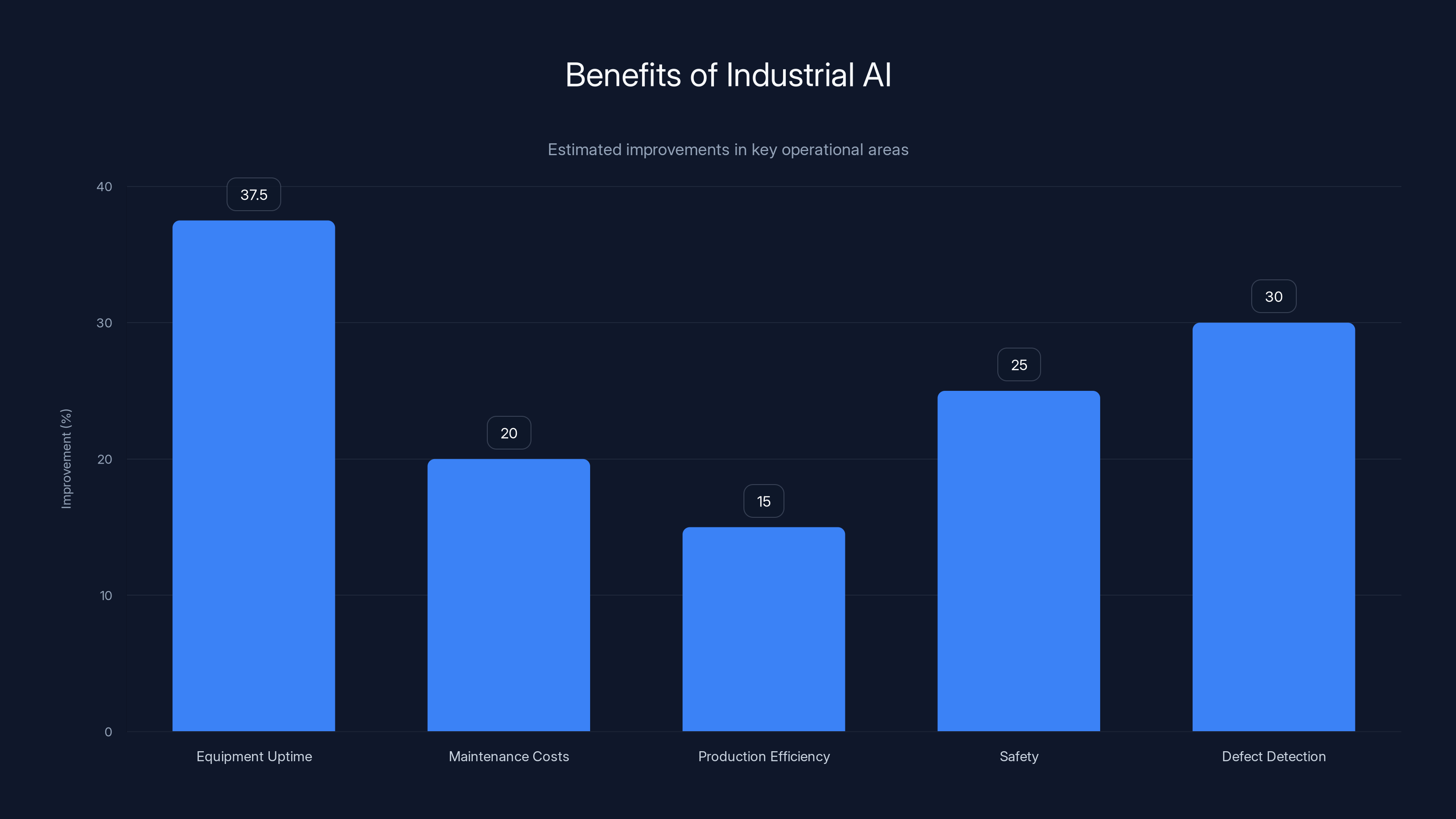

The impact is dramatic. Companies implementing predictive maintenance see equipment downtime reduction of 25-50%, maintenance cost reductions of 15-25%, and equipment lifespan extensions of 20-40%. Those aren't small numbers. For a large manufacturer with $100 million in annual revenue, that translates to millions in recovered productivity.

But it only works if the system is designed for the actual workflow of technicians. Not product designers in San Francisco imagining what field workers need. But actual technicians saying, "Here's what I see every day. Here's what would help me." That's where Industrial AI starts to diverge from the broader AI narrative.

Industrial AI can significantly enhance operations, with estimated improvements ranging from 15% to 37.5% across various areas. (Estimated data)

Understanding Industrial AI: Beyond Buzzwords

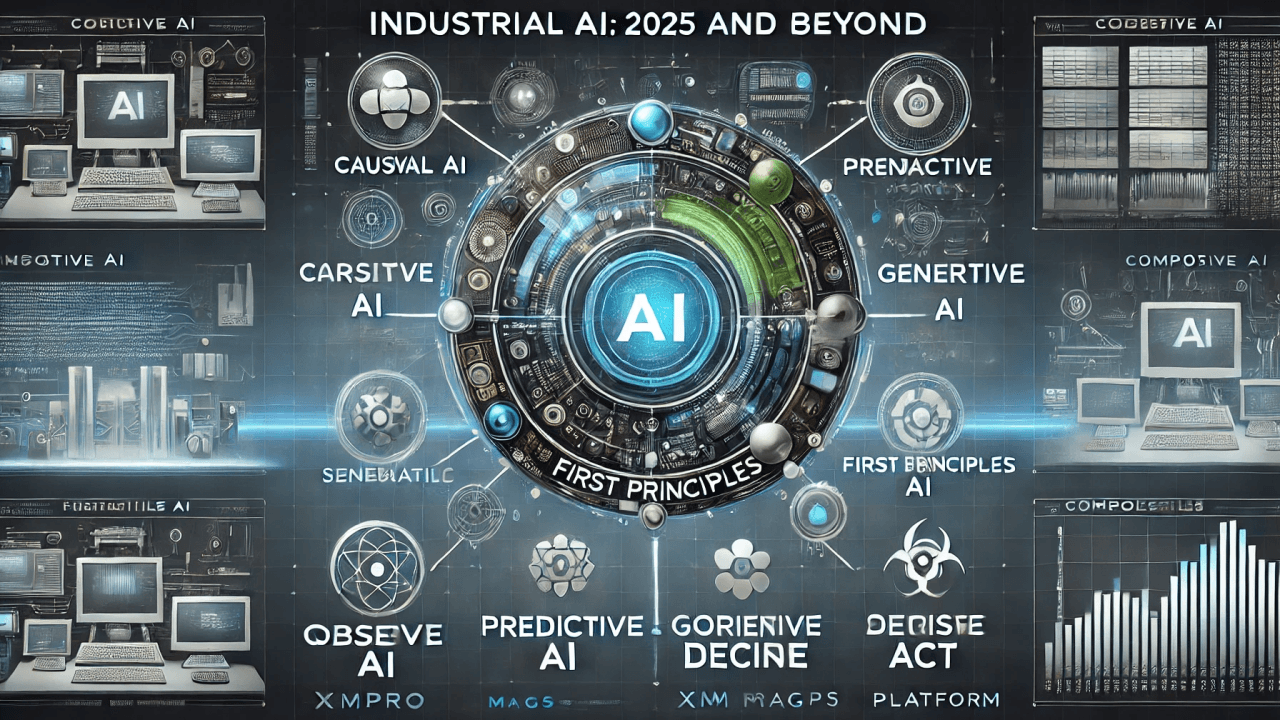

Industrial AI isn't a single technology. It's a convergence of several established techniques applied to the specific challenges of physical operations.

Predictive analytics uses historical data to forecast future equipment states, resource needs, or process outcomes. A steel mill learns that certain vibration signatures precede bearing failure. An energy utility learns that specific weather patterns, time of day, and grid loads predict demand spikes. A logistics network learns which routes face congestion and when.

Anomaly detection identifies when operations deviate from normal patterns, often indicating problems before they cascade into failures. A refinery's AI system catches a small pressure deviation that precedes a major rupture. A power grid's system flags an unusual current draw that indicates equipment stress. A manufacturing line catches a subtle variation in part dimensions before thousands of defective units are produced.

Automated scheduling and optimization replaces manual planning with algorithms that consider hundreds of variables simultaneously. Maintenance scheduling that minimizes production impact. Logistics routing that reduces fuel consumption and delivery time. Production sequencing that maximizes throughput and minimizes changeovers.

Sensor integration and real-time monitoring connects disparate equipment, systems, and data sources into a cohesive picture. A modern factory floor has thousands of sensors. Traditional systems treat each one independently. AI synthesizes them into actionable intelligence. A temperature sensor alone is noise. Combined with vibration, acoustic, and electrical data, it becomes a reliable predictor of failure.

Computer vision for quality assurance, safety monitoring, and process observation. A camera watching a production line can catch defects faster and more consistently than human inspectors. Computer vision systems can monitor worker safety, flagging situations that violate safety protocols before incidents happen.

Each of these technologies has existed for years. What's changed is the combination. When you connect real-time data from every aspect of an operation, apply multiple analytical techniques to that data, and integrate the insights back into workflow systems, you get something genuinely different.

That integration is what makes Industrial AI practical. It's not the individual technologies. It's how they work together to augment human decision-making and automate routine tasks.

Why Traditional AI Pilots Fail in Industrial Environments

If Industrial AI is so valuable, why don't we see it everywhere?

The answer has less to do with technology and more to do with organizational dynamics.

Most enterprise AI projects follow a familiar pattern: executive sponsor gets excited about AI potential, data science team builds a model in a sandbox environment, pilot shows impressive metrics in controlled conditions, organization tries to scale it, and... it fails. Or limps along at minimal value. Or becomes a cost center that eventually gets defunded.

Research across global industries shows what they call an "execution gap." Organizations are adopting AI faster than they're becoming ready to use it effectively. The gap is widening, not narrowing.

Let's walk through why.

First: Data quality and availability. Industrial systems often have decades of accumulated data. Some of it's well-maintained. Much of it isn't. A manufacturing facility might have a historian database tracking production metrics, but those records might have gaps, duplicates, or inconsistencies. Equipment from 15 years ago logged data differently than modern systems. Merging that data into a training set takes months. Cleaning it takes more months. By the time you have viable data, stakeholders are impatient.

Second: The skills gap. Building a predictive maintenance model requires understanding three separate domains: machine learning, industrial operations, and the specific equipment being monitored. Most data scientists know machine learning. Few understand industrial operations. Fewer still have worked with the specific equipment. So you get models that are statistically sound but practically useless because they don't account for how the equipment actually behaves in the real world.

Third: Integration challenges. Most factories have legacy systems that were never designed to talk to each other. A PLC (programmable logic controller) from 2008 doesn't have APIs. The SCADA system runs on isolated networks for security reasons. The maintenance tracking system is a 20-year-old database nobody wants to touch. Getting data out of these systems and into a machine learning pipeline is a months-long engineering project.

Fourth: Change management is underestimated. A new AI system means technicians do their jobs differently. Maintenance workers who've done diagnostics the same way for 20 years now follow a system's recommendations instead of their intuition. That creates friction. Some workers see it as a threat to their expertise. If management doesn't handle the transition carefully, the system gets ignored or sabotaged in subtle ways.

Fifth: Trust erosion. When an AI system makes a wrong call, people remember it. A predictive maintenance model flags equipment for replacement that still works. Now you've wasted thousands on unnecessary parts. The same model misses a real failure the next month. Technicians lose trust. "The AI was wrong before, so I'm not trusting it now." Trust lost is hard to rebuild.

So organizations don't fail at the technical level. They fail at the organizational level. The model is fine. The problem is everything else.

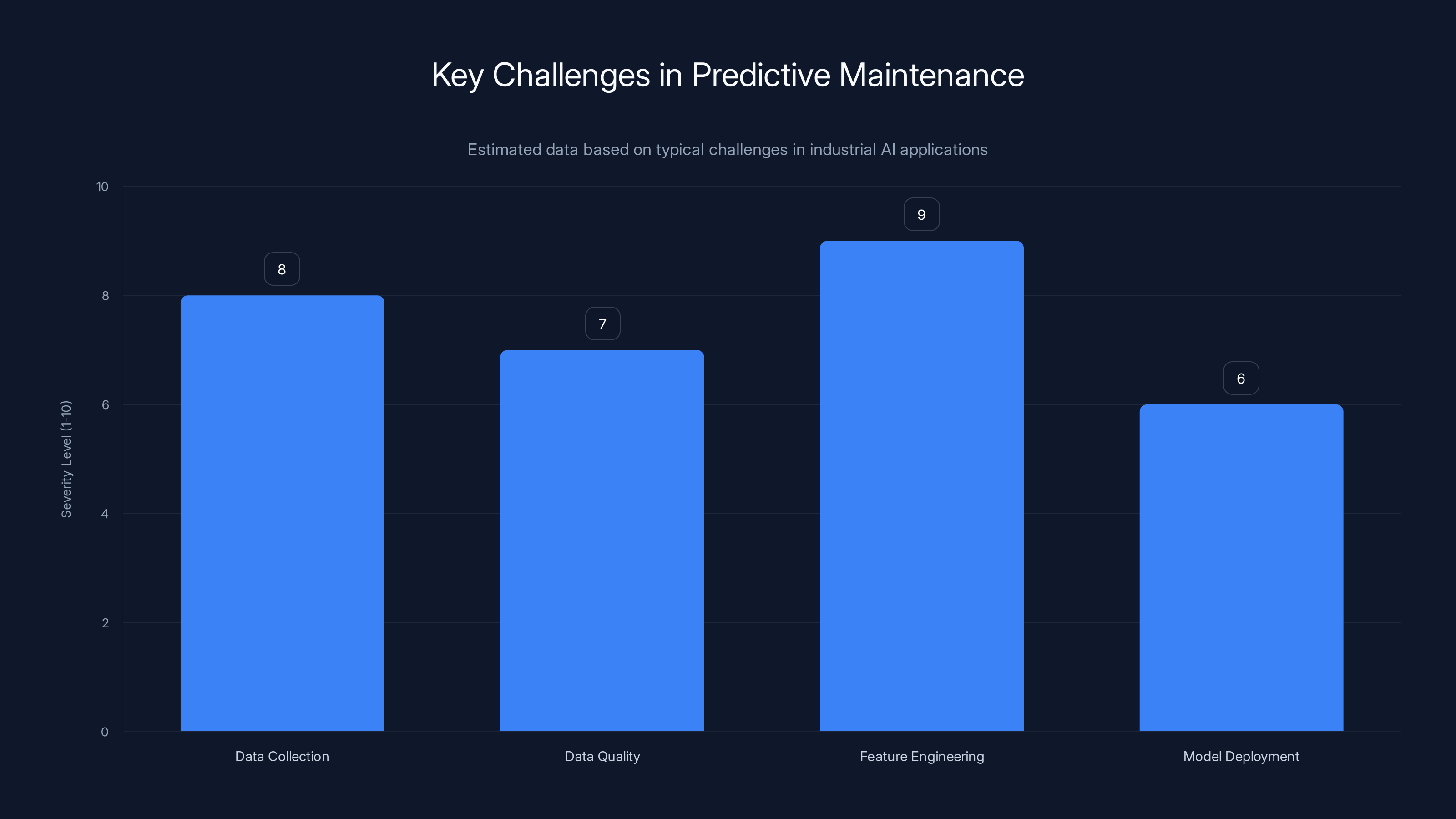

Feature engineering is the most severe challenge in predictive maintenance, followed by data collection and quality issues. Estimated data based on industry insights.

The New Industrial Workforce: Humans, AI Agents, and Robots Working in Tandem

Industrial AI isn't replacing workers. That's important to say clearly because it's the fear driving a lot of resistance.

What it's actually doing is restructuring what work looks like.

Traditionally, a manufacturing floor had technicians, maintenance workers, operators, and supervisors. Each role had specific responsibilities and boundaries. A technician diagnosed equipment. An operator ran it. A maintenance worker fixed it. Those boundaries were clear because human capacity was the constraint.

Now consider what's possible when AI handles diagnostics and scheduling, robotic systems handle hazardous tasks, and humans focus on judgment and orchestration.

You need fewer routine diagnostics because AI does that. You need fewer maintenance workers handling routine fixes because robots can do precision work and hazardous tasks. But you need more people in roles that require judgment, problem-solving, and understanding context.

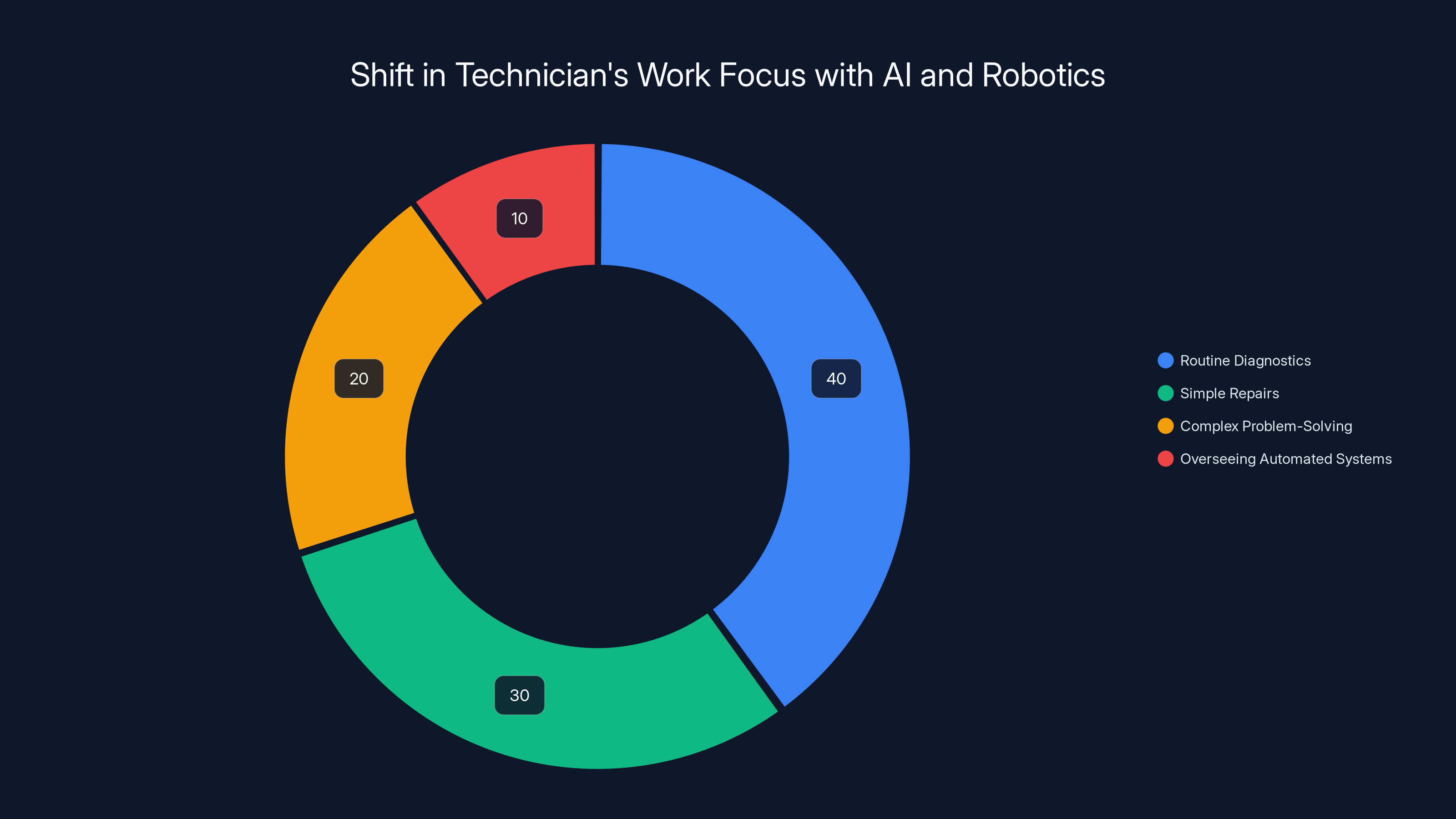

A technician's job shifts. Instead of spending 40% of time doing routine diagnostics and 30% doing simple repairs, they spend 70% on complex problem-solving and 30% overseeing automated systems. Their expertise becomes more valuable, not less. They make higher-level decisions. They handle the exceptions that AI can't. They teach the AI system when it's wrong.

This creates what's sometimes called the "10X workforce." The same number of people, or fewer, delivering 10 times the output because they're amplified by intelligent systems.

It works because the mix is right. Humans for judgment and context. AI agents for continuous monitoring, pattern recognition, and diagnostics. Robotic systems for tasks that are dangerous or require precision beyond human capability. Together, they cover what each is bad at.

Humans are terrible at monitoring 10,000 sensors for 24 hours straight. AI agents are perfect at it. AI agents are terrible at knowing when an exception requires human intervention. Humans are good at it. Robots are dangerous to use on a crowded factory floor. Humans know the workflow and can guide them safely.

The transition isn't free. It requires retraining. It requires rebuilding workflows. It requires changing how roles relate to each other. But the output is undeniable.

Predictive Maintenance: The Most Mature Industrial AI Application

Predictive maintenance is the closest thing Industrial AI has to a proven, repeatable use case.

It's straightforward conceptually: collect data about how equipment behaves, build a model that predicts failure, alert humans before failure happens. Replace reactive maintenance with proactive maintenance.

The business case is solid. Unplanned downtime is expensive. Planned downtime is cheaper because you can schedule it during low-production periods and have parts ready. Even better is preventing downtime entirely. A production line that doesn't go down makes more product. A power plant that doesn't fail serves more customers.

But there's a gap between the concept and the execution.

The data challenge: Not all equipment generates useful data. Old equipment has no sensors at all. Some equipment has sensors but they're not monitored. Some facilities have data but it's siloed. Bringing all that together is step one. Then you have the quality problem. Data from years ago might be corrupt or inconsistent. Missing values, duplicate entries, and drift in sensor calibration over time all add noise.

A manufacturing company I worked with had vibration sensor data going back eight years. Seemed like plenty for training. But they'd replaced the sensor hardware twice. The sensor mounting changed. The sampling rate changed. The equipment was upgraded. So the "eight years of data" was really four different datasets. Building a model that worked across all of them required significant feature engineering and data transformation.

The feature engineering challenge: A bearing doesn't fail because vibration reaches X Hz. It fails because vibration signatures change in specific ways that precede failure. Those patterns might be obvious in retrospect but aren't obvious in the raw data. You need experts who understand both the equipment and machine learning to extract the right features.

In that same manufacturing example, vibration, temperature, and electrical current data were available. But the most predictive signal came from the rate of change in vibration over a 48-hour window combined with temperature in the previous 72 hours. A generic machine learning model would miss that because it requires domain understanding.

The false positive problem: Predictive models aren't perfect. They flag equipment that's actually fine. You schedule maintenance, spend money on parts and labor, and the equipment works fine. Do it enough times and maintenance teams ignore the alerts.

The best predictive maintenance systems don't just flag equipment. They provide confidence scores and context. "There's a 78% chance this bearing will fail within 30 days based on vibration signature changes and temperature trends. Recommend replacement during the next planned maintenance window." That's actionable and specific.

The integration problem: A good predictive model in a laptop is useless. You need to feed it real-time data, make predictions, and push alerts to the right people. That integration work is often invisible in success stories but accounts for significant project time.

When predictive maintenance works, it works really well. Equipment uptime improvements of 25-50%. Maintenance cost reductions of 15-25%. Reduced overtime because failures don't happen during evenings or weekends. But it only works when you've solved these problems.

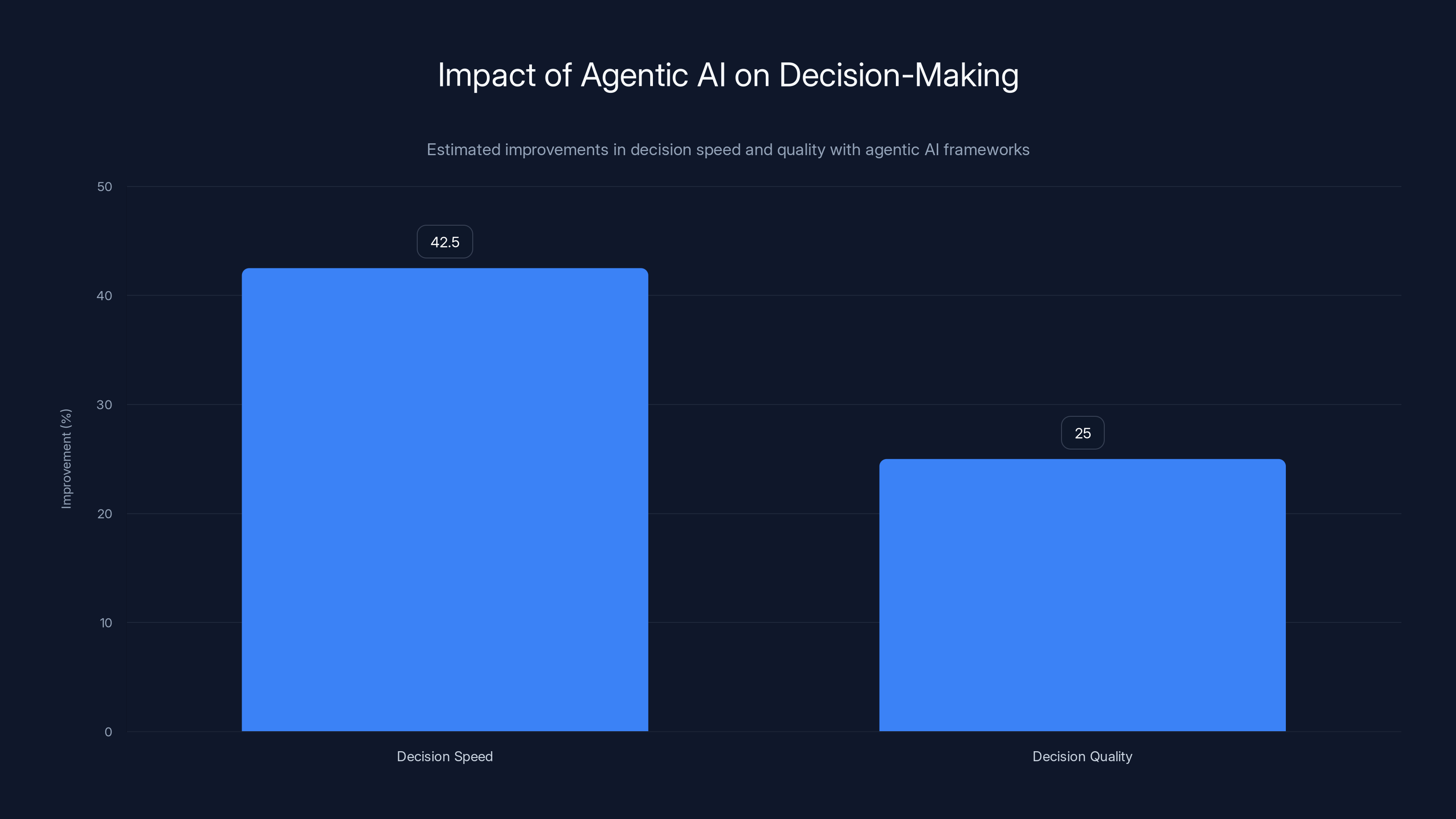

Organizations using agentic AI frameworks report an average 42.5% improvement in decision speed and a 25% improvement in decision quality. Estimated data based on reported ranges.

Anomaly Detection: Finding Problems Before They Find You

Predictive maintenance looks at specific equipment. Anomaly detection is broader. It flags anything that deviates from normal, across entire systems.

A refinery is complex. Thousands of variables. Pumps, compressors, heat exchangers, distillation columns, control systems. Each variable influences others. Normal operation looks like specific ranges and relationships between variables. Abnormal means something's wrong.

Manually monitoring all of that is impossible. A human operator can watch maybe 30-50 parameters. Miss the relationships. An AI system can watch thousands simultaneously and understand multivariate relationships.

The classic anomaly detection example is a power grid. Electricity demand follows patterns. Weekday morning in winter looks different from Sunday afternoon in summer. Weather affects demand. Time of day affects demand. Major events affect demand. A grid operator has to balance generation with demand in real time.

An anomaly in a power grid is a load pattern that doesn't match what's expected. Could indicate a problem with a generator. Could indicate unusual consumption. Could indicate an equipment failure. A human operator would notice unusual demand, but notice it late, after some problem has developed. An anomaly detection system catches it as soon as it deviates from expected patterns.

That doesn't always mean failure. Sometimes anomalies are just unusual circumstances. New load on the grid. Seasonal shift. But catching anomalies early gives the operator time to investigate before it becomes a problem.

Anomaly detection works well because it's flexible. You don't need a model for every possible failure mode. You just need a model of "normal." Anything sufficiently different from normal gets flagged. New failure modes that never happened before? The system still catches them because they'll look abnormal.

The challenge is false positives. A sunny day is anomalous in winter. Is that a problem or just weather? A new customer signing up creates unusual load patterns. Is that an anomaly or business growth? You need to filter noise from signal.

When anomaly detection systems work well, they catch problems early enough to prevent catastrophic failures. A pressure anomaly in a pipeline that precedes a rupture. An electrical anomaly in a transformer that precedes failure. A production anomaly that indicates a die is degrading and will fail in hours.

Quality Control and Computer Vision in Manufacturing

Quality assurance is expensive. A factory employs people to inspect products coming off production lines. They look for defects. It's tedious, repetitive, and humans get tired and miss things.

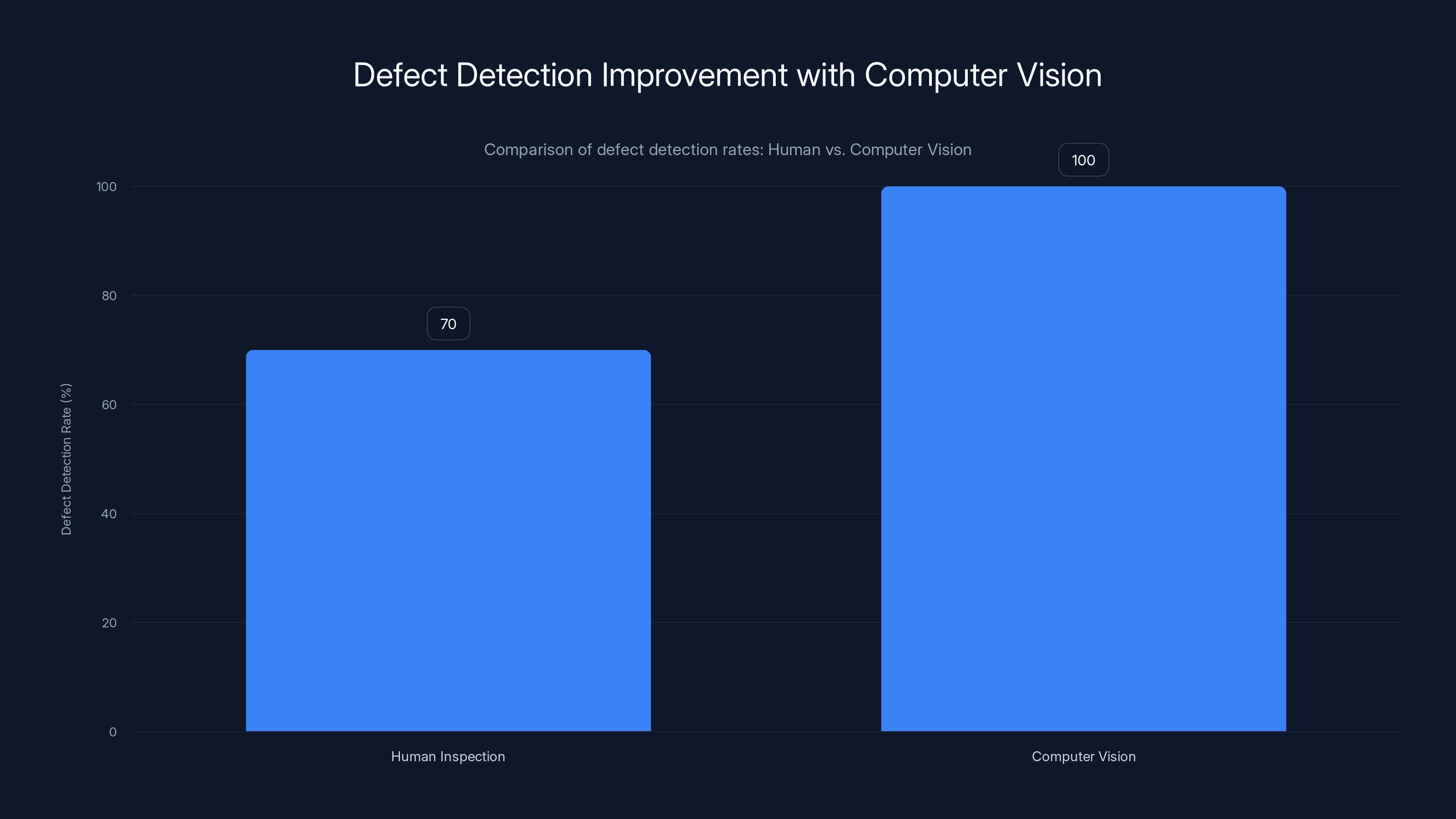

Computer vision changes that. Cameras watch the production line continuously. AI models identify defects faster and more consistently than human inspectors.

The challenge is that product defects are varied. A scratch on a surface. A dent. A color variation. A size variance. Misalignment. Each type of defect requires the model to recognize it. Train on images of good parts and bad parts. The model learns to distinguish them.

The business impact is substantial. Factories catch defects immediately instead of discovering them when products reach customers. Reduces warranty costs, recall costs, and reputation damage. Increases first-pass yield, meaning more good parts and less waste.

But the technology works best with consistent lighting, angles, and conditions. When you move to a new factory, you might need to retrain. When the product changes, you need new training data. When part of the production line gets refactored, camera angles change and the model might need adjustment.

It's not plug-and-play. It's a maintained system. But the return is obvious. Many factories report defect detection improvements of 30-50% compared to human inspection, plus detection of defect types humans consistently miss.

Estimated data shows a significant shift in technicians' focus from routine tasks to complex problem-solving and overseeing automated systems, enhancing their role and productivity.

The Trust Challenge: Why Organizations Hesitate to Let AI Decide

Here's the uncomfortable truth: most executives don't actually trust AI systems with consequential decisions.

It's not unreasonable. When an AI system makes a mistake, the consequences can be real. A false positive in predictive maintenance means unnecessary downtime and expense. A false negative means a failure nobody saw coming. In high-stakes environments like power generation, pharmaceuticals, or aviation, mistakes aren't acceptable.

So organizations build lots of human oversight. AI recommends maintenance, a human approves it. AI flags an anomaly, an engineer reviews it. The system is designed so AI never makes independent decisions.

This limits the upside. You're paying for AI capability but not using it fully because you don't trust it.

A better mental model is to treat AI like a new employee. You don't hire a fresh graduate and give them full authority on day one. They're trained, supervised, given progressively more responsibility as they prove competent. You watch them. You check their work. Gradually, as they show good judgment, you give them more autonomy.

The same approach works with AI. Start by having the system make recommendations. Humans make the final decision but follow the recommendation. Track the recommendation quality. If accuracy is high, give the system more autonomy. Maybe it makes some decisions independently but logs them for review. If it shows consistent good judgment, allow more independent decisions.

Over time, the system earns trust through demonstrated competence. This is how AI systems go from tools that assist humans to agents that operate with meaningful autonomy.

Trust also depends on explainability. When an AI system flags equipment for maintenance, can you understand why? A system that just says "yes, replace this bearing" is harder to trust than a system that says "bearing vibration signatures match patterns that preceded failure in equipment X, Y, and Z. Recommend replacement within 30 days."

The best Industrial AI systems are explainable. Not just "the model said so." But here's the evidence. Here's the historical precedent. Here's the confidence level.

Workflow Automation and Intelligent Scheduling

Much of industrial work is scheduling. Maintenance work. Production runs. Equipment changeovers. Shipping logistics. Coordinating hundreds of tasks, each with dependencies, constraints, and timing requirements.

Traditional scheduling is manual or uses simple rule-based systems. A production planner decides what to make and when. A maintenance scheduler figures out when to do maintenance without disrupting production. A logistics dispatcher routes trucks.

Each person makes reasonable decisions, but they can only consider a subset of variables. They don't have the capacity to optimize across all constraints simultaneously.

AI-based scheduling considers thousands of variables and constraints. Optimize for throughput and minimize changeovers. Optimize for equipment availability while respecting maintenance windows. Optimize for fuel efficiency and delivery time in logistics. The model finds solutions humans wouldn't find because the solution space is too large to explore manually.

The impact is efficiency gains of 10-20% in throughput, reduced changeover time, reduced fuel consumption, and better equipment availability.

The challenge is getting the constraints right. Real-world scheduling has implicit constraints nobody writes down. "We never schedule maintenance on Tuesdays because the sales team always wants demos then." "Equipment A and B can't run simultaneously because they share cooling capacity." "Truck routes must respect driver rest requirements."

A scheduling system that doesn't know these constraints optimizes in ways that don't work in practice. You have to encode the actual operational constraints, not just the theoretical ones.

Computer vision improves defect detection rates by 30-50% over human inspection, leading to fewer defects reaching customers. Estimated data.

The Execution Gap: Why Adoption Outpaces Readiness

Organizations are adopting AI faster than they're becoming ready to use it well.

This is the core problem facing Industrial AI right now. The technology works. The use cases are clear. But implementations fail because organizations aren't ready.

The gap shows up in several ways.

Skills gap: Organizations need people who understand both the industrial domain and machine learning. Few people have both. So they hire data scientists without industrial experience or hire operations people and try to teach them machine learning. Neither solution works well.

Process gap: Using AI requires different processes. Different decision-making workflows. Different roles and responsibilities. Organizations design processes for human decision-makers. When you introduce AI, those processes become obsolete. Redesigning them takes time and creates resistance.

Cultural gap: Industrial companies tend to be cautious. Risk-averse. Decades of operations have built organizational muscles around reliability and predictability. AI introduces uncertainty. Even if the expected value is better, the uncertainty makes people uncomfortable.

Integration gap: AI doesn't live in isolation. It has to integrate with existing systems, data, and workflows. That integration is often the hardest part of a project, but it's underestimated because it's not technically interesting.

Closing the execution gap requires attention to all of these. Not just the technology. The skills, the processes, the culture, and the integration.

Organizations that succeed aren't necessarily the ones with the best technology. They're the ones that address all four gaps simultaneously.

Agentic AI: The Next Phase of Industrial Intelligence

The current generation of AI in industrial settings is still mostly advisory. AI recommends. Humans decide. Over time, as systems prove reliable, authority shifts to autonomous agents.

Agentic AI is AI that makes decisions and takes actions with less human supervision. Not fully autonomous, but genuinely autonomous within its domain. A maintenance agent that schedules repairs without human approval, but logs its decisions for review. A logistics agent that optimizes routes in real time. A quality control agent that stops production when defect rates exceed thresholds.

This is distinct from today's systems, which are mostly tools that augment human decision-making. Agentic AI is decision-making with human oversight, not human decision-making with AI input.

The shift requires two things. First, the systems have to be reliable enough that autonomous action is acceptable. Second, organizations have to build frameworks for overseeing agents without micromanaging them.

It's similar to how management works with people. A manager doesn't approve every decision a good employee makes. They set boundaries, review exceptions, and trust the employee to exercise judgment within those boundaries. Agentic AI systems need similar frameworks.

The resistance to agentic AI is significant. "We're not comfortable letting a computer make that decision." That's understandable when decisions have real consequences. But humans make mistakes too. Bias, fatigue, incomplete information, rushed decisions. The question isn't whether AI is perfect. It's whether AI is better than the human alternative.

For many industrial decisions, AI is already better. But the psychological comfort with human decision-making is high. It's going to take time and evidence for that to shift.

Servitization: From Selling Products to Selling Outcomes

Industrial AI is enabling a fundamental shift in business models for industrial companies.

Traditionally, manufacturers sold equipment. A customer bought a pump, a compressor, a turbine. The manufacturer got paid once. The customer owned it, operated it, maintained it, dealt with failures.

Servitization flips that. The manufacturer sells availability or performance, not the equipment itself. A customer doesn't buy a pump. They buy "99% uptime for compressed air." Or they buy "5000 gallons per hour at X pressure." The manufacturer owns the equipment, operates it, maintains it, and guarantees the outcome.

That model makes AI indispensable. If you're guaranteeing uptime, you need to predict failures before they happen. If you're charging for availability, preventing downtime is your profit margin. AI does that.

It also changes the incentives. In the old model, if equipment fails, the customer bears the cost. In servitization, the manufacturer bears the cost. So the manufacturer is highly motivated to prevent failures.

This is already happening in some industries. Engine manufacturers no longer sell engines to airlines. They sell "power by the hour." The manufacturer owns the engine, the airline leases it, the manufacturer maintains it and guarantees availability. AI and predictive maintenance make that model work.

It's spreading. Industrial equipment manufacturers are moving toward similar models. Industrial AI is the enabler.

Sustainability and ESG: AI as a Compliance Tool

Regulations around environmental reporting are becoming mandatory globally. Organizations have to track and report emissions, resource consumption, and environmental impact.

Compliance is expensive. Data collection is scattered across systems. Calculations are complex. Reporting deadlines are tight.

AI helps in several ways. It aggregates data from multiple sources into a unified view. It automates calculations. It identifies optimization opportunities.

More importantly, AI helps optimize operations to reduce environmental impact, which isn't just good for compliance. It's good for costs. Optimizing energy consumption reduces energy bills. Reducing waste reduces material costs. Improving equipment efficiency reduces fuel consumption.

So Environmental, Social, and Governance (ESG) compliance becomes a driver for operational improvements. What started as regulatory burden becomes operational advantage.

This is where Industrial AI is uniquely positioned. It can track actual emissions in real time, identify which operations consume the most resources, optimize production to minimize waste, and predict equipment failures (preventing emergency interventions that require more resources).

Building an Industrial AI Strategy That Actually Works

If your organization is considering Industrial AI, here's what actually matters.

Start with the right problem. Not the most interesting problem. Not the sexiest problem. The right problem is one where (1) you have good data, (2) the payoff is clear, (3) success is measurable, and (4) failure is survivable. Predictive maintenance on high-downtime equipment checks all those boxes. General optimization across your entire operation? That's harder and riskier.

Invest in data infrastructure first. Before you build a model, make sure you can access and integrate data from your systems. That's not a nice-to-have. It's foundational. Many projects fail because data is too messy, too isolated, or too incomplete. Fix that first.

Hire for domain expertise, not just ML expertise. A data scientist who knows your industry beats a brilliant data scientist who doesn't. You need people who understand both the technical and the operational side.

Design for explainability. Your systems need to explain their reasoning. Not just predictions. Why did it flag this equipment? What historical patterns does it match? What confidence level?

Plan for integration and change management. The technology is the easy part. Everything else is harder. Budget time and resources for integrating AI into existing workflows, retraining people, and building trust.

Start small and scale gradually. A successful pilot builds institutional confidence. Failure at scale demoralizes. Start with a narrow use case, prove the concept, then expand.

Measure relentlessly. What's the ROI? Uptime improvements? Cost savings? Safety improvements? Document everything. You need concrete evidence because Industrial AI is still somewhat unfamiliar to many organizations.

The Future of Industrial AI: From Pilots to Embedded Systems

The future is embedded AI. Not a separate system bolted onto legacy operations. But AI woven into the fabric of how industrial operations work.

Equipment will have embedded sensors and edge computing. Systems will make local decisions and coordinate globally. Humans will operate in oversight roles, making judgment calls and handling exceptions. Robots will handle hazardous tasks. Processes will be optimized in real time based on actual conditions rather than planned conditions.

This is a multi-year transition. Organizations are currently in the pilot and early adoption phase. The next five years will see increasing scale and integration.

The competitive advantage goes to companies that embed AI earliest. They'll see efficiency gains, cost reductions, and quality improvements. Competitors will struggle to catch up because closing the gap requires sustained investment and organizational change.

But there's no magic formula. Success comes from understanding the specific problems, investing in the right infrastructure and people, managing organizational change carefully, and maintaining focus on measurable outcomes.

Industrial AI is real. It's working. But it requires discipline to implement well.

The Unsexy Revolution: Why Industrial AI Matters More Than Chat GPT

If you're looking for dramatic breakthroughs, Industrial AI is boring. No viral moments. No impressive demos. Just steady, measurable improvements in how critical industries operate.

But that's exactly what makes it important.

While the media obsesses over Chat GPT and Midjourney, engineers and operators are quietly using AI to prevent equipment failures that could disrupt supply chains. To optimize power grids serving millions of people. To improve safety in hazardous work environments. To optimize logistics networks that move global commerce.

The impact of Chat GPT is still uncertain. Maybe it fundamentally changes knowledge work. Maybe it's a productivity tool that becomes normal over time. We're still figuring that out.

The impact of Industrial AI is already clear. Better uptime. Lower costs. Safer operations. Measurable returns. These impacts compound over years.

That's why Industrial AI matters. Not because it's flashy. But because it solves real problems for real people in the industries that keep civilization running.

The quiet revolution is the one that lasts.

FAQ

What is Industrial AI?

Industrial AI refers to the application of machine learning, predictive analytics, and intelligent automation to optimize operations in manufacturing, energy, utilities, and logistics. It includes predictive maintenance (preventing equipment failure before it happens), anomaly detection (identifying abnormal operations), quality control (automated defect detection), and workflow optimization (intelligent scheduling and resource allocation). Unlike general AI focused on office automation and content generation, Industrial AI solves problems specific to physical operations and the workers who maintain them.

How does Industrial AI differ from traditional automation?

Traditional industrial automation uses programmable logic controllers and rule-based systems that follow fixed instructions. Industrial AI, by contrast, learns from data and adapts to changing conditions. A traditional system might follow a set sequence of operations. An AI system learns which sequences are optimal given current conditions and adjusts in real time. Traditional automation handles repetitive, well-defined tasks. Industrial AI handles complex, variable situations where the optimal approach depends on patterns in data.

What are the main benefits of Industrial AI?

Measurable benefits include equipment uptime improvements of 25-50%, maintenance cost reductions of 15-25%, production efficiency gains of 10-20%, improved safety through hazard prediction and prevention, faster defect detection in quality assurance, optimized scheduling that reduces changeover times, and better resource allocation across operations. Beyond immediate operational gains, Industrial AI enables business model shifts toward servitization (selling outcomes rather than products) and supports ESG compliance through real-time emissions and resource tracking.

Why do most Industrial AI pilots fail to scale?

Failures typically stem from organizational factors rather than technical ones. Common reasons include insufficient data quality and integration (data is siloed across legacy systems), skills gaps (lacking people who understand both machine learning and industrial operations), inadequate change management (workflows and roles aren't redesigned for AI), and insufficient trust in AI systems (resistance to autonomous or semi-autonomous decisions). Organizations that succeed address all four areas simultaneously, not just the technical implementation.

How long does it take to implement Industrial AI?

Timeline depends heavily on starting conditions. If data is well-organized and accessible, a proof-of-concept can be built in 3-6 months. Integration into production workflows typically takes another 2-6 months. Scaling across an organization takes 1-2 years. However, organizations with poor data infrastructure or significant legacy systems should expect 12-18 months just for data integration before model development can start effectively. Starting with a narrow, well-defined use case (like predictive maintenance on a single equipment type) accelerates timelines compared to attempting broad organizational transformation.

What skills do organizations need for Industrial AI success?

You need a mix of data science expertise and industrial domain knowledge. Ideally, you'll hire data scientists who have worked in industrial settings, or pair domain experts with data scientists during projects. You also need systems engineers to handle data integration, operations experts to ensure the AI fits actual workflows, and change management professionals to guide organizational transition. Many organizations underestimate the need for skilled integration engineers and operations-focused people, focusing too heavily on data scientists alone.

How much does Industrial AI cost to implement?

Costs vary widely based on scope and current infrastructure. A focused proof-of-concept with good data might cost

What's the difference between predictive maintenance and preventive maintenance?

Preventive maintenance runs on a schedule (replace equipment every X hours or years) without knowing the actual condition of the equipment. Predictive maintenance monitors actual equipment condition and schedules maintenance only when data indicates failure is likely. Preventive maintenance wastes resources by replacing equipment that still has useful life. Predictive maintenance optimizes timing based on actual deterioration patterns, reducing costs while improving uptime. Industrial AI enables predictive maintenance by continuously analyzing sensor data to identify failure indicators.

How do organizations build trust in AI-driven decisions?

Trust builds through demonstrated competence and transparency. Start by having AI make recommendations while humans decide, then track accuracy and recommendation quality. As accuracy improves and humans see that the system makes good recommendations consistently, expand autonomous decision-making gradually. Ensure systems provide explainable reasoning (not just predictions, but why it made that recommendation). The best approach treats AI like a new employee: trained, supervised initially, then given progressively more responsibility as competence is demonstrated.

What's the relationship between Industrial AI and ESG compliance?

Industrial AI enables real-time tracking of emissions, energy consumption, and resource use across operations. This simplifies ESG reporting and compliance with regulations like the EU Corporate Sustainability Reporting Directive. Beyond compliance, AI optimizes operations to reduce environmental impact, which also reduces costs. Lower energy consumption reduces energy bills. Reduced waste reduces material costs. Improved equipment efficiency reduces fuel consumption. So ESG compliance becomes an operational advantage rather than just a regulatory burden.

Conclusion

The AI industry likes to talk about transformative technology and moonshot applications. But the real transformation isn't happening in research labs or startup demo days. It's happening on factory floors and in power plants and at distribution centers, where engineers and technicians are using AI to solve problems that cost their organizations millions every year.

Industrial AI is different from the broader AI narrative because it's not speculative. It's not theoretical. It's applied. Real companies are using it right now. The payoff is measurable. The ROI is clear. And it's working.

The challenge isn't the technology. Machine learning has been around for decades. Predictive maintenance is not a new concept. What's new is that the infrastructure is finally in place to make it practical at scale. Cloud computing. Accessible machine learning tools. Better sensors. Faster integration platforms. The pieces fit together now in ways they didn't five years ago.

But technology is the easy part. The hard part is organizational. Rethinking roles. Retraining people. Redesigning workflows. Building trust in systems that are making important decisions. Those challenges take time.

That's why the future of Industrial AI is gradual, not revolutionary. Organizations will move from pilots to embedded systems over the next five years. The ones that execute well will see significant competitive advantages. The ones that struggle will fall behind.

But unlike many technology revolutions, this one isn't optional for long. As competitors implement Industrial AI and capture efficiency gains, the pressure on laggards grows. Within a decade, Industrial AI will be the norm, not the exception. The question for most organizations isn't whether to adopt it, but how quickly.

The good news is that the path forward is clear. Start with problems where you have good data and clear payoff. Invest in people and infrastructure. Manage the organizational transition carefully. Measure relentlessly. Scale gradually.

There's nothing sexy about it. But there's nothing uncertain about it either. Industrial AI works. And for the 70% of the global workforce that sits in offices never visiting a factory floor, that quiet revolution happening far from public view is going to reshape how the world operates.

Key Takeaways

- Industrial AI is solving real operational problems (predictive maintenance, anomaly detection) with measurable ROI, unlike speculative AI applications

- 70% of the global workforce in manufacturing, energy, and logistics has been overlooked by AI innovation focused on office automation

- Execution gap is the real problem: organizations adopt AI faster than they become ready to use it effectively, due to skills gaps, change management, and trust issues

- Agentic AI represents the next evolution, where AI systems make autonomous decisions within defined boundaries rather than just providing recommendations

- Servitization business model (selling outcomes vs. products) is becoming viable because AI enables companies to guarantee performance metrics

Related Articles

- Boston Dynamics Atlas Robot 2028: Complete Guide & Automation Alternatives

- How to Watch Hyundai's CES 2026 Press Conference Live [2026]

- AI Factories: The Enterprise Foundation for Scale [2025]

- Boston Dynamics Atlas Production Robot: The Future of Industrial Automation [2025]

- Home Robots in 2026: Why Specialized Bots Beat the Robot Butler Dream [2026]

- Boston Dynamics Atlas Production Robot: Enterprise Transformation [2025]

![Industrial AI Applied: Where the Real Revolution is Happening [2025]](https://tryrunable.com/blog/industrial-ai-applied-where-the-real-revolution-is-happening/image-1-1767973261190.jpg)