Introduction: When Toys Meet Engineering Ambition

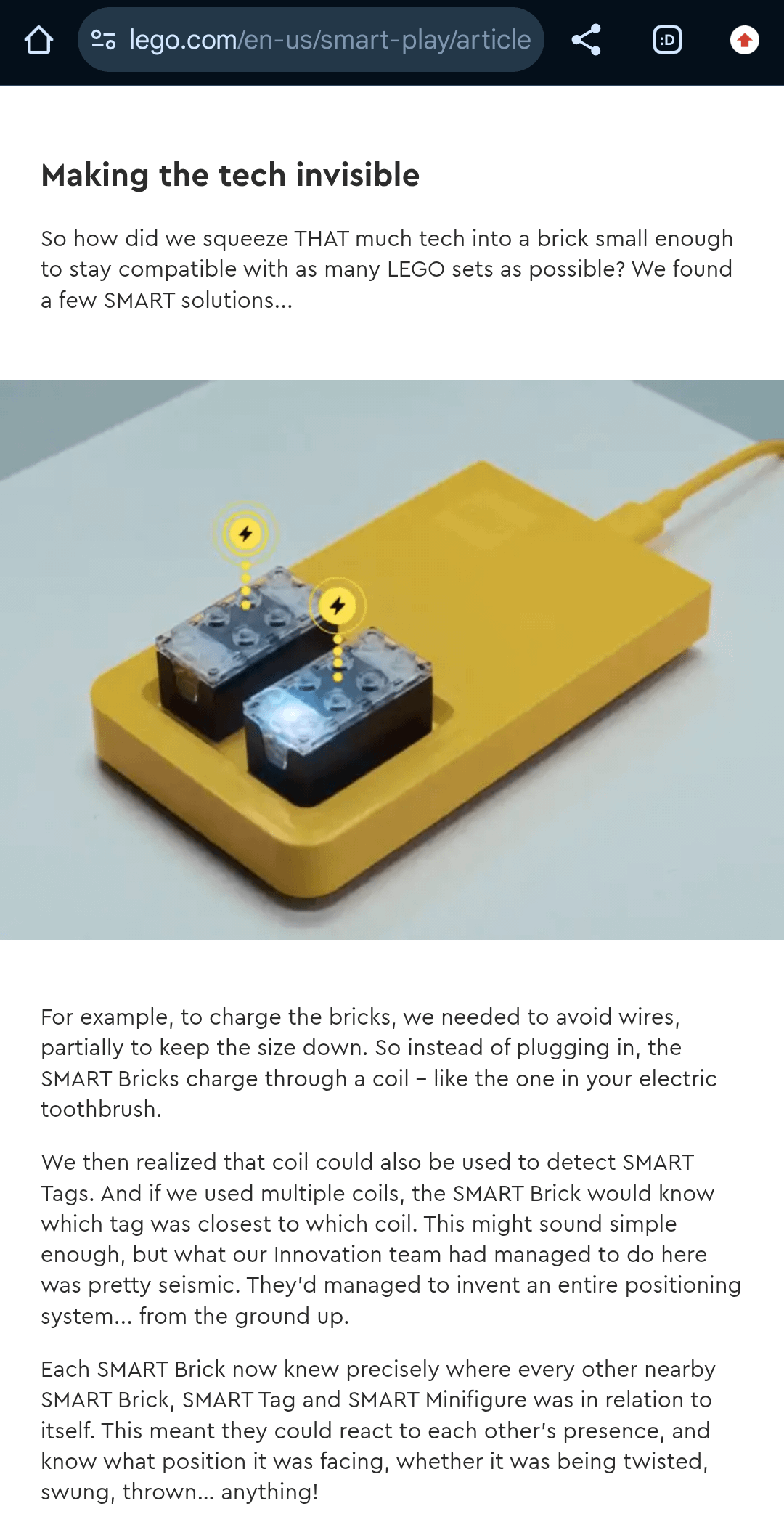

Lego just did something most toy companies would never attempt. Instead of slapping existing charging technology into their new Smart Bricks system, they built wireless charging from the ground up. Not the generic Qi charging you find in phones. Something custom. Something that needed to work inside tiny plastic bricks while maintaining structural integrity and keeping costs reasonable.

This decision reveals something interesting about how consumer electronics actually get made. When you're designing products at scale, you don't just grab off-the-shelf components and call it done. Sometimes the constraints are so specific that you have to invent your own solutions.

The Lego Smart Bricks system represents a significant moment in toy technology evolution. These aren't just LED-equipped bricks or simple motorized elements. They're connected modules with microcontrollers, sensors, and batteries all squeezed into pieces that need to feel and function like traditional Lego bricks. The engineering challenges multiply when you add wireless charging into that equation.

What makes this story particularly compelling is how transparent Lego's team has been about their design decisions. They didn't hide behind marketing speak. Instead, they explained the genuine technical reasons why they couldn't just use standard solutions. And those reasons teach us something about what happens when established toy manufacturers finally embrace modern electronics in meaningful ways.

This deep dive explores exactly what Lego engineers faced, why custom wireless charging became necessary, how the technology actually works, and what this means for the future of connected physical play. We'll examine the constraints that shaped their design, the trade-offs they navigated, and the innovation hiding inside those apparently simple plastic bricks.

The story begins with ambition. High ambition, according to the Lego team themselves.

TL; DR

- Custom Wireless Charging Required: Standard Qi charging couldn't fit Lego's size and design constraints, forcing custom engineering

- Structural Integration Challenge: Battery placement and charging contacts needed to work within traditional brick dimensions without compromising play experience

- Connected Play Future: Smart Bricks represent Lego's commitment to merging digital experiences with physical building in ways that feel natural to users

- Technical Trade-offs: Engineers had to balance power delivery, charging speed, cost, and durability across millions of units

- Market Implications: This approach signals how legacy toy manufacturers are now competing directly in the IoT and smart toy space

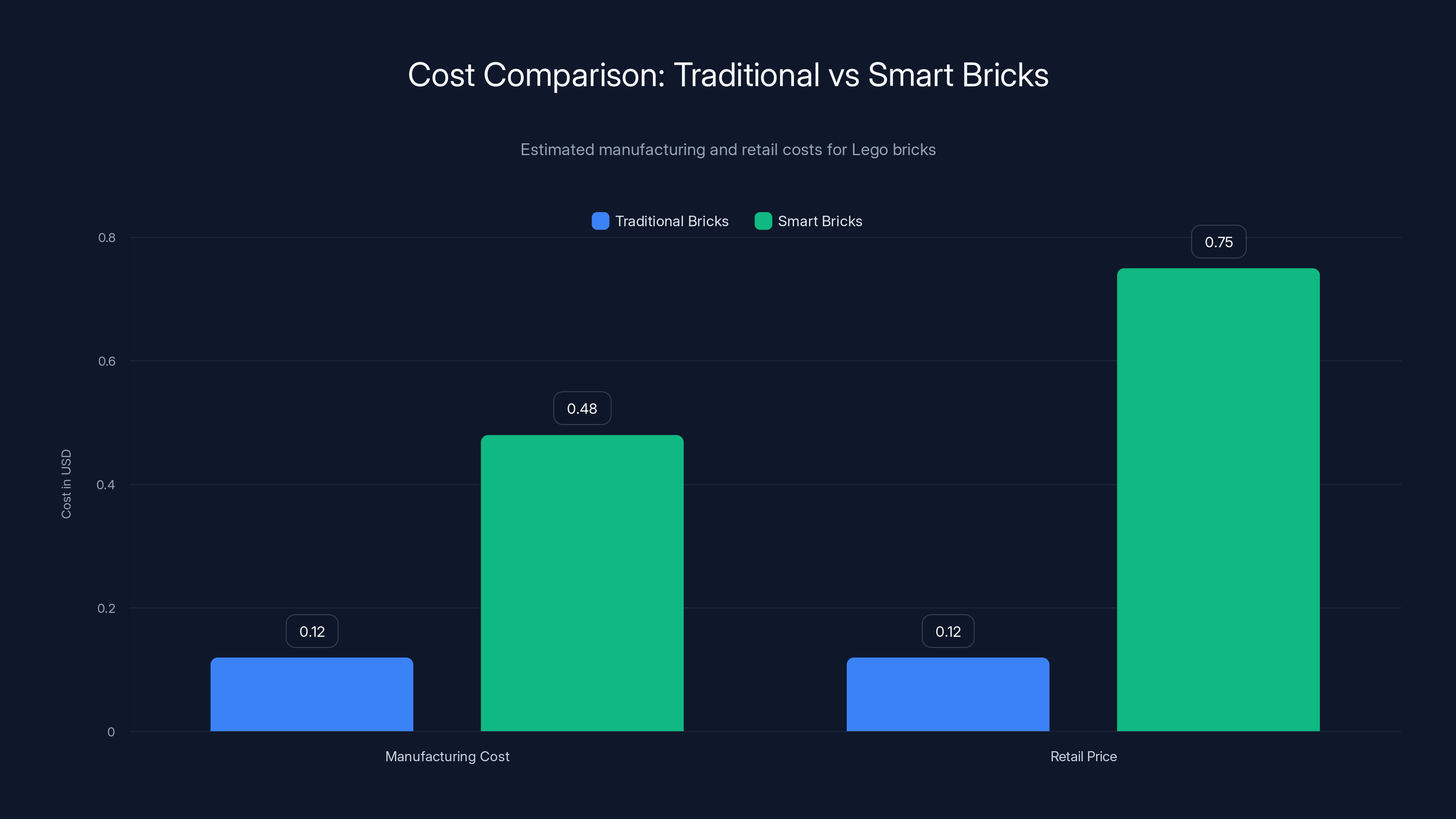

Smart Bricks cost significantly more to manufacture and retail than traditional bricks, reflecting their advanced features and complexity. Estimated data based on typical price ranges.

What Exactly Are Lego Smart Bricks?

Lego Smart Bricks aren't your childhood Lego collection with a software update slapped on. These are fundamentally different components designed from scratch to function as both traditional building blocks and computational devices.

At their core, Smart Bricks contain microcontrollers that communicate wirelessly with other bricks and with companion applications. This means structures you build aren't just physical—they're also digital. A wall of Smart Bricks can sense when it's been touched, respond to commands, change colors, produce sounds, and interact with programmed logic. Building a structure becomes programming that structure simultaneously.

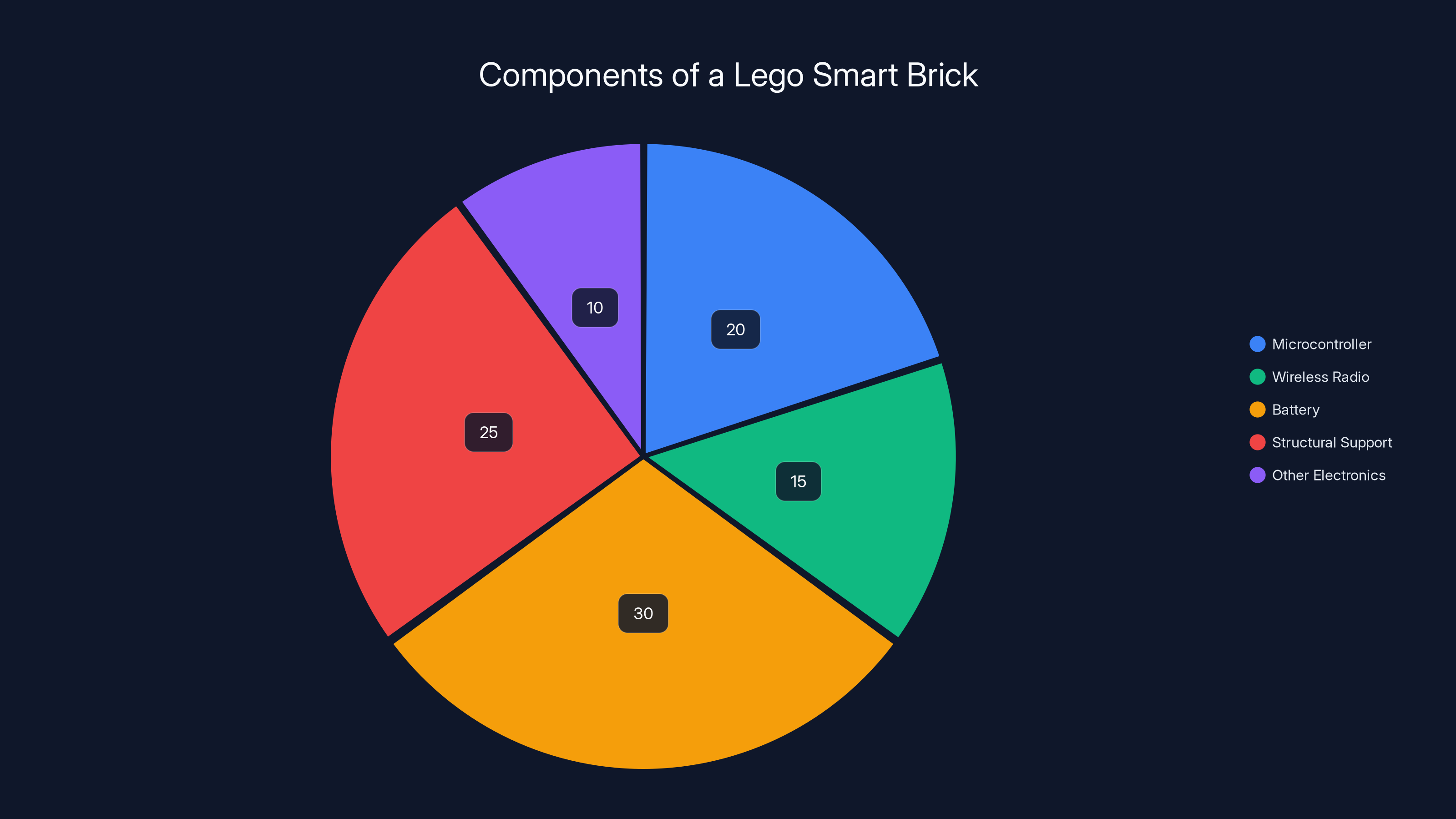

The system architecture relies on distributed computing across multiple connected bricks. Each brick contains its own processor, memory, and wireless radio. They form a mesh network where data can route through multiple paths. This distributed approach provides resilience. If one brick loses connection briefly, signals can travel through neighboring bricks to reach their destination.

Lego faced a fundamental problem here that traditional toy makers never encountered. Traditional Lego bricks draw no power. They're passive, inert plastic. Suddenly introducing powered electronics creates entirely new design challenges.

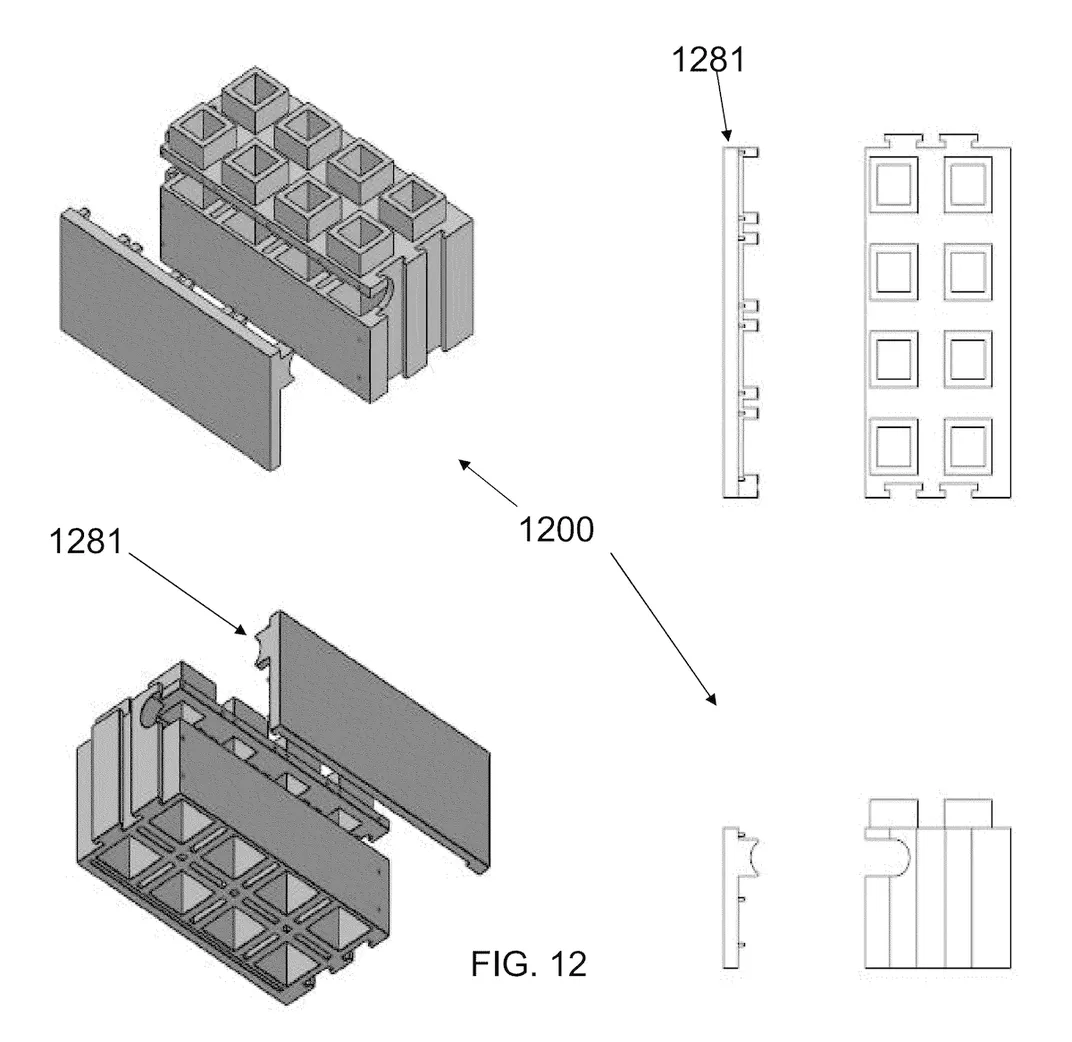

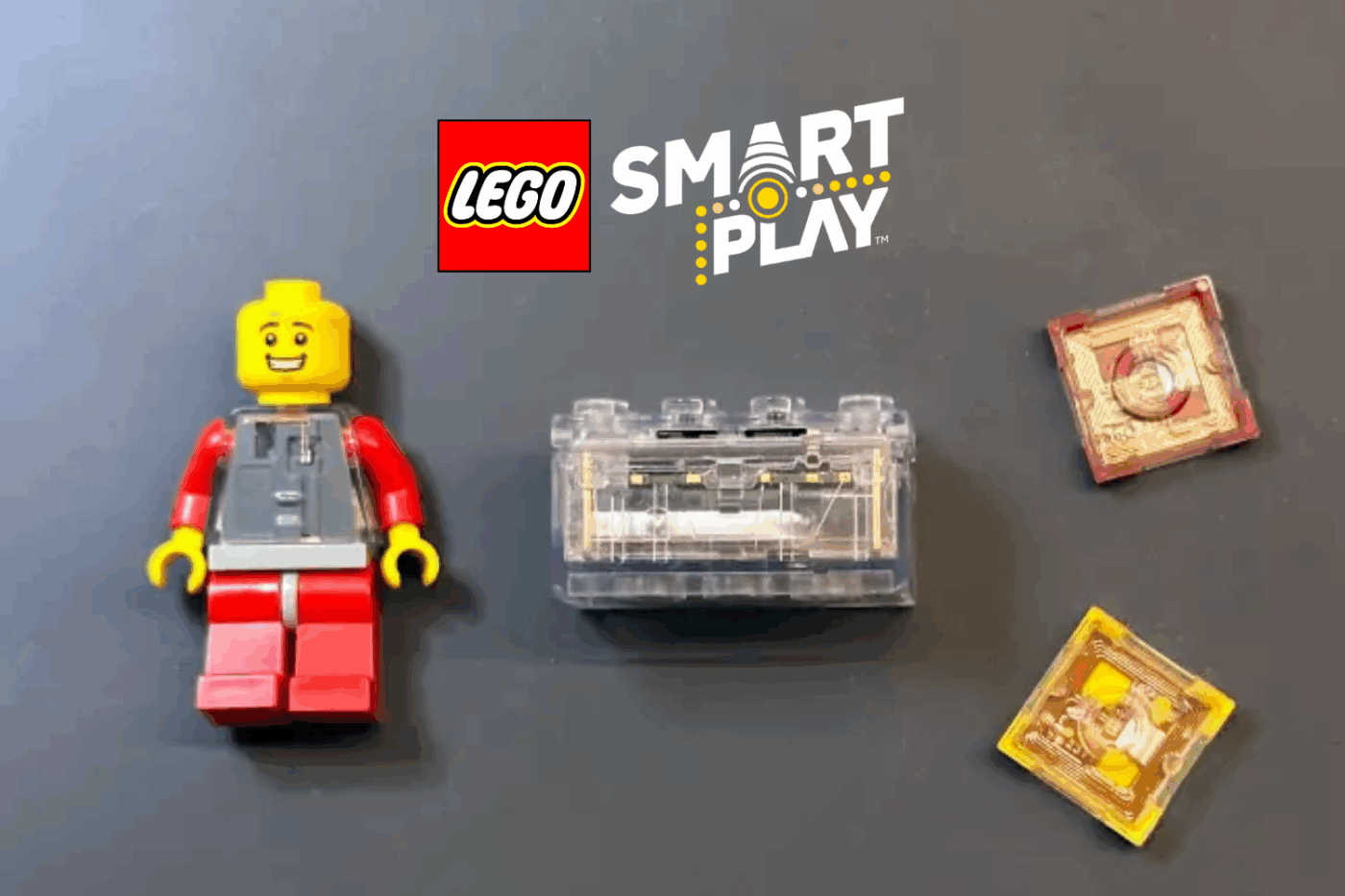

Size constraints define everything. A standard Lego brick stud—that's the little dot on top—measures 8mm in diameter. The overall brick measures roughly 16mm wide and 24mm long in the most common configurations. Now try fitting a microcontroller, radio, battery, and charging circuitry into that space while maintaining the brick's structural integrity and ability to connect to other bricks.

The battery presents the first obvious challenge. Lithium-ion cells you'd find in phones are too thick. The engineering team needed something smaller, which meant researching emerging battery technologies and commissioning custom cell designs. They opted for pouch-style batteries that could conform better to brick geometry than traditional cylindrical cells.

The wireless radio represents another constraint. Bluetooth Low Energy offered the right power profile for toy applications, but the antenna needed careful design and placement. Standard PCB antennas might not work inside plastic brick structures. The material properties of ABS plastic, which Lego uses, have known effects on radio propagation. Engineers had to model and test antenna performance extensively.

The microcontroller itself needed to be small, power-efficient, and capable of the relatively simple tasks required—sensor reading, wireless communication, and basic logic operations. Nothing too exotic. An ARM Cortex-M4 derivative would do the job, but integrating it with everything else required custom PCB design and careful power management.

This was just the beginning of the engineering journey.

The Charging Problem That Sparked Custom Engineering

Here's where the story gets genuinely interesting. Lego could have used USB-C connectors on each brick. Clunky, yes. But technically feasible. They could have used standard Qi wireless charging pads that your phone uses. But neither solution satisfied their actual requirements.

USB-C creates immediate problems. First, you'd need a port on each brick. Drilling ports into bricks changes their feel and structural properties. More importantly, it breaks the mental model of what Lego bricks are. Part of Lego's appeal is simplicity and standardization. Every brick connects the same way. Adding connectors to some bricks (the smart ones) and not others (the regular ones) creates cognitive friction for users. Kids building with both types simultaneously would constantly encounter inconsistency.

Wired charging also means downtime. You'd need to connect bricks to a charging station between play sessions. With dozens of bricks potentially in a set, managing individual charging cycles becomes tedious. Lego wanted a system where you charge multiple bricks simultaneously without any connectors or special procedures.

Standard Qi charging seemed promising. Billions of people use Qi-enabled phones. The technology is mature, well-understood, and standardized. But Qi chargers operate at roughly 5-15 watts of power transfer, with charging coils that need reasonable separation between transmitter and receiver. A typical Qi charger transmitter is several centimeters in diameter.

Now try miniaturizing that to fit inside a Lego brick. The coil size shrinks dramatically. Power transfer efficiency drops. And you're trying to charge dozens of bricks simultaneously on a single charging pad, meaning the electromagnetic field becomes complex and unpredictable.

Lego engineers ran the numbers and realized standard Qi charging wouldn't meet their real-world usage requirements. They needed to charge 50+ bricks on a single charging pad, in under 30 minutes, with minimal electromagnetic interference issues, and without heating components to dangerous levels.

That's when custom wireless charging became the only viable path.

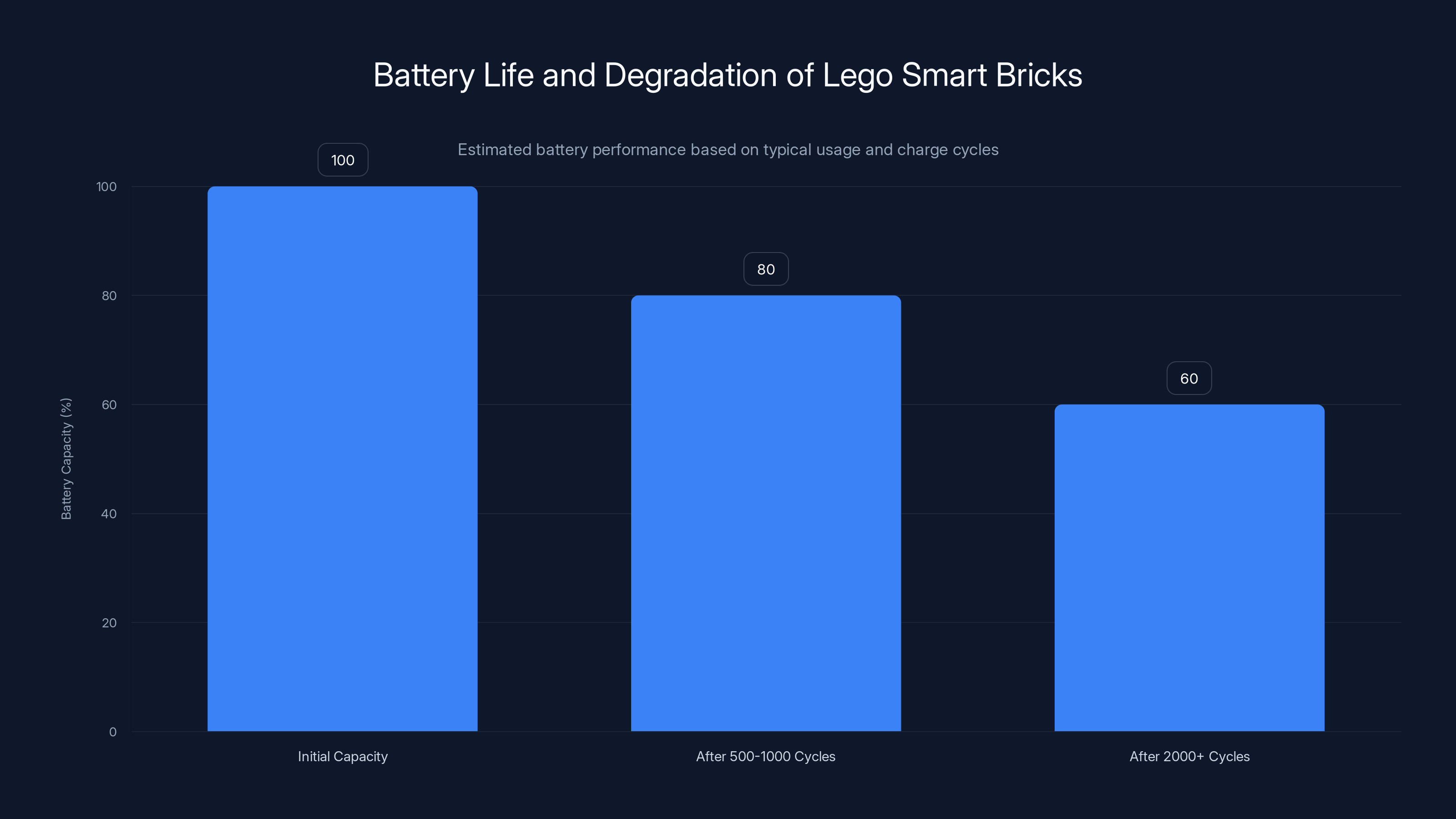

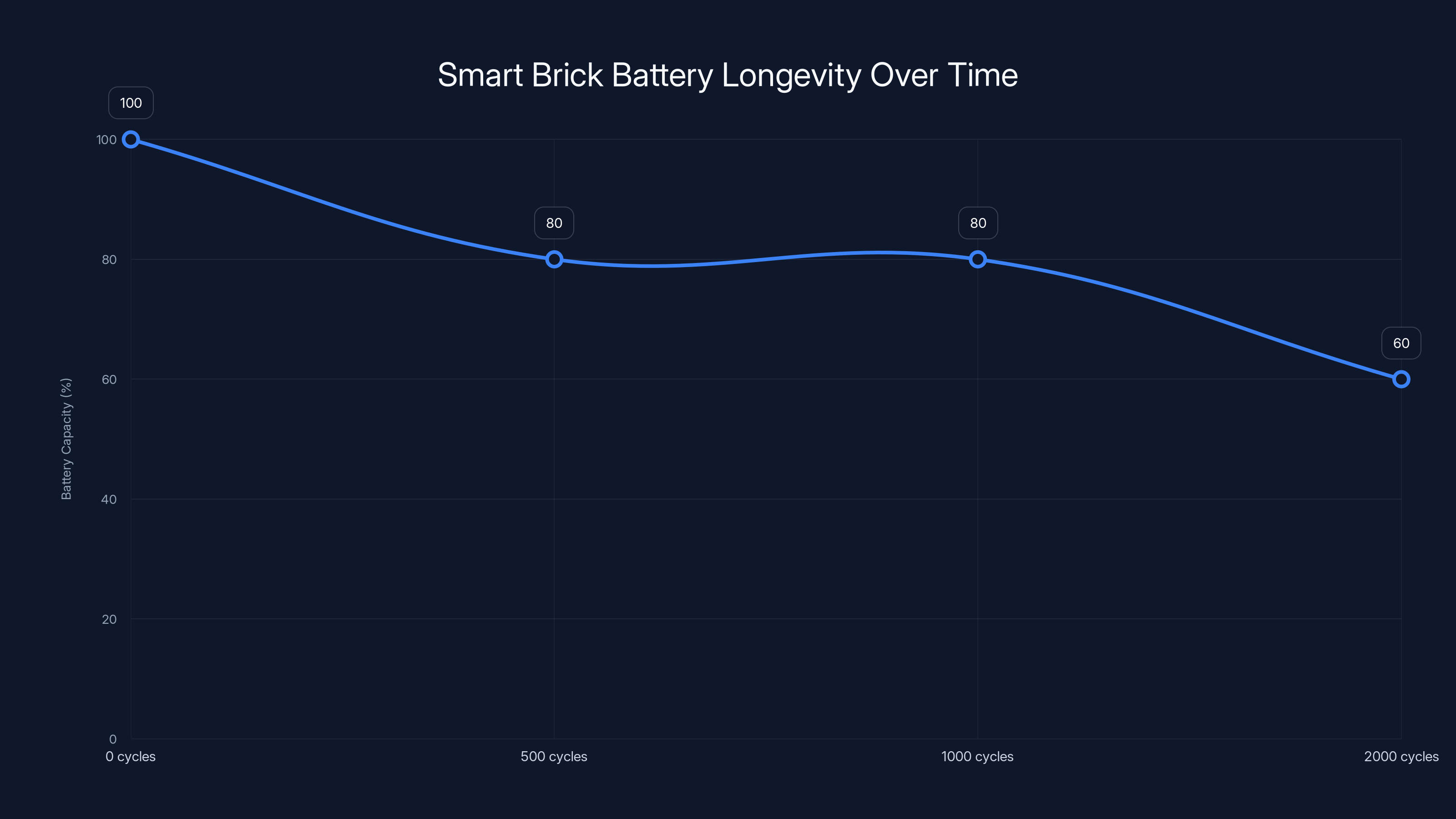

Lego Smart Bricks maintain about 80% capacity after 500-1000 charge cycles and 60% after 2000+ cycles, ensuring several years of use.

Engineering Custom Wireless Charging from Scratch

When Lego decided to build proprietary wireless charging, they weren't starting completely from scratch. The fundamental physics of inductive coupling is well-established. Power can be transferred wirelessly through electromagnetic induction, the same principle that transformed phone charging in the last decade.

But optimization for their specific use case required significant customization.

The engineering team needed to solve several interconnected problems simultaneously. The charging coil had to be small enough to fit inside a brick without compromising strength. The power delivery had to be sufficient for reasonably fast charging but not so aggressive that thermal management became problematic. The entire system needed to work reliably across manufacturing tolerances.

Lego went with a modular approach. Smart Bricks come in different sizes, and not all of them need identical charging hardware. The smallest bricks might use a simplified charging circuit, while larger bricks could accommodate more sophisticated circuitry. This lets them maintain relatively consistent charging pad designs while optimizing each brick's internals separately.

The charging coil design proved particularly tricky. Flat coils can be embedded into brick surfaces, but they're less efficient than 3D coil designs. Lego's engineers explored various geometries—trying to maximize power transfer while keeping the total footprint minimal and the brick's structural integrity intact.

They faced a decision: maximize efficiency or maximize surface area for distributed charging? They chose a middle path. The coils use a flat spiral design that fits nicely into the brick architecture while maintaining reasonable efficiency. It's a compromise, but one that works in practice.

Power regulation circuits also needed customization. Standard wireless charging receivers expect standard power delivery profiles. Lego's bricks have varying battery capacities depending on size. A standard charging circuit might over-deliver power to smaller bricks or under-deliver to larger ones. Custom charging controllers could adapt to each brick type and detect when batteries reached full charge, preventing overcharging and extending battery life.

The charging pad itself represents another engineering effort. Unlike Qi chargers that are roughly the size of a coaster, Lego's pad needed to accommodate dozens of bricks arranged in any pattern. This required sophisticated coil arrays under the surface, intelligent power management that could handle multiple simultaneous charging operations, and thermal management to dissipate heat generated during charging.

Lego engineers designed the charging pad with multiple transmit coils arranged in a grid pattern. Power electronics determine which coils to activate based on where bricks are positioned. If a brick sits between two coil areas, the charging system might activate both coils at reduced power levels to optimize efficiency and prevent hot spots.

Temperature management became critical. Batteries are sensitive to heat. Charging generates heat through resistive losses in coils and power conversion circuits. Run it too aggressively and you degrade battery lifespan or create safety issues. The charging system needed thermal sensors and algorithms that could throttle power delivery if temperatures climbed.

Size Constraints That Drove Design Decisions

Every engineering constraint forces simplification or innovation somewhere else. Lego's size constraints were severe.

The brick couldn't get significantly larger or thicker. That would break compatibility with existing Lego collections and ruin the play experience. Kids expect Lego bricks to feel like Lego bricks. Add too much mass or change the proportions and the tactile feel changes fundamentally.

This size constraint propagated through every design decision. The battery had to be compact. The microcontroller had to be small. The power management circuits had to be miniaturized. The charging coil had to be thin. Every component needed optimization for space.

Battery technology became the first real bottleneck. Traditional alkaline batteries wouldn't work because you'd need to replace them constantly, which contradicts the entire wireless charging vision. Rechargeable batteries were necessary, but the smallest lithium-ion cells available were still quite large.

Lego's solution was commissioning custom prismatic cells from suppliers. These cells have flat profiles rather than cylindrical shapes. They pack more capacity into the space available while still fitting the brick's geometry. The trade-off is custom manufacturing means higher costs per unit compared to buying standard cells. But at Lego's scale, ordering millions of custom cells becomes economically viable.

The microcontroller selection followed similar logic. There's no shortage of small ARM-based microcontrollers. But finding one that offered sufficient processing power, good Bluetooth support, and small form factor required careful evaluation. Lego settled on controllers with integrated Bluetooth radios, eliminating the need for separate radio modules that would consume additional space.

Package density drove PCB design. Every trace, every component had to be optimized for minimal area. Multi-layer PCBs with controlled impedance traces became necessary. Surface-mount components eliminated the need for through-hole parts that would consume additional space vertically.

The wireless charging coil itself faced severe size constraints. Flat spiral coils can be etched directly onto PCBs, but their efficiency drops compared to 3D designs. Lego explored ultra-thin 3D coils wound from specialized wire, but manufacturing complexity and cost limited those approaches for production.

Ultimately, the engineering team settled on embedded flat coils manufactured as part of the PCB fabrication process. Not maximally efficient, but sufficient for the application and manufacturable at scale.

Power Management and Battery Technology Innovations

Power management in tiny connected toys reveals interesting engineering challenges.

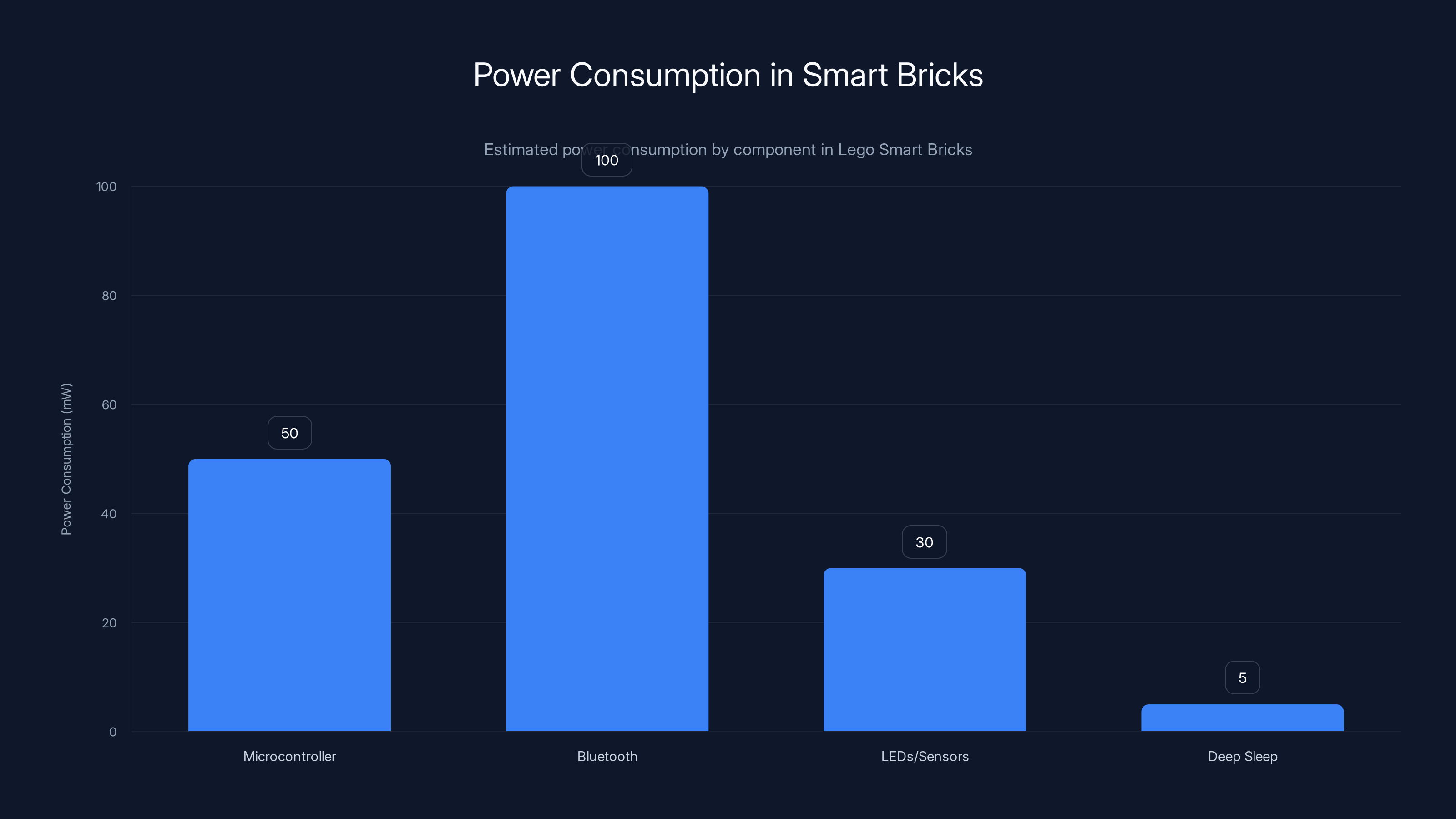

The microcontroller inside each Smart Brick runs continuously, consuming power even when the brick isn't actively being used. Bluetooth communication consumes significant current when transmitting. LEDs or sensors in certain brick types draw power. The battery needs to sustain all these loads for weeks between charging sessions.

Lego engineers implemented sophisticated power management at the firmware level. The microcontroller enters deep sleep states when not communicating or detecting activity. This reduces average power consumption dramatically. Only when the wireless charging pad is detected nearby does the system wake up fully.

The charging efficiency itself depends on getting power delivered properly into the battery. Standard charging profiles assume typical battery capacities and expected discharge curves. Custom batteries with different electrochemistry required custom charging algorithms.

Lego opted for lithium-ion chemistry because it offers the best energy density for small form factors. But lithium-ion batteries are sensitive to charging parameters. Overcharge them and they degrade or fail catastrophically. Charge them too slowly and the overall experience becomes frustrating. The charging controller needed to implement proper constant-current, constant-voltage charging profiles.

The custom cells Lego commissioned have onboard protection circuits built in, similar to what you'd find in any rechargeable battery. But the charging pad also includes sophisticated logic that monitors charging status and adapts power delivery to optimize speed and safety.

Temperature monitoring happens through thermal sensors in contact with the battery cells. If a brick's temperature exceeds safe limits, the charging system reduces power automatically. This prevents thermal runaway while still providing reasonable charging speed under normal conditions.

Lego engineers also considered battery cycle life in their power management design. A user might charge their Smart Bricks thousands of times over the product lifespan. Every design decision that reduces charging stress extends battery life. This means proper float voltage management at end-of-charge, avoiding overcharge conditions, and protecting against deep discharge damage.

The charging pad stores enough energy capacity to charge multiple bricks simultaneously. This required substantial onboard power storage in the charging station itself. Capacitors and supporting power delivery circuitry ensure stable voltage delivery to all active coils during peak charging demands.

One fascinating detail: Lego's charging system includes fault detection. If a coil detects metallic foreign objects on the charging surface—a coin, a paperclip, something conductive—the system can detect the anomaly through impedance changes and deactivate that coil. This prevents heating of foreign objects and maintains charging pad safety.

Smart Brick batteries retain about 80% capacity after 500-1000 cycles and 60% after 2000 cycles. Estimated data.

Structural Integrity: Keeping Bricks, Well, Brick-Like

This is perhaps the most elegant constraint Lego's engineering team faced. The brick had to remain a brick.

Adding electronics fundamentally changes how you design physical components. You need space for circuits, batteries, and coils. You need compliance with electrical safety standards. You need thermal management. All of this pushes toward making the brick larger, thicker, or heavier.

But Lego's entire business model depends on bricks being compatible. A Smart Brick needs to connect to traditional Lego bricks seamlessly. Studs on top need proper spacing. Underside tubes need correct depth. Weight shouldn't be dramatically different or the play experience becomes weird.

The engineering approach here was ruthless optimization. Every millimeter of space got allocated with purpose. The battery was one of the largest components, and its form factor was specifically chosen to fit efficiently without changing brick dimensions.

Lego's manufacturing process for Smart Bricks is fundamentally different from traditional plastic injection molding. Traditional bricks are just ABS plastic. Smart Bricks require assembly steps where the PCB, battery, and coil get installed inside the molded plastic shell.

The structural design needed to account for this assembly process. The plastic shell provides structural strength, but cutouts are needed to accommodate components. Ribs and reinforcement structures prevent the thin plastic walls from warping under stress. The design had to maintain the brick's durability when stressed by typical Lego building—bricks get snapped together thousands of times, yanked apart, dropped, and thrown into bins.

Quality control became more complex for Smart Bricks than traditional bricks. Not only does the plastic injection need to be correct, but every assembled unit needs verification that electronics work, charging functions properly, and wireless communication operates reliably. Lego implemented extensive testing at manufacturing sites to verify every brick before it ships.

The weight distribution inside the brick also needed careful consideration. An imbalanced brick would feel wrong and might affect how kids build with it. Even distribution of battery and PCB components throughout the brick's internal volume helped maintain the proper feel.

Structural stress testing proved necessary. The brick needs to withstand repeated assembly and disassembly without electronic components failing. The internal components needed shock protection and vibration damping to survive the mechanical stresses of typical play.

This is why you see some Smart Bricks feature protective foam or gel encapsulation around delicate electronic components. It's not excessive engineering. It's necessary protection for electronics operating in an environment where they get subjected to mechanical stress and potential moisture exposure.

Heat Dissipation Challenges in Small Spaces

Wireless charging generates heat. Computers generate heat. Put them in a tiny plastic brick and heat management becomes a real engineering problem.

The charging coil produces resistive heating as current flows through the wire. The power conversion electronics that regulate voltage and current generate losses. The microcontroller and radio consume power, converting electrical energy into heat and radio waves. All of this heat has nowhere to go in a small, enclosed plastic component.

Lego's approach to thermal management is passive—there are no fans or active cooling solutions in Smart Bricks. Instead, the thermal design relies on careful material selection and component placement.

The PCB material was chosen for its thermal conductivity. Standard FR-4 fiberglass is typical for PCBs, but Lego explored materials with better heat transfer properties. The battery cells sit in thermal contact with parts of the plastic shell that can dissipate heat to the surrounding environment.

The charging pad was designed with larger thermal mass. While individual bricks don't have much capacity to absorb heat, the charging station itself can accumulate heat without reaching problematic temperatures. The design includes ventilation passages that allow convection cooling, essential for scenarios where you're charging 50+ bricks simultaneously.

Software also plays a role in thermal management. The microcontroller monitors its own die temperature through internal sensors. If temperature climbs toward safe limits, the software reduces processing demands or instructs the charging system to lower power delivery. This self-throttling prevents dangerous temperature conditions.

The charging algorithm itself was optimized to minimize heat generation. Rather than charging at maximum possible current, the system uses a stepped approach. Initial charging happens at moderate current, transitioning to lower current as the battery charges. This reduces total heat generation while still achieving reasonable overall charging time.

Lego also considered ambient temperature in the charging design. Charging a brick in a warm environment generates more heat stress than charging in a cool environment. The charging system can detect ambient temperature and adjust charging profiles accordingly.

Ventilation around the charging pad matters. If you place the charging pad inside an enclosed space with poor air circulation, heat accumulation becomes problematic. Lego's design guidance recommends keeping the pad in open air with adequate space around it for convection cooling.

Wireless Communication and Mesh Networking

The wireless charging infrastructure isn't the only custom wireless system Lego built. The Smart Bricks also need to communicate with each other and with external devices.

Bluetooth Low Energy became the obvious choice for wireless communication. It's an established standard, widely supported in phones and computers, and designed for battery-powered devices. BLE also offers reasonable range for typical room-size play scenarios.

But individual bricks can't communicate directly with a phone if they're more than 30-40 meters away. Lego wanted to support larger structures that might span a larger play space. The solution was implementing a mesh network where bricks relay messages through each other.

This mesh networking adds complexity to the firmware running on each brick. The microcontroller needs to handle not just its own sensors and outputs, but also relay traffic from neighboring bricks. The routing algorithm needs to be intelligent—avoiding loops, finding efficient paths, and adapting when bricks move or network topology changes.

The mesh approach makes the system remarkably resilient. If one brick loses connection temporarily, messages can take alternate routes through neighboring bricks. This mimics how cellular networks or internet infrastructure works, but simplified for toy applications.

Security was a design consideration from the start. Smart Bricks communicate wirelessly, potentially with personally identifiable information about the user (which child, what they built, how they played). Lego implemented encryption for sensitive communications and security protocols that prevent unauthorized devices from joining the network.

The Bluetooth implementation itself was optimized for low power consumption. The radio chip goes into sleep states between communication bursts. Firmware manages timing of wireless updates to balance responsiveness with battery life.

Interestingly, the wireless communication protocol is entirely proprietary to Lego, not direct Bluetooth Low Energy messages. This custom protocol layer provides additional control over how bricks communicate, allows features that standard BLE doesn't support easily, and prevents competing toy systems from hijacking bricks with their own communications.

Estimated data: The battery occupies the largest space within a Lego Smart Brick, followed by structural support and microcontroller components.

Manufacturing at Scale: From Prototype to Millions of Units

Lego's annual production runs to billions of bricks. Scaling custom electronics from prototype to that volume introduces entirely new engineering challenges.

Each component needs to be sourced reliably. Custom battery cells require dedicated manufacturing capacity. The PCB fabrication needs precision laser alignment for the embedded charging coils. The plastic injection molding needs calibration to ensure components fit properly inside the brick after assembly.

Lego works with established contract manufacturers who specialize in electronics assembly. But contract manufacturing at Lego's scale means building dedicated manufacturing lines specific to Smart Bricks. The cost of these lines is substantial, which is why Lego is committed to Smart Bricks being a core product line, not a limited edition experiment.

Yield is a critical metric in electronics manufacturing. Not every assembled unit works perfectly the first time. Solder joints might be cold. Components might be damaged during assembly. Firmware programming might fail. Each defect reduces yields, increasing per-unit costs.

Lego implemented extensive inline testing to catch defects early. As soon as a Smart Brick completes assembly, it enters a test station where technicians verify that electronics work, wireless charging functions, and firmware loads correctly. Failed units go back for rework or scrap.

Quality control extends beyond simple functionality testing. Lego tests wireless communication range, charging efficiency, and battery capacity sampling. They test thermal performance, structural strength, and durability under simulated play conditions.

Raw material supply chains matter too. The lithium for batteries must come from reliable suppliers. The copper for coils needs consistent specifications. The ABS plastic must meet strict standards for color and mechanical properties. Supply chain management ensures continuous production without material bottlenecks.

Mold maintenance for plastic injection becomes more complex when you're producing components with tight internal tolerances. The molds need frequent inspection and polishing to maintain dimensional accuracy across billions of cycles.

Lego also built in design margins throughout manufacturing. Components are specified with tolerance bands that are tighter than strictly necessary. This ensures that even when manufacturing tolerances stack up across multiple components, the final brick functions reliably. It's more expensive than minimal tolerance manufacturing, but it ensures quality.

Testing and Reliability: What Lego Put Smart Bricks Through

Before Smart Bricks ship to customers, Lego's quality assurance teams subjected them to remarkable testing regimens.

Accelerated life testing simulates years of use in compressed timeframes. Smart Bricks are charged and discharged thousands of times in test chambers. They're subjected to temperature cycles that simulate seasonal changes and various storage conditions. They're mechanically stressed, testing the durability of components under realistic play scenarios.

Charge cycle testing is particularly important for battery reliability. A brick might be charged thousands of times over its useful lifetime. Test benches automatically cycle bricks, monitoring battery capacity degradation over thousands of charge-discharge cycles. Lego's goal is ensuring that batteries maintain 80% of original capacity even after many years of use.

Thermal testing occurred at extremes. Smart Bricks were tested in ovens at 60°C to verify they don't overheat. They were tested at freezing temperatures to ensure the battery chemistry still functions reliably in cold conditions. They were tested in humid environments to verify moisture protection.

Wireless communication testing verified range, reliability, and interference resistance. Test chambers shielded bricks to verify they don't emit unsafe electromagnetic radiation. Coexistence testing confirmed that the bricks operate properly alongside WiFi, cellular networks, and other Bluetooth devices.

Dropping tests verified that the bricks survive the inevitable accidents. Bricks were dropped from heights onto various surfaces—carpet, hard floors, concrete. Impacts were measured to ensure no internal damage occurred. The plastic shells were inspected for cracks, and electronics were tested for functionality after impact.

Water resistance testing happened in controlled environments. While Smart Bricks aren't fully waterproof, they're splash-resistant for typical play scenarios. Bricks were exposed to water spray and partially submerged briefly to verify electronics remain protected.

Stress testing of the plastic connectors—the studs and underside tubes—verified they maintain proper tolerances even after repeated assembly and disassembly. Bricks were snapped together thousands of times, and dimensional measurements confirmed that connector tolerances remained within specification.

Durability testing also included simulated child play. Test rigs assembled structures, yanked them apart, reassembled them differently, and repeated. The goal was ensuring that the repeated mechanical stress of building doesn't damage electronics or connectors.

Conductivity testing verified that despite containing electronics and batteries, the bricks don't pose electrical hazards. Ground resistance and isolation between circuits and the brick shell were measured to ensure user safety.

Battery Life and Longevity Expectations

How long do Smart Brick batteries last between charges? This is a practical question every parent or educator asks.

Lego's engineering targeted typical play sessions lasting 2-3 hours before needing to recharge. A Smart Brick's battery should last through a reasonable afternoon of building and playing before the wireless charging pad enters the picture.

The actual battery life depends significantly on usage patterns. A brick with an LED that's continuously on drains power faster than a brick using only wireless communication. A brick with a vibration motor consumes more power during active use than a brick with passive sensors.

Lego's power management firmware implements intelligence here. Features only draw power when needed. LEDs might flash periodically rather than stay constantly on. Sensors sample at intervals rather than continuously. Wireless updates batch together to reduce the number of radio transmissions required.

In typical usage, Lego estimates Smart Bricks should last 1-2 weeks between full charge cycles for moderate to heavy play. Light usage might stretch this to 3-4 weeks. Heavy use with always-on features might require recharging more frequently.

Battery degradation is inevitable with rechargeable chemistry. Over time, the battery's capacity diminishes. After 500-1000 charge cycles, the battery might hold only 80% of original capacity. After 2000+ cycles, capacity might drop to 60%. This timeline depends on charging conditions, usage patterns, and storage temperature.

For a child's toy, this probably translates to several years of usable life. A Smart Brick used heavily for 3-4 years would likely see measurable battery capacity reduction but should still function reasonably. After 5-6 years, battery life might become noticeably shorter, requiring more frequent charging.

Lego designed the system assuming most users would eventually buy replacement bricks as their collections grew. They're not positioned as disposable, but they're also not expected to function like new indefinitely.

The battery replacement process itself isn't designed for user repair. Opening a Smart Brick to replace the battery would damage the plastic housing and potentially expose users to electrical hazards. Instead, Lego offers a recycling program where used bricks can be returned for proper battery disposal and electronic waste recycling.

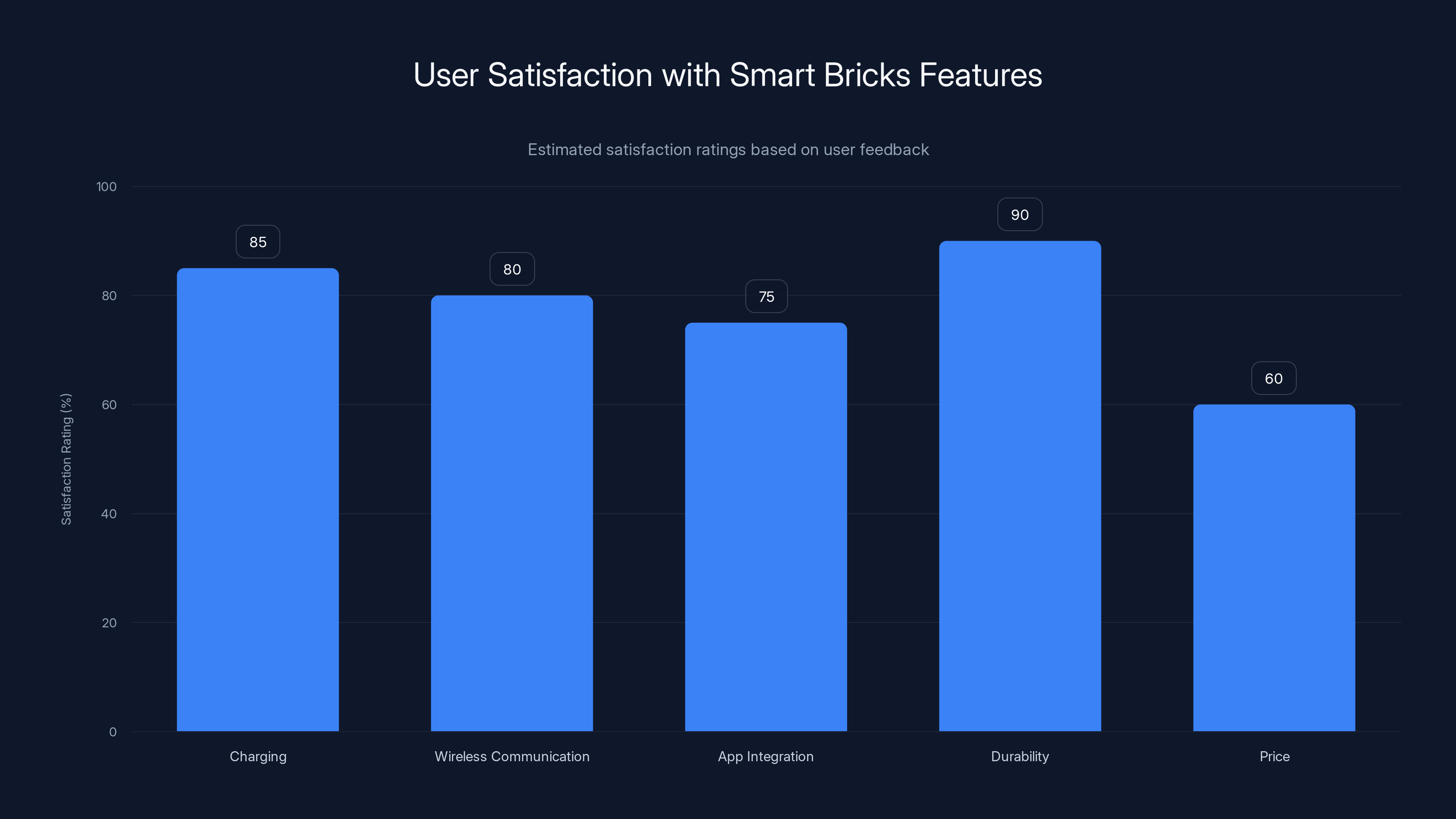

Users are generally satisfied with Smart Bricks' charging and durability, but the price is a common concern. (Estimated data)

Cost Implications and Manufacturing Economics

Custom wireless charging technology adds real costs to Smart Bricks compared to traditional bricks.

A traditional plastic Lego brick costs roughly 10-15 cents to manufacture at scale. The plastic injection molding is highly optimized. Materials are inexpensive. Manufacturing is extremely efficient.

A Smart Brick, by comparison, likely costs 3-5 times more to manufacture. The custom battery cells are expensive when commissioned in small numbers. The PCB fabrication with embedded coils adds manufacturing steps. The assembly process is more complex, requiring electronics assembly expertise and equipment. Quality control testing is more extensive.

Retail pricing reflects this cost structure. Traditional Lego bricks in a set cost roughly 10-15 cents per brick when you calculate based on set price and brick count. Smart Bricks in sets are typically priced at 50-100 cents per brick, sometimes higher. The multiplier accounts for manufacturing costs, profit margins, and the additional value proposition of connected features.

Lego's strategy seems to be positioning Smart Bricks as a premium addition to the core Lego line, not a replacement. Traditional bricks remain the backbone of most sets. Smart Bricks appear in specific sets designed around connected play experiences.

The charging pad is another cost item. The pad needs substantial electronics—power supplies, multiple charging coils, control circuits, thermal management. A charging pad probably costs

Economic viability at scale depends on volume. If Lego sells millions of Smart Bricks annually, the per-unit manufacturing cost drops through improved yields, supplier discounts for volume purchases, and manufacturing line optimization. If sales are disappointing, manufacturing costs stay higher, reducing profit margins.

This is why Lego is investing heavily in marketing Smart Bricks and designing compelling sets around the technology. Volume sales are essential for the economics to work long-term. Lower-than-expected adoption would force either price increases or strategic retreat from the smart brick market.

Environmental Considerations and Sustainability

Adding batteries and electronics to toys creates environmental implications that traditional Lego bricks don't have.

Batteries contain materials that require careful sourcing and responsible end-of-life handling. Lithium mining has environmental impacts. Cobalt sourcing involves ethical considerations. Lego's supply chain management needs to ensure that battery suppliers meet environmental and labor standards.

The plastic shell of Smart Bricks still uses ABS polymer, like traditional bricks. ABS is durable and recyclable, but it's a fossil fuel-derived plastic. Electronics inside can't really be recycled with the plastic. They need to be separated and processed through electronic waste recycling streams.

Lego designed Smart Bricks with this end-of-life scenario in mind. The plastic shell can be separated from the electronic internals relatively easily. The company provides information on how to recycle Smart Bricks responsibly through appropriate e-waste recycling programs in most countries.

The wireless charging pad is also electronics that eventually reaches end-of-life. Power supplies, coils, transformers, and control circuitry all need proper disposal. Again, Lego provides guidance on responsible recycling.

From an environmental impact calculation, the question is whether the benefits of connected play and digital learning experiences justify the manufacturing and recycling costs. Lego argues that Smart Bricks enable richer play experiences that might reduce parents' motivation to constantly buy more traditional bricks. A child engaged with connected building might build more meaningfully rather than accumulating larger and larger collections.

It's a reasonable argument, but the environmental footprint is definitely higher than traditional plastic bricks. Each Smart Brick requires more energy to manufacture, involves battery production with mining and refining impacts, and generates electronic waste at end-of-life.

Lego's long-term vision likely includes more sustainable battery chemistry, renewable energy manufacturing, and improved recycling infrastructure. But these improvements are still years away for mainstream production.

The Future of Smart Toy Engineering

Lego's Smart Bricks represent a significant milestone in toy manufacturing, but they're just the beginning of a larger trend.

Other toy manufacturers are certainly watching carefully. Mattel, Hasbro, and other established toy companies recognize that connected, digital-first play experiences resonate with modern families. They're investing in their own smart toy platforms, though most are still several years behind Lego's engineering sophistication.

The wireless charging technology that Lego developed for Smart Bricks is generally applicable to other small electronics in toys. Future products might use similar approaches for charged action figures, intelligent building blocks from competitors, or entirely new toy categories that haven't been invented yet.

Battery technology will likely continue improving. Solid-state batteries promise higher energy density and better safety characteristics. When these mature, smart toys will have longer battery life and require less frequent charging. The downside is that solid-state batteries are even more expensive initially, which might delay their adoption in toy applications.

Wireless charging standards might evolve. Researchers are exploring over-the-air wireless power transfer at greater distances and efficiency. Imagine Smart Bricks that charge wirelessly from a base station anywhere in a room, without needing to sit on a dedicated charging pad. This technology is still in research phases, but it's theoretically possible.

Augmented reality integration will almost certainly become more sophisticated. Smart Bricks could pair with AR applications that show additional visual layers when viewed through a phone camera. Buildings made with Smart Bricks might animate in AR, or structures might have digital functionality visible only through the app.

Artificial intelligence could make smart toys genuinely interactive in new ways. A Smart Brick structure might detect how a child built it and offer suggestions for improvements or new building challenges. The toy becomes not just a play platform but an intelligent learning companion.

The broader trend is clear: electronics and digital connectivity are becoming fundamental to toy design, not optional extras. Companies that execute well on this transition—like Lego appears to be doing—will define what toy manufacturing looks like in the 2030s and beyond.

Bluetooth communication is the largest power consumer in Smart Bricks, while deep sleep states significantly reduce power usage. Estimated data.

Lessons for Electronics Engineering in Constrained Environments

Lego's Smart Brick engineering provides valuable lessons applicable well beyond toys.

Whenever you're designing electronics for small form factors, the constraints multiply. A smartphone has 5+ millimeters of thickness to work with. Smart Bricks have perhaps 1-2 millimeters of useful space for electronics. The optimization intensity required is qualitatively different.

Custom solutions sometimes outperform generic ones. Standard Qi charging would never work inside a Lego brick. Lego's engineers recognized this early and invested in custom wireless charging rather than forcing a technology into an unsuitable application. This willingness to build custom solutions rather than adapting existing ones separates good engineering from great engineering.

Thermal management in small spaces requires multidisciplinary thinking. It's not just about heat dissipation—it's about material selection, component placement, algorithm design, and user interface considerations. Lego's thermal solutions involved hardware engineers, software engineers, materials scientists, and industrial designers working together.

Quality control at manufacturing scale is an engineering discipline in itself. Testing thousands of units per day to verify that complex systems work reliably is as challenging as designing them. Lego's approach to automated testing and inline quality checkpoints is worth studying by anyone building electronics at scale.

Mesh networking in resource-constrained environments requires elegant algorithm design. Mesh protocols designed for internet infrastructure often won't work in toy-scale systems where you can't afford complex routing tables or frequent synchronization. Lego's firmware engineers had to implement protocols that were robust but computationally simple.

Legacy product compatibility is a powerful constraint that forces innovation. Lego couldn't just redesign bricks from scratch. They had to maintain compatibility with existing collections. This constraint forced more creative engineering solutions than if they'd had a blank slate.

Industry Standards and Regulatory Considerations

Bringing smart electronics into toys involves regulatory oversight that traditional toy manufacturing largely avoids.

Safety standards for toys are well-established. Toys need to be non-toxic, have no sharp edges, and not pose strangulation or choking hazards. Traditional Lego bricks meet these standards easily.

Smart Bricks need to meet traditional toy safety standards plus electrical safety standards. Batteries require safety certification. Wireless devices need to comply with electromagnetic spectrum regulations. Chargers need electrical safety approval. Each jurisdiction adds requirements—EU standards differ from US requirements, which differ from Chinese requirements.

Lego navigates these regulations through established product certification processes. Third-party testing labs verify that wireless devices meet FCC regulations (US), CE marking requirements (EU), and equivalent standards in other markets.

Data privacy regulations also apply. If Smart Bricks collect user data—and the connected system likely does—GDPR and similar regulations apply. Lego needed to implement privacy protections and obtain appropriate parental consent for children's data.

Lego's engineering teams included compliance specialists from the start of the project. Building regulatory compliance into the product design is far cheaper than trying to retrofit compliance later. This involved selecting components from suppliers with appropriate certifications, designing circuits that meet EMI/RFI standards, and implementing firmware that protects user privacy.

The warranty and support implications are significant too. Lego offers extended warranty support for Smart Bricks, knowing that occasional failures will occur despite rigorous testing. Support operations need to handle returns, replacements, and troubleshooting for customers experiencing issues.

Real-World Performance and User Expectations

How well does this sophisticated engineering actually perform when Smart Bricks arrive in kids' homes?

User feedback suggests that Smart Bricks mostly work as intended. Charging functions reliably for most users. Wireless communication operates over reasonable distances. Battery life meets expectations for typical usage patterns.

There are inevitable edge cases and issues. Occasionally a brick experiences charging problems or wireless connectivity issues. These failures are rare enough that they don't undermine overall product satisfaction, but they happen often enough that Lego's support teams see regular case volume.

The user experience for charging is notably positive compared to alternative approaches. Simply dropping a collection of Smart Bricks onto the charging pad is intuitive and friction-free. Users appreciate not having to manage individual USB cables or connectors.

Integration with the companion app and digital experiences seems to resonate with families. The combination of physical building with digital rewards and challenges creates engagement beyond what either medium provides alone.

Some users note that the proprietary wireless communication means the bricks don't work with third-party applications or competing toy systems. This is by design—Lego wants to control the entire ecosystem. But for users hoping to integrate Smart Bricks with other technologies, this is a limitation.

Price point criticism appears regularly in user feedback. Smart Brick sets cost significantly more than equivalent traditional Lego sets. Parents who don't see the value in connected features feel the price premium is unjustified. But families who engage deeply with the digital experiences generally feel the cost is reasonable.

Durability reports have been positive so far. Smart Bricks seem to hold up to rough play and extended storage similarly to traditional bricks. Battery life degradation over time aligns with Lego's engineering expectations.

Competitive Landscape and Future Platforms

Lego isn't alone in pursuing smart toy platforms. Other manufacturers are developing competing approaches.

Mattel's Mega Bloks line includes motorized components, though they haven't achieved the same level of wireless integration. Hasbro has explored app-connected toy lines. Proprietary systems like Sphero offer robotics-focused connected play experiences.

None have matched Lego's scale or sophistication yet. Lego's advantages include their established supply chain, manufacturing expertise, enormous brand recognition, and decades of experience with building compatibility. These advantages aren't easily matched.

But competitive pressure is coming. As Lego's Smart Bricks prove successful and generate revenue, other major toy companies will accelerate their own smart toy development. Expect to see more sophisticated connected play platforms from competitors within the next 2-3 years.

Lego's strategy seems to be establishing Smart Bricks as the de facto standard for connected building systems before serious competition materializes. They're investing heavily in developer relations and ecosystem building to attract third-party developers who can create add-ons and applications.

The long-term competitive landscape might feature multiple compatible standards for connected toys, similar to how different Bluetooth device types coexist. Or it might coalesce around a single dominant standard if one company's approach proves overwhelmingly superior.

Lego's engineering investments in wireless charging and mesh networking put them in a strong position for leadership in whatever that future landscape looks like.

Conclusion: Engineering Ambition Meets Practical Reality

Lego's decision to build custom wireless charging for Smart Bricks reflects deeper truths about how modern electronics get designed and manufactured.

When you're building products at billion-unit scale, standard solutions often won't work. The constraints are too specific. The requirements too precise. The cost-benefit calculation too tight. Sometimes the only option is inventing custom solutions.

Lego's engineering team exemplified this. They could have forced standard Qi charging into bricks and shipped the product. It would have worked, barely, with compromises everywhere. Instead, they invested in understanding the fundamental constraints and designing solutions that actually solved the problem well.

The resulting Smart Bricks system represents legitimate innovation. Not revolutionary—wireless charging and connected toys weren't invented by Lego. But the execution, the attention to detail, the willingness to optimize across every possible dimension, that's where the innovation lives.

The fact that Lego was transparent about their engineering decisions is notable too. They didn't hide the complexity. They explained it. They helped customers understand what was actually happening inside those plastic bricks. That transparency builds trust and respect for the engineering effort.

For anyone involved in electronics design, manufacturing, or product development, Lego's approach offers genuine lessons. Constraints aren't obstacles to work around. They're guides pointing toward better solutions. Ambitious goals demand custom engineering. Scale requires ruthless optimization. User experience trumps technical elegance.

Smart Bricks probably aren't perfect. No manufactured product is. But they represent the genuine state of the art in combining physical play with digital connectivity at scale. They prove that legacy toy manufacturers can innovate meaningfully when they commit resources and accept that traditional approaches won't suffice.

The next generation of smart toys will build on what Lego learned. The wireless charging technology will improve. The battery chemistry will advance. The artificial intelligence integration will deepen. The environmental impact will hopefully decrease.

But the fundamental lesson—that custom engineering for specific constraints produces better products than forcing generic solutions—that will remain valid long after Smart Bricks become the obvious baseline for connected toys.

Lego's ambition levels were indeed quite high. And remarkably, their engineering delivered on the promise.

FAQ

What are Lego Smart Bricks and how do they differ from regular Lego bricks?

Lego Smart Bricks are electronically enhanced building components that integrate microcontrollers, batteries, sensors, and wireless communication capabilities into traditional Lego brick form factors. Unlike regular plastic bricks, Smart Bricks can communicate wirelessly with each other and companion applications, enabling structures to respond to commands, light up, make sounds, and interact with programmed logic. They maintain physical compatibility with traditional Lego collections while adding a digital dimension to the building experience.

Why did Lego develop custom wireless charging instead of using standard Qi technology?

Standard Qi wireless charging couldn't meet Lego's specific requirements for their Smart Bricks application. The size constraints of individual bricks made standard Qi coils impossible to fit while maintaining structural integrity and play experience. Additionally, Lego needed to charge 50+ bricks simultaneously on a single pad, which standard Qi chargers aren't designed to support. Custom wireless charging allowed Lego to optimize for their specific use case, balancing efficiency, charging speed, thermal management, and cost across millions of units.

How long do Smart Brick batteries last between charges?

Lego engineered Smart Bricks to provide 2-3 hours of active play per charge under typical usage conditions. In real-world scenarios, battery life depends significantly on feature usage—LEDs and motors consume more power than passive sensors and wireless communication. Most users report that Smart Bricks require recharging every 1-2 weeks with regular play. Battery capacity gradually degrades over time, with typical bricks maintaining about 80% capacity after 500-1000 charge cycles, and 60% capacity after 2000+ cycles, which translates to several years of usable lifespan for typical children's toys.

What makes the charging pad different from standard wireless chargers?

Lego's custom charging pad features multiple embedded charging coils arranged in a grid pattern under the surface, allowing it to charge dozens of Smart Bricks simultaneously regardless of their placement. The pad includes sophisticated power management electronics that activate specific coil combinations based on brick positions, thermal sensors that prevent overheating, intelligent fault detection that prevents foreign objects from being heated, and adaptive charging algorithms that adjust power delivery based on individual brick types and charging status. These features make it dramatically more capable than standard consumer wireless charging pads designed for individual devices.

Are Smart Bricks compatible with regular Lego bricks?

Yes, Smart Bricks are fully compatible with traditional Lego bricks from a structural standpoint. They connect using the same studs and underside tubes as regular bricks and can be integrated into structures made with traditional plastic bricks. However, the wireless features and digital capabilities of Smart Bricks only work with other Smart Bricks and compatible Lego applications—traditional bricks don't have wireless communication abilities. This allows users to gradually add Smart Bricks to existing collections and mix both types within the same structure.

What safety standards and regulatory approvals did Smart Bricks require?

Smart Bricks needed to meet traditional toy safety standards (no toxic materials, sharp edges, or choking hazards) plus electrical safety standards for the batteries and wireless charger. The wireless communication components required FCC approval in the United States and CE marking compliance in Europe. Battery cells needed safety certification. The charging pad required electrical safety approval. Additionally, data privacy regulations like GDPR applied because the connected system potentially collects user information. Lego achieved these certifications through third-party testing labs and built compliance requirements into the product design from the beginning.

How does the mesh networking in Smart Bricks work?

Smart Bricks implement a mesh network where each brick not only sends and receives its own wireless signals but also relays messages from neighboring bricks. This creates multiple communication paths between bricks and the central app, so if one brick temporarily loses connection, messages can route through neighboring bricks to reach their destination. The microcontroller in each brick runs routing algorithms that avoid loops, find efficient paths, and adapt when bricks move or network topology changes. This approach makes the system remarkably resilient compared to simple point-to-point wireless communication.

What happens when Smart Brick batteries eventually degrade?

Battery capacity gradually decreases over years of use—this is normal for rechargeable lithium-ion chemistry. After several years of regular use, bricks might require more frequent charging or feature reduced brightness from LEDs. Lego doesn't designed Smart Bricks for user battery replacement, as opening them would damage the plastic shell. Instead, Lego provides a recycling program where aged bricks can be returned for proper electronic waste recycling and battery disposal. Most users will replace bricks through new set purchases long before battery degradation becomes completely limiting.

How does the cost of Smart Bricks compare to regular Lego bricks?

Smart Bricks typically cost 3-5 times more to manufacture than traditional plastic bricks, resulting in retail prices roughly 50-100 cents per brick compared to 10-15 cents for regular bricks. This cost premium reflects custom battery cell production, PCB fabrication with embedded charging coils, electronics assembly complexity, extensive quality control testing, and the wireless charging infrastructure. Lego positions Smart Bricks as a premium addition to their core product line rather than a replacement, maintaining traditional brick prices while charging more for connected play experiences.

What does the future of smart toys look like based on Lego's approach?

Lego's Smart Bricks demonstrate that custom engineering for specific constraints produces superior products compared to forcing existing technologies into unsuitable applications. Future smart toys will likely feature improved battery technology with longer life and faster charging, more sophisticated augmented reality integration showing digital layers overlaid on physical structures, artificial intelligence that makes toys genuinely interactive and adaptive to individual users, and potentially over-the-air wireless charging at greater distances as the technology matures. Competing manufacturers are accelerating development of their own connected toy platforms, though none have yet matched Lego's integration of scale, compatibility, and technical sophistication.

Key Takeaways

- Lego engineered custom wireless charging for Smart Bricks because standard Qi technology couldn't meet size, density, and efficiency requirements for tiny connected bricks.

- Smart Bricks required integration of microcontroller, custom battery cells, embedded charging coil, and wireless radio into dimensions barely larger than traditional Lego bricks.

- Manufacturing at billion-unit scale demanded ruthless optimization across every component, trade-off between efficiency and cost, and extensive quality control testing.

- Thermal management, structural integrity, and power delivery all required novel engineering solutions tailored to Lego's specific constraints rather than adapting existing technologies.

- Smart Bricks represent legacy toy manufacturers successfully competing in IoT space by investing in custom engineering rather than settling for generic solutions.

Related Articles

- LEGO Smart Bricks: From Toy to Experience Company [2025]

- Robot Lawn Mowers 2026: 3 Game-Changing Trends [2025]

- How BYD Beat Tesla: The EV Revolution [2025]

- How Chinese EV Batteries Conquered the World [2025]

- Fellow Coffee Maker Secret Video Game: How to Play [2025]

- Next-Gen Battery Tech Beyond Silicon-Carbon [2025]

![Lego Smart Bricks Wireless Charging: Engineering Innovation Explained [2025]](https://tryrunable.com/blog/lego-smart-bricks-wireless-charging-engineering-innovation-e/image-1-1769211431135.jpg)