Olympic Bobsledding Technology: The Gear Behind Gold [2026]

Olympic bobsledding isn't just about athletic prowess anymore. It's become a sophisticated blend of physics, materials science, biomechanics, and artificial intelligence. Athletes racing down icy tracks at speeds approaching 145 kilometers per hour don't just rely on their muscles—they rely on a complex ecosystem of engineered equipment that's been refined over decades.

The sport often gets compared to Formula 1 racing, and the comparison holds up. Teams spend millions optimizing every fraction of a second. A tenth of a second separates gold from fourth place. Sometimes it's less. That's where technology comes in. From the materials that make up the sled to the custom footwear athletes wear during the crucial push phase, every component has been designed, tested, and optimized through rigorous experimentation and data analysis.

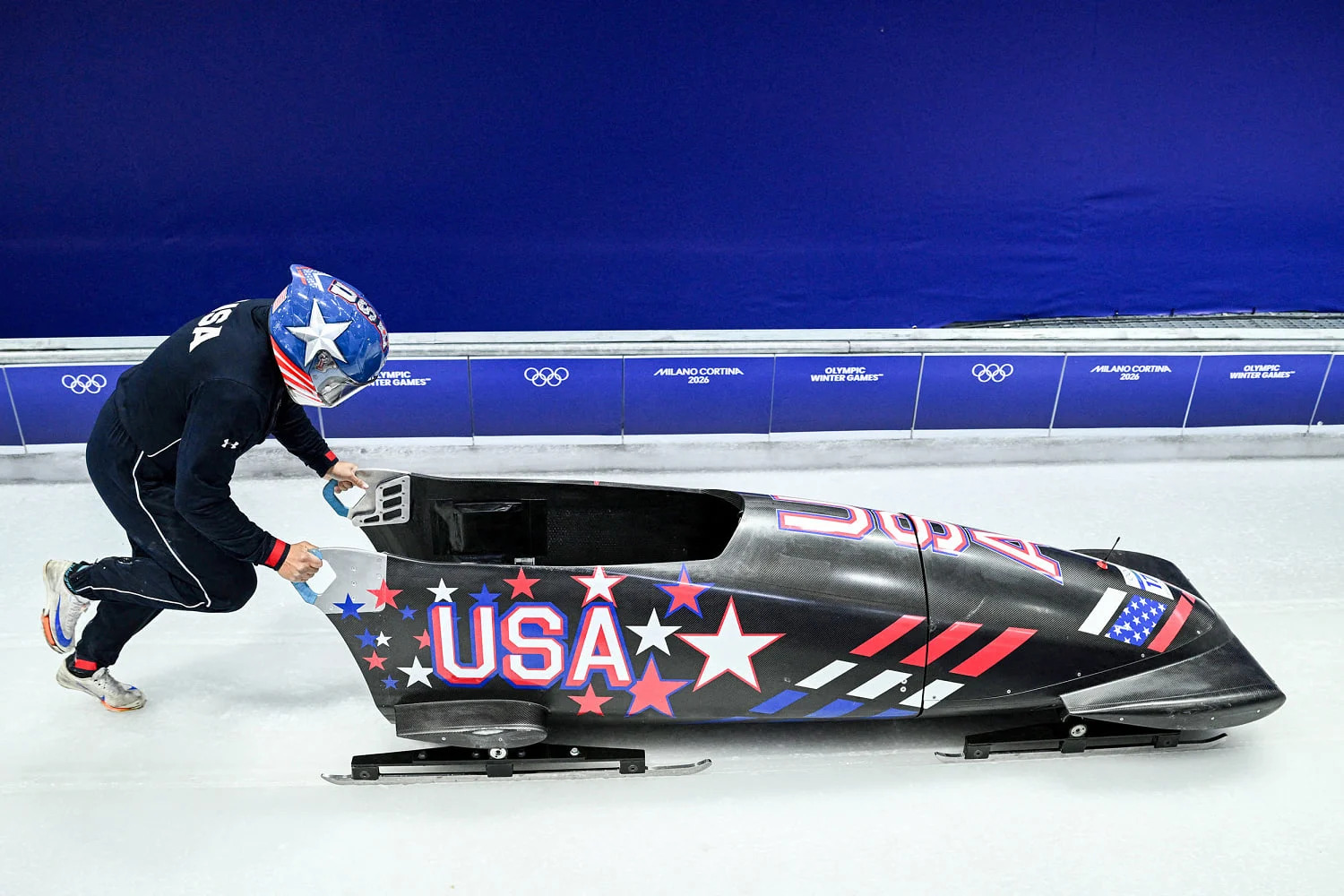

At the 2026 Milano Cortina Winter Games, teams competing across men's four-person, women's two-person, and monobob events will be using technology that was unimaginable just ten years ago. German teams will be testing custom studded shoes developed by BMW. American athletes will be wearing dynamic insoles engineered to return energy to their bodies. Coaches will be analyzing performance data through AI systems that track everything from push mechanics to sled trajectory around curves.

But bobsledding's technological arms race didn't happen overnight. It's evolved alongside the sport itself, shaped by constraints designed to keep competition fair and athletes safe. Understanding where the technology comes from and what it actually does requires diving into the history, the physics, and the specific challenges that engineers have had to solve.

TL; DR

- Custom footwear matters most: BMW's 3D-printed studded shoes improve push acceleration, the phase that often decides races

- AI coaching systems are now standard: Teams use machine learning to analyze sensor data and optimize athlete positioning

- Material science wins: Carbon fiber and advanced composites reduce sled weight while maintaining structural integrity under extreme forces

- Data-driven optimization: Even hundredths of a second improvements come from analyzing thousands of data points per run

- Safety constraints shape innovation: Weight limits and equipment regulations force teams to innovate within boundaries that protect athletes

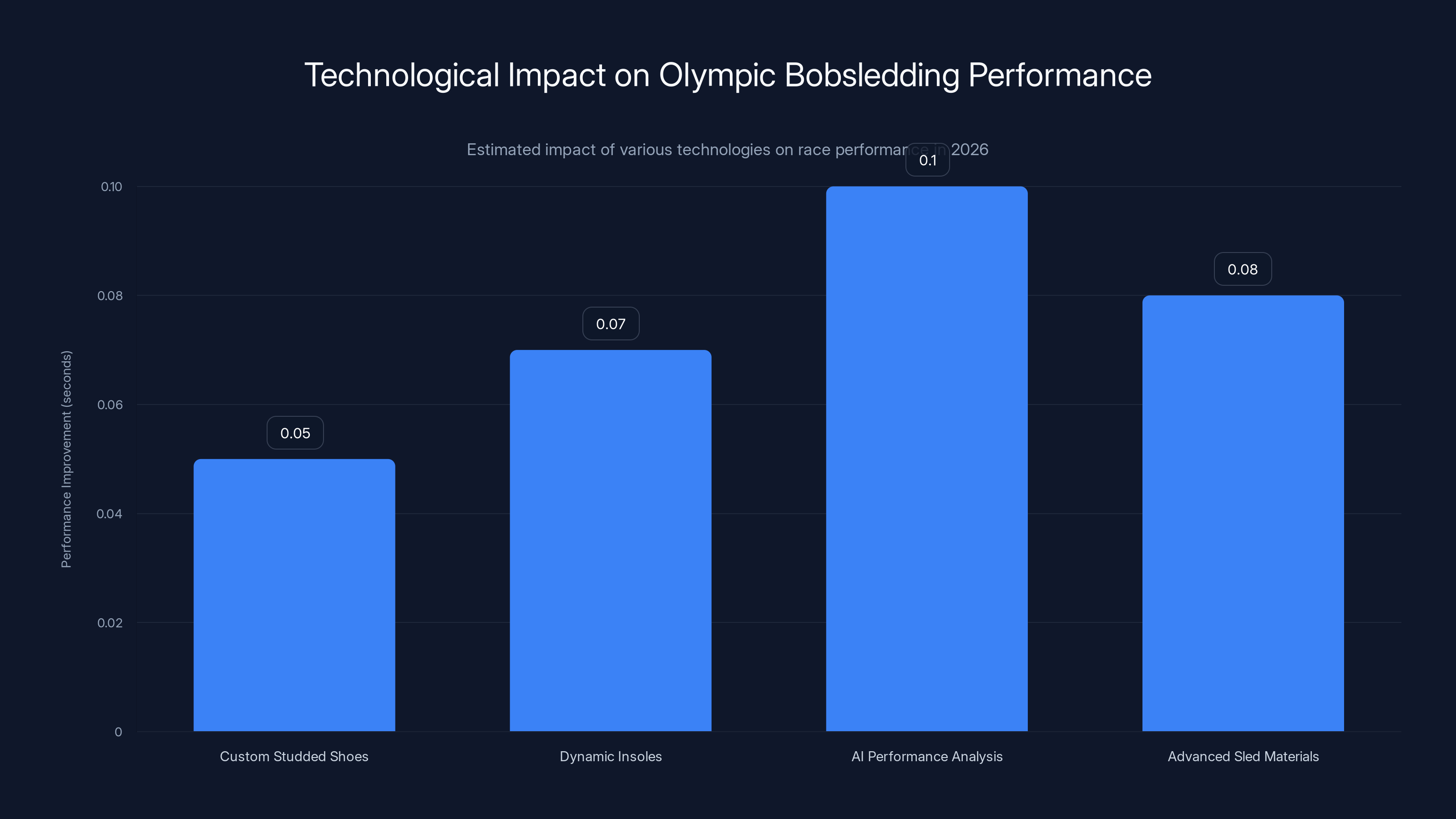

Estimated data suggests AI performance analysis offers the highest improvement, potentially shaving 0.10 seconds off race times, crucial in a sport where fractions of a second determine winners.

A Brief History of Bobsledding and Why Technology Matters

Bobsledding entered the Olympic stage in 1924 at Chamonix, France. The earliest sleds were constructed from wood—a material that seems laughably inadequate by modern standards. Over the decades, the sport transitioned to steel, which provided better durability and performance characteristics. But steel is heavy. And weight matters enormously in bobsledding.

Today's sleds are built from carbon fiber and other advanced composite materials. This shift happened gradually, driven by the same principle that governs all competitive sport: do more with less. Carbon fiber provides the strength of steel at a fraction of the weight, allowing athletes to push harder and maintain higher speeds without exceeding equipment regulations.

Women's two-person bobsledding didn't join the Olympics until 2002 at Salt Lake City—a full 78 years after men's four-person. Women's monobob, an individual event, arrived even more recently in 2022 at Beijing. The relatively recent inclusion of women's events hasn't slowed innovation. If anything, it's accelerated it. More athletes competing means more data, more experimentation, and more pressure to find marginal gains.

The sport's evolution reflects a broader truth about Olympic competition: once a sport reaches a certain level of maturity, most improvements come from technology, not just training harder. The margin between first and fifth place is often determined by equipment differences that most fans will never see or understand.

The Physics of Speed: Understanding Forces and Acceleration

Before diving into specific technologies, it's worth understanding the physics that drives bobsledding innovation. The sport imposes extreme gravitational forces on athletes' bodies. During turns and braking, bobsledders experience forces exceeding 5 gravitational units (5g). That means if an athlete weighs 100 kilograms, their body experiences forces equivalent to 500 kilograms of pressure. No wonder their necks and spines take a beating.

The race itself breaks into distinct phases, each with different physical demands:

The Push Phase runs for approximately 30 to 50 meters—roughly the first five to six seconds of the race. During this phase, athletes propel the sled from a standstill to maximum velocity. This is where bobsledders spend their energy budget, and it's also where technology provides the biggest performance edge. The athletes who push hardest with the most efficient technique gain a crucial advantage that's almost impossible to overcome later in the race.

The Jump Phase occurs immediately after the push, when team members board the moving sled. Any inefficiency here—bumping between athletes, misaligned timing, or suboptimal positioning—translates into lost speed and wasted energy.

The Driving Phase involves steerage and trajectory optimization on the ice track. The pilot (driver) controls the sled's path through curves while navigating the track's complexities. Speed is important here, but line choice matters just as much.

The Braking Phase comes at the finish. The athlete responsible for braking pulls a handle that engages brake pads against the sled's runners. Braking technique can cost or gain hundredths of a second, but more importantly, it keeps the sled and athletes from crashing after crossing the finish line.

Each phase presents unique engineering challenges. Most technological innovation has focused on the first two phases—the push and jump—because that's where competitive differences are largest.

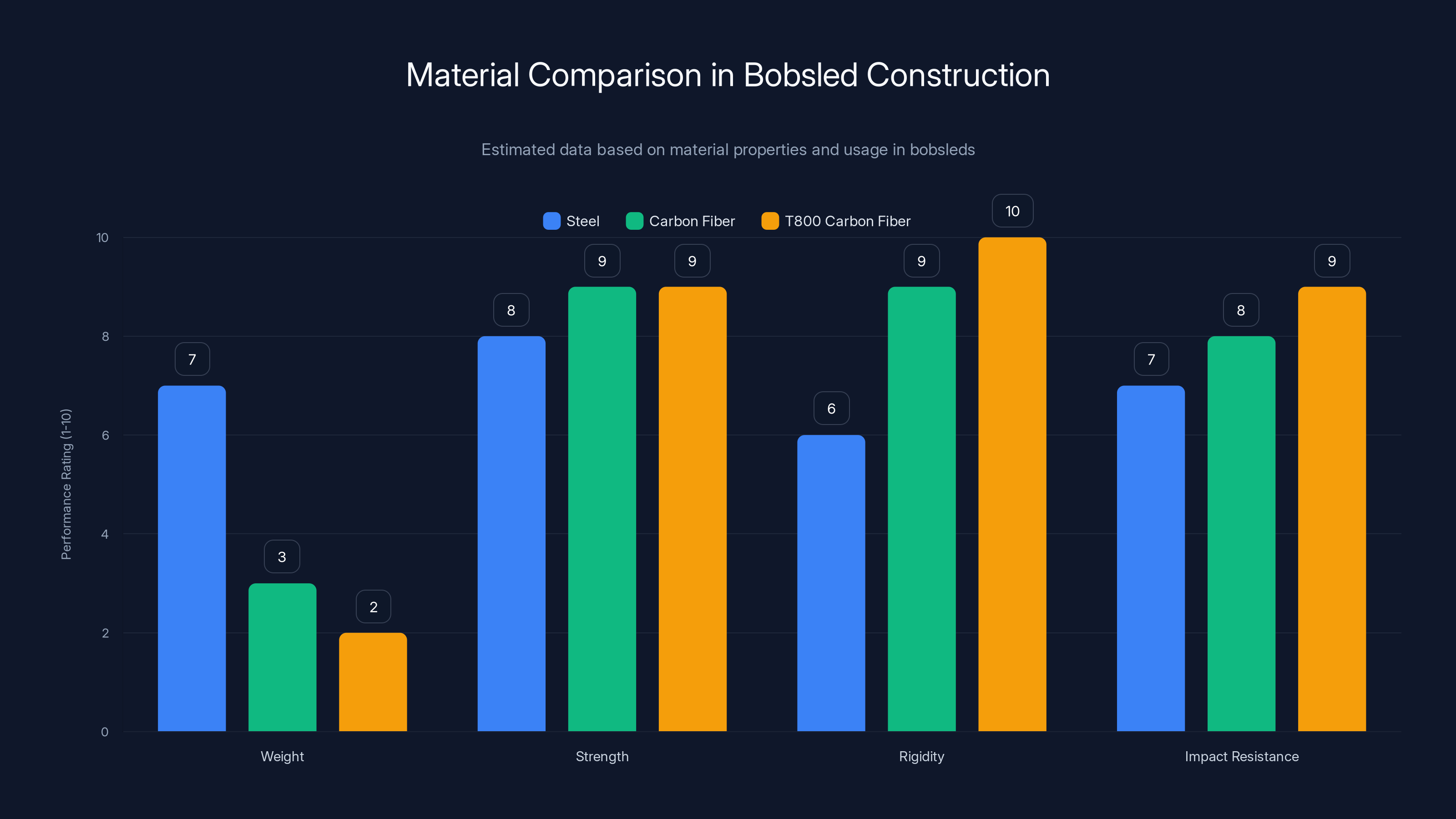

T800 carbon fiber offers superior rigidity and weight reduction compared to traditional materials, enhancing bobsled performance. Estimated data based on typical material properties.

Equipment Regulations: The Constraints That Drive Innovation

Olympic bobsledding operates under strict equipment regulations. These rules exist for two reasons: to ensure athlete safety and to maintain competitive balance. Without regulations, teams with unlimited budgets could build sleds so specialized they'd be unbalancing.

For a two-person bobsled, the maximum length is 2.7 meters (8.9 feet) and the maximum weight is 390 kilograms (859.8 pounds), including the crew. A four-person sled cannot exceed 630 kilograms (1,388.9 pounds) and must be no longer than 3.8 meters (12.47 feet).

These weight limits were implemented partly to equalize conditions between teams with different budgets, but also to prevent excessive specialization. Historically, some teams would recruit specialized pushers—athletes who weren't primarily bobsledders but excelled at moving heavy objects. By capping total weight, the regulations forced teams to rely on athletes who were skilled at both pushing and driving, maintaining the sport's integrity.

These constraints have shaped every major technological development in bobsledding. Engineers can't make sleds heavier to absorb impacts better. They can't make them longer to reduce air resistance. They have to work within fixed parameters. This limitation actually drives more creative engineering solutions—teams must choose between lightweight materials, aerodynamic design, durability, and performance characteristics.

The Custom Footwear Revolution: Where Push Efficiency Begins

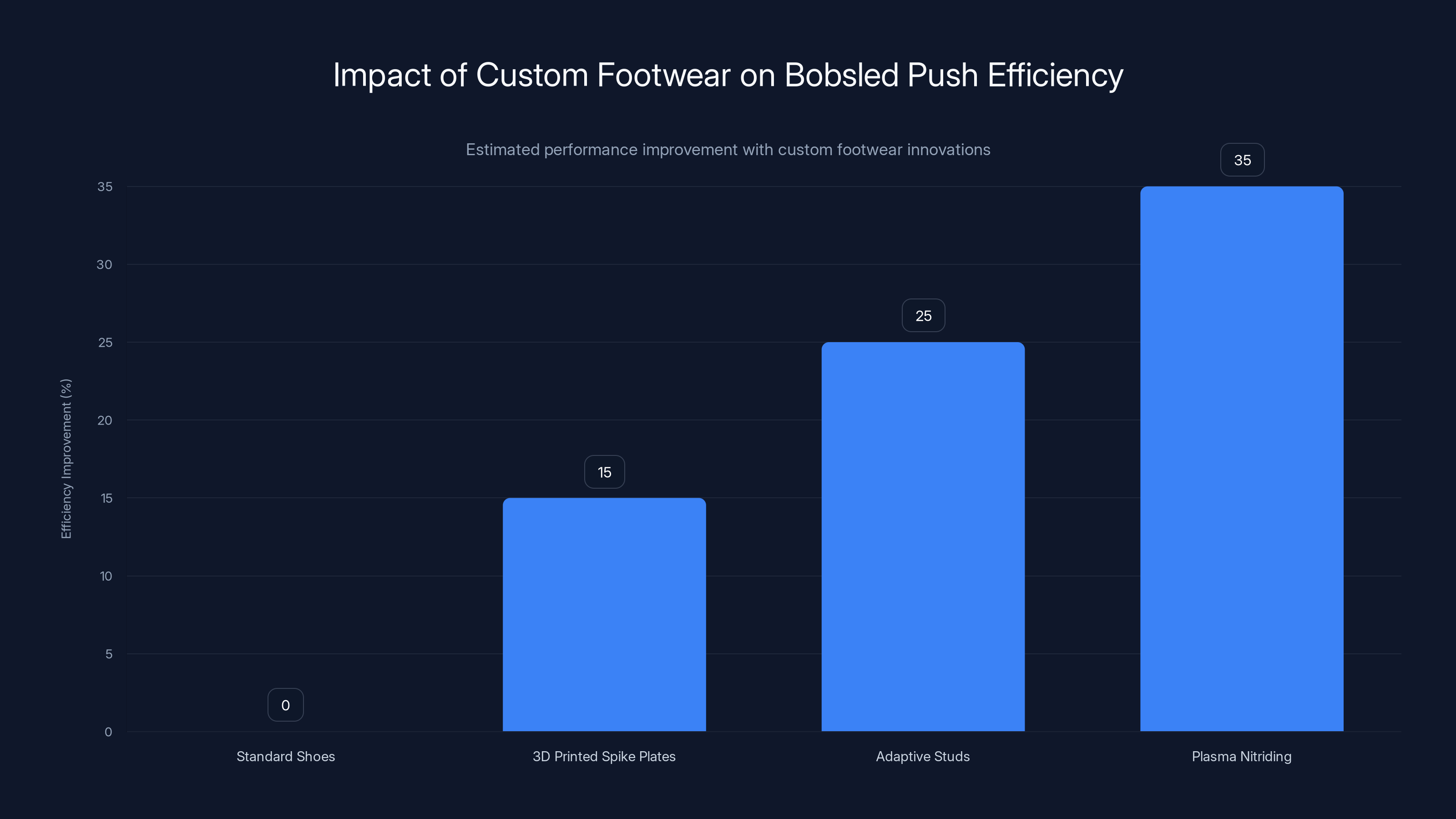

For decades, bobsledders wore standard athletic shoes. But a few years ago, engineers at BMW realized something crucial: the shoe-to-ice interface during the push phase was leaving performance on the table. The initial acceleration determines much of the race outcome. Optimize the push, and everything downstream becomes easier.

BMW, which serves as a strategic partner to the German bobsledding federation (Bob- und Schlittenverband für Deutschland), developed custom studded shoes using a sophisticated process. The approach involved several innovations working in concert.

First, BMW used 3D printing technology to create custom spike plates that could be integrated into any shoe type. This flexibility was crucial—different athletes have different foot shapes, different shoe preferences, and different biomechanical needs. Rather than designing a one-size-fits-all solution, BMW's approach allowed personalization.

Second, the company engineered the studs themselves to be adaptive. The stiffness and shape of each spike were designed to match individual athletes' needs and specific shoe characteristics. A heavier athlete pushing with different mechanics might benefit from studs with slightly different compliance than a lighter athlete. The 3D printing process made rapid iteration possible—engineers could test a design, gather feedback, and modify it within days rather than weeks.

Third, BMW applied plasma nitriding, a surface hardening process used in aerospace manufacturing. Nitrogen gas is ionized in a high-temperature vacuum and diffused into the steel spike surface. This process increases hardness dramatically, preventing excessive wear or spike breakage during intense training and competition. The spikes can withstand repeated impacts against ice that would otherwise damage them.

The result is footwear that provides measurably better traction and power transfer during the push phase. When athletes are accelerating a sled weighing hundreds of kilograms from a standstill, the quality of their grip on the ice determines how much force they can transfer. Better traction means more force. More force means higher acceleration. Higher acceleration in the first 50 meters often determines the final race outcome.

Dynamic Insoles: Energy Return and Biomechanical Optimization

While BMW was innovating in Germany, the United States was pursuing a different technological approach through VKTRY Gear, a company that has partnered with the U. S. Bobsleigh and Skeleton Federation for over a decade.

VKTRY's innovation centers on dynamic insoles—specifically engineered footbeds that fundamentally differ from traditional athletic insoles. Conventional insoles are primarily passive devices. They absorb impact and provide cushioning and structural support. They're designed to be comfortable and reduce stress on the feet.

But VKTRY's insoles operate on a different principle entirely. According to the company's founder Matt Arciuolo, the insole is shaped to only touch the heel and toe when placed on a flat surface. This architecture creates a curved, arch-like structure that functions as an energy storage and return system.

Here's how it works: when an athlete presses down during the push phase, the insole flexes and stores energy—much like a spring compressing. As the athlete pushes off the ice and their foot extends, that stored energy returns to the foot, amplifying the push motion. The insole provides what engineers call "useful energy return." It's not just support; it's active assistance.

Elite bobsledders using VKTRY insoles report enhanced performance during the push phase specifically. The insoles provide "a higher level of stiffness and useful energy return to optimize effort during the bobsled push," according to athletes like Kaillie Humphries, a Canadian bobsledder competing for the United States who won gold in the women's monobob at the 2022 Beijing Games.

What makes this technology particularly effective is that it works within the sport's constraints. The insole is a shoe component, not a piece of equipment subject to separate regulations. Athletes wear them inside their shoes. Opponents never directly see them, but they feel their effects in the results.

Like BMW's studded spikes, VKTRY's insoles exemplify how innovation in bobsledding focuses on small, measurable improvements in athletes' mechanical efficiency. A few percentage points of improvement in push power translates into tenths of a second faster times—the difference between medals and fourth place.

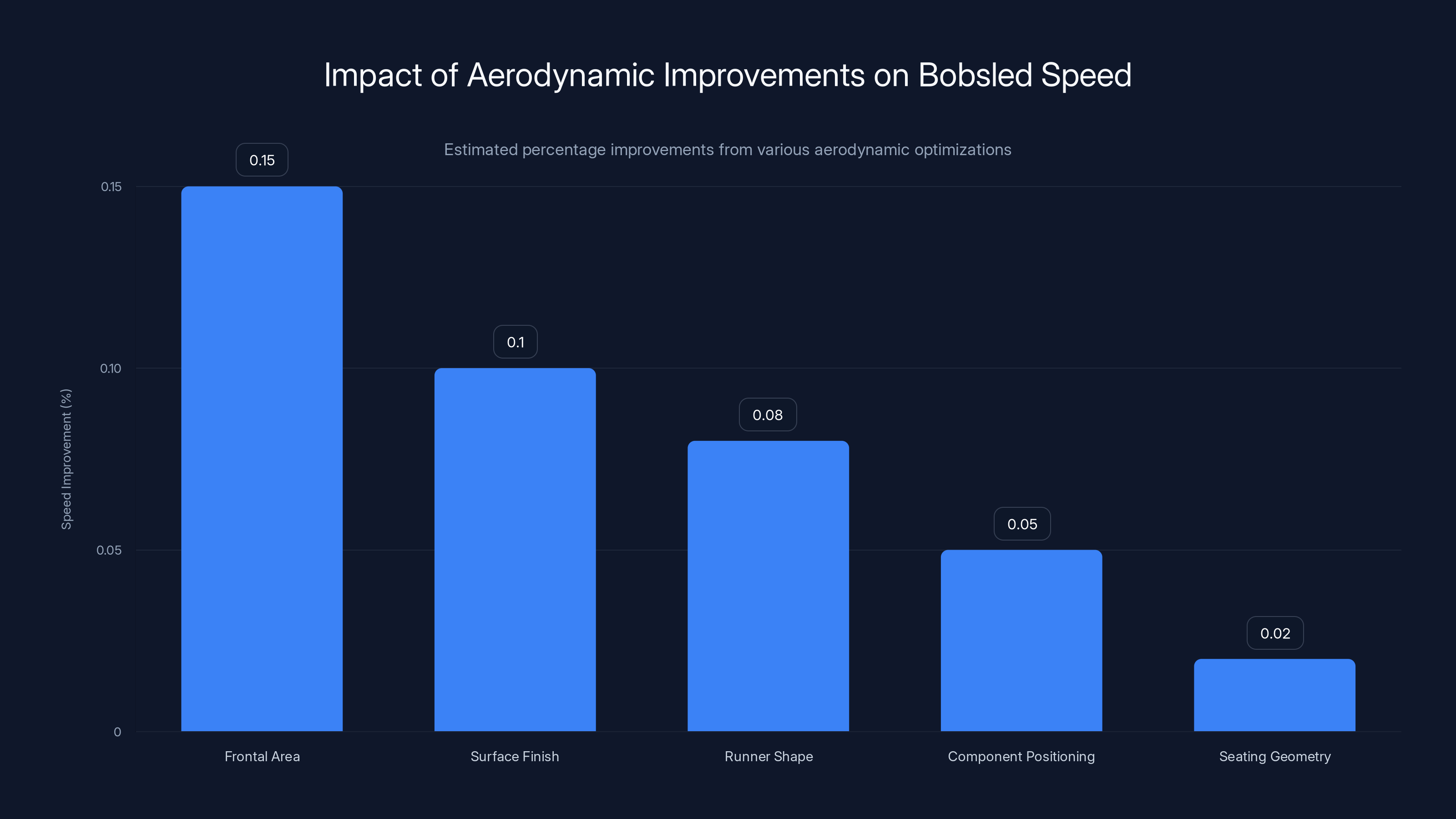

Estimated data: Frontal area adjustments offer the highest potential speed improvement at 0.15%, while seating geometry offers the least at 0.02%. Even small enhancements can be crucial in competitive bobsledding.

The Sled: Material Science and Structural Engineering

If footwear optimizes the push phase, the sled itself determines overall performance and safety throughout the entire race. The evolution from wooden sleds to steel to carbon fiber composites represents one of the sport's most dramatic technological shifts.

Carbon fiber offers extraordinary advantages. It's significantly lighter than steel while actually being stronger in terms of strength-to-weight ratio. Modern bobsleds use advanced carbon fiber composites, often carbon fiber combined with other materials, to achieve the ideal balance of weight, strength, rigidity, and impact resistance.

But there's complexity beyond simply "lighter is better." Different sections of the sled have different requirements. The runners—the blades that contact the ice—must be extraordinarily hard and precise. Runners are typically made from steel and are machined to exacting tolerances. The blade curve, the edge thickness, and the surface finish all affect how the sled grips the ice and travels through turns.

The sled's body must be light, strong, and aerodynamic. Carbon fiber composite construction allows engineers to build structures that meet all three requirements. The material can be laid up in different orientations and densities in different parts of the sled to optimize structural properties where needed most.

China's bobsled program recently introduced sleds made from T800 carbon fiber, a composite material typically used in aerospace applications. This particular material is prized for its lightness and rigidity. Chinese engineers reportedly achieved nearly a 20% weight reduction compared to conventional sled models while maintaining structural integrity under extreme impact forces. The reduced weight allows athletes to push the sled faster without exceeding equipment weight limits. The improved rigidity helps the sled maintain shape during high-speed turns, preventing energy loss from flex and distortion.

Durability matters as much as performance. Serious bobsled accidents happen during runway exits, collisions, and crash scenarios. A sled that's too fragile will break under impact, potentially injuring athletes. Engineers must design sleds that protect occupants while remaining light enough to be competitive. This balance explains why modern composites have become essential—they provide options that pure steel could never achieve.

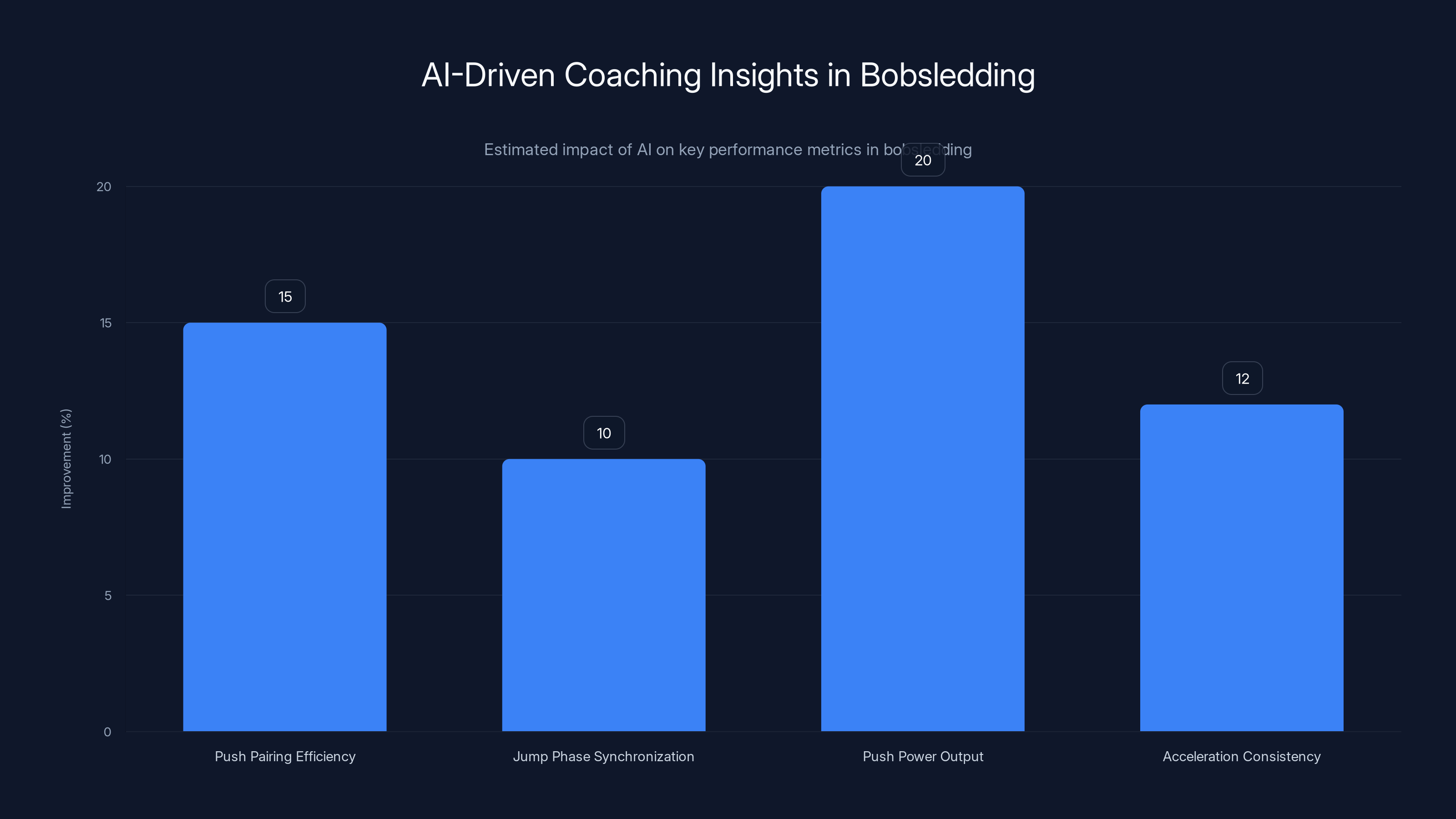

Data Analytics and AI: The Coaching Revolution

Equipment optimization only goes so far. At the elite level, the biggest performance improvements now come from data analysis and AI-driven coaching. The United States and Germany have both made substantial investments in converting bobsledding into a data-rich sport.

The U. S. Bobsleigh and Skeleton Federation partnered with Snowflake, a data analytics company, to develop AI systems that analyze bobsledder performance. The system uses machine learning algorithms to process vast quantities of sensor data and provide actionable coaching insights.

Here's what the system does: during training runs, sensors track athlete positioning, sled acceleration, impact forces, and trajectory. The AI analyzes this data to identify patterns. It answers questions like:

- Which push pairings work best for specific athletes in two-person and four-person crews?

- Are there inefficiencies during the jump phase—moments when athletes bump into each other or lose synchronization?

- How do different coaching cues or techniques affect push power output?

- Which athletes accelerate fastest and which have the longest "push window"?

The AI system can identify issues that human coaches might miss. For example, subtle bumping between athletes during the jump phase might shave hundredths of a second off overall time. To a human observer watching the run, this bumping might be imperceptible. But when you analyze sensor data showing acceleration changes and position shifts frame-by-frame, the inefficiency becomes obvious.

Snowflake's system integrates data from multiple runs across multiple athletes, building a model of optimal technique for each team. This allows coaches to provide highly personalized feedback. Instead of generic advice like "push harder," coaches can tell specific athletes exactly how their technique differs from optimal performance and what changes would improve results.

Germany has developed a parallel system called Data Coach, engineered by Julian von Schleinitz, a former world luge champion who now leads BMW Group's tech and AI solutions division. Data Coach focuses on trajectory and racing strategy. The system uses sensors embedded in the sled to track position, acceleration, and forces throughout the entire race.

With this data, coaches can analyze the optimal line through each curve. They can identify sections of track where their sled is losing time compared to competitors. They can test different configurations—weight distribution, sled setups, brake timing—and see how each change affects performance without waiting for race day results.

Data Coach has become sophisticated enough that teams can now use it to test new sled components before committing them to competition. Rather than building a new sled component and hoping it works faster, engineers can run sensor simulations and see predicted performance improvements before manufacturing. This approach reduces wasted experimentation and focuses engineering efforts on modifications with the highest probability of delivering results.

Aerodynamics: The Invisible Performance Factor

Bobsledding takes place on a track that's typically longer than 1.5 kilometers (nearly a mile). Much of that distance is traveled at high speeds. While the push phase focuses on acceleration efficiency, the rest of the race involves managing speed and minimizing energy loss.

Air resistance (drag) increases exponentially with speed. At 90 mph (145 km/h), aerodynamic efficiency matters significantly. A sled that's even slightly more aerodynamic than competitors will maintain speed longer and require less steering adjustment through curves, reducing overall time.

Bobsled aerodynamics present interesting engineering challenges. The sled must accommodate four athletes (in the four-person version) sitting in a specific configuration. You can't simply streamline the shape like an aircraft or a race car because you're constrained by athlete positioning. The crew arrangement is non-negotiable from a practical standpoint.

What engineers can optimize:

- Frontal area: Making the sled's cross-sectional profile slightly narrower reduces drag

- Surface finish: A smoother surface reduces turbulent flow and associated drag

- Runner shape: The shape and profile of the runners affect airflow around the sled's underside

- Component positioning: Moving sensors, brakes, and other components to positions where they create less air disturbance

- Seating geometry: While athletes' seating position is primarily dictated by comfort and control, minor adjustments to seat profile can slightly reduce drag

Aerodynamic improvements rarely deliver dramatic gains—perhaps 0.2 to 0.5% improvement in speed. But in a sport where races are decided by hundredths of a second, even 0.2% improvements matter. Multiple small improvements across footwear, sled design, aerodynamics, and athlete technique compound together to produce meaningful competitive advantages.

Custom footwear innovations, such as 3D printed spike plates and plasma nitriding, significantly enhance push efficiency in bobsledding. Estimated data based on technological advancements.

Materials Science Beyond Carbon Fiber

While carbon fiber dominates sled construction, engineers have experimented with numerous other advanced materials. The broader field of materials science has produced options that bobsled engineers explore constantly.

Aluminum-lithium alloys offer lighter weight than traditional aluminum while maintaining rigidity. Some sled components use these alloys in place of carbon fiber for specific applications where aluminum's fatigue resistance proves beneficial.

Titanium and titanium alloys are sometimes used for high-stress connection points and attachment hardware. Titanium is extraordinarily strong and light, but it's also expensive and difficult to machine. Only the most critical components justify titanium's cost.

Composite laminates combine carbon fiber with other fibers like glass or aramid (Kevlar). Different fiber combinations offer different properties. Aramid fibers provide excellent impact resistance, making them valuable in areas where the sled might experience contact or impact.

Advanced ice-gripping materials for the runners have become increasingly sophisticated. The runners aren't simply steel—they're precision-engineered steel with specific hardness profiles, surface coatings, and edge geometries. Some teams experiment with specialized coatings that subtly alter how the runner interfaces with ice.

Material selection involves complex trade-offs. Lighter materials are generally more expensive. Materials that provide excellent performance characteristics in one dimension might underperform in another. Engineers must balance cost, weight, strength, durability, repairability, and performance across the entire sled structure.

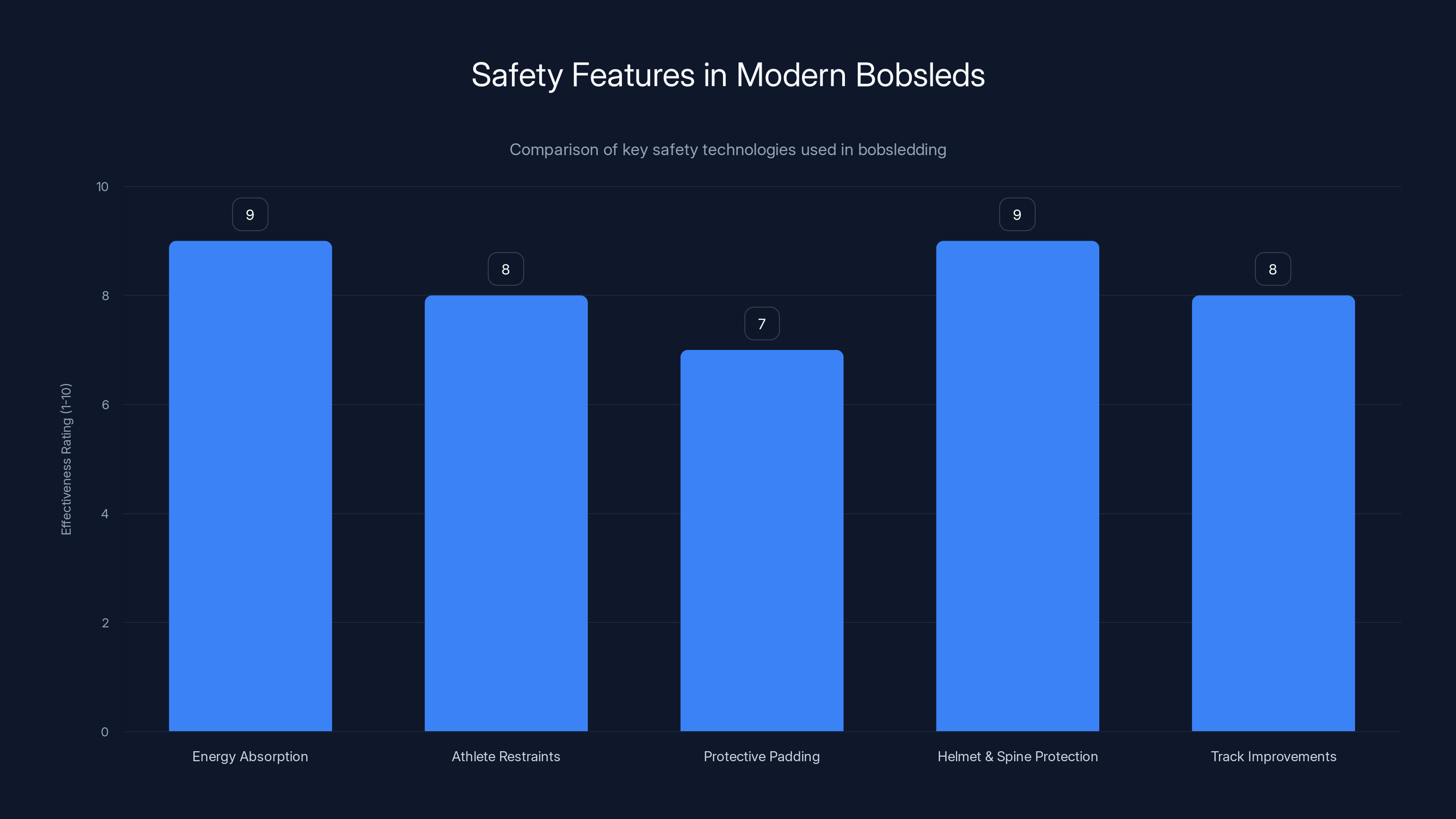

Safety Technology: Protecting Athletes at Extreme Speeds

All the performance optimization in the world means nothing if athletes are injured in the process. Bobsledding is inherently risky. Athletes travel at 90+ mph down a track filled with curves and elevation changes. Crashes happen. When they do, athletes experience tremendous impact forces.

Safety innovations have been as important as performance innovations. Modern sleds are designed with multiple safety features:

Energy absorption: The sled's structure must absorb impact energy without transmitting it directly to athletes' bodies. Carbon fiber composites are excellent at this—they can deform and absorb energy without breaking suddenly like brittler materials.

Athlete restraints: Modern bobsleds have evolved restraint systems that keep athletes securely positioned while allowing necessary movement during the push phase. These systems must be tight enough to prevent injury but loose enough not to restrict breathing or cause circulation problems.

Protective padding: Strategic padding in the sled protects athletes from striking hard surfaces during turbulent moments.

Helmet and spine protection: Bobsledders wear specialized helmets rated for multi-impact situations (unlike motorcycle helmets designed for single impacts). Many also wear spine protectors to guard against the extreme forces experienced during turns and braking.

Track improvements: The venues themselves have been constantly improved. Modern tracks include better wall padding, improved barrier systems, and improved surface consistency that reduces the likelihood of sled failures mid-race.

The sport's governing bodies have made deliberate choices to enhance safety even when those choices slightly reduce performance. For example, regulations now limit how aggressive sled runners can be—a sharper runner might provide better grip through curves but could be more dangerous in accident scenarios. The regulations reflect a balance between safety and competition.

The Push Phase Breakdown: Where Fractions of Seconds Matter

Let's zoom in on the push phase, where most technological innovation focuses. This 30 to 50-meter sprint determines competitive positioning for the entire race.

During the push phase, athletes are applying maximum force. In four-person sleds, you have four athletes pushing a 630-kilogram load. In two-person sleds, you have two athletes pushing a 390-kilogram load. The force required is enormous. Bobsledders' legs and core muscles are among the strongest in sports—comparable to Olympic weightlifters and American football linemen.

The physics equation governing acceleration is:

Where

- Maximize applied force (): Athletes train their strength continuously

- Minimize sled mass (): Advanced materials reduce weight

- Optimize force transfer: Better footwear ensures force applied translates into forward motion

- Minimize inefficiencies: Data analytics identify and correct technique problems

Each component of the equation represents an area where technology provides improvements.

Force application efficiency depends heavily on footwear and the sled's push handles. Custom spikes provide better grip, meaning more of the force applied by athletes' legs transfers into forward sled motion. Without good grip, athletes are wasting energy pushing against ice that slides beneath their feet.

The push handles themselves have become sophisticated. The shape, angle, and grip material affect how effectively athletes can transmit force. Different athletes have different hand sizes and grip preferences, so custom-fitted handles might provide marginal improvements for some teams.

Timing synchronization matters enormously. In a four-person sled, all four athletes pushing in perfect synchronization delivers more force than if their pushes are slightly out of sync. Data Coach and Snowflake's system both focus extensively on identifying synchronization problems that human coaches can't easily see.

Modern bobsleds incorporate various safety features with high effectiveness ratings, ensuring athlete protection at extreme speeds. Estimated data based on typical safety evaluations.

The Jump Phase: Milliseconds and Positioning

Immediately after the push phase comes the jump—the moment when athletes board the moving sled. This transition must be perfectly executed.

As the final pushing athlete releases the sled, their teammates must jump onto it. The timing must be precise. Too early, and the athlete boards before the sled reaches maximum speed, introducing drag. Too late, and the sled is already slowing down—they're jumping onto a decelerating platform. The optimal moment is essentially instantaneous.

Positioning is equally critical. If an athlete jumps and lands with their center of gravity offset from the sled's centerline, it introduces sideways forces that disturb the sled's trajectory. All four athletes must land smoothly, almost simultaneously, with their weight perfectly distributed.

In practice, microscopic positioning errors create detectable inefficiencies. Data Coach identifies these errors through sensor analysis. Coaches can then work with athletes on body positioning, timing cues, and approach angles to improve jump execution.

The jump phase lasts only about 1-2 seconds, but imperfections during this brief window can cost 0.05 to 0.1 seconds in overall race time. That's the difference between gold and fourth place in many competitions.

The Driving Phase: Line Choice and Speed Management

Once all athletes are aboard and the sled is accelerating through the straightaway, the pilot (driver) takes control. The driving phase involves steering through curves, managing trajectory, and maintaining speed.

Bobsled tracks are carefully designed with precisely banked curves. The banking is engineered to optimize speed through that specific curve. A pilot who follows the exact center of the bank maintains optimal speed. Deviations from the ideal line waste speed and energy.

Here's where track familiarity becomes critical. Pilots who have practiced thousands of times on a specific track develop intuitive knowledge of the fastest lines. Data Coach augments this knowledge. The system analyzes trajectory data and identifies precisely where the fastest line runs on each curve, what approach speeds work best, and where braking should occur to prepare for the next section.

Tire drafting isn't a factor in bobsledding like it is in NASCAR, but aerodynamics become relevant at high speeds. A sled that can maintain speed through turns better than competitors gains cumulative advantages throughout the race. This depends on sled design, runner quality, and driving technique—all factors that technology and coaching can optimize.

The Braking Phase: Final Seconds and Safety

The race ends when the sled crosses the finish line and the brake operator engages the brake system. The operation is simple in concept: pull a handle connected to brake pads that press against the runners, slowing the sled.

Braking technique affects final race time by a small amount but impacts safety significantly. An athlete who brakes too early wastes the opportunity to gain additional speed. An athlete who brakes too late risks crashing through the finish line barrier.

Braking technology includes:

- Brake pad materials: Specialized compounds that provide consistent friction regardless of ice temperature

- Runner surface preparation: The runners' surface affects braking efficiency

- Brake lever ergonomics: The handle must be positioned where the brake operator can engage it with explosive force while traveling at 90+ mph

Braking is less frequently optimized through technology compared to other phases, simply because the time differential is smaller. But elite teams still focus on consistent braking technique and equipment that delivers predictable results.

AI-driven coaching can significantly enhance bobsledding performance by improving push pairing efficiency, synchronization during the jump phase, push power output, and acceleration consistency. Estimated data based on AI analysis capabilities.

International Competition and the Technology Arms Race

Olympic bobsledding involves a limited number of truly competitive nations. Germany, the United States, Canada, Switzerland, and a handful of others consistently medal. These countries have the resources to invest in technological development.

Germany maintains a particular advantage partly due to the sport's long history in the country and partly due to institutional support from partners like BMW. The partnership between the German bobsled federation and BMW represents exactly the kind of corporate-sport partnership that drives technological advancement. BMW gets research opportunities and technology transfer potential. German bobsled gets access to cutting-edge engineering expertise.

The United States has pursued technology partnerships differently, relying on specialized companies like VKTRY Gear and partnerships with data analytics firms like Snowflake. This approach has produced strong results—American teams have been consistently competitive internationally.

Canada, despite smaller budget resources than Germany or the US, has produced elite bobsledders who excel internationally. Canadian bobsled success demonstrates that technological advantage isn't everything—coaching quality, athlete selection, and training programs matter tremendously.

The technology arms race in bobsledding remains relatively contained compared to sports like Formula 1 or cycling, but the competitive intensity is genuine. Teams that lag behind in technology development eventually lag behind in competition.

Future Directions: What's Next for Bobsled Technology

Looking ahead to the 2026 Milano Cortina Winter Games and beyond, several technological trends seem likely to accelerate:

Enhanced AI and machine learning will become more sophisticated. Current systems analyze performance data after runs. Future systems might provide real-time coaching cues during runs—imagine a coach able to communicate split-second adjustments to a driver mid-race through subtle haptic feedback or audio signals. Regulations currently prohibit this, but as technology becomes capable, governing bodies will need to decide whether to permit such innovations.

Advanced sensors will become smaller and more comprehensive. Current sleds include accelerometers and position tracking. Future sensors might include muscle activation sensors, heart rate monitoring, force distribution analysis, and other biometric data. This information would provide coaching insights at the biomechanical level.

Materials science innovation will continue. New composite materials with even better strength-to-weight ratios might become available. Advanced coatings for runners might offer subtle friction improvements. Printed materials might replace traditional machined components in less critical applications.

Biomechanics research will deepen understanding of optimal push mechanics. High-speed video analysis combined with force plate data and 3D motion capture might reveal subtle technique improvements that could be taught to future athletes.

Environmental considerations might drive some innovation. As concerns about sustainability grow, the sport might gradually shift toward more recyclable or renewable materials, or manufacturing processes with lower environmental impact.

The Philosophy Behind Equipment Limits

Understanding bobsledding's technology requires understanding why equipment regulations exist. The sport's governing bodies have deliberately chosen to limit technological development in specific ways.

Weight restrictions prevent wealthy teams from building sleds so optimized they'd be unbeatable. By capping total weight, the sport ensures that athletic ability remains central. A team with marginal athletes can't overcome that limitation by engineering their way out through superior equipment.

Length restrictions prevent aerodynamic optimization beyond practical limits. By restricting sled length, authorities ensure that bobsled design remains recognizable as bobsled, not something transformed into a completely different shape.

Runner specifications prevent teams from engineering runners so specialized they'd require custom-built tracks. Runners must work on standard Olympic tracks maintained to specific standards. This ensures that performance differences reflect athlete ability and general equipment quality, not track-specific specialization.

These regulations frustrate some engineers who see technological possibilities they can't explore. But they serve an essential purpose: they keep the sport balanced, competitive, and recognizable. Without such constraints, bobsledding might become an engineering competition where the team with the biggest R&D budget would always win—regardless of athlete quality.

Case Study: Germany's Competitive Success

Germany's dominance in bobsledding (and luge and skeleton) provides a useful case study in how technology and institutions combine to produce competitive success.

Germany's advantages include:

-

Historical tradition: Bobsledding has deep roots in German culture and sporting institutions. Multiple generations of coaching expertise exist.

-

Institutional support: The German bobsled federation (Bob- und Schlittenverband für Deutschland) receives government support and has strong relationships with private partners like BMW.

-

Manufacturing expertise: Germany's engineering and manufacturing sectors are world-class. The country has existing expertise in materials science, precision manufacturing, and advanced materials that transfers naturally to bobsled equipment.

-

Training infrastructure: Germany has ice tracks and training facilities specifically designed for sliding sports. Athletes can train year-round on facilities engineered to world-class standards.

-

Corporate partnership model: BMW's partnership with the bobsled federation provides resources and expertise that individual athletes or even national federations alone couldn't access.

-

Data-driven approach: Germany's adoption of systems like Data Coach demonstrates institutional commitment to technology-driven improvement.

Germany's success isn't purely technological. Coaching quality, athlete selection, and training programs matter tremendously. But technology support has been a consistent advantage that contributes to overall competitive success.

Athlete Perspectives: What Elite Bobsledders Say About Technology

Elite athletes offer valuable insights into how technology actually affects competition. Kaillie Humphries, a top-level bobsledder competing for the United States and winner of Olympic gold in the women's monobob, has noted that technologies like VKTRY's dynamic insoles provide "a higher level of stiffness and useful energy return to optimize effort during the bobsled push."

This professional assessment from an elite athlete validates the engineering assumptions underlying these innovations. Humphries isn't endorsing the technology as marketing hype—she's describing actual performance benefits based on competing at the highest level.

Other elite bobsledders have noted that while equipment matters, training, coaching, and athlete selection ultimately determine success. No amount of technological advantage compensates for poor training or inferior coaching. Technology is a multiplier on top of fundamentals. Get the fundamentals right, then let technology provide marginal improvements.

This perspective aligns with research in sports science generally. At elite levels, marginal gains often compound. A 1% improvement in equipment efficiency, combined with 1% improvements in coaching, 1% in technique, and 1% in training methods produces roughly a 4% overall improvement. That 4% might be the difference between gold and fourth place.

Comparing Bobsled Technology to Other Winter Sports

Bobsledding's approach to technology resembles but differs from other winter Olympic sports.

Alpine skiing focuses technological development on ski and binding design, boot geometry, and clothing aerodynamics. Alpine skiers benefit from extensive sponsorship and corporate R&D. However, alpine skiing involves less standardization than bobsledding—regulations permit more varied equipment designs.

Speed skating involves highly specialized equipment including custom-fitted skates and skin suits designed for optimal aerodynamics. Speed skating's technology development resembles bobsledding in focusing on marginal improvements in speed. However, speed skating permits more radical equipment innovation than bobsledding.

Luge, which shares many characteristics with bobsledding, faces similar equipment constraints. Luge athletes also benefit from custom footwear, sled design optimization, and data analysis. The sports' similar nature creates competitive pressure to develop parallel technologies.

Bobsledding's equipment constraints are actually more restrictive than many winter sports. This reflects the sport's particular history and philosophy. By limiting technological variation, the sport preserves its competitive balance and ensures that athlete ability remains primary.

The Future of Data-Driven Coaching in Winter Olympics

Data analytics in bobsledding represents a broader trend across Olympic sports. As sensors become cheaper and more capable, and as AI tools improve, every winter sport is becoming increasingly data-driven.

Figure skating, historically viewed as purely artistic, is now being analyzed with biomechanical data. Cross-country skiing programs track athlete power output and efficiency. Curling teams now analyze precisely how rocks' trajectories differ based on release angles and ice conditions.

Bobsledding's data revolution, driven by systems like Snowflake's analytics and BMW's Data Coach, is part of this broader shift. The sport that might have seemed least susceptible to data optimization—after all, physical strength and technique are obviously crucial—is being transformed by AI and analytics.

This trend will likely accelerate. Within a few years, athletes who aren't training with comprehensive data analytics will be at competitive disadvantage. Teams without access to real-time performance data and AI coaching will lag behind teams that do.

The competitive arms race has shifted from pure R&D investment in equipment to investment in data infrastructure and analytical expertise. Teams need not just engineers but data scientists and AI specialists.

Conclusion: Technology, Competition, and the Future of Olympic Bobsledding

Olympic bobsledding has become a sophisticated blend of athletic excellence and technological innovation. From custom-engineered footwear to AI-driven coaching systems, every element of the sport now reflects decades of careful engineering and optimization.

The technologies powering the 2026 Milano Cortina Winter Games represent the current cutting edge—but they'll be surpassed within years. Equipment regulations will evolve. New materials will become available. AI systems will become more sophisticated. Coaching methods will improve.

What won't change is the fundamental reality of Olympic competition: marginal gains matter immensely. The difference between gold and fourth place is often measured in hundredths of a second. Technology provides tools for chasing those marginal gains. Smart coaching, elite athletes, and rigorous training ultimately determine who wins.

Bobsledding's technology arms race remains relatively constrained compared to some sports, thanks to deliberate equipment regulations designed to keep competition balanced. But within those constraints, teams continuously innovate. BMW develops better studded shoes. VKTRY refines insole technology. Engineers optimize carbon fiber structures. Coaches develop new training methods informed by data analysis.

The athletes sliding down icy tracks at 90+ mph carry with them centuries of accumulated engineering knowledge. Every element of their equipment has been refined countless times. Yet the sport remains fundamentally about human capability—strength, skill, courage, and competitive spirit. Technology amplifies these human qualities. It never replaces them.

For spectators watching the 2026 Winter Olympics, the technological complexity underlying bobsledding might remain invisible. You see athletes pushing sleds and navigating turns. You don't see the years of engineering development, the data analysis, the material science, the biomechanical optimization. But that invisible technology is absolutely present, shaping every race outcome and constantly pushing the sport toward new levels of performance.

FAQ

What is Olympic bobsledding?

Olympic bobsledding is a winter sport where teams of athletes push a specialized sled down an icy track, then ride it through turns and curves at high speeds. Teams compete in three categories: men's four-person, women's two-person, and monobob (individual athletes). The sport debuted at the 1924 Chamonix Olympics and has evolved from wooden sleds to modern carbon fiber systems equipped with advanced technology.

How fast do Olympic bobsleds travel?

Olympic bobsleds reach speeds approaching 145 kilometers per hour (90 miles per hour) on the track. The initial push phase accelerates the sled from a standstill to maximum velocity over approximately 30 to 50 meters in just 5 to 6 seconds. Athletes aboard the sled experience gravitational forces exceeding 5g during turns, equivalent to multiple times their body weight pressing against them.

What role does technology play in bobsledding performance?

Technology affects bobsledding performance in several critical areas: custom footwear improves push efficiency, carbon fiber construction minimizes sled weight, AI coaching systems identify technique problems, and data analytics optimize race strategy. While athletes' strength and skill remain primary, technological advantages in equipment and coaching can provide marginal gains worth fractions of a second—the difference between medals and fourth place in competitive racing.

How does BMW's partnership with German bobsledding work?

BMW serves as a strategic partner to the German bobsled federation (Bob- und Schlittenverband für Deutschland), investing in equipment innovation and engineering expertise. BMW has developed custom studded shoes using 3D printing technology to optimize push phase efficiency. The partnership also produced Data Coach, an AI system that analyzes sled sensor data to optimize trajectory and racing strategy. This partnership exemplifies how corporate resources and manufacturing expertise enhance competitive performance.

What are VKTRY dynamic insoles and how do they work?

VKTRY dynamic insoles are specially engineered footbeds that work differently from traditional athletic insoles. Rather than simply absorbing impact and providing support, VKTRY insoles are shaped to only contact the heel and toe when placed on a flat surface, creating an arch-like structure that stores and returns energy. When athletes push during the initial acceleration phase, the insoles compress and store energy, then release that energy as the athlete extends, amplifying push force. This energy return system helps bobsledders generate more force during the critical first 50 meters of the race.

Why do bobsledding regulations limit equipment weight and size?

Equipment regulations exist for two important reasons: to maintain competitive balance and to ensure athlete safety. Weight limits prevent wealthy teams from building so-optimized sleds that they become unbeatable regardless of athlete quality. Length restrictions prevent aerodynamic optimization beyond practical limits. These constraints force engineers to innovate within boundaries that preserve the sport's balance and keep athletic ability central to competition. Without such regulations, bobsledding might become purely an engineering competition where budget determines outcomes.

What is the push phase and why does it matter most?

The push phase is the first 30 to 50 meters of the race, when athletes accelerate the sled from a standstill. This phase typically lasts 5 to 6 seconds. It matters most because the acceleration achieved during the push phase largely determines competitive positioning throughout the entire race. Athletes can't overcome a poor push by driving better or braking better later. Most technological innovation focuses on the push phase because improvements there have the largest impact on final race times.

How do data analytics improve bobsledding performance?

Data analytics systems like Snowflake's AI tools and BMW's Data Coach collect sensor data during training runs and races, then use machine learning to identify performance patterns. These systems can identify inefficiencies invisible to human observation—like subtle bumping between athletes during the jump phase or suboptimal pushing mechanics. Coaches use these insights to provide highly specific feedback that helps athletes correct technique problems. The systems also analyze which push pairings work best and identify optimal lines through race tracks, allowing teams to develop data-driven racing strategies.

What materials are modern Olympic bobsleds made from?

Modern Olympic bobsleds are constructed primarily from carbon fiber and advanced composite materials, often combined with other materials like aluminum or titanium alloys in specific components. Carbon fiber offers an ideal strength-to-weight ratio—it's significantly lighter than steel while actually being stronger in terms of material properties. The runners that contact the ice are typically made from precision-engineered steel machined to exact specifications. Some teams now use T800 carbon fiber, an aerospace-grade composite offering even better performance characteristics than conventional carbon fiber.

How important is footwear in bobsledding success?

Footwear plays a crucial role, particularly during the push phase when athletes need maximum grip on the ice. Custom studded shoes developed by BMW for German bobsledders use 3D printing to create spike plates precisely fitted to individual athletes' needs. The spikes are hardened through plasma nitriding to prevent wear and breakage. Better footwear means better grip, which translates to more efficient force transfer from athletes' legs to the sled. In a sport where races are decided by hundredths of a second, improved footwear can mean the difference between medals and fourth place.

Key Takeaways

- Custom footwear technology, pioneered by BMW with 3D printing and plasma nitriding, improves push-phase efficiency by optimizing ice-contact grip and force transfer

- Dynamic insoles from VKTRY Gear store and return energy during the push phase, providing measurable acceleration improvements for elite bobsledders

- AI coaching systems like Snowflake's analytics and BMW's Data Coach analyze sensor data to identify technique problems and optimize racing strategy at the hundredths-of-a-second level

- Carbon fiber composite construction reduces sled weight by up to 20% compared to conventional materials while maintaining structural integrity under 5g+ forces

- Equipment regulations deliberately constrain technological optimization to maintain competitive balance and ensure athlete ability remains central to bobsledding competition

- The push phase—just 30 to 50 meters lasting 5 to 6 seconds—determines most of the race outcome, making equipment and technique optimization critical

- Germany's institutional partnerships, particularly BMW's involvement with the German bobsled federation, demonstrate how corporate R&D resources enhance competitive performance

- Data analytics has shifted from post-race analysis to real-time coaching, allowing teams to provide split-second feedback based on comprehensive performance metrics

Related Articles

- Ilia Malinin's Quadruple Axel: The Physics and History Behind Figure Skating's Greatest Innovation [2025]

- Heated Rivalry Hockey Effect: LGBTQ+ Inclusion & The 2026 Olympics [2025]

- Quadruple Axel Physics: How Ilia Malinin Defies Gravity [2025]

- Curling's High-Tech Revolution: The Shoes and Brooms Dominating 2026 [2025]

- 2026 Winter Olympics Environmental Impact: Snowpack Loss and Climate Crisis [2025]

- How to Watch the 2026 Milan Cortina Winter Olympics Opening Ceremony [2025]

![Olympic Bobsledding Technology: The Gear Behind Gold [2026]](https://tryrunable.com/blog/olympic-bobsledding-technology-the-gear-behind-gold-2026/image-1-1771155397132.jpg)