Space X's Super Heavy Booster Aces Cryoproof Testing: What It Means for Starship V3

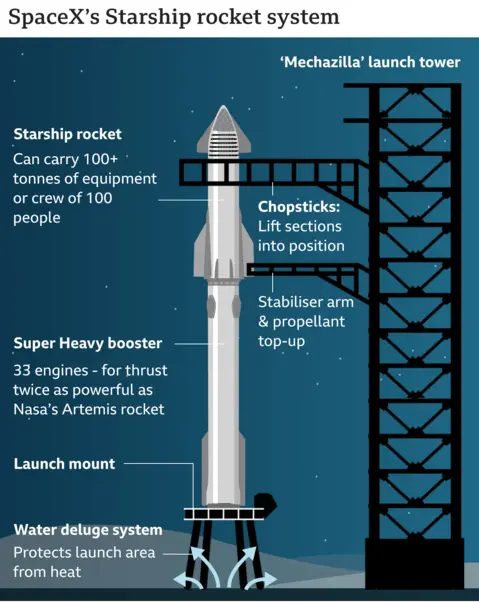

Space X just hit a major milestone that most people outside the space industry probably missed. On a Tuesday in early February 2026, the company announced something that might sound mundane on the surface but actually represents a crucial step toward the Moon, Mars, and everything beyond: a 237-foot-tall stainless-steel booster passed its cryogenic proof testing without exploding. According to Air & Space Forces Magazine, this marks a significant advancement in SpaceX's efforts to develop reusable rocket technology.

Now, why should you care about a rocket booster sitting in the Texas heat getting doused with liquid nitrogen? Because this test clears the path for the first flight of Starship V3, Space X's upgraded mega-rocket. And that flight is a stepping stone toward something NASA desperately needs: orbital refueling in space. Without this technology working reliably, human missions to the lunar surface get pushed back years. Maybe decades. As reported by Universe Magazine, delays in such technologies can significantly impact timelines for lunar missions.

Let's break down what actually happened, why it matters, and what comes next for one of the most ambitious rocket programs in human history.

Understanding Cryoproof Testing: Why Rockets Need to Survive Cold

Cryogenic proof testing sounds technical, but the concept is straightforward. Imagine filling a massive metal tank with liquid that's colder than the surface of Pluto. The metal contracts. Pressures build. Seams flex. Things that look rock-solid at room temperature can suddenly crack, leak, or catastrophically fail.

That's exactly what happened to the previous Super Heavy booster designated for Starship V3's first flight. In November 2025, ground crews at Space X's Starbase facility in Texas ran a pressure test on that booster. During the test, the liquid oxygen tank ruptured under pressure. Not a small leak. A catastrophic failure. The booster was scrapped, and the company moved on to the next vehicle in line: Booster 19. This incident was detailed in a report by USA Today.

Cryoproof testing exists specifically to catch these problems before they happen at launch. Engineers roll the booster out to Massey's Test Site, a facility a few miles from the main factory. They run pressure tests first at ambient temperature—basically, room temperature. This gives baseline data on how the structure performs under normal conditions.

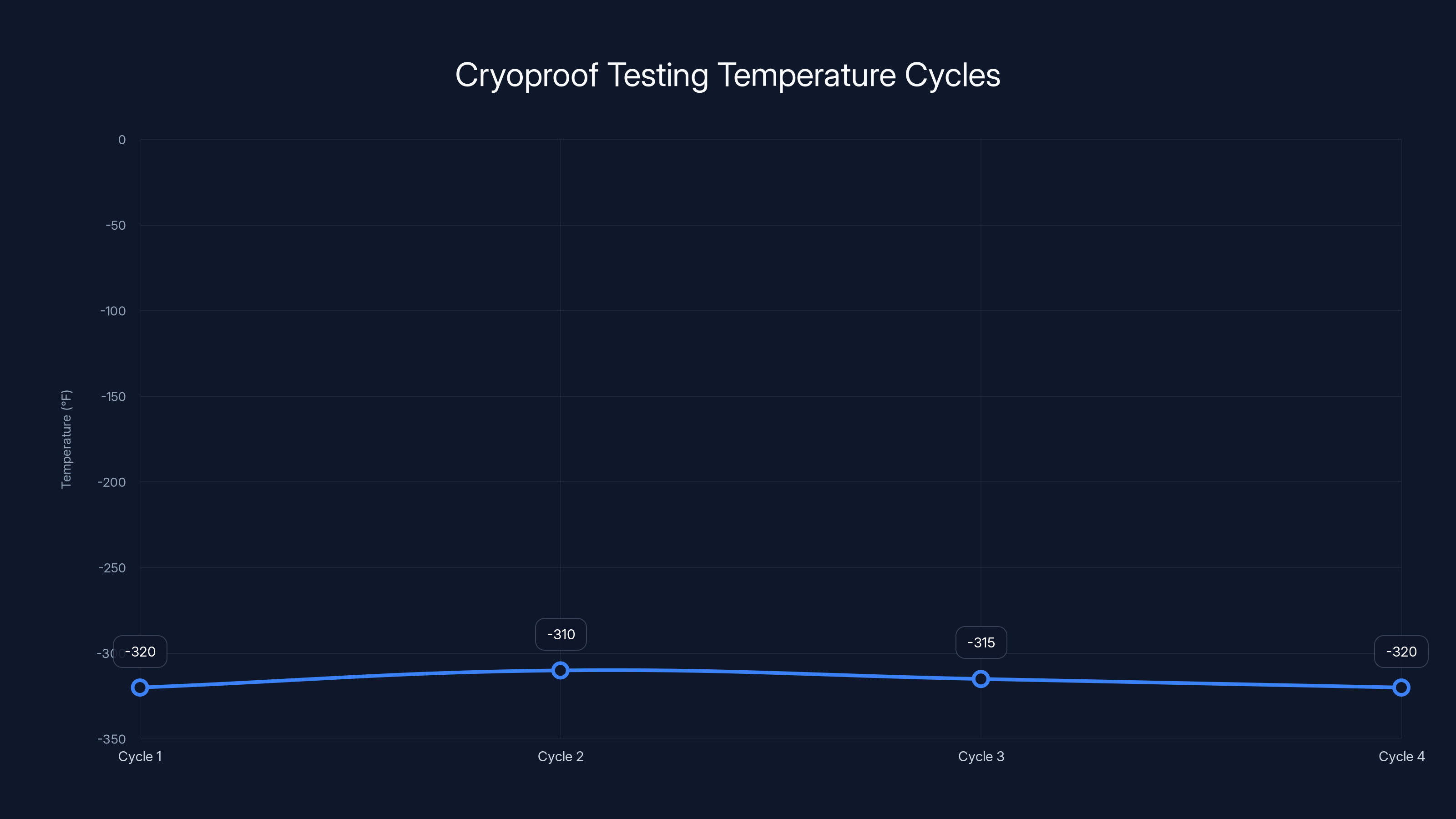

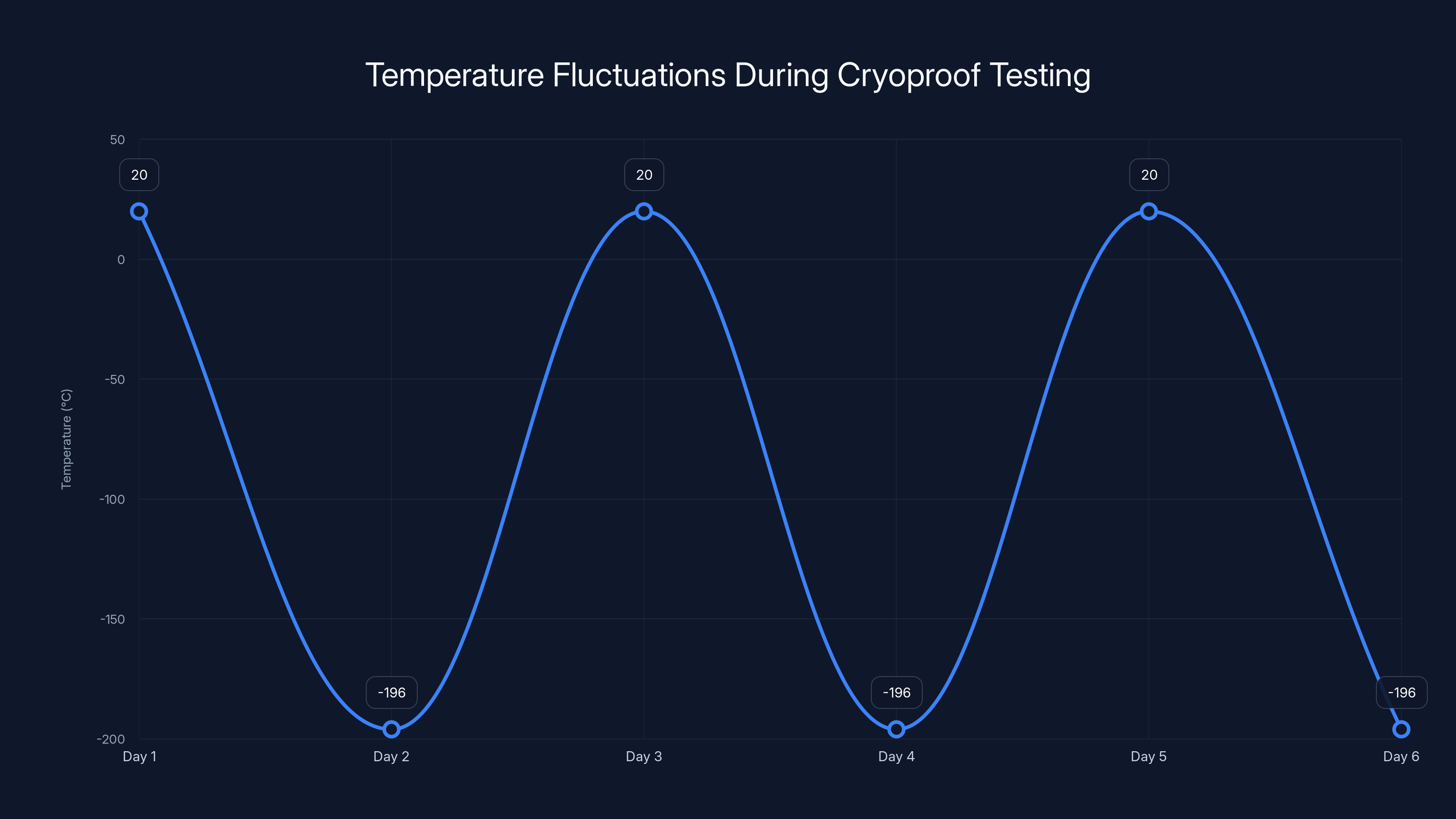

Then comes the cryogenic part. Teams load super-cold liquid nitrogen into the booster's tanks four separate times over the course of six days. Liquid nitrogen sits at about minus 320 degrees Fahrenheit (minus 196 Celsius). It's not quite as cold as the liquid methane and liquid oxygen that will actually fuel the booster at launch, but it's close enough to simulate the real thermal and pressure stresses the rocket will experience.

Each cycle puts the booster through dramatic temperature swings. The metal heats up, cools down, flexes, and contracts. Seams experience stress. Welds get tested. Structural components get pushed to their limits. If something's going to fail, cryoproof testing will usually reveal it before the rocket ever gets to the launch pad.

The chart illustrates the estimated prevalence of common misconceptions about Starship testing, highlighting that test failures are often misunderstood as program failures. Estimated data.

The Evolution of Space X's Starship: From V2 to V3

To understand why Booster 19's successful cryoproof test matters, you need context about where Space X's been with this rocket. The company has been testing and refining Starship for years now, and each major version represents significant engineering changes.

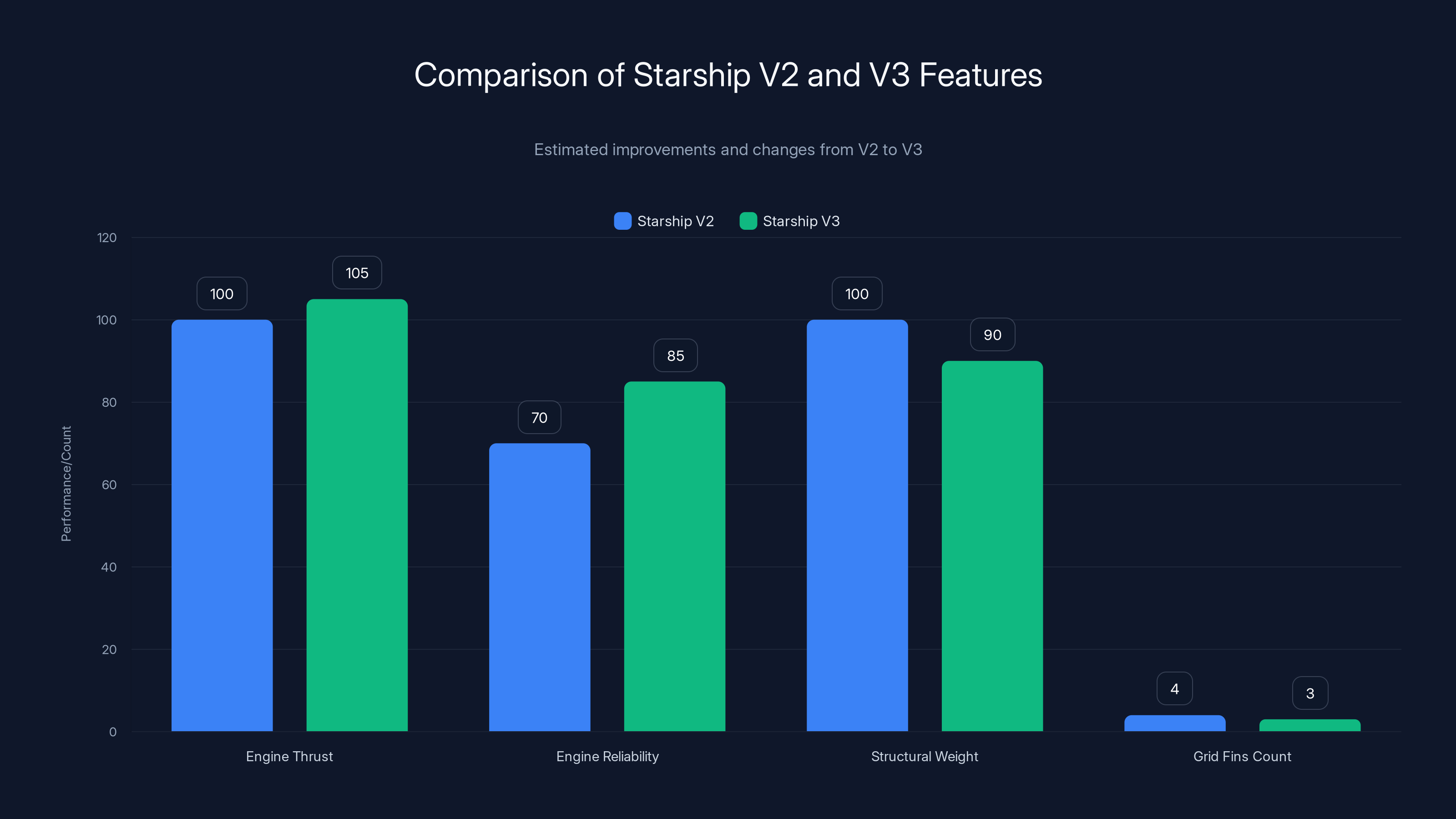

Starship V2 flew five times last year. The first three test flights didn't achieve Space X's goals—they had failures, anomalies, things that didn't go according to plan. But the last two flights succeeded. Space X got what it needed from V2, learned its lessons, and moved on to designing V3. This iterative process is part of SpaceX's strategy, as noted by Live Science.

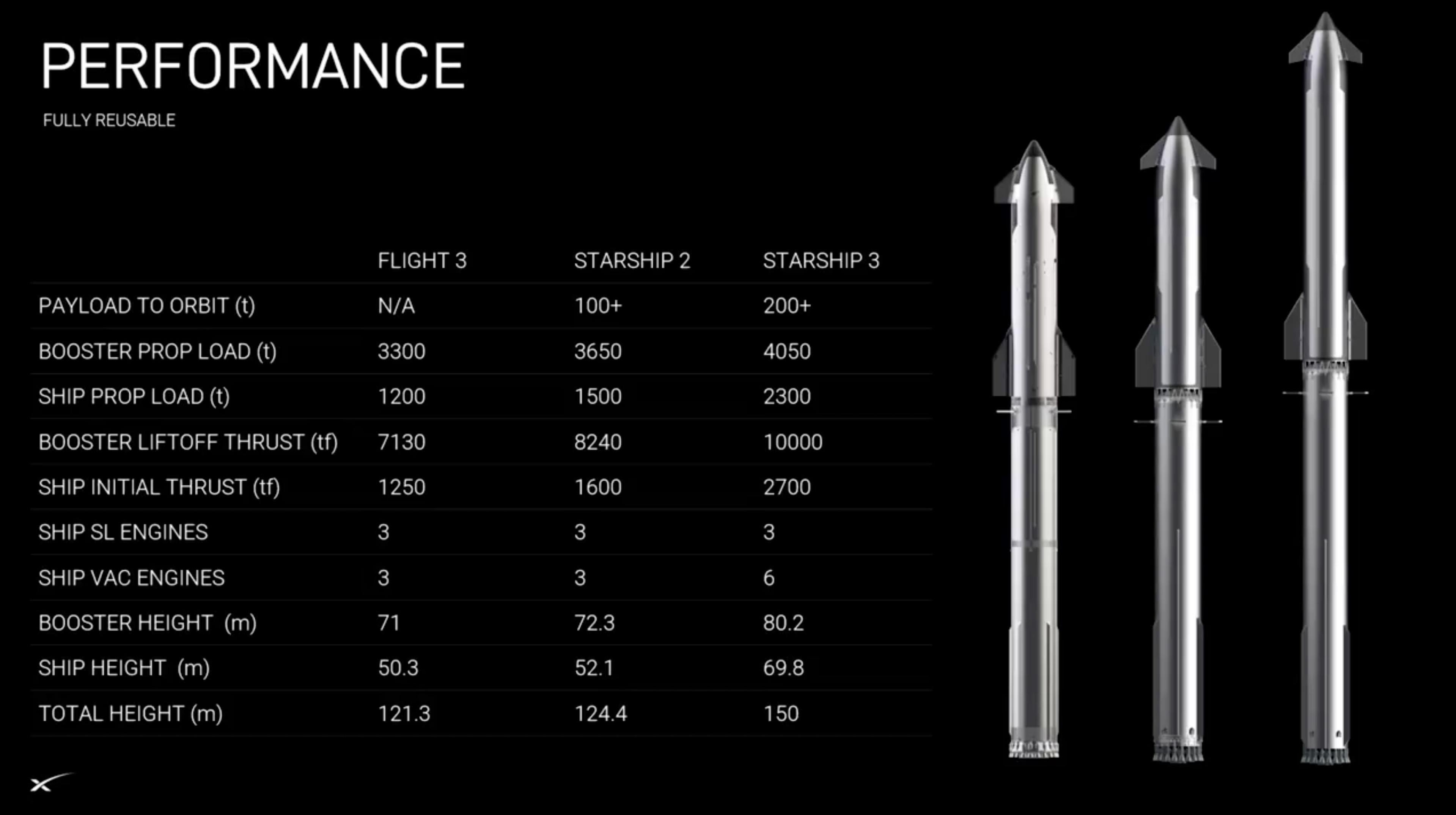

Starship V3 is the next generation, and it's not just a minor tweak. It's a significant redesign with multiple improvements across the booster and the upper stage. The changes focus on three main areas: the engines, the structural design, and the reusability systems.

First, the engines. Starship V3 will use Raptor 3 engines instead of the previous Raptor 2 engines. The Raptor 3 produces more thrust—about 5% more—and more importantly, includes design changes meant to improve reliability. These engines are lighter. They integrate the plumbing and sensors directly into the engine's main structure instead of running separate lines. This eliminates the need for self-contained heat shields that had to sit between engines at the base of the rocket. That's simpler, lighter, and theoretically less likely to fail.

Second, the structural changes. The new Super Heavy booster will only use three grid fins instead of four. Grid fins are aerosurfaces that help stabilize the rocket as it falls back to Earth after the booster separation. Fewer grid fins means less drag during descent, which affects recovery operations but also reduces complexity and weight.

Third, the hot-staging ring at the top of the booster has been redesigned. On previous Starship flights, this component was jettisoned after the booster and upper stage separated—it was expended, meaning thrown away. On V3, the hot-staging ring is integrated with the booster itself, which enables the booster to return to Earth and be reused. This is a critical step toward making Starship truly reusable and economical.

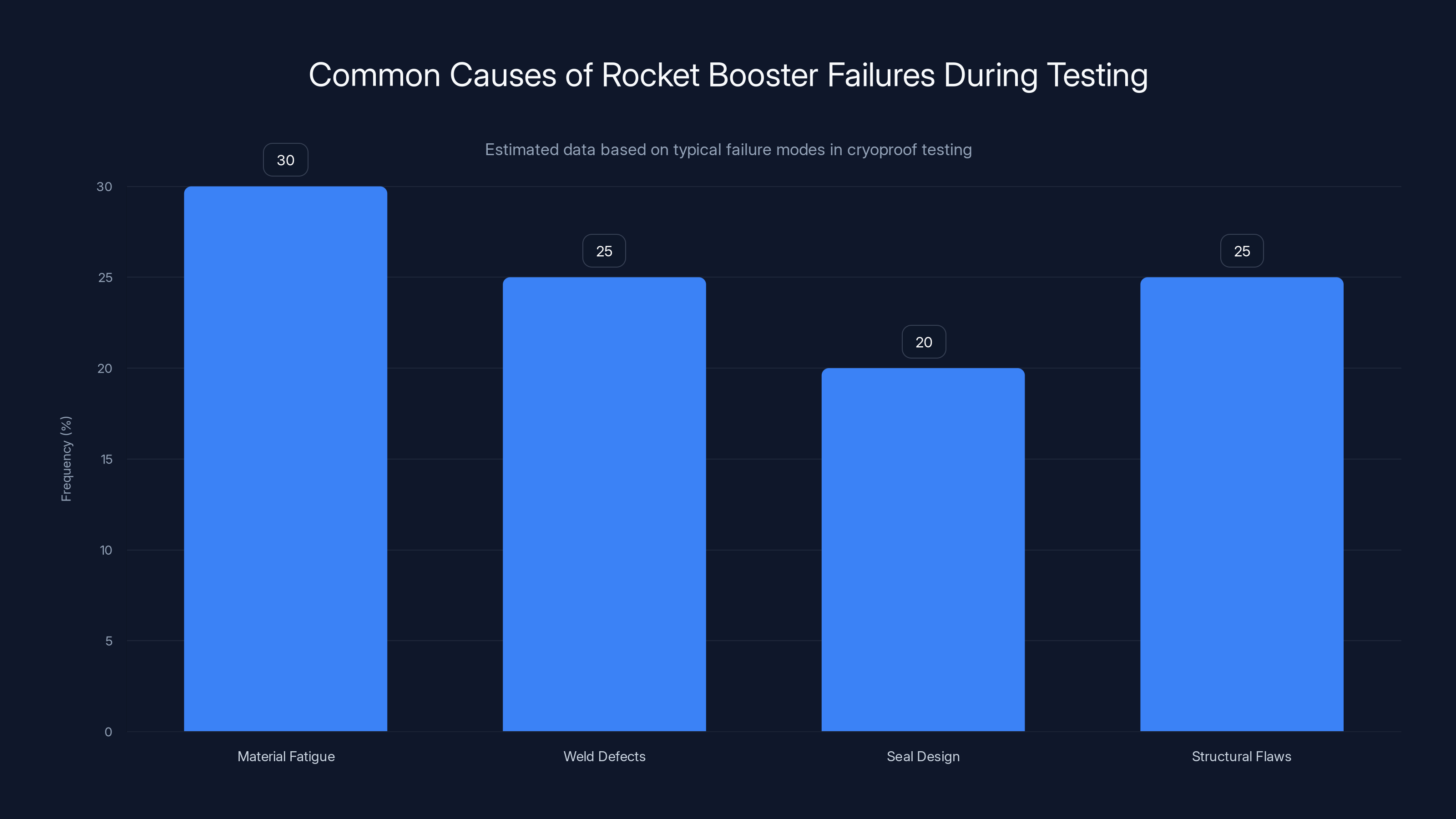

Material fatigue and structural flaws are the most common causes of rocket booster failures during cryoproof testing. Estimated data.

Why This Particular Test Failed Before (And Why That Matters)

The booster that failed in November wasn't a surprise failure in the sense that it was unpredictable. It failed during a standard test procedure. What made it significant is what it revealed about the design at that time.

Liquid oxygen tanks operate at extreme pressures and temperatures. The engineering has to account for every variable: the temperature differential between the cryogenic liquid and the surrounding air, the pressure buildup from boil-off, the structural stress from the weight of the liquid itself, and the vibrations and accelerations that happen during launch.

When that first booster's LOX tank ruptured, it told Space X engineers something was wrong with either the tank design, the materials used, the welding process, or some combination. Rather than trying to salvage it, Space X made the decision to scrap it and move to the next booster in the production queue. This approach is consistent with SpaceX's rapid iteration philosophy, as highlighted by Ars Technica.

This approach—test, fail, learn, move on to the next unit—is actually part of Space X's philosophy. The company builds multiple vehicles in parallel. When one fails testing, they investigate the root cause, implement fixes in future units, and keep moving forward. It's not ideal, but it's faster than trying to repair a booster that's already shown structural problems under stress.

Booster 19 was built with whatever lessons were learned from that failure. Maybe the tank design was refined. Maybe the welding procedures were updated. Maybe materials were changed. Space X doesn't always disclose the specific engineering changes, but the fact that Booster 19 passed cryoproof testing suggests the fixes worked.

The Multi-Day Cryoproof Campaign: What Actually Happened

Let's walk through the actual testing procedure that Booster 19 went through. This gives you a real sense of what's involved in proving out a mega-rocket structure.

Ground teams at Starbase rolled the 237-foot booster out of the factory and transported it a few miles to Massey's Test Site. This itself is logistically complex. A booster this size and weight requires specialized transport. Once it arrives at the test facility, engineers begin setting up.

Day one focuses on ambient pressure testing. The booster sits in the open air. Engineers pressurize the tanks and structural elements with nitrogen gas at room temperature. This establishes baseline data on how the structure behaves under pressure without the complication of extreme cold.

Days two through five involve the cryogenic cycles. On day two, teams load super-cold liquid nitrogen into the booster's tanks. The nitrogen enters, the temperature drops dramatically, and engineers monitor every sensor on the rocket. They're watching for anything unusual: pressure spikes, temperature anomalies, structural creep, anything that might indicate a problem.

As the nitrogen heats up naturally and boils off, the temperature gradually normalizes. The booster goes back to room temperature. Then, on day three, they do it again. And day four. And day five. Four separate cryogenic cycles over six days.

This repeated cycling is crucial. It's not just about surviving one cold soak. It's about surviving multiple thermal cycles, which is harder. Every time the temperature changes, everything in the booster expands or contracts. Materials fatigue. Welds experience stress. After four cycles, engineers have a pretty good sense of whether the booster can handle what'll happen on launch day.

After six days of testing, Booster 19 had passed. No ruptures. No failures. No catastrophic problems. Ground crews returned it to the factory early Monday, where technicians would prepare it for the next phase: installing the actual rocket engines and other systems.

Starship V3 introduces a 5% increase in engine thrust, improved reliability, reduced structural weight, and one less grid fin compared to V2. Estimated data based on described changes.

What Comes Next: Engine Installation and Ground Testing

Once a booster passes cryoproof testing, it moves into the next phase of preparation. For Booster 19, that means returning to the factory and getting outfitted with all the components that make it an actual launch vehicle.

The most critical installation is the engines. Booster 19 will receive 33 Raptor 3 engines. That's 33 individual engines that need to be mounted, plumbed, and tested. The engines go at the base of the booster in a specific cluster pattern. Each one needs fuel lines, oxidizer lines, ignition systems, and sensor connections.

Installation of this many large engines is incredibly complex. The engineers have to ensure perfect alignment. They have to check and recheck the plumbing. Any mistake here could mean mission failure or worse.

Beyond the engines, the booster needs its grid fins installed. As mentioned, V3 uses only three grid fins instead of four. These aerosurfaces need to be perfectly positioned and actuated. They'll be controlled during descent to guide the booster back toward the landing pad.

Once the booster is fully assembled and all components are installed, it rolls out to the launch pad at Starbase. There, it undergoes static fire testing. Space X fills it with actual methane and liquid oxygen—not nitrogen—and fires all 33 engines. This is the dress rehearsal before the real thing.

The static fire test serves multiple purposes. It verifies that all 33 engines can ignite reliably. It checks that fuel and oxidizer flow properly under launch conditions. It provides real-world data on engine performance, vibration, acoustics, and thermal behavior. It's the closest thing to an actual launch without leaving the ground.

Assuming everything passes, the booster is ready to fly. But that's just half the equation.

Starship Upper Stage: Matching the Booster's Readiness

While Booster 19 was undergoing cryoproof testing, Space X's teams were preparing the corresponding upper stage—the actual Starship vehicle that would sit on top of the booster and become the payload.

The first of Space X's upgraded Starship upper stages, Starship V3, needs its own cryoproof test. After Booster 19 returned to the factory, the upper stage would travel to Massey's Test Site to run through the same rigorous multi-day cryogenic testing procedure.

The upper stage is smaller than the booster but arguably more critical to mission success. It carries the actual payload or crew, and it's the vehicle that will eventually land on the Moon, refuel in orbit, or head to Mars. Getting its structure right is just as important.

After cryoproof testing, the upper stage would also undergo a static fire test of its six Raptor engines. These tests would verify that both the booster and upper stage are ready to fly together.

Cryoproof testing involves four cycles of extreme temperature changes using liquid nitrogen to simulate the thermal stress rockets face. Estimated data based on typical testing procedures.

The Timeline: When Can Space X Launch Starship V3?

If everything continues on schedule and nothing else breaks or fails, Space X could be in position to launch Starship V3 before the end of March 2026. That's roughly six weeks from the cryoproof test completion.

This timeline assumes no major setbacks during the engine installation, ground testing, or static fire testing phases. Historically, Space X sometimes encounters issues during these phases that push things back. A valve might malfunction. A sensor might give bad readings. A test might reveal something that requires investigation.

But assuming favorable conditions, a March 2026 launch window is realistic. This would make Starship V3 the 12th full-scale test flight of the combined Starship-Super Heavy system.

When it launches, the flight profile will likely mirror previous Starship tests. The booster and upper stage will separate over the Atlantic Ocean. The booster will attempt to return to Earth and land back at Starbase or on a drone ship. The upper stage will continue downrange, arc halfway around the world, and conduct a controlled reentry and splashdown in the Indian Ocean.

Nobody's expecting to land the booster vertically or recover the upper stage. Those capabilities are still in development. This flight is about validating the upgraded systems and proving that V3 is reliable enough for more ambitious missions coming later.

Why NASA Cares: The Artemis Program and Moon Landing

If you're wondering why Space X's rocket testing dominates headlines, part of the answer is NASA. The space agency is watching Starship V3's development closely because Starship is central to NASA's plan to return humans to the Moon.

NASA's Artemis program aims to land astronauts on the lunar surface. The current plan relies on multiple components: the Space Launch System (SLS) to launch astronauts from Earth, the Orion spacecraft to carry them to lunar orbit, and a human-rated version of Starship to descend to the surface and return.

Starship is NASA's primary option for the lunar lander component. A human-rated Starship would carry astronauts from lunar orbit down to the surface and back to orbit. This is scheduled for the Artemis III mission, which won't happen until well into the late 2020s. As noted by Air & Space Forces Magazine, the integration of Starship into the Artemis program is a pivotal element of NASA's lunar exploration strategy.

But before NASA can trust Starship with human crews on the Moon, Space X needs to demonstrate several critical capabilities. The most important near-term capability is orbital refueling.

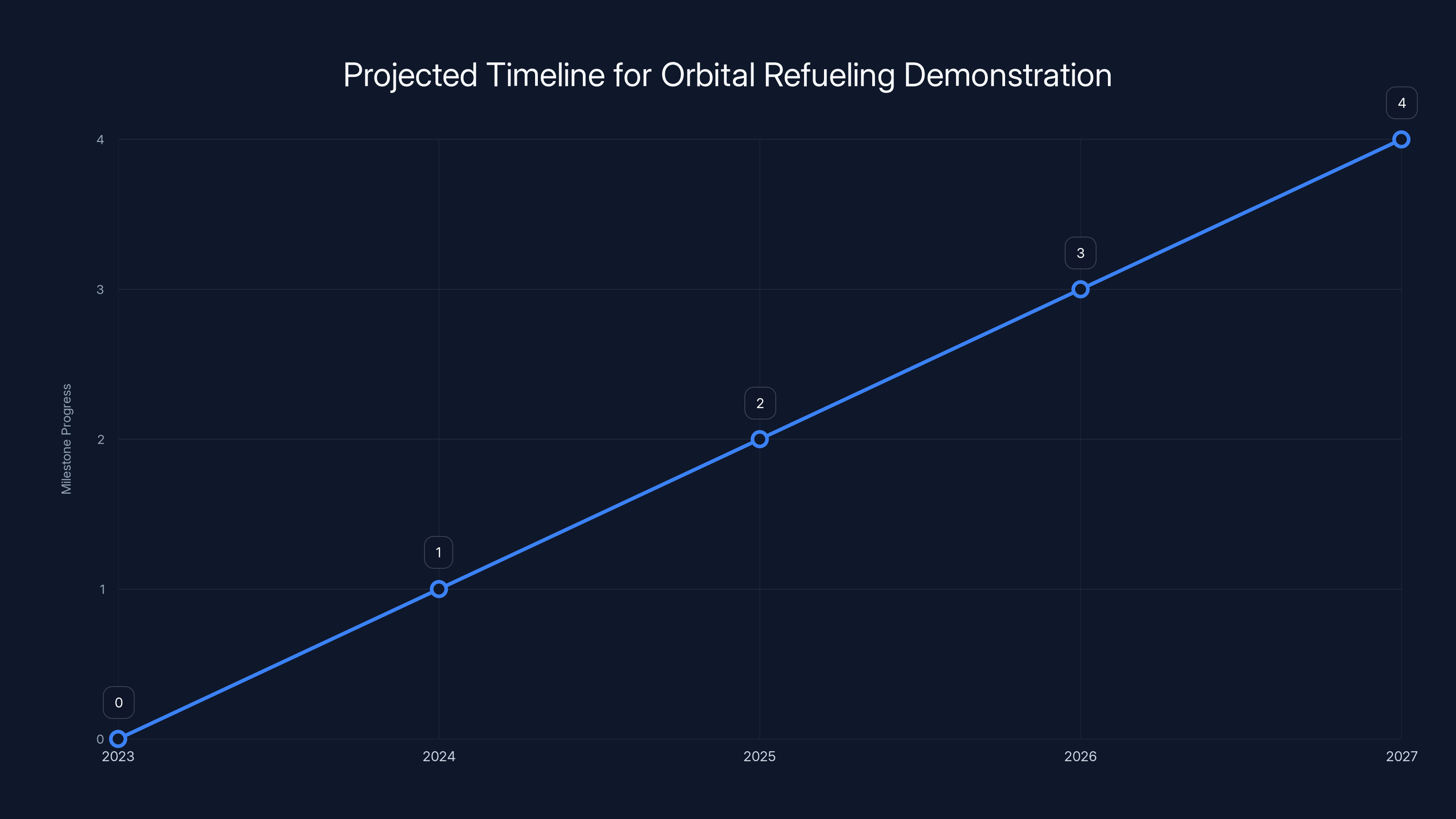

Estimated data: The timeline shows key milestones leading up to and following the Starship V3 launch in 2026, culminating in the orbital refueling demonstration.

Orbital Refueling: The Critical Capability for Beyond-Earth Missions

Here's a physics problem: a fully fueled Starship leaving Earth for the Moon or Mars is incredibly heavy. The fuel it needs for the journey weighs almost as much as the spacecraft itself. But rockets are more efficient the lighter they are.

The solution is orbital refueling. Launch a Starship to space with a minimal fuel load. Dock it with another Starship that's been launched purely to serve as a fuel tanker. Transfer fuel from the tanker to the main vehicle. Then the main vehicle has enough fuel for the journey.

This is simple in theory but devilishly hard in practice. You have to rendezvous two vehicles in orbit traveling at 17,500 miles per hour. You have to dock them without damage. You have to transfer fuel from one to the other in the vacuum of space where everything is weightless and temperatures swing wildly.

Space X has planned a demonstration of this capability for Starship V3 or shortly after. The mission would launch multiple Starships—one would carry cargo or a dummy payload, others would serve as fuel tankers. They'd rendezvous and dock in orbit. Fuel would be transferred. Then the main vehicle would continue to space to demonstrate that it has enough fuel to reach the intended target.

NASA considers this demonstration a stepping stone. Once Space X proves orbital refueling works reliably, NASA will have more confidence that human-rated Starships can reach the Moon and return safely. Without this capability working, the entire Artemis timeline gets compressed and constrained.

The March 2026 Starship V3 launch isn't the orbital refueling demonstration itself—that's planned for a future flight—but it's a necessary prerequisite. V3 has to prove it's reliable and capable before Space X can attempt something more ambitious.

The Competitive Context: Why This Matters Beyond NASA

Space X isn't the only company building heavy-lift rockets. Blue Origin is developing New Glenn. Relativity Space is working on 3D-printed rockets. China has Long March vehicles. But right now, Starship is the only super-heavy-lift rocket that's actually been tested at scale, and the only one designed from the ground up to be fully reusable.

This gives Space X an enormous advantage in the commercial space market. Companies that want to launch massive satellites or space stations can charter flights on Starship. The cost per kilogram of payload to orbit would be dramatically lower than competing systems.

Beyond commercial launches, there's the space tourism market. Space X is planning private missions where paying customers would fly around the Moon in Starship. These missions require the same level of reliability needed for NASA's crewed missions.

Then there's the military and national security applications. The U.S. military is interested in using Starship for rapid global transport. The idea is to launch people or cargo on a Starship, have it arc around the world, and land it anywhere. It's faster than aircraft and could theoretically land anywhere with a reasonably flat surface.

All of these applications require the same fundamental capability: a reliable, reusable, super-heavy-lift rocket. Booster 19 passing cryoproof testing is one brick in the wall of proving Space X can deliver that.

The cryoproof testing involved significant temperature fluctuations, with the booster undergoing four cryogenic cycles from room temperature to -196°C over six days. Estimated data.

Common Misconceptions About Starship Testing

If you read about Starship tests and get confused about what's happening, you're not alone. The testing program is complex, and media coverage often oversimplifies or misunderstands what Space X is actually doing.

First misconception: test failures mean the program is doomed. They don't. Space X explicitly expects test failures. The company is learning through rapid iteration. A booster that fails cryoproof testing and gets scrapped is actually valuable because it teaches engineers what doesn't work. Space X would rather fail in testing than in flight.

Second misconception: Starship is just a bigger Falcon 9 with a different name. It's not. Starship is built entirely from scratch on different engineering principles. It's made of stainless steel instead of aluminum. It's designed to be fully reusable instead of partially reusable. The engines are different. The structure is different. It's a fundamentally different approach.

Third misconception: Starship launch costs are already cheaper than competing rockets. They're not. The company is still in testing and development. Launch costs will eventually be cheaper—that's the goal—but currently, launching Starship is expensive because the program is young and every launch is experimental. Commercial pricing will drop significantly once the system matures.

Fourth misconception: Space X can't actually land and reuse a Starship booster. This is partially true today, but it's changing. Space X has demonstrated controlled descent of booster stages. They've demonstrated booster catch with mechanical arms. Full reusability is coming.

The Path Forward: What Happens After Starship V3

Assuming Starship V3 launches successfully in March 2026 and completes its test objectives, Space X won't stop there. The company has outlined an ambitious roadmap for the next few years.

Immediate post-V3 plans include the orbital refueling demonstration. This would happen on a subsequent Starship flight, possibly the 13th or 14th full-scale test. Multiple Starships would launch, rendezvous in orbit, and transfer fuel. Success here would be a watershed moment for the program because it would validate the approach for lunar and Mars missions.

Following the refueling demonstration, Space X would likely push toward higher-velocity re-entries and more sophisticated landing attempts. The company wants to eventually land Starship booster stages with precision, using the mechanical arms at Starbase to catch them out of the sky. This sounds like science fiction, but Space X has been testing and refining this concept with Falcon 9 boosters for years.

Longer-term, we're looking at human-rated variants of Starship. NASA wants to certify Starship for crewed lunar missions by the late 2020s. This means more testing, more validation, more flight history before NASA will trust it with astronauts. But the trajectory is clear: Space X is building toward that capability methodically.

Beyond NASA, Space X is developing a crewed version for its own private Moon missions. The company has announced plans for point-to-point hypersonic transportation on Earth using Starship, which would launch and land vertically in major cities. These are future concepts, but they all depend on Starship becoming routine, reliable, and reusable—the exact qualities that Booster 19 passing cryoproof testing is validating.

Key Insights from the Testing Approach

If you step back and look at Space X's approach to testing mega-rockets, a few things stand out. First is the emphasis on testing at scale. Space X doesn't spend years on ground models or small-scale prototypes. They build full-size vehicles and test them. This is expensive but fast.

Second is the acceptance of failure as part of the learning process. The booster that ruptured in November wasn't a tragedy—it was data. Space X investigated, implemented fixes, and moved on. This mindset allows for rapid progress.

Third is the parallel production approach. Space X builds multiple booster and upper stage vehicles simultaneously. When one fails testing, the next one is ready. This is expensive but ensures the program doesn't get stuck waiting for repairs.

Fourth is the transparency. Space X actually announces these milestones—including failures and problems—via social media and press releases. This is unusual for aerospace. Traditional aerospace companies tend to keep testing results quiet until they're ready to announce success. Space X is the opposite.

Fifth is the focus on reusability from day one. Most aerospace programs test expendable vehicles first, then later add reusability. Space X is building reusability in from the beginning. This makes the engineering harder, but it's essential for reducing long-term costs.

Engineering Lessons From Cryogenic Testing

For engineers and space enthusiasts who want to understand what Space X is actually learning from tests like this, there are some specific technical insights.

Cryogenic testing reveals whether material properties are being used correctly. Stainless steel, which Space X uses for Starship, has different properties at cryogenic temperatures than at room temperature. Engineers need to account for this. A design that looks structurally sound at room temperature might fail when exposed to minus 320-degree temperatures. Testing proves whether the design actually works in the real environment.

Cryogenic testing also reveals whether welds are sound. Welds are often the weak point in structures. The heat-affected zone around a weld has different material properties than the base metal. Under extreme temperature cycling, cracks can initiate at welds. Cryoproof testing puts stress on every weld in the structure.

Another critical insight is about seals and interfaces. Any place where two components meet—like where a fuel line connects to a tank—is a potential leak point. Cryogenic temperatures change dimensions and can cause previously-sealed interfaces to separate. Cryoproof testing reveals which seals and interfaces are adequate and which need redesign.

Finally, cryogenic testing provides data on pressure relief systems. Most rocket tanks have vents and pressure relief valves. These systems need to work correctly under thermal cycling. A vent that works fine at room temperature might freeze up at cryogenic temperatures. Testing reveals these failure modes.

The Bigger Picture: Why Rocket Testing Matters to Everyone

You might be wondering why you should care about Space X testing a booster in Texas. The short answer is that rockets enabled modern civilization. Without rockets, we don't have GPS, weather satellites, communications satellites, or launch vehicles for scientific missions.

More broadly, Space X's push toward reusable, affordable rockets is changing the space industry. Historically, rockets were incredibly expensive because you could only use them once. You built one, flew it once, and threw away a multi-billion-dollar vehicle. Space X proved you could land boosters and reuse them. This is driving costs down across the industry.

Lower launch costs enable more space activities. More satellites. More missions. More science. More commercial applications. Eventually, more people in space—not just astronauts, but space tourists, space residents, and people working in space industries.

The path to this future goes through tests like Booster 19's cryoproof campaign. Every successful test builds confidence that the technology works. Every failure teaches engineers what needs to be fixed. Both move the program forward.

Timeline and Future Milestones

For those tracking Space X's progress, here are the milestones to watch for in 2026:

Q1 2026: Booster 19 completes cryoproof testing (done), static fire test (expected), and Starship V3 upper stage begins testing.

Q1/Q2 2026: Starship V3 first flight, currently targeted for late March but potentially slipping to April or May depending on how testing proceeds.

Q2-Q3 2026: Orbital refueling demonstration flight(s). This is the big technical hurdle that Space X and NASA are both focused on.

Late 2026 and beyond: Additional Starship flights, increasing complexity and ambition, leading eventually to crewed lunar lander certification.

These dates are ambitious. Space X typically encounters delays. But the trajectory is clear: the company is moving forward methodically, testing thoroughly, and working toward the capability to sustain human missions beyond Earth orbit.

The Role of Starbase and Texas Infrastructure

None of this is possible without Starbase, Space X's facility in South Texas near the small town of Boca Chica. Starbase is where Space X builds Starships, tests them, and launches them. The facility has evolved dramatically since Space X began operations there.

Today, Starbase includes the factory where Booster 19 was built, the Massey's Test Site where it was cryoproof tested, the launch pads where vehicles are fired, and various support facilities. Space X has invested billions in the facility, and the company continues to expand and improve it.

The infrastructure investments are strategic. Space X wants to be able to test and launch Starships frequently. Every booster and spacecraft they build goes through similar testing. Having everything in one location—factory, test site, launch pad, landing zone—makes the logistics simpler and the operations faster.

Texas provided land, regulatory approval, and support from local authorities. Space X has become the major employer in the region. The company contributes to the local economy while pursuing its space ambitions.

FAQ

What is cryoproof testing and why is it necessary?

Cryoproof testing is a multi-day process where a rocket booster is pressurized and exposed to super-cold cryogenic liquids like liquid nitrogen to verify it can withstand the extreme thermal stresses and pressures of actual spaceflight. It's necessary because materials behave differently at extreme temperatures, and components that function fine at room temperature can fail catastrophically when exposed to cryogenic temperatures. By putting a booster through repeated thermal cycles before flight, engineers identify structural weaknesses, seal failures, and design flaws that could cause mission-critical failures on launch day.

How long does cryoproof testing take?

A typical cryoproof campaign takes between four and six days. The process includes an initial ambient-temperature pressure test, followed by four separate cryogenic cycles where the booster is subjected to super-cold liquid nitrogen. Each cycle involves loading the liquid, monitoring the vehicle while it's cold, and allowing it to warm back up naturally. The time is compressed into a few days because the testing is intensive and continuous, with ground teams working around the clock to monitor all the rocket's systems and data.

What causes rocket booster failures during testing?

Booster failures during testing typically stem from material fatigue, weld defects, inadequate seal design, or structural flaws that weren't apparent at room temperature. The booster that failed before Booster 19 had its liquid oxygen tank rupture under pressure during cryogenic testing, suggesting either the tank walls weren't thick enough, the welding had defects, or the materials couldn't handle the combination of pressure and extreme cold. Cryoproof testing is specifically designed to reveal these failure modes so engineers can fix them in subsequent vehicles before attempting flight.

Why is Starship V3 important for NASA's Artemis program?

Starship V3 is critical for Artemis because NASA has selected a human-rated variant of Starship to serve as the lunar lander for the Artemis III mission, which will land astronauts on the Moon. Before NASA will trust Starship with human crews on the lunar surface, Space X needs to demonstrate that the vehicle is reliable and capable. Starship V3's successful testing, particularly the planned orbital refueling demonstration, will validate the technologies and approaches that NASA depends on for its Moon landing program. Without Starship functioning as a lunar lander, NASA's timeline for Artemis would be severely compromised.

What is orbital refueling and why does it matter?

Orbital refueling is the process of launching one spacecraft with minimal fuel, then docking it in orbit with another spacecraft that serves as a fuel tanker, and transferring fuel between them. This matters because a fully fueled Starship leaving Earth for the Moon or Mars is too heavy. By launching multiple Starships—some as cargo carriers and some as fuel tankers—and combining them in orbit, Space X can give long-distance missions the fuel they need to reach their destination. NASA and Space X both consider a successful demonstration of this capability to be essential for beyond-Earth-orbit missions.

When will Space X attempt to land and reuse Starship booster stages?

Space X is already practicing booster recovery techniques with Falcon 9 boosters, which regularly land and are reused. For Starship, the timeline is less certain. The company has tested controlled descent of booster stages and has demonstrated mechanical arm catches with test articles. A fully successful booster catch—where a Starship booster descends and is caught by the mechanical arms at Starbase rather than landing on a pad—could happen as early as 2026 or 2027, but the exact timing depends on how testing proceeds. The priority right now is proving the booster structure is sound and the vehicle can complete basic test flights successfully.

How does Space X test multiple boosters in parallel?

Space X maintains a production pipeline where multiple Super Heavy boosters and Starship upper stages are being built simultaneously at different stages of completion. While Booster 19 was undergoing cryoproof testing, the next booster in line was being built in the factory. If Booster 19 had failed testing, it would be scrapped, and the next booster would move into the test queue. This parallel approach is expensive—it requires more vehicles, more facilities, and more staff—but it prevents delays when one vehicle fails. Space X can afford this approach because launch costs are becoming cheaper, and the company wants to accelerate its testing cadence.

What happens if Starship V3 successfully launches but doesn't achieve all its test objectives?

Partial success is common in Space X test flights. Even if Starship V3 doesn't accomplish every goal on its first flight, Space X gains valuable data about how the vehicle actually behaves in flight. The company can learn from the partial success, fix whatever didn't work, and try again on the next test flight. For example, if booster recovery doesn't work as planned but the upper stage reaches orbit, that's still a successful test of the core vehicle. Space X has built a culture where learning from partially successful missions is part of the process, not a failure.

How much does it cost to build and test a Super Heavy booster like Booster 19?

Space X doesn't publicly disclose detailed costs, but industry estimates suggest that building a single Super Heavy booster costs somewhere in the range of

Conclusion

Booster 19's successful cryoproof testing might not make headlines outside the space community, but it represents a crucial step forward in Space X's quest to build a fully reusable super-heavy-lift rocket. The test proved that the upgraded Super Heavy design can withstand the extreme thermal and pressure stresses of spaceflight. It cleared the path for Starship V3's first test flight, currently targeted for late March 2026.

Beyond Space X's own ambitions, this test matters because NASA is depending on Starship for its Artemis lunar program. The successful cryoproof test is one more data point showing that the vehicle is on track. The planned orbital refueling demonstration will be the next critical milestone. If Space X can prove it can transfer fuel between vehicles in orbit, NASA will have much more confidence that crewed Starships can reach the Moon and return safely.

The path from a booster passing a cryogenic test to humans walking on the Moon isn't short or simple. There are many more tests, failures, and refinements ahead. But every successful milestone makes the goal more achievable. The engineering work happening in Texas right now is laying the foundation for a future where multiple human missions operate beyond Earth orbit simultaneously—to the Moon, to Mars, and eventually beyond.

For anyone interested in space exploration, advanced engineering, or the future of human spaceflight, watching Starship's development is watching the future being built in real time. Booster 19 is just one vehicle among many. But successful tests like this, accumulated over months and years, are how engineering teams move from ambitious goals to actual capability. The work continues, and the next test is always just weeks away.

Key Takeaways

- Booster 19's successful cryoproof testing validates the upgraded Super Heavy design can handle extreme thermal and pressure stresses required for flight

- SpaceX expects to launch Starship V3's first test flight before end of March 2026, pending completion of engine installation and static fire testing

- Starship V3 introduces significant improvements: Raptor 3 engines with 5% more thrust, integrated reusability systems, and refined structural design

- Orbital refueling demonstration is the critical next capability SpaceX must prove to enable lunar and Mars missions, directly supporting NASA's Artemis program

- The cryoproof testing failure of the previous booster (November 2025) demonstrates SpaceX's rapid parallel development approach, moving to the next vehicle rather than repairs

Related Articles

- SpaceX Starship V3 Test Flight: What the Mid-March Launch Means [2026]

- Commercial Deep Space Program: Congress Shifts NASA Strategy [2025]

- NASA's Fraggle Rock Space Adventure: Muppets Meet Moon Exploration [2025]

- SpaceX's Moon Base Strategy: Why Mars Takes a Backseat in 2025 [2025]

- NASA Crew-12 Mission to ISS: Everything About February 11 Launch [2025]

- NASA Astronauts Can Now Bring Smartphones to the Moon [2025]

![SpaceX Super Heavy Booster Cryoproof Testing Explained [2025]](https://tryrunable.com/blog/spacex-super-heavy-booster-cryoproof-testing-explained-2025/image-1-1770768470837.jpg)