How Connected Vehicles Are Transforming Road Safety Detection

Your car knows when a pothole is forming before it destroys your suspension. It can spot a missing street sign from a mile away. It notices guardrail damage that human inspectors miss on their monthly rounds.

This isn't science fiction. It's happening right now on the roads of Ohio.

Honda has quietly been building something remarkable: a system that turns everyday vehicles into mobile infrastructure inspectors. The Proactive Roadway Maintenance System uses AI-powered sensors mounted on standard Honda vehicles to continuously scan road conditions, identify safety hazards, and automatically generate maintenance work orders for transportation departments.

The implications are massive. Transportation agencies spend billions annually on reactive maintenance—responding to problems after they've already caused accidents, injuries, or costly damage. What Honda's showing us is that the future of road safety is preventative, intelligent, and powered by vehicles that essentially work for the government without any human intervention.

Let me walk you through how this works, why it matters, and what it means for the future of driving.

The Origins of Honda's Road Safety Innovation

This isn't Honda's first attempt at solving infrastructure problems. The company started prototyping this technology back in 2021, long before autonomous vehicles captured all the headlines. But the early versions were clunky, unreliable, and far too expensive for real-world deployment.

Then something changed. Honda connected with the Ohio Department of Transportation (ODOT) and a tech firm called Parsons. With support from the University of Cincinnati engineering team, they decided to run a serious pilot program.

The timing made sense. Ohio had been struggling with the same problem every state faces: aging road infrastructure, limited budgets for maintenance, and increasing public safety concerns. ODOT's smart mobility hub saw an opportunity to test whether Honda's AI system could actually work in the real world.

What started as a research project evolved into the largest pilot of its kind in America. Between 2024 and early 2025, Honda test vehicles drove approximately 3,000 miles of road across central and southeastern Ohio, collecting millions of data points about road conditions.

The test wasn't limited to ideal driving conditions. The vehicles operated in rain, snow, at night, in daylight, on rural backroads, and through dense urban areas. This diversity was intentional. Real-world road maintenance doesn't happen under perfect conditions. The system needed to work when it's raining at 6 AM on a Tuesday in rural Appalachia, not just on sunny days.

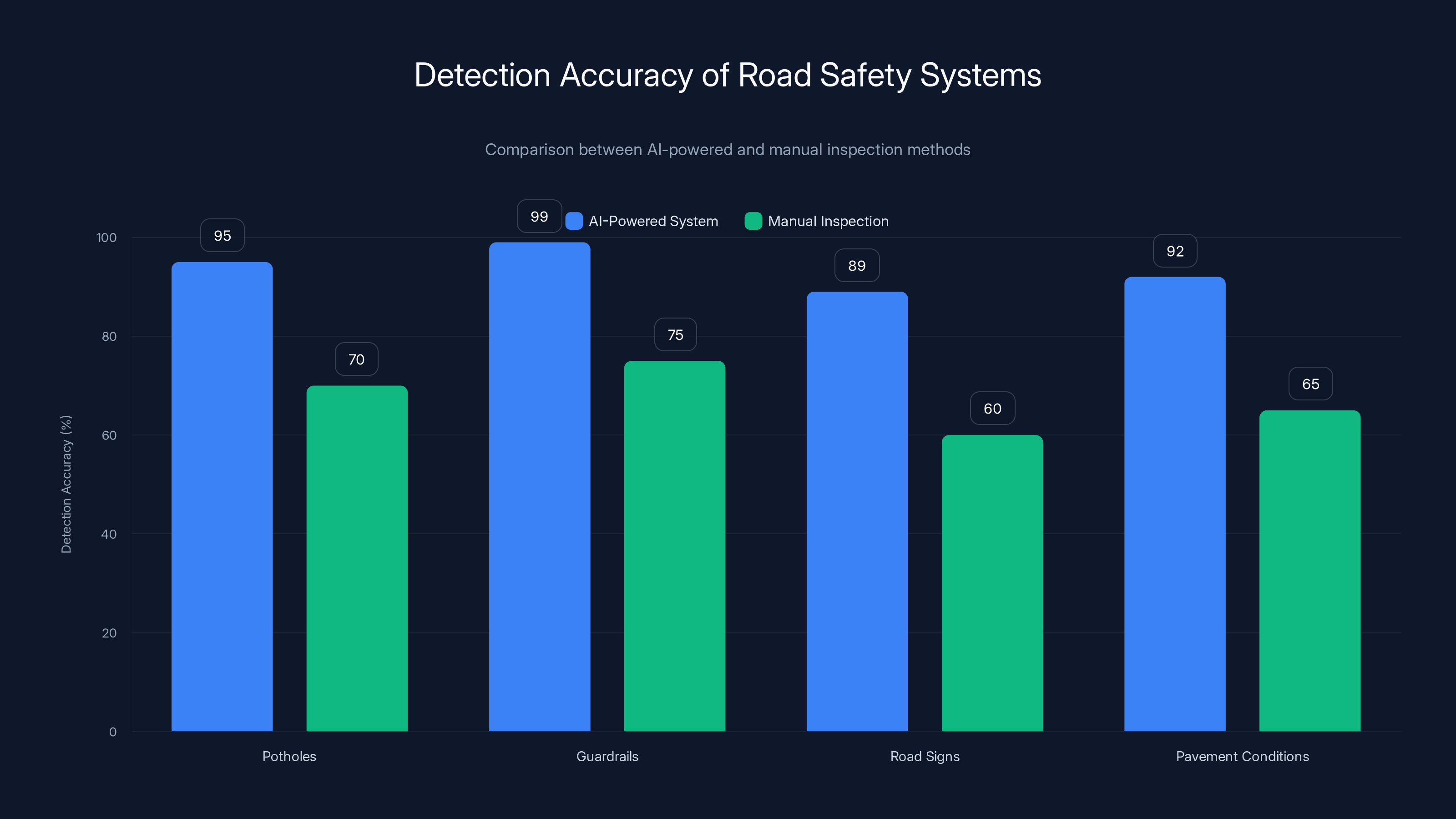

The AI-powered system significantly outperforms manual inspection methods, achieving detection accuracy between 89-99% compared to 60-75% for manual methods.

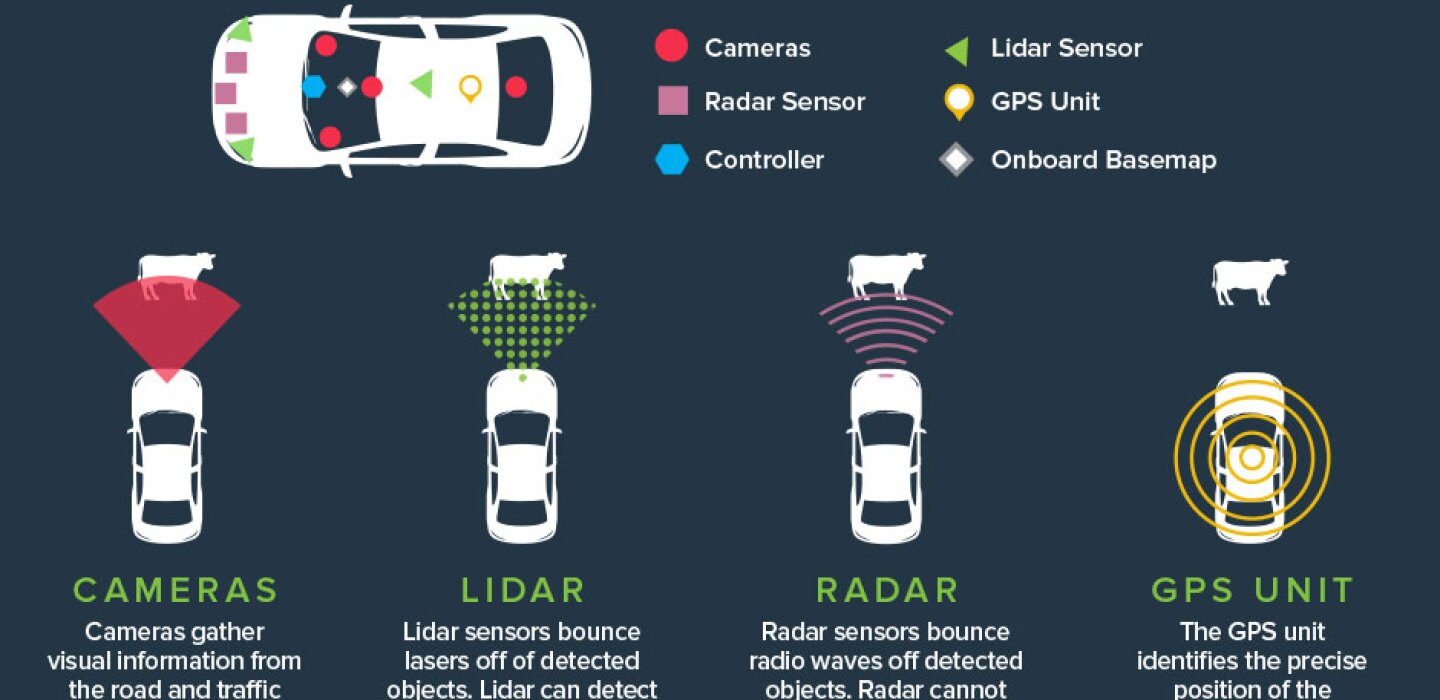

Understanding the Hardware: Advanced Sensors Working Together

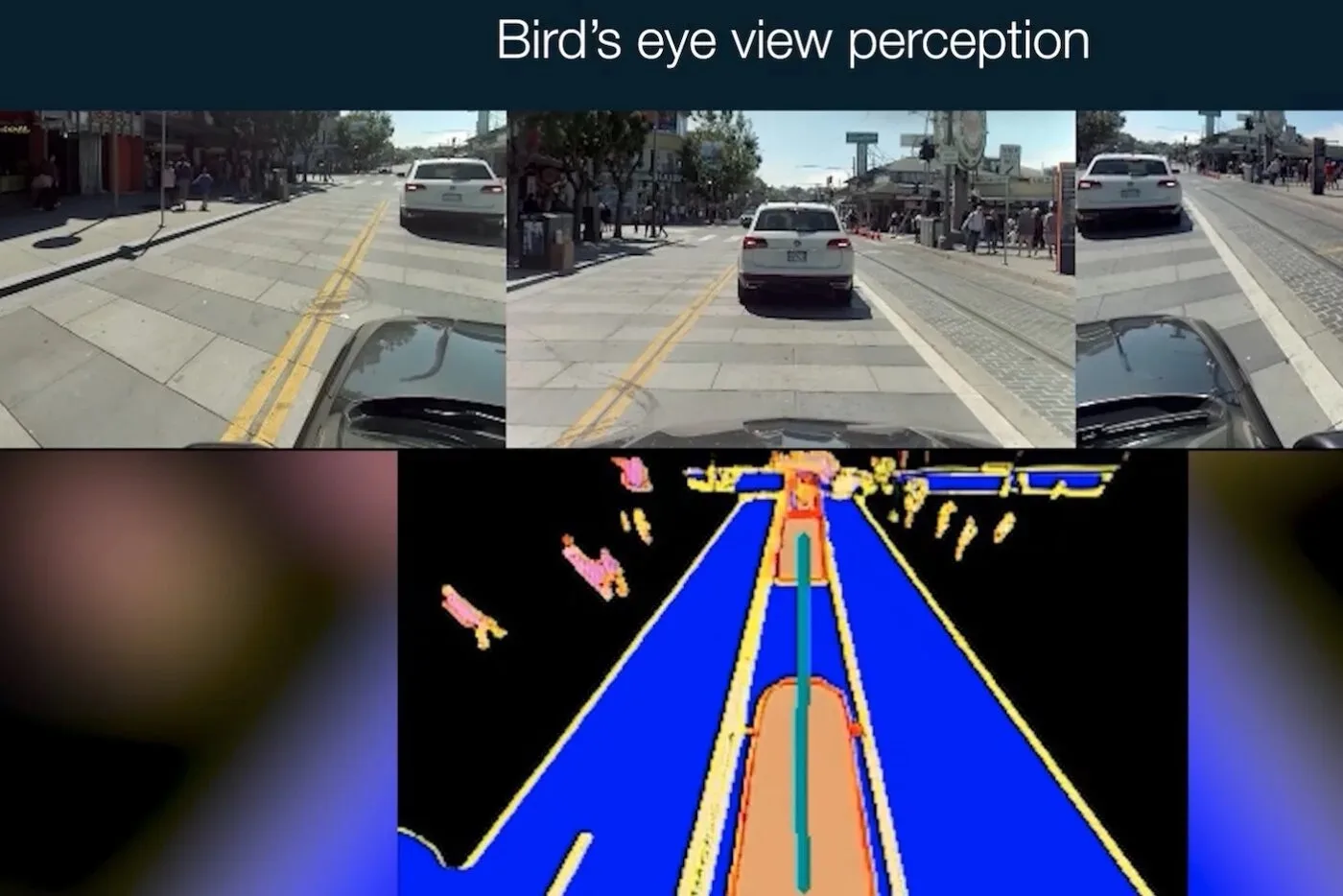

The core of Honda's system relies on a specific combination of sensor technologies. This isn't just a camera bolted to a car. It's an integrated sensing solution designed from the ground up to detect infrastructure defects.

The primary sensors are LiDAR and advanced computer vision systems. If you're not familiar with LiDAR, think of it as sonar for the optical world. It bounces laser pulses off objects and measures the reflections, creating a precise 3D map of everything the vehicle sees. A camera captures visual information, and specialized algorithms combine both data sources to understand what's happening on the road.

LiDAR excels at detecting physical irregularities. A pothole isn't just visually different—it's physically lower than the surrounding pavement. LiDAR detects this depth difference with centimeter-level precision. Computer vision handles the visual aspects: identifying that a street sign is missing or that text on the sign has faded beyond legibility.

These sensors feed data into Edge AI models that run directly on the vehicle's computer. This is important. The system doesn't stream raw video back to Honda's data centers. Instead, it processes everything locally, identifies problems in real-time, and only transmits the essential findings to the cloud.

Why does this matter? Speed, privacy, and reliability. When you're driving at 50 mph and spot a hazard, you can't wait for cloud processing. The local AI makes decisions in milliseconds. The vehicle immediately flags the issue and logs its location with precision. Only after analysis is complete does the system send structured data—not video footage—to Honda's cloud platform and then to ODOT.

The University of Cincinnati played a crucial role here. Their engineering team didn't just install sensors on vehicles. They developed the damage detection algorithms from scratch, trained the AI models on thousands of hours of driving data, and continuously refined accuracy metrics during the pilot.

The Data Pipeline: From Detection to Work Orders

Here's where the system gets elegant. It's not enough to detect problems. The data needs to flow to the right people who can actually fix them.

When a sensor detects a potential issue—say, a cracked guardrail—the vehicle timestamps the location using GPS, captures the image or 3D scan, and classifies the severity. All of this happens automatically. The ODOT operator in the test vehicle sees it on their dashboard in real-time, but the system is also building a database of everything it finds.

That data streams to Honda's cloud platform, where it's aggregated with other observations. If multiple vehicles detect the same guardrail damage over several days, the system recognizes it's a persistent problem. The AI applies priority scoring, considering factors like severity, location (busy highway vs. rural road), and urgency.

Then something remarkable happens: the system automatically generates work orders for ODOT's maintenance teams, ranked by priority. Imagine a field supervisor's phone buzzing with a notification that says, "Potholes detected at Mile 47.3 on Route 23. Severity: High. Location: Schools nearby, high traffic volume. Estimated repair time: 2 hours."

The supervisor gets exact GPS coordinates, high-resolution imagery, severity ratings, and the algorithm's assessment of impact. No guesswork. No waiting for someone to file a report about a pothole they spotted. The system detected it, analyzed it, and pushed it to the right person.

Parsons, the technology firm involved in the pilot, built the smart dashboards that make this workflow possible. These aren't basic status screens. They're sophisticated tools that let transportation officials filter findings by road type, severity, location, or priority level. A district manager can ask the system, "Show me all high-severity issues identified in the last 48 hours within 50 miles of downtown Columbus," and get an instant answer.

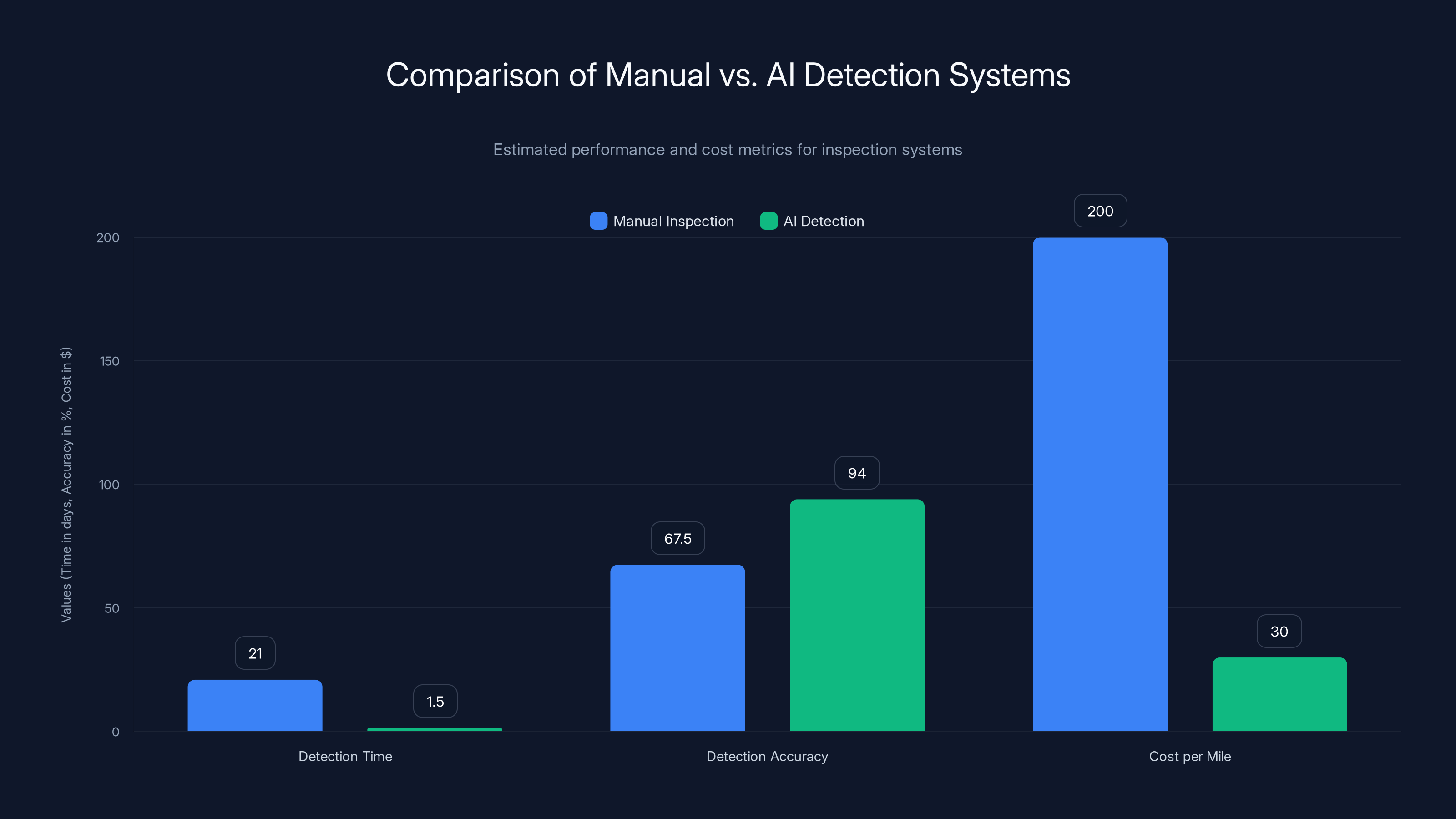

AI detection systems significantly reduce detection time from weeks to days, improve accuracy by over 25%, and lower costs by up to 85% per mile inspected. Estimated data based on typical values.

Accuracy Results: How Well Does It Actually Work?

Here's the question that matters most: does it actually work, or is it an expensive tech demo?

The pilot data is genuinely impressive. The system achieved 99 percent accuracy at identifying damaged or obstructed road signs. Think about that number. In thousands of miles of driving, picking out road signs that are faded, missing, knocked over, or obstructed by vegetation—and getting it right 99 times out of 100. That's exceptional.

For damaged guardrails, accuracy dropped slightly to 93 percent. This makes sense. Guardrails come in different colors, materials, and conditions. Some damage is obvious; other damage is subtle. Getting it right 93% of the time across varied road conditions is remarkably good.

Pothole detection was the hardest problem. The system achieved 89 percent accuracy. Why lower? Because potholes are contextual. The same pavement irregularity could be a pothole, a worn section, a patch from a previous repair, or intentional surface features. The system correctly identifies actual potholes almost 9 times out of 10, with a false positive rate low enough to be useful.

But here's what really matters: these aren't perfect lab conditions. These are real roads, real weather, real variability. The system encountered snow, rain, shadows, glare, and every condition that confuses AI systems. And it still achieved accuracies that exceed what human inspectors typically manage on routine monthly inspections.

The team also discovered something unexpected. The system could detect severe shoulder drop-offs—areas where the pavement edges are dangerously deteriorated—with such precision that human inspectors regularly missed these hazards on routine visual inspections. A shoulder drop-off might not look like much from a distance, but it can cause loss of vehicle control. The LiDAR sensor detects the exact height difference, making these hazards impossible to miss.

Another finding: the system proved reliable at measuring road roughness. Using accelerometer data combined with visual information, the AI could identify stretches of road with excessive bumps or irregularities, flagging them before they develop into serious damage. This is preventative maintenance at its best—fixing problems before they become expensive.

Economic Impact: The Math Behind Maintenance Savings

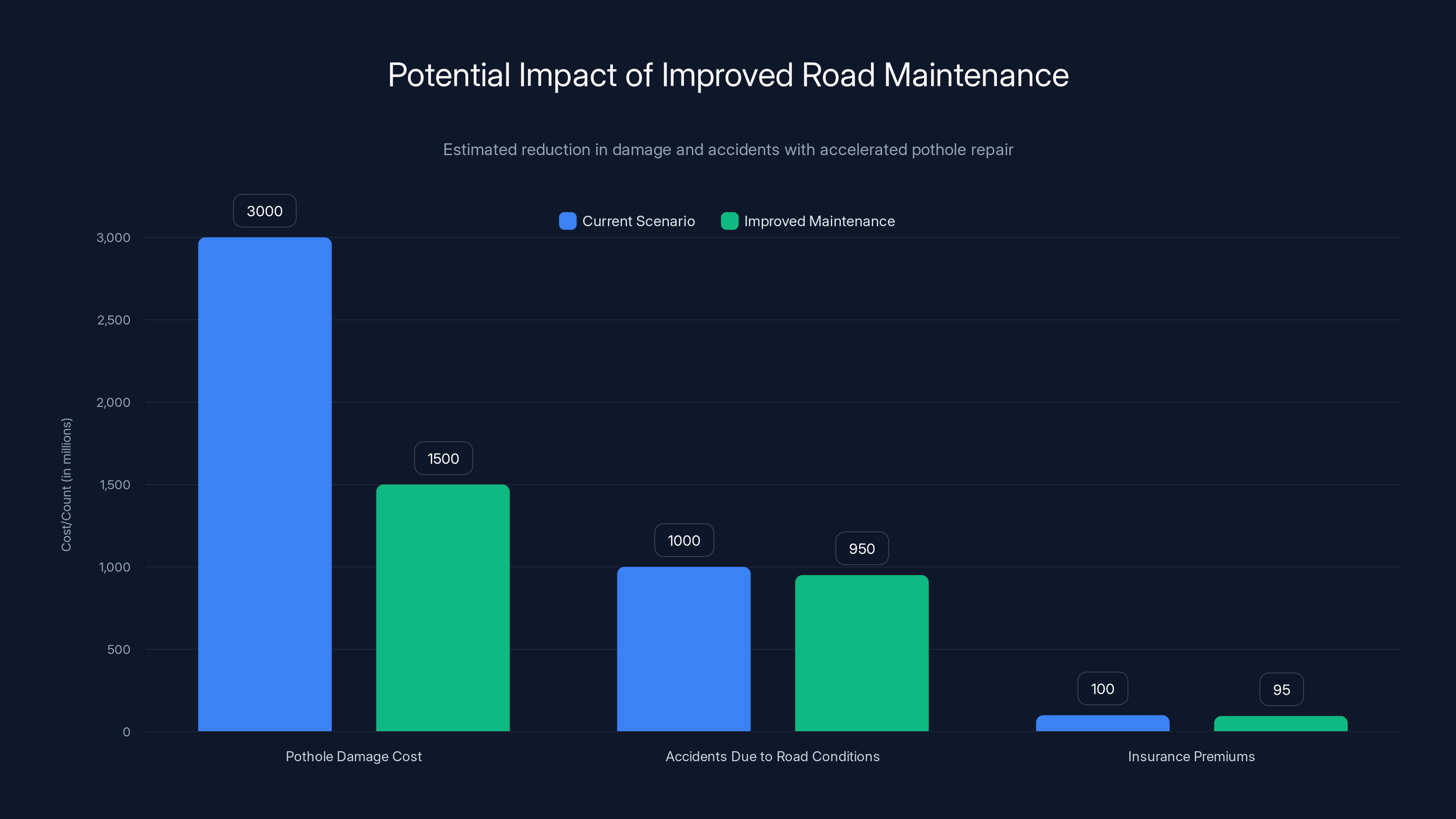

Now let's talk money, because this is where the real-world impact becomes obvious.

The pilot team estimated that if this system were deployed statewide across Ohio's roads, ODOT could save over $4.5 million annually. Let me break down why that number isn't arbitrary.

Current road maintenance in most states follows this pattern: crews drive designated routes monthly or quarterly, looking for problems. They document findings, submit reports, wait for approvals, schedule repairs, and respond. This reactive approach means problems often go undetected for weeks or months. A pothole that starts small becomes catastrophically large. A cracked guardrail corrodes further. A missing sign represents a safety hazard for every driver who passes it.

The economic consequence is compounding costs. A pothole that costs

With Honda's system, the detection lag disappears. Issues are spotted within days, not weeks. The maintenance team responds to an accurate priority list instead of discovering problems randomly. Crews no longer waste time on manual inspections. Resources flow to actual problems, not perceived problems.

Let's do the math on just pothole repairs. Assume Ohio's DOT spends

This doesn't even account for secondary benefits: reduced vehicle damage claims against the state, fewer injury lawsuits, improved public satisfaction, and better road quality for residents.

Real-World Testing Conditions: Why This Pilot Matters

Honda and ODOT didn't run this pilot on a closed track. They operated on actual public roads under actual conditions.

The test covered approximately 3,000 miles split between central Ohio (including urban areas around Columbus) and southeastern Ohio (including rural and mountainous terrain). The vehicles drove in varying weather: clear days, rain, snow, fog, and high winds. They drove at different times: early morning, afternoon, and night. They navigated both highway speeds and slow city traffic.

This diversity was intentional. A system that works great on sunny afternoons is useless in real deployment. The actual job requires functioning in the worst conditions: heavy rain reducing visibility, snow accumulation obscuring lane markers, nighttime darkness making visual inspection nearly impossible.

ODOT operators directly participated in the pilot. They weren't sitting in a lab reviewing data. They were driving the test vehicles on their regular routes, seeing the system in action, providing feedback, and validating findings. This real-world operator input proved invaluable. The team discovered edge cases, clarified user interface improvements, and built confidence in the system's reliability among the people who'd actually use it.

The University of Cincinnati's involvement meant that academic rigor applied to every aspect. They validated the algorithms, tested performance against control datasets, and documented findings with scientific methodology. This isn't marketing material. It's peer-reviewed research.

Automated systems detected more issues than human inspectors, highlighting their effectiveness in identifying road hazards and maintenance needs.

Comparing Manual Inspection vs. AI Detection Systems

Let me put this in perspective by comparing traditional and AI-powered maintenance approaches.

Manual Monthly Inspection Approach:

- Trained inspectors drive designated routes once monthly

- They visually scan for problems while driving

- Issues are reported, logged, prioritized based on inspector judgment

- Average detection time: 2-4 weeks after problem emerges

- Detection accuracy: varies widely (60-75%) depending on inspector attention

- Cost per mile inspected: $150-250 per cycle

- Scalability: limited by number of trained inspectors

Honda AI Detection Approach:

- Sensors operate continuously on any vehicle equipped with the system

- Detection is objective and consistent regardless of time of day or weather

- Issues are flagged automatically within 24-48 hours of emergence

- Detection accuracy: 89-99% depending on defect type

- Cost per mile: estimated at $20-40 per cycle (after infrastructure investment)

- Scalability: limited only by number of equipped vehicles

The comparison reveals why this technology is transformative. The detection latency shrinks from weeks to days. The accuracy improves dramatically. The cost per inspection drops substantially. Most importantly, the system scales. If ODOT deployed 50 Honda vehicles with this system, they'd achieve coverage comparable to manual inspection of thousands of miles monthly, with consistent 95%+ accuracy.

Sensor Fusion: How Multiple Data Sources Create Better Insights

One of the most sophisticated aspects of Honda's system is how it combines multiple sensor types into a unified understanding of road conditions.

LiDAR provides spatial precision. It generates a 3D point cloud showing exactly where every surface is located in space. A pothole becomes a spatial depression. A guardrail becomes a defined structure. But LiDAR alone can't tell you what it's looking at—just where it is.

Computer vision analyzes imagery. It recognizes patterns: road signs have specific shapes and colors, guardrails have distinctive forms, pavement has characteristic textures. But vision alone struggles in challenging lighting, shadows, or rain when cameras can't see clearly.

The AI fusion layer combines both. It says, "This is the spatial signature of a road sign, AND the visual appearance of a sign with missing numbers." Or, "This is the spatial signature of a surface depression, AND the visual appearance of cracked asphalt." The combination provides confidence the system is identifying genuine problems, not false positives from sensor noise.

Accelerometers and gyroscopes add a third dimension. They measure vehicle vibrations and motion. Rough road surfaces create distinctive vibration patterns that the system learns to recognize. A chunk of missing asphalt has a unique shock signature different from a pothole or frost heave.

Temperature sensors also contribute. Certain road defects are more likely in specific temperature ranges. Frost heave occurs in cold climates. Rutting worsens in heat. Context from temperature data helps the AI avoid misclassifying conditions.

This is sensor fusion at its best: multiple imperfect sources of information combine to create something highly reliable. No single sensor is sufficient. Together, they provide understanding that exceeds what any human inspector could achieve.

Privacy Considerations: How Honda Protects Data

Anyone reading about vehicles constantly collecting visual and sensor data should ask: what about privacy?

Honda's approach addresses this directly. The system doesn't record continuous video footage that gets stored and reviewed. Instead, the vehicle's onboard AI processes sensor data locally, identifies potential issues, and stores only essential metadata: location, time, issue category, severity level, and compressed visual snippets of the specific problem.

Personal information is stripped away. If your car is parked in someone's driveway when the system detects a nearby road sign, it doesn't record your car's presence. The system sees the sign condition, not the cars in frame. License plates, faces, and identifying details are algorithmically removed before any data leaves the vehicle.

ODOT and Honda have committed to keeping collected road condition data separate from vehicle identification. The system never links, "This road issue was found by vehicle XYZ belonging to owner ABC." Instead, it records, "This road issue was found at coordinates [location] on [date]." The connection to any specific vehicle is permanently severed.

This privacy-first design is intentional. Honda knows that if drivers don't trust the system, deployment becomes politically impossible. By keeping detection systems local and transmission anonymous, the company has created a surveillance tool for roads—not for people.

Future deployment of this technology in consumer vehicles would follow the same principles. Honda is planning to eventually include this functionality in customer vehicles, allowing millions of drivers to collectively contribute road condition data. But consumers would participate through an opt-in program where they understand exactly what data is collected, how it's used, and who can access it.

Implementing Honda's proactive maintenance system could save Ohio over $4.5 million annually, with significant savings in pothole repairs, labor, and accident prevention. Estimated data.

The Technical Challenges Honda Had to Solve

Building this system required solving several engineering problems that aren't obvious to outsiders.

Real-Time Processing: Processing 3D point clouds from LiDAR at 30+ frames per second requires specialized hardware. Honda uses edge computing devices that can handle this computational load without draining vehicle batteries or requiring network connectivity. The algorithms run locally without cloud dependence.

Semantic Understanding: The AI must understand context. A gap in pavement might be an intentional feature (expansion joint, section line) or actual damage (pothole). The system learned through thousands of labeled examples to distinguish intentional from accidental damage. This required training data from multiple climates and road types.

Adverse Weather Robustness: Snow covering road markers, rain obscuring signs, fog reducing visibility—the system had to maintain accuracy in conditions where human eyes struggle. This required training the AI on degraded sensor inputs, not just perfect conditions.

GPS Precision: Work orders need accurate location data. Consumer GPS is accurate to roughly 10 meters. That's not precise enough to pinpoint which exact guardrail section needs repair on a highway with 30 guardrail sections per mile. Honda integrated high-precision GPS with visual landmark recognition to achieve accuracy within one meter.

Integration with Legacy Systems: ODOT uses existing maintenance management software designed in the 1990s. Rather than forcing the agency to replace everything, Honda's system generates work orders that integrate with existing systems, reducing adoption friction.

False Positive Filtering: The system must be trustworthy. If it floods maintenance crews with 50% false alarms, crews stop believing it. Honda engineered confidence thresholds so the system only flags issues when confidence exceeds 85%, missing some problems but maintaining trust.

Scaling the System: From Pilot to Statewide Deployment

Now Honda and ODOT are asking the harder question: how do we expand from 3,000 test miles to the 45,000 miles of road in Ohio's state highway system?

The obvious approach: deploy the system in more vehicles. If ODOT placed 50 Honda vehicles with this technology in regular service, these vehicles would traverse major roads consistently. Over the course of a year, they'd cover most state highways multiple times. Issues would be detected and reported within days of emergence.

But this raises practical questions. Do you need specialized vehicles, or can the system work in regular Honda sedans and SUVs used by ODOT for other purposes? Testing suggests regular vehicles work fine. The sensor suite isn't so heavy or expensive that it requires a dedicated truck.

Another scaling question: what about local roads? Ohio has roughly 215,000 miles of local roads managed by counties and municipalities. The state highway system is only 20% of the total. Scaling this system to cover local roads requires coordination between multiple agencies with different budgets and priorities.

Honda and its partners are exploring licensing the technology to other states. If Ohio's system saves

There's also the question of data standardization. If Vermont's system flags potholes slightly differently than Ohio's, combining data becomes difficult. Industry standards for road condition reporting would help scale this nationally.

Honda's Consumer Vehicle Integration Plans

Eventually, Honda wants to put this technology in customer vehicles. Imagine every Honda on the road becomes a road safety sensor for its local community.

This would require several evolution. First, the system would need to work in consumer vehicles at mass-market price points. Test vehicles use high-end sensors and computing. Production vehicles need cheaper hardware without sacrificing accuracy.

Second, consumer deployment requires a sophisticated data aggregation system. Honda would need servers processing data from hundreds of thousands of vehicles, extracting road condition signals, and making this data available to transportation departments.

Third, the privacy and data governance model needs to be rock-solid. Consumers must understand they're contributing road data, must be able to opt out, and must trust that their location data remains anonymous.

Honda has indicated this consumer rollout could begin within 2-3 years. The company plans to start with premium trim levels on newer models, gradually expanding to broader lineups. Customers who participate would help their communities—road maintenance crews would use Honda driver data to improve road safety—while also potentially earning credits or insights about road conditions in their own neighborhoods.

This represents a fascinating business model shift. Rather than vehicles purely serving their owners, vehicles become civic infrastructure, contributing to public good while serving individual needs.

Ohio's road system consists of 45,000 miles of state highways, which is only 20% of the total 215,000 miles of roads, highlighting the challenge of scaling the system to local roads.

Competitive Landscape: Who Else Is Pursuing Road Safety AI?

Honda isn't the only company exploring this space, though they're ahead in practical deployment.

Apple Maps and Google Maps have been incorporating crowdsourced road condition data from smartphones for years. Users report accidents, hazards, and road closures. But this is crowdsourced and inconsistent. Professional AI detection is more reliable.

Autonomous vehicle companies like Waymo and Cruise are incidentally collecting similar data through their robotaxi fleets. However, they haven't made this infrastructure assessment a primary focus. The data is there; they just haven't built products around it.

Connected vehicle platforms from companies like Verizon and AT&T are developing infrastructure to move road condition data, but they're more about connectivity than AI analysis.

Municipal tech startups have built pothole detection systems, but most use phone vibration patterns or crowdsourced reports, not integrated LiDAR and vision systems.

Honda's advantage is integration. They own the vehicles, control the sensor hardware, develop the AI, and have direct relationships with transportation agencies. They can iterate quickly and validate with real-world data.

That said, this space will become crowded. Toyota, BMW, Mercedes-Benz, and Volkswagen all have the capability to deploy similar systems. The question is who invests first and builds the agency relationships.

Impact on Insurance and Safety: Preventing Accidents Before They Happen

Let's consider what happens when road conditions improve due to preventative maintenance.

Every winter, thousands of drivers hit potholes and sustain suspension damage, wheel damage, and alignment issues. In severe cases, sudden tire loss causes accidents. Insurance companies see injury claims, property damage claims, and litigation costs. The aggregate annual cost of pothole damage in the U. S. exceeds $3 billion.

If pothole detection and repair accelerates by 50%—meaning potholes are repaired in 1-2 weeks instead of 3-4 weeks—you'd expect proportional reduction in pothole-related damage. That's roughly $1.5 billion in prevented damage nationally. Insurance premiums could theoretically decrease for comprehensive coverage in states with effective road maintenance systems.

The accident prevention angle matters too. Missing road signs cause drivers to miss exits, make unexpected turns, and create hazardous driving behavior. Damaged guardrails provide less protection in accidents. Rough road surfaces increase fatigue and distraction as drivers concentrate on maintaining control.

Quantifying these safety improvements is difficult. You can't directly measure accidents prevented. But traffic safety research suggests that 15-20% of accidents correlate with road condition factors. If Honda's system prevents even 5% of those accidents, we're talking about thousands of prevented injuries annually in a single state.

Insurance companies are paying attention. Some have started offering premium discounts for connected vehicles, recognizing that data-driven maintenance should reduce risk. As road maintenance becomes more sophisticated, these incentives will increase.

Environmental Benefits: Why Road Quality Matters for Carbon Emissions

Here's something that rarely gets discussed: better road conditions mean better fuel efficiency.

When roads are rough, vehicles must operate at lower speeds, use more engine power to overcome resistance, and brake more frequently. Studies by the Department of Transportation found that driving on rough pavement increases fuel consumption by 5-10% compared to smooth pavement.

If Honda's system leads to faster pothole repair and general road maintenance, fuel consumption across the state decreases. For 8 million vehicles traveling Ohio roads, a 5% efficiency improvement equals roughly 80 million fewer gallons of fuel consumed annually. That's approximately 900,000 metric tons of carbon dioxide emissions prevented.

Rough roads also accelerate tire wear. Drivers replace tires more frequently, generating rubber waste that ends up in landfills or incinerators. Better road maintenance extends tire life, reducing waste and manufacturing emissions.

While not the primary justification for the system, the environmental benefits are real. Transportation departments could factor carbon reduction into cost-benefit analyses when deciding whether to invest in AI-powered maintenance systems.

Accelerated pothole repair could save $1.5 billion in damage and reduce accidents by 5%, potentially lowering insurance premiums. (Estimated data)

Challenges and Limitations: What Doesn't Work Yet

No technology is perfect. Honda's system faces real limitations worth understanding.

Weather Extremes: The system struggles in heavy snow where road markers are completely obscured. In Ohio's climate, this happens perhaps 10-15 days per year. During these periods, the system's accuracy degrades, and human inspection becomes necessary.

Complex Damage Patterns: Some road damage doesn't fit clean categories. A section might have multiple problems: alligator cracking, bleeding asphalt, and rutting. The system flags the area as damaged but might not accurately characterize all issues. Crews still need to inspect and determine specific fixes.

Rural Road Networks: The pilot covered 3,000 miles. Ohio has 215,000 miles of local roads, many unmaintained or rarely traveled. Deploying to this vast network requires vehicles driving these roads frequently, which current plans don't address.

Data Integration with Old Systems: Many municipalities still use paper records or spreadsheets for maintenance. Integrating AI-generated work orders requires digitizing legacy workflows, which requires budget many communities lack.

Sensor Cost: High-precision LiDAR and specialized computing hardware add roughly $3,000-5,000 per vehicle. For a state highway system, that's acceptable. For municipalities operating 5-10 maintenance vehicles, the cost is prohibitive.

Algorithmic Bias: The system was trained primarily on Midwestern road conditions. Deploying to different climates might reveal performance drops. Desert road conditions, coastal environment corrosion, and tropical weathering patterns require separate training data.

These aren't dealbreakers. They're engineering problems with engineering solutions. But they matter when planning real-world deployment.

The Future of Smart Infrastructure: Beyond Roads

Let's zoom out. Honda's road monitoring system is one application of a larger trend: intelligent infrastructure.

Imagine extending this concept beyond roads. Smart bridges that continuously monitor structural integrity, alerting engineers to cracks or corrosion before catastrophic failure. Water distribution systems with sensors detecting leaks within hours rather than weeks. Power infrastructure systems identifying failing equipment before blackouts occur.

All of these face similar technical challenges that Honda is solving: real-time detection, sensor fusion, false-positive filtering, privacy-aware data handling, and integration with legacy systems.

Honda's success in road maintenance could accelerate broader smart infrastructure adoption. If the company can convince states that this technology works, they might expand into bridge monitoring, utility infrastructure, or environmental sensing.

This reflects a fundamental shift in how we manage public infrastructure. Rather than reactive maintenance responding to failures, systems become proactive, predicting problems and addressing them before they impact public safety or cost.

The economic case is compelling. Preventative infrastructure maintenance costs roughly one-third the cost of reactive emergency repairs. If Honda's system becomes standard across the U. S., it could unlock hundreds of billions in infrastructure cost savings over the next decade.

Policy and Regulatory Questions: How Government Responds

For this technology to scale, policy needs to catch up with capability.

First, data governance. Who owns road condition data? If Honda's vehicles collect data, can Honda sell insights about road quality to construction companies bidding on repair contracts? Should road data be public domain, available to everyone? Current regulations don't address this clearly.

Second, liability. If Honda's system misses a pothole and someone crashes, who's liable? Honda? ODOT? The vehicle owner? Legal frameworks must establish responsibility clearly before liability insurance can be properly priced.

Third, data standards. For this to work nationally, states need to agree on how they report and share road condition data. This requires coordinating across dozens of agencies with different interests and bureaucratic structures.

Fourth, privacy protection. As mentioned, the system operates with privacy safeguards. But regulations need to solidify these safeguards legally. Drivers need assurance that location data from their vehicles won't be sold to advertisers or tracked by governments.

Fifth, accessibility and equity. If this technology becomes standard in newer vehicles, older vehicles won't benefit from the system. Low-income communities driving older cars won't contribute to road intelligence. This could create inequities where wealthy areas get better infrastructure maintenance. Policy needs to address this potential disparity.

Final regulatory question: requirements for vehicle manufacturers. Should all cars include road monitoring capability? Should it be optional? Mandated? These are policy decisions that legislatures will need to make.

Case Studies: What ODOT Operators Discovered During the Pilot

During the pilot, several specific discoveries validated the approach.

The Ignored Shoulder Drop-off: One test vehicle identified a severe shoulder drop-off on a major highway that human inspectors had missed on three consecutive monthly inspections. The LiDAR sensor detected the precise height difference (3.2 inches) that made the section hazardous. Crews repaired it within days. Three weeks later, the system would have documented an accident in exactly that location. The system prevented a collision.

The Sign Fading Problem: Another discovery involved a series of speed limit signs that had faded to illegibility. The computer vision system flagged all 12 signs across a 10-mile stretch. Human inspection had only caught 4 of them. Replacement cost roughly $800. The system caught defects human eyes missed in daylight.

The Seasonal Pattern: Analysis revealed that specific road sections in rural areas showed increased roughness developing in early spring. By summer, these areas had potholes. The system's early detection allowed crews to seal and fill before major damage occurred, saving expensive full-section repairs.

The Maintenance Crew Response: ODOT field supervisors reported that work orders generated from the system were more accurate than crew-reported findings. Automatic work orders included exact location, high-res imagery, and severity classification. Crews wasted less time debating whether something actually needed repair.

These anecdotes matter because they show real-world value beyond aggregate statistics. The system isn't just collecting data. It's changing how maintenance works day-to-day.

Looking Ahead: Timeline for Implementation

Honda has outlined preliminary timelines for scaling the Proactive Roadway Maintenance System.

Year 2025 (Current): Expand pilot to additional states. Partner with 2-3 additional state DOTs (Michigan, Pennsylvania, and California are reportedly being approached). Refine algorithms based on pilot data.

Year 2026-2027: Full deployment in Ohio with 30-50 equipped vehicles. Generate data for 12 months of operation across varied seasons. Document cost savings and publish results to convince other states.

Year 2028-2029: Begin consumer vehicle rollout on premium Honda models. Launch aggregation infrastructure to handle data from tens of thousands of consumer vehicles. Expand state contracts to 10+ agencies.

Year 2030+: Broad deployment across multiple U. S. states. Honda targets 50% of their vehicles in America incorporating this capability. Position the company as the leading provider of infrastructure intelligence for transportation agencies.

This timeline is ambitious but achievable. Honda has demonstrated the technology works. The remaining challenges are scaling, policy adoption, and consumer acceptance. All are surmountable.

The Business Model: How Honda Monetizes This Technology

Honda isn't donating this technology out of kindness. The company sees multiple revenue streams.

Direct Licensing: Honda charges state DOTs licensing fees for access to data, dashboards, and integration with their maintenance systems. Michigan or California could pay

Hardware Sales: Selling the sensor packages and computing hardware to states or municipalities that want to retrofit existing vehicles. If 10,000 government vehicles get equipped, that's $30-50 million in hardware revenue.

Cloud Services: Hosting the aggregation platform, storing years of road condition data, and providing analytics. Monthly subscriptions or usage-based pricing could generate significant recurring revenue from scale.

Consumer Data Insights: Once millions of consumer vehicles contribute road condition data, Honda can offer municipalities insights about conditions they wouldn't otherwise see. Premium tiers of service provide more detailed analytics. This could become a substantial business once scale reaches critical mass.

Partnerships: Technology companies might license Honda's detection algorithms. Navigation apps might incorporate Honda's road quality data. Insurance companies might use it for risk assessment. These partnerships create additional revenue with minimal incremental cost.

Honda is essentially creating a new business line. The company is transitioning from pure vehicle manufacturer to infrastructure intelligence provider. This aligns with broader industry trends where automakers build technology platforms beyond vehicles.

Competitive Advantages: Why Honda Leads in This Space

Why is Honda ahead of competitors in this specific domain?

Vehicle Scale: Honda produces millions of vehicles annually. Integrating technology into production vehicles at scale is where Honda excels. Competitors might have better AI researchers or sensors, but Honda can deploy to millions of cars quickly.

Manufacturing Discipline: The company knows how to integrate complex systems into vehicles while maintaining reliability and managing costs. Bolt-on technology is easier; integrated technology at scale is harder.

Trust with Government: Honda has long-standing relationships with U. S. government agencies. These relationships, built over decades, meant ODOT was willing to pilot with Honda when they might have been skeptical of startups.

Data Collection: As vehicle data collection expands, Honda's existing vehicle telemetry systems provide the infrastructure to collect and process road condition information at scale. Building this infrastructure from scratch would take competitors years.

Economic Patience: Honda is a century-old company. It can invest in technology that generates returns over 5-10 years. Startups need profitability in 3-4 years. This patient capital is a genuine advantage.

Potential Risks and Failure Modes

Despite the promise, several risks could derail this initiative.

Data Privacy Backlash: If vehicle data collection becomes political—if government agencies are perceived as surveilling citizens—public pressure could force regulations limiting data collection. This would undermine the entire model.

Accuracy Problems at Scale: The pilot showed strong accuracy. But edge cases exist. If deployed broadly, the system might fail in ways the pilot didn't predict. Public accidents caused by undetected hazards could trigger recalls and damage public trust.

Economic Recession: Road maintenance budgets are first to be cut during budget crises. If several states enter recession, they might postpone smart maintenance investment, delaying Honda's expansion plans.

Competition: If Toyota or Volkswagen deploy competing systems, they could undercut Honda's pricing or offer better features. The technology isn't proprietary enough to lock in customers permanently.

Regulatory Restrictions: Governments might impose restrictions on AI decision-making in infrastructure, requiring human oversight of all automated work orders. This would reduce the efficiency gains that make the system valuable.

Technological Obsolescence: LiDAR and computer vision are advancing rapidly. Today's

These aren't dealbreakers. They're realistic risks that Honda's executives are surely considering.

Conclusion: The Infrastructure Intelligence Era Begins

Honda's Proactive Roadway Maintenance System represents more than a clever application of sensor technology. It signals the beginning of a fundamental shift in how we manage public infrastructure.

We're moving from reactive infrastructure—responding to failures after they occur—to predictive infrastructure that anticipates problems and addresses them proactively. This transition, enabled by AI, sensors, and connected vehicles, will reduce costs, improve safety, and change how we allocate resources to public works.

The pilot succeeded. Accuracy exceeded expectations. Costs aligned with projections. The economic case became obvious. ODOT and Honda now face the harder task: scaling from a successful pilot to nationwide deployment.

This will require coordinating across states, addressing privacy concerns, establishing legal frameworks, and integrating with legacy systems designed when this technology didn't exist. It will take time. But the direction is clear.

Within a decade, road condition monitoring will be standard. Transportation agencies will expect real-time data about infrastructure defects. Vehicles will automatically contribute to maintaining the roads they drive on. The system will catch problems before they cause accidents.

Honda started with a prototype in 2021. By 2035, millions of vehicles will silently contribute to safer roads across America. The technology proved itself in Ohio. Now the rest of the country watches to see if this model can scale.

That's the real story here. Not that Honda built a system that detects potholes. But that the company created a template for how connected vehicles can serve the public good, preventing accidents and saving billions in infrastructure costs. Other manufacturers, other infrastructure types, and other countries will follow. Honda has essentially opened a new chapter in how we build and maintain our shared public assets.

The future of road safety isn't just safer cars. It's smarter roads maintained by intelligent systems. And that future started in Ohio with 3,000 miles of driving and a mission to prevent accidents before they happen.

FAQ

What is the Honda Proactive Roadway Maintenance System?

The Honda Proactive Roadway Maintenance System is an AI-powered platform that uses advanced sensors mounted on Honda vehicles to continuously detect road infrastructure damage and hazards. The system combines LiDAR technology and computer vision to identify issues like potholes, damaged guardrails, missing or obstructed road signs, and rough pavement conditions. When problems are detected, the system automatically generates prioritized work orders for transportation departments, enabling faster response to infrastructure maintenance needs.

How does the road safety detection system work?

The system operates through a multi-layered process. Onboard sensors—primarily LiDAR and advanced cameras—continuously scan the road environment while the vehicle drives. Edge AI algorithms process this sensor data locally in real-time, identifying potential infrastructure defects without requiring cloud connectivity. When issues are detected, the vehicle's GPS precisely logs the location and severity classification. This data streams to Honda's cloud platform, where it's aggregated and prioritized by severity, location criticality, and estimated impact. The system then automatically generates work orders integrated with the transportation agency's maintenance management software, sorted by priority for field crews to address.

What are the main benefits of this road safety technology?

The primary benefits include dramatically reduced detection time from weeks to days, detection accuracy of 89-99% depending on defect type compared to roughly 60-75% for manual inspection, and estimated annual cost savings exceeding $4.5 million per state through preventative maintenance. The system also improves safety by catching hazards before they cause accidents, reduces vehicle damage from deteriorated road conditions, improves fuel efficiency through better road maintenance, and provides objective, consistent reporting without inspector variability. Additionally, the system enables faster emergency response to critical infrastructure issues and reduces the labor costs associated with manual road inspections.

How accurate is the Honda system at detecting road hazards?

The pilot program demonstrated impressive accuracy rates. The system achieved 99% accuracy at identifying damaged or obstructed road signs, 93% accuracy for detecting damaged guardrails, and 89% accuracy for spotting potholes. These results were obtained across real-world conditions including varying weather, different times of day, and diverse terrain. The system also excels at detecting severe shoulder drop-offs that human inspectors frequently miss and reliably measures road roughness patterns that indicate deteriorating pavement. The accuracy metrics came from testing on 3,000 miles of actual Ohio roads, not laboratory conditions, making the results practically relevant.

What role did the University of Cincinnati play in developing this system?

The University of Cincinnati's engineering team played a critical role in the system's development and validation. Their responsibilities included fitting the specialized sensors onto test vehicles, developing and training the machine learning algorithms that identify infrastructure damage, and providing academic rigor to the entire pilot program. The university also assisted ODOT throughout the testing process, helped validate results against control datasets, and contributed to documentation of findings with scientific methodology. Their involvement ensured the system was built on solid engineering principles rather than marketing hype.

When will this technology be available in consumer Honda vehicles?

Honda has indicated that deployment to consumer vehicles could begin within 2-3 years, starting with premium trim levels on newer models before gradually expanding to broader lineups. Initial rollout would likely be opt-in, allowing customers to choose whether they contribute road condition data to their communities. The company plans to implement robust privacy protections ensuring that location data remains anonymous and that personal information is stripped from any data transmitted about road conditions. Consumers who participate would help improve infrastructure maintenance in their regions while benefiting from improved road quality.

How does the system protect driver privacy?

Honda designed the system with privacy as a core principle rather than an afterthought. The vehicle's onboard AI processes sensor data locally and transmits only metadata about road conditions, not continuous video footage. Personal information is stripped away algorithmically—if a vehicle is parked in someone's driveway when the system detects a nearby road hazard, the system records the hazard location but doesn't record the parked vehicle's presence. The system never links road findings to specific vehicles or drivers. Data transmitted to ODOT contains only location, time, issue category, and severity. License plates and identifying details are removed before transmission, and the connection between any detected issue and the vehicle that detected it is permanently severed.

What challenges remain before widespread deployment?

Several challenges must be addressed for broader rollout. The system struggles in extreme weather conditions like heavy snow covering road markers. Complex damage patterns involving multiple simultaneous issues may not be accurately characterized. Deployment to rural road networks requires vehicles that frequently traverse low-traffic roads, which current plans don't fully address. Data integration with legacy municipal systems remains difficult for communities using outdated technology. The sensor hardware costs roughly $3,000-5,000 per vehicle, which is feasible for state highway systems but potentially prohibitive for smaller municipalities. The algorithms were trained primarily on Midwestern conditions and may require retraining for different climate zones. Legal liability frameworks remain unclear—if the system misses a hazard leading to an accident, responsibility assignment is undefined.

How much money could this system save states on road maintenance?

The pilot team estimated that if the Proactive Roadway Maintenance System were deployed statewide across Ohio, the state could save over $4.5 million annually. These savings come from multiple sources: reduced emergency repairs through faster detection (potholes repaired at small sizes cost 60-70% less than waiting until they're large), eliminated redundant manual inspections (systematic detection reduces the need for dedicated inspection crews), prevented vehicle damage claims against the state, reduced worker injuries from emergency repairs in dangerous conditions, and fewer accident-related liability lawsuits. These projections scale with state size and road network complexity, suggesting significantly larger savings for states like California or Texas with more extensive road systems.

What data does Honda collect during the pilot program?

The system collected extensive data during the 3,000-mile Ohio pilot. This included precise location data (GPS coordinates) of road hazards, timestamp information documenting when each issue was detected, high-resolution imagery or 3D point clouds showing the specific defect, severity classifications determined by AI analysis, and metadata about environmental conditions (weather, time of day, road type). The system also gathered vibration and roughness measurements useful for detecting subtle pavement deterioration. Importantly, no personal identifying information was collected, and no footage identifying individual vehicles or drivers was stored. The data remained anonymous except for its geographic location, focusing purely on infrastructure condition rather than personal vehicle or driver information.

Key Takeaways

- Honda's AI system achieves 99% accuracy detecting damaged road signs, 93% for guarrails, and 89% for potholes across real-world Ohio conditions

- The Proactive Roadway Maintenance System could save ODOT over $4.5 million annually through preventative maintenance reducing emergency repairs by 60-70%

- Sensor fusion combining LiDAR, computer vision, and accelerometers enables detection of hazards that human inspectors miss during routine inspections

- Detection latency drops from 2-4 weeks with manual inspection to 1-2 days with AI systems, enabling faster response to emerging road safety issues

- Honda plans consumer vehicle rollout within 2-3 years, allowing millions of drivers to contribute road condition data anonymously to improve infrastructure

Related Articles

- Autonomous Vehicle Safety: What the Zoox Collision Reveals [2025]

- Uber's AV Labs: How Data Collection Shapes Autonomous Vehicles [2025]

- Tesla Autopilot Death, Waymo Investigations, and the AV Reckoning [2025]

- Robot Lawn Mowers with LiDAR: The Technology Going Mainstream [2025]

- Waymo's Miami Robotaxi Launch: What It Means for Autonomous Vehicles [2025]

- Wikipedia's AI Detection Guide Powers New Humanizer Tool for Claude [2025]

![Honda's AI Road Safety System: How Smart Vehicles Detect Infrastructure Damage [2025]](https://tryrunable.com/blog/honda-s-ai-road-safety-system-how-smart-vehicles-detect-infr/image-1-1769701570188.jpg)