The UK Manufacturing Crisis: Why 49,000 Jobs Sit Empty

The United Kingdom's manufacturing sector is facing an existential challenge. Right now, about 49,000 jobs sit vacant. That's not a small number—it's a symptom of something much bigger breaking down.

When you talk to manufacturers about what keeps them up at night, the answer is consistent: finding and keeping skilled workers. A mid-2024 survey showed something stark. Nearly 98 percent of UK manufacturers said talent shortage and retention is a significant business challenge. Not "important." Not "something we're thinking about." A significant challenge.

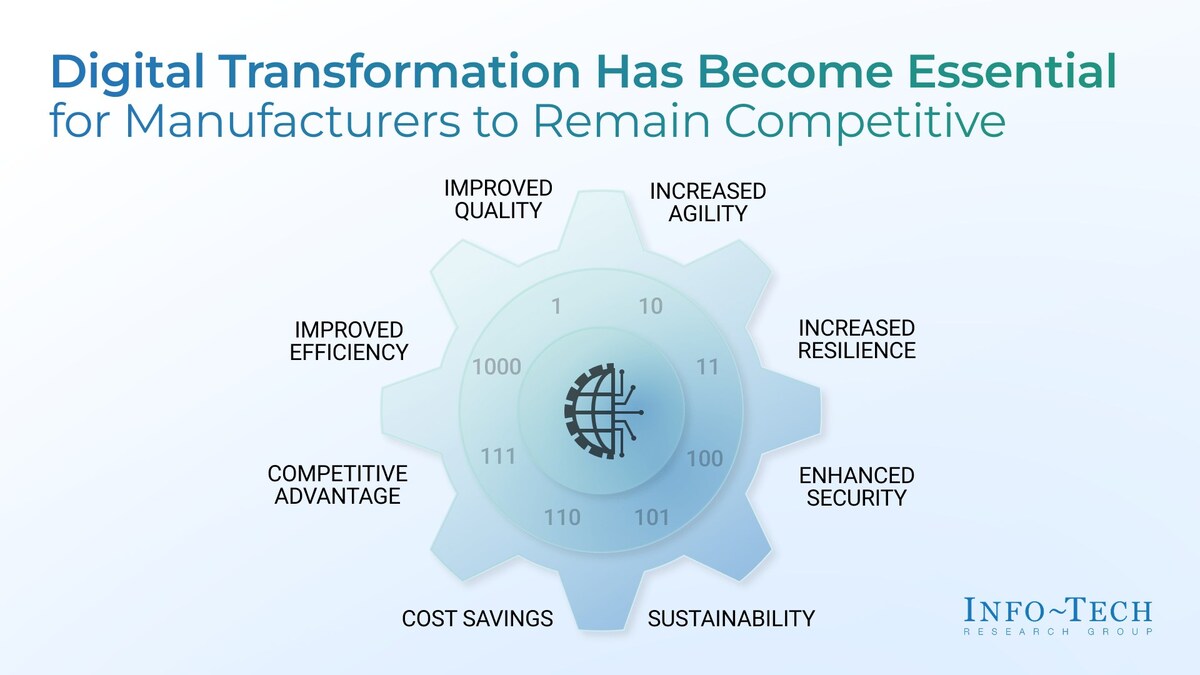

Here's where it gets weird though. The manufacturing sector invested heavily in robotics, artificial intelligence, advanced analytics, and connected systems. They spent millions on digital transformation. But they can't find the people who know how to use it.

The problem isn't just the shortage itself. It's that manufacturers must compete against tech companies, financial services, and software firms for digital talent. Those sectors have better brand appeal. Cleaner offices. Faster career progression. No welding fumes. When you're a brilliant software engineer fresh out of university, manufacturing doesn't exactly scream "future." It whispers "factory floor from 1987."

Yet the irony is thick here. Digital technology created this mess in the first place. The same AI and automation that manufacturers adopted to stay competitive also eliminated millions of routine jobs. Now they face the consequences: a workforce trained for yesterday's manufacturing, not tomorrow's.

But here's the counterintuitive part. The same technologies causing the crisis could also solve it.

TL; DR

- 49,000 UK manufacturing jobs are vacant, with 98% of manufacturers citing skills shortage as a major challenge

- Digital technology is both the problem and the solution, having eliminated routine work while creating demand for specialized digital skills

- AI-powered learning platforms democratize training, allowing employees to learn at their own pace with personalized, on-the-job micro-modules

- Automation frees workers from repetitive tasks, letting them focus on innovation and complex problem-solving instead

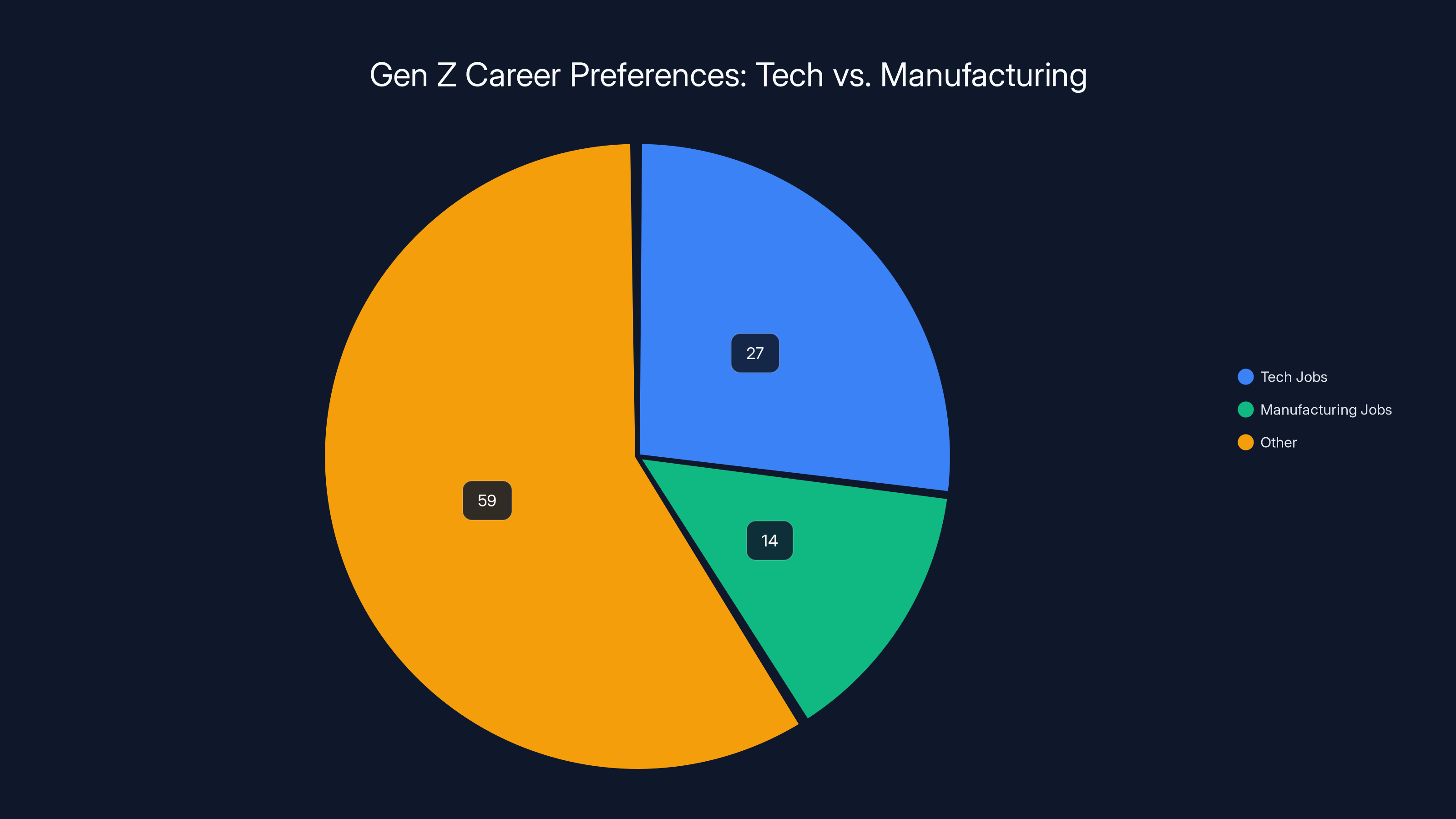

- Modern technology attracts Gen Z talent, with 27% of young workers wanting to work with cutting-edge tools compared to only 14% interested in traditional industrial work

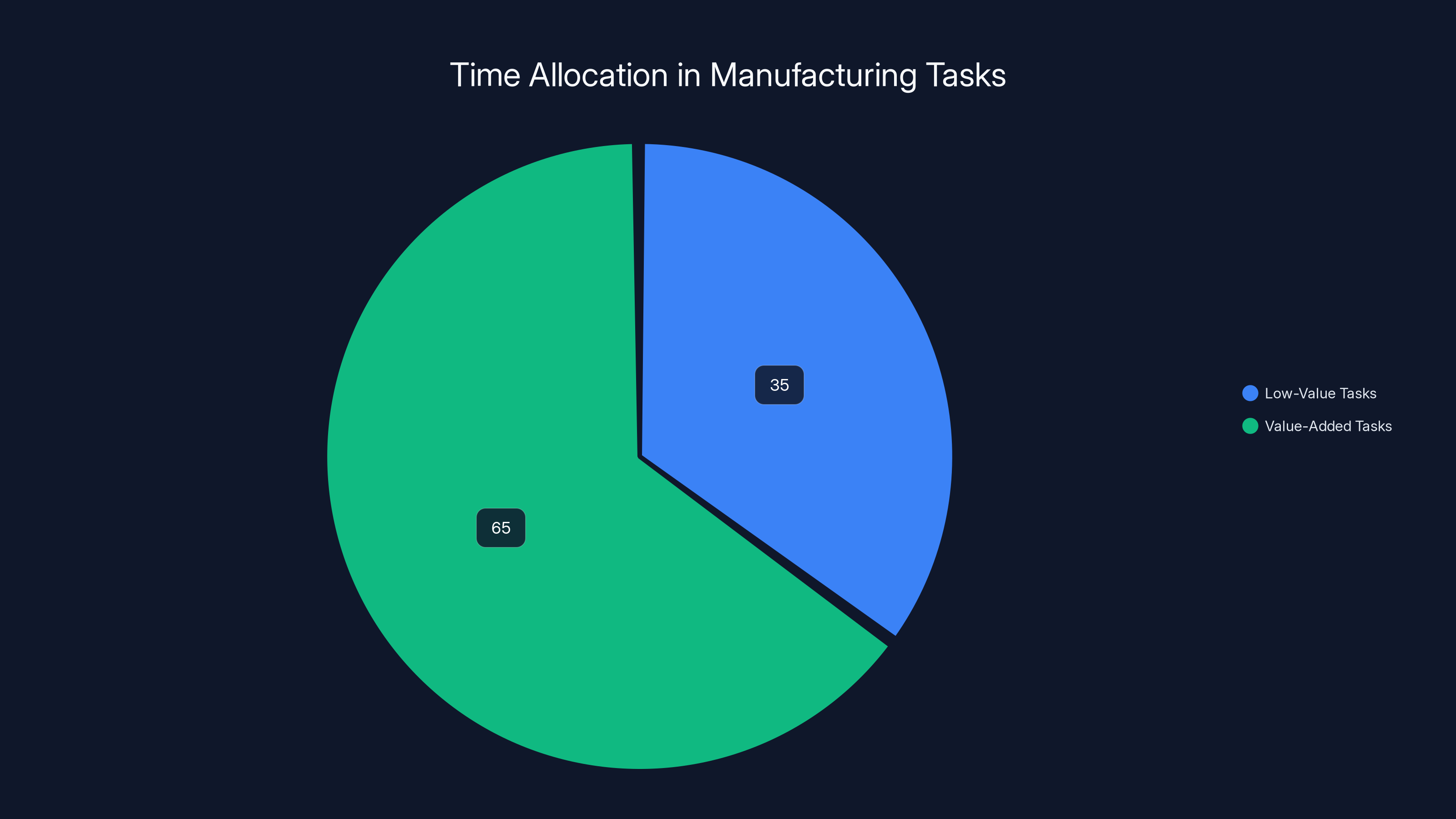

Estimated data suggests that 35% of manufacturing worker time is spent on low-value tasks, highlighting the potential for automation to enhance productivity and job satisfaction.

Understanding the Dual Nature of Digital Disruption in Manufacturing

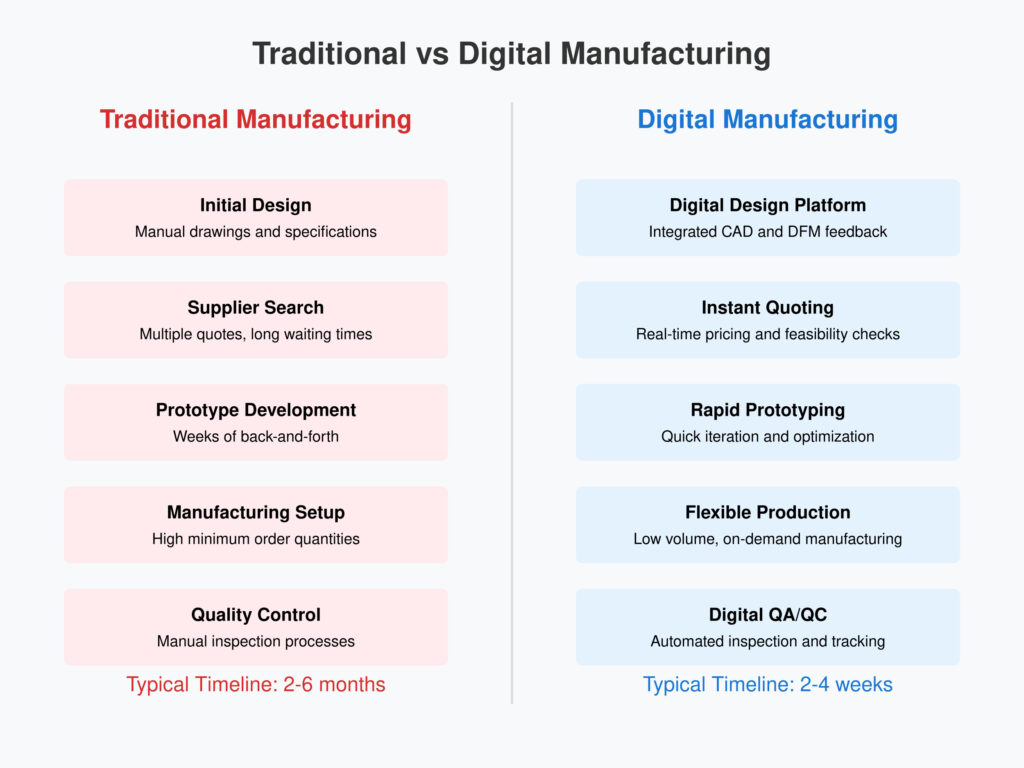

Manufacturing has always been about transformation. Raw materials become finished goods. Workers develop specialized knowledge. Companies build competitive advantages through process excellence and skill.

Digital technology disrupted all that. And yes, "disrupted" is the right word here because it cut both ways.

On one hand, robotics and AI eliminated entire categories of jobs. The repetitive, low-skill, high-volume work that once employed thousands? Gone. Or automated. Or offshored. The workers who spent 30 years doing assembly work suddenly found their expertise worthless.

On the other hand, those same technologies created entirely new roles. Jobs that didn't exist five years ago. Roles requiring skills nobody teaches in traditional manufacturing apprenticeships. You need people who understand machine learning, IoT systems, predictive analytics, digital twins, and cloud infrastructure. These aren't traditional manufacturing jobs. They're hybrid roles sitting at the intersection of engineering and software.

The result? A brutal mismatch. You have experienced manufacturing workers whose skills are obsolete. You have young people who could learn digital skills, but they're not interested in manufacturing because it's not perceived as a tech career. And you have manufacturers unable to find the bridge between these two groups.

Manufacturing companies face three specific talent gaps:

Digital Skills Gap: The technical knowledge required to implement and maintain advanced manufacturing systems. Programmers, data scientists, systems engineers.

Operational Skills Gap: The specialized knowledge about manufacturing processes themselves. Process engineers, quality specialists, production planners who understand both the old way and the new digital way.

Leadership Gap: Managers and decision-makers who understand both manufacturing and digital transformation strategy. This is perhaps the hardest gap to fill because it requires rare people with hybrid expertise.

Each gap requires a different solution. And here's what's interesting: digital technology can address all three.

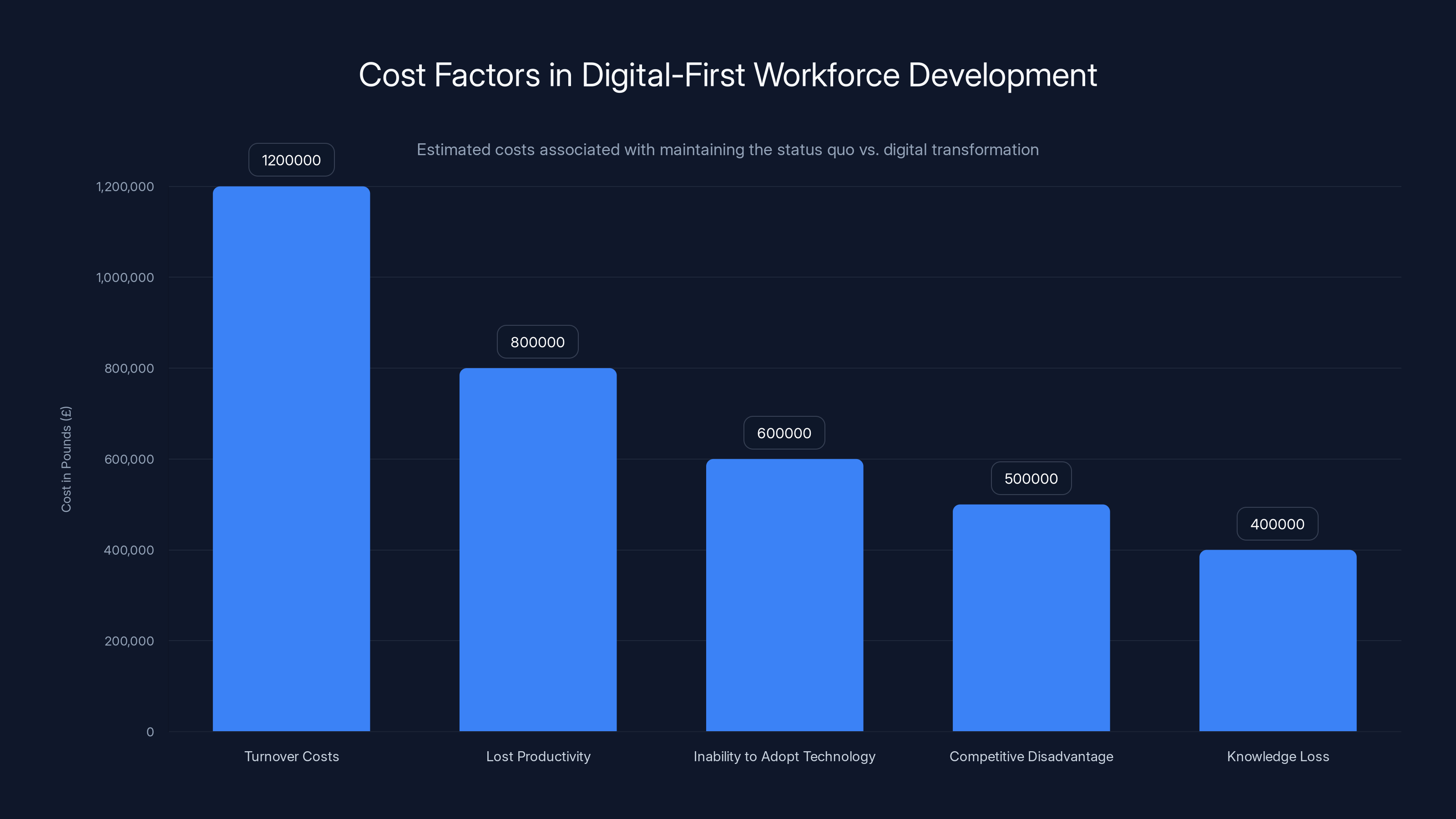

Estimated data shows that turnover costs are the highest, followed by lost productivity. Investing in digital-first workforce development can mitigate these expenses significantly.

How AI-Powered Learning Platforms Democratize Workforce Training

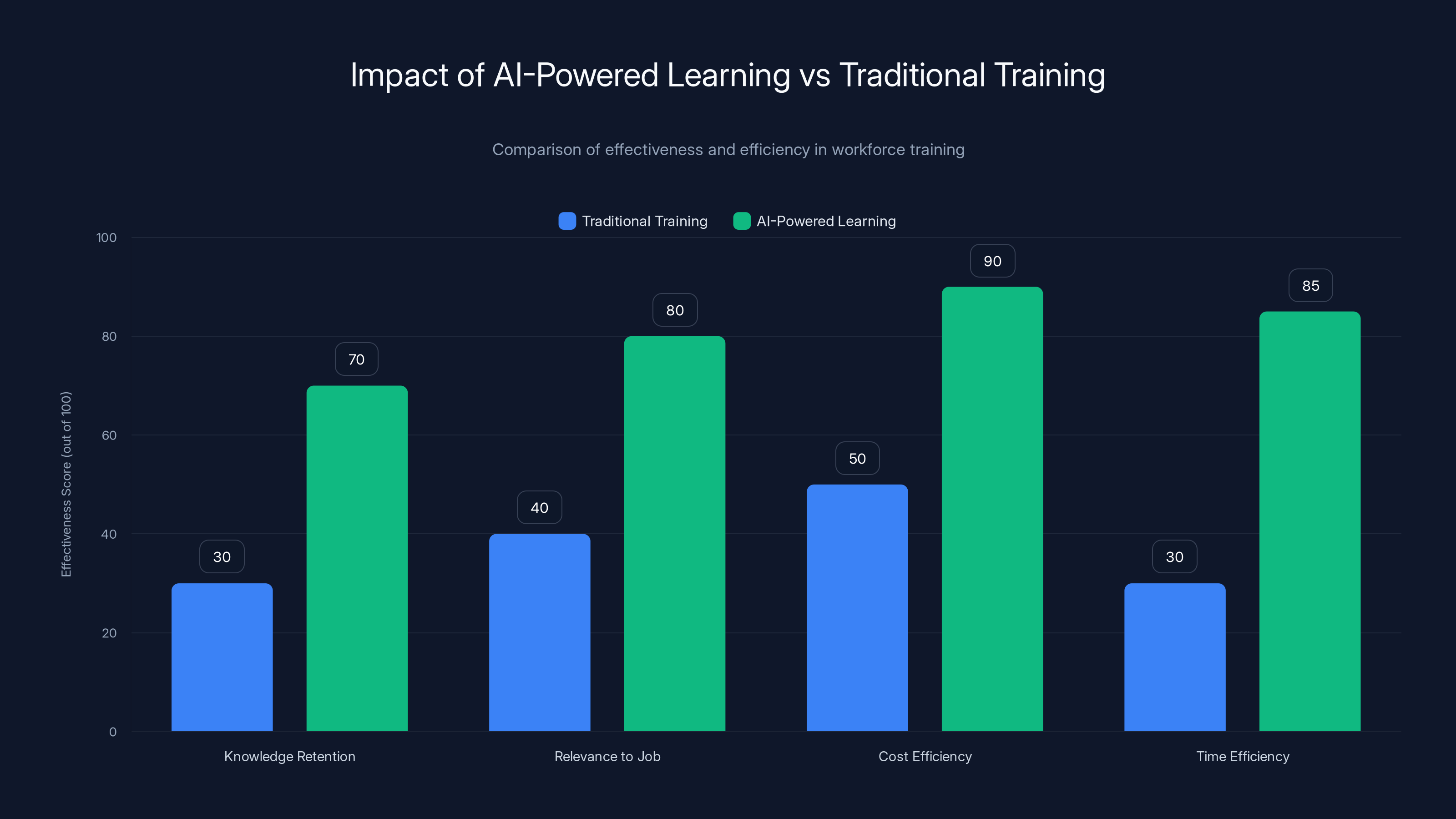

Traditional manufacturing training looks like this: you send a worker to a classroom for a week. They sit with 20 other people listening to an instructor. The content is standardized, generic, and rarely fits their specific job. Half of it they already know. Half of it is irrelevant to what they actually do. They forget 70 percent of it within two weeks.

Then they go back to work and try to apply knowledge they don't quite remember to problems slightly different from what they learned about.

Digital has destroyed that model. Partly because workers demand better. Partly because it simply doesn't work anymore. Technology changes too fast.

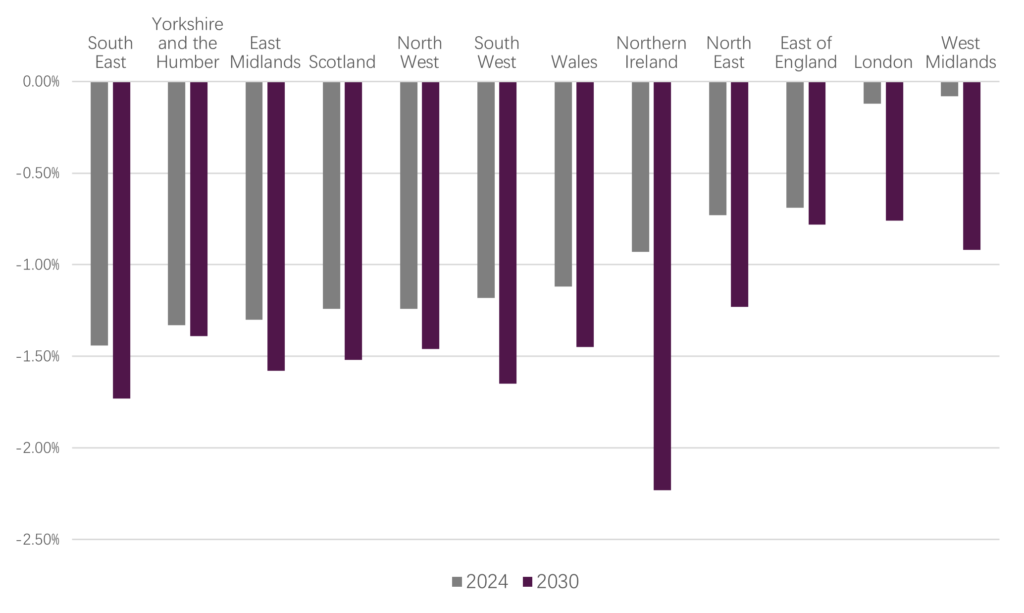

Consider the half-life concept. Technology knowledge becomes outdated in roughly five years. Digital systems. Programming languages. Manufacturing platforms. Best practices. All of it. Five years. That means if you train someone today, they'll need significant retraining by 2030.

You can't keep sending people to classrooms. It's too expensive, too slow, and too disconnected from actual work.

AI-powered learning platforms flip this approach. Instead of standardized, instructor-led training, you get personalized, on-demand learning delivered exactly when and where workers need it.

Here's how this actually works in practice:

A production technician encounters a problem on the shop floor. A sensor is reading incorrectly. They don't know what to do. Instead of asking someone (tribal knowledge is disappearing as experienced workers retire), they pull up the learning platform on their tablet. The system identifies their role, experience level, and the specific problem they're facing. Within seconds, they get a micro-learning module specifically about that sensor type. Three-minute video. Two-minute interactive simulation. Maybe a checklist of diagnostic steps. Done.

That's learning at the moment of need. Hyper-personalized. Immediately applicable.

The platform tracks what they learned. If they struggle with the same problem again, it adapts. Next time, maybe it includes more detail. Maybe it suggests they take a deeper course on sensor diagnostics. Maybe it connects them with an expert.

This approach also solves the knowledge capture problem. Manufacturing companies are hemorrhaging expertise as experienced workers retire. That 25-year veteran with deep process knowledge? When they leave, all that knowledge walks out the door. Unless you've captured it.

AI systems can help capture and codify that knowledge:

Expert Recording: Have experienced workers explain their processes. AI transcribes and categorizes the knowledge.

Process Mining: Advanced analytics watch how work actually happens and identify undocumented best practices.

Data-Driven Insights: Connected operations generate millions of data points. AI finds patterns that become training content. "When temperature drops below 18 degrees, calibration drifts by 0.3mm—here's what to do."

Real-Time Adaptation: As new problems arise and workers solve them, those solutions become training material for others.

The result isn't a static course. It's a living knowledge system that evolves as the business evolves.

But here's the honest part: implementing this isn't simple. It requires culture change. Workers used to classroom training sometimes resist learning from a screen. Systems need robust data infrastructure. You need people who can manage the platform. The upfront investment is significant.

But the payoff compounds. Over time, your workforce becomes more self-sufficient. Training cycles accelerate. Knowledge doesn't disappear when people leave. New employees ramp faster.

Digital Twins: Safe Training Without Shutting Down Production

Imagine training someone on an expensive, mission-critical piece of equipment. Maybe it's a precision machining center costing £500,000. It runs 24/7. Downtime costs thousands an hour. You can't just let a new operator practice on it. The risk of damage is enormous.

Traditionally, you either:

- Train on an older, slower machine that's less productive anyway

- Have an experienced operator watch carefully while they practice

- Send them to a training facility away from the shop floor

- Accept that they'll be slow and make mistakes for months

Digital twins offer a fourth option. A complete virtual replica of the actual machine. Running on the same control software. With the same interface. Responding the same way. But if they mess up, nothing breaks. Nothing costs money. Nothing shuts down production.

Workers can practice dangerous operations safely. They can make mistakes and learn from them without consequences. They can run scenarios that would be too risky on real equipment. And they do all this while production runs on schedule.

This matters more than it sounds. Consider hazardous operations. Welding. Chemical handling. High-temperature processes. Equipment that can crush or burn. You can't teach this well on the actual equipment. The fear factor alone prevents learning.

With immersive training using digital twins and mixed reality, workers practice in a safe environment that feels real. They make mistakes, learn, get feedback, adjust. When they move to real equipment, they're already confident. Already competent.

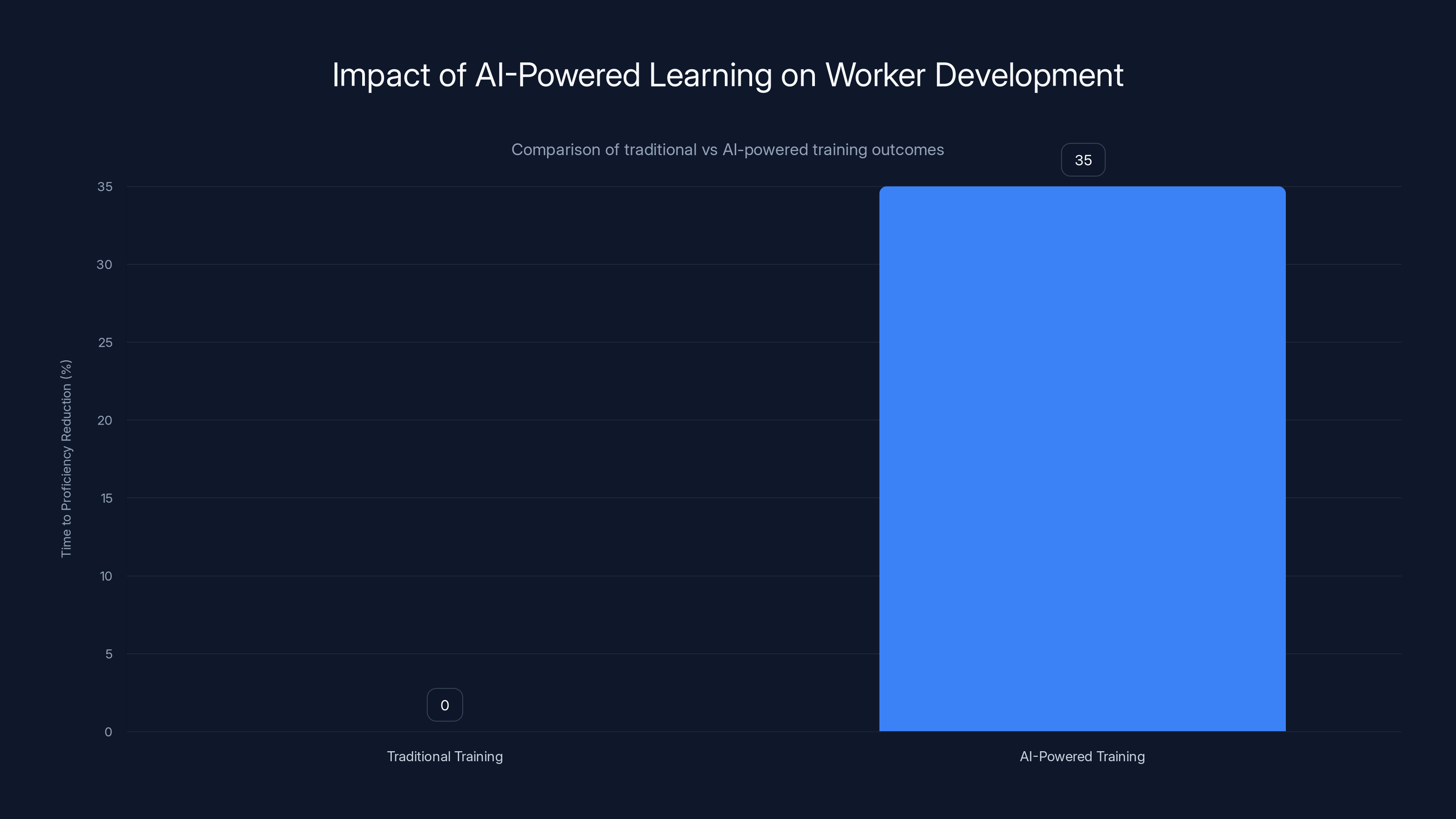

The data shows this works. Workers trained on digital twins typically reach proficiency 30-40 percent faster than traditional training methods. They make fewer mistakes on real equipment. They're more confident. They're safer.

Plus, digital twins provide another benefit: continuous improvement. As equipment is upgraded or processes change, the digital twin updates. Training stays current automatically. Workers learn the new version without waiting for training to be developed.

Think about what that means for knowledge retention. An experienced operator learns the machine deeply through years of hands-on experience. A digital twin lets new operators acquire that knowledge in weeks instead of years. You compress the learning curve dramatically.

AI-powered learning platforms reduce the time to worker proficiency by an estimated 30-40% compared to traditional training methods, highlighting their effectiveness in improving training outcomes.

Automation as the Solution to Worker Fatigue and Burnout

Manufacturing is brutal work. Not all of it, but a lot of it. Long hours. Repetitive motions that cause injury. Heat. Noise. Chemicals. Stress. And honestly, a lot of boring tasks.

Workers spend enormous amounts of time on low-value work. Manual data entry. Moving materials by hand. Redundant inspections. Double-checking someone else's work. Filling out paperwork. Looking for things. Waiting for information.

Some estimates suggest 30-40 percent of manufacturing worker time goes to tasks that don't add value. They're just necessary because of how the system is organized.

Automation here isn't about replacing workers. It's about liberating them from the soul-crushing parts of the job so they can do the meaningful parts.

Consider a simple example: material handling. A worker spends hours moving components from one station to the next. Repetitive. Physical. Boring. You automate this with mobile robots that move materials. Suddenly that worker has time for something else. Maybe they monitor quality on three stations instead of one. Maybe they solve problems that have been nagging production for months. Maybe they train newer workers.

Or data entry. Factory systems generate mountains of data. Someone has to key it in. Manual labor that's error-prone and tedious. Automation software (RPA, robotic process automation) can do this faster and more accurately. The worker who spent 4 hours a day on data entry now spends 20 minutes reviewing what the system did and focusing on exceptions.

This actually improves working conditions:

Reduced Physical Strain: Less manual handling, fewer repetitive stress injuries, more comfortable work.

Increased Engagement: Workers spend time on skilled, varied tasks instead of monotonous routines.

Better Outcomes: More focus on quality and problem-solving rather than just getting through the day.

Higher Safety: Automation takes on the most dangerous tasks, reducing accident risk.

Here's something that surprises people: workers generally like this. They don't want to do boring tasks all day. When you give them interesting work instead, engagement increases. Retention improves. They feel valued.

Of course, this only works if you actually redeploy them. You can't automate the repetitive work and then lay people off. That destroys trust and makes any future change initiative impossible. You have to say: "We're automating the tedious parts. Here's your new role where you'll do more interesting work."

That requires different skills, so training becomes necessary. But it's easier to train someone to do interesting work than to force them to do tedious work well.

There's also predictive maintenance. Advanced analytics monitor equipment continuously. They identify patterns that predict failure. Machine learning models spot degradation weeks before actual failure. So you fix it during scheduled maintenance, not at 2 AM when something breaks and production halts for eight hours.

What does this have to do with workers? Everything. Emergency maintenance is stressful, chaotic, and often unsafe. Workers get called in on short notice. They work tired. They make mistakes. Predictive maintenance eliminates most of that chaos. Workers maintain equipment on schedule, when they're fresh and prepared.

The data supports this approach. Companies that implement automation strategically (focusing on low-value tasks rather than eliminating jobs) report 15-25 percent improvement in worker satisfaction and a notable reduction in turnover.

Attracting Next-Generation Talent: Why Gen Z Wants Tech Jobs, Not Factory Jobs

Here's a statistic that should concern every UK manufacturer: only 14 percent of Gen Z workers surveyed said they'd pursue a career in industrial or manufacturing work. Meanwhile, 27 percent explicitly said they want to work for companies using cutting-edge technology like AI, drones, IoT, and virtual reality.

That's almost double. And it's not close.

This isn't about wages. It's about perception. Manufacturing has a brand problem. Young people think of factories as old, dirty, dangerous places where you stand in the same spot for eight hours doing the same motion. Tech companies are cool, innovative, where smart people solve complex problems.

But here's the thing: if you make your manufacturing operation genuinely modern and tech-forward, you can flip that perception.

A manufacturing facility using digital twins, predictive analytics, connected equipment, autonomous systems, and AI looks different. It feels different. You're not standing at a machine all day. You're monitoring operations from a control center. You're analyzing data to optimize processes. You're programming robots. You're solving problems that require real technical skill.

That appeals to Gen Z. Seriously. They want that job description.

So part of the solution to the skills crisis is genuinely implementing modern technology, yes. But the other part is marketing that reality.

Take a Gen Z recruit through a modern manufacturing facility. Show them the digital systems. Explain the technical problems they'd solve. Let them see that it's engineering work, not repetitive factory work. Suddenly manufacturing becomes interesting.

Companies that do this report a noticeable improvement in recruitment. They attract younger talent. They attract people with better technical backgrounds. And those people stay longer because the work is actually interesting.

There's a psychological element here. Workers want to feel safe and respected. They want flexibility in how they work. They want to use technology. They want the company to care about their development. Modern, digital-forward manufacturing can deliver on all of this.

Older manufacturing operations often can't. Workers are squeezed into rigid schedules. Technology is aging. There's little opportunity to develop skills. Safety concerns are real but sometimes understated. The culture feels stuck in the past.

Generation Z is voting with their feet. They're going to tech companies instead.

But the flip side is opportunity. Manufacturing companies that genuinely modernize position themselves as tech companies that happen to make physical goods. That's a much more attractive employer brand.

AI-powered learning platforms significantly improve knowledge retention, job relevance, cost, and time efficiency compared to traditional training methods. Estimated data based on typical industry observations.

Building a Culture of Continuous Learning and Upskilling

Here's what kills transformation initiatives: starting them, then forgetting about them.

You launch a digital learning platform. Big announcement. Everyone's excited. Then you don't integrate it into how work actually happens. You don't make it mandatory. You don't reward people for completing training. Workers don't see their managers using it. So adoption flatlines. By year two, nobody uses it.

Building a learning culture requires intentionality. You have to change how people think about skill development.

Traditionally, manufacturing workers see learning as separate from work. You go to training when you're sent. It's an interruption. You return to work and hope you remember something.

Modern manufacturing needs to flip this. Learning is woven into work. It's continuous. It's expected. It's valued.

How do you create this?

Leadership modeling: If your managers aren't learning, nobody else will. Make it visible that leaders use the learning platform. Talk about skills they're developing. Allocate time for it.

Integration into workflow: Learning shouldn't be extra. It should be how work happens. When someone encounters a new problem, the learning platform is how they solve it. When a process changes, the learning platform is how they adapt. It's not a separate system; it's how the job gets done.

Recognition and reward: Acknowledge people who develop skills. Career progression tied to learning. Pay increases for certifications. Internal mobility for people who upskill. Make it clear that learning leads somewhere.

Peer learning: Experienced workers should spend time mentoring newer people. Make mentoring a valued part of the job, not something they do on the side. Create systems that capture and share what peer mentors teach.

Feedback loops: Workers should see results from learning. "You took the maintenance module, and look how many failures you prevented." "You completed the quality course, and your defect rate dropped." Connect learning to outcomes.

Psychological safety: People won't try new skills if failure means punishment. You need a culture where mistakes in learning are expected and valuable. "You tried that approach, it didn't work, here's what we learned." Not "You failed, that's bad."

Manufacturing companies that build this culture see dramatic differences. Turnover drops. Innovation increases. Problem-solving improves. New equipment adoption accelerates. Workers feel valued. Productivity improves.

Companies that don't? They stay stuck. Workers feel like they're doing the same thing forever. The smart ones leave. The experienced ones retire and take knowledge with them. Problems don't get solved. Change initiatives fail.

The gap between these two paths widens over time. A company investing in learning culture gets compounding benefits. Every year, the workforce becomes more skilled, more engaged, more productive. A company ignoring it gets compounding problems.

Addressing the Skills Gap in Digital Leadership

There's a level to this that often gets overlooked: leadership.

You can have world-class digital systems, AI platforms, automation. But if your managers don't understand them, you're stuck. They can't make good decisions about where to invest. They can't prioritize initiatives. They can't align the technology with business strategy. They can't troubleshoot when things go wrong.

Manufacturing is full of skilled operations managers who came up through the ranks. They know how to run a factory, manage people, hit targets. But they didn't grow up with digital systems. They don't instinctively understand data and algorithms and automation.

They need a different kind of training. Not how to use a particular system (though they might need that too). But how digital transformation works. What's actually possible. What it costs. How to manage the risks.

This is often neglected because it's unglamorous. Everyone wants to talk about AI and robots. Nobody wants to fund "manager digital literacy." But it's critical.

Managers need to understand:

Technology Fundamentals: What's actually possible with AI, IoT, automation, analytics. What's hype. What's practical. What are the real timelines and costs.

Data Thinking: How to interpret metrics. What data actually tells you. How to spot when data is misleading or incomplete.

Change Management: How people respond to new technology. How to bring workers along instead of just imposing change. How to identify and address resistance.

Financial Impact: How to calculate ROI on digital initiatives. What to measure. How long change takes to pay off.

Risk Management: What goes wrong with digital projects. How to mitigate those risks. How to build in resilience.

When managers lack this knowledge, digital initiatives fail in predictable ways. You buy an expensive system and don't use it fully. You automate the wrong process. You invest in technology that doesn't align with business goals. Workers resist because change is poorly managed. Projects cost 50 percent more than expected and take twice as long.

Investing in manager development on digital topics is unsexy but essential. It accelerates every other initiative. A well-informed leadership team makes better decisions, manages change better, and unlocks more value from technology investments.

Gen Z shows a strong preference for tech jobs (27%) over manufacturing jobs (14%), highlighting a perception issue in the manufacturing sector. Estimated data.

The Economics of Digital-First Workforce Development

Here's the question manufacturers always ask: "How much does this cost?"

It's the right question. Digital transformation requires significant investment. Learning platforms. Automation. Digital twins. Training the trainers. Ongoing platform management.

But the calculation is more subtle than just "cost of solution." You have to consider the alternative.

The status quo is also expensive:

Turnover Costs: Every time you lose a skilled worker, you spend money recruiting a replacement. Training the replacement. Reduced productivity while they ramp up. Industry data suggests replacing a skilled manufacturing worker costs 50-100 percent of their annual salary. If you have 20 percent turnover (common in manufacturing), that's enormous.

Lost Productivity: Workers without modern training take longer to adapt to new equipment or processes. They make more mistakes. They're less efficient. This is an ongoing cost that never shows up as a line item.

Inability to Adopt Technology: If you can't find people who understand your digital systems, you can't fully implement them. So you get partial value. You invested £1 million in software and you're only using 40 percent of it.

Competitive Disadvantage: Competitors modernizing faster will outpace you. They'll have better efficiency, lower costs, better quality. Over time, they'll take market share.

Knowledge Loss: Every experienced worker who retires takes decades of knowledge. That knowledge is gone. You have to rebuild it through trial and error, which is slow and expensive.

When you factor all this in, the ROI on systematic workforce development is positive, often significantly.

Let's do a rough calculation. Assume a manufacturing operation with 200 workers:

Baseline Problems:

- 15% annual turnover = 30 workers replaced per year

- Cost per replacement = £40,000 (50% of average £80,000 salary)

- Annual cost from turnover = 30 × £40,000 = £1,200,000

- Add lost productivity from new workers ramping up: £300,000

- Add inability to fully utilize new technology: £500,000

- Total annual cost of status quo: £2,000,000

Digital-First Development Program:

- Learning platform: £150,000/year

- Digital twins for key equipment: £200,000 one-time

- Manager digital literacy training: £50,000/year

- Additional trainers/platform management: £100,000/year

- Total annual investment: £300,000 + £100,000 depreciation = £400,000

Expected improvements:

- Reduce turnover from 15% to 10% = save £400,000 in replacement costs

- Faster ramp for new workers = £150,000 productivity improvement

- Better technology utilization = £300,000 value unlock

- Fewer errors and safety incidents = £100,000 savings

- Total annual benefit: £950,000

Net benefit: £550,000 per year (and that's conservative)

Obviously, every company is different. But the math typically shows that systematic workforce development pays for itself in cost avoidance, even before you count the gains from higher productivity and better technology utilization.

The trick is patience. Most of the benefits compound over 2-3 years. If you're looking for immediate payoff, you'll be disappointed. If you're thinking about building long-term competitive advantage, it's one of the best investments you can make.

Implementing Digital Solutions Without Disrupting Operations

Here's a real problem: you can't shut down a manufacturing facility to retrain everyone. Production doesn't pause. Orders still need to ship. You have to transform while the plane is flying.

This requires a different implementation approach than typical software projects.

Phased rollout: Don't implement everything at once. Start with one department or product line. Learn what works. Fix problems. Then expand. This lets you perfect the approach on a smaller scale before going company-wide.

Parallel running: Run old and new systems together for a period. Workers learn the new system while still using the old one. This creates overlap and inefficiency, yes. But it prevents total failure if something goes wrong. You can always fall back to the old system.

Scheduled training: Schedule learning time during natural gaps in production. Not during peak production times. Maybe during slower seasons. Maybe scheduled shift changes. Or early morning before full production starts. This requires planning but minimizes disruption.

Super-users first: Identify enthusiastic workers and train them thoroughly. They become internal champions who help train peers. They solve problems. They answer questions. This distributes the training burden and creates peer advocates.

Start with compelling use cases: Don't implement the whole system. Start with the most painful problem. "This new automation eliminates four hours of manual data entry per day." People see the benefit immediately and become advocates. Then expand to other use cases.

Clear communication: Workers resist change primarily when they don't understand it. Explain what's changing, why, how it affects them, and what's expected. Repeat this constantly. Answer questions. Address fears.

Measure and showcase results: As improvements happen, highlight them. "Since we implemented this, we've reduced quality defects by 8 percent." "This automation freed up 40 hours per week that workers now spend on higher-value tasks." Make the benefits visible and undeniable.

Anticipate problems: Digital implementations often have unexpected issues. Plan for them. Build in time buffers. Have contingency plans. Have technical support available. Prepare for the learning curve to be longer than planned.

Companies that implement this way transform successfully with minimal disruption. Companies that try to force big changes overnight usually create chaos. Workers resist. Systems break. Everyone becomes cynical about digital initiatives.

The boring approach—phased, thoughtful, measured—actually works better.

Technology fundamentals and data thinking are crucial for digital leadership, with high importance ratings. Estimated data.

Measuring Success: Which Metrics Actually Matter

If you can't measure it, you don't know if it's working.

But manufacturing often measures the wrong things when it comes to workforce development. They measure "training hours completed." Or "percentage of workers certified." These are activity metrics, not outcome metrics.

Activity metrics tell you what happened. Outcome metrics tell you what changed.

Outcome metrics that actually matter:

Turnover rates: Are people staying longer? This is the most important metric. If people are leaving, nothing else matters. If you reduce turnover, you're winning.

Time to proficiency: How long does it take a new worker to reach full productivity? Can you reduce this from 6 months to 3 months? That's a big deal.

Error rates and defects: Are workers making fewer mistakes? Better quality? This directly impacts product quality and cost.

Equipment downtime: Are you reducing unplanned downtime through better maintenance and more skilled operators? This has huge financial impact.

Technology adoption: Are workers actually using the new systems? Are they using them well? Partial adoption = partial value.

Safety incidents: Are you reducing accidents? Fewer injuries? This is both humane and financially important.

Worker engagement scores: Are people more satisfied? More engaged? Willing to recommend the company as a place to work? This predicts retention and productivity.

Productivity per worker: Can workers get more done in the same time? This compounds across the entire workforce.

Cost of training: How much does it cost to get a worker to proficiency? Is this decreasing over time as systems improve?

Instead of tracking hours of training completed, track these outcomes. Maybe you do less training (shorter, more focused) but get better results. That's a win.

Build dashboards around these metrics. Make them visible. Track them monthly. Use them to improve programs. This turns workforce development from a check-box activity into something genuinely strategic.

Overcoming Common Implementation Challenges

Digital workforce development sounds great in theory. In practice, it hits obstacles.

Resistance from experienced workers: "I've been doing this for 20 years. I don't need a computer telling me how to do my job." This is real and you have to address it with respect. Show how digital tools make their job easier, not replace them. Involve them in design. Let them see benefits firsthand.

Insufficient IT infrastructure: Learning platforms need reliable network connectivity. You might have patchy Wi-Fi on the shop floor. You need to invest in infrastructure first. This costs money and isn't glamorous but it's essential.

Technology overwhelm: You can't implement AI, automation, digital twins, and new management software all at once. Pick priorities. Do them sequentially. Let people adapt to one change before introducing the next.

Lack of internal expertise: You might not have people who can manage these systems internally. You'll need to hire them or contract with vendors. Budget for this. Don't assume existing staff can just figure it out.

Data quality issues: AI and analytics only work if data is accurate and complete. Many manufacturing operations have messy data. Garbage in, garbage out. You need data quality initiatives before analytics.

Inconsistent management support: If leadership championing the initiative moves on, momentum stops. Make sure there's institutional commitment, not just individual champions.

Budget constraints: Digital transformation isn't cheap. If you're underfunding it, you'll get partial results. Commit real resources or don't bother.

Fear of disruption: "What if the new system doesn't work and we lose production?" This fear is reasonable. Address it with robust testing, parallel running, and clear contingency plans. Don't dismiss the concern.

Every successful implementation I've observed had to navigate these obstacles. The ones that succeeded treated them as normal and planned for them. The ones that failed pretended these problems wouldn't happen.

Future-Proofing Your Workforce in a Rapidly Changing Industry

Here's the uncomfortable truth: whatever you implement today will be outdated in five years.

This isn't a reason to panic. It's a reason to build systems that adapt, rather than systems that are fixed.

Build learning cultures that expect continuous change. Implement flexible technology platforms that can be updated without wholesale replacement. Hire and develop people who are comfortable with uncertainty and learning.

Instead of asking "What skills do we need right now?" ask "What kind of workers can adapt to whatever skills we'll need in the future?"

The answer is workers who are comfortable learning. Who see problems as opportunities to figure things out. Who work well with AI and automation (because that's the future). Who can move between different technologies and pick up new ones quickly.

You're not training people for specific jobs that won't exist in five years. You're developing people who can learn whatever job comes next.

This changes everything about how you approach development:

Learning agility over specific skills: Hire and develop people who learn quickly, not just people with specific technical backgrounds.

Adaptability over specialization: Workers who can do multiple roles are more valuable than specialists in a single area.

Curiosity and problem-solving over credentials: Someone with a degree but no inclination to figure things out is less valuable than someone with high school education and a drive to understand systems.

Collaboration and communication: In a world of human-AI teams, the ability to work with others (including AI) matters more than individual expertise.

Continuous learning habits: People who read, experiment, and stay current on industry trends will stay relevant. People who learn once then coast will become obsolete.

Companies building this kind of culture will thrive even as technology changes. Companies focused on training people for today's jobs will struggle as those jobs disappear.

FAQ

What exactly is causing the UK manufacturing workforce shortage?

The shortage stems from multiple converging factors. Digital technology eliminated many routine manufacturing jobs, leaving experienced workers with obsolete skills. Simultaneously, it created demand for specialized digital skills that manufacturers compete for with tech companies. Young people perceive manufacturing as low-tech and undesirable compared to tech careers. Additionally, experienced workers are retiring faster than they're being replaced, taking tribal knowledge with them. The result is a vicious cycle where skill gaps worsen, making it harder to implement new technology, which further widens the gap.

How do AI-powered learning platforms actually improve training outcomes?

Traditional manufacturing training delivers standardized content to groups, with poor retention and limited application. AI-powered platforms personalize learning based on individual role, experience, and immediate needs. They deliver micro-learning modules exactly when workers need them (at the moment of problem). The systems track what workers learn and adapt subsequent training. They capture expert knowledge from experienced workers and codify it into reusable training content. This approach dramatically improves knowledge retention and accelerates time to proficiency. Companies report 30-40 percent faster worker development using these platforms compared to traditional methods.

What is a digital twin and why does it matter for manufacturing training?

A digital twin is a complete virtual replica of physical manufacturing equipment or processes, using the same control systems and responding identically to the real equipment. Workers can practice on the digital version without risk of damage or production disruption. This allows safe training on expensive equipment, practice with dangerous operations in controlled environments, and continuous updates as equipment changes. Workers reach proficiency 30-40 percent faster through digital twin training because they practice extensively without the fear and constraints of real equipment. It's particularly valuable for hazardous operations where traditional training is risky or ineffective.

How does automation address the workforce shortage rather than worsen it?

Automation that focuses on eliminating low-value, repetitive tasks frees workers to do higher-value, more engaging work. Instead of replacing workers wholesale, it redirects their time from tedious data entry or material handling to problem-solving, quality oversight, and innovation. This improves job satisfaction, reduces burnout, and actually makes manufacturing work more appealing. Workers appreciate having less monotonous work. Pairing automation with upskilling creates opportunity rather than job loss. Companies that implement automation this way report improved retention and higher engagement compared to those who automate to simply reduce headcount.

Why are young people more interested in tech companies than manufacturing, even when manufacturing is increasingly digital?

Perception lags reality. Manufacturing still carries an outdated image of dirty factories, repetitive work, and limited innovation. Most Gen Z workers grow up with that perception and never reconsider it. Tech companies have actively cultivated a "cool" image with modern offices, visible innovation, and appealing culture. Manufacturers haven't done the same marketing around their modernization. However, when young people actually see modern manufacturing operations—with digital systems, automation, data analysis, and real engineering work—their perception shifts dramatically. The solution is both genuine modernization (which must happen anyway) and aggressive marketing of that reality to prospective workers.

What's the typical ROI on digital workforce development investments?

ROI varies significantly by company and implementation approach, but well-executed programs typically show positive returns within 18-24 months. The main value sources are reduced turnover (enormous savings), faster ramp time for new workers (immediate productivity gain), better technology utilization (unlocking value from previous investments), and improved safety and quality (ongoing cost reduction). A typical medium-sized manufacturer might invest £300-400K annually in comprehensive digital workforce development and realize £800K-1.2M in annual benefits through turnover reduction, productivity gains, and cost avoidance. These are conservative estimates that don't include innovation gains or competitive advantage from a more skilled workforce.

How do you maintain data quality when implementing AI-powered learning systems?

Data quality is critical because AI systems learn from the data you feed them. Poor data produces poor insights and training content. Start by auditing your data. Most manufacturing operations have incomplete or inconsistent data. Establish data governance—clear ownership, standards, validation processes. Make data entry a valued activity, not an afterthought. Use the learning platform itself to catch errors (if the system flags an anomaly, investigate). Gradually improve data quality over time rather than trying to fix everything at once. Poor initial data quality is normal; the key is improving it continuously as the system highlights problems.

What's the first digital transformation initiative a manufacturer should prioritize?

Start with something that solves a real, visible problem and delivers quick benefits. Don't start with the most complex or strategically important initiative. Start with something like automating a painful manual process that workers hate. Or implementing a predictive maintenance system for equipment that frequently breaks. Or a learning platform for ramp-up of new workers. Something where the benefit is clear within 3-6 months. This builds confidence, demonstrates ROI, and creates internal advocates who support subsequent initiatives. Save the complex, multi-year transformation efforts for later when you have experience and credibility.

How do you address worker resistance to digital transformation?

Resistance comes primarily from uncertainty and fear of the unknown. Address this by communicating continuously, answering questions, and involving workers in design. Show explicitly how changes benefit them personally (less boring work, safer conditions, clearer career path). Implement in phases so people adapt gradually rather than experiencing shock. Identify and support super-users who become advocates. Acknowledge and respect concerns; don't dismiss them. Show results visibly and quickly. Demonstrate management commitment. Avoid surprise implementations. Address fears about job security directly and honestly. Workers will accept significant change if they understand it, see the benefit, and feel respected in the process.

Why is leadership digital literacy as important as worker training?

Leaders make decisions about where to invest, how to prioritize, what to measure, and how to manage change. If they don't understand digital technology, they make poor decisions. They might invest in the wrong solutions. They might implement only partial solutions because they don't understand what's possible. They might mismanage change and create resistance. They might fail to measure impact properly. Digital-literate leaders make faster decisions, commit appropriate resources, manage change effectively, and extract more value from technology investments. The impact of good leadership decision-making cascades across the entire organization. It's arguably more important to develop leader capability than to train workers on specific systems.

Conclusion: Digital Technology as the Path Forward

The United Kingdom's manufacturing sector faces a genuine crisis. Nearly 98 percent of manufacturers report that workforce skills shortage is a significant business challenge. Forty-nine thousand jobs sit vacant. The situation worsens as experienced workers retire and younger workers choose other careers.

But this isn't a crisis without solutions. It's a crisis of misalignment. The tools exist to address it. AI-powered learning platforms. Automation. Digital twins. Advanced analytics. Modern technologies that can upskill existing workers, attract new talent, and make manufacturing work genuinely appealing.

The question isn't whether solutions exist. The question is whether manufacturers will commit to implementing them.

There's no magic bullet. No single technology that fixes everything. It requires systematic, thoughtful approach: capturing and democratizing expert knowledge through digital platforms, automating tedious work to free workers for meaningful tasks, using digital twins for safe, effective training, modernizing operations to appeal to next-generation talent, building cultures of continuous learning, investing in leadership development, measuring the right outcomes.

It's work. It requires sustained investment and management attention. It's not quick or cheap.

But the alternative is worse. Without action, skill gaps widen. Manufacturers can't fully utilize the digital systems they've invested in. Competitive advantage erodes. Growth stalls. The best talent goes elsewhere.

The companies that will thrive in the next decade aren't those with the newest technology. They're those with the most skilled, engaged, adaptable workforce. That's the real competitive advantage. And digital technology, deployed intelligently with real commitment to workforce development, is how you build it.

The path forward is clear. The technology works. The ROI is positive. The question now is execution. Which UK manufacturers will commit to genuine workforce transformation? They're the ones that will thrive.

Start your digital workforce transformation today. The skills gap won't close itself, and every year you wait, the problem compounds. Audit your current state. Identify your worst pain points. Start small with a focused initiative that delivers quick wins. Build from there. Your future workforce—and your competitive position—depends on it.

Key Takeaways

- 49,000 UK manufacturing jobs are vacant with 98% of manufacturers struggling with skills retention and recruitment

- Digital technology caused the workforce crisis by automating routine jobs while creating demand for specialized digital skills manufacturers can't fill

- AI-powered learning platforms personalize training, accelerate worker development by 30-40%, and capture expert knowledge before experienced workers retire

- Automation frees workers from repetitive, low-value tasks, improving job satisfaction and enabling redeployment to higher-value problem-solving roles

- Modern, tech-forward manufacturing operations attract Gen Z talent—27% want to work with cutting-edge technology compared to only 14% interested in traditional manufacturing

- Digital twins and VR training enable safe, immersive practice on expensive or hazardous equipment without disrupting production

- Well-implemented workforce development programs show positive ROI within 18-24 months through reduced turnover, faster productivity ramps, and better technology utilization

- Leadership digital literacy is as critical as worker training—managers who understand digital transformation make better decisions and manage change more effectively

- Phased, thoughtful implementation with parallel systems running alongside legacy equipment minimizes disruption while allowing workers to adapt gradually

- Building continuous learning cultures where upskilling is woven into daily work—not separate from it—creates compounding competitive advantage over time

Related Articles

- Humanoid Robots in Factories: The Real Shift Away From Labs [2025]

- Larry Ellison's 1987 AI Warning: Why 'The Height of Nonsense' Still Matters [2025]

- Honda's AI Road Safety System: How Smart Vehicles Detect Infrastructure Damage [2025]

- AI Glasses & the Metaverse: What Zuckerberg Gets Wrong [2025]

- Tesla Discontinues Model S and X to Focus on Optimus Robots [2025]

- Tesla Optimus Gen 3: Everything About the 2026 Humanoid Robot [2025]

![How Digital Technology Solves UK Manufacturing's Workforce Crisis [2025]](https://tryrunable.com/blog/how-digital-technology-solves-uk-manufacturing-s-workforce-c/image-1-1770651405314.jpg)