Humanoid Robots in Factories: The Real Shift Away From Labs

You've probably heard the hype about humanoid robots. They're coming. They're inevitable. They're going to change everything.

But here's what actually matters: they're already here. Not in a science fiction way. In a very practical, very boring way.

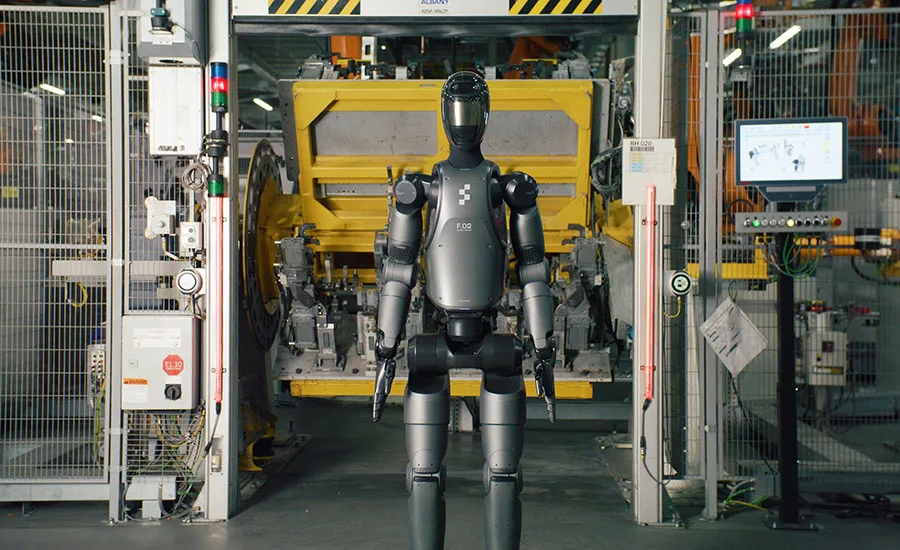

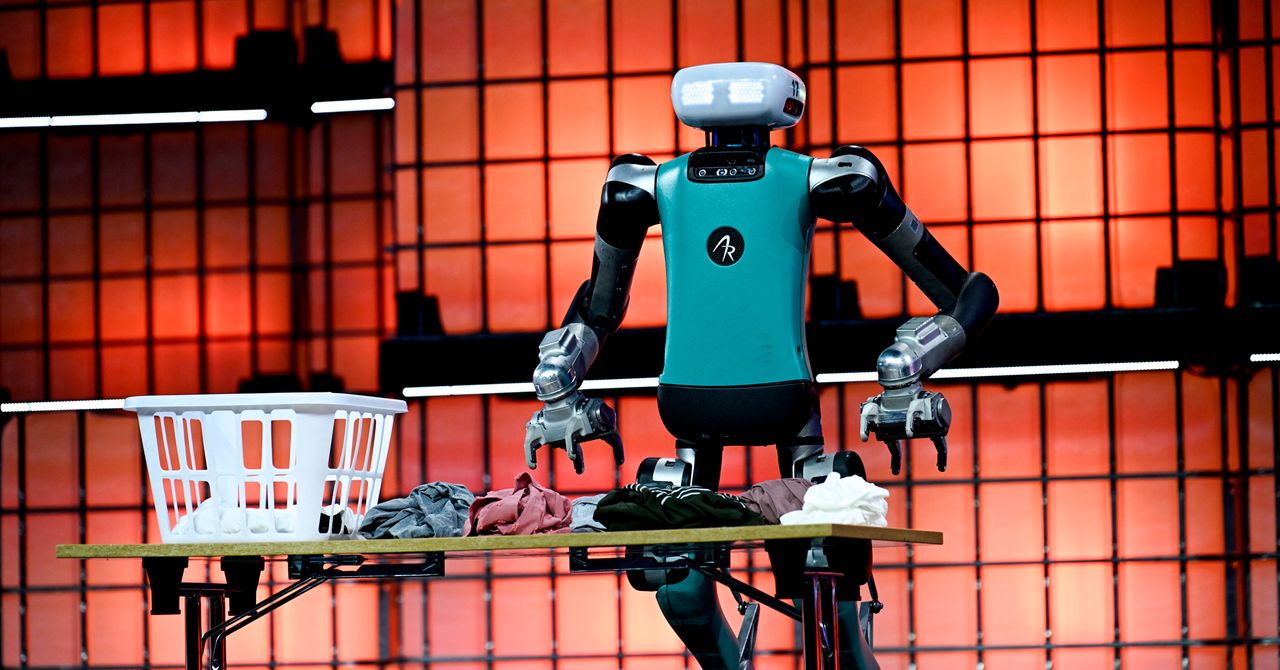

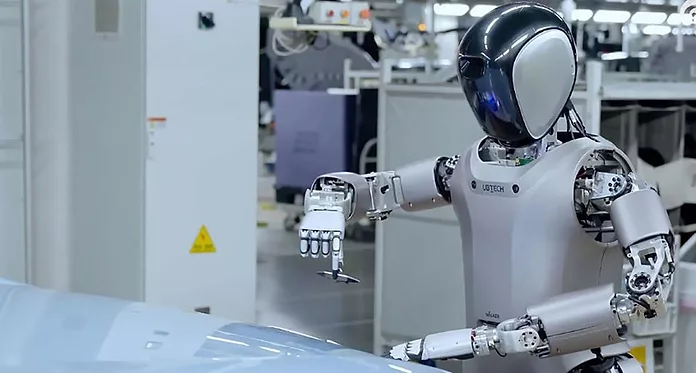

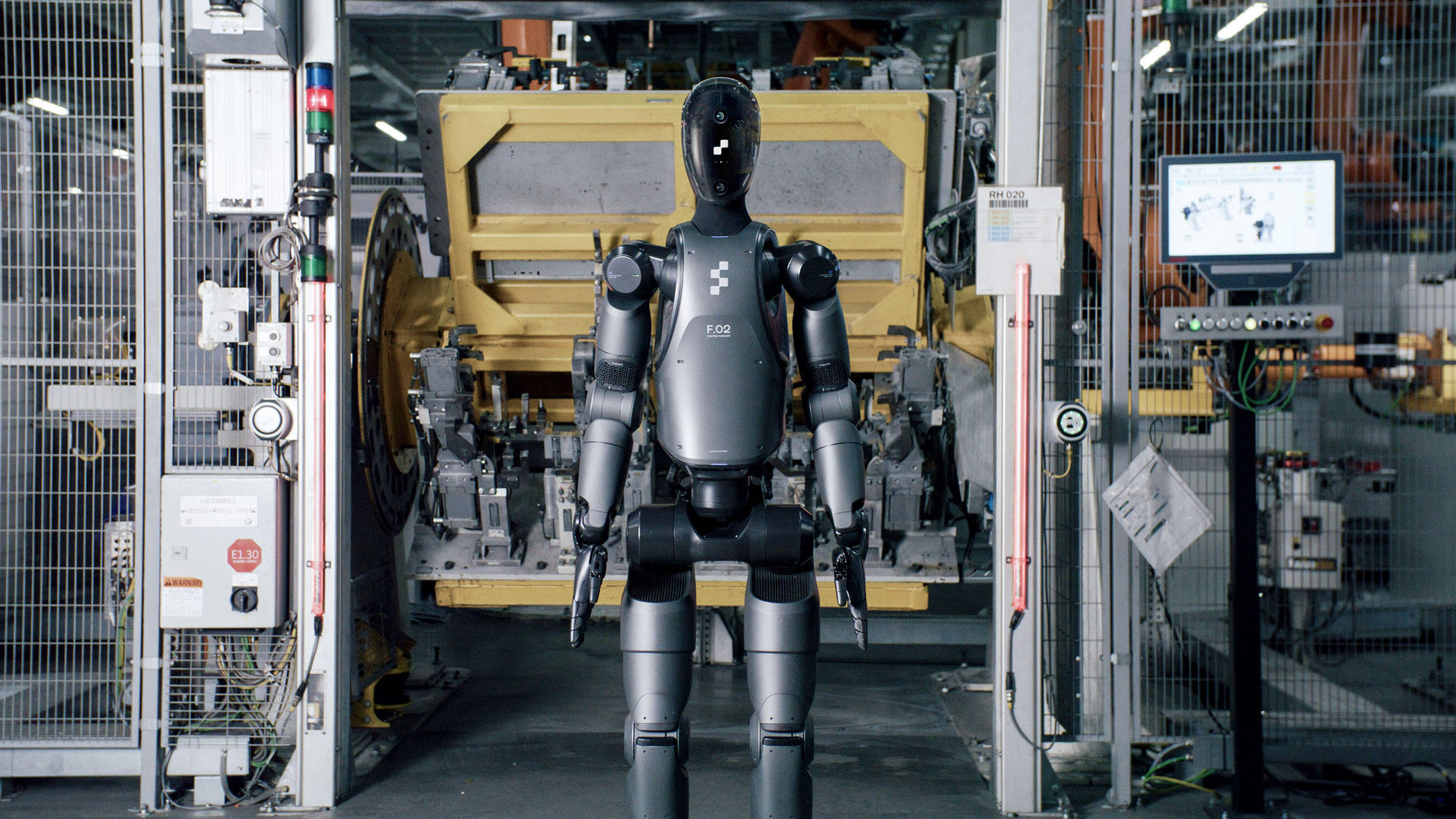

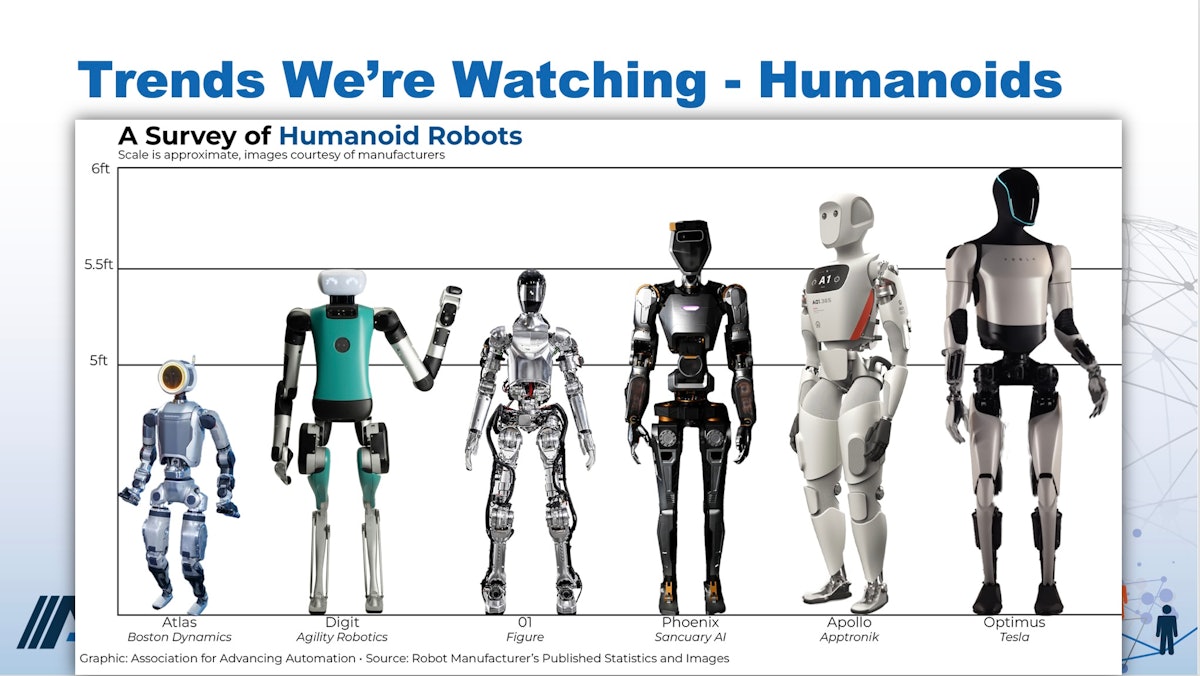

Right now, humanoid robots are walking through factory floors, moving objects on warehouse shelves, and performing tasks that humans have been avoiding for decades. Tesla's Optimus is in testing phases. Figure AI's humanoids are handling real logistics work. Boston Dynamics robots are carrying boxes and sorting items. This isn't speculation anymore. This is operational deployment.

The shift from laboratory prototypes to real-world factory floors represents one of the most significant workforce changes happening quietly right now. Unlike the dramatic AI announcements that flood tech news, this one is moving slower, steadier, and with less fanfare. That might be exactly why it matters more.

TL; DR

- Humanoid robots are leaving controlled lab environments and entering real manufacturing and warehouse settings right now

- Labor shortages in repetitive, hazardous, and physically demanding roles are the primary driver, not technological obsolescence

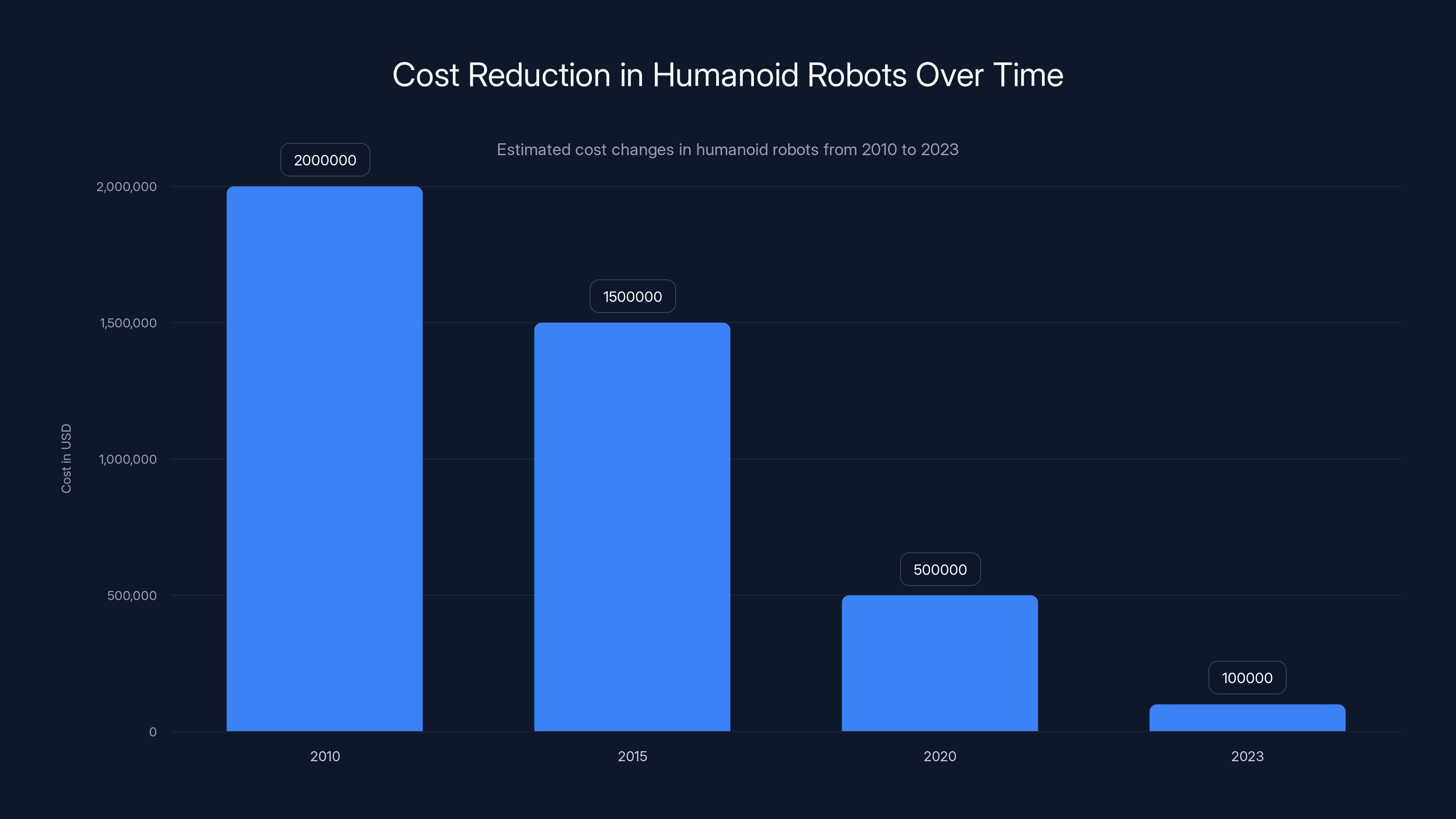

- Production costs have dropped from millions to roughly $100,000 per unit, making deployment economically viable at scale

- Early deployments focus on narrow, task-specific roles that human workers consistently avoid or struggle to fill

- Widespread adoption faces real barriers: energy efficiency gaps, high deployment costs, and supply chain dependencies on critical minerals

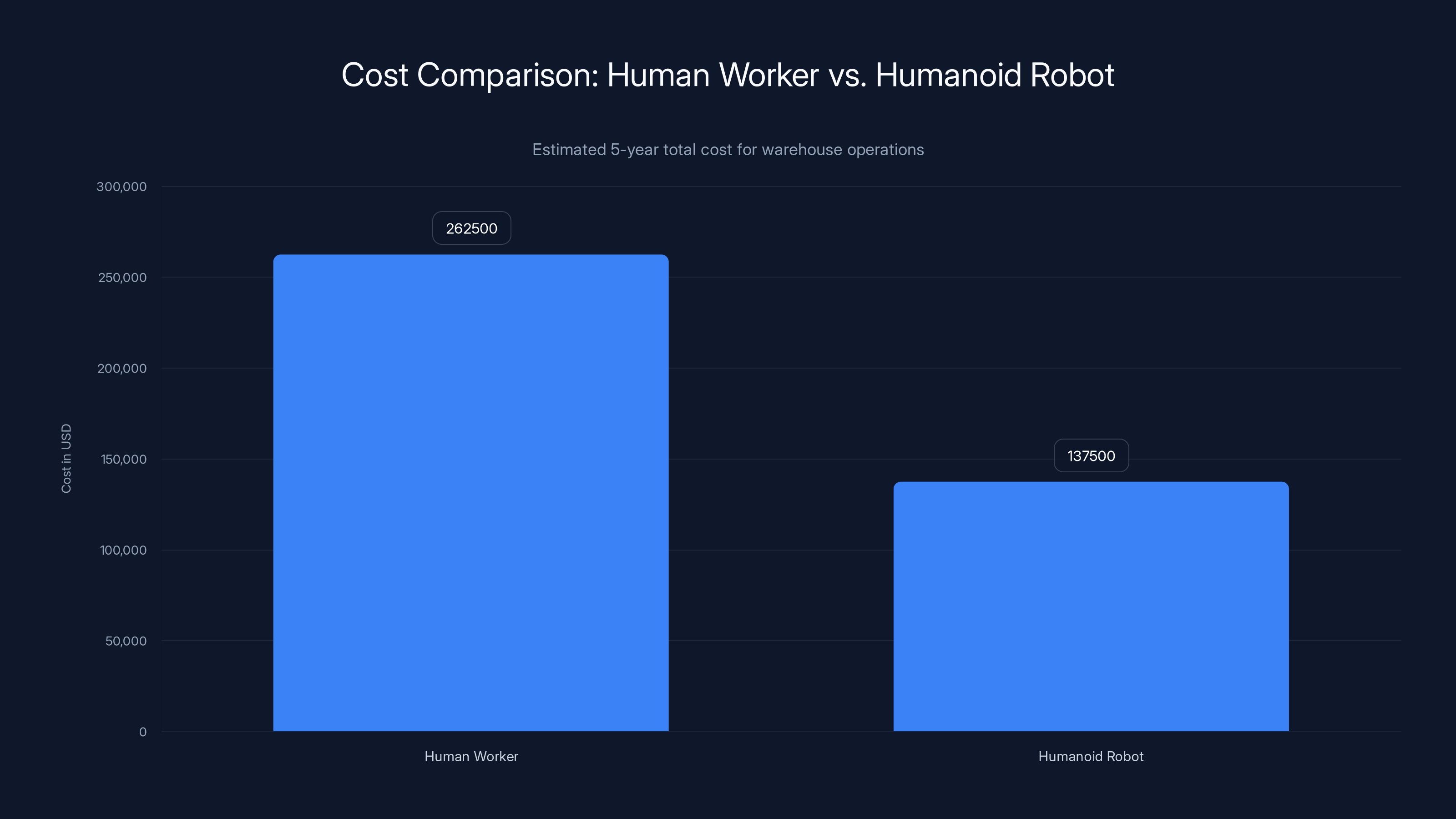

Estimated data shows that over 5 years, a humanoid robot costs significantly less than a human worker, making it a cost-effective option for consistent, predictable tasks in warehouses.

The Real Story: Why Humanoid Robots Are Actually Leaving The Lab

Let's be clear about something first. The robot revolution isn't happening because robots are suddenly smarter or more capable than they were five years ago. It's happening because humans are unavailable.

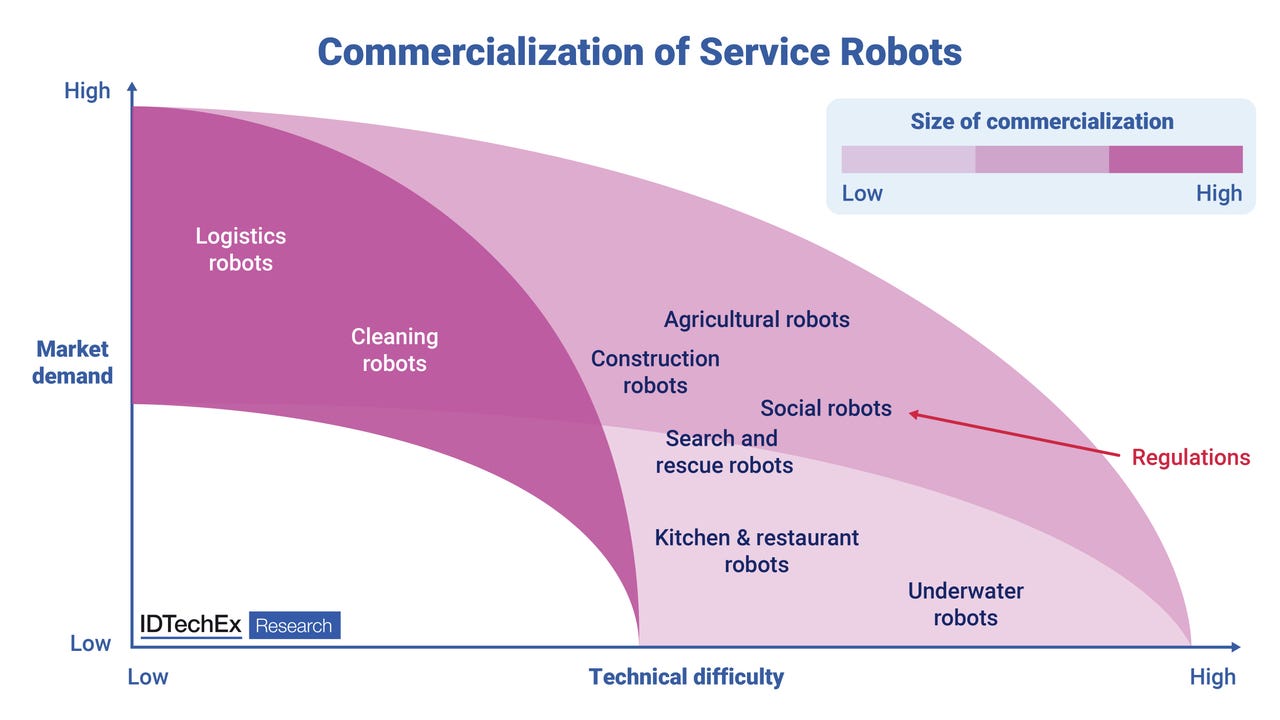

Labor shortages across manufacturing, agriculture, logistics, and healthcare aren't theoretical problems anymore. They're operational crises. Manufacturing facilities can't find enough workers willing to do repetitive assembly work. Warehouse operations struggle with turnover rates that make staffing impossible. Agriculture needs thousands of seasonal workers that simply don't show up.

This creates a specific market condition: demand for labor in jobs humans actively avoid. And that's where humanoid robots fit perfectly.

The problem with earlier automation solutions was inflexibility. Traditional robotic arms work brilliantly on assembly lines where every motion is predictable. But they require human environments to be redesigned around them. You can't ask a robot arm to pick items from varying heights, move between different workstations, climb stairs, or adapt when a shelf is arranged differently.

Humanoid robots solve this by doing something that seems obvious but proved incredibly difficult: they function in human-designed spaces without modification. They have legs to navigate floors. Arms with dexterous hands to manipulate objects. Sensors to understand spatial relationships. And increasingly, AI systems that let them adapt when conditions change.

The cost factor changed the timeline dramatically. A decade ago, building a humanoid robot cost millions of dollars. Each unit was experimental. Each deployment required engineering support. The economics made sense only for replacing highly specialized, expensive labor.

Today's humanoid robots cost roughly

The cost reduction came from multiple sources. Computing hardware got cheaper and more efficient. Battery technology improved dramatically. But the biggest factor was actuators, the systems that translate digital commands into physical movement. Advances in electric actuation brought costs down and reliability up simultaneously.

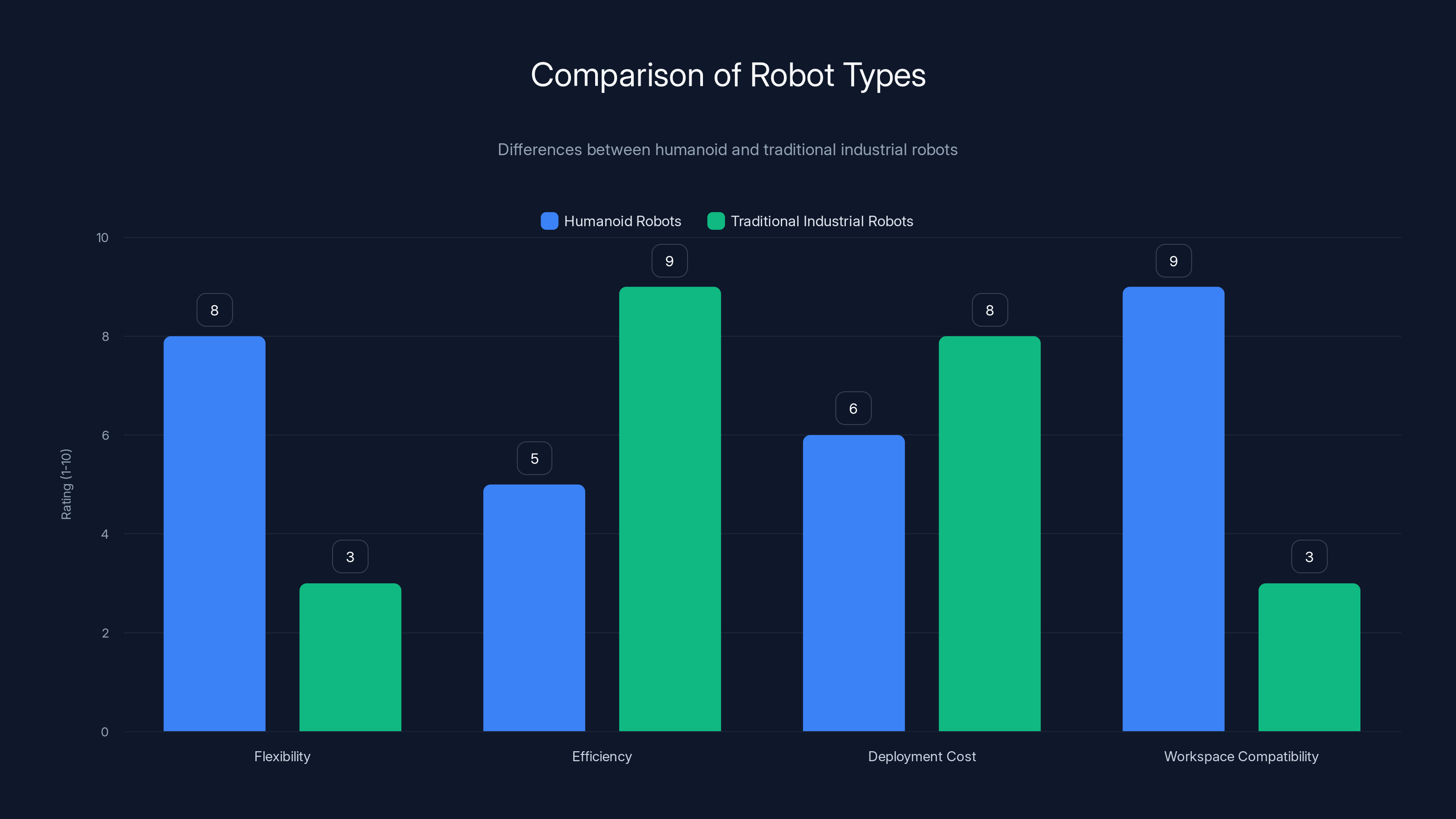

Humanoid robots excel in flexibility and workspace compatibility but lag in efficiency compared to traditional industrial robots. Estimated data.

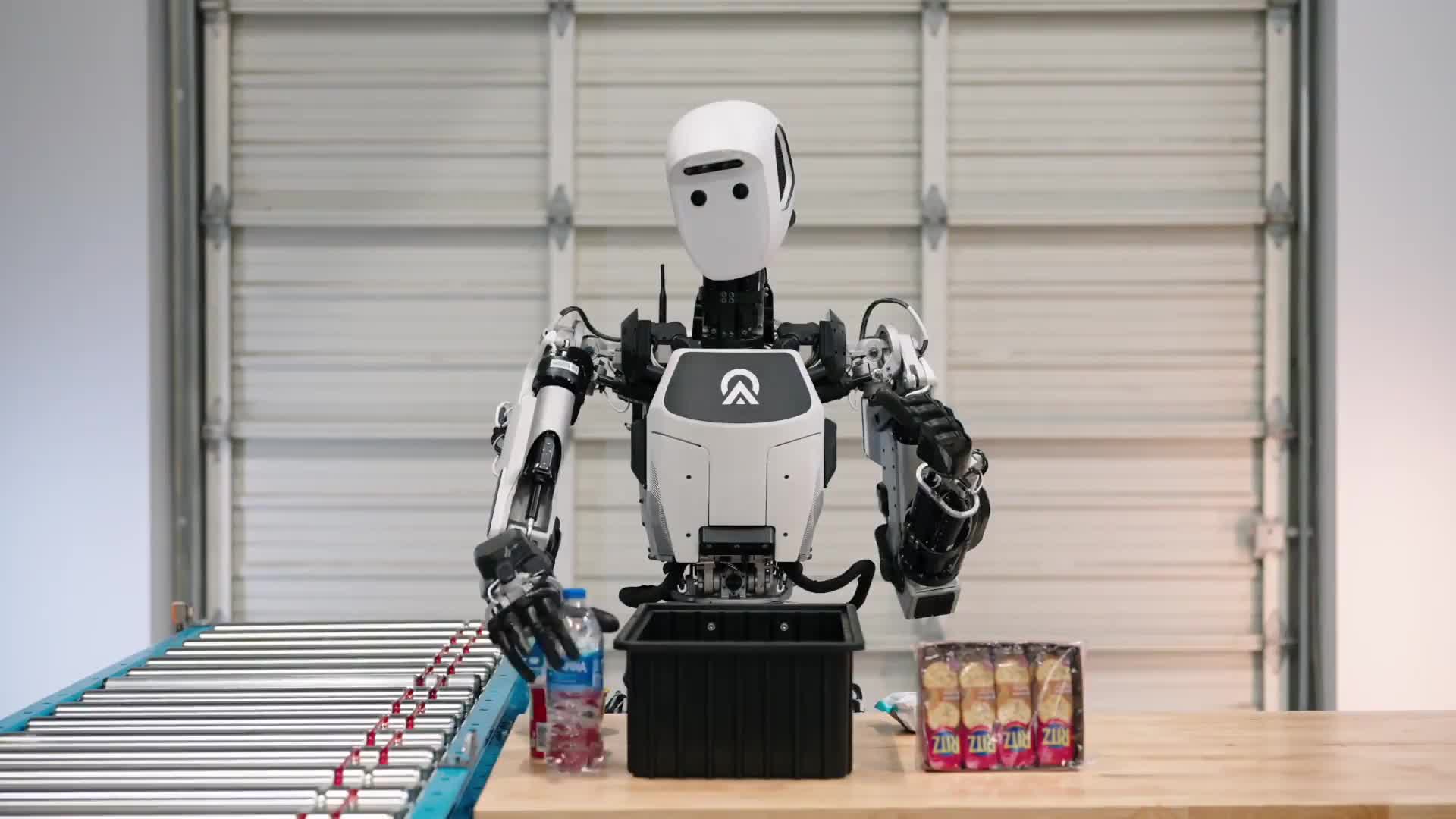

Where Humanoid Robots Are Actually Deployed Right Now

The real deployments happening today are very specific. They're not replacing entire factories. They're not eliminating job categories wholesale. They're filling gaps.

Manufacturing assembly lines use humanoid robots for tasks that frustrate human workers: repetitive picking and placing of components, quality inspection involving standing in one spot for hours, assembly of lightweight items that don't require significant force but demand precision and consistency.

Warehouse operations deploy them for item retrieval in high-density storage systems, goods sorting at conveyor speeds humans struggle to maintain without exhaustion, and order fulfillment in environments where constant walking and reaching is required.

Logistics centers use them for unloading trucks where boxes repeat endlessly, pallet movement in tight spaces where human injury risk is high, and inventory management in shelving systems designed for human scale but causing repetitive strain injuries.

Food processing and packaging uses humanoid robots for tasks health departments would prefer robots handle anyway, positions involving constant cold exposure or chemical contact, and production speeds that would cause fatigue-related mistakes in human workers.

The common thread across all these deployments is clear: the jobs humanoid robots currently fill are ones where worker turnover is chronically high, injury rates exceed industry averages, or skill requirements are genuinely minimal. These aren't prestigious positions. These aren't careers. These are jobs humans take when nothing else is available.

The Technological Breakthroughs That Made This Possible

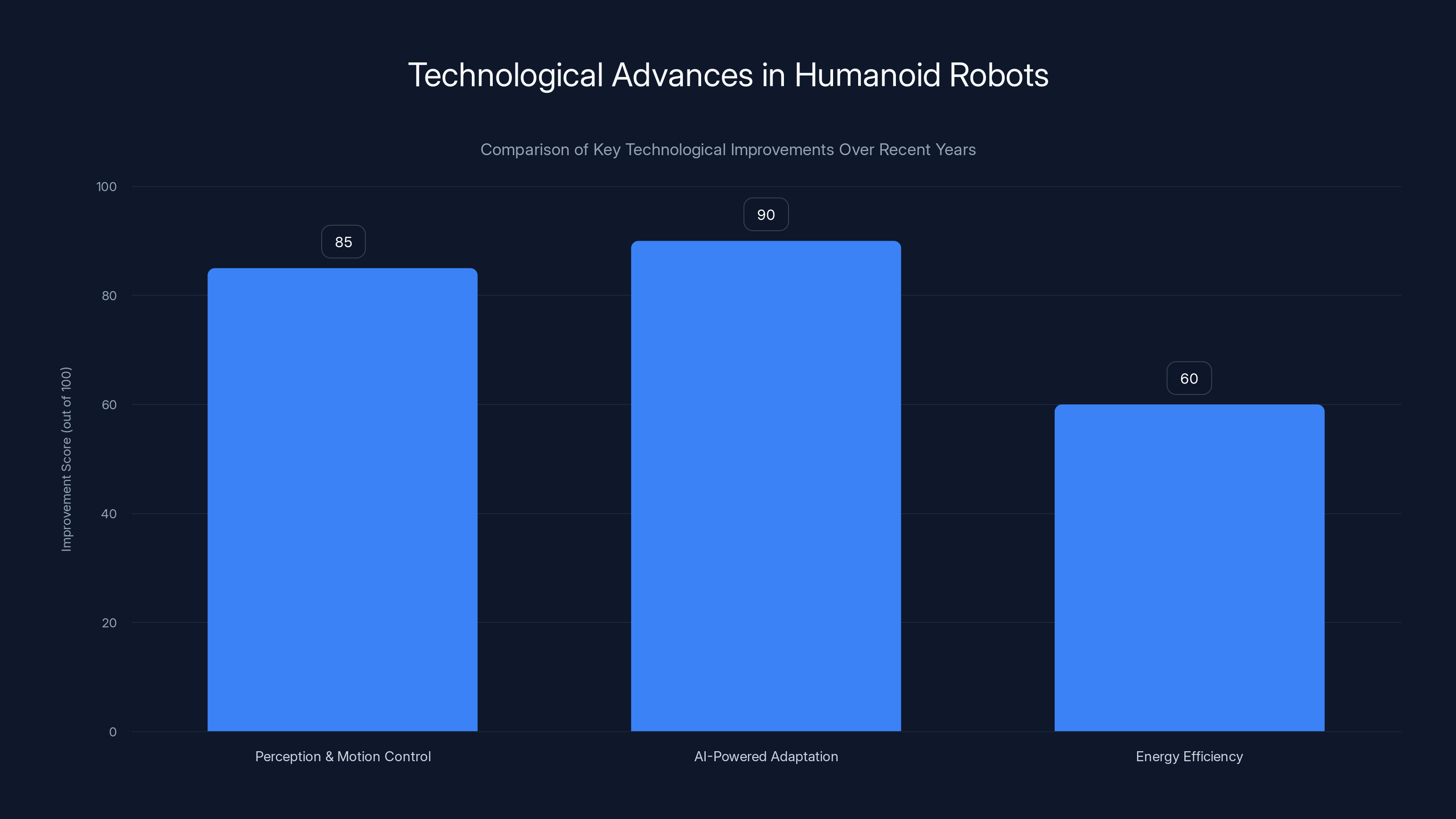

Three distinct technological advances made real-world humanoid deployment feasible in a way it wasn't just 3-4 years ago.

Perception and Motion Control: Earlier humanoid robots struggled with object recognition in unstructured environments. Show them a box in a warehouse where lighting varies, backgrounds are cluttered, and objects are partially obscured, and older systems would frequently fail. Modern vision systems trained on massive image datasets now recognize objects reliably even with variation. Motion control algorithms improved simultaneously, reducing the jerkiness and spatial errors that made earlier robots unreliable for tasks requiring precision.

AI-Powered Adaptation: Humanoid robots today don't follow rigid sequences of commands. They use AI systems to understand context. A robot can recognize that a shelf is arranged differently than expected and adjust its approach. It can understand that a box is heavier than typical and modify its grip strength accordingly. It can handle unexpected variations that would have caused older robots to halt entirely.

Energy Efficiency Progress: This remains an area where humanoid robots lag human performance significantly. Humans operate on roughly 100 watts of continuous energy. Current humanoid robots burn 2,000-5,000 watts during active work. But the trajectory is improving. Battery technology advances mean robots can run longer between charges. Mechanical efficiency improvements mean less wasted motion and energy.

None of this represents consciousness, true artificial intelligence, or anything resembling human-level reasoning. These are relatively straightforward perception and motion systems combined with decision trees and trained neural networks. They work because the tasks are specific, the environments are bounded, and the variation is manageable.

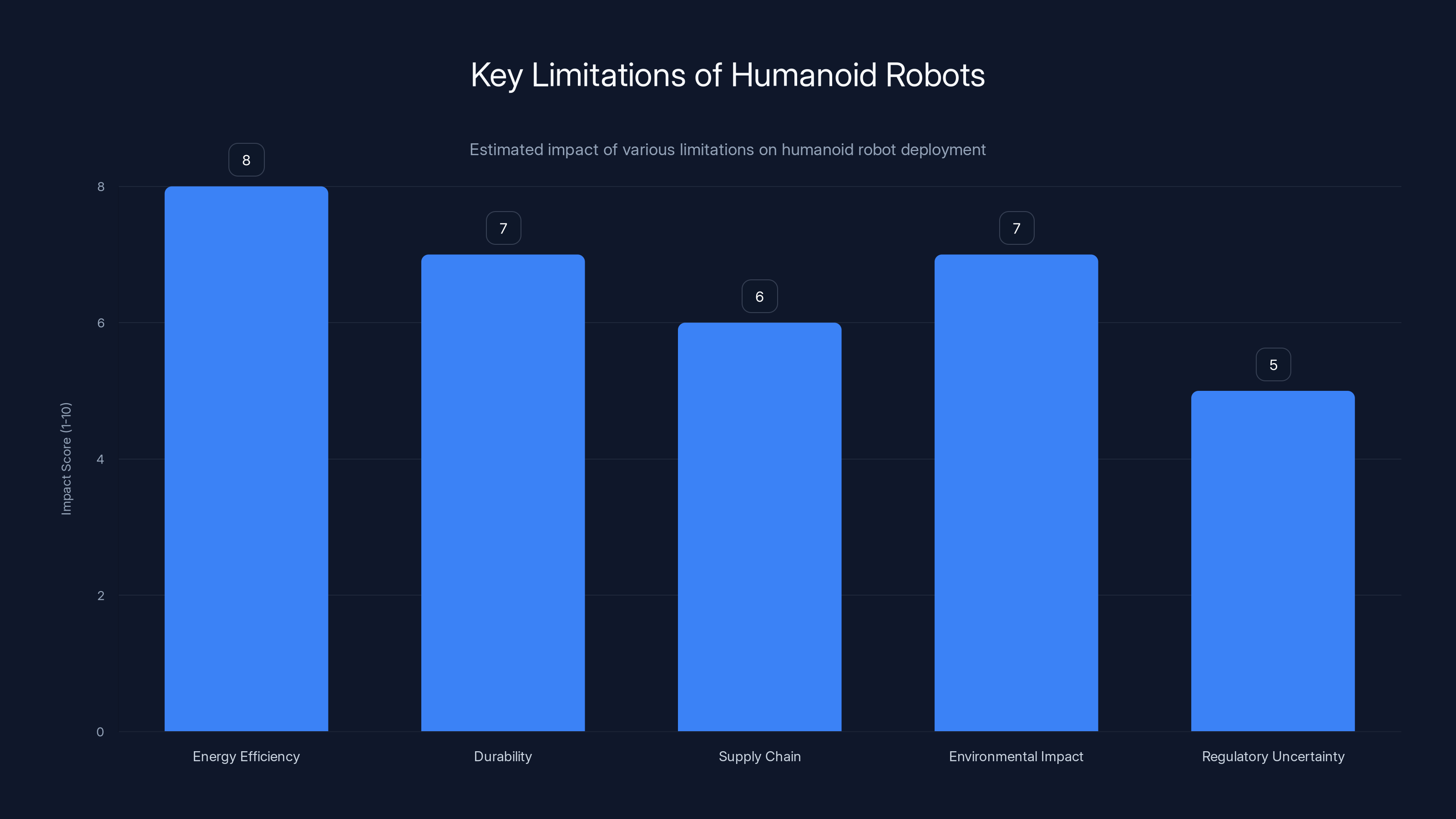

The chart highlights key limitations affecting humanoid robot deployment, with energy efficiency and durability posing the highest challenges. (Estimated data)

The Economic Math That Makes Deployment Make Sense

Here's the actual calculation manufacturers are doing right now:

A warehouse worker in most developed countries costs between

A humanoid robot costs

The math:

But here's the part that actually matters: a robot works 24/7 if you want. It doesn't need vacation, doesn't call in sick, doesn't get injured, doesn't require training beyond software updates, and doesn't leave for a better opportunity.

A single robot running 24/7 can theoretically replace 2-3 human workers on different shifts. That's when the math becomes compelling. One

This isn't universal. The math only works for specific job types. It requires consistent, predictable tasks. It demands environments that won't change significantly. It needs positions where continuous operation has value. But those conditions exist in thousands of facilities across the world.

Labor Shortages: The Real Driver, Not Job Displacement

There's a narrative floating around that humanoid robots are coming to eliminate jobs. That's not what's happening.

What's actually happening is that certain jobs have already been effectively eliminated by worker preferences. Nobody wants them. Not at current wages. Not at improved wages. Not really.

Manufacturing and logistics companies aren't choosing robots over available workers. They're deploying robots because workers aren't available, period. The positions are going unfilled.

This distinction matters enormously. When a company can't hire anyone for a position, they have three options: raise wages significantly (which may not be economically viable given the task), automate the task, or simply don't do the work. Most are choosing automation where feasible.

The worker shortage is real and verifiable. Demographic shifts in developed countries mean aging populations and fewer young people entering the workforce. Urban migration means rural and declining areas can't attract workers. Younger workers specifically avoid physically demanding, repetitive work, preferring service roles, knowledge work, or creative positions.

Agricultural labor shortages are particularly acute. Seasonal farmwork is grueling, temporary, and offers minimal benefits. In developed countries, it's become nearly impossible to fill these positions domestically. Companies that historically relied on seasonal workers now can't staff their operations.

Manufacturing has similar dynamics. Assembly line work, which once provided stable middle-class employment, now attracts almost nobody. The positions still exist. The work still needs doing. But the labor supply to fill those positions has simply evaporated.

This is where humanoid robots become economically rational. They're not necessarily more efficient than humans at individual tasks. But they're available when humans aren't, they don't require benefits or time off, and they work continuously.

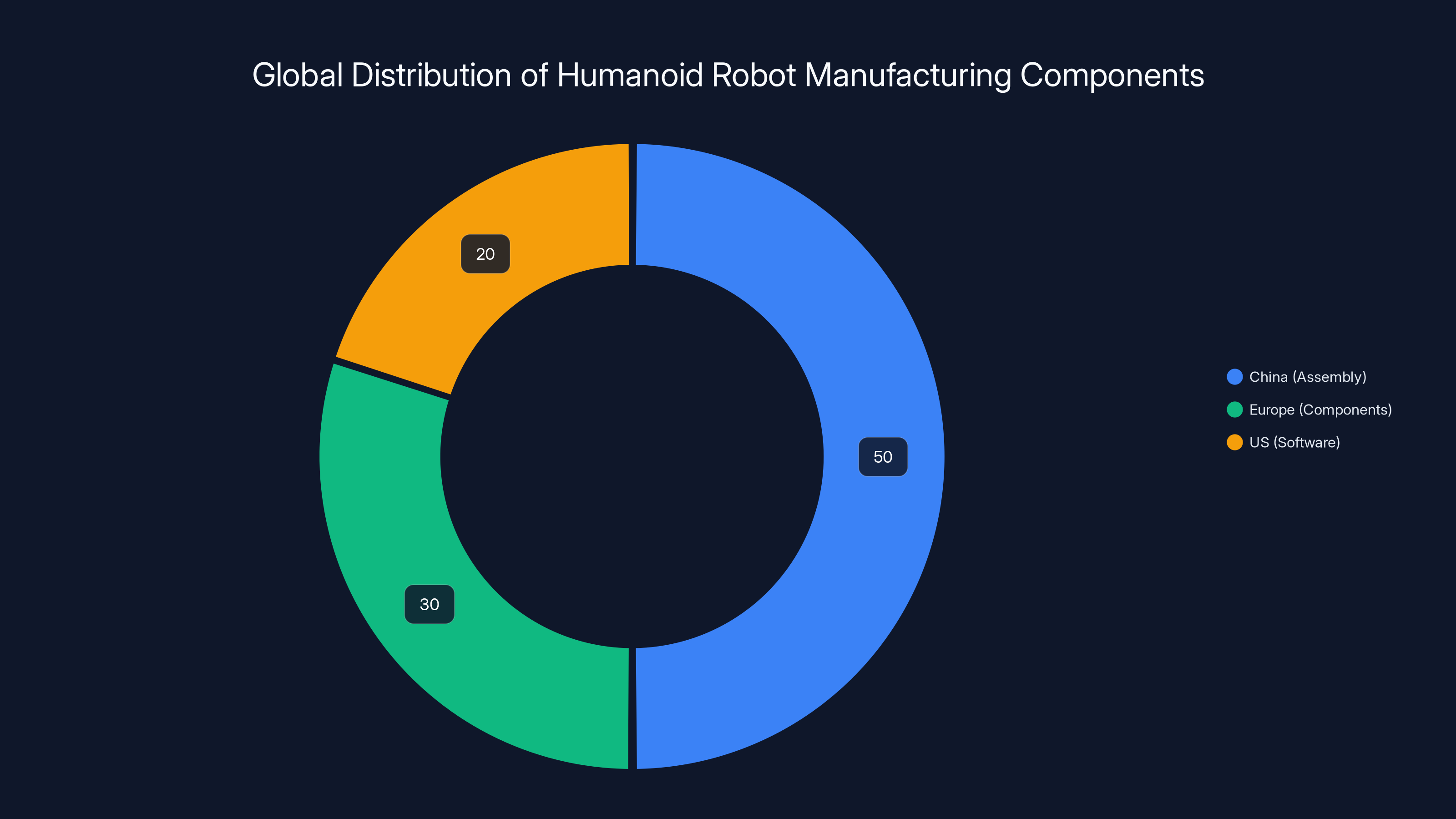

China leads in assembly with 50% of the market, Europe provides 30% of high-precision components, and the US contributes 20% through software and AI development. Estimated data.

China's Manufacturing Dominance And Europe's Supply Chain Role

The humanoid robot market is developing with a specific geographic structure that's worth understanding because it mirrors patterns we've seen in other technology sectors.

China dominates manufacturing and assembly. This is where most humanoid robots are actually being built. Companies like Ubtech and others have set up production lines producing units at scale. The cost advantages from manufacturing in China created by labor costs, supply chain proximity, and production experience are substantial. When you're building a product designed to replace labor, it makes sense to build it where labor is cheapest and automation is most established.

But there's a catch. Humanoid robots require high-precision mechanical components. The actuators that create movement, the joints that permit varied motion, the gears that manage force and speed, the sensors that measure position and force—all of these require exceptional precision manufacturing.

Europe supplies many of these components. German precision manufacturing, Swiss engineering, and Italian mechanical specialists provide the high-quality components that make humanoid robots reliable. A robot assembled in China using European components is a more accurate description of current manufacturing than thinking of robots as purely Chinese products.

This matters because it creates supply chain resilience factors and cost structures that affect deployment timelines. Disruptions in European component supply affect global robot availability. Increased demand from Chinese manufacturers for precision components increases global prices and potentially constrains supply.

The US, meanwhile, is focused on software, AI systems, and proprietary designs. Companies like Tesla and Figure AI develop the technology and the control systems, but often outsource manufacturing to China or contract with manufacturers globally.

The Real Limitations Nobody Talks About

If humanoid robots are already leaving labs, why aren't factories completely transformed yet? Because significant limitations remain, and they're not being magically solved by incremental improvements.

Energy Efficiency: A humanoid robot working continuously uses far more electricity than a human performing the same task. In settings where power costs matter, this is a real constraint. A robot running 24/7 might use enough electricity to cost an additional

Durability Questions: Current humanoid robots undergo testing and early deployment. Real long-term operational data doesn't exist yet. How long before mechanical wear requires major service? What's the actual maintenance cost at scale? How many of these robots will still be operational after 5 years? Early returns suggest the technology is reliable, but genuine long-term data from thousands of deployed units working in real conditions will take years to accumulate.

Supply Chain Vulnerabilities: Humanoid robots require rare earth minerals for magnets, specialized metals for actuators, and precision electronics. These components come from concentrated sources globally. Disruptions to supply chains can halt robot production entirely. This mirrors issues seen with semiconductor shortages and battery material constraints.

Environmental Impact: Manufacturing a humanoid robot has significant environmental cost. The minerals extracted, the energy used in production, the electronics manufacturing—all carry carbon footprints. A robot must operate long enough to recoup that environmental cost. In some cases, the energy efficiency gains never fully compensate for manufacturing impact.

Regulatory Uncertainty: As humanoid robots enter more workplaces, regulatory frameworks are developing. Worker safety regulations, labor protections for adjacent human workers, liability for robot accidents—these are all being determined now. Future regulations could significantly increase deployment costs or restrict deployment in certain environments.

Technological Ceiling: Humanoid robots today work well in specific, bounded, repetitive tasks. They're not approaching human flexibility anytime soon. Complex assembly involving judgment calls, problem-solving, or adaptation beyond trained scenarios remains firmly in human territory. The tasks robots will ultimately fill are inherently limited.

The cost of humanoid robots has significantly decreased from

Real-World Deployment Examples and Early Results

Testing and early deployment are happening right now across multiple companies and industries. Here's what's actually occurring:

Tesla's Optimus: Working in Tesla's own manufacturing facilities, these robots are being tested on battery pack assembly, parts moving, and assembly line support. Early reports suggest competence in specific, controlled tasks but ongoing challenges in complex scenarios. No independent verification of performance metrics has been made public, which is telling.

Figure AI Deployments: Working with BMW and other manufacturers on logistics and assembly tasks, these robots have demonstrated capability in warehouse environments. The company has been more transparent about both successes and limitations than some competitors, which actually increases credibility.

Boston Dynamics Commercial Units: Their robots have moved from viral YouTube videos to actual commercial deployment. Spot (the quadruped) handles inspection and data gathering in industrial environments. Atlas (humanoid) is being tested in manufacturing. Boston Dynamics has been explicit about both capabilities and limitations, which is refreshingly honest.

ABB and KUKA Integration: Established industrial robotics companies are moving into humanoid space. They bring decades of manufacturing partnership experience but also legacy business models that might slow adaptation.

Across all these deployments, the pattern is similar: robots handle specific tasks well when conditions are relatively stable. Performance degrades when variation increases. They require significant operational support. They're not yet plug-and-play solutions.

The Jobs That Will Be Affected First

Think about which jobs disappear first when humanoid robots become reliable and affordable. They're not the prestigious jobs. They're not the skilled trades. They're not management or professional roles.

They're the positions that:

- Involve repetitive motion in assembly or packing

- Require standing in one location for extended periods

- Demand physical strength but not significant skill

- Have chronic labor shortages because nobody wants them

- Involve hazardous conditions where automation is already desired

- Require 24/7 coverage that's expensive with human labor

- Have high injury rates that create liability and recruitment problems

Warehouse order fulfillment positions are on this list. Assembly line roles in manufacturing are vulnerable. Certain agricultural tasks will disappear. Some logistics operations will shift from human-intensive to robot-intensive.

But notice what's not on the list: skilled trades, creative work, jobs requiring judgment, positions involving human interaction, work requiring problem-solving beyond pattern matching.

This doesn't mean nobody is displaced. In specific geographic areas where employment is concentrated in vulnerable sectors, the disruption is real. But it's not civilization-ending. It's the continuation of a trend that's been happening for decades: hazardous and repetitive work gradually moves out of human hands.

Perception and motion control, along with AI-powered adaptation, have seen significant improvements, making humanoid robots more reliable. Energy efficiency, while improved, still lags behind other advancements. Estimated data.

Why This Moment Is Different From Past Automation Waves

We've been through automation transformations before. Steam power. Electricity. Assembly lines. Computerization. Each one displaced workers. Each one also created new opportunities.

But the humanoid robot wave has a different character because it's happening simultaneously with demographic collapse in many developed countries.

Previous automation waves happened when populations were growing and available labor was abundant. Workers displaced from agriculture moved to factories. Workers displaced from factories moved to service roles. Workers displaced from service roles moved to knowledge work. At each transition, there was demand for labor elsewhere.

Humanoid robots are being deployed into a fundamentally different demographic situation. Populations in most developed countries are aging. Birth rates are below replacement. Net immigration can't fully compensate for natural population decline in many regions.

This means that unlike past automation waves, there isn't necessarily a natural next sector absorbing displaced workers. There's no obvious path for a 55-year-old warehouse worker to transition into the next thing because there might not be enough labor demand in the next thing.

This doesn't mean crisis is inevitable. It means policy responses matter more than they did in previous transitions. Education, retraining, social support systems, geographic mobility—these factors will determine whether automation becomes transformation or stagnation.

But those are policy decisions, not technology inevitabilities. And policy moves slowly.

The Supply Chain For Humanoid Robot Components

Understanding where humanoid robots actually come from matters because it affects availability, cost, and reliability going forward.

Let's trace a simplified path:

Raw Materials: Mines globally extract rare earth minerals, cobalt, lithium, and specialized metals. Political instability in some key mining regions creates supply volatility. Environmental restrictions in other regions limit extraction. These materials are expensive and becoming more valuable as demand for electrified and automated systems increases.

Component Manufacturing: Raw materials move to smelters and refiners, primarily in China, who transform them into usable forms. Precision manufacturing of actuators, gears, and joints happens in Germany, Switzerland, Japan, and increasingly China. Battery cells come from dedicated battery manufacturers in multiple countries. Electronics components are made globally but assembled primarily in Asia.

Robot Assembly: Components converge in assembly facilities, mostly in China, where robots are integrated, tested, and packaged. Quality control varies significantly between manufacturers.

Deployment and Support: Robots ship to end customers who require technical support, software updates, spare parts, and maintenance. This support infrastructure is building but remains immature in most regions outside major tech hubs.

Disruptions anywhere in this chain affect the whole pipeline. A shortage of rare earth minerals increases cost for every robot. Manufacturing delays in precision components delay entire robot production runs. Battery supply constraints that emerged in 2023-2024 highlighted how dependent robots are on commodity markets beyond the robotics industry itself.

Regulation, Safety, and Liability Questions

As humanoid robots move into workplaces where humans also work, regulatory questions become operational questions.

Worker Safety Standards: What safety protocols must be in place when humanoid robots and human workers share the same space? Current OSHA standards address robotic safety in industrial settings, but those standards were written for stationary robots with defined work areas. Mobile humanoid robots that navigate human spaces present novel safety challenges.

Liability and Insurance: If a humanoid robot injures a worker, who's liable? The robot manufacturer? The facility owner? The company deploying the robot? Insurance products covering humanoid robot liability are just being developed, and the cost is uncertain.

Data and Privacy: Humanoid robots in facilities collect video and sensor data about their environment and their surroundings. That data might include workers. Privacy regulations in Europe (GDPR) and other regions are creating constraints on what data can be collected and how it can be used.

Labor Laws: Some jurisdictions are exploring whether humanoid robots should be subject to labor taxation or other obligations currently applied to workers. These ideas are experimental and unlikely to pass, but the uncertainty creates planning challenges.

Algorithmic Accountability: As humanoid robots make decisions (which workers to hand off tasks to, how to prioritize workload, how to respond to unexpected situations), questions about algorithmic bias and accountability emerge. Current frameworks for addressing these in AI systems don't cleanly map to robots.

None of these regulatory questions has clear answers yet. They're being worked through in real time as deployment happens. This creates uncertainty for both manufacturers and deployers, which tends to slow adoption.

The Environmental Cost That Nobody's Really Calculating

When we talk about humanoid robot efficiency, the conversation usually focuses on operational cost and labor replacement. Environmental cost is barely mentioned.

Building a humanoid robot requires significant resource extraction and energy input. Mining and processing materials for the actuators, rare earth magnets, battery components, and electronics all have environmental costs measured in kilograms of CO2 per unit.

Estimates suggest manufacturing a single humanoid robot creates a carbon footprint between 2-5 tons of CO2, depending on materials and manufacturing location. That's roughly equivalent to the annual carbon footprint of a human in many developed countries.

For that investment to make environmental sense, the robot must operate long enough to recoup that carbon cost through energy efficiency relative to human labor. A human worker generates roughly 2 tons of CO2 annually in most developed country contexts through electricity, transportation, heating, and food. A robot running continuously uses far more electricity.

The environmental case for humanoid robots is actually questionable unless:

- The tasks they perform genuinely can't be done by humans (hazardous work, for example)

- The robot operates long enough (5-10+ years) for efficiency to overcome manufacturing cost

- The electricity powering the robot comes from renewable sources

- Manufacturing is optimized for minimal waste

Most current deployments don't meet all these criteria. They're not optimized for environmental impact. They're optimized for labor cost reduction. This matters for actual sustainability planning but gets minimal discussion in industry coverage.

Timeline Predictions: When Will This Actually Happen At Scale?

Predicting technological adoption is notoriously unreliable, but we can look at historical patterns and current indicators.

Current state: Maybe 5,000-15,000 humanoid robots deployed globally. Small number. Mostly testing and early deployment. Most in controlled environments with significant technical support.

Next 2-3 years: Likely expansion to 50,000-100,000 units. Deployment in larger number of facilities. Better reliability data. More refined task specifications. Price pressure as competition increases. Regulatory frameworks beginning to solidify. This is the critical period where deployment becomes normal rather than experimental.

Next 5 years: Potential deployment of hundreds of thousands of units. Standardization of task categories. Integration with other automation. Visible impact on labor markets in specific sectors and regions. Real data on long-term reliability and maintenance costs. This is when the economic model gets genuinely tested at scale.

Beyond 5 years: Unknown. Depends entirely on whether reliability meets expectations and whether energy efficiency improves. If robots work as projected, widespread adoption becomes possible. If they disappoint, deployment might plateau. If regulations become restrictive, growth slows.

The important note: this is not an exponential adoption curve like smartphones or social media. This is industrial technology adoption, which moves slower. It's more like how robots entered manufacturing—gradual, sector-by-sector, location-by-location, task-by-task.

Comparing Humanoid Robots To Incumbent Automation

Humanoid robots aren't replacing traditional industrial robotics. They're complementing and expanding automation into spaces where traditional robots don't fit.

Traditional Industrial Robots (robotic arms, welding systems, etc.):

- Highly specialized for specific tasks

- Extremely reliable and efficient

- Require facility redesign to implement

- High capital cost but extraordinary productivity in narrow tasks

- Hundreds of thousands deployed globally, well-established market

Humanoid Robots:

- Generalist systems handling varied tasks

- Still developing reliability and efficiency

- Function in existing human-designed spaces

- Lower unit cost, but requires more support infrastructure

- Tens of thousands deployed, market developing

Collaborative Robots (Cobots):

- Designed to work alongside humans

- Moderate specialization

- Safe for shared workspace

- Growing segment of industrial robotics market

- Tens of thousands deployed, established market

The future likely involves all three categories. Traditional robots for high-volume identical tasks. Humanoid robots for varied tasks in human spaces. Collaborative robots for hybrid human-robot work. Different tool for different jobs.

This actually suggests that humanoid robots won't be the dominant automation form. They'll be one tool among many, valuable in specific scenarios but not universal replacements for labor.

What Workers Should Actually Be Thinking About

If you work in a field that might be affected by humanoid robots, here's what actually matters:

First, understand what your job actually is. If 80% of your work is repetitive, physical, doesn't require judgment, and could be specified precisely to a machine, your job is vulnerable. If your work requires judgment, problem-solving, human interaction, or constant adaptation, you're safer.

Second, recognize that this isn't happening tomorrow. The timeline is measured in years and decades, not months. You have time to adapt, learn, and transition if necessary.

Third, look at what's actually being deployed in your industry. Are companies actually automating or just talking about it? Early adoption usually happens in specific regions or companies first. Pay attention to what's actually happening in your market.

Fourth, consider your location. Automation deployment patterns have geography. Major manufacturing hubs and logistics centers get robots first. Rural areas and small facilities get them much later, if ever. Where you work matters.

Fifth, invest in skills that are harder to automate. Problem-solving, communication, training others, understanding complex systems, leadership. These are all less automatable than repetitive physical tasks.

Finally, stay aware of what's actually happening. This technology is real and deployment is accelerating. But it's not the robot apocalypse. It's the next phase of work transformation, continuing a century-long trend of moving dangerous and repetitive work out of human hands.

The Geopolitical Dimension That Matters

Humanoid robots aren't just a technology or economics question. They're also a geopolitical issue that affects global competition and economic power.

Countries with strong humanoid robot manufacturing capacity gain multiple advantages:

They can automate their own industries faster, potentially improving competitiveness while managing labor supply issues differently than other nations. They create domestic manufacturing jobs building robots, even as they reduce jobs elsewhere. They accumulate technological knowledge and patents. They position themselves as technological leaders in the global economy.

The US, China, Japan, and Europe are all competing to establish dominance in humanoid robotics. China leads in manufacturing capacity and deployment. The US leads in software and AI systems. Europe leads in precision components. Japan has both hardware and software expertise.

This competition affects availability, pricing, and investment flows globally. Countries investing heavily in humanoid robot development create advantages for their industries and workforce. Countries that fall behind might face competitive disadvantages as other nations automate their labor-intensive sectors.

This geopolitical competition also affects regulation. Different countries will likely develop different standards, creating fragmented global markets and incentivizing manufacturers to focus on key regions first.

The Path Forward: Reasonable Expectations

Humanoid robots are neither savior technology nor civilization-ending threat. They're practical automation tools for specific problems.

They will gradually move into roles where human labor is difficult to attract, where work is genuinely hazardous, where 24/7 operation has value, and where tasks are sufficiently repetitive to automate. This is meaningful but not total workforce disruption.

They will face real limitations from energy efficiency, cost, durability, and reliability concerns that won't be magically solved. The technology will improve but won't become universally applicable.

They will require supportive policy responses to manage workforce transitions in regions and sectors where deployment is concentrated. Education, retraining, and support systems matter. They're not automatic, but they're manageable with appropriate investment.

They will create new job categories even as they eliminate existing ones. Robot maintenance, programming, deployment support, and management of robotics systems will all require humans. The jobs won't be in the same places or available to the same workers, but they'll exist.

Most importantly, they're already happening. This isn't a future question. It's a present reality that will incrementally become more normal over the next 5-10 years.

The relevant question isn't whether humanoid robots will be deployed. It's how we manage that deployment to maximize benefits and minimize disruption for workers and communities affected.

FAQ

What exactly is a humanoid robot?

A humanoid robot is a machine designed to resemble human form and function, featuring legs for movement, arms with dexterous hands, a torso, and sensors for perception. These robots are built to operate in human-designed spaces without requiring facility modifications, unlike traditional industrial robotics. Current humanoid robots use AI systems, perception technology, and mechanical engineering to handle varied tasks in real-world environments, though they remain specialized for specific use cases rather than achieving true general-purpose capability.

How do humanoid robots differ from traditional industrial robots?

Traditional industrial robots are highly specialized machines optimized for specific, repetitive tasks in controlled environments. They're extraordinarily reliable and efficient but require workspaces redesigned around their fixed positions and motion patterns. Humanoid robots, conversely, function in existing human environments and can transition between different tasks without facility redesign. This flexibility comes at the cost of specialization and efficiency in individual tasks. Traditional robots dominate manufacturing today with hundreds of thousands deployed. Humanoid robots are still early-stage deployment but excel where flexibility and human-compatible workspaces matter more than maximum efficiency in narrow tasks.

Why are companies deploying humanoid robots now?

Companies are deploying humanoid robots because labor shortages in repetitive, physically demanding, and hazardous roles have become critical operational problems. The demographic and cultural shifts in developed countries mean fewer workers are available for jobs people actively avoid. Simultaneously, production costs for humanoid robots dropped from millions to roughly $100,000 per unit, making deployment economically viable when labor costs are considered. Early testing shows these robots can reliably handle specific tasks without continuous technical support. The combination of labor shortage urgency, improved technology, and acceptable cost created the conditions for real-world deployment rather than laboratory-only experiments.

What tasks can humanoid robots actually do right now?

Current humanoid robots excel at repetitive assembly tasks, warehouse sorting and item retrieval, goods movement and pallet handling, and quality inspection in manufacturing. They can work in environments with varying lighting and temperature. They adapt to minor variations in task conditions. However, they struggle with tasks requiring fine manipulation, tasks with constantly changing parameters, work that demands judgment and decision-making beyond trained patterns, and scenarios with unpredictable environmental conditions. Current deployments focus on narrow task categories repeated thousands of times where variation is minimal. This is actually the sweet spot for robotic deployment regardless of form factor, but it's important to recognize that current humanoid robots aren't approaching general-purpose capability.

What are the real limitations of humanoid robots?

Energy efficiency remains a significant limitation. Humanoid robots running continuously consume 2,000-5,000 watts, roughly 20-50 times more power than humans performing equivalent tasks. Long-term reliability data doesn't exist yet because most robots have been deployed very recently, creating uncertainty about actual maintenance costs and operational lifespan beyond manufacturer projections. Supply chain vulnerabilities are real, as robots depend on rare earth minerals, specialized metals, and precision components from concentrated global sources. Environmental impact of manufacturing isn't well understood or optimized, potentially offsetting energy savings from replacing human labor. Regulatory uncertainty creates planning challenges for companies considering deployment. And perhaps most importantly, humanoid robots remain task-specific despite their general appearance. They're not approaching human flexibility anytime soon, which inherently limits their applicability.

How much do humanoid robots cost?

Unit costs for commercially available humanoid robots range from approximately

Will humanoid robots replace all factory workers?

No, humanoid robots will replace specific roles, not entire job categories or workforces. Replacement happens where work is repetitive, task-specific, physically demanding, and difficult to staff with human workers. Positions requiring judgment, problem-solving, complex human interaction, or constant adaptation remain firmly in human territory. Most manufacturing facilities will maintain human workers in supervisory, engineering, programming, quality control, and problem-solving roles while robots handle narrow, repetitive tasks. Geographic variation matters too. Facilities with severe labor shortages deploy robots more aggressively. Facilities in areas with abundant labor deploy them more slowly. The overall impact is meaningful but localized rather than universal job elimination.

What about job displacement and worker impacts?

Job displacement will be real in specific sectors and regions where humanoid robots are deployed at scale. Workers in warehouse operations, food processing, and certain manufacturing roles face the highest risk if repetitive task-based positions are where they work. However, displacement is not immediate or universal. Timeline stretches across years and decades, not months. Most impact will concentrate in geographic areas with manufacturing or logistics density, not uniformly across all industries or regions. Supported transitions through retraining programs, geographic mobility support, and educational investments can significantly mitigate disruption. Historical precedent from previous automation waves shows that while displacement is real, adaptation and new opportunity creation also occur. Policy responses matter enormously in determining whether the outcome is managed transition or economic disruption.

What's the timeline for widespread humanoid robot adoption?

Current deployment involves perhaps 5,000-15,000 robots globally, mostly in testing and early commercial phases. Over the next 2-3 years, expect deployment to expand to tens of thousands as reliability improves and cost decreases. Within 5 years, hundreds of thousands of units could be deployed as the technology becomes standardized and proven. Beyond that, adoption depends entirely on whether the technology delivers on projections for reliability, efficiency, and capability. Rapid exponential adoption is unlikely since this is industrial technology, not consumer technology. Adoption follows the pattern of industrial robotics more than smartphones. It's measured sector by sector, facility by facility, task by task. This is a decades-long transition, not a sudden transformation.

How does this compare to AI and software automation?

Humanoid robots and software-based AI automation are complementary rather than competitive technologies. Software automation excels at digital tasks, data processing, and communication workflows. Humanoid robots handle physical tasks in real-world environments. Many operations will adopt both simultaneously, using AI to optimize processes while robots handle physical work. In jobs involving both digital and physical components, the combination of software automation for cognitive tasks and robotic automation for physical tasks might be more impactful than either alone. The convergence of AI and physical robotics represents the next frontier rather than them being alternative solutions to the same problems.

What should workers do to prepare?

First, understand whether your job consists primarily of repetitive physical tasks in a bounded environment (higher risk) or involves judgment, problem-solving, and adaptation (lower risk). Second, develop skills that are harder to automate, including communication, problem-solving, teaching others, and understanding complex systems. Third, stay aware of what's actually happening in your industry rather than generic predictions. Real deployment is concentrated in specific sectors and regions. Fourth, maintain geographic and career flexibility to adapt if necessary. Fifth, monitor what your employer is actually doing. Companies discussing robots and companies actually deploying robots are different. Sixth, participate in workforce development discussions in your region or industry. Policy responses to automation matter enormously. Finally, remember that automation is a decades-long process with manageable timeline for adaptation at individual and societal levels.

Humanoid robots are leaving the lab. They're not coming to eliminate all jobs tomorrow. They're starting to fill specific, narrow roles that have become persistently unfilled by human workers. Understanding where they're being deployed, why, and what actually works versus what's hype separates informed adaptation from reactive panic.

The real shift happening isn't fundamentally different from automation waves that came before. It's the continuation of moving dangerous, repetitive, and undesirable work out of human hands. That's been the trajectory for centuries. Humanoid robots are just the next chapter in that ongoing story.

What's different this time is that we're in a demographic moment where there aren't enough workers to fill labor-intensive roles regardless of automation. Humanoid robots aren't creating disruption. They're responding to disruption that already exists. Understanding that distinction changes everything about how we think about what's actually happening and what responses actually make sense.

Key Takeaways

- Humanoid robots are actively deployed in real manufacturing, warehouse, and logistics environments today, not just in research labs

- Labor shortages in repetitive, physically demanding roles are the primary economic driver, not technological inevitability

- Production costs dropped from millions to roughly $100,000 per unit, making deployment economically viable when labor replacement is calculated

- Early deployments focus on narrow, task-specific work that humans actively avoid or that facilities struggle to staff with human workers

- Real limitations remain including energy efficiency gaps, durability questions, supply chain vulnerabilities, and regulatory uncertainty that will slow widespread adoption

Related Articles

- Skild AI Hits $14B Valuation: Robotics Foundation Models Explained [2025]

- CES 2026 Robots: The Good, Bad, and Revolutionary [2025]

- Industrial AI Applied: Where the Real Revolution is Happening [2025]

- Sharpa's Humanoid Robot with Dexterous Hand: The Future of Autonomous Task Execution [2026]

- How Bucket Robotics Conquered CES 2026: YC Startup's First Big Show [2026]

- Anthropic's Economic Index 2025: What AI Really Does for Work [Data]

![Humanoid Robots in Factories: The Real Shift Away From Labs [2025]](https://tryrunable.com/blog/humanoid-robots-in-factories-the-real-shift-away-from-labs-2/image-1-1768854976373.jpg)